MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1021 of 1500

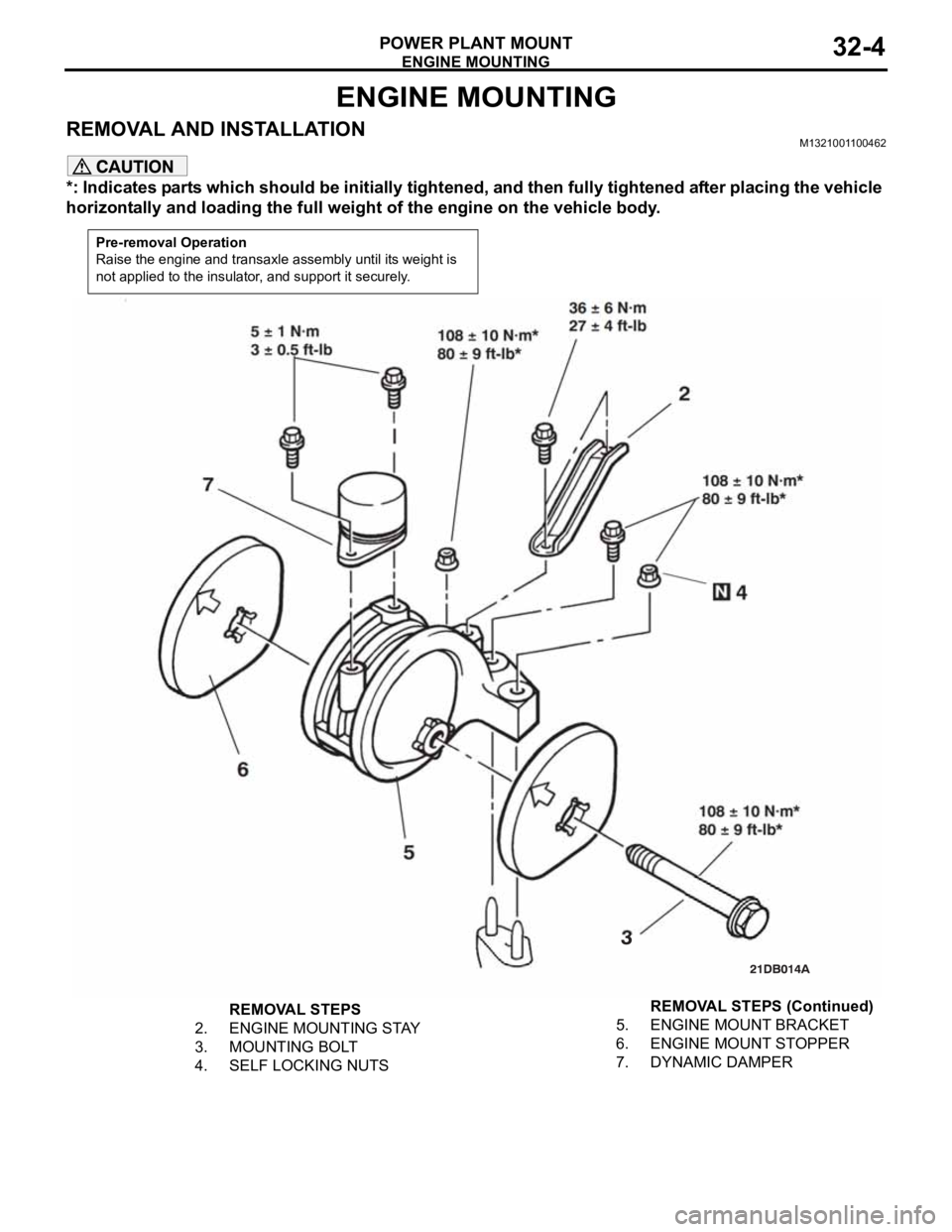

ENGINE MOUNTING

POWER PLANT MOUNT32-4

ENGINE MOUNTING

REMOVAL AND INSTALLATIONM1321001100462

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transaxle assembly until its weight is

not applied to the insulator, and support it securely.

REMOVAL STEPS

2. ENGINE MOUNTING STAY

3. MOUNTING BOLT

4. SELF LOCKING NUTS5. ENGINE MOUNT BRACKET

6. ENGINE MOUNT STOPPER

7. DYNAMIC DAMPERREMOVAL STEPS (Continued)

Page 1022 of 1500

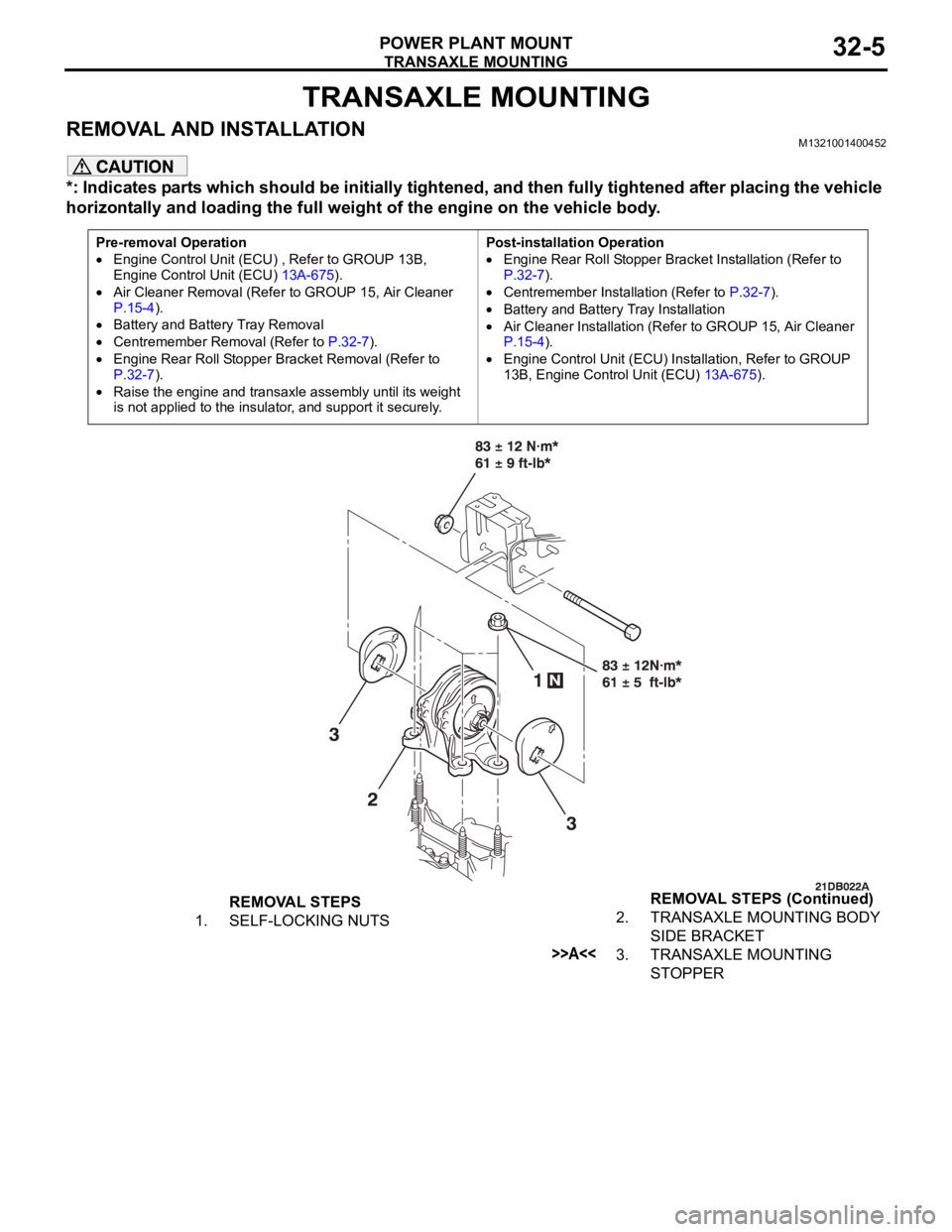

TRANSAXLE MOUNTING

POWER PLANT MOUNT32-5

TRANSAXLE MOUNTING

REMOVAL AND INSTALLATIONM1321001400452

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Engine Control Unit (ECU) , Refer to GROUP 13B,

Engine Control Unit (ECU) 13A-675).

Air Cleaner Removal (Refer to GROUP 15, Air Cleaner

P.15-4).

Battery and Battery Tray Removal

Centremember Removal (Refer to P.32-7).

Engine Rear Roll Stopper Bracket Removal (Refer to

P.32-7).

Raise the engine and transaxle assembly until its weight

is not applied to the insulator, and support it securely.Post-installation Operation

Engine Rear Roll Stopper Bracket Installation (Refer to

P.32-7).

Centremember Installation (Refer to P.32-7).

Battery and Battery Tray Installation

Air Cleaner Installation (Refer to GROUP 15, Air Cleaner

P.15-4).

Engine Control Unit (ECU) Installation, Refer to GROUP

13B, Engine Control Unit (ECU) 13A-675).

REMOVAL STEPS

1. SELF-LOCKING NUTS2. TRANSAXLE MOUNTING BODY

SIDE BRACKET

>>A<<3. TRANSAXLE MOUNTING

STOPPER REMOVAL STEPS (Continued)

Page 1023 of 1500

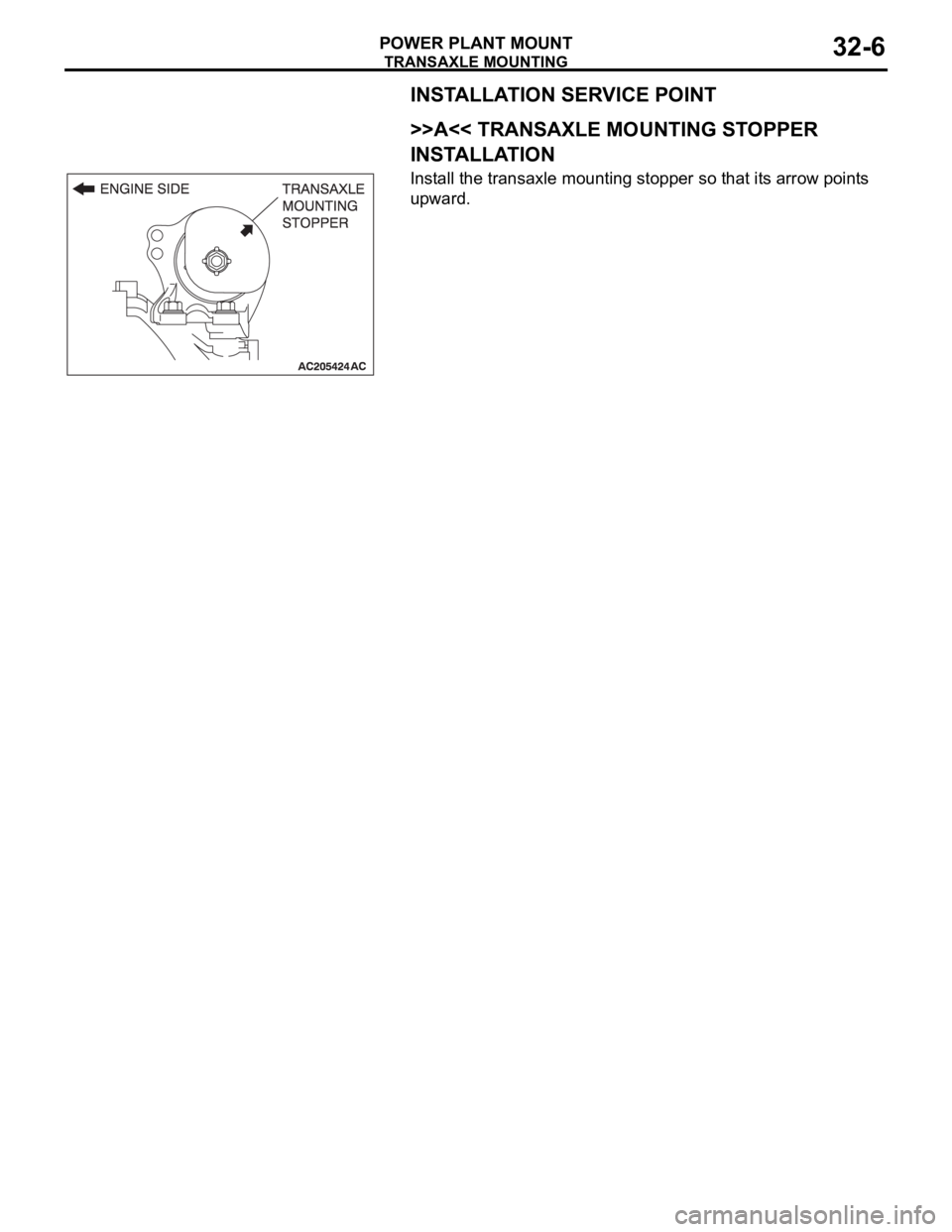

TRANSAXLE MOUNTING

POWER PLANT MOUNT32-6

INSTALLATION SERVICE POINT

.

>>A<< TRANSAXLE MOUNTING STOPPER

INSTALLATION

Install the transaxle mounting stopper so that its arrow points

upward.

Page 1024 of 1500

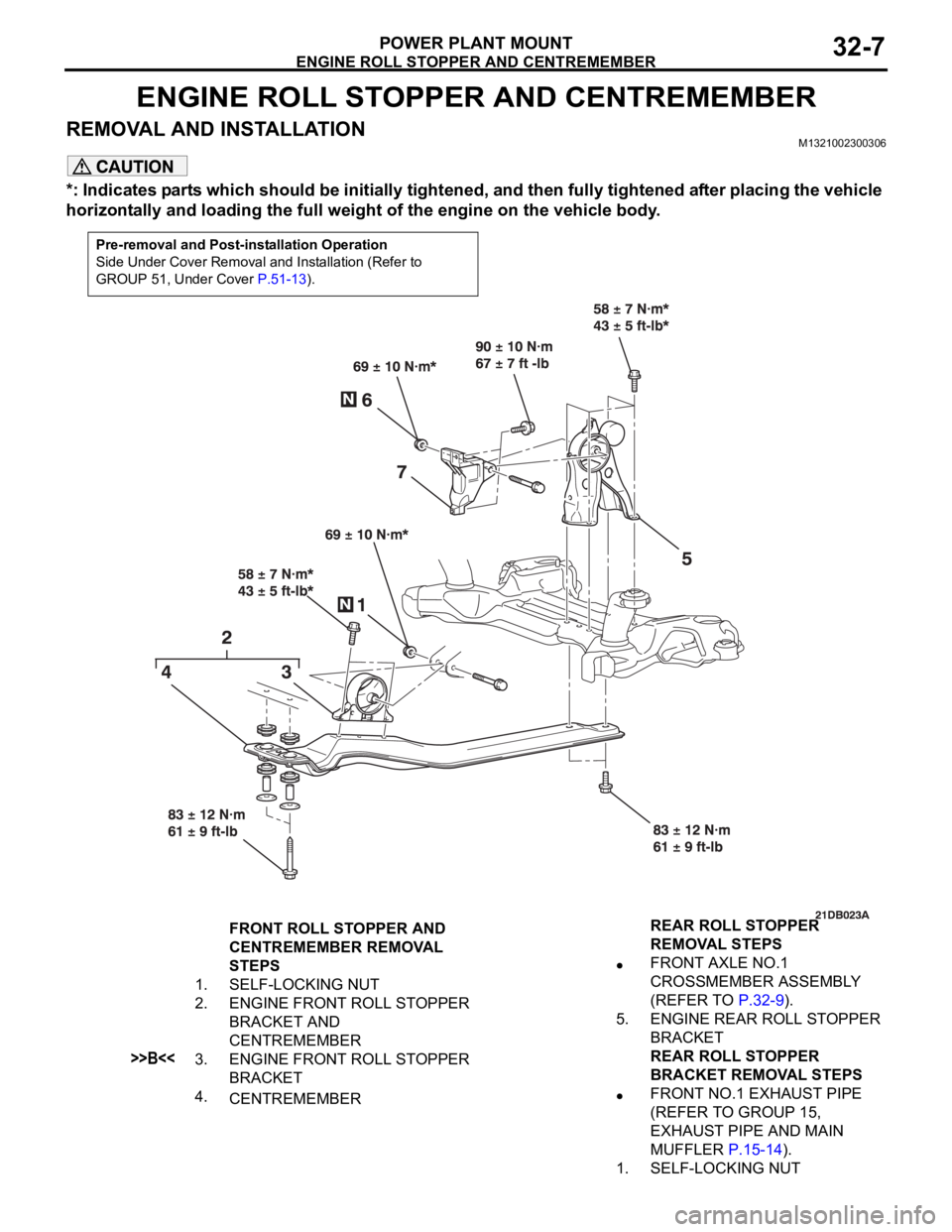

ENGINE ROLL STOPPER AND CENTREMEMBER

POWER PLANT MOUNT32-7

ENGINE ROLL STOPPER AND CENTREMEMBER

REMOVAL AND INSTALLATIONM1321002300306

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Side Under Cover Removal and Installation (Refer to

GROUP 51, Under Cover P.51-13).

FRONT ROLL STOPPER AND

CENTREMEMBER REMOVAL

STEPS

1. SELF-LOCKING NUT

2. ENGINE FRONT ROLL STOPPER

BRACKET AND

CENTREMEMBER

>>B<<3. ENGINE FRONT ROLL STOPPER

BRACKET

4.

CENTREMEMBERREAR ROLL STOPPER

REMOVAL STEPS

FRONT AXLE NO.1

CROSSMEMBER ASSEMBLY

(REFER TO P.32-9).

5. ENGINE REAR ROLL STOPPER

BRACKET

REAR ROLL STOPPER

BRACKET REMOVAL STEPS

FRONT NO.1 EXHAUST PIPE

(REFER TO GROUP 15,

EXHAUST PIPE AND MAIN

MUFFLER P.15-14).

1. SELF-LOCKING NUT

Page 1025 of 1500

ENGINE ROLL STOPPER AND CENTREMEMBER

POWER PLANT MOUNT32-8

INSTALLATION SERVICE POINTS

.

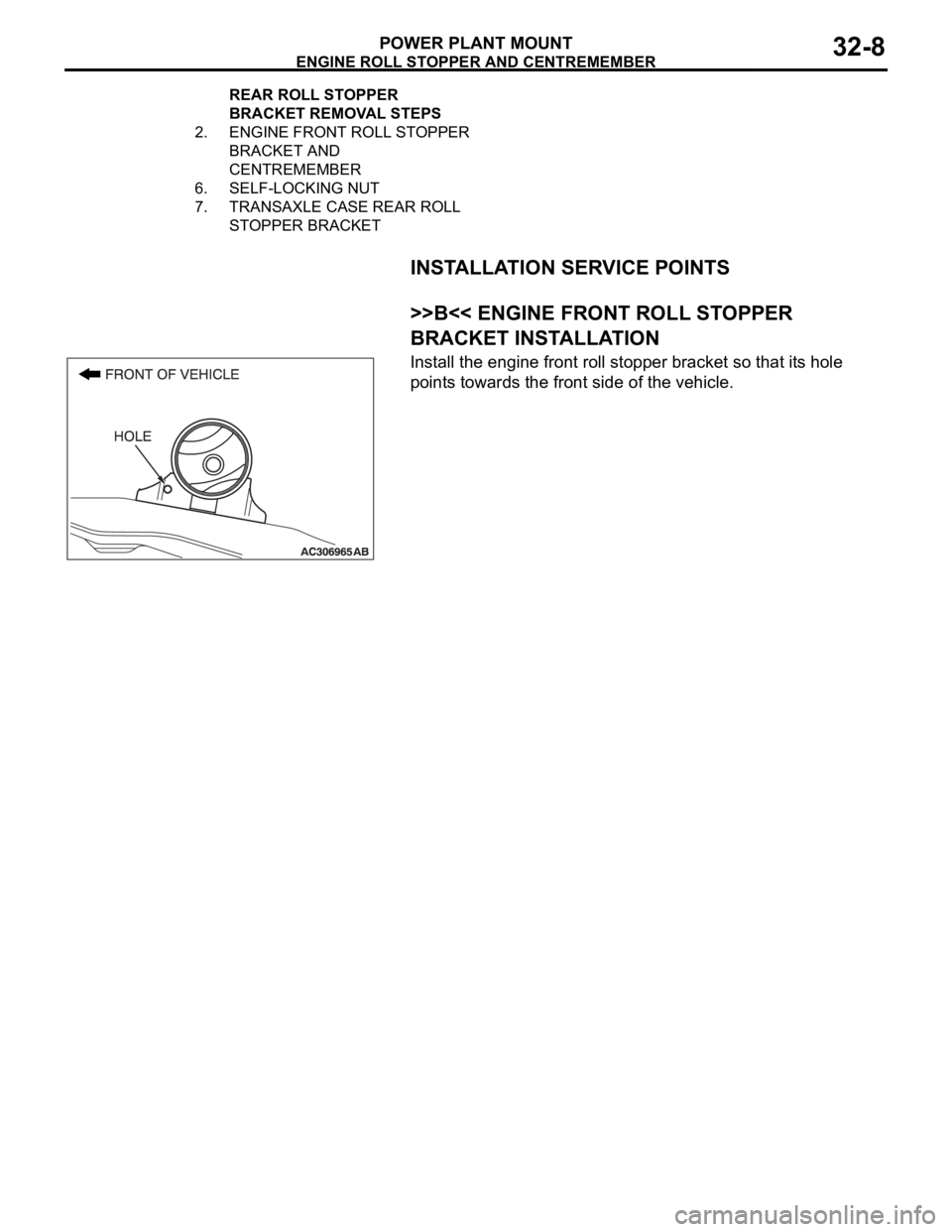

>>B<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its hole

points towards the front side of the vehicle.

2. ENGINE FRONT ROLL STOPPER

BRACKET AND

CENTREMEMBER

6. SELF-LOCKING NUT

7. TRANSAXLE CASE REAR ROLL

STOPPER BRACKET REAR ROLL STOPPER

BRACKET REMOVAL STEPS

Page 1026 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-9

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200551

Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions (P.52B-16), Air bag Module and Clock Spring (P.52B-237). Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in the unladen condition.

Pre-removal Operation

Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Hoses Removal and Installation (Refer to

GROUP 37, Power Steering Hoses P.37A-57).

Air Bag Module and Steering Wheel Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-23).

Clock Spring Removal (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Floor Console Assembly Removal (Refer to GROUP 52A,

Floor Console Assembly P.52A-10).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Removal

(Refer to GROUP 52A, Trims P.52A-11).

Trunk Lid Release Handle Cover Removal (Refer to

GROUP 42, Trunk Lid P.42-63).

Accelerator Stopper Removal (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Front Floor Carpet Removal

Centremember Removal (Refer to P.32-7).Post-installation Operation

Centremember Installation (Refer to P.32-7).

Front Floor Carpet Installation

Accelerator Stopper Installation (Refer to GROUP 17,

Accelerator Pedal P.17-9).

Trunk Lid Release Handle Cover Installation (Refer to

GROUP 42, Trunk Lid P.42-63).

Front Scuff Plate (LH) and Cowl Side Trim (LH) Installa-

tion (Refer to GROUP 52A, Trims P.52A-11).

Floor Console Assembly Installation (Refer to GROUP

52A, Floor Console Assembly P.52A-10).

Clock Spring Installation (Refer to GROUP 52B, Air Bag

Module and Clock Spring P.52B-237).

Steering Wheel Assembly and Air Bag Module Installation

(Refer to P.37-23).

Check the dust cover for cracks or damage by pushing it

with your finger.

Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service Fluid Replacement P.37-18).

Power Steering Fluid Line Bleeding (Refer to P.37-18).

Checking Steering Wheel Position with Wheels Straight

Ahead.

Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

Front Wheel Alignment Check and

Adjustment P.33-6).

Page 1027 of 1500

Page 1028 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-11

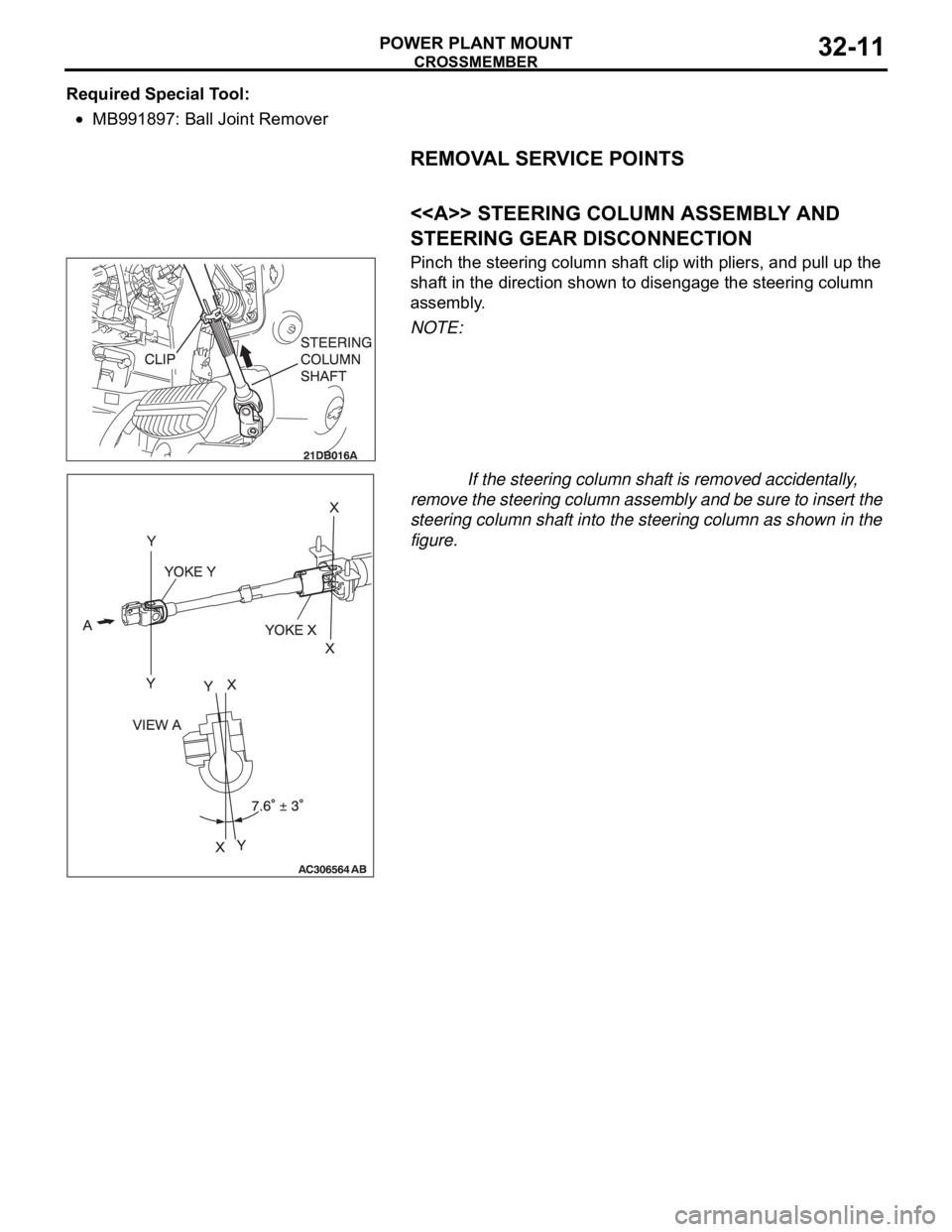

Required Special Tool:

MB991897: Ball Joint Remover

REMOVAL SERVICE POINTS

.

<> STEERING COLUMN ASSEMBLY AND

STEERING GEAR DISCONNECTION

Pinch the steering column shaft clip with pliers, and pull up the

shaft in the direction shown to disengage the steering column

assembly.

NOTE:

If the steering column shaft is removed accidentally,

remove the steering column assembly and be sure to insert the

steering column shaft into the steering column as shown in the

figure.

.

Page 1029 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-12

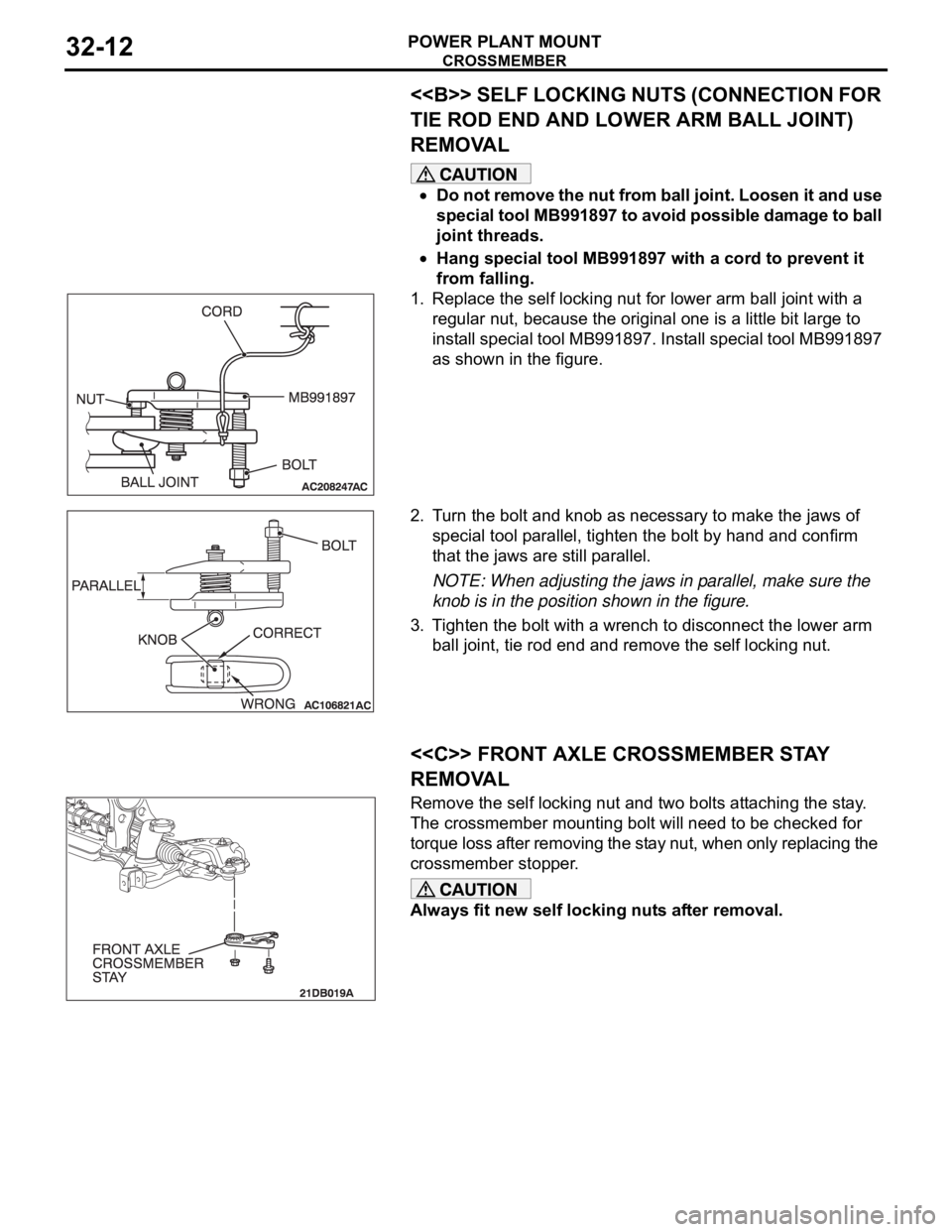

<> SELF LOCKING NUTS (CONNECTION FOR

TIE ROD END AND LOWER ARM BALL JOINT)

REMOVAL

Do not remove the nut from ball joint. Loosen it and use

special tool MB991897 to avoid possible damage to ball

joint threads.

Hang special tool MB991897 with a cord to prevent it

from falling.

1. Replace the self locking nut for lower arm ball joint with a

regular nut, because the original one is a little bit large to

install special tool MB991897. Install special tool MB991897

as shown in the figure.

2. Turn the bolt and knob as necessary to make the jaws of

special tool parallel, tighten the bolt by hand and confirm

that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make sure the

knob is in the position shown in the figure.

3. Tighten the bolt with a wrench to disconnect the lower arm

ball joint, tie rod end and remove the self locking nut.

.

<

REMOVAL

Remove the self locking nut and two bolts attaching the stay.

The crossmember mounting bolt will need to be checked for

torque loss after removing the stay nut, when only replacing the

crossmember stopper.

Always fit new self locking nuts after removal.

.

Page 1030 of 1500

CROSSMEMBER

POWER PLANT MOUNT32-13

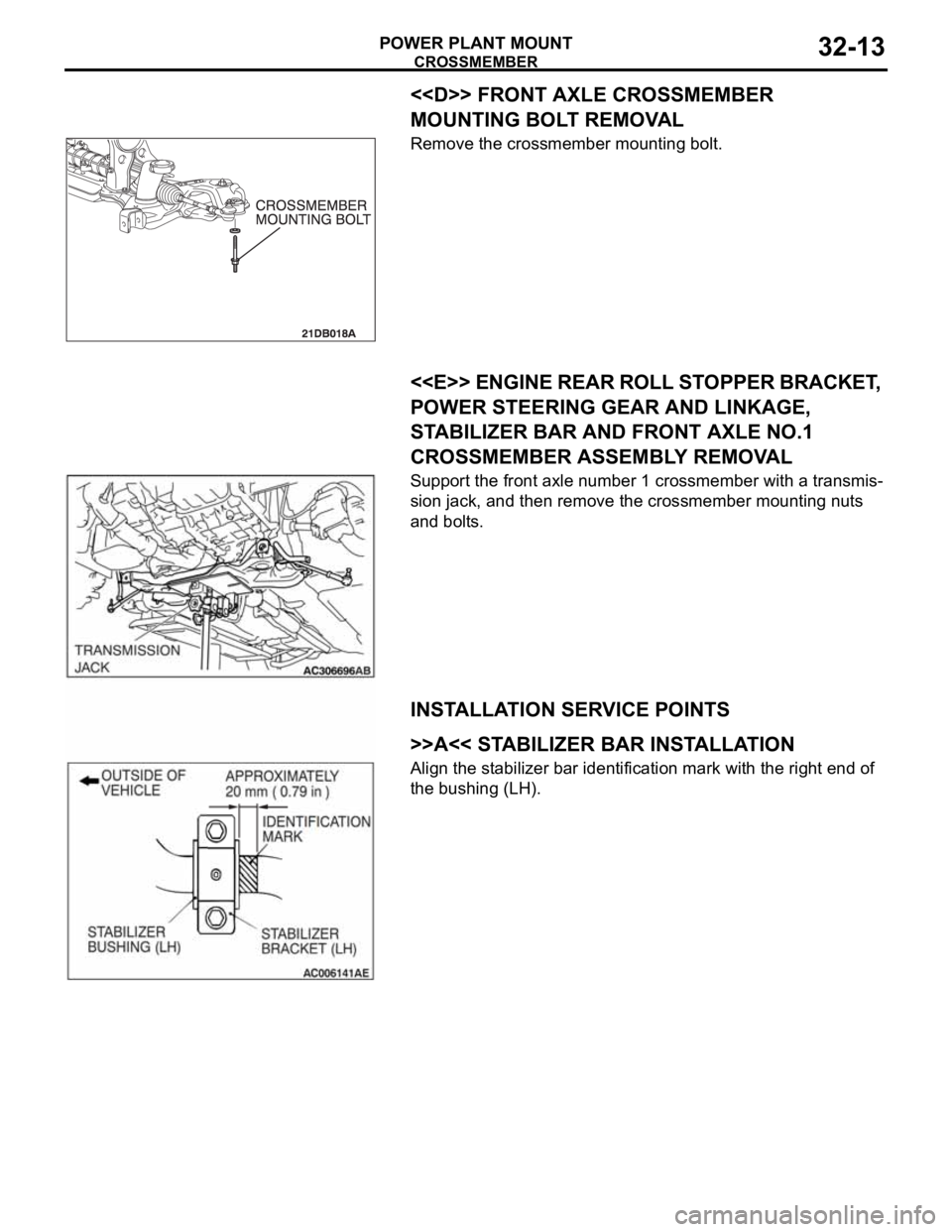

<

MOUNTING BOLT REMOVAL

Remove the crossmember mounting bolt.

.

<

POWER STEERING GEAR AND LINKAGE,

STABILIZER BAR AND FRONT AXLE NO.1

CROSSMEMBER ASSEMBLY REMOVAL

Support the front axle number 1 crossmember with a transmis-

sion jack, and then remove the crossmember mounting nuts

and bolts.

INSTALLATION SERVICE POINTS

.

>>A<< STABILIZER BAR INSTALLATION

Align the stabilizer bar identification mark with the right end of

the bushing (LH).

.