Battery MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1137 of 1500

KEYLESS ENTRY SYSTEM

BODY42-70

HOW TO REPLACE THE TRANSMITTER

BATTERY

BGBCHGFB

Do not allow water or dust to enter the inside of the trans-

mitter when it is opened. Also, do not touch the precision

electronic device.

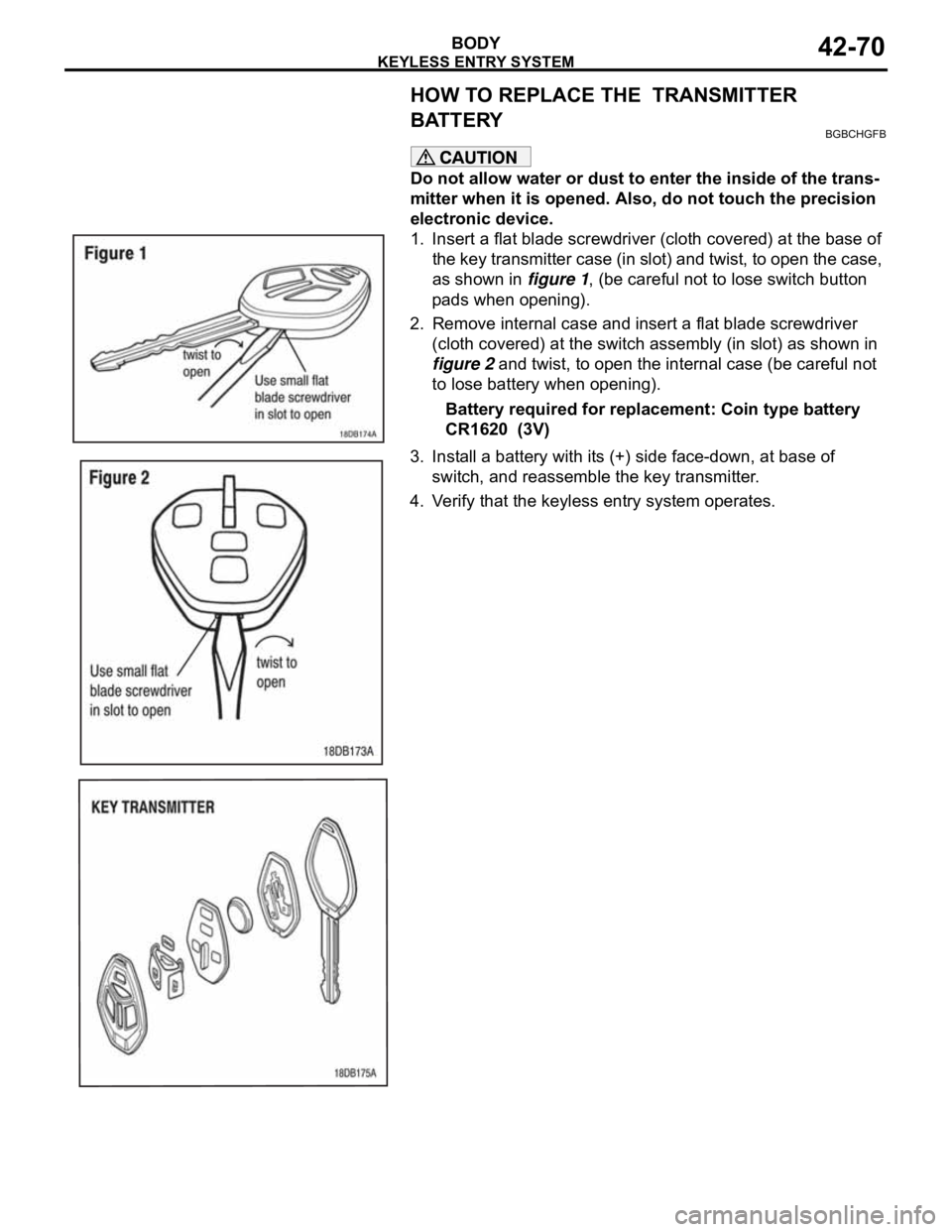

1. Insert a flat blade screwdriver (cloth covered) at the base of

the key transmitter case (in slot) and twist, to open the case,

as shown in figure 1, (be careful not to lose switch button

pads when opening).

2. Remove internal case and insert a flat blade screwdriver

(cloth covered) at the switch assembly (in slot) as shown in

figure 2 and twist, to open the internal case (be careful not

to lose battery when opening).

Battery required for replacement: Coin type battery

CR1620 (3V)

3. Install a battery with its (+) side face-down, at base of

switch, and reassemble the key transmitter.

4. Verify that the keyless entry system operates.

Page 1191 of 1500

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM35A-26

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

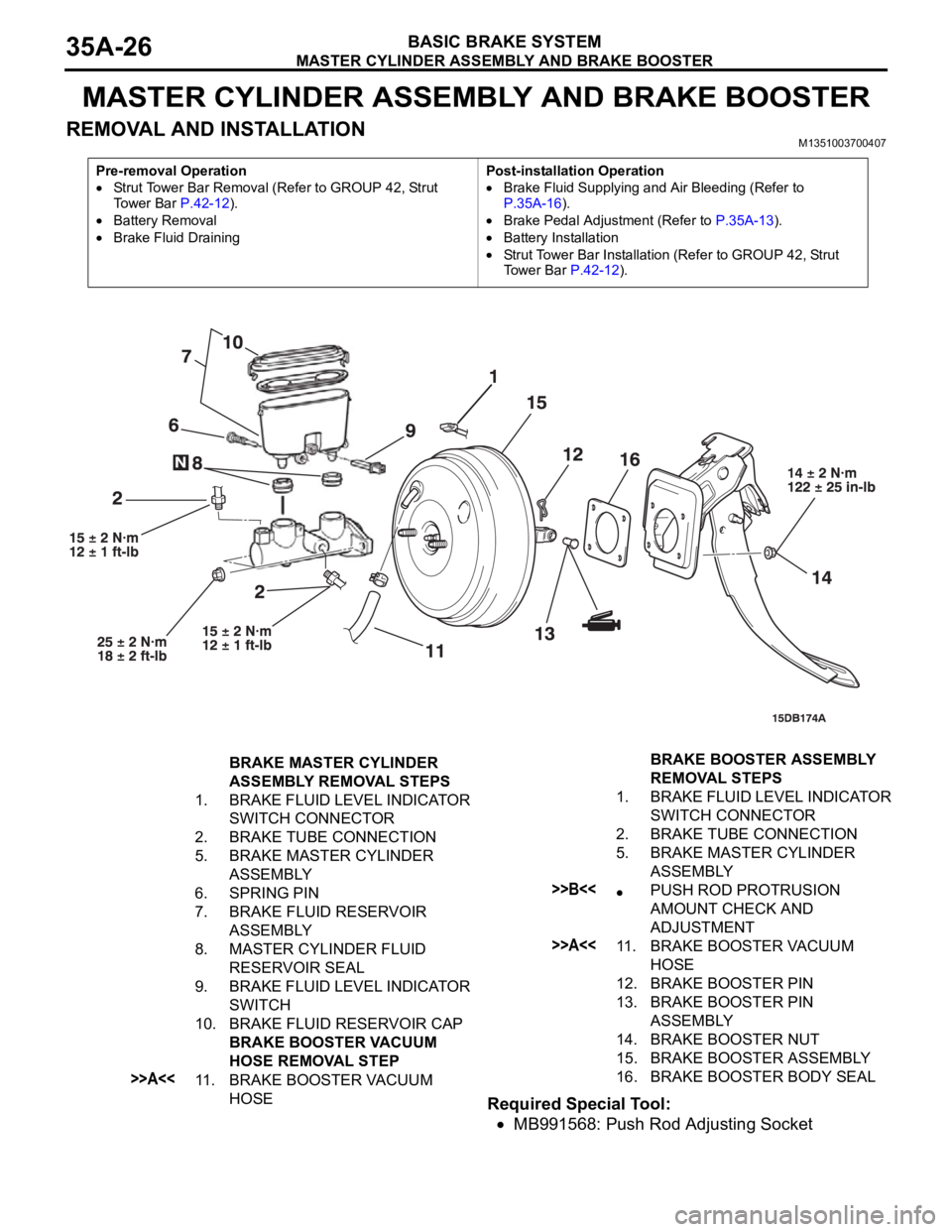

REMOVAL AND INSTALLATIONM1351003700407

Required Special Tool:

MB991568: Push Rod Adjusting Socket

Pre-removal Operation

Strut Tower Bar Removal (Refer to GROUP 42, Strut

To w e r B a r P.42-12).

Battery Removal

Brake Fluid DrainingPost-installation Operation

Brake Fluid Supplying and Air Bleeding (Refer to

P.35A-16).

Brake Pedal Adjustment (Refer to P.35A-13).

Battery Installation

Strut Tower Bar Installation (Refer to GROUP 42, Strut

Tower Bar P.42-12).

BRAKE MASTER CYLINDER

ASSEMBLY REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

6. SPRING PIN

7. BRAKE FLUID RESERVOIR

ASSEMBLY

8. MASTER CYLINDER FLUID

RESERVOIR SEAL

9. BRAKE FLUID LEVEL INDICATOR

SWITCH

10. BRAKE FLUID RESERVOIR CAP

BRAKE BOOSTER VACUUM

HOSE REMOVAL STEP

>>A<<11. BRAKE BOOSTER VACUUM

HOSE BRAKE BOOSTER ASSEMBLY

REMOVAL STEPS

1. BRAKE FLUID LEVEL INDICATOR

SWITCH CONNECTOR

2. BRAKE TUBE CONNECTION

5. BRAKE MASTER CYLINDER

ASSEMBLY

>>B<

ADJUSTMENT

>>A<<11. BRAKE BOOSTER VACUUM

HOSE

12. BRAKE BOOSTER PIN

13. BRAKE BOOSTER PIN

ASSEMBLY

14. BRAKE BOOSTER NUT

15. BRAKE BOOSTER ASSEMBLY

16. BRAKE BOOSTER BODY SEAL

Page 1243 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-22

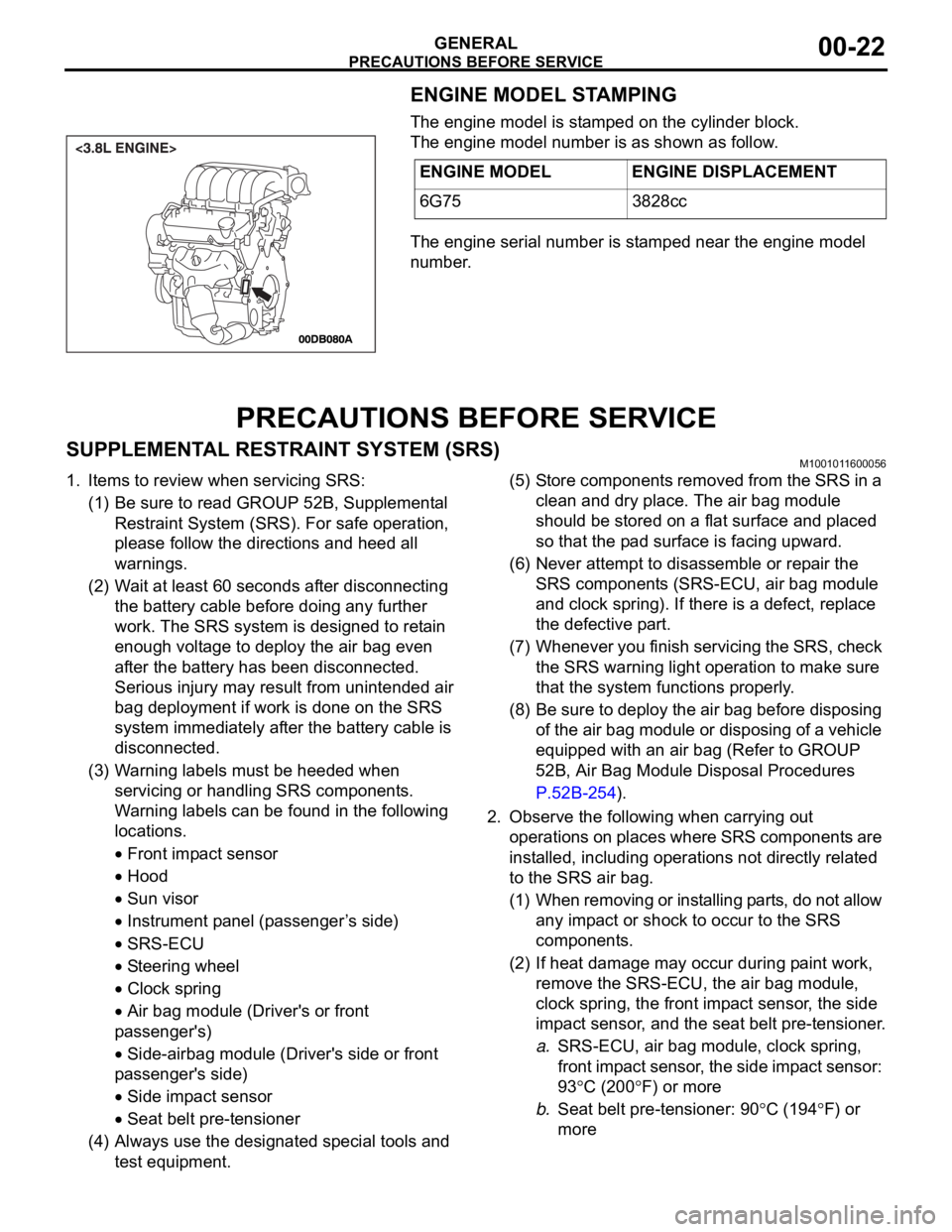

ENGINE MODEL STAMPING

The engine model is stamped on the cylinder block.

The engine model number is as shown as follow.

The engine serial number is stamped near the engine model

number.

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)M1001011600056

1. Items to review when servicing SRS:

(1) Be sure to read GROUP 52B, Supplemental

Restraint System (SRS). For safe operation,

please follow the directions and heed all

warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

Warning labels can be found in the following

locations.

Front impact sensor

Hood

Sun visor

Instrument panel (passenger ’s side)

SRS-ECU

Steering wheel

Clock spring

Air bag module (Driver's or front

passenger's)

Side-airbag module (Driver's side or front

passenger's side)

Side impact sensor

Seat belt pre-tensioner

(4) Always use the designated special tools and

test equipment.(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag (Refer to GROUP

52B, Air Bag Module Disposal Procedures

P.52B-254).

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

a.SRS-ECU, air bag module, clock spring,

front impact sensor, the side impact sensor:

93

C (200F) or more

b.Seat belt pre-tensioner: 90

C (194F) or

more ENGINE MODEL ENGINE DISPLACEMENT

6G75 3828cc

Page 1245 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-24

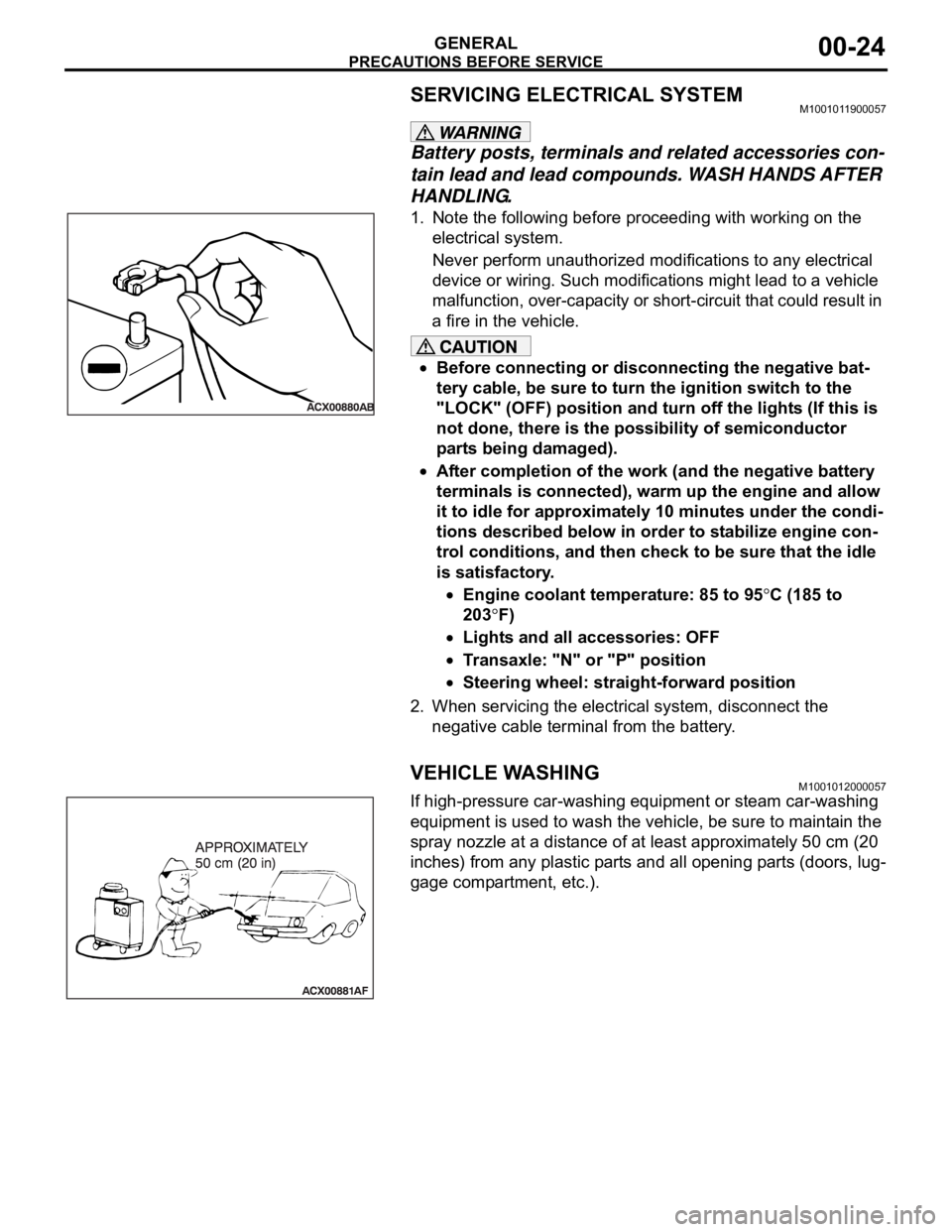

SERVICING ELECTRICAL SYSTEMM1001011900057

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Note the following before proceeding with working on the

electrical system.

Never perform unauthorized modifications to any electrical

device or wiring. Such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result in

a fire in the vehicle.

Before connecting or disconnecting the negative bat-

tery cable, be sure to turn the ignition switch to the

"LOCK" (OFF) position and turn off the lights (If this is

not done, there is the possibility of semiconductor

parts being damaged).

After completion of the work (and the negative battery

terminals is connected), warm up the engine and allow

it to idle for approximately 10 minutes under the condi-

tions described below in order to stabilize engine con-

trol conditions, and then check to be sure that the idle

is satisfactory.

Engine coolant temperature: 85 to 95C (185 to

203

F)

Lights and all accessories: OFF

Transaxle: "N" or "P" position

Steering wheel: straight-forward position

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

VEHICLE WASHINGM1001012000057

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least approximately 50 cm (20

inches) from any plastic parts and all opening parts (doors, lug-

gage compartment, etc.).

Page 1272 of 1500

MAINTENANCE SERVICE

GENERAL00-51

18. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE)

M1001009600048

Visually inspect the front/rear suspension components for dete-

rioration and damage. Re-tighten the front/rear suspension

components retaining bolts to specified torque.

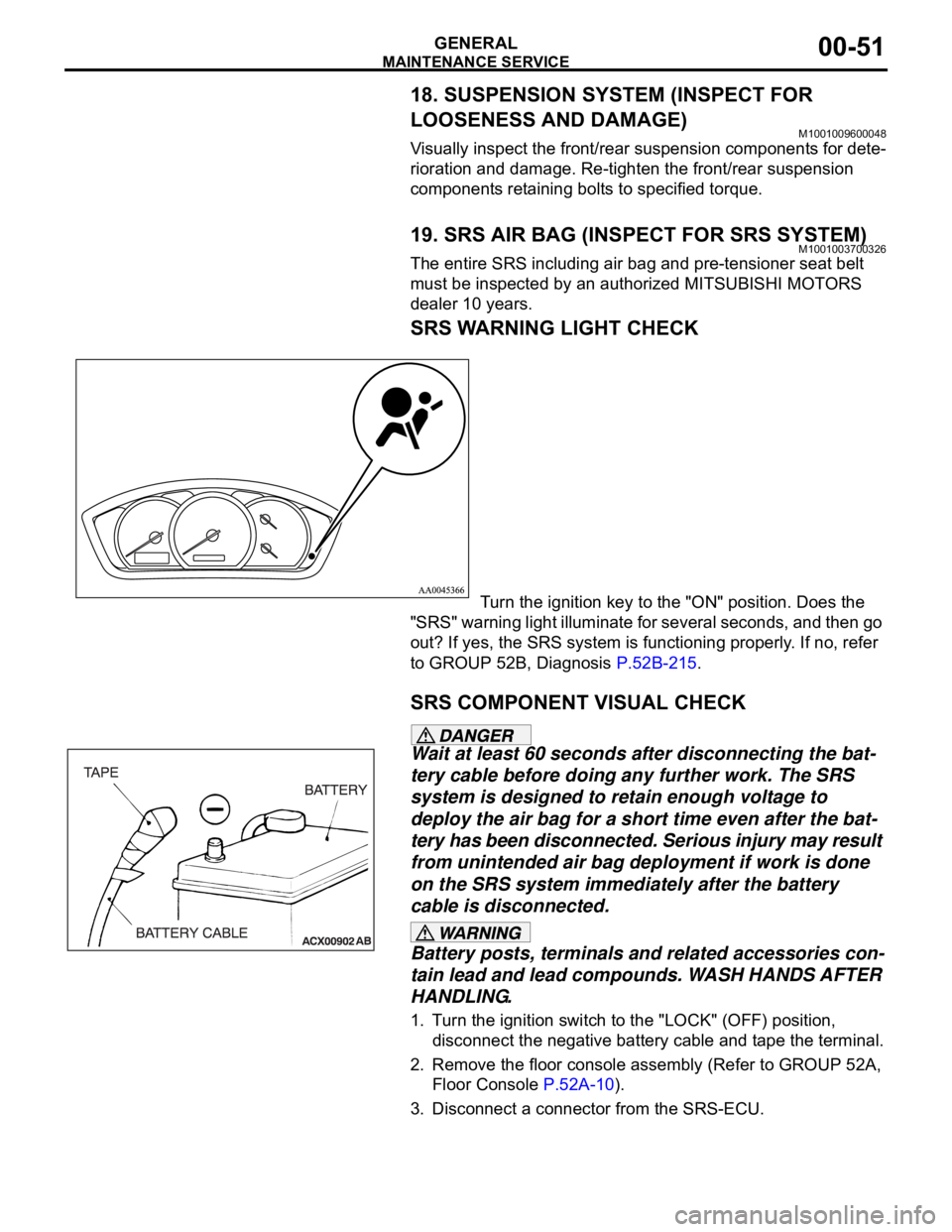

19. SRS AIR BAG (INSPECT FOR SRS SYSTEM)M1001003700326

The entire SRS including air bag and pre-tensioner seat belt

must be inspected by an authorized MITSUBISHI MOTORS

dealer 10 years.

SRS WARNING LIGHT CHECK

Turn the ignition key to the "ON" position. Does the

"SRS" warning light illuminate for several seconds, and then go

out? If yes, the SRS system is functioning properly. If no, refer

to GROUP 52B, Diagnosis P.52B-215.

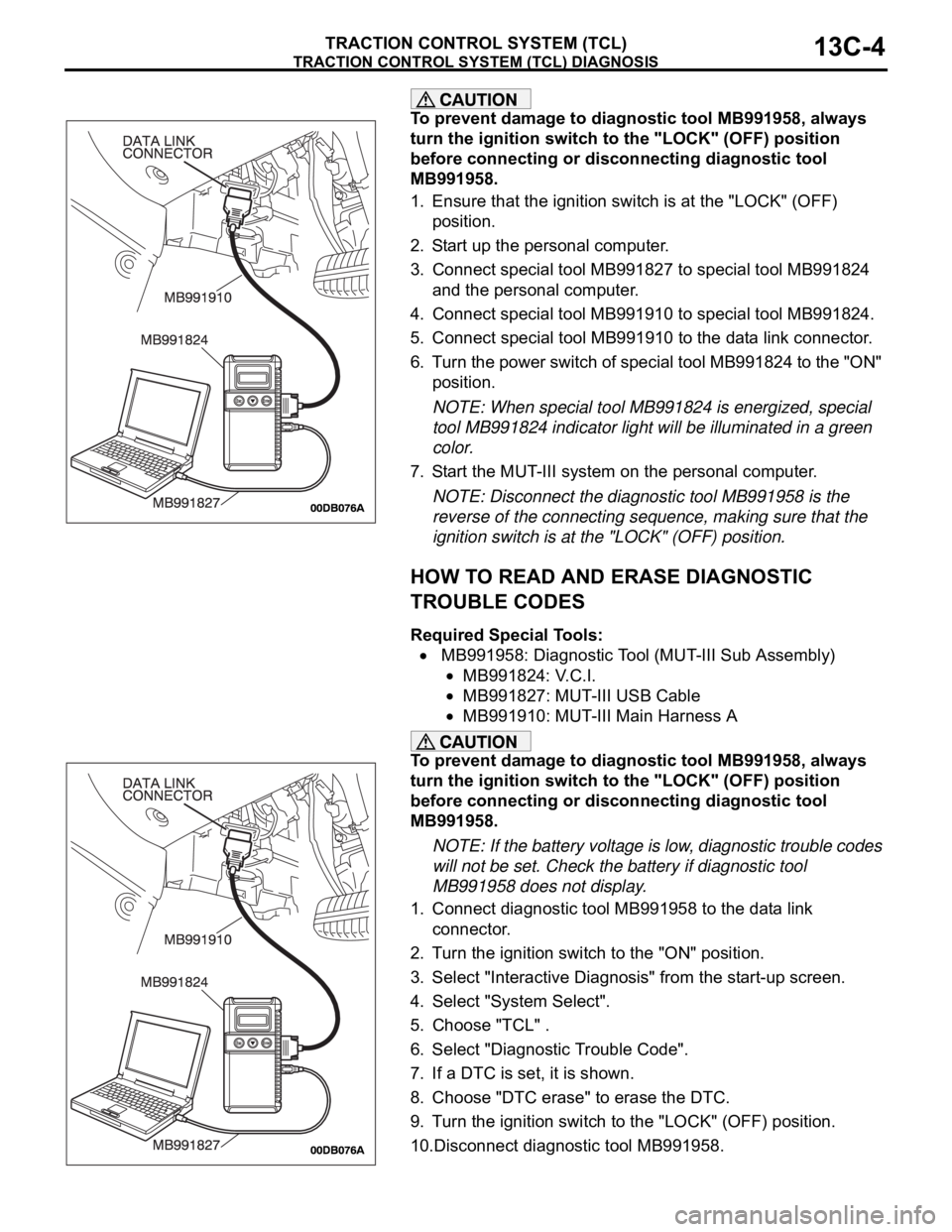

SRS COMPONENT VISUAL CHECK

Wait at least 60 seconds after disconnecting the bat-

tery cable before doing any further work. The SRS

system is designed to retain enough voltage to

deploy the air bag for a short time even after the bat-

tery has been disconnected. Serious injury may result

from unintended air bag deployment if work is done

on the SRS system immediately after the battery

cable is disconnected.

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Turn the ignition switch to the "LOCK" (OFF) position,

disconnect the negative battery cable and tape the terminal.

2. Remove the floor console assembly (Refer to GROUP 52A,

Floor Console P.52A-10).

3. Disconnect a connector from the SRS-ECU.

Page 1283 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-4

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824.

5. Connect special tool MB991910 to the data link connector.

6. Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When special tool MB991824 is energized, special

tool MB991824 indicator light will be illuminated in a green

color.

7. Start the MUT-III system on the personal computer.

NOTE: Disconnect the diagnostic tool MB991958 is the

reverse of the connecting sequence, making sure that the

ignition switch is at the "LOCK" (OFF) position.

HOW TO READ AND ERASE DIAGNOSTIC

TROUBLE CODES

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

NOTE: If the battery voltage is low, diagnostic trouble codes

will not be set. Check the battery if diagnostic tool

MB991958 does not display.

1. Connect diagnostic tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System Select".

5. Choose "TCL" .

6. Select "Diagnostic Trouble Code".

7. If a DTC is set, it is shown.

8. Choose "DTC erase" to erase the DTC.

9. Turn the ignition switch to the "LOCK" (OFF) position.

10.Disconnect diagnostic tool MB991958.

Page 1315 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-36

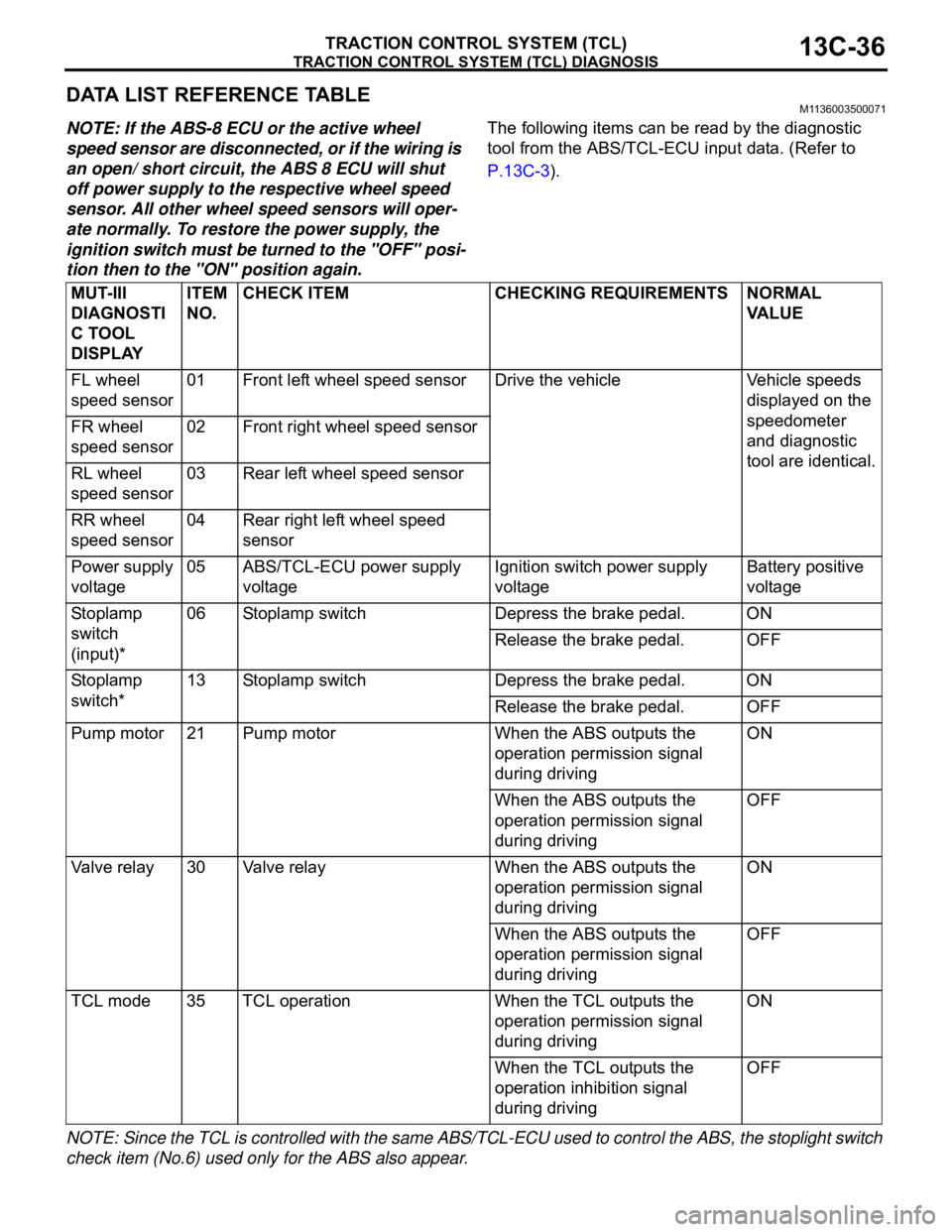

DATA LIST REFERENCE TABLEM1136003500071

NOTE: If the ABS-8 ECU or the active wheel

speed sensor are disconnected, or if the wiring is

an open/ short circuit, the ABS 8 ECU will shut

off power supply to the respective wheel speed

sensor. All other wheel speed sensors will oper-

ate normally. To restore the power supply, the

ignition switch must be turned to the "OFF" posi-

tion then to the "ON" position again.The following items can be read by the diagnostic

tool from the ABS/TCL-ECU input data. (Refer to

P.13C-3).

NOTE: Since the TCL is controlled with the same ABS/TCL-ECU used to control the ABS, the stoplight switch

check item (No.6) used only for the ABS also appear.MUT-III

DIAGNOSTI

C TOOL

DISPLAYITEM

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL

VA L U E

FL wheel

speed sensor01 Front left wheel speed sensor Drive the vehicle Vehicle speeds

displayed on the

speedometer

and diagnostic

tool are identical. FR wheel

speed sensor02 Front right wheel speed sensor

RL wheel

speed sensor03 Rear left wheel speed sensor

RR wheel

speed sensor04 Rear right left wheel speed

sensor

Power supply

voltage05 ABS/TCL-ECU power supply

voltageIgnition switch power supply

voltageBattery positive

voltage

Stoplamp

switch

(input)*06 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Stoplamp

switch*13 Stoplamp switch Depress the brake pedal. ON

Release the brake pedal. OFF

Pump motor 21 Pump motor When the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

Valve relay 30 Valve relayWhen the ABS outputs the

operation permission signal

during drivingON

When the ABS outputs the

operation permission signal

during drivingOFF

TCL mode 35 TCL operation When the TCL outputs the

operation permission signal

during drivingON

When the TCL outputs the

operation inhibition signal

during drivingOFF

Page 1317 of 1500

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-38

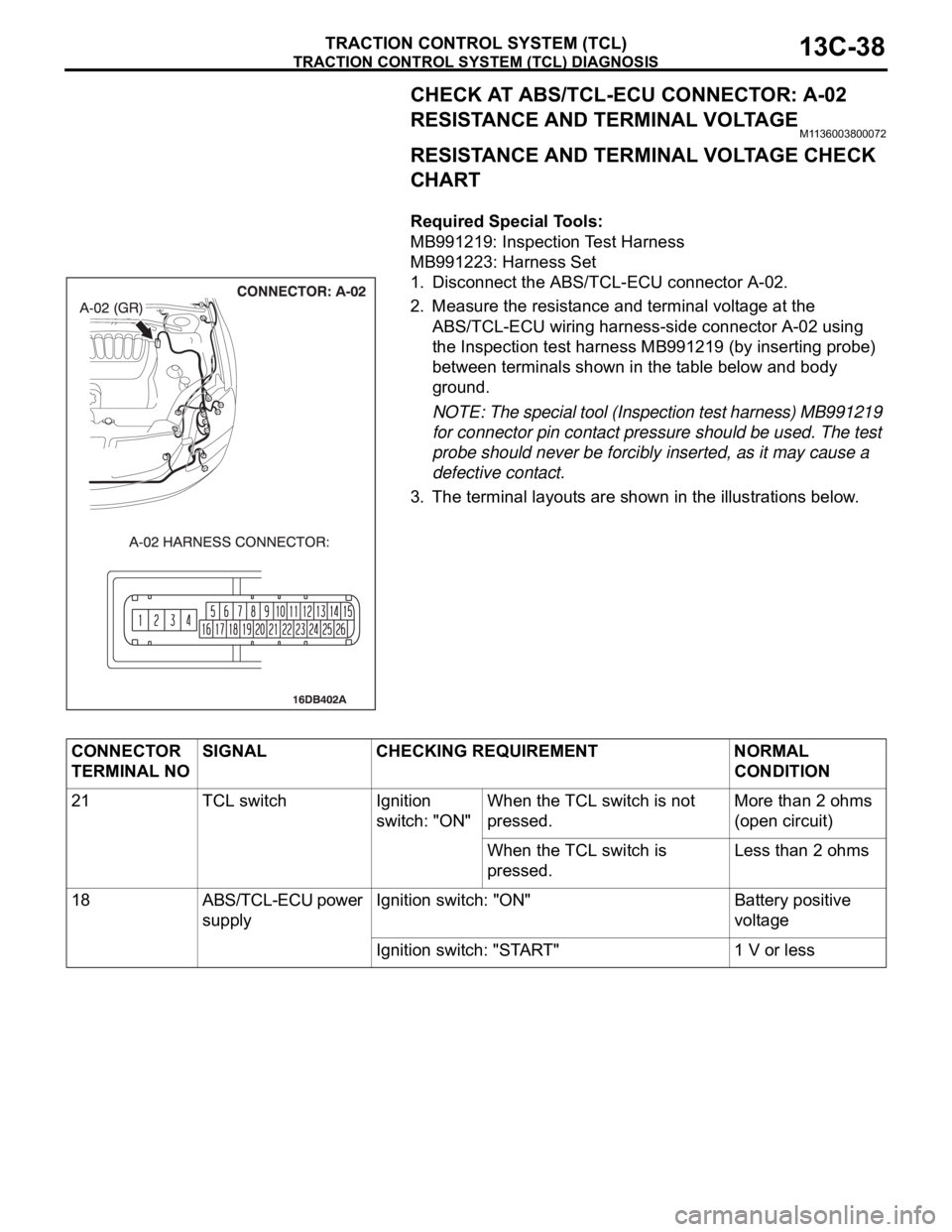

CHECK AT ABS/TCL-ECU CONNECTOR: A-02

RESISTANCE AND TERMINAL VOLTAGE

M1136003800072

RESISTANCE AND TERMINAL VOLTAGE CHECK

CHART

.

Required Special Tools:

MB991219: Inspection Test Harness

MB991223: Harness Set

1. Disconnect the ABS/TCL-ECU connector A-02.

2. Measure the resistance and terminal voltage at the

ABS/TCL-ECU wiring harness-side connector A-02 using

the Inspection test harness MB991219 (by inserting probe)

between terminals shown in the table below and body

ground.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

3. The terminal layouts are shown in the illustrations below.

CONNECTOR

TERMINAL NOSIGNAL CHECKING REQUIREMENT NORMAL

CONDITION

21 TCL switch Ignition

switch: "ON" When the TCL switch is not

pressed.More than 2 ohms

(open circuit)

When the TCL switch is

pressed.Less than 2 ohms

18 ABS/TCL-ECU power

supplyIgnition switch: "ON" Battery positive

voltage

Ignition switch: "START" 1 V or less

Page 1343 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-12

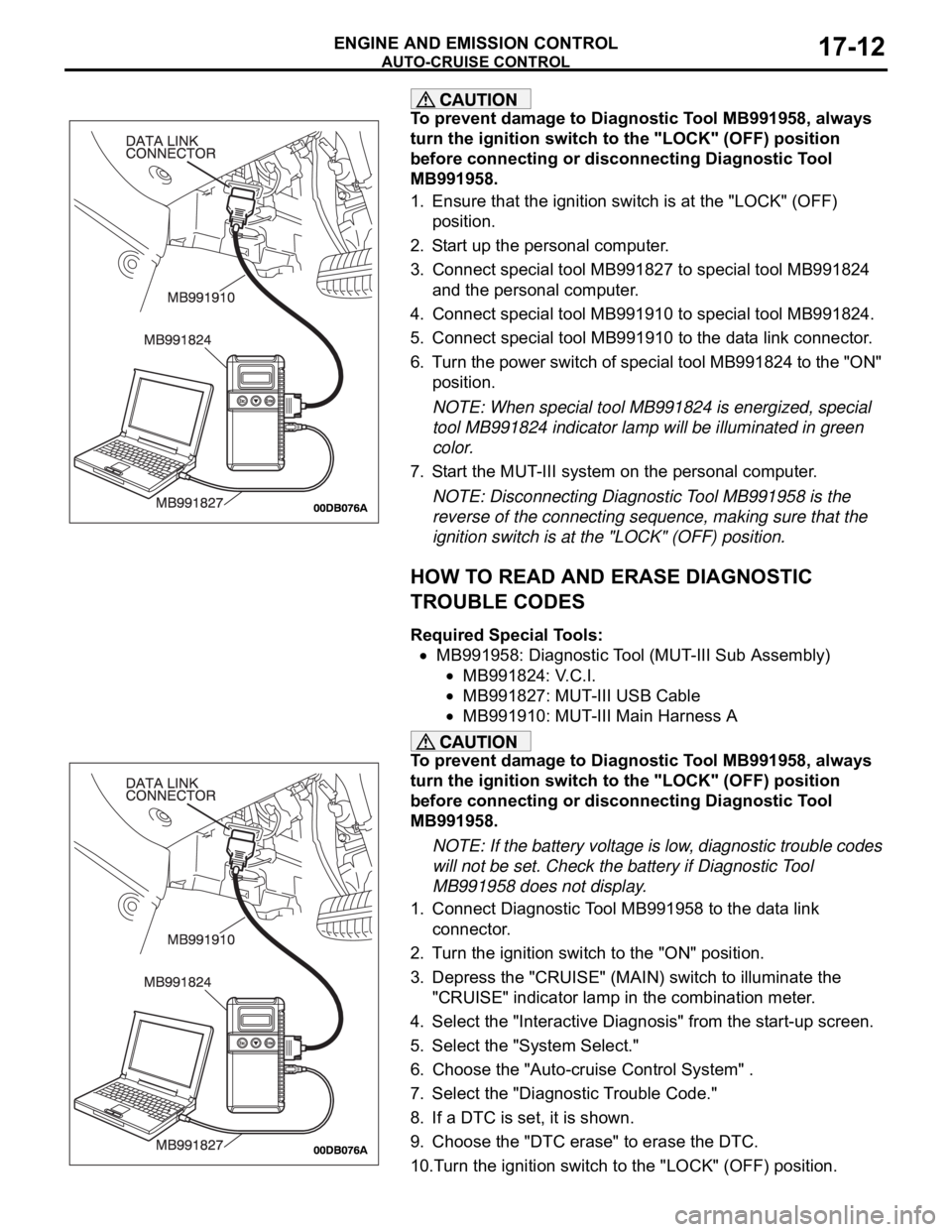

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

1. Ensure that the ignition switch is at the "LOCK" (OFF)

position.

2. Start up the personal computer.

3. Connect special tool MB991827 to special tool MB991824

and the personal computer.

4. Connect special tool MB991910 to special tool MB991824.

5. Connect special tool MB991910 to the data link connector.

6. Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When special tool MB991824 is energized, special

tool MB991824 indicator lamp will be illuminated in green

color.

7. Start the MUT-III system on the personal computer.

NOTE: Disconnecting Diagnostic Tool MB991958 is the

reverse of the connecting sequence, making sure that the

ignition switch is at the "LOCK" (OFF) position.

HOW TO READ AND ERASE DIAGNOSTIC

TROUBLE CODES

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

NOTE: If the battery voltage is low, diagnostic trouble codes

will not be set. Check the battery if Diagnostic Tool

MB991958 does not display.

1. Connect Diagnostic Tool MB991958 to the data link

connector.

2. Turn the ignition switch to the "ON" position.

3. Depress the "CRUISE" (MAIN) switch to illuminate the

"CRUISE" indicator lamp in the combination meter.

4. Select the "Interactive Diagnosis" from the start-up screen.

5. Select the "System Select."

6. Choose the "Auto-cruise Control System" .

7. Select the "Diagnostic Trouble Code."

8. If a DTC is set, it is shown.

9. Choose the "DTC erase" to erase the DTC.

10.Turn the ignition switch to the "LOCK" (OFF) position.

Page 1348 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-17

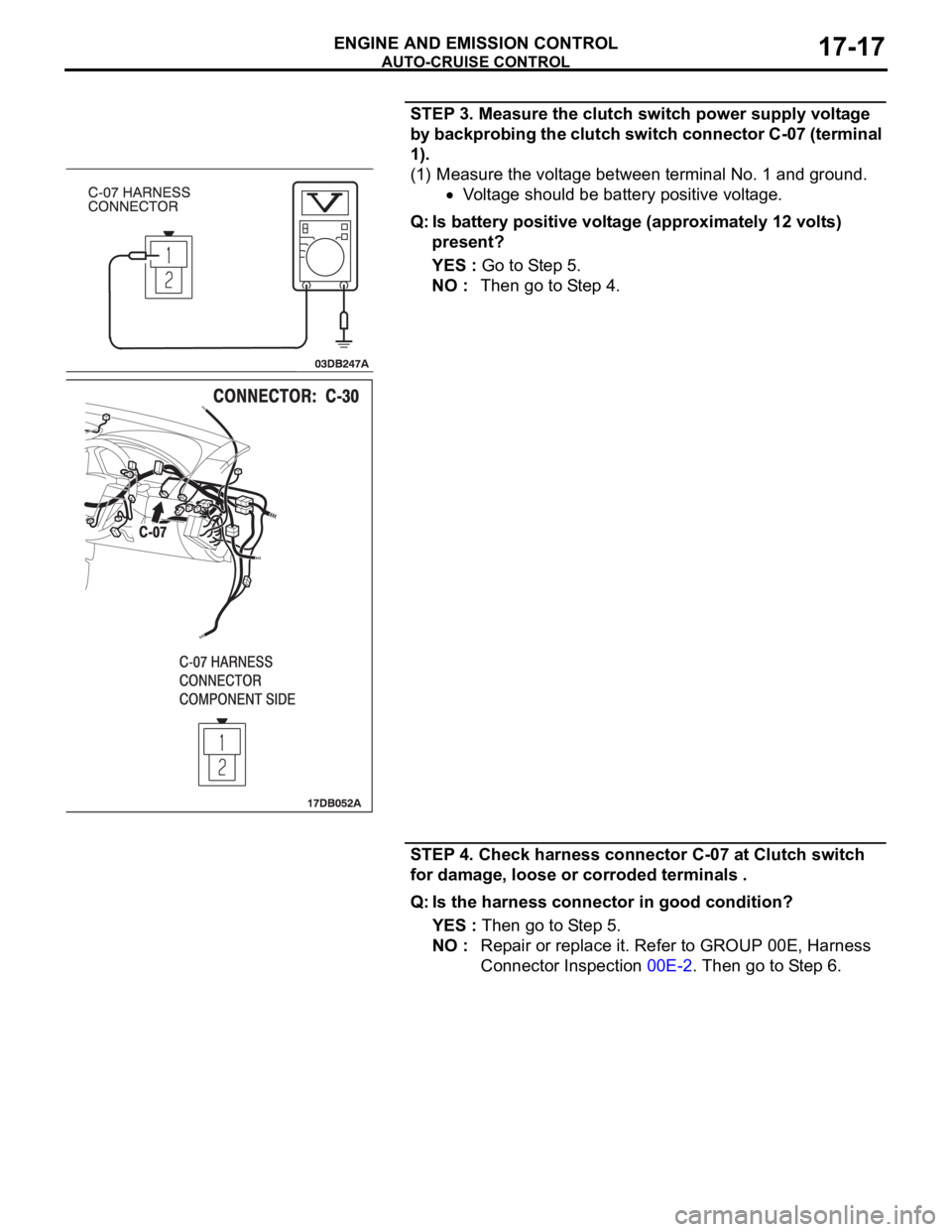

STEP 3. Measure the clutch switch power supply voltage

by backprobing the clutch switch connector C-07 (terminal

1).

(1) Measure the voltage between terminal No. 1 and ground.

Voltage should be battery positive voltage.

Q: Is battery positive voltage (approximately 12 volts)

present?

YES : Go to Step 5.

NO : Then go to Step 4.

STEP 4. Check harness connector C-07 at Clutch switch

for damage, loose or corroded terminals .

Q: Is the harness connector in good condition?

YES : Then go to Step 5.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection 00E-2. Then go to Step 6.