Battery MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1062 of 1500

DOOR MIRROR

EXTERIOR51-29

REMOVAL SERVICE POINT

.

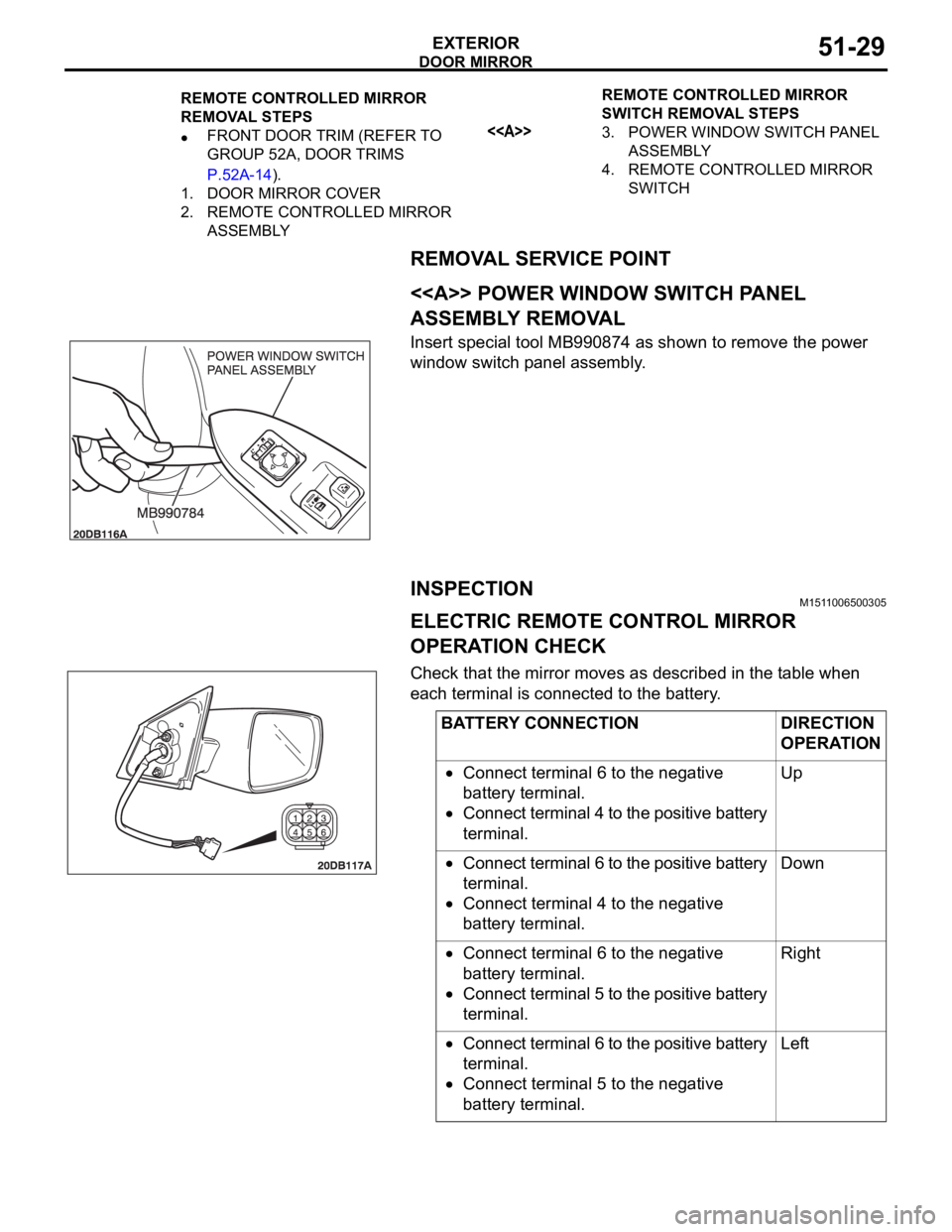

<> POWER WINDOW SWITCH PANEL

ASSEMBLY REMOVAL

Insert special tool MB990874 as shown to remove the power

window switch panel assembly.

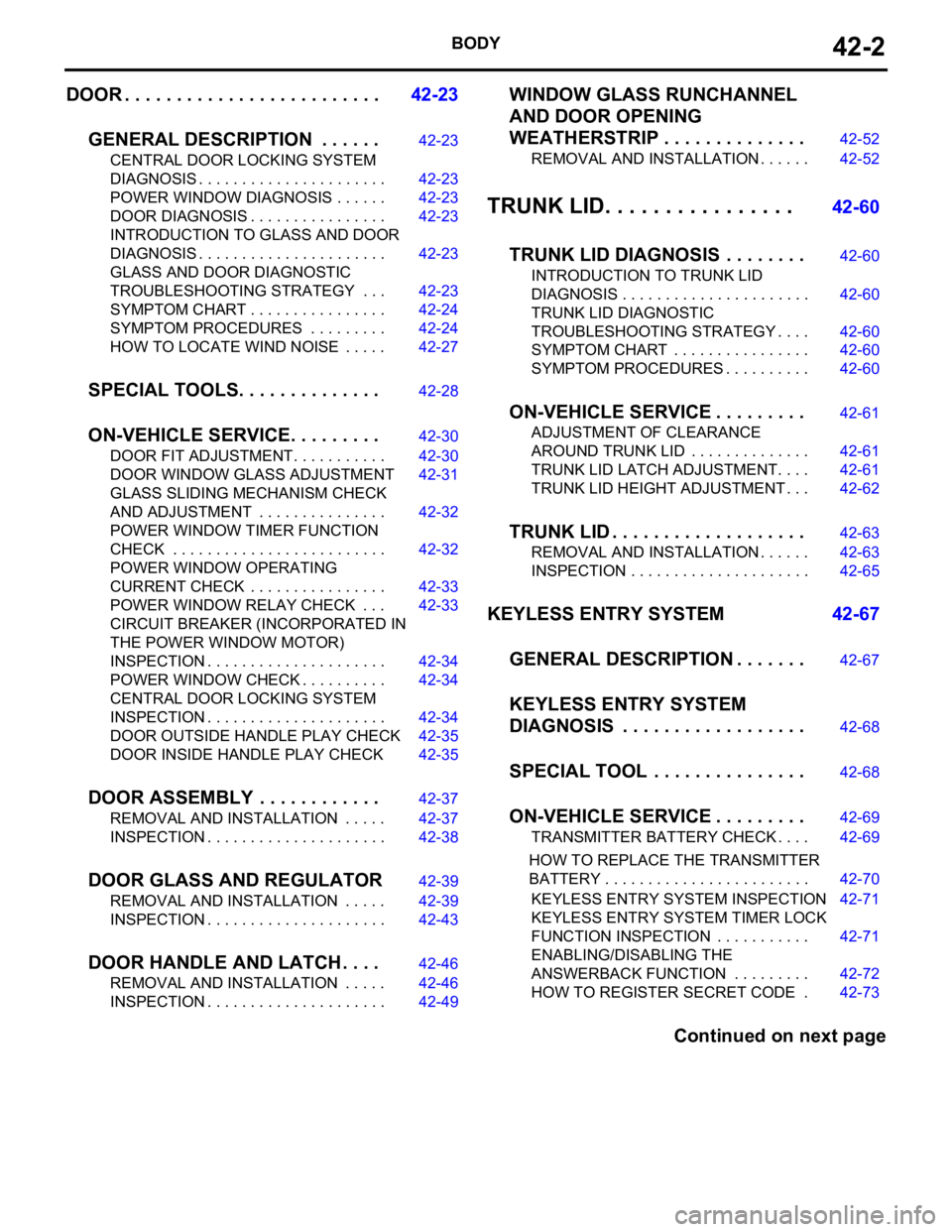

INSPECTIONM1511006500305

ELECTRIC REMOTE CONTROL MIRROR

OPERATION CHECK

Check that the mirror moves as described in the table when

each terminal is connected to the battery.

REMOTE CONTROLLED MIRROR

REMOVAL STEPS

FRONT DOOR TRIM (REFER TO

GROUP 52A, DOOR TRIMS

P.52A-14).

1. DOOR MIRROR COVER

2. REMOTE CONTROLLED MIRROR

ASSEMBLYREMOTE CONTROLLED MIRROR

SWITCH REMOVAL STEPS<>3. POWER WINDOW SWITCH PANEL

ASSEMBLY

4. REMOTE CONTROLLED MIRROR

SWITCH

BATTERY CONNECTION DIRECTION

OPERATION

Connect terminal 6 to the negative

battery terminal.

Connect terminal 4 to the positive battery

terminal.Up

Connect terminal 6 to the positive battery

terminal.

Connect terminal 4 to the negative

battery terminal.Down

Connect terminal 6 to the negative

battery terminal.

Connect terminal 5 to the positive battery

terminal.Right

Connect terminal 6 to the positive battery

terminal.

Connect terminal 5 to the negative

battery terminal.Left

Page 1069 of 1500

BODY42-2

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-23

GENERAL DESCRIPTION . . . . . .

42-23

CENTRAL DOOR LOCKING SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

POWER WINDOW DIAGNOSIS . . . . . . 42-23

DOOR DIAGNOSIS . . . . . . . . . . . . . . . . 42-23

INTRODUCTION TO GLASS AND DOOR

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

GLASS AND DOOR DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . 42-23

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-24

SYMPTOM PROCEDURES . . . . . . . . . 42-24

HOW TO LOCATE WIND NOISE . . . . . 42-27

SPECIAL TOOLS. . . . . . . . . . . . . .42-28

ON-VEHICLE SERVICE. . . . . . . . .42-30

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-30

DOOR WINDOW GLASS ADJUSTMENT42-31

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-32

POWER WINDOW TIMER FUNCTION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-32

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-33

POWER WINDOW RELAY CHECK . . . 42-33

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

POWER WINDOW CHECK . . . . . . . . . . 42-34

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR OUTSIDE HANDLE PLAY CHECK42-35

DOOR INSIDE HANDLE PLAY CHECK 42-35

DOOR ASSEMBLY . . . . . . . . . . . .42-37

REMOVAL AND INSTALLATION . . . . . 42-37

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-38

DOOR GLASS AND REGULATOR42-39

REMOVAL AND INSTALLATION . . . . . 42-39

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-43

DOOR HANDLE AND LATCH . . . .42-46

REMOVAL AND INSTALLATION . . . . . 42-46

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-49

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-52

REMOVAL AND INSTALLATION . . . . . . 42-52

TRUNK LID. . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSIS . . . . . . . .

42-60

INTRODUCTION TO TRUNK LID

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-60

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-60

SYMPTOM PROCEDURES . . . . . . . . . . 42-60

ON-VEHICLE SERVICE . . . . . . . . .42-61

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-61

TRUNK LID LATCH ADJUSTMENT. . . . 42-61

TRUNK LID HEIGHT ADJUSTMENT . . . 42-62

TRUNK LID . . . . . . . . . . . . . . . . . . .42-63

REMOVAL AND INSTALLATION . . . . . . 42-63

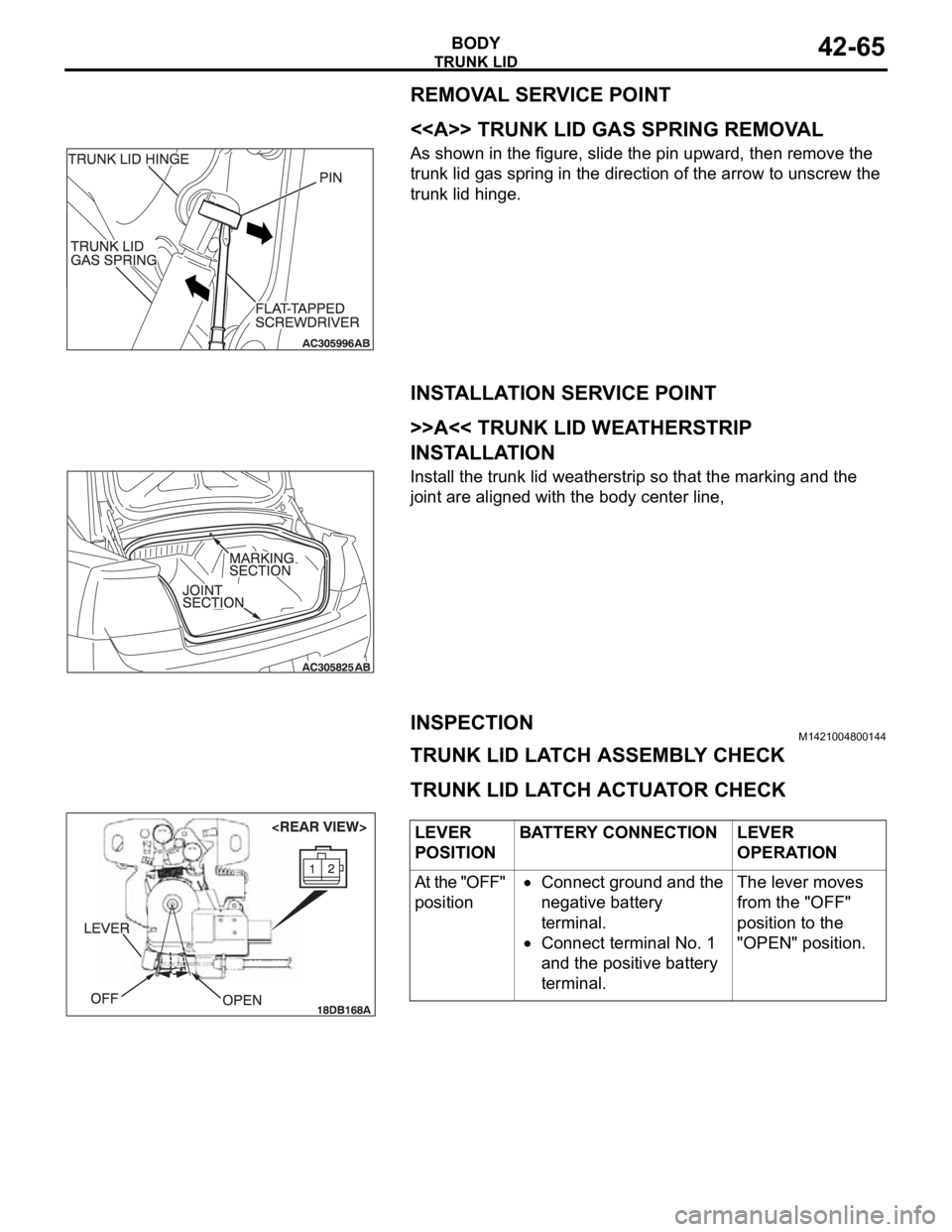

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-65

KEYLESS ENTRY SYSTEM 42-67

GENERAL DESCRIPTION . . . . . . .

42-67

KEYLESS ENTRY SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . .

42-68

SPECIAL TOOL . . . . . . . . . . . . . . .42-68

ON-VEHICLE SERVICE . . . . . . . . .42-69

TRANSMITTER BATTERY CHECK . . . . 42-69

HOW TO REPLACE THE TRANSMITTER

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . 42-70

KEYLESS ENTRY SYSTEM INSPECTION42-71

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION . . . . . . . . . . . 42-71

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-72

HOW TO REGISTER SECRET CODE . 42-73

Continued on next page

Page 1100 of 1500

DOOR

BODY42-33

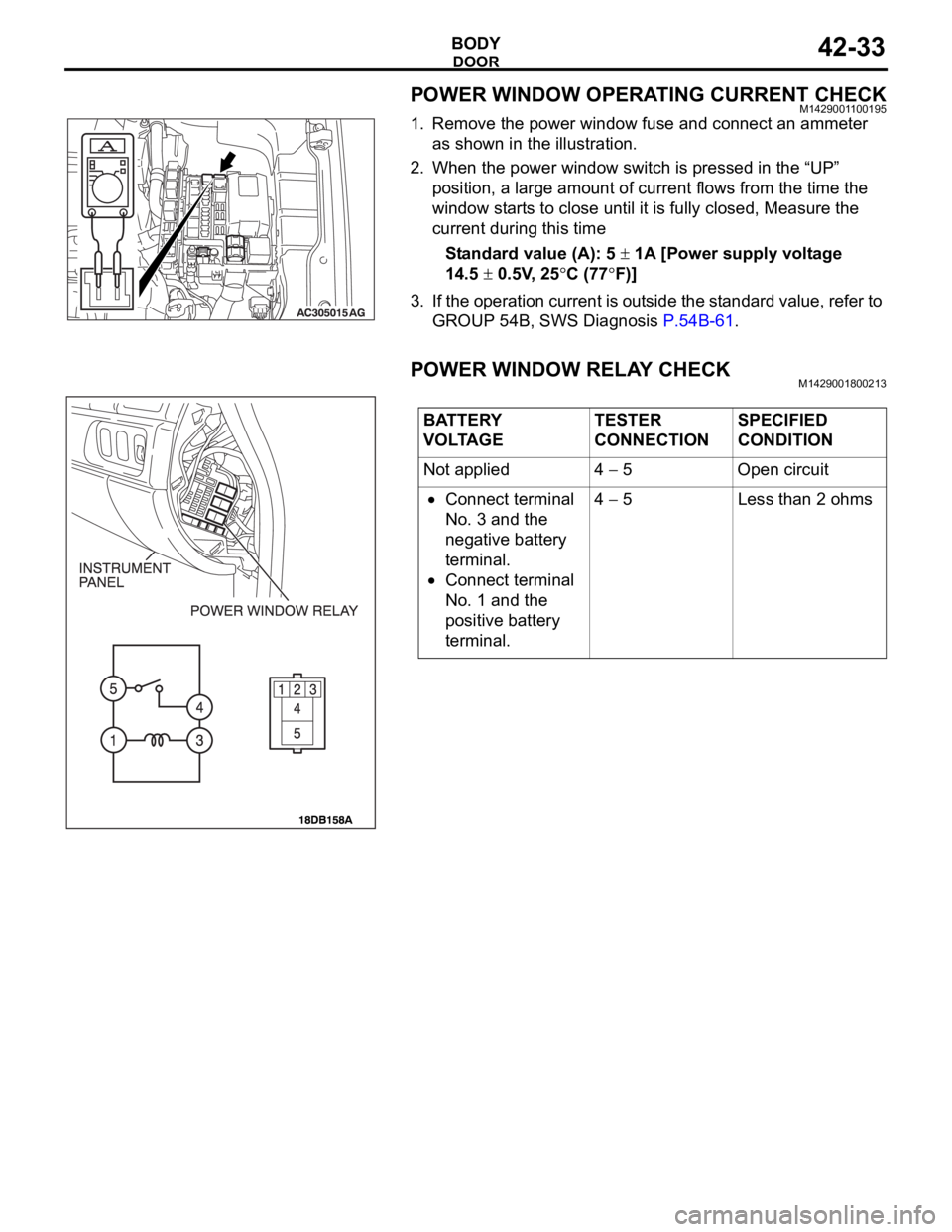

POWER WINDOW OPERATING CURRENT CHECKM1429001100195

1. Remove the power window fuse and connect an ammeter

as shown in the illustration.

2. When the power window switch is pressed in the “UP”

position, a large amount of current flows from the time the

window starts to close until it is fully closed, Measure the

current during this time

Standard value (A): 5

1A [Power supply voltage

14.5

0.5V, 25C (77F)]

3. If the operation current is outside the standard value, refer to

GROUP 54B, SWS Diagnosis P.54B-61.

POWER WINDOW RELAY CHECKM1429001800213

BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect terminal

No. 3 and the

negative battery

terminal.

Connect terminal

No. 1 and the

positive battery

terminal.4

5 Less than 2 ohms

Page 1110 of 1500

DOOR

BODY42-43

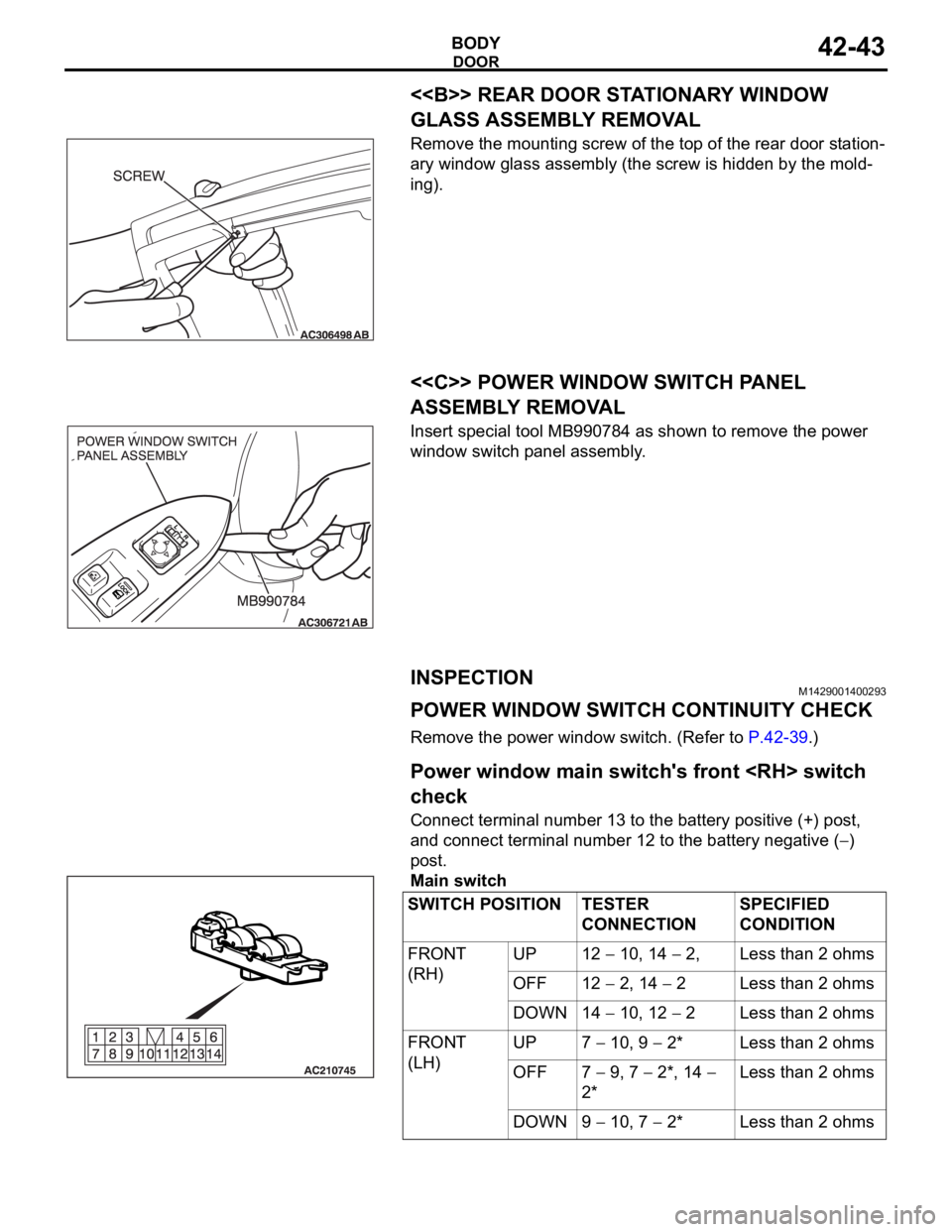

<> REAR DOOR STATIONARY WINDOW

GLASS ASSEMBLY REMOVAL

Remove the mounting screw of the top of the rear door station-

ary window glass assembly (the screw is hidden by the mold-

ing).

.

<

ASSEMBLY REMOVAL

Insert special tool MB990784 as shown to remove the power

window switch panel assembly.

INSPECTIONM1429001400293

POWER WINDOW SWITCH CONTINUITY CHECK

Remove the power window switch. (Refer to P.42-39.).

Power window main switch's front

check

Connect terminal number 13 to the battery positive (+) post,

and connect terminal number 12 to the battery negative (

)

post.

Main switch

SWITCH POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

FRONT

(RH)UP 12

10, 14 2, Less than 2 ohms

OFF 12

2, 14 2 Less than 2 ohms

DOWN 14

10, 12 2 Less than 2 ohms

FRONT

(LH)UP 7

10, 9 2* Less than 2 ohms

OFF 7

9, 7 2*, 14

2*Less than 2 ohms

DOWN 9

10, 7 2* Less than 2 ohms

Page 1112 of 1500

DOOR

BODY42-45

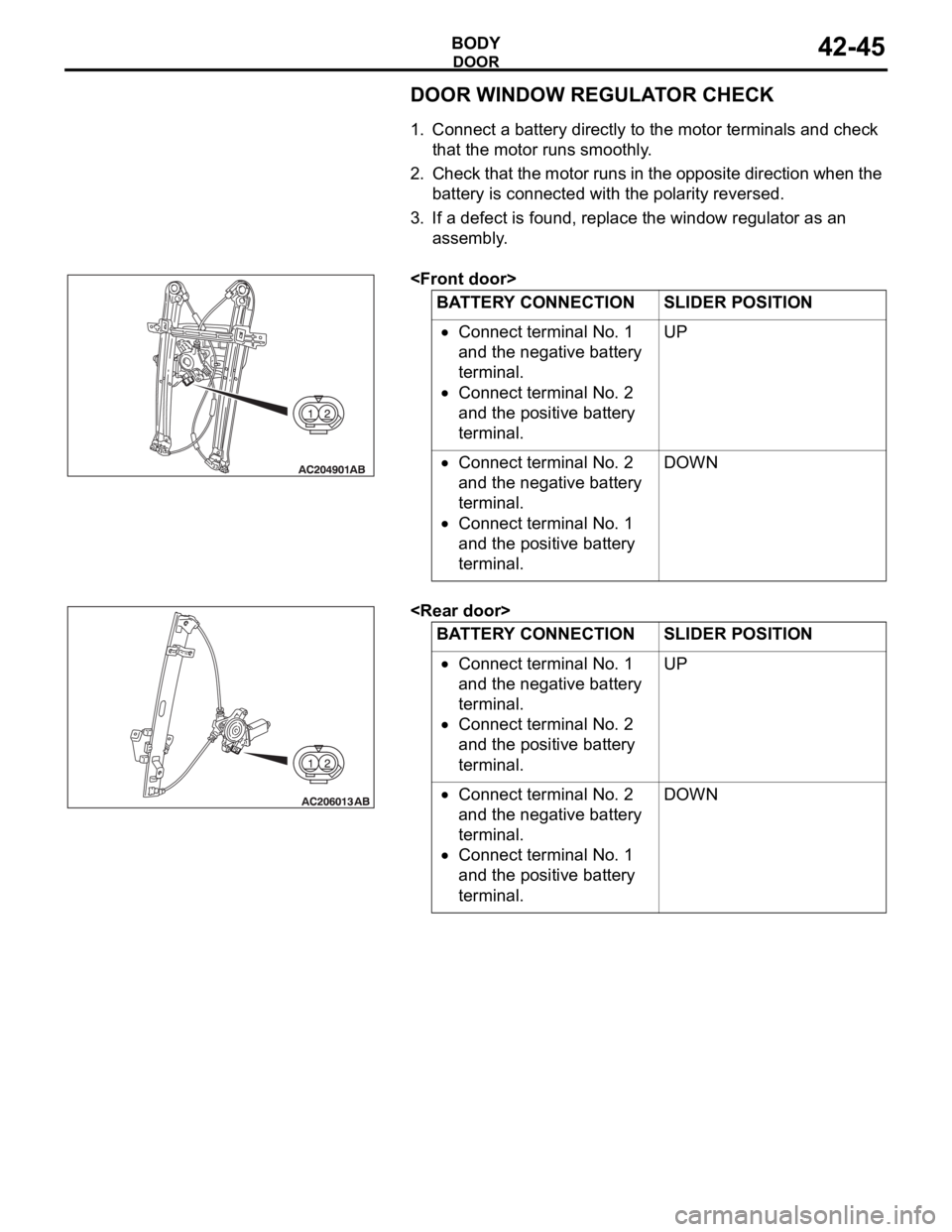

DOOR WINDOW REGULATOR CHECK

.

1. Connect a battery directly to the motor terminals and check

that the motor runs smoothly.

2. Check that the motor runs in the opposite direction when the

battery is connected with the polarity reversed.

3. If a defect is found, replace the window regulator as an

assembly.

.

.

Connect terminal No. 1

and the negative battery

terminal.

Connect terminal No. 2

and the positive battery

terminal.UP

Connect terminal No. 2

and the negative battery

terminal.

Connect terminal No. 1

and the positive battery

terminal.DOWN

BATTERY CONNECTION SLIDER POSITION

Connect terminal No. 1

and the negative battery

terminal.

Connect terminal No. 2

and the positive battery

terminal.UP

Connect terminal No. 2

and the negative battery

terminal.

Connect terminal No. 1

and the positive battery

terminal.DOWN

Page 1116 of 1500

DOOR

BODY42-49

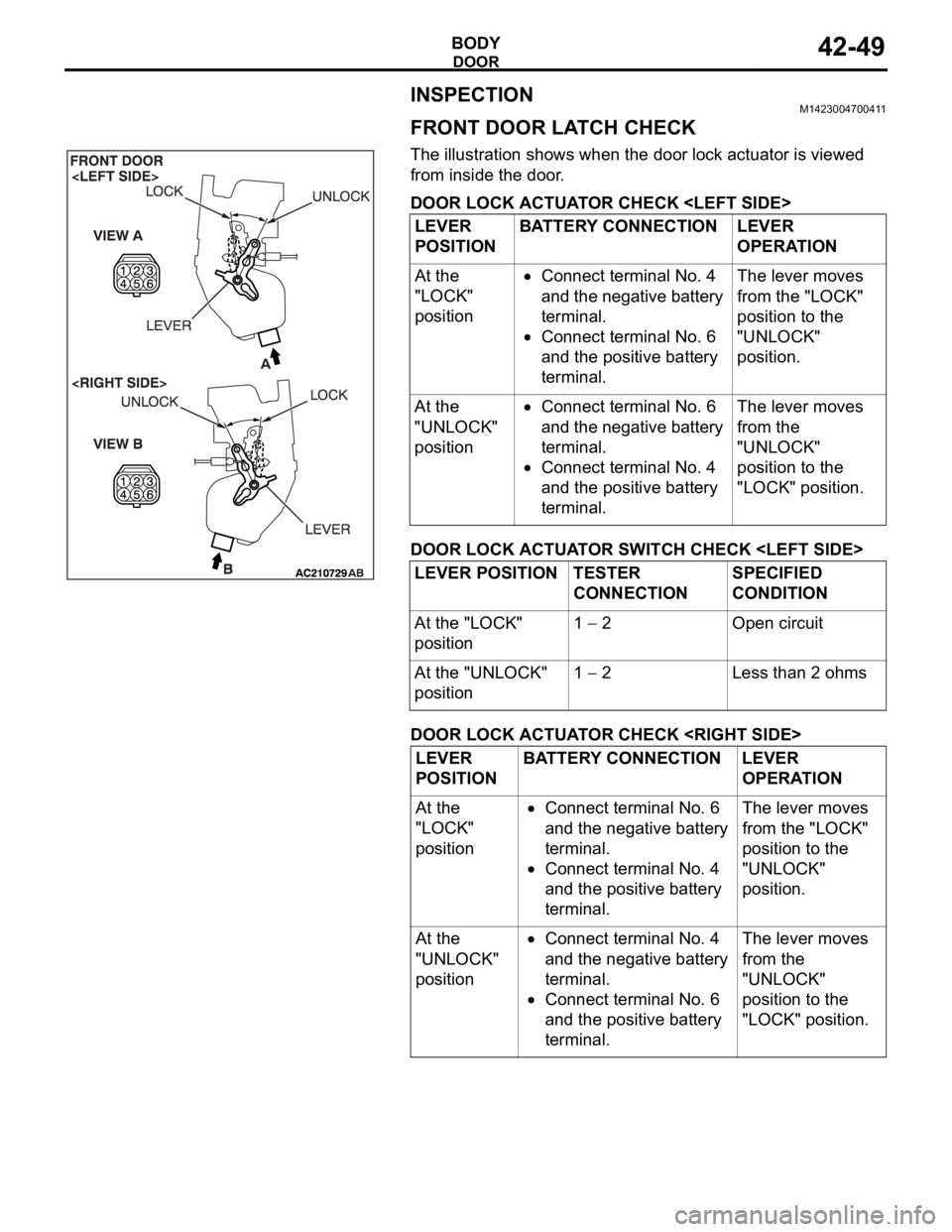

INSPECTIONM1423004700411

FRONT DOOR LATCH CHECK

The illustration shows when the door lock actuator is viewed

from inside the door.

DOOR LOCK ACTUATOR CHECK

DOOR LOCK ACTUATOR SWITCH CHECK

DOOR LOCK ACTUATOR CHECK

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

LEVER POSITION TESTER

CONNECTIONSPECIFIED

CONDITION

At the "LOCK"

position1

2 Open circuit

At the "UNLOCK"

position1

2 Less than 2 ohms

LEVER

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

Page 1117 of 1500

DOOR

BODY42-50

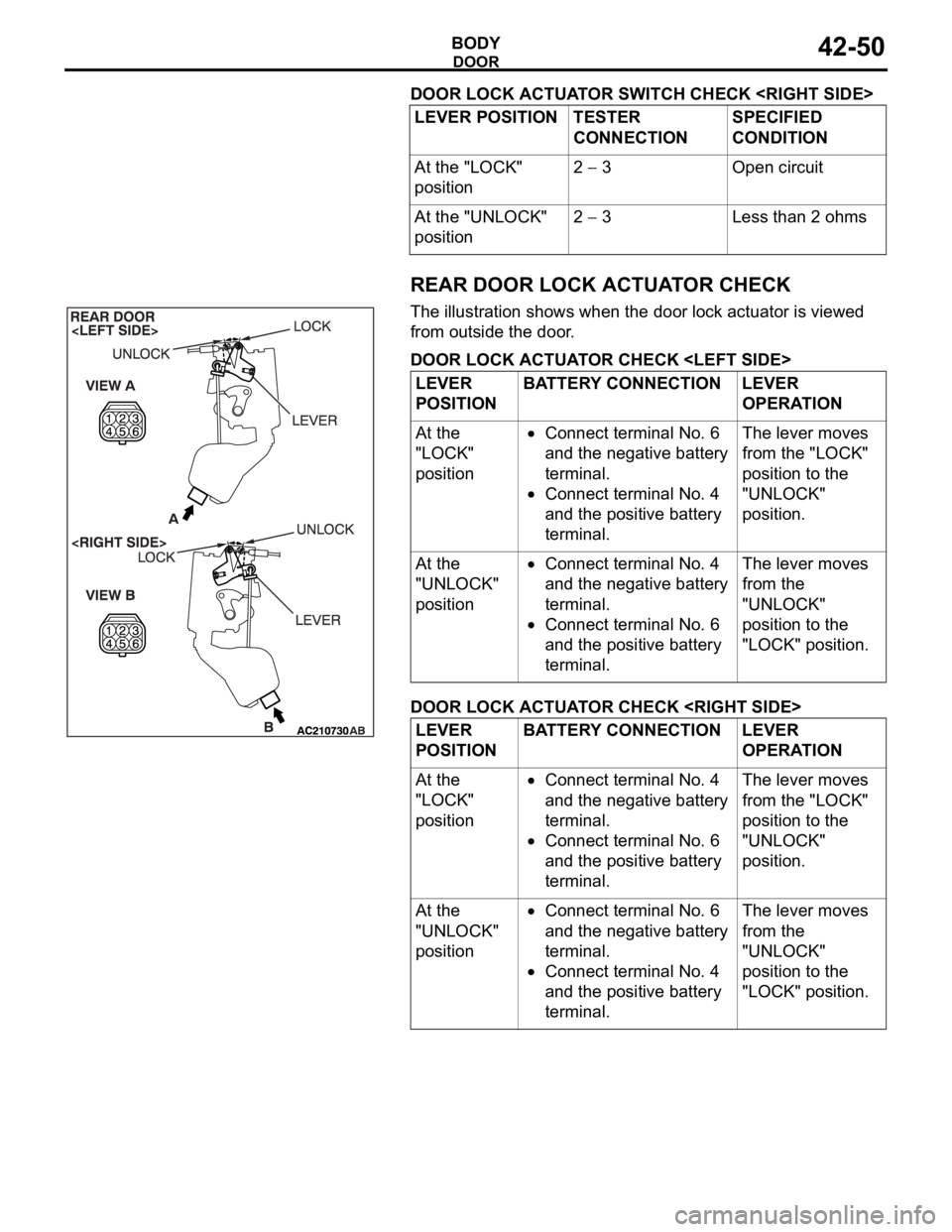

DOOR LOCK ACTUATOR SWITCH CHECK

REAR DOOR LOCK ACTUATOR CHECK

The illustration shows when the door lock actuator is viewed

from outside the door.

DOOR LOCK ACTUATOR CHECK

DOOR LOCK ACTUATOR CHECK

CONNECTIONSPECIFIED

CONDITION

At the "LOCK"

position2

3 Open circuit

At the "UNLOCK"

position2

3 Less than 2 ohms

LEVER

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

LEVER

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 4

and the negative battery

terminal.

Connect terminal No. 6

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 6

and the negative battery

terminal.

Connect terminal No. 4

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

Page 1118 of 1500

DOOR

BODY42-51

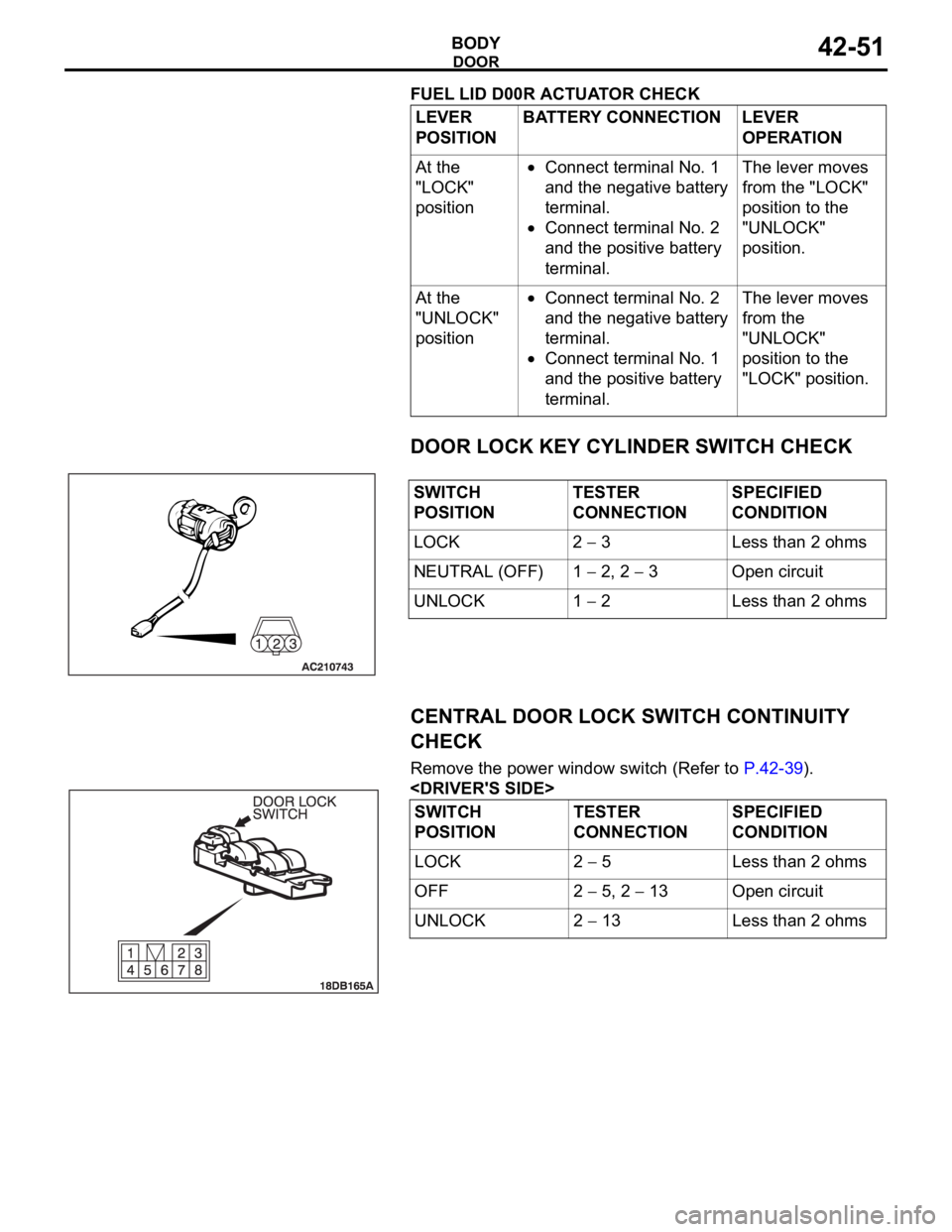

FUEL LID D00R ACTUATOR CHECK

DOOR LOCK KEY CYLINDER SWITCH CHECK

CENTRAL DOOR LOCK SWITCH CONTINUITY

CHECK

Remove the power window switch (Refer to P.42-39).

POSITIONBATTERY CONNECTION LEVER

OPERATION

At the

"LOCK"

position

Connect terminal No. 1

and the negative battery

terminal.

Connect terminal No. 2

and the positive battery

terminal.The lever moves

from the "LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position

Connect terminal No. 2

and the negative battery

terminal.

Connect terminal No. 1

and the positive battery

terminal.The lever moves

from the

"UNLOCK"

position to the

"LOCK" position.

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

LOCK 2

3 Less than 2 ohms

NEUTRAL (OFF) 1

2, 2 3 Open circuit

UNLOCK 1

2 Less than 2 ohms

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

LOCK 2

5 Less than 2 ohms

OFF 2

5, 2 13 Open circuit

UNLOCK 2

13 Less than 2 ohms

Page 1132 of 1500

Page 1136 of 1500

KEYLESS ENTRY SYSTEM

BODY42-69

ON-VEHICLE SERVICE

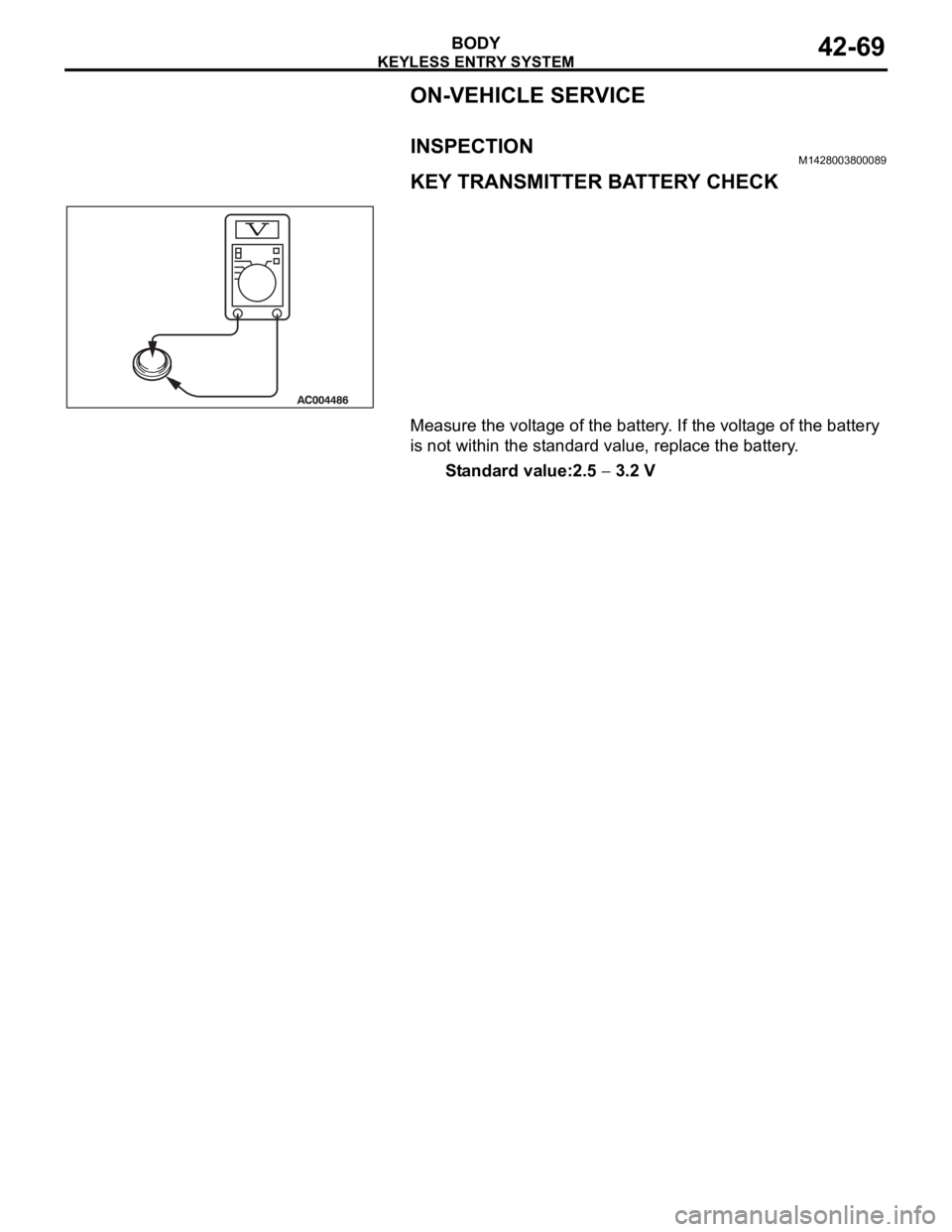

INSPECTIONM1428003800089

KEY TRANSMITTER BATTERY CHECK

Measure the voltage of the battery. If the voltage of the battery

is not within the standard value, replace the battery.

Standard value:2.5

3.2 V