MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 181 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-181

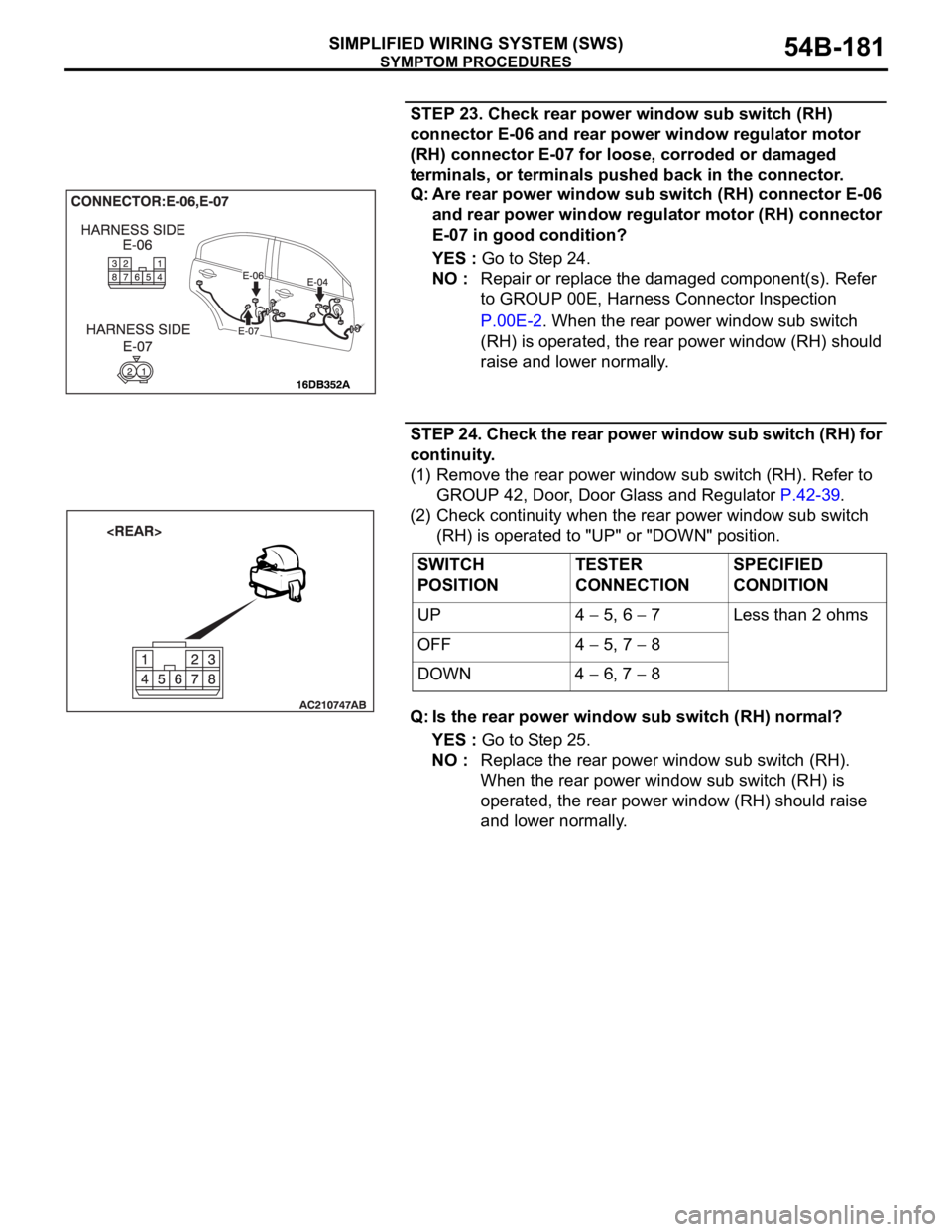

STEP 23. Check rear power window sub switch (RH)

connector E-06 and rear power window regulator motor

(RH) connector E-07 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Q: Are rear power window sub switch (RH) connector E-06

and rear power window regulator motor (RH) connector

E-07 in good condition?

YES : Go to Step 24.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. When the rear power window sub switch

(RH) is operated, the rear power window (RH) should

raise and lower normally.

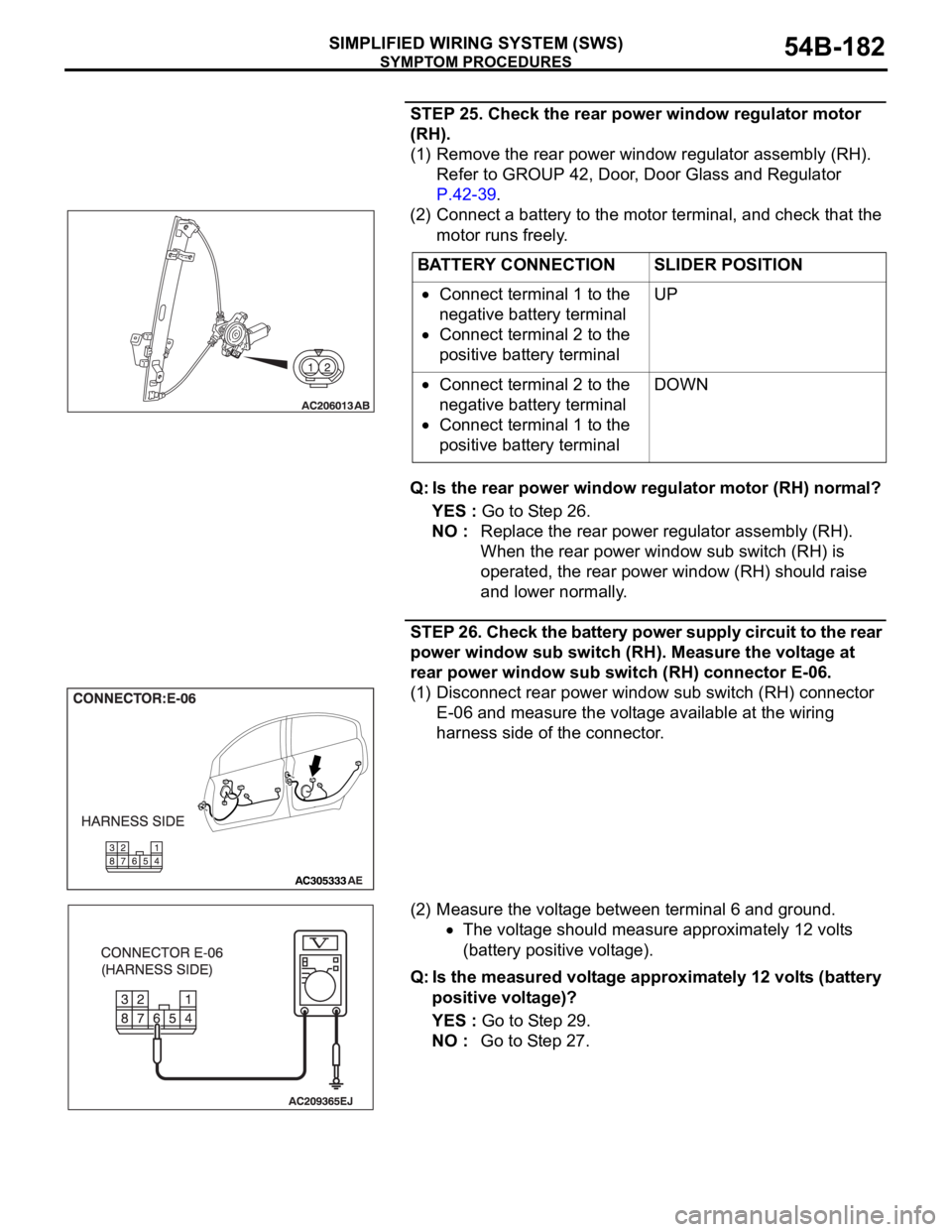

STEP 24. Check the rear power window sub switch (RH) for

continuity.

(1) Remove the rear power window sub switch (RH). Refer to

GROUP 42, Door, Door Glass and Regulator P.42-39.

(2) Check continuity when the rear power window sub switch

(RH) is operated to "UP" or "DOWN" position.

Q: Is the rear power window sub switch (RH) normal?

YES : Go to Step 25.

NO : Replace the rear power window sub switch (RH).

When the rear power window sub switch (RH) is

operated, the rear power window (RH) should raise

and lower normally.

SWITCH

POSITIONTESTER

CONNECTIONSPECIFIED

CONDITION

UP 4

5, 6 7 Less than 2 ohms

OFF 4

5, 7 8

DOWN 4

6, 7 8

Page 182 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-182

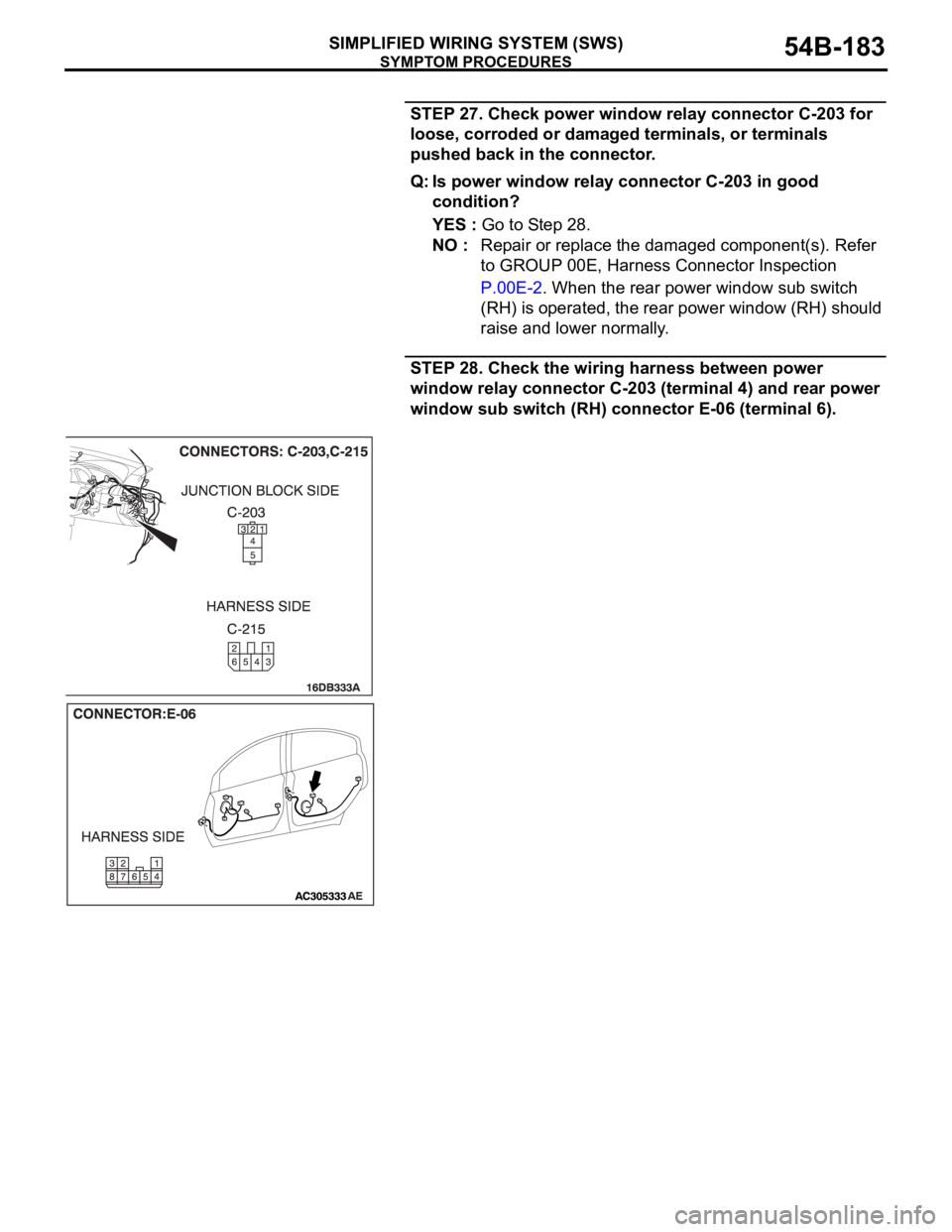

STEP 25. Check the rear power window regulator motor

(RH).

(1) Remove the rear power window regulator assembly (RH).

Refer to GROUP 42, Door, Door Glass and Regulator

P.42-39.

(2) Connect a battery to the motor terminal, and check that the

motor runs freely.

Q: Is the rear power window regulator motor (RH) normal?

YES : Go to Step 26.

NO : Replace the rear power regulator assembly (RH).

When the rear power window sub switch (RH) is

operated, the rear power window (RH) should raise

and lower normally.

STEP 26. Check the battery power supply circuit to the rear

power window sub switch (RH). Measure the voltage at

rear power window sub switch (RH) connector E-06.

(1) Disconnect rear power window sub switch (RH) connector

E-06 and measure the voltage available at the wiring

harness side of the connector.

(2) Measure the voltage between terminal 6 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 29.

NO : Go to Step 27. BATTERY CONNECTION SLIDER POSITION

Connect terminal 1 to the

negative battery terminal

Connect terminal 2 to the

positive battery terminalUP

Connect terminal 2 to the

negative battery terminal

Connect terminal 1 to the

positive battery terminalDOWN

Page 183 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-183

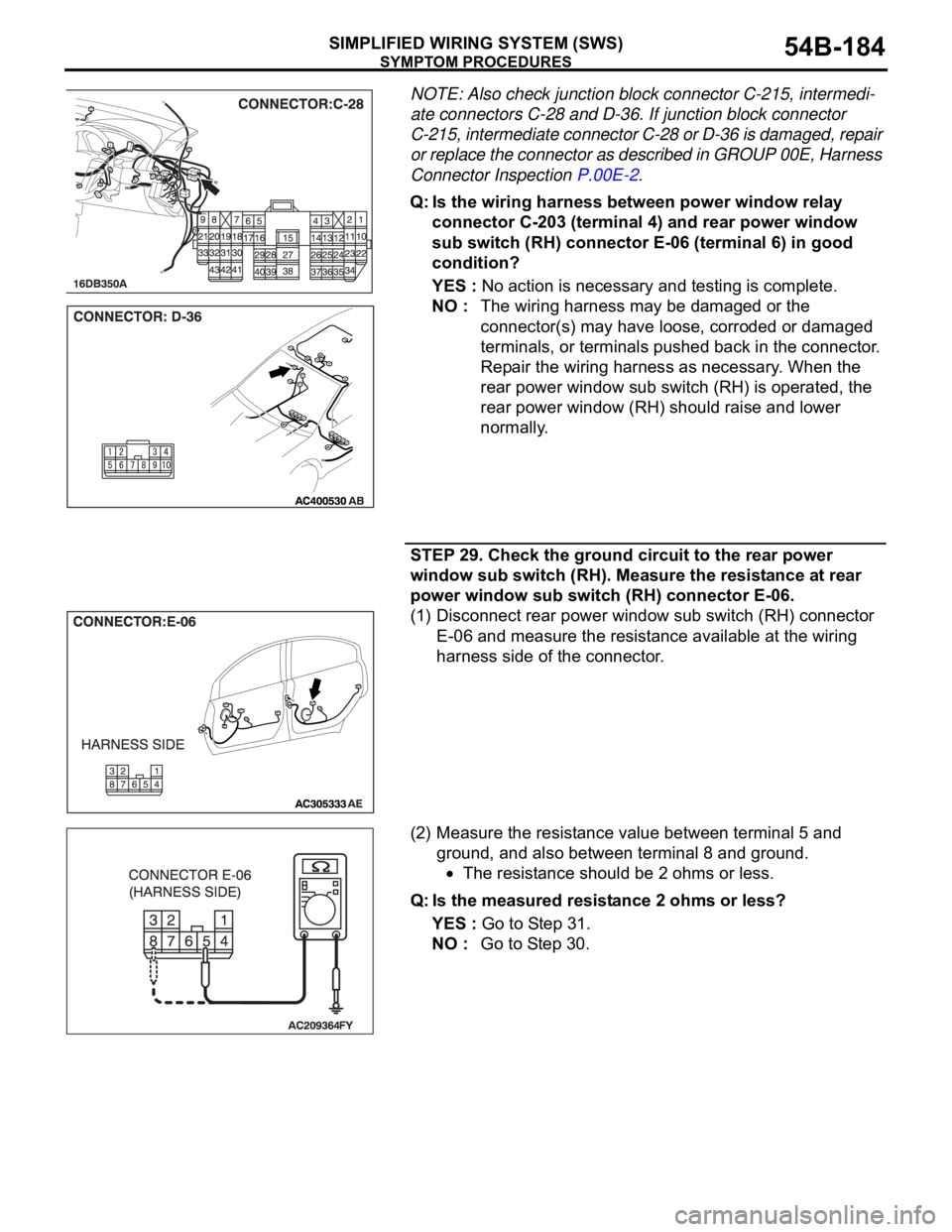

STEP 27. Check power window relay connector C-203 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power window relay connector C-203 in good

condition?

YES : Go to Step 28.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. When the rear power window sub switch

(RH) is operated, the rear power window (RH) should

raise and lower normally.

STEP 28. Check the wiring harness between power

window relay connector C-203 (terminal 4) and rear power

window sub switch (RH) connector E-06 (terminal 6).

Page 184 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-184

NOTE: Also check junction block connector C-215, intermedi-

ate connectors C-28 and D-36. If junction block connector

C-215, intermediate connector C-28 or D-36 is damaged, repair

or replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and rear power window

sub switch (RH) connector E-06 (terminal 6) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

rear power window sub switch (RH) is operated, the

rear power window (RH) should raise and lower

normally.

STEP 29. Check the ground circuit to the rear power

window sub switch (RH). Measure the resistance at rear

power window sub switch (RH) connector E-06.

(1) Disconnect rear power window sub switch (RH) connector

E-06 and measure the resistance available at the wiring

harness side of the connector.

(2) Measure the resistance value between terminal 5 and

ground, and also between terminal 8 and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 31.

NO : Go to Step 30.

Page 185 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-185

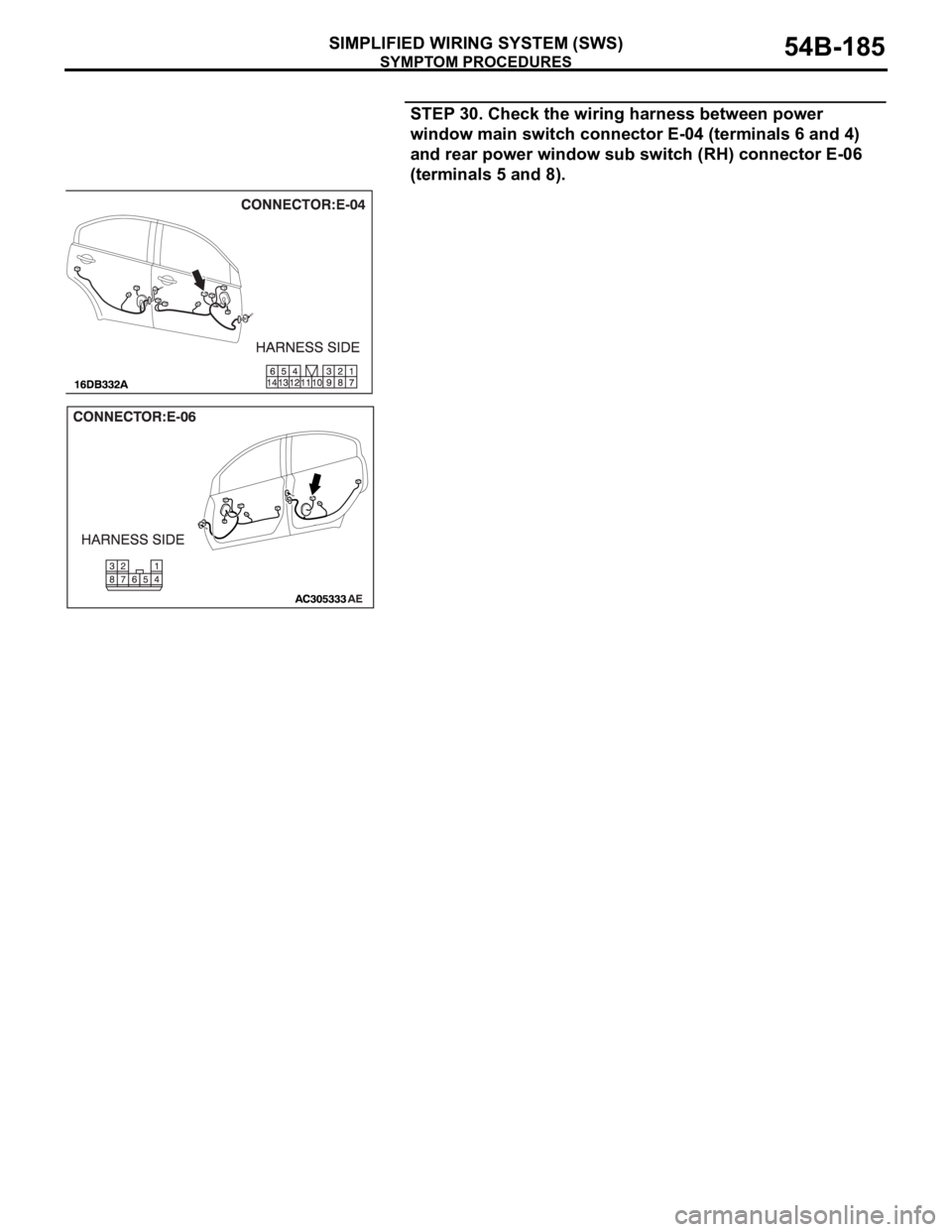

STEP 30. Check the wiring harness between power

window main switch connector E-04 (terminals 6 and 4)

and rear power window sub switch (RH) connector E-06

(terminals 5 and 8).

Page 186 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-186

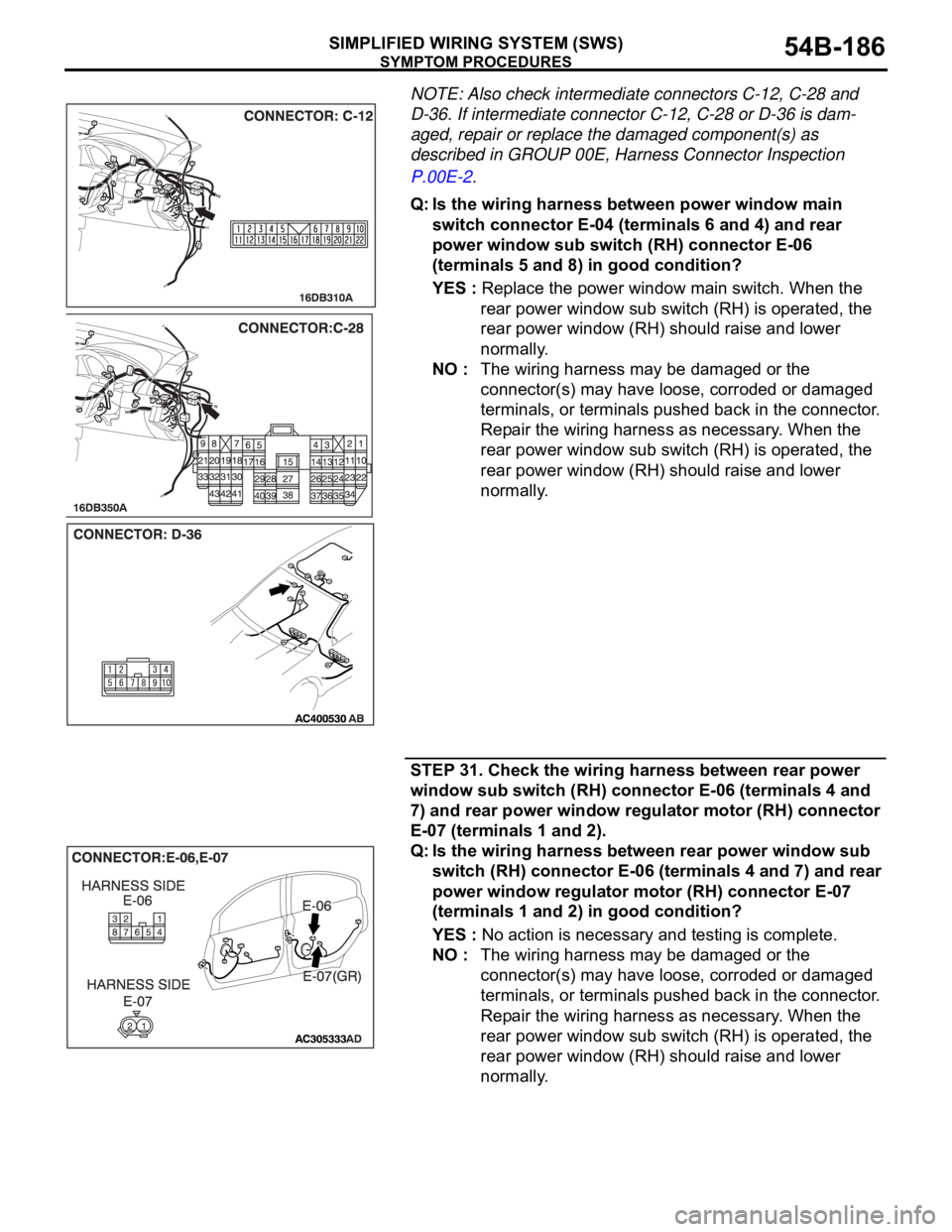

NOTE: Also check intermediate connectors C-12, C-28 and

D-36. If intermediate connector C-12, C-28 or D-36 is dam-

aged, repair or replace the damaged component(s) as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between power window main

switch connector E-04 (terminals 6 and 4) and rear

power window sub switch (RH) connector E-06

(terminals 5 and 8) in good condition?

YES : Replace the power window main switch. When the

rear power window sub switch (RH) is operated, the

rear power window (RH) should raise and lower

normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

rear power window sub switch (RH) is operated, the

rear power window (RH) should raise and lower

normally.

STEP 31. Check the wiring harness between rear power

window sub switch (RH) connector E-06 (terminals 4 and

7) and rear power window regulator motor (RH) connector

E-07 (terminals 1 and 2).

Q: Is the wiring harness between rear power window sub

switch (RH) connector E-06 (terminals 4 and 7) and rear

power window regulator motor (RH) connector E-07

(terminals 1 and 2) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

rear power window sub switch (RH) is operated, the

rear power window (RH) should raise and lower

normally.

Page 187 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-187

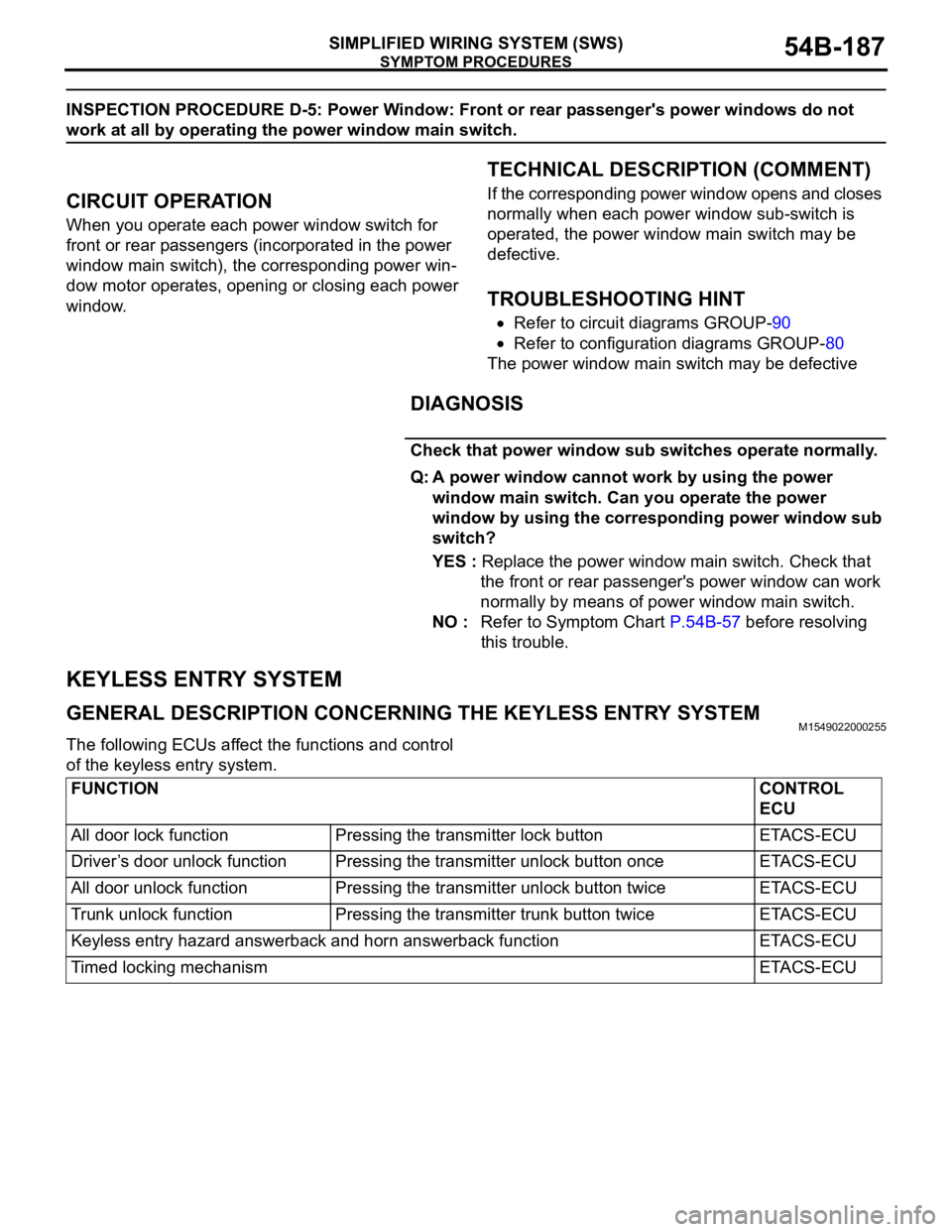

INSPECTION PROCEDURE D-5: Power Window: Front or rear passenger's power windows do not

work at all by operating the power window main switch.

.

CIRCUIT OPERATION

When you operate each power window switch for

front or rear passengers (incorporated in the power

window main switch), the corresponding power win-

dow motor operates, opening or closing each power

window.

.

TECHNICAL DESCRIPTION (COMMENT)

If the corresponding power window opens and closes

normally when each power window sub-switch is

operated, the power window main switch may be

defective.

.

TROUBLESHOOTING HINT

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The power window main switch may be defective

DIAGNOSIS

Check that power window sub switches operate normally.

Q: A power window cannot work by using the power

window main switch. Can you operate the power

window by using the corresponding power window sub

switch?

YES : Replace the power window main switch. Check that

the front or rear passenger's power window can work

normally by means of power window main switch.

NO : Refer to Symptom Chart P.54B-57 before resolving

this trouble.

KEYLESS ENTRY SYSTEM

GENERAL DESCRIPTION CONCERNING THE KEYLESS ENTRY SYSTEMM1549022000255

The following ECUs affect the functions and control

of the keyless entry system.

FUNCTIONCONTROL

ECU

All door lock function Pressing the transmitter lock button ETACS-ECU

Driver’s door unlock function Pressing the transmitter unlock button once ETACS-ECU

All door unlock function Pressing the transmitter unlock button twice ETACS-ECU

Trunk unlock function Pressing the transmitter trunk button twice ETACS-ECU

Keyless entry hazard answerback and horn answerback function ETACS-ECU

Timed locking mechanism ETACS-ECU

Page 188 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-188

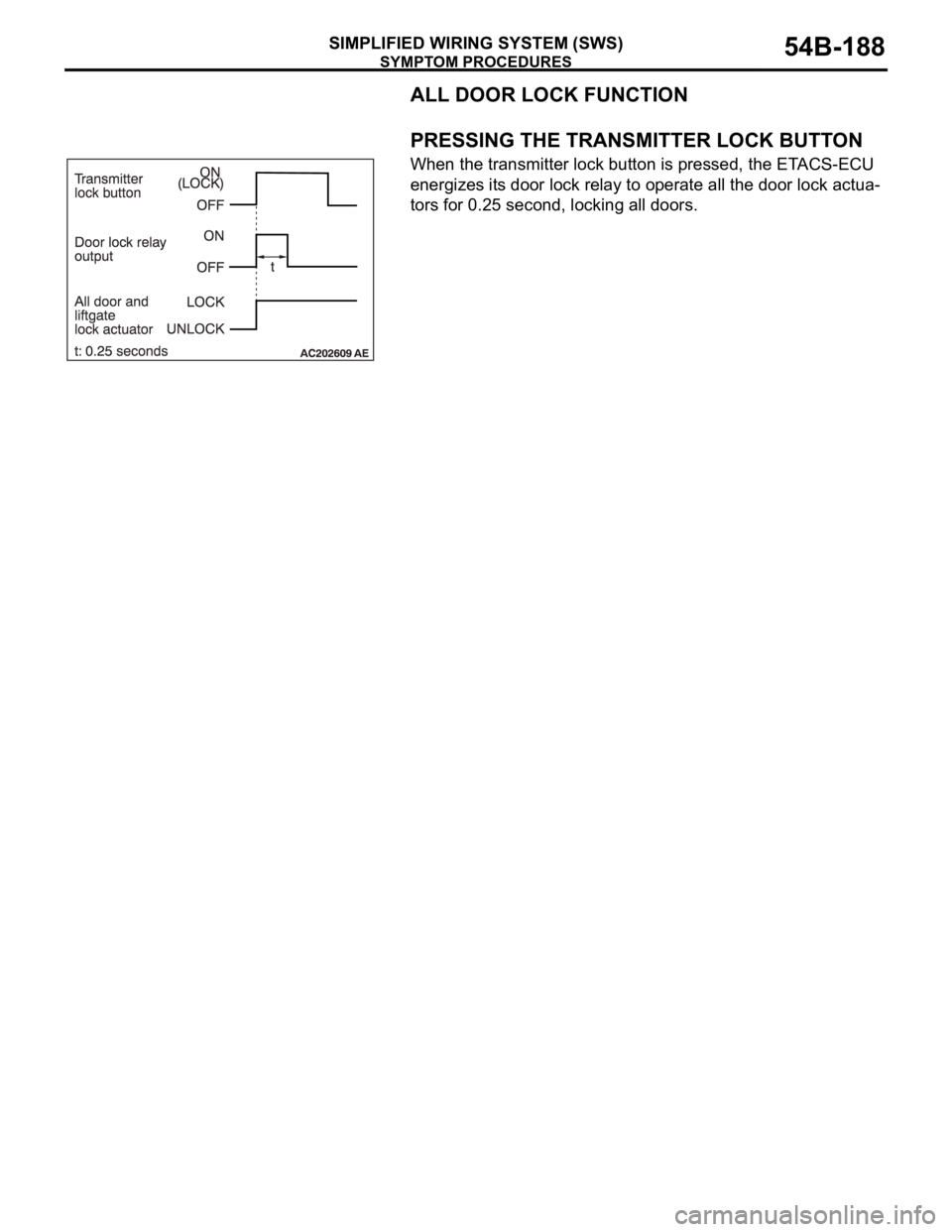

ALL DOOR LOCK FUNCTION

.

PRESSING THE TRANSMITTER LOCK BUTTON

When the transmitter lock button is pressed, the ETACS-ECU

energizes its door lock relay to operate all the door lock actua-

tors for 0.25 second, locking all doors.

Page 189 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-189

DRIVER’S DOOR UNLOCK FUNCTION

.

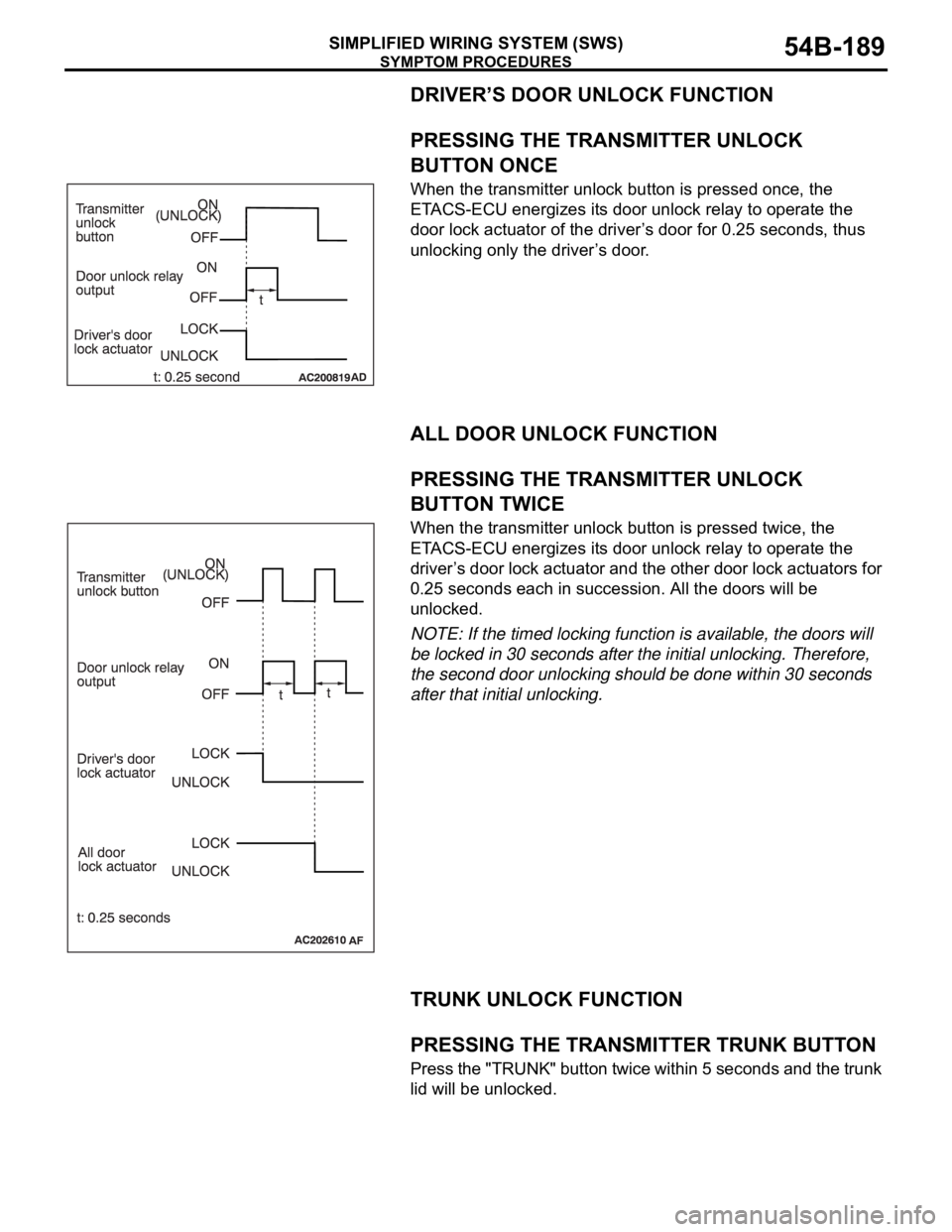

PRESSING THE TRANSMITTER UNLOCK

BUTTON ONCE

When the transmitter unlock button is pressed once, the

ETACS-ECU energizes its door unlock relay to operate the

door lock actuator of the driver’s door for 0.25 seconds, thus

unlocking only the driver’s door.

ALL DOOR UNLOCK FUNCTION

.

PRESSING THE TRANSMITTER UNLOCK

BUTTON TWICE

When the transmitter unlock button is pressed twice, the

ETACS-ECU energizes its door unlock relay to operate the

driver’s door lock actuator and the other door lock actuators for

0.25 seconds each in succession. All the doors will be

unlocked.

NOTE: If the timed locking function is available, the doors will

be locked in 30 seconds after the initial unlocking. Therefore,

the second door unlocking should be done within 30 seconds

after that initial unlocking.

TRUNK UNLOCK FUNCTION

.

PRESSING THE TRANSMITTER TRUNK BUTTON

Press the "TRUNK" button twice within 5 seconds and the trunk

lid will be unlocked.

Page 190 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-190

KEYLESS ENTRY HAZARD ANSWERBACK AND

HORN ANSWERBACK FUNCTION

.

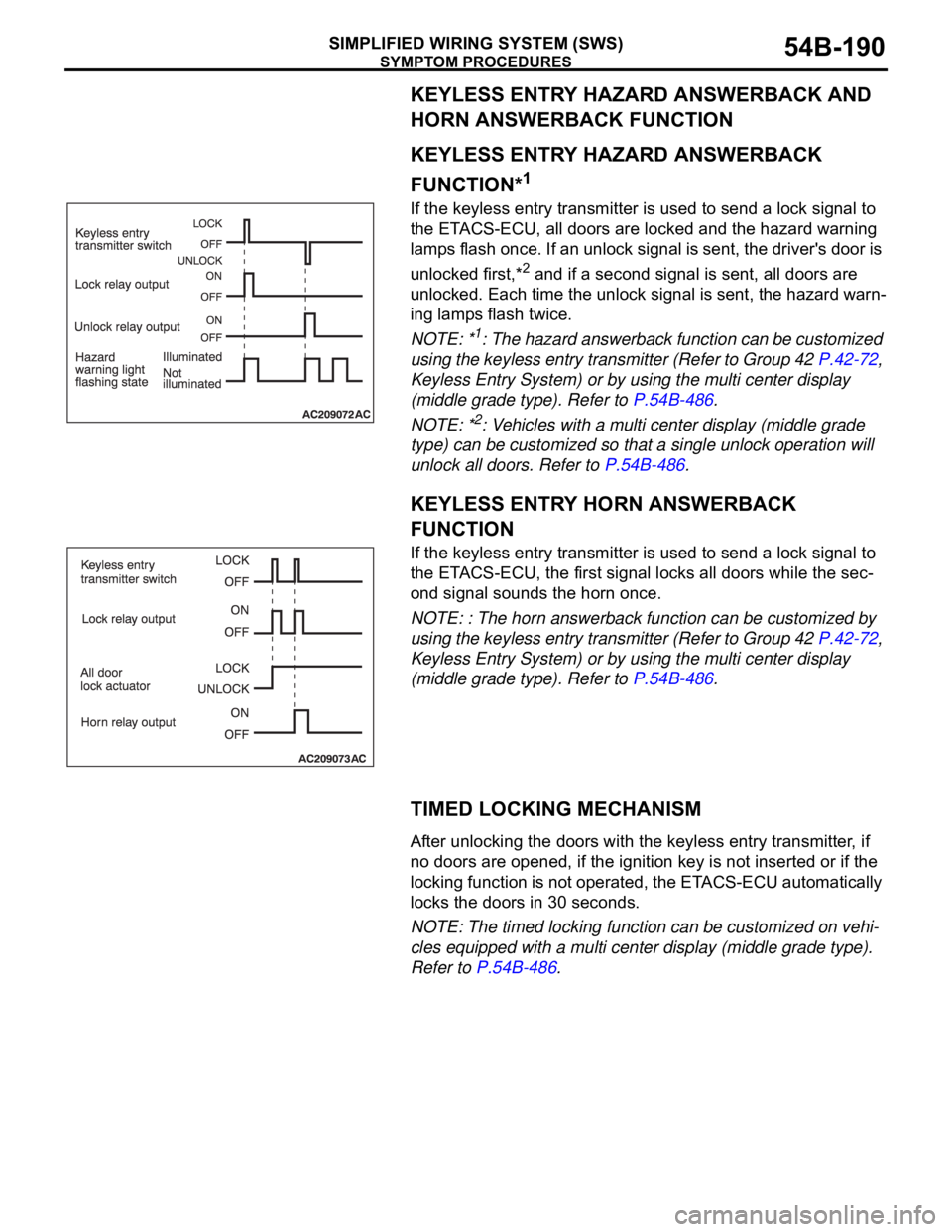

KEYLESS ENTRY HAZARD ANSWERBACK

FUNCTION*

1

If the keyless entry transmitter is used to send a lock signal to

the ETACS-ECU, all doors are locked and the hazard warning

lamps flash once. If an unlock signal is sent, the driver's door is

unlocked first,*

2 and if a second signal is sent, all doors are

unlocked. Each time the unlock signal is sent, the hazard warn-

ing lamps flash twice.

NOTE: *

1: The hazard answerback function can be customized

using the keyless entry transmitter (Refer to Group 42 P.42-72,

Keyless Entry System) or by using the multi center display

(middle grade type). Refer to P.54B-486.

NOTE: *

2: Vehicles with a multi center display (middle grade

type) can be customized so that a single unlock operation will

unlock all doors. Refer to P.54B-486.

.

KEYLESS ENTRY HORN ANSWERBACK

FUNCTION

If the keyless entry transmitter is used to send a lock signal to

the ETACS-ECU, the first signal locks all doors while the sec-

ond signal sounds the horn once.

NOTE: : The horn answerback function can be customized by

using the keyless entry transmitter (Refer to Group 42 P.42-72,

Keyless Entry System) or by using the multi center display

(middle grade type). Refer to P.54B-486.

TIMED LOCKING MECHANISM

.After unlocking the doors with the keyless entry transmitter, if

no doors are opened, if the ignition key is not inserted or if the

locking function is not operated, the ETACS-ECU automatically

locks the doors in 30 seconds.

NOTE: The timed locking function can be customized on vehi-

cles equipped with a multi center display (middle grade type).

Refer to P.54B-486.