bulb MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 294 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-294

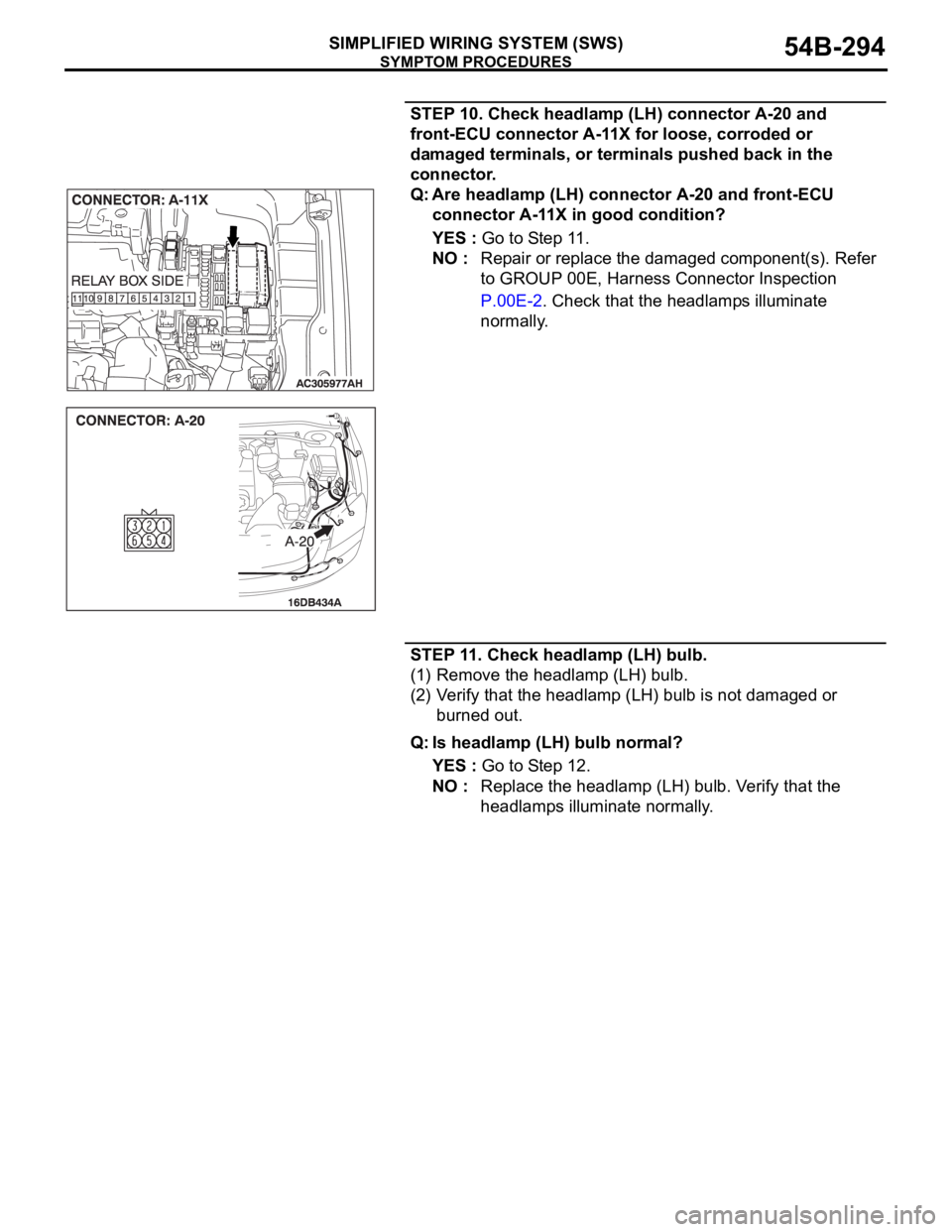

STEP 10. Check headlamp (LH) connector A-20 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (LH) connector A-20 and front-ECU

connector A-11X in good condition?

YES : Go to Step 11.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

STEP 11. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 12.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.

Page 296 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-296

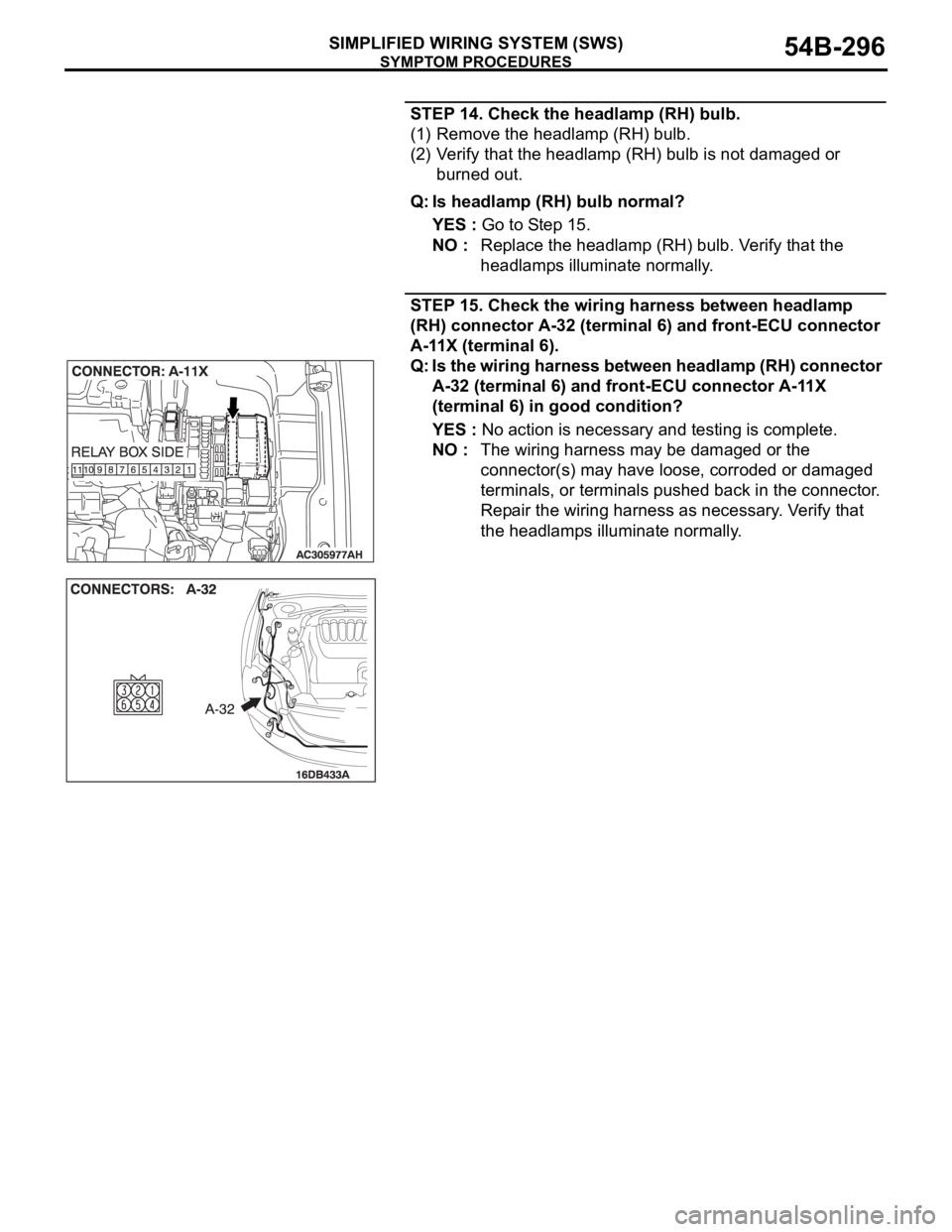

STEP 14. Check the headlamp (RH) bulb.

(1) Remove the headlamp (RH) bulb.

(2) Verify that the headlamp (RH) bulb is not damaged or

burned out.

Q: Is headlamp (RH) bulb normal?

YES : Go to Step 15.

NO : Replace the headlamp (RH) bulb. Verify that the

headlamps illuminate normally.

STEP 15. Check the wiring harness between headlamp

(RH) connector A-32 (terminal 6) and front-ECU connector

A-11X (terminal 6).

Q: Is the wiring harness between headlamp (RH) connector

A-32 (terminal 6) and front-ECU connector A-11X

(terminal 6) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

Page 297 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-297

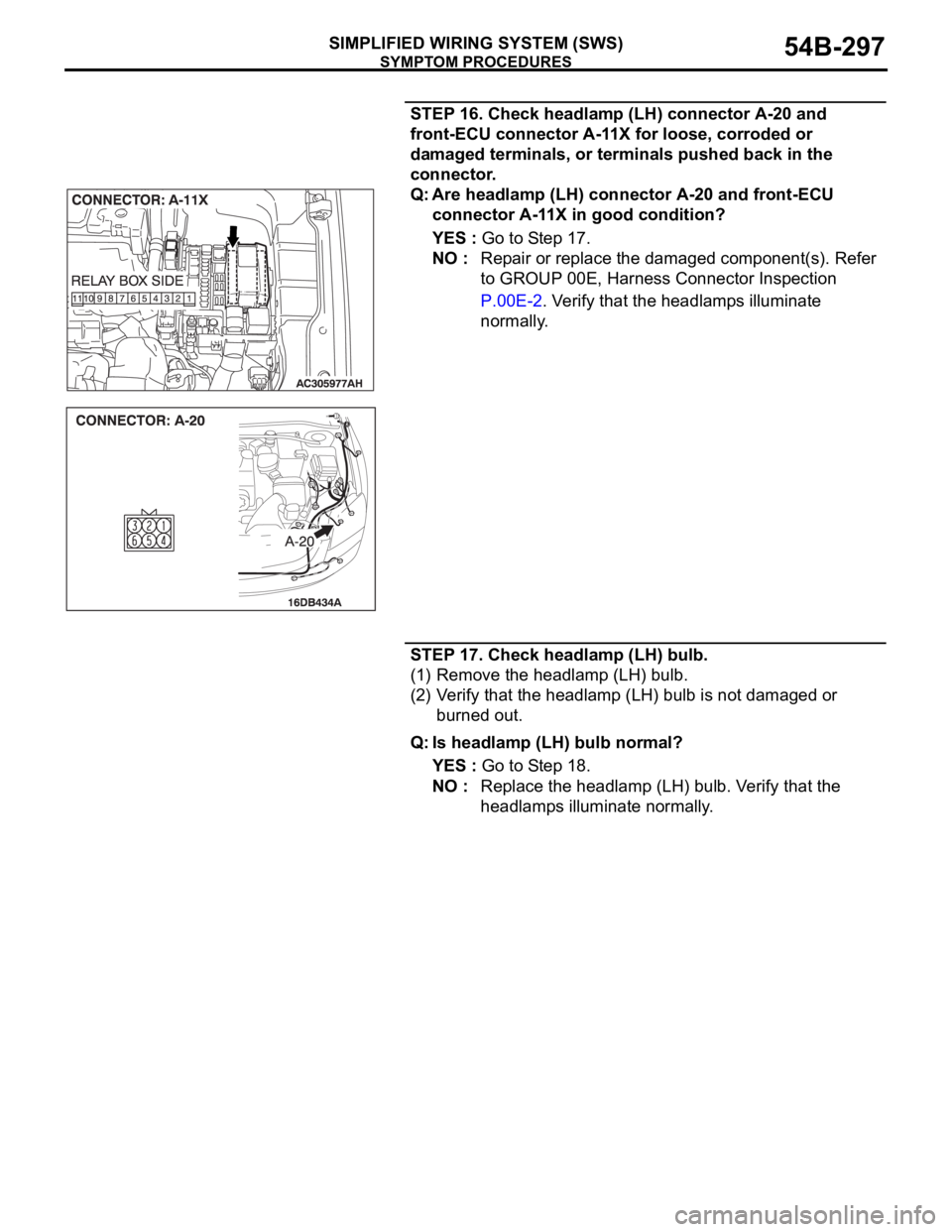

STEP 16. Check headlamp (LH) connector A-20 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (LH) connector A-20 and front-ECU

connector A-11X in good condition?

YES : Go to Step 17.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the headlamps illuminate

normally.

STEP 17. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 18.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.

Page 299 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-299

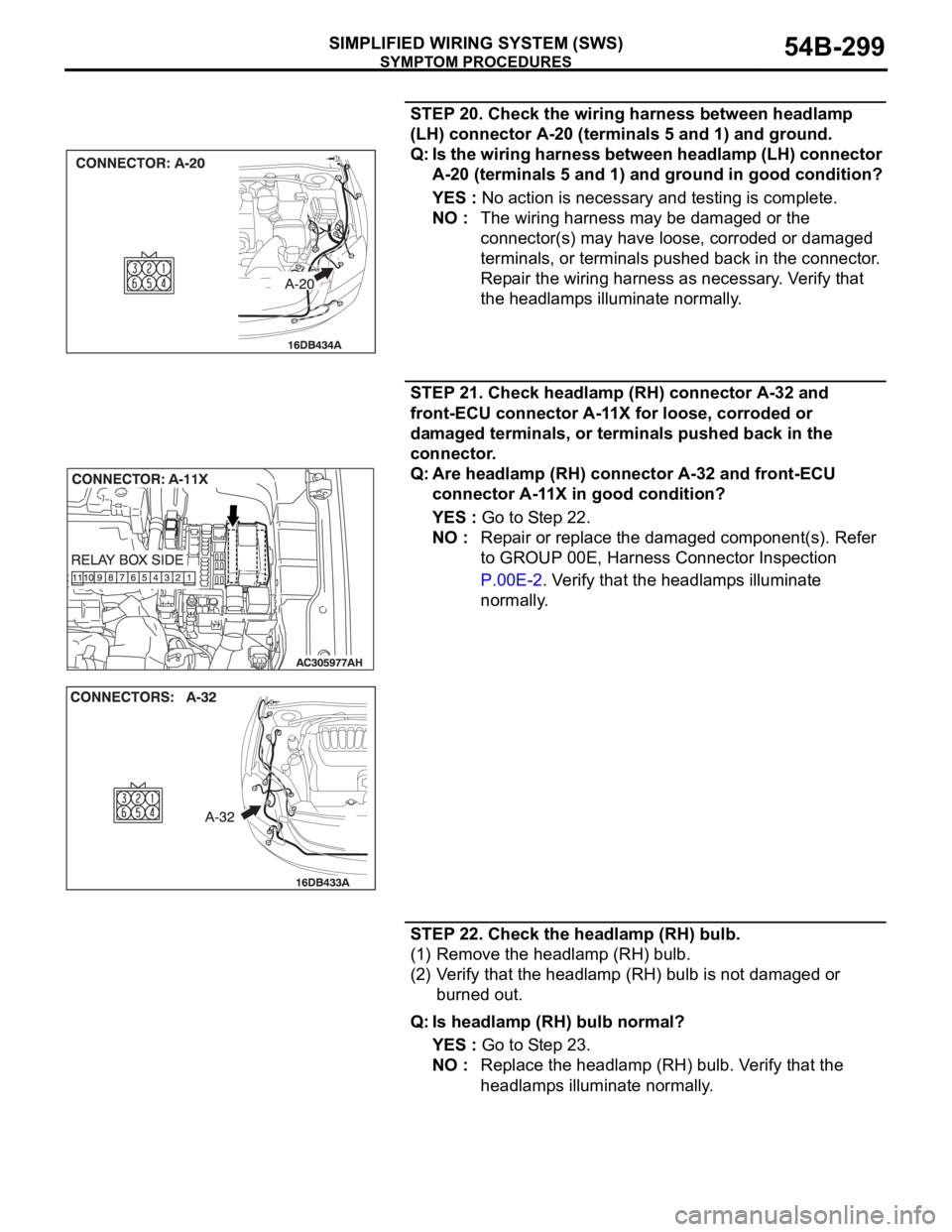

STEP 20. Check the wiring harness between headlamp

(LH) connector A-20 (terminals 5 and 1) and ground.

Q: Is the wiring harness between headlamp (LH) connector

A-20 (terminals 5 and 1) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

STEP 21. Check headlamp (RH) connector A-32 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (RH) connector A-32 and front-ECU

connector A-11X in good condition?

YES : Go to Step 22.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the headlamps illuminate

normally.

STEP 22. Check the headlamp (RH) bulb.

(1) Remove the headlamp (RH) bulb.

(2) Verify that the headlamp (RH) bulb is not damaged or

burned out.

Q: Is headlamp (RH) bulb normal?

YES : Go to Step 23.

NO : Replace the headlamp (RH) bulb. Verify that the

headlamps illuminate normally.

Page 309 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-309

FLASHER TIMER

GENERAL DESCRIPTION CONCERNING THE FLASHER TIMERM1549023600238

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80The following ECUs affect the functions and control

of the flasher timer.

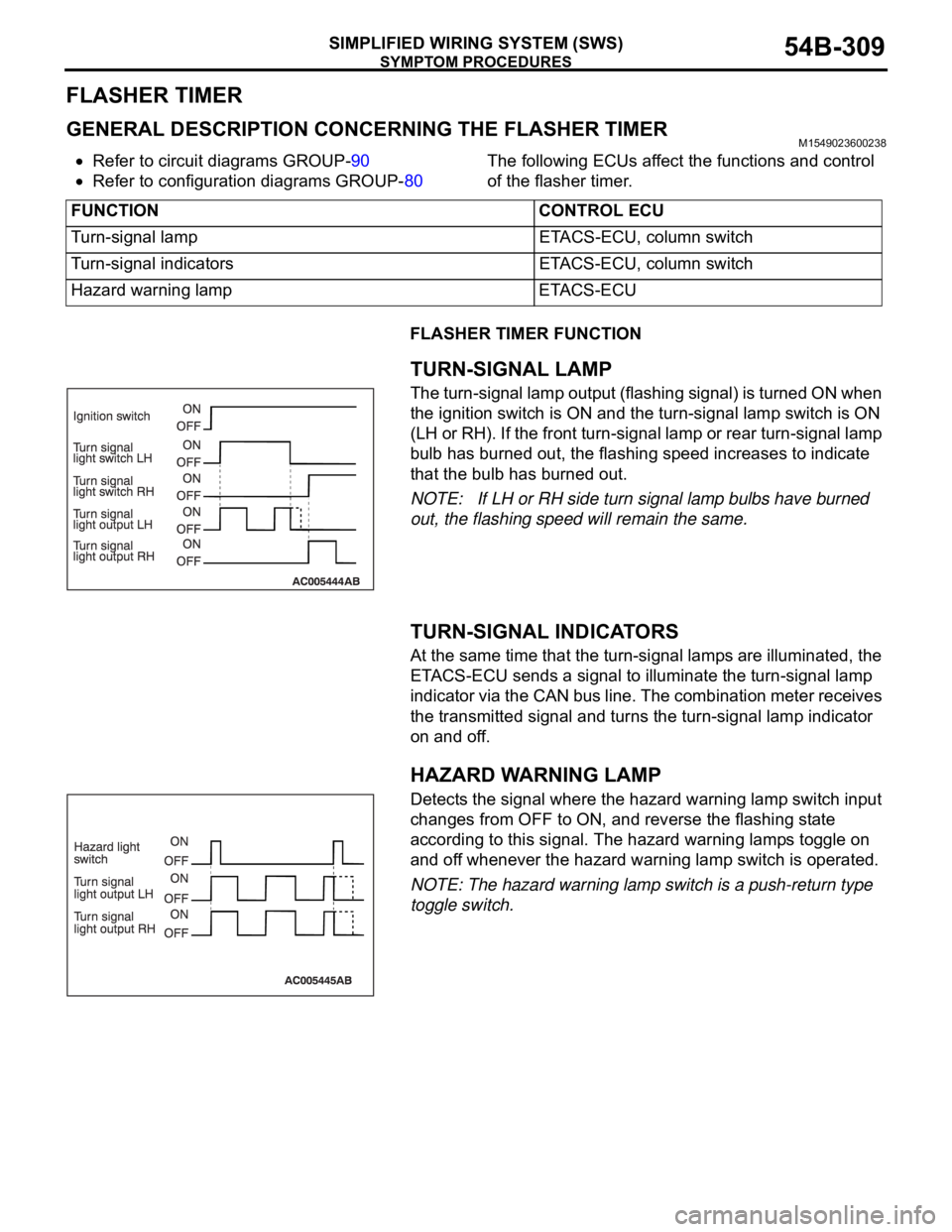

FLASHER TIMER FUNCTION

.

TURN-SIGNAL LAMP

The turn-signal lamp output (flashing signal) is turned ON when

the ignition switch is ON and the turn-signal lamp switch is ON

(LH or RH). If the front turn-signal lamp or rear turn-signal lamp

bulb has burned out, the flashing speed increases to indicate

that the bulb has burned out.

NOTE: If LH or RH side turn signal lamp bulbs have burned

out, the flashing speed will remain the same.

.

TURN-SIGNAL INDICATORS

At the same time that the turn-signal lamps are illuminated, the

ETACS-ECU sends a signal to illuminate the turn-signal lamp

indicator via the CAN bus line. The combination meter receives

the transmitted signal and turns the turn-signal lamp indicator

on and off.

.

HAZARD WARNING LAMP

Detects the signal where the hazard warning lamp switch input

changes from OFF to ON, and reverse the flashing state

according to this signal. The hazard warning lamps toggle on

and off whenever the hazard warning lamp switch is operated.

NOTE: The hazard warning lamp switch is a push-return type

toggle switch. FUNCTION CONTROL ECU

Turn-signal lamp ETACS-ECU, column switch

Turn-signal indicators ETACS-ECU, column switch

Hazard warning lamp ETACS-ECU

Page 316 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-316

INSPECTION PROCEDURE I-3: Flasher Timer: One of the turn-signal lamps does not illuminate.

.

TECHNICAL DESCRIPTION (COMMENT)

If the right or left turn-signal lamp does not illuminate,

their bulb may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The turn-signal lamp bulb may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

.

Page 317 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-317

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

STEP 1. Check the hazard warning lamp.

Q: Which turn-signal lamp does not illuminate?

front turn-signal lamp (LH) : Go to Step 2.

side turn-signal lamp (LH) : Go to Step 8.

front turn-signal lamp (RH) : Go to Step 14.

side turn-signal lamp (RH) : Go to Step 20.

rear combination lamp (LH) : Go to Step 26.

rear combination lamp (RH) : Go to Step 32.

Turn-signal indicators : Refer to Inspection Procedure I-4

"The turn-signal lamp indicator does not illuminate

normally P.54B-335."

LH side only : Refer to Inspection Procedure I-1

"Turn-signal lamps do not flash when the turn-signal

lamp switch is turned on P.54B-310."

RH side only : Refer to Inspection Procedure I-1

"Turn-signal lamps do not flash when the turn-signal

lamp switch is turned on P.54B-310."

Both LH and RH sides : Refer to Inspection Procedure I-2

"Hazard warning lamps do not flash when the hazard

warning lamp switch is turned on P.54B-314."

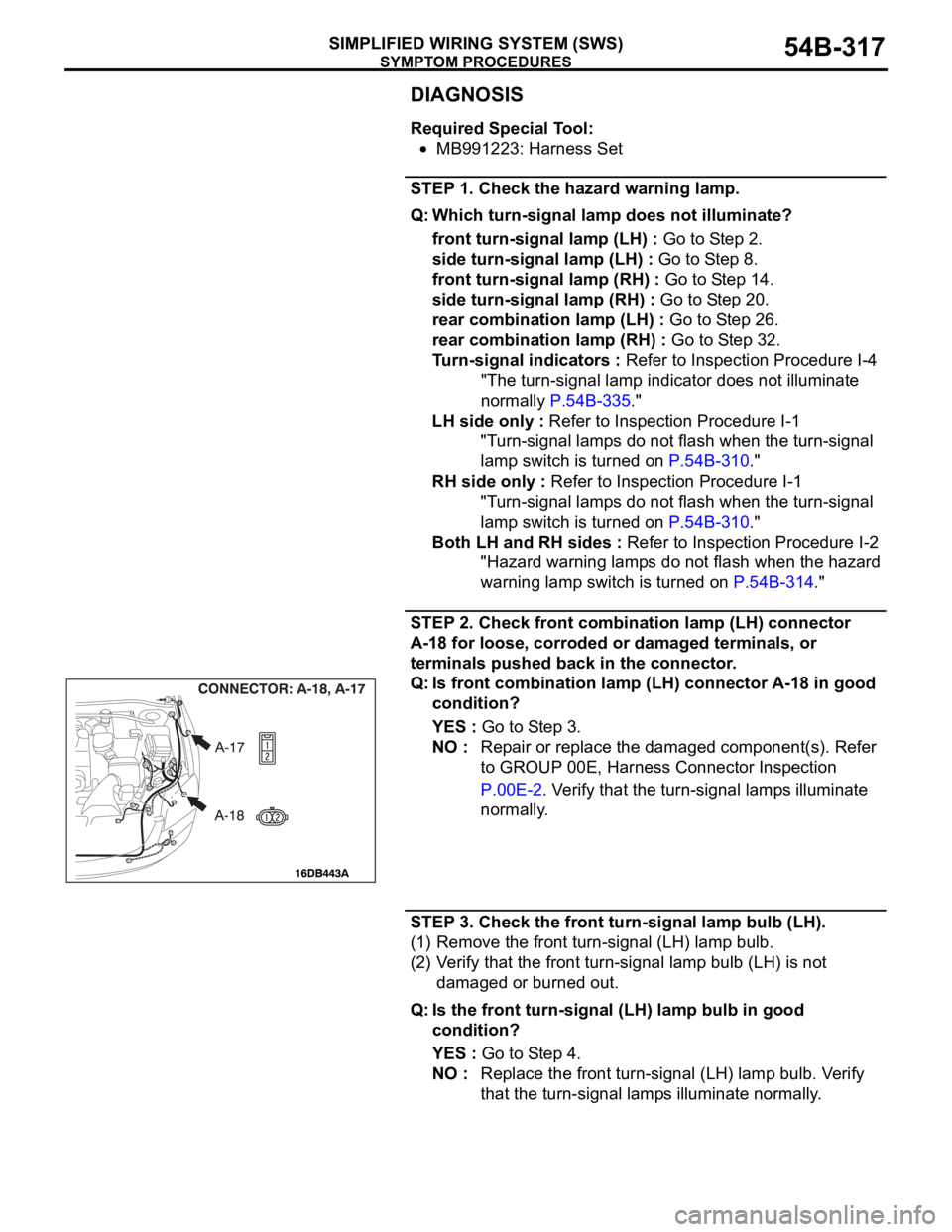

STEP 2. Check front combination lamp (LH) connector

A-18 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is front combination lamp (LH) connector A-18 in good

condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the turn-signal lamps illuminate

normally.

STEP 3. Check the front turn-signal lamp bulb (LH).

(1) Remove the front turn-signal (LH) lamp bulb.

(2) Verify that the front turn-signal lamp bulb (LH) is not

damaged or burned out.

Q: Is the front turn-signal (LH) lamp bulb in good

condition?

YES : Go to Step 4.

NO : Replace the front turn-signal (LH) lamp bulb. Verify

that the turn-signal lamps illuminate normally.

Page 320 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-320

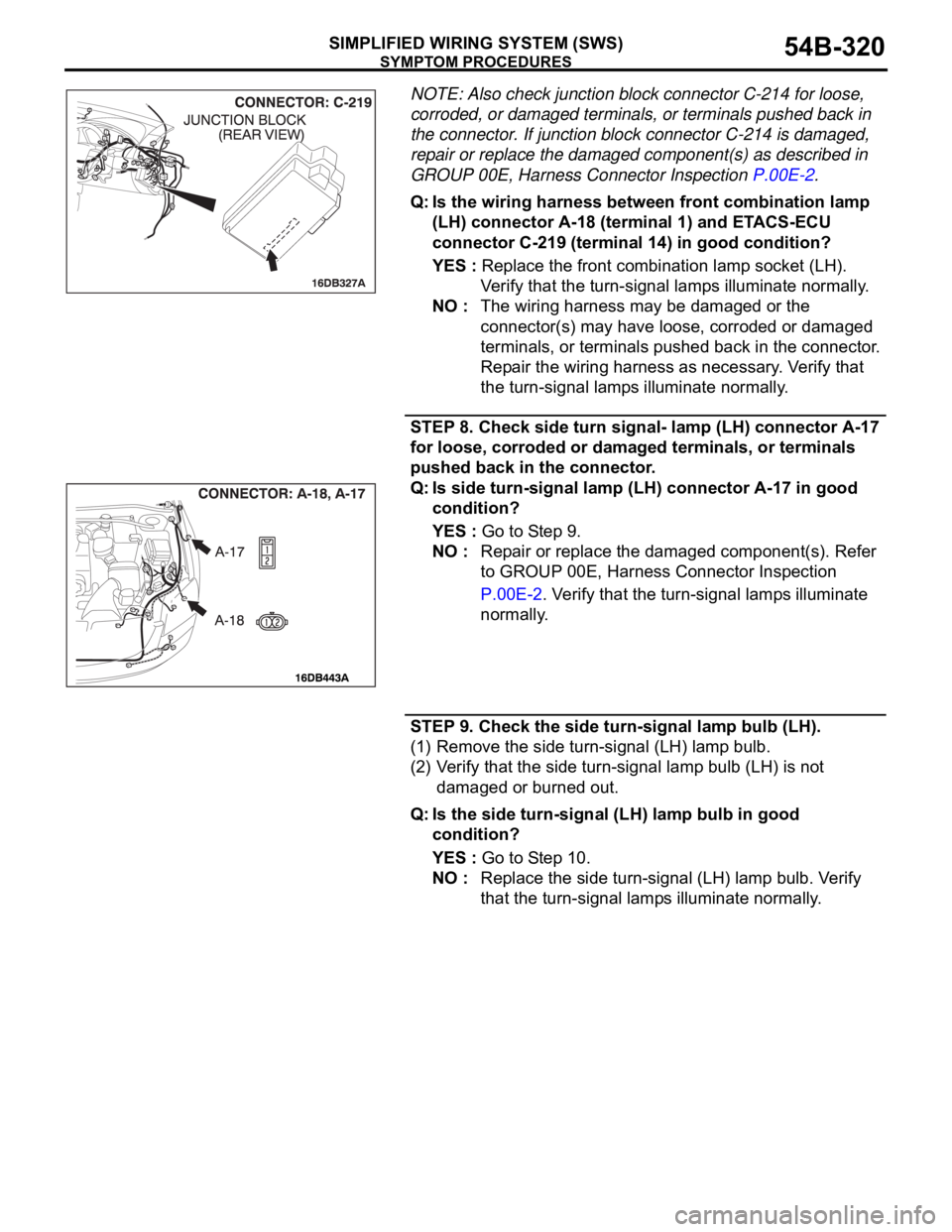

NOTE: Also check junction block connector C-214 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-214 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between front combination lamp

(LH) connector A-18 (terminal 1) and ETACS-ECU

connector C-219 (terminal 14) in good condition?

YES : Replace the front combination lamp socket (LH).

Verify that the turn-signal lamps illuminate normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the turn-signal lamps illuminate normally.

STEP 8. Check side turn signal- lamp (LH) connector A-17

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is side turn-signal lamp (LH) connector A-17 in good

condition?

YES : Go to Step 9.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the turn-signal lamps illuminate

normally.

STEP 9. Check the side turn-signal lamp bulb (LH).

(1) Remove the side turn-signal (LH) lamp bulb.

(2) Verify that the side turn-signal lamp bulb (LH) is not

damaged or burned out.

Q: Is the side turn-signal (LH) lamp bulb in good

condition?

YES : Go to Step 10.

NO : Replace the side turn-signal (LH) lamp bulb. Verify

that the turn-signal lamps illuminate normally.

Page 323 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-323

NOTE: Also check junction block connector C-214 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-214 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between side turn-signal lamp

(LH) connector A-17 (terminal 1) and ETACS-ECU

connector C-219 (terminal 14) in good condition?

YES : Replace the side turn-signal lamp socket (LH). Verify

that the turn-signal lamps illuminate normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the turn-signal lamps illuminate normally.

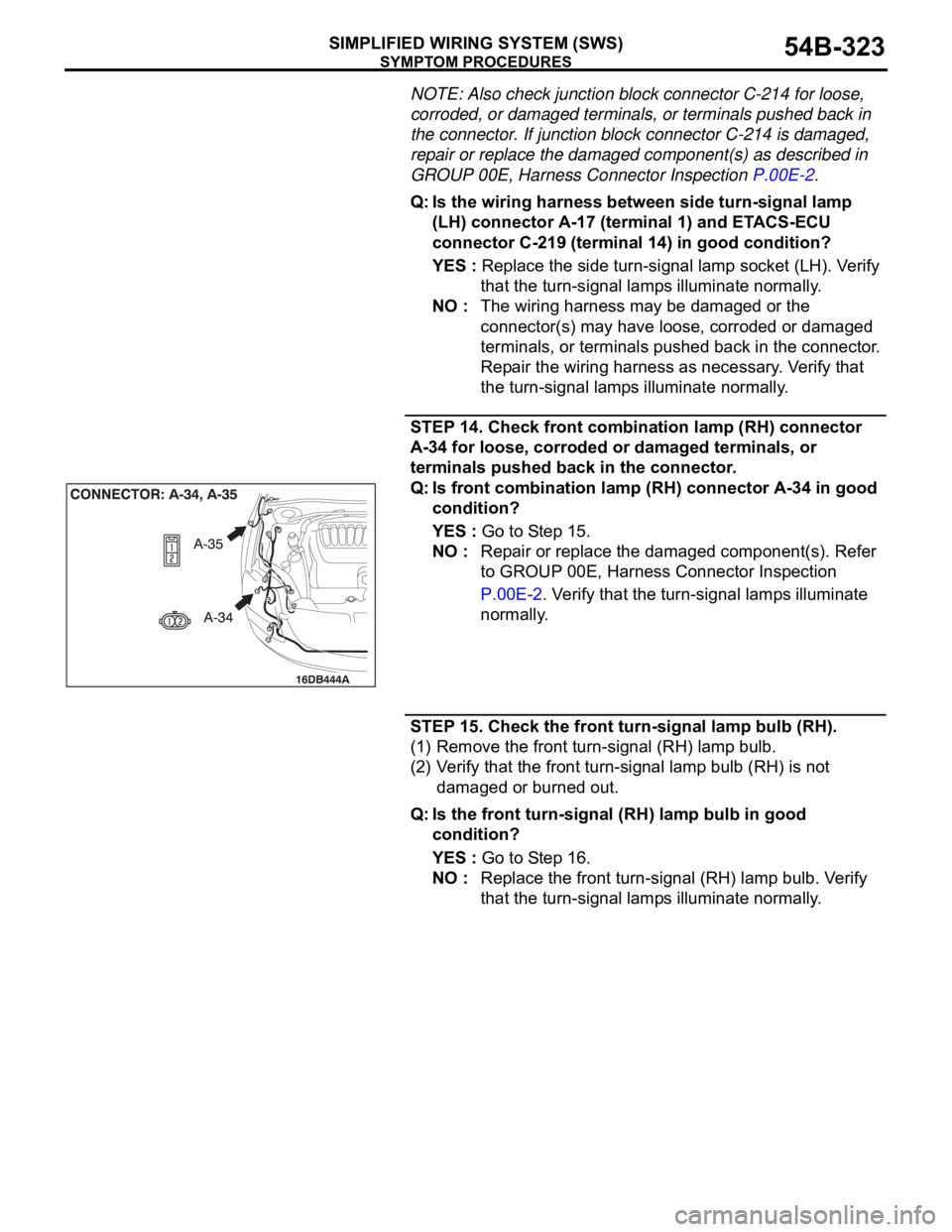

STEP 14. Check front combination lamp (RH) connector

A-34 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is front combination lamp (RH) connector A-34 in good

condition?

YES : Go to Step 15.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the turn-signal lamps illuminate

normally.

STEP 15. Check the front turn-signal lamp bulb (RH).

(1) Remove the front turn-signal (RH) lamp bulb.

(2) Verify that the front turn-signal lamp bulb (RH) is not

damaged or burned out.

Q: Is the front turn-signal (RH) lamp bulb in good

condition?

YES : Go to Step 16.

NO : Replace the front turn-signal (RH) lamp bulb. Verify

that the turn-signal lamps illuminate normally.

Page 326 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-326

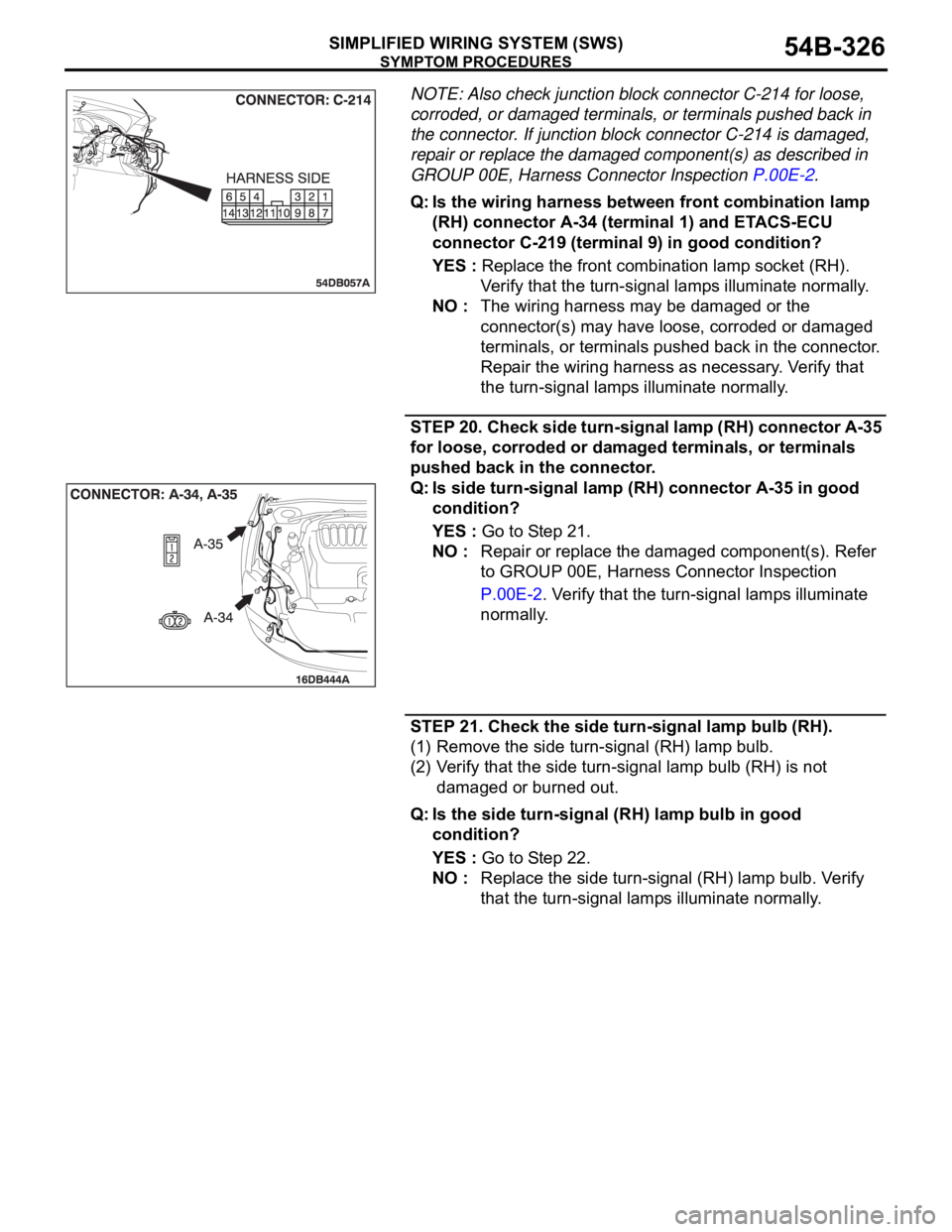

NOTE: Also check junction block connector C-214 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-214 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between front combination lamp

(RH) connector A-34 (terminal 1) and ETACS-ECU

connector C-219 (terminal 9) in good condition?

YES : Replace the front combination lamp socket (RH).

Verify that the turn-signal lamps illuminate normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the turn-signal lamps illuminate normally.

STEP 20. Check side turn-signal lamp (RH) connector A-35

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is side turn-signal lamp (RH) connector A-35 in good

condition?

YES : Go to Step 21.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the turn-signal lamps illuminate

normally.

STEP 21. Check the side turn-signal lamp bulb (RH).

(1) Remove the side turn-signal (RH) lamp bulb.

(2) Verify that the side turn-signal lamp bulb (RH) is not

damaged or burned out.

Q: Is the side turn-signal (RH) lamp bulb in good

condition?

YES : Go to Step 22.

NO : Replace the side turn-signal (RH) lamp bulb. Verify

that the turn-signal lamps illuminate normally.