bulb MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 329 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-329

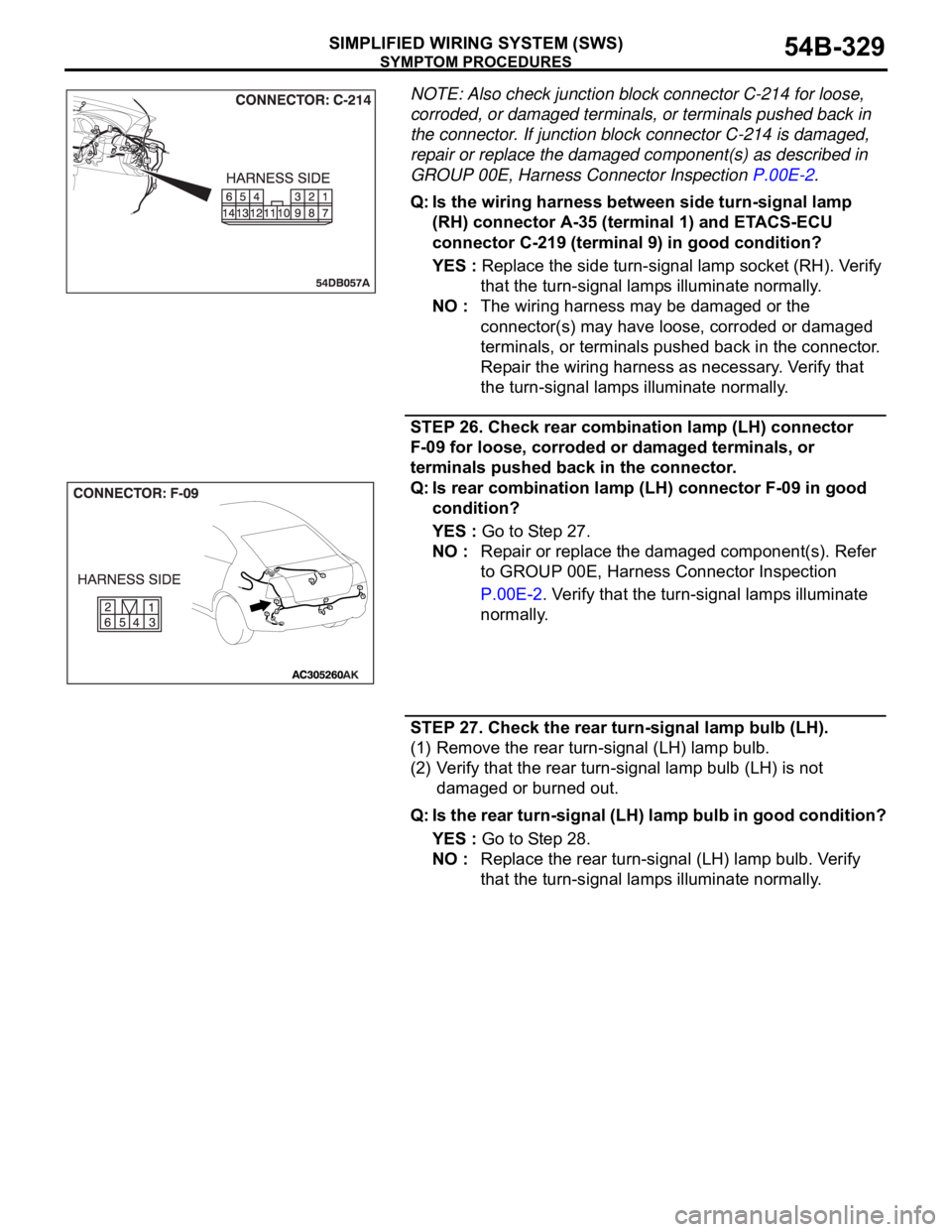

NOTE: Also check junction block connector C-214 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-214 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between side turn-signal lamp

(RH) connector A-35 (terminal 1) and ETACS-ECU

connector C-219 (terminal 9) in good condition?

YES : Replace the side turn-signal lamp socket (RH). Verify

that the turn-signal lamps illuminate normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the turn-signal lamps illuminate normally.

STEP 26. Check rear combination lamp (LH) connector

F-09 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is rear combination lamp (LH) connector F-09 in good

condition?

YES : Go to Step 27.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the turn-signal lamps illuminate

normally.

STEP 27. Check the rear turn-signal lamp bulb (LH).

(1) Remove the rear turn-signal (LH) lamp bulb.

(2) Verify that the rear turn-signal lamp bulb (LH) is not

damaged or burned out.

Q: Is the rear turn-signal (LH) lamp bulb in good condition?

YES : Go to Step 28.

NO : Replace the rear turn-signal (LH) lamp bulb. Verify

that the turn-signal lamps illuminate normally.

Page 332 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-332

NOTE: Also check junction block connector C-204 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-204 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between rear combination lamp

(LH) connector F-09 (terminal 5) and ETACS-ECU

connector C-219 (terminal 14) in good condition?

YES : Replace the rear combination lamp socket assembly

(LH). Verify that the turn-signal lamps illuminate

normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the turn-signal lamps illuminate normally.

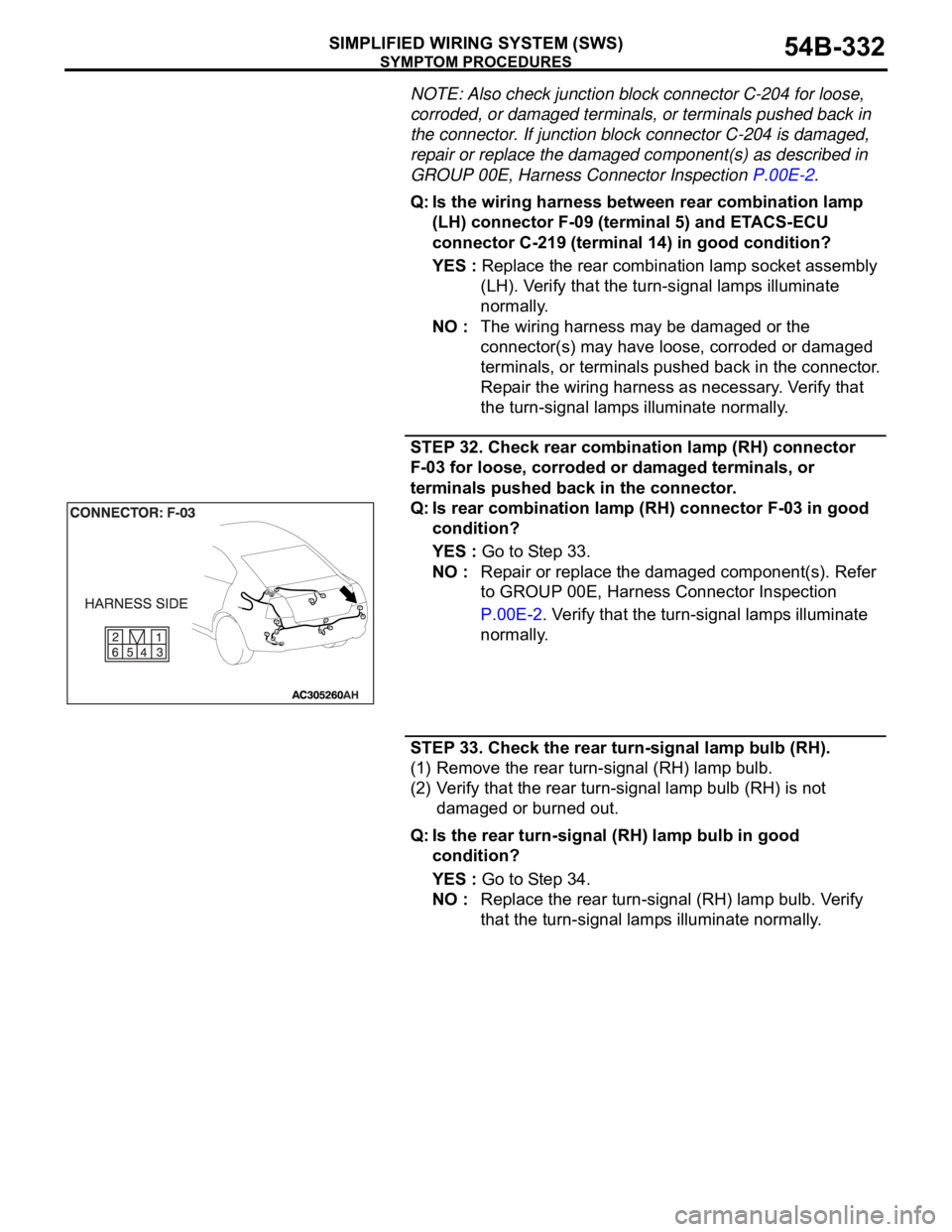

STEP 32. Check rear combination lamp (RH) connector

F-03 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is rear combination lamp (RH) connector F-03 in good

condition?

YES : Go to Step 33.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the turn-signal lamps illuminate

normally.

STEP 33. Check the rear turn-signal lamp bulb (RH).

(1) Remove the rear turn-signal (RH) lamp bulb.

(2) Verify that the rear turn-signal lamp bulb (RH) is not

damaged or burned out.

Q: Is the rear turn-signal (RH) lamp bulb in good

condition?

YES : Go to Step 34.

NO : Replace the rear turn-signal (RH) lamp bulb. Verify

that the turn-signal lamps illuminate normally.

Page 345 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-345

INSPECTION PROCEDURE J-2: Fog Light: Fog lamps do not go out when the headlamps (low-beam)

are turned off while the fog lamps are on.

.

TECHNICAL DESCRIPTION (COMMENT)

If the trouble above occurs, the front-ECU may be

defective.

.

TROUBLESHOOTING HINT

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The front-ECU may be defective

DIAGNOSIS

Replace the front-ECU.

The fog lamps should go out when the headlamps (low-beam)

are turned off while the fog lamps are on.

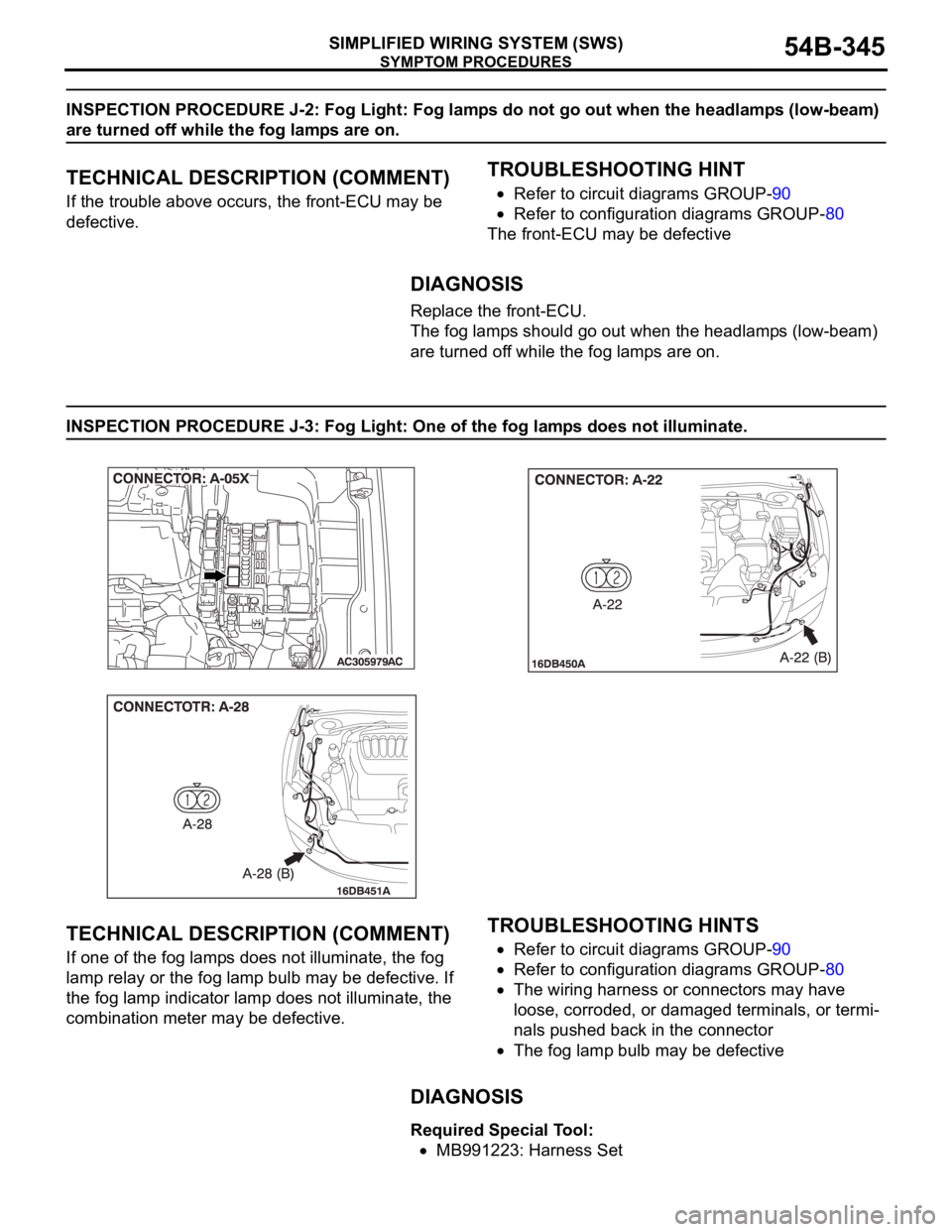

INSPECTION PROCEDURE J-3: Fog Light: One of the fog lamps does not illuminate.

.

TECHNICAL DESCRIPTION (COMMENT)

If one of the fog lamps does not illuminate, the fog

lamp relay or the fog lamp bulb may be defective. If

the fog lamp indicator lamp does not illuminate, the

combination meter may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The fog lamp bulb may be defective

.

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

Page 346 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-346

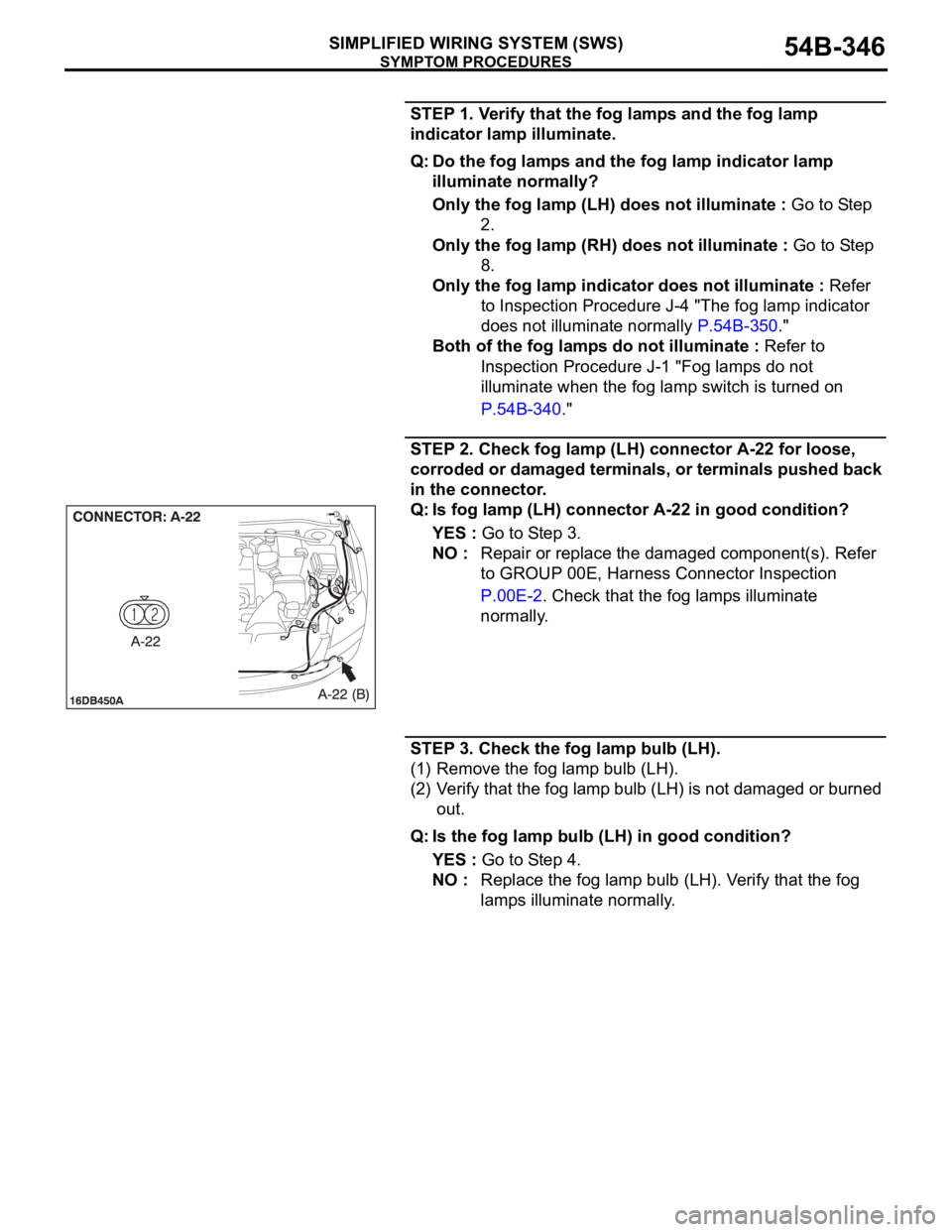

STEP 1. Verify that the fog lamps and the fog lamp

indicator lamp illuminate.

Q: Do the fog lamps and the fog lamp indicator lamp

illuminate normally?

Only the fog lamp (LH) does not illuminate : Go to Step

2.

Only the fog lamp (RH) does not illuminate : Go to Step

8.

Only the fog lamp indicator does not illuminate : Refer

to Inspection Procedure J-4 "The fog lamp indicator

does not illuminate normally P.54B-350."

Both of the fog lamps do not illuminate : Refer to

Inspection Procedure J-1 "Fog lamps do not

illuminate when the fog lamp switch is turned on

P.54B-340."

STEP 2. Check fog lamp (LH) connector A-22 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp (LH) connector A-22 in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the fog lamps illuminate

normally.

STEP 3. Check the fog lamp bulb (LH).

(1) Remove the fog lamp bulb (LH).

(2) Verify that the fog lamp bulb (LH) is not damaged or burned

out.

Q: Is the fog lamp bulb (LH) in good condition?

YES : Go to Step 4.

NO : Replace the fog lamp bulb (LH). Verify that the fog

lamps illuminate normally.

Page 348 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-348

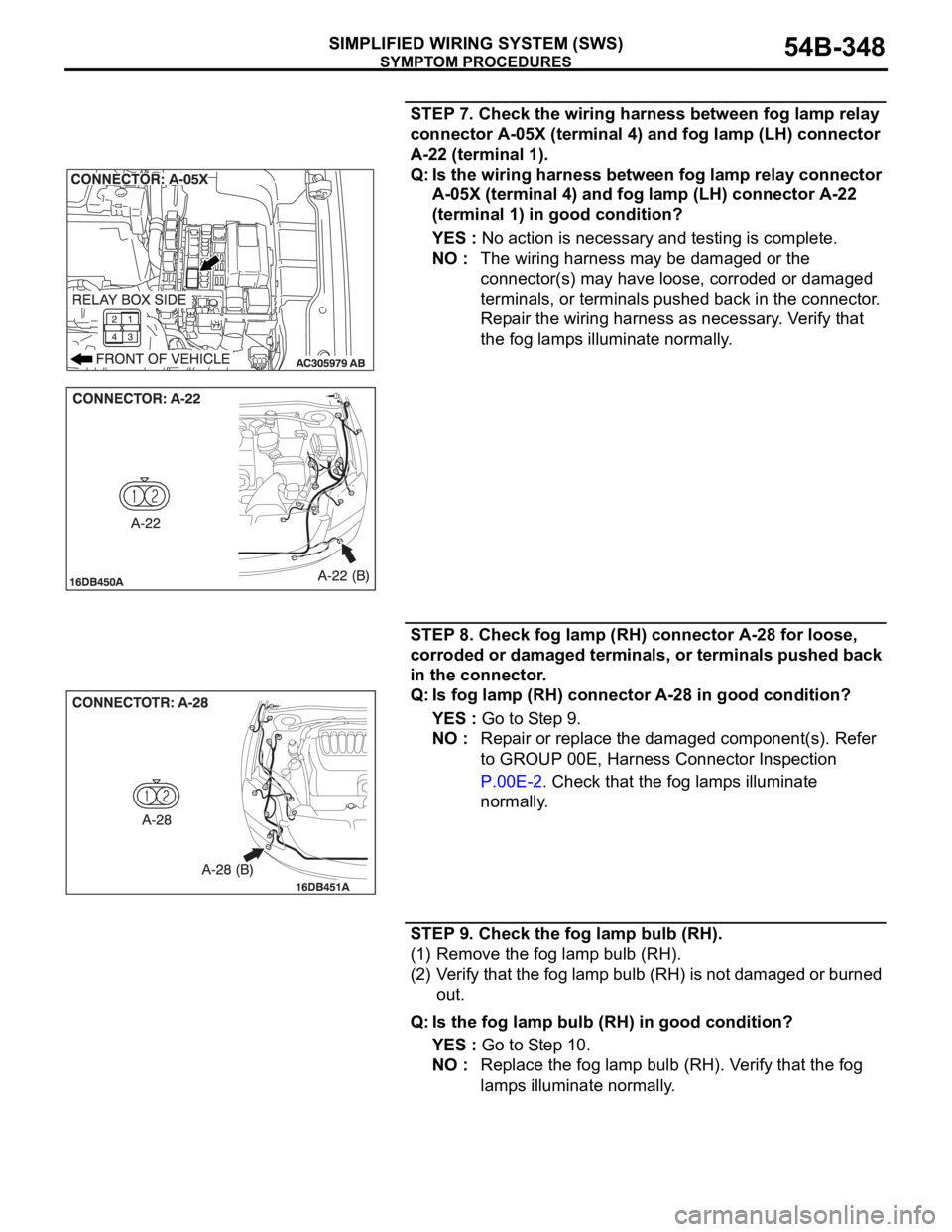

STEP 7. Check the wiring harness between fog lamp relay

connector A-05X (terminal 4) and fog lamp (LH) connector

A-22 (terminal 1).

Q: Is the wiring harness between fog lamp relay connector

A-05X (terminal 4) and fog lamp (LH) connector A-22

(terminal 1) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the fog lamps illuminate normally.

STEP 8. Check fog lamp (RH) connector A-28 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is fog lamp (RH) connector A-28 in good condition?

YES : Go to Step 9.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the fog lamps illuminate

normally.

STEP 9. Check the fog lamp bulb (RH).

(1) Remove the fog lamp bulb (RH).

(2) Verify that the fog lamp bulb (RH) is not damaged or burned

out.

Q: Is the fog lamp bulb (RH) in good condition?

YES : Go to Step 10.

NO : Replace the fog lamp bulb (RH). Verify that the fog

lamps illuminate normally.

Page 359 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-359

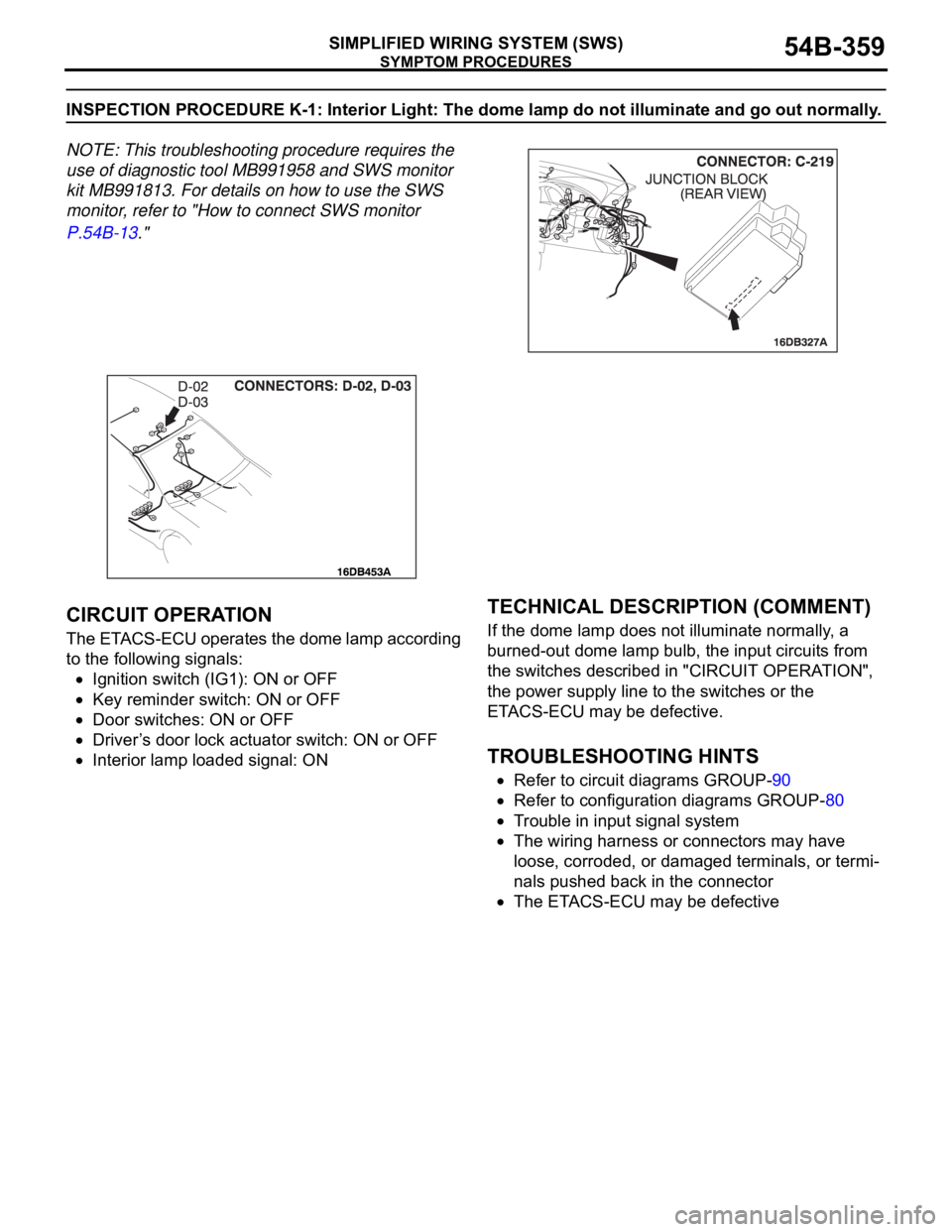

INSPECTION PROCEDURE K-1: Interior Light: The dome lamp do not illuminate and go out normally.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The ETACS-ECU operates the dome lamp according

to the following signals:

Ignition switch (IG1): ON or OFF

Key reminder switch: ON or OFF

Door switches: ON or OFF

Driver’s door lock actuator switch: ON or OFF

Interior lamp loaded signal: ON

.

TECHNICAL DESCRIPTION (COMMENT)

If the dome lamp does not illuminate normally, a

burned-out dome lamp bulb, the input circuits from

the switches described in "CIRCUIT OPERATION",

the power supply line to the switches or the

ETACS-ECU may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 367 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-367

TECHNICAL DESCRIPTION (COMMENT)

Is the dome lamp does not flash normally, a

burned-out dome lamp bulb, the input circuits from

the switches described in "CIRCUIT OPERATION",

the power supply line to the switches or the

ETACS-ECU may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The front dome lamp bulb may be defective

The rear dome lamp bulb may be defective

The trunk lamp bulb may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 369 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-369

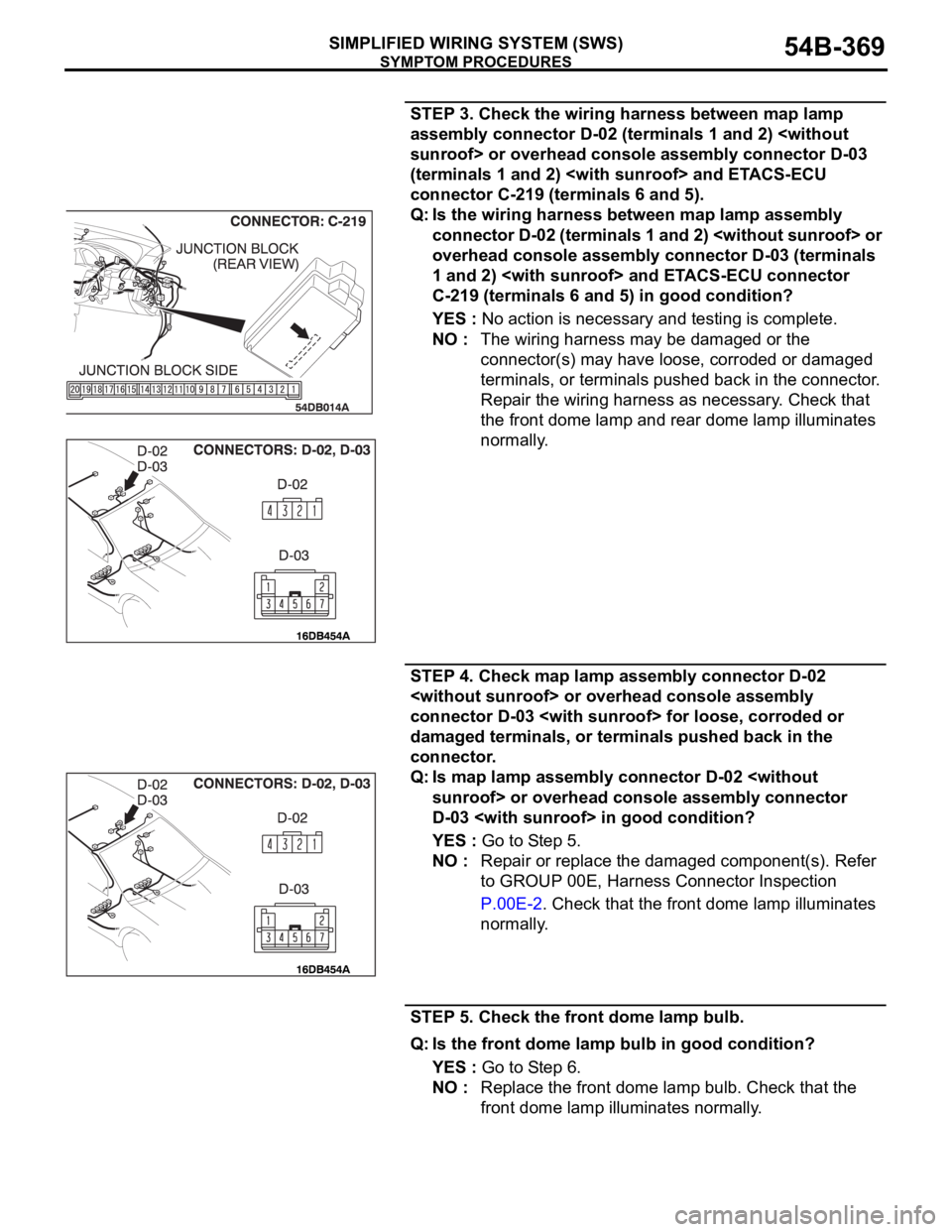

STEP 3. Check the wiring harness between map lamp

assembly connector D-02 (terminals 1 and 2)

(terminals 1 and 2)

connector C-219 (terminals 6 and 5).

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminals 1 and 2)

overhead console assembly connector D-03 (terminals

1 and 2)

C-219 (terminals 6 and 5) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the front dome lamp and rear dome lamp illuminates

normally.

STEP 4. Check map lamp assembly connector D-02

connector D-03

damaged terminals, or terminals pushed back in the

connector.

Q: Is map lamp assembly connector D-02

D-03

YES : Go to Step 5.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the front dome lamp illuminates

normally.

STEP 5. Check the front dome lamp bulb.

Q: Is the front dome lamp bulb in good condition?

YES : Go to Step 6.

NO : Replace the front dome lamp bulb. Check that the

front dome lamp illuminates normally.

Page 371 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-371

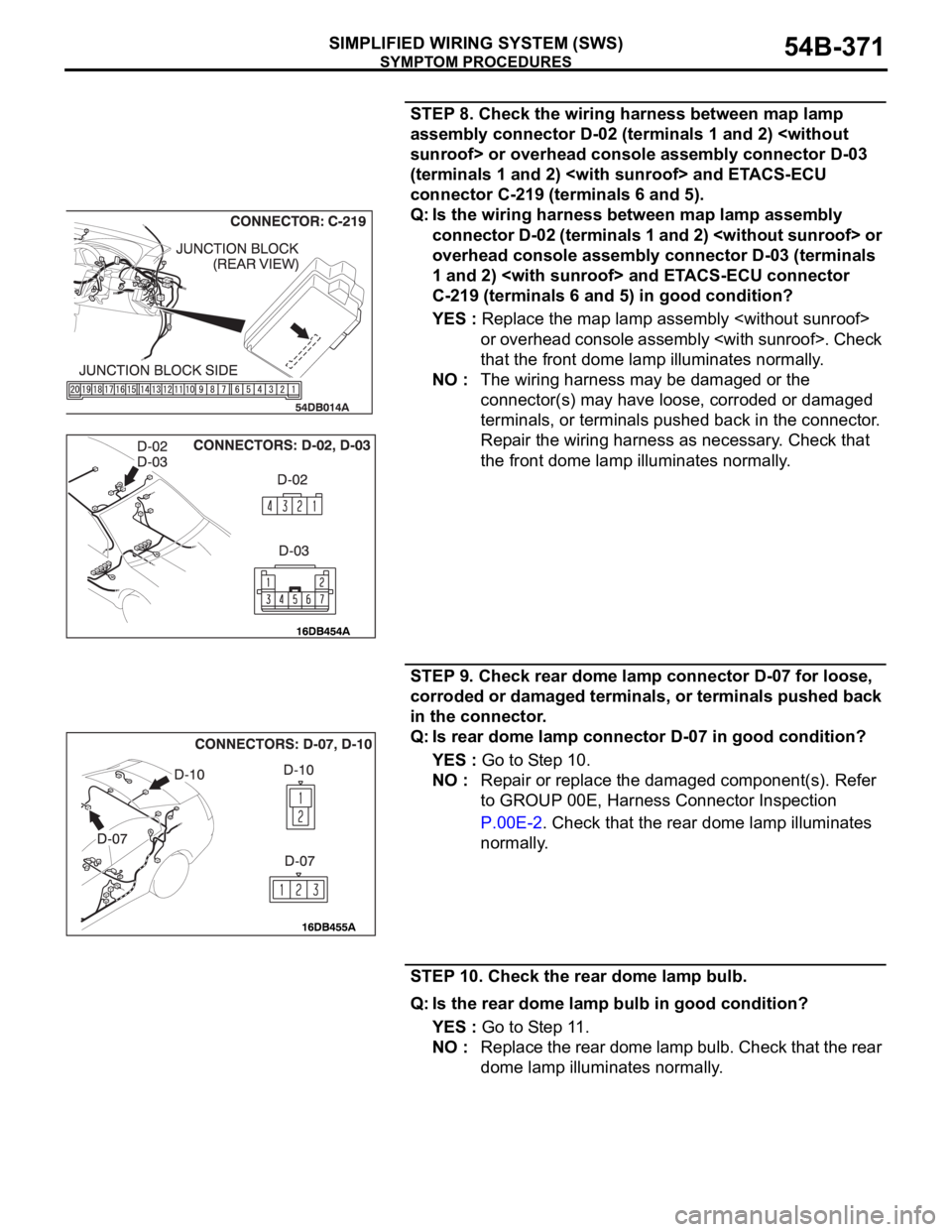

STEP 8. Check the wiring harness between map lamp

assembly connector D-02 (terminals 1 and 2)

(terminals 1 and 2)

connector C-219 (terminals 6 and 5).

Q: Is the wiring harness between map lamp assembly

connector D-02 (terminals 1 and 2)

overhead console assembly connector D-03 (terminals

1 and 2)

C-219 (terminals 6 and 5) in good condition?

YES : Replace the map lamp assembly

or overhead console assembly

that the front dome lamp illuminates normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Check that

the front dome lamp illuminates normally.

STEP 9. Check rear dome lamp connector D-07 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is rear dome lamp connector D-07 in good condition?

YES : Go to Step 10.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the rear dome lamp illuminates

normally.

STEP 10. Check the rear dome lamp bulb.

Q: Is the rear dome lamp bulb in good condition?

YES : Go to Step 11.

NO : Replace the rear dome lamp bulb. Check that the rear

dome lamp illuminates normally.

Page 374 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-374

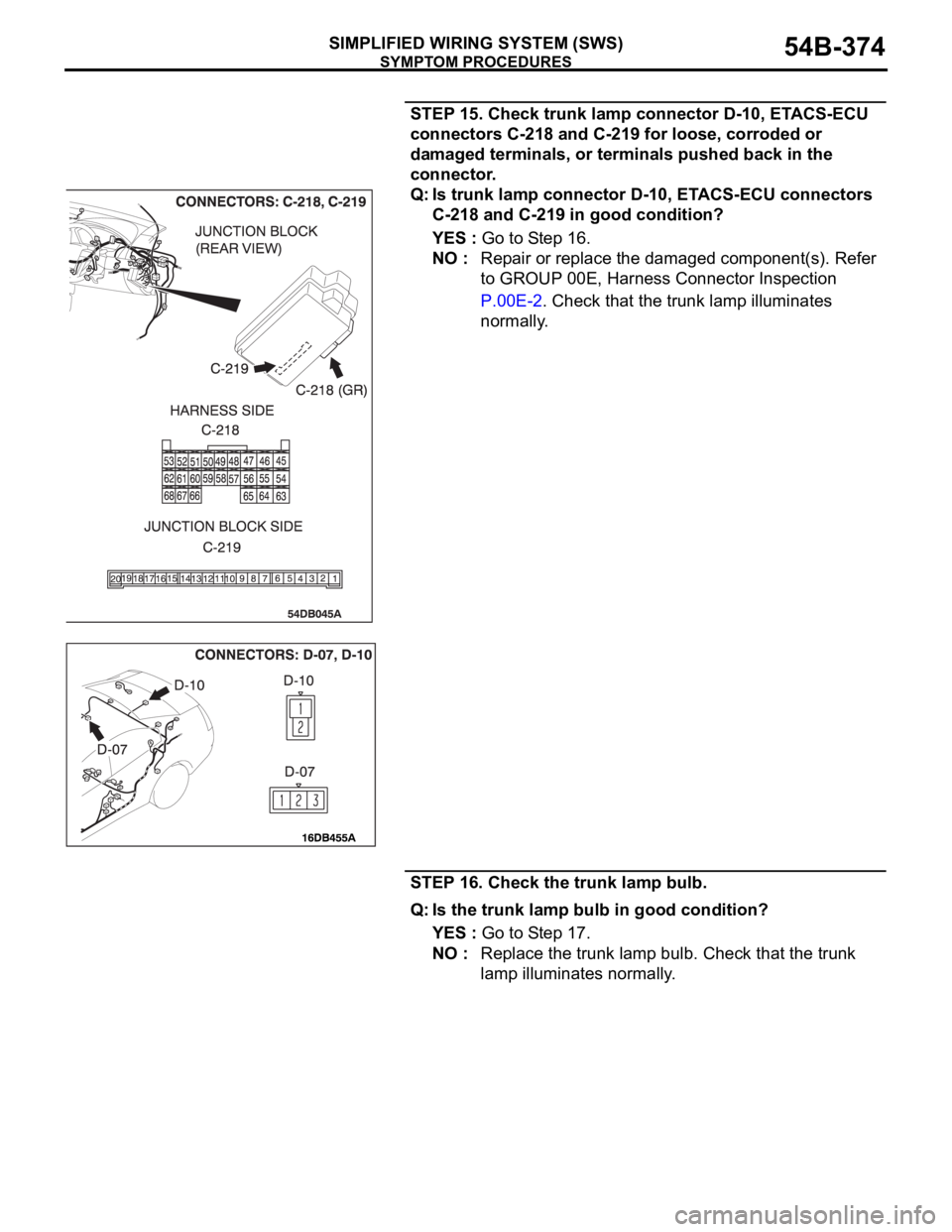

STEP 15. Check trunk lamp connector D-10, ETACS-ECU

connectors C-218 and C-219 for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Is trunk lamp connector D-10, ETACS-ECU connectors

C-218 and C-219 in good condition?

YES : Go to Step 16.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the trunk lamp illuminates

normally.

STEP 16. Check the trunk lamp bulb.

Q: Is the trunk lamp bulb in good condition?

YES : Go to Step 17.

NO : Replace the trunk lamp bulb. Check that the trunk

lamp illuminates normally.