bulb MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 381 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-381

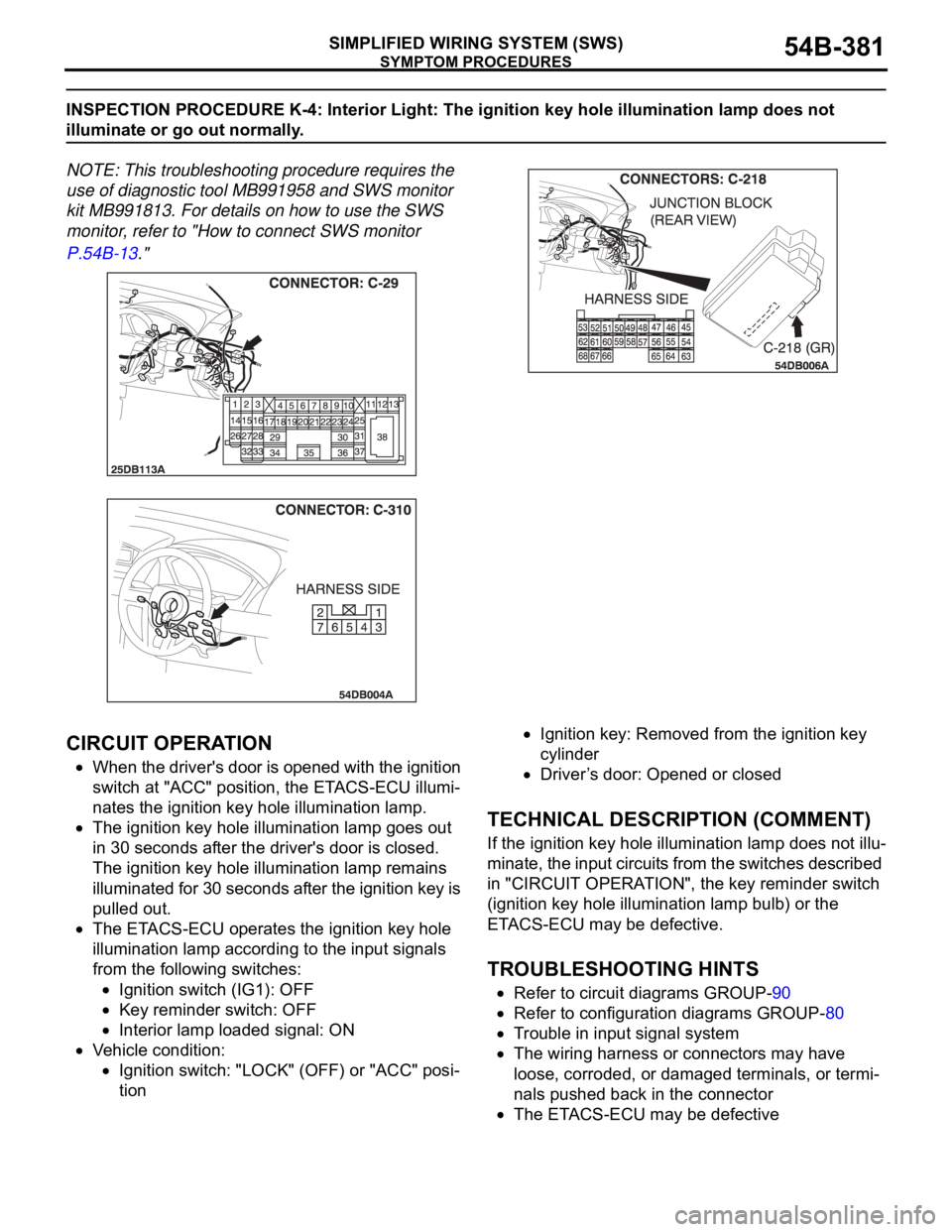

INSPECTION PROCEDURE K-4: Interior Light: The ignition key hole illumination lamp does not

illuminate or go out normally.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

When the driver's door is opened with the ignition

switch at "ACC" position, the ETACS-ECU illumi-

nates the ignition key hole illumination lamp.

The ignition key hole illumination lamp goes out

in 30 seconds after the driver's door is closed.

The ignition key hole illumination lamp remains

illuminated for 30 seconds after the ignition key is

pulled out.

The ETACS-ECU operates the ignition key hole

illumination lamp according to the input signals

from the following switches:

Ignition switch (IG1): OFF

Key reminder switch: OFF

Interior lamp loaded signal: ON

Vehicle condition:

Ignition switch: "LOCK" (OFF) or "ACC" posi-

tion

Ignition key: Removed from the ignition key

cylinder

Driver’s door: Opened or closed

.

TECHNICAL DESCRIPTION (COMMENT)

If the ignition key hole illumination lamp does not illu-

minate, the input circuits from the switches described

in "CIRCUIT OPERATION", the key reminder switch

(ignition key hole illumination lamp bulb) or the

ETACS-ECU may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 386 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-386

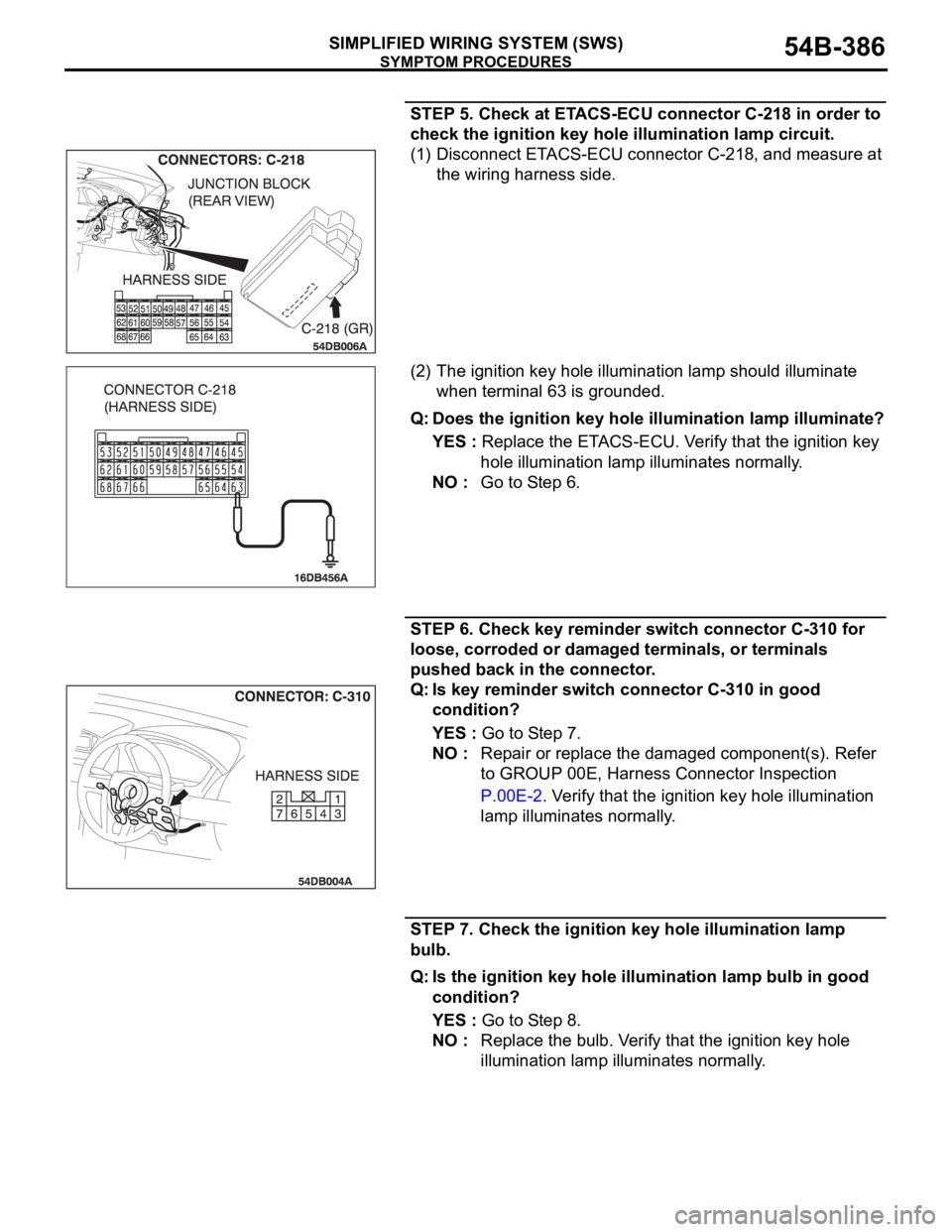

STEP 5. Check at ETACS-ECU connector C-218 in order to

check the ignition key hole illumination lamp circuit.

(1) Disconnect ETACS-ECU connector C-218, and measure at

the wiring harness side.

(2) The ignition key hole illumination lamp should illuminate

when terminal 63 is grounded.

Q: Does the ignition key hole illumination lamp illuminate?

YES : Replace the ETACS-ECU. Verify that the ignition key

hole illumination lamp illuminates normally.

NO : Go to Step 6.

STEP 6. Check key reminder switch connector C-310 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is key reminder switch connector C-310 in good

condition?

YES : Go to Step 7.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the ignition key hole illumination

lamp illuminates normally.

STEP 7. Check the ignition key hole illumination lamp

bulb.

Q: Is the ignition key hole illumination lamp bulb in good

condition?

YES : Go to Step 8.

NO : Replace the bulb. Verify that the ignition key hole

illumination lamp illuminates normally.

Page 387 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-387

STEP 8. Check the key reminder switch (ignition key hole

illumination).

(1) Disconnect key reminder switch connector C-310.

(2) Remove the ignition key hole illumination lamp bulb. Then

measure the resistance value between the bulb terminals.

(3) Install a bulb to the key remainder switch, and measure the

resistance between connector C-310 terminals 1 and 2. The

measured resistance value should be roughly the same as

the value measured in Step (2).

Q: Are these two resistance values extremely different?

YES : Replace the key reminder switch. Verify that the

ignition key hole illumination lamp illuminates

normally.

NO :

STEP 9. Check the battery power supply circuit to the key

reminder switch circuit. Measure the voltage at key

reminder switch connector C-310.

(1) Disconnect key reminder switch connector C-310, and

measure the voltage available at the wiring harness side of

the connector.

(2) Measure the voltage between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 11.

NO : Go to Step 10.

Page 906 of 1500

HOW TO DIAGNOSE

GENERAL

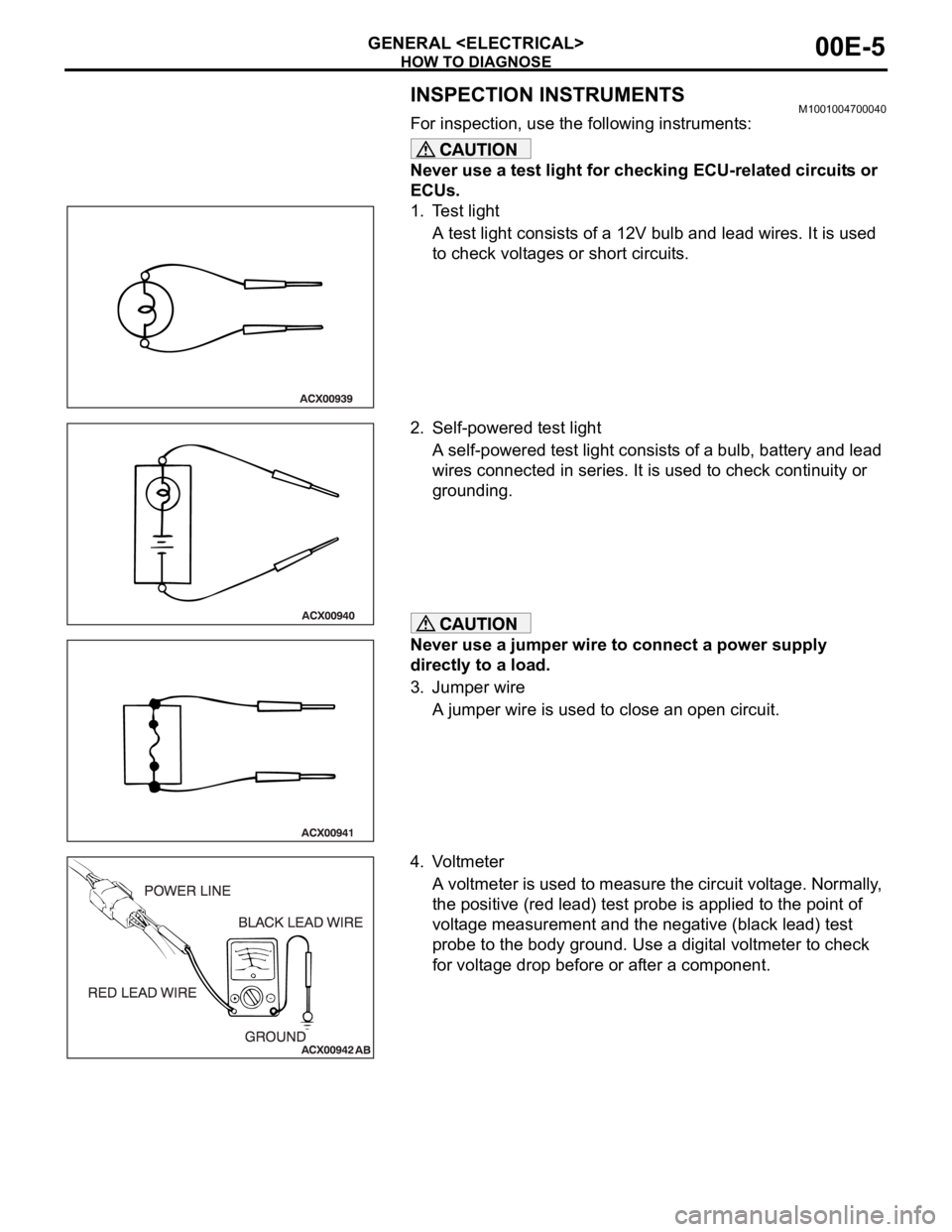

INSPECTION INSTRUMENTSM1001004700040

For inspection, use the following instruments:

Never use a test light for checking ECU-related circuits or

ECUs.

1. Test light

A test light consists of a 12V bulb and lead wires. It is used

to check voltages or short circuits.

2. Self-powered test light

A self-powered test light consists of a bulb, battery and lead

wires connected in series. It is used to check continuity or

grounding.

Never use a jumper wire to connect a power supply

directly to a load.

3. Jumper wire

A jumper wire is used to close an open circuit.

4. Voltmeter

A voltmeter is used to measure the circuit voltage. Normally,

the positive (red lead) test probe is applied to the point of

voltage measurement and the negative (black lead) test

probe to the body ground. Use a digital voltmeter to check

for voltage drop before or after a component.

Page 980 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

CHARGING SYSTEM DIAGNOSISM1161000700427

TROUBLESHOOTING HINTS

Alternator malfunction light dose not go on when the ignition

switch is turned to ON, before the engine starts.

Check the bulb.

Alternator malfunction light dose not switch off after the engine

starts.

Check the IC voltage regulator inside the

alternatoralternator.

Discharged or overcharged battery.

Check the IC voltage regulator inside the alternator.

The alternator malfunction light illuminates dimly.

Check the diode (inside the combination meter) for a

short-circuit.

TROUBLESHOOTING GUIDE

The charging system troubleshooting guide is shown in the fol-

lowing steps.

STEP 1.

Q: Is the battery in good condition? (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

YES : Go to Step 2.

NO : Charge or replace the battery.

STEP 2.

Q: Is the alternator drive belt in good condition? (Refer to

GROUP 00, General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

YES : Go to Step 3.

NO : Adjust the belt tension or replace the belt.

STEP 3.

Q: Does the alternator malfunction light come on when the

ignition switch is turned on?

YES : Go to Step 4.

NO :

Check the ignition switch. (Refer to GROUP 54A,

Chassis Electrical

Ignition Switch Ignition

Switch

Inspection P.54A-44.)

Check for burnt-out alternator malfunction light.

Check the alternator. (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

Check the alternator malfunction light-related

circuits.

Page 1303 of 1500

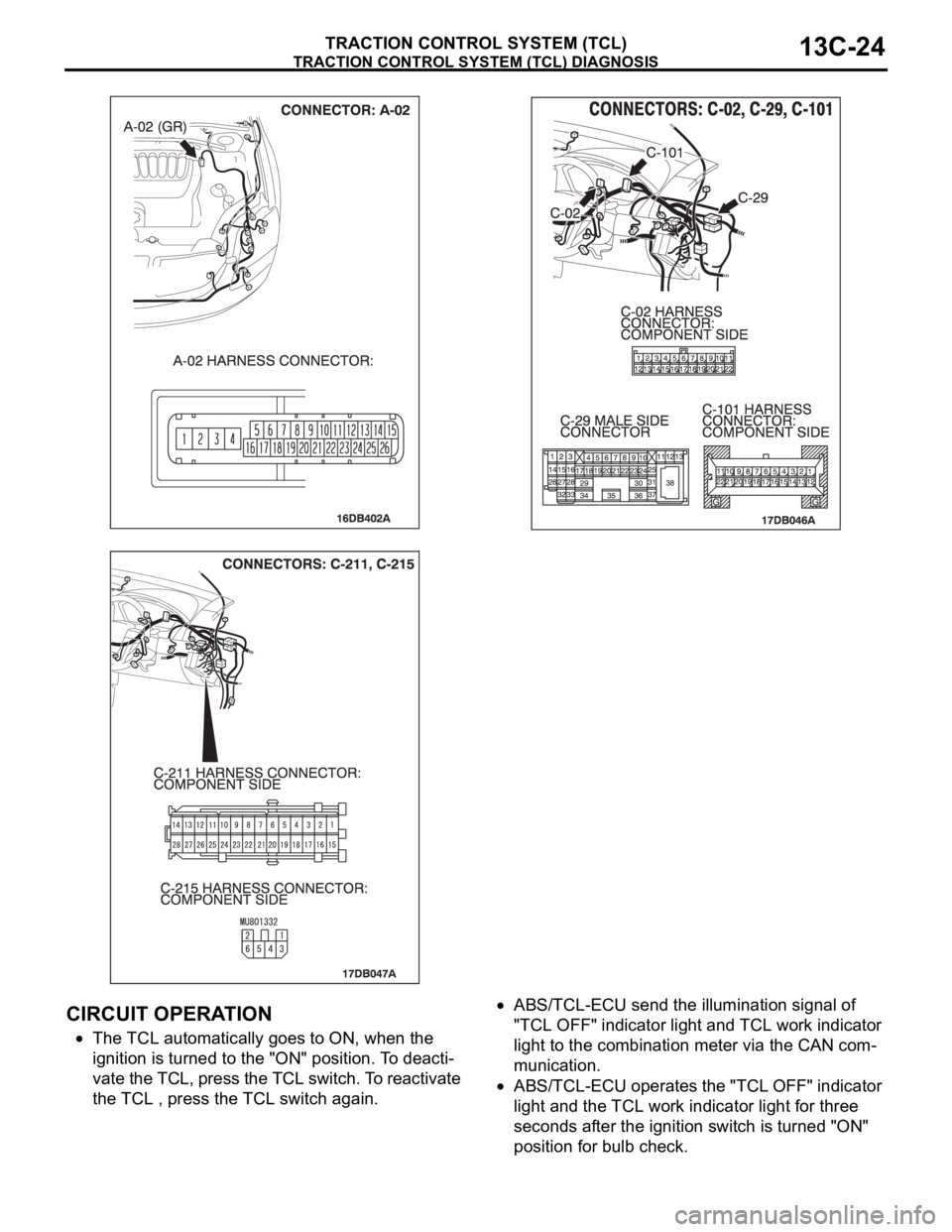

TRACTION CONTROL SYSTEM (TCL) DIAGNOSIS

TRACTION CONTROL SYSTEM (TCL)13C-24

.

CIRCUIT OPERATION

The TCL automatically goes to ON, when the

ignition is turned to the "ON" position. To deacti-

vate the TCL, press the TCL switch. To reactivate

the TCL , press the TCL switch again.

ABS/TCL-ECU send the illumination signal of

"TCL OFF" indicator light and TCL work indicator

light to the combination meter via the CAN com-

munication.

ABS/TCL-ECU operates the "TCL OFF" indicator

light and the TCL work indicator light for three

seconds after the ignition switch is turned "ON"

position for bulb check.