check oil MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 909 of 1500

HOW TO DIAGNOSE

GENERAL

CHECKING RELAYSM1001004900152

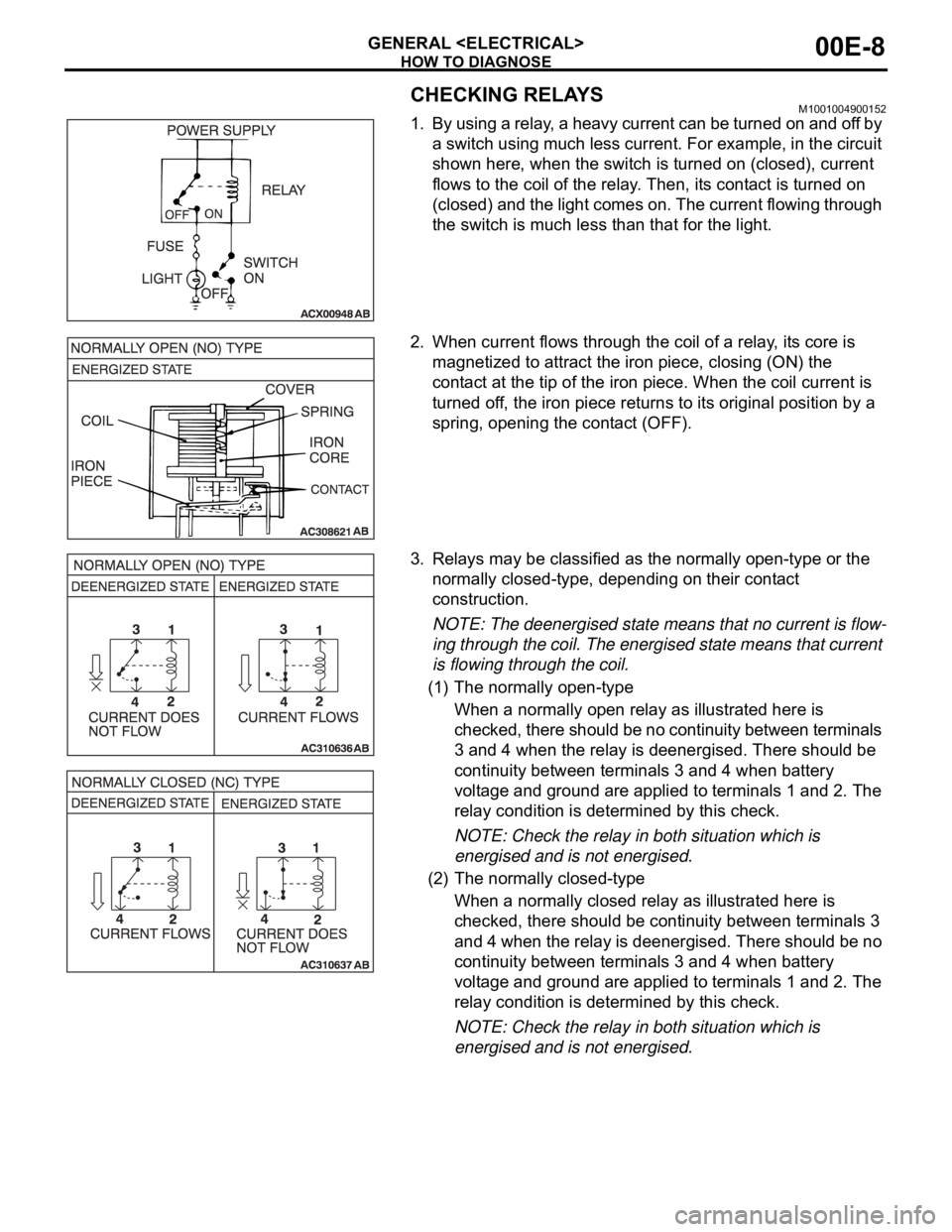

1. By using a relay, a heavy current can be turned on and off by

a switch using much less current. For example, in the circuit

shown here, when the switch is turned on (closed), current

flows to the coil of the relay. Then, its contact is turned on

(closed) and the light comes on. The current flowing through

the switch is much less than that for the light.

2. When current flows through the coil of a relay, its core is

magnetized to attract the iron piece, closing (ON) the

contact at the tip of the iron piece. When the coil current is

turned off, the iron piece returns to its original position by a

spring, opening the contact (OFF).

3. Relays may be classified as the normally open-type or the

normally closed-type, depending on their contact

construction.

NOTE: The deenergised state means that no current is flow-

ing through the coil. The energised state means that current

is flowing through the coil.

(1) The normally open-type

When a normally open relay as illustrated here is

checked, there should be no continuity between terminals

3 and 4 when the relay is deenergised. There should be

continuity between terminals 3 and 4 when battery

voltage and ground are applied to terminals 1 and 2. The

relay condition is determined by this check.

NOTE: Check the relay in both situation which is

energised and is not energised.

(2) The normally closed-type

When a normally closed relay as illustrated here is

checked, there should be continuity between terminals 3

and 4 when the relay is deenergised. There should be no

continuity between terminals 3 and 4 when battery

voltage and ground are applied to terminals 1 and 2. The

relay condition is determined by this check.

NOTE: Check the relay in both situation which is

energised and is not energised.

Page 919 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-4

INSPECTION PROCEDURE 2: Engine Overheating

DIAGNOSIS

STEP 1. Remove the radiator cap and check for coolant

contamination.

Q: Is the coolant contaminated with rust and oil?

YES : Replace it. Refer to P.14-27.

NO : There is no action to be taken. Go to Step 2.

STEP 2. Check the radiator cap valve opening pressure.

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

(1) Use a cap adapter to attach the cap to the tester.

(2) Increase the pressure until the gauge indicator stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

Q: Does the reading remain at or above the minimum limit?

YES : Go to Step 3.

NO : Replace the radiator cap. Then go to Step 5.

STEP 3. Check thermostat operation.

Refer to 38.

Q: Does the thermostat operate correctly?

YES : Go to Step 4.

NO : Replace the thermostat, then go to Step 5.

STEP 4. Check the drive belt for slippage or damage.

Refer to GROUP 00, Maintenance Service

Drive Belts

(Check Condition). <3.8L Engine>39 .

Q: Is the drive belt loose or damaged?

YES : Adjust or replace the drive belt, then go to Step 5.

NO : There is no action to be taken.

STEP 5. Retest the system.

Check the engine coolant temperature.

Q: Is the engine coolant temperature abnormally high?

YES : Return to Step 2.

NO : The procedure is complete.

Page 947 of 1500

RADIATOR

ENGINE COOLING14-32

RADIATOR

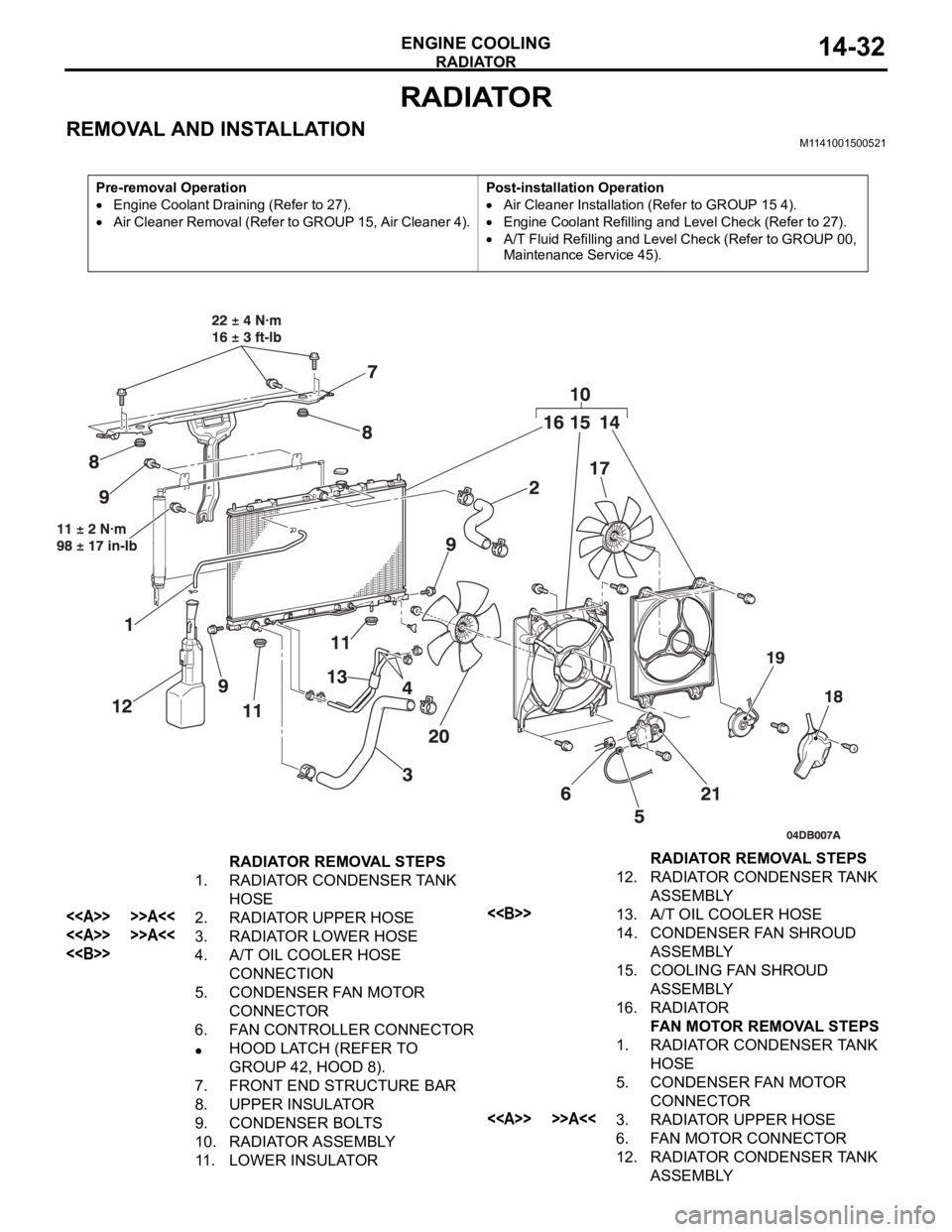

REMOVAL AND INSTALLATIONM1141001500521

Pre-removal Operation

Engine Coolant Draining (Refer to 27).

Air Cleaner Removal (Refer to GROUP 15, Air Cleaner 4).Post-installation Operation

Air Cleaner Installation (Refer to GROUP 15 4).

Engine Coolant Refilling and Level Check (Refer to 27).

A/T Fluid Refilling and Level Check (Refer to GROUP 00,

Maintenance Service 45).

RADIATOR REMOVAL STEPS

1. RADIATOR CONDENSER TANK

HOSE

<> >>A<<2. RADIATOR UPPER HOSE

<> >>A<<3. RADIATOR LOWER HOSE

<>4. A/T OIL COOLER HOSE

CONNECTION

5. CONDENSER FAN MOTOR

CONNECTOR

6. FAN CONTROLLER CONNECTOR

HOOD LATCH (REFER TO

GROUP 42, HOOD 8).

7. FRONT END STRUCTURE BAR

8. UPPER INSULATOR

9. CONDENSER BOLTS

10. RADIATOR ASSEMBLY

11. LOWER INSULATOR12. RADIATOR CONDENSER TANK

ASSEMBLY

<>13. A/T OIL COOLER HOSE

14. CONDENSER FAN SHROUD

ASSEMBLY

15. COOLING FAN SHROUD

ASSEMBLY

16. RADIATOR

FAN MOTOR REMOVAL STEPS

1. RADIATOR CONDENSER TANK

HOSE

5. CONDENSER FAN MOTOR

CONNECTOR

<> >>A<<3. RADIATOR UPPER HOSE

6. FAN MOTOR CONNECTOR

12. RADIATOR CONDENSER TANK

ASSEMBLY RADIATOR REMOVAL STEPS

Page 956 of 1500

WATER HOSE AND WATER PIPE

ENGINE COOLING14-41

INSTALLATION SERVICE POINTS

.

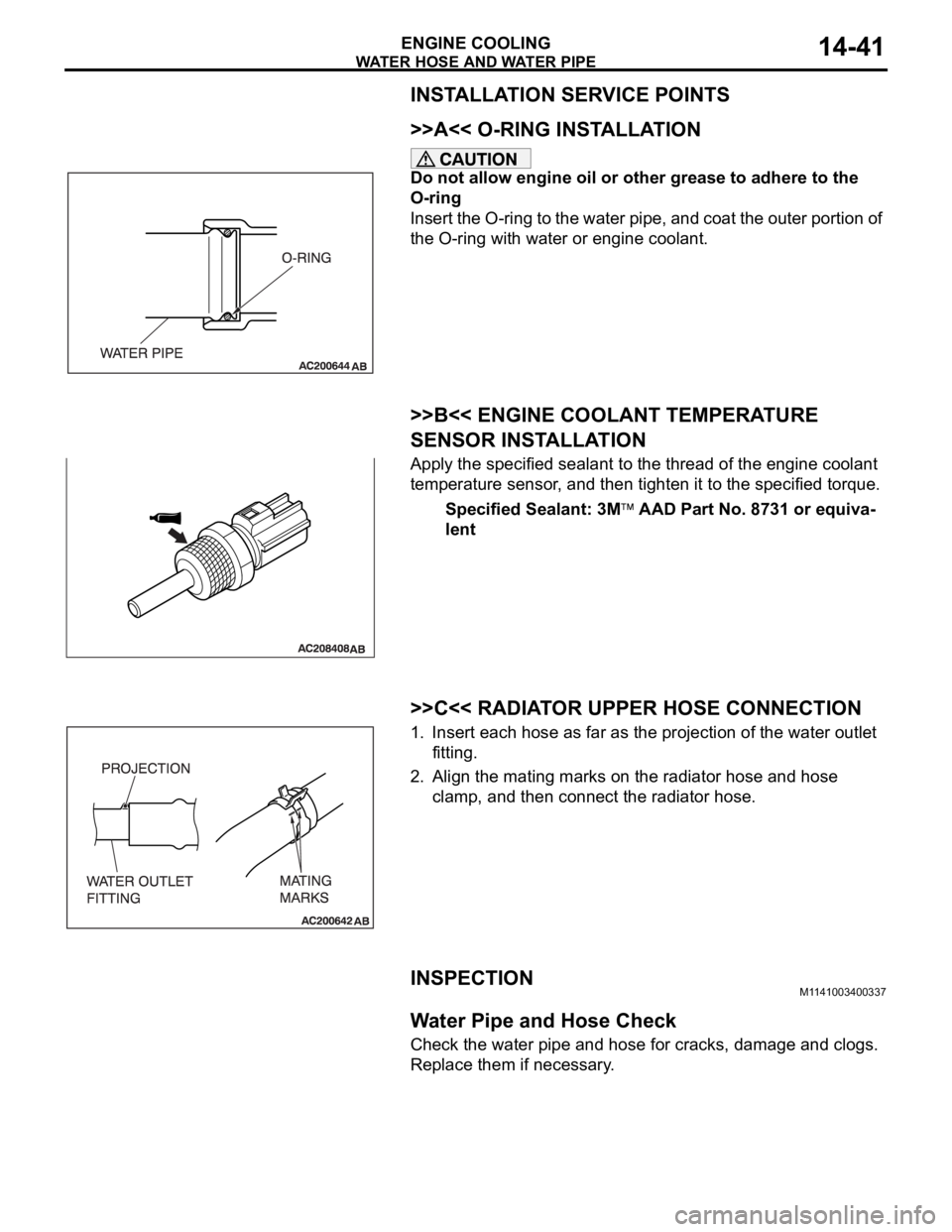

>>A<< O-RING INSTALLATION

Do not allow engine oil or other grease to adhere to the

O-ring

Insert the O-ring to the water pipe, and coat the outer portion of

the O-ring with water or engine coolant.

.

>>B<< ENGINE COOLANT TEMPERATURE

SENSOR INSTALLATION

Apply the specified sealant to the thread of the engine coolant

temperature sensor, and then tighten it to the specified torque.

Specified Sealant: 3M

AAD Part No. 8731 or equiva-

lent

.

>>C<< RADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water outlet

fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTIONM1141003400337.

Water Pipe and Hose Check

Check the water pipe and hose for cracks, damage and clogs.

Replace them if necessary.

Page 968 of 1500

INTAKE MANIFOLD

INTAKE AND EXHAUST15-9

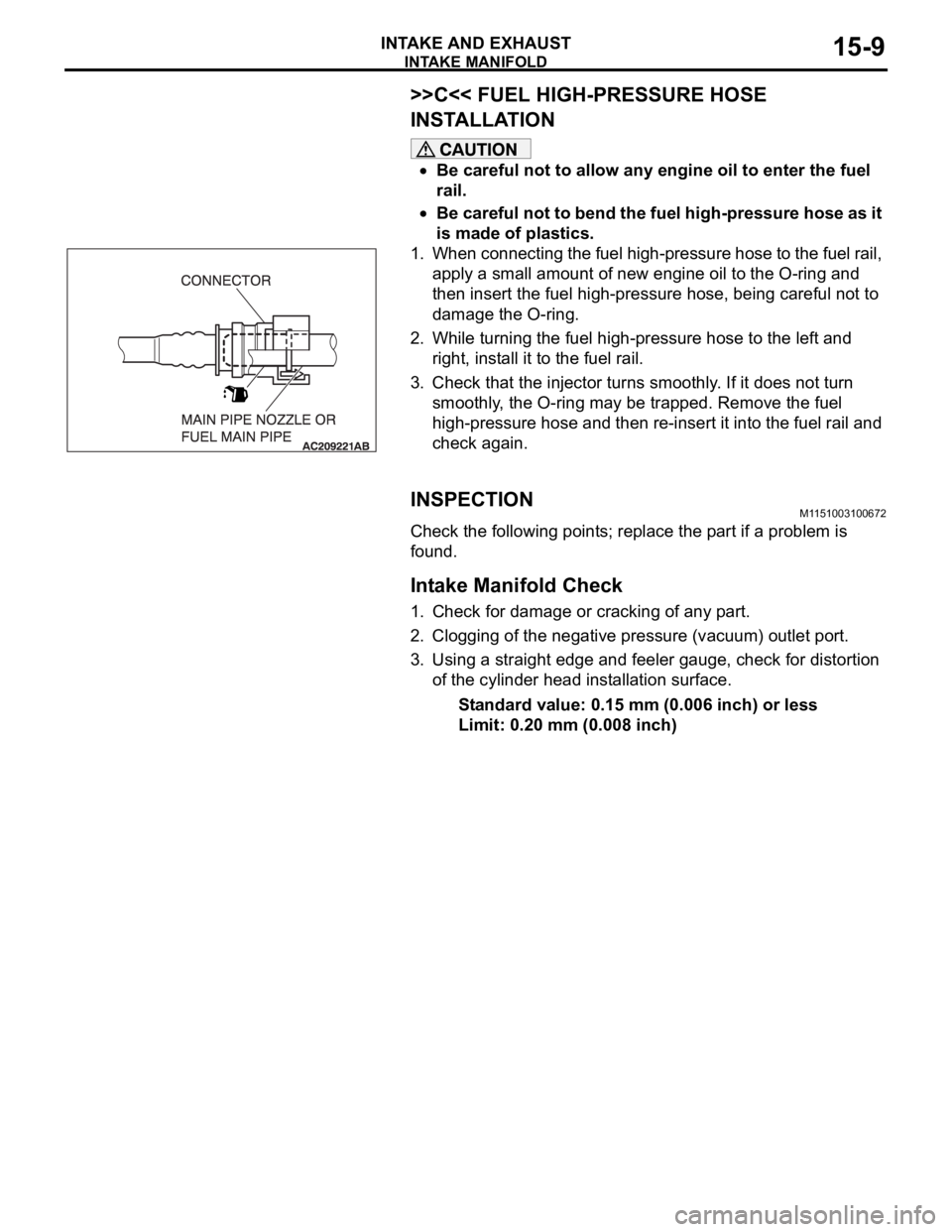

>>C<< FUEL HIGH-PRESSURE HOSE

INSTALLATION

Be careful not to allow any engine oil to enter the fuel

rail.

Be careful not to bend the fuel high-pressure hose as it

is made of plastics.

1. When connecting the fuel high-pressure hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the fuel high-pressure hose, being careful not to

damage the O-ring.

2. While turning the fuel high-pressure hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the fuel

high-pressure hose and then re-insert it into the fuel rail and

check again.

INSPECTIONM1151003100672

Check the following points; replace the part if a problem is

found.

.

Intake Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 978 of 1500

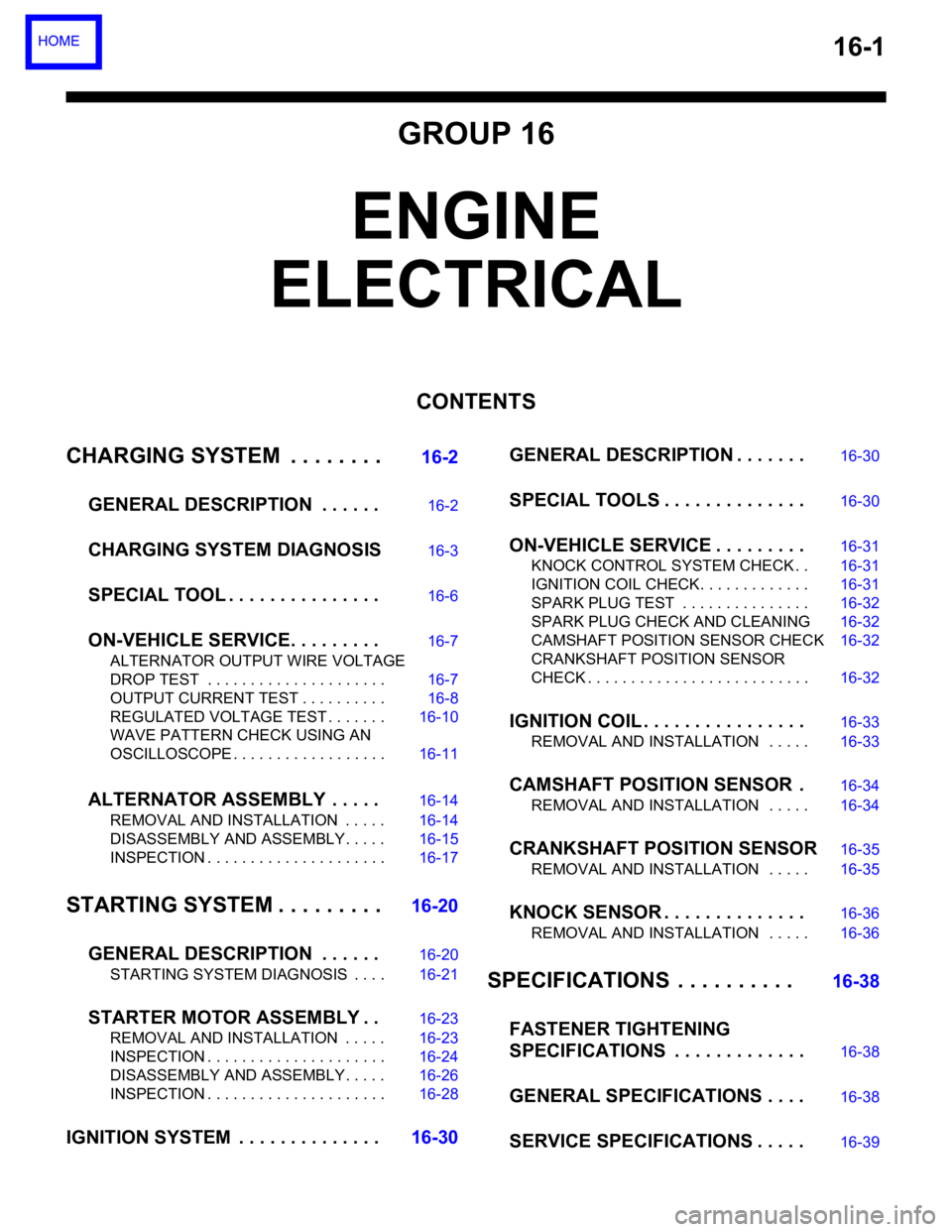

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .

16-2

GENERAL DESCRIPTION . . . . . .

16-2

CHARGING SYSTEM DIAGNOSIS16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-6

ON-VEHICLE SERVICE. . . . . . . . .16-7

ALTERNATOR OUTPUT WIRE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-7

OUTPUT CURRENT TEST . . . . . . . . . . 16-8

REGULATED VOLTAGE TEST . . . . . . . 16-10

WAVE PATTERN CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-11

ALTERNATOR ASSEMBLY . . . . .16-14

REMOVAL AND INSTALLATION . . . . . 16-14

DISASSEMBLY AND ASSEMBLY. . . . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-20

GENERAL DESCRIPTION . . . . . .

16-20

STARTING SYSTEM DIAGNOSIS . . . . 16-21

STARTER MOTOR ASSEMBLY . .16-23

REMOVAL AND INSTALLATION . . . . . 16-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-24

DISASSEMBLY AND ASSEMBLY. . . . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-28

IGNITION SYSTEM . . . . . . . . . . . . . .16-30GENERAL DESCRIPTION . . . . . . .

16-30

SPECIAL TOOLS . . . . . . . . . . . . . .16-30

ON-VEHICLE SERVICE . . . . . . . . .16-31

KNOCK CONTROL SYSTEM CHECK . . 16-31

IGNITION COIL CHECK. . . . . . . . . . . . . 16-31

SPARK PLUG TEST . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING16-32

CAMSHAFT POSITION SENSOR CHECK16-32

CRANKSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

IGNITION COIL . . . . . . . . . . . . . . . .16-33

REMOVAL AND INSTALLATION . . . . . 16-33

CAMSHAFT POSITION SENSOR .16-34

REMOVAL AND INSTALLATION . . . . . 16-34

CRANKSHAFT POSITION SENSOR16-35

REMOVAL AND INSTALLATION . . . . . 16-35

KNOCK SENSOR . . . . . . . . . . . . . .16-36

REMOVAL AND INSTALLATION . . . . . 16-36

SPECIFICATIONS . . . . . . . . . . 16-38

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . .

16-38

GENERAL SPECIFICATIONS . . . .16-38

SERVICE SPECIFICATIONS . . . . .16-39

Page 993 of 1500

Page 994 of 1500

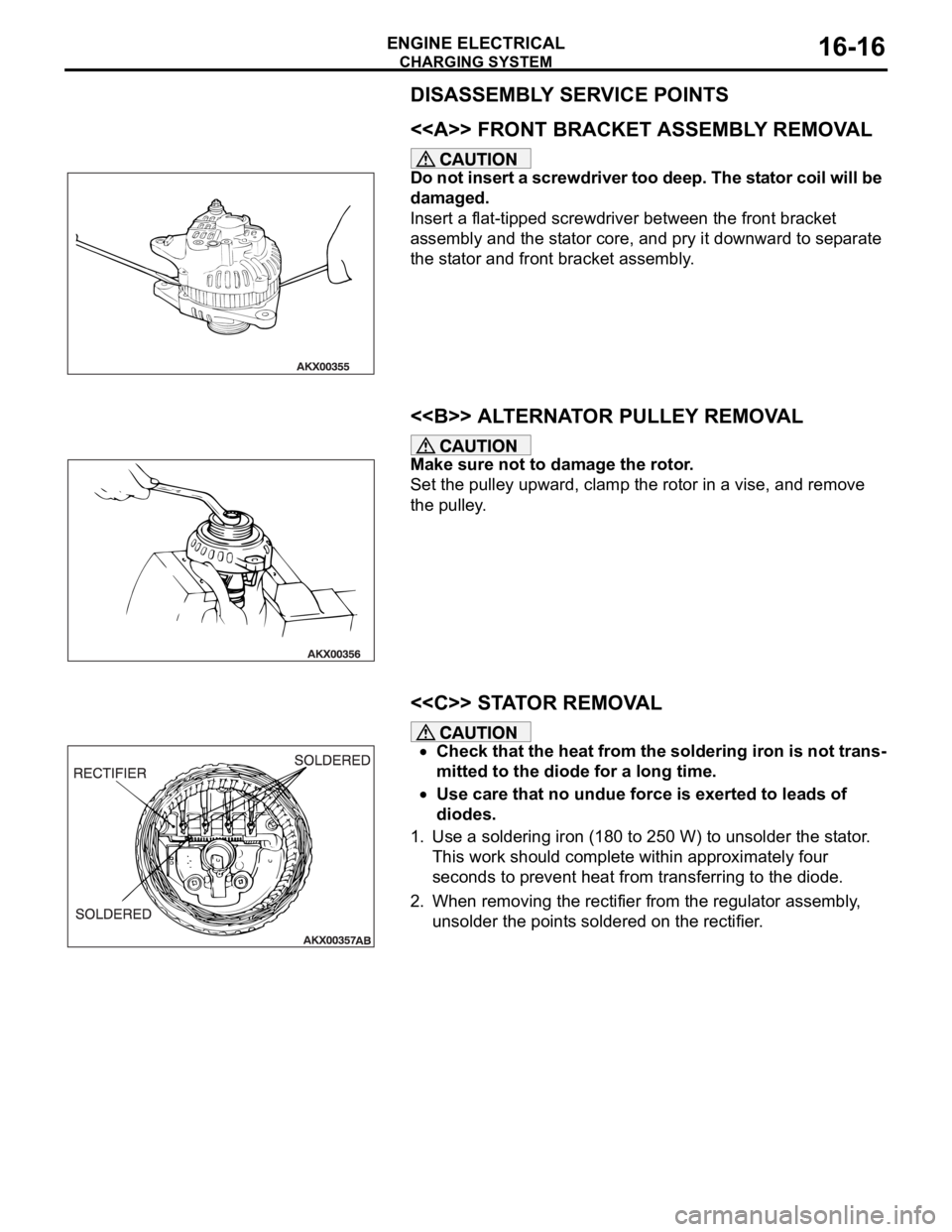

CHARGING SYSTEM

ENGINE ELECTRICAL16-17

ASSEMBLY SERVICE POINTS

.

>>A<< REGULATOR ASSEMBLY INSTALLATION

After installing the regulator assembly, insert a wire through the

hole provided on the rear bracket while pressing down on the

brush, and secure the brush.

NOTE: By inserting a wire, the brush will be secured in place,

and the installation of the rotor will be easier.

.

>>B<< ROTOR ASSEMBLY INSTALLATION

After installing the rotor, remove the wire used to secure the

brush.

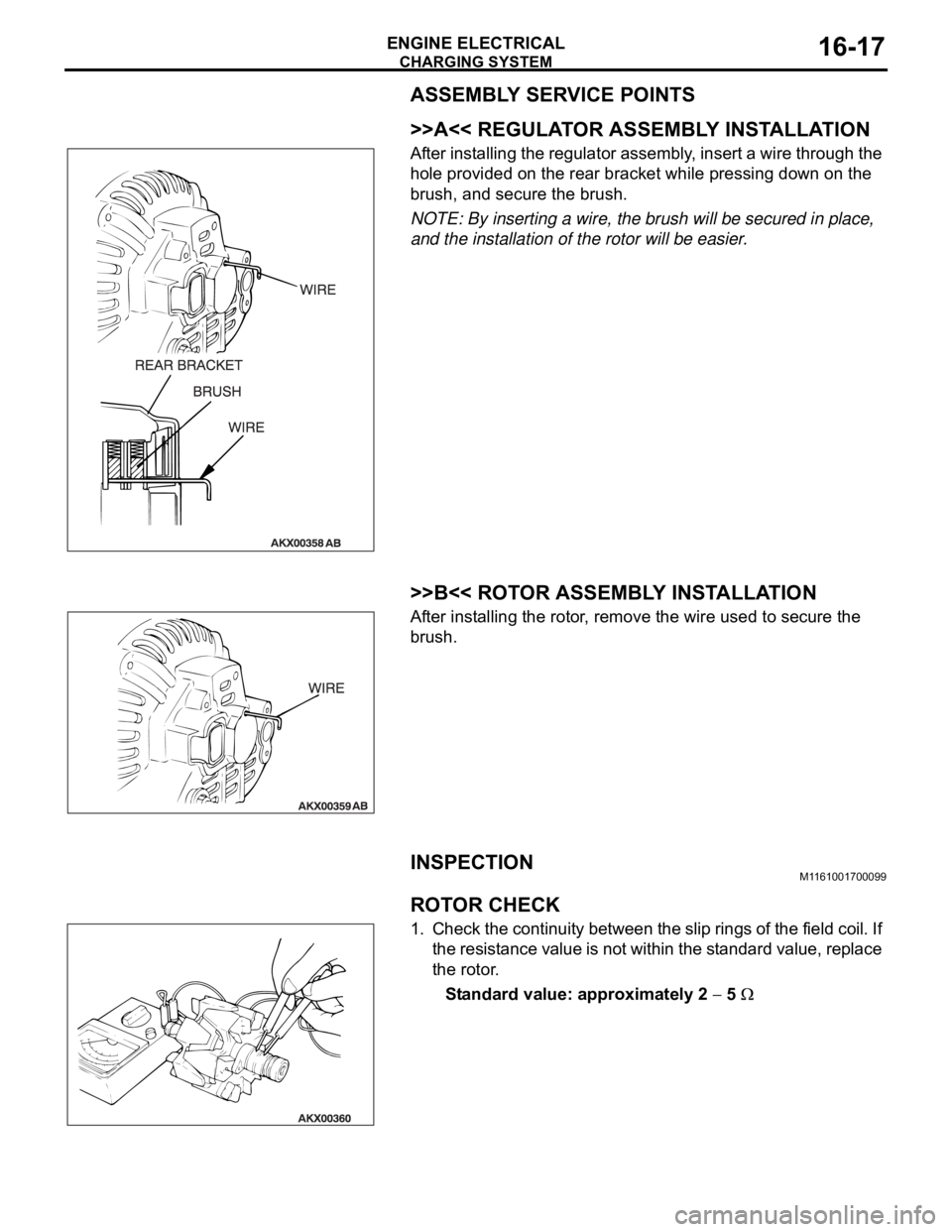

INSPECTIONM1161001700099.

ROTOR CHECK

1. Check the continuity between the slip rings of the field coil. If

the resistance value is not within the standard value, replace

the rotor.

Standard value: approximately 2

5

Page 995 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

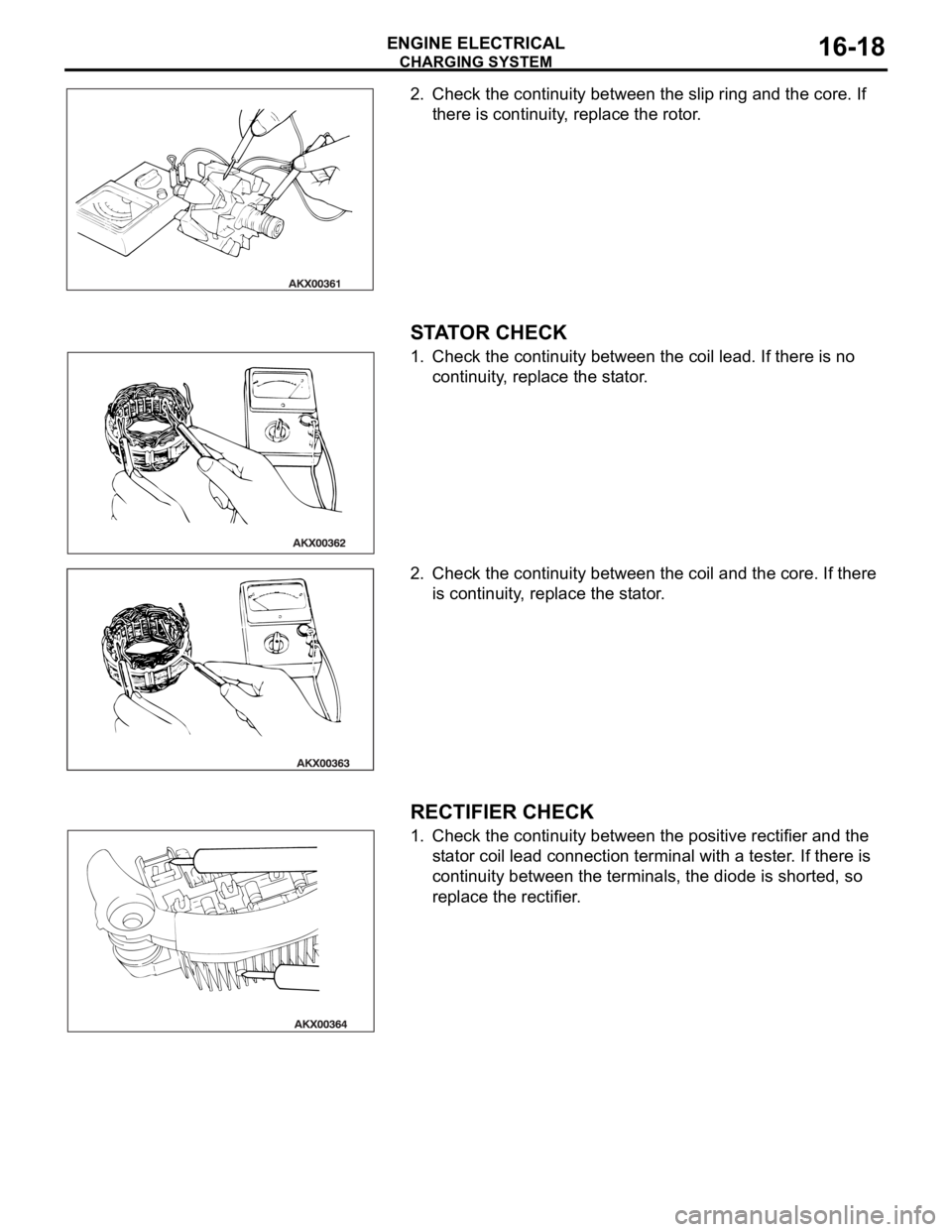

2. Check the continuity between the slip ring and the core. If

there is continuity, replace the rotor.

.

STATOR CHECK

1. Check the continuity between the coil lead. If there is no

continuity, replace the stator.

2. Check the continuity between the coil and the core. If there

is continuity, replace the stator.

.

RECTIFIER CHECK

1. Check the continuity between the positive rectifier and the

stator coil lead connection terminal with a tester. If there is

continuity between the terminals, the diode is shorted, so

replace the rectifier.

Page 996 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-19

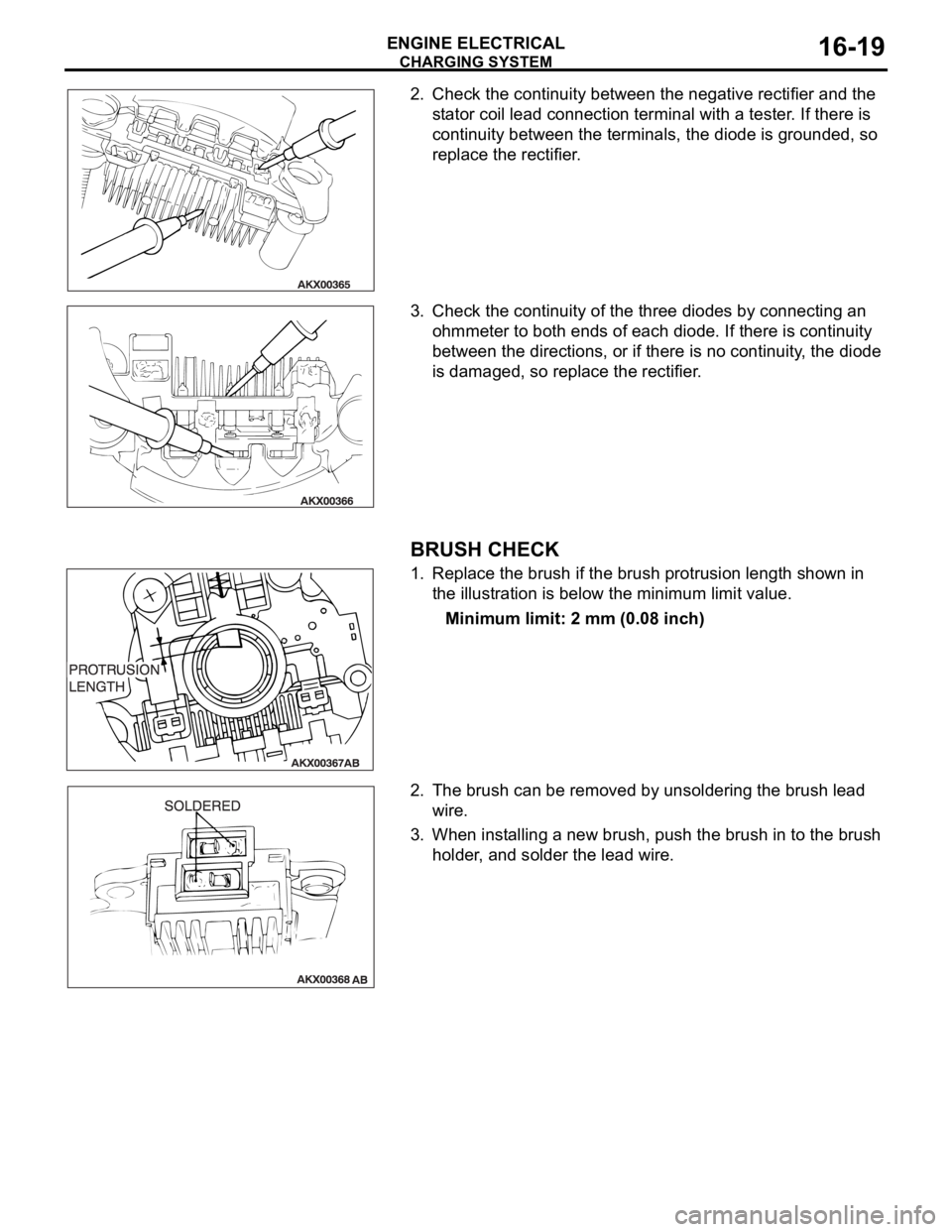

2. Check the continuity between the negative rectifier and the

stator coil lead connection terminal with a tester. If there is

continuity between the terminals, the diode is grounded, so

replace the rectifier.

3. Check the continuity of the three diodes by connecting an

ohmmeter to both ends of each diode. If there is continuity

between the directions, or if there is no continuity, the diode

is damaged, so replace the rectifier.

.

BRUSH CHECK

1. Replace the brush if the brush protrusion length shown in

the illustration is below the minimum limit value.

Minimum limit: 2 mm (0.08 inch)

2. The brush can be removed by unsoldering the brush lead

wire.

3. When installing a new brush, push the brush in to the brush

holder, and solder the lead wire.