AC temperature sensor MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 805 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-104

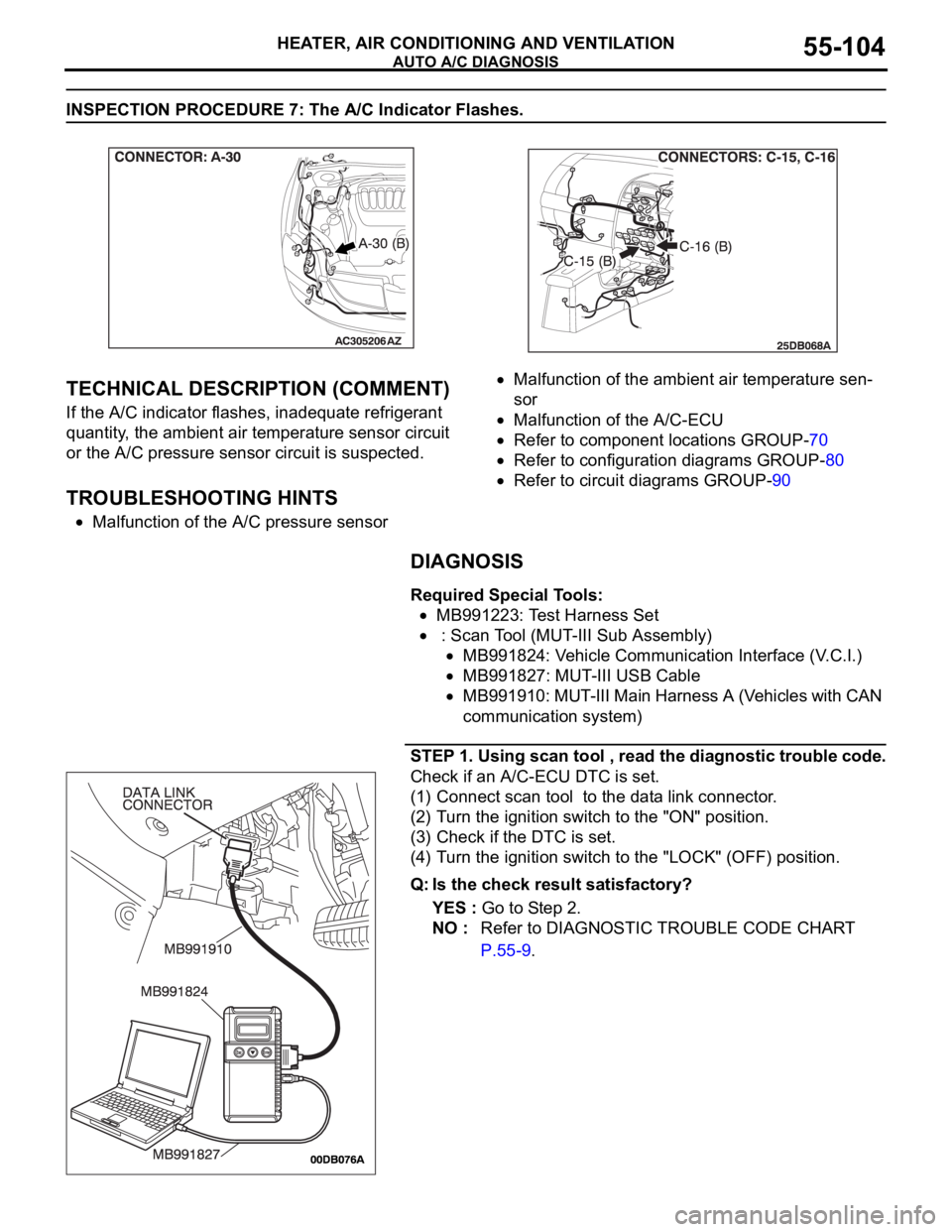

INSPECTION PROCEDURE 7: The A/C Indicator Flashes.

.

TECHNICAL DESCRIPTION (COMMENT)

If the A/C indicator flashes, inadequate refrigerant

quantity, the ambient air temperature sensor circuit

or the A/C pressure sensor circuit is suspected.

.

TROUBLESHOOTING HINTS

Malfunction of the A/C pressure sensor

Malfunction of the ambient air temperature sen-

sor

Malfunction of the A/C-ECU

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

MB991223: Test Harness Set

: Scan Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

STEP 1. Using scan tool , read the diagnostic trouble code.

Check if an A/C-ECU DTC is set.

(1) Connect scan tool to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Check if the DTC is set.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the check result satisfactory?

YES : Go to Step 2.

NO : Refer to DIAGNOSTIC TROUBLE CODE CHART

P.55-9.

Page 829 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-128

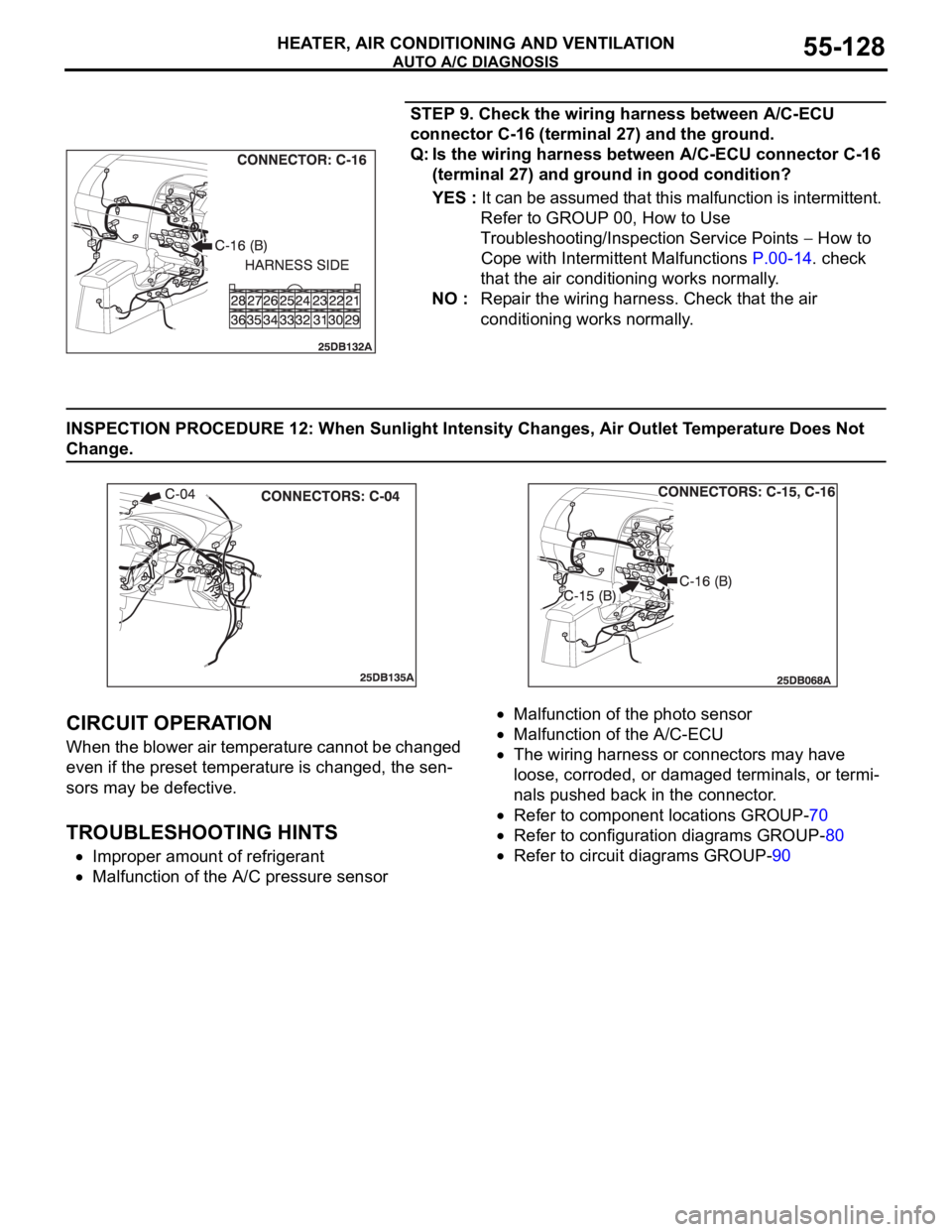

STEP 9. Check the wiring harness between A/C-ECU

connector C-16 (terminal 27) and the ground.

Q: Is the wiring harness between A/C-ECU connector C-16

(terminal 27) and ground in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14. check

that the air conditioning works normally.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

INSPECTION PROCEDURE 12: When Sunlight Intensity Changes, Air Outlet Temperature Does Not

Change.

.

CIRCUIT OPERATION

When the blower air temperature cannot be changed

even if the preset temperature is changed, the sen-

sors may be defective.

.

TROUBLESHOOTING HINTS

Improper amount of refrigerant

Malfunction of the A/C pressure sensor

Malfunction of the photo sensor

Malfunction of the A/C-ECU

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector.

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

Page 834 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-133

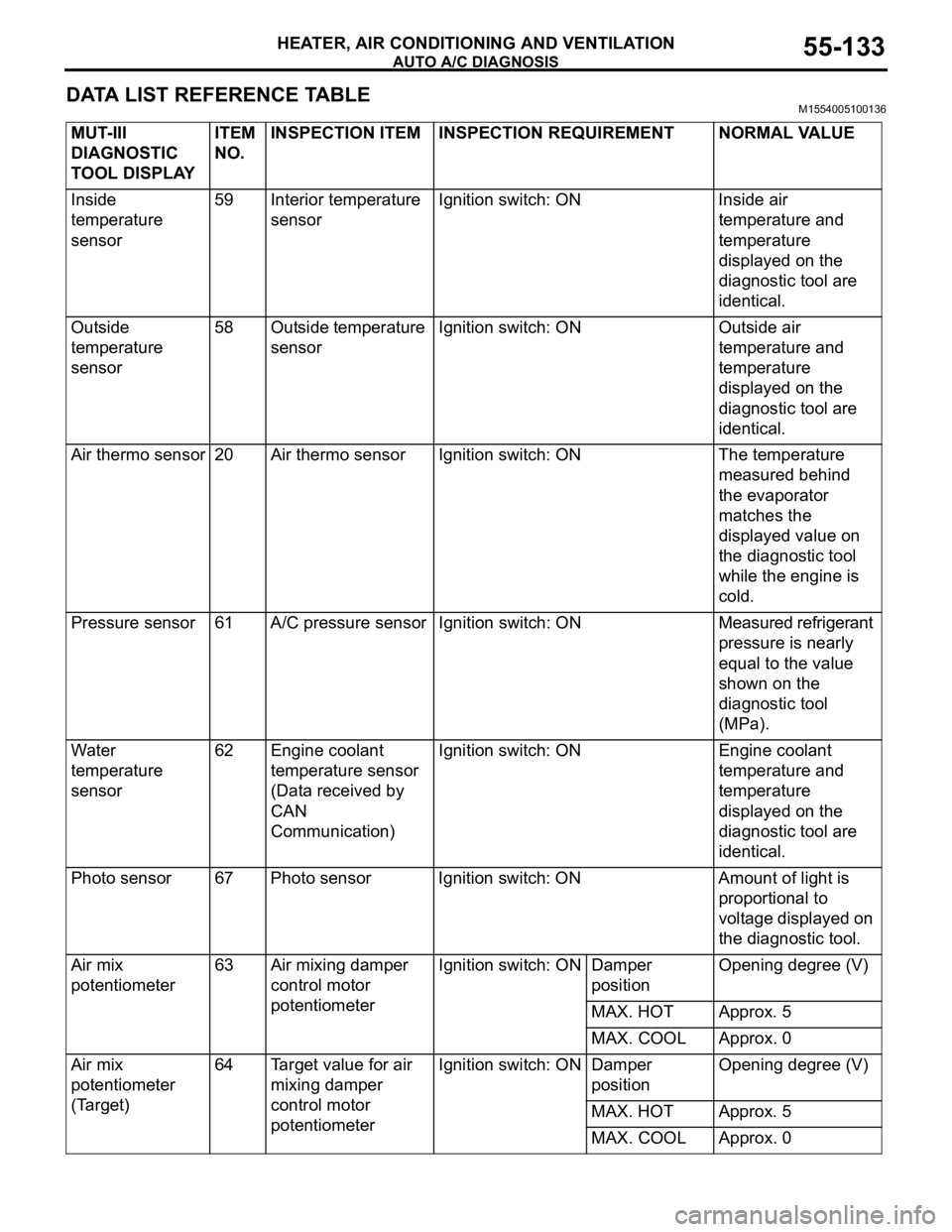

DATA LIST REFERENCE TABLEM1554005100136

MUT-III

DIAGNOSTIC

TOOL DISPLAYITEM

NO.INSPECTION ITEM INSPECTION REQUIREMENT NORMAL VALUE

Inside

temperature

sensor59 Interior temperature

sensorIgnition switch: ON Inside air

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Outside

temperature

sensor58 Outside temperature

sensorIgnition switch: ON Outside air

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Air thermo sensor 20 Air thermo sensor Ignition switch: ON The temperature

measured behind

the evaporator

matches the

displayed value on

the diagnostic tool

while the engine is

cold.

Pressure sensor 61 A/C pressure sensor Ignition switch: ON Measured refrigerant

pressure is nearly

equal to the value

shown on the

diagnostic tool

(MPa).

Water

temperature

sensor62 Engine coolant

temperature sensor

(Data received by

CAN

Communication)Ignition switch: ON Engine coolant

temperature and

temperature

displayed on the

diagnostic tool are

identical.

Photo sensor 67 Photo sensor Ignition switch: ON Amount of light is

proportional to

voltage displayed on

the diagnostic tool.

Air mix

potentiometer63 Air mixing damper

control motor

potentiometerIgnition switch: ON Damper

positionOpening degree (V)

MAX. HOT Approx. 5

MAX. COOL Approx. 0

Air mix

potentiometer

(Target)64 Target value for air

mixing damper

control motor

potentiometerIgnition switch: ON Damper

positionOpening degree (V)

MAX. HOT Approx. 5

MAX. COOL Approx. 0

Page 839 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-138

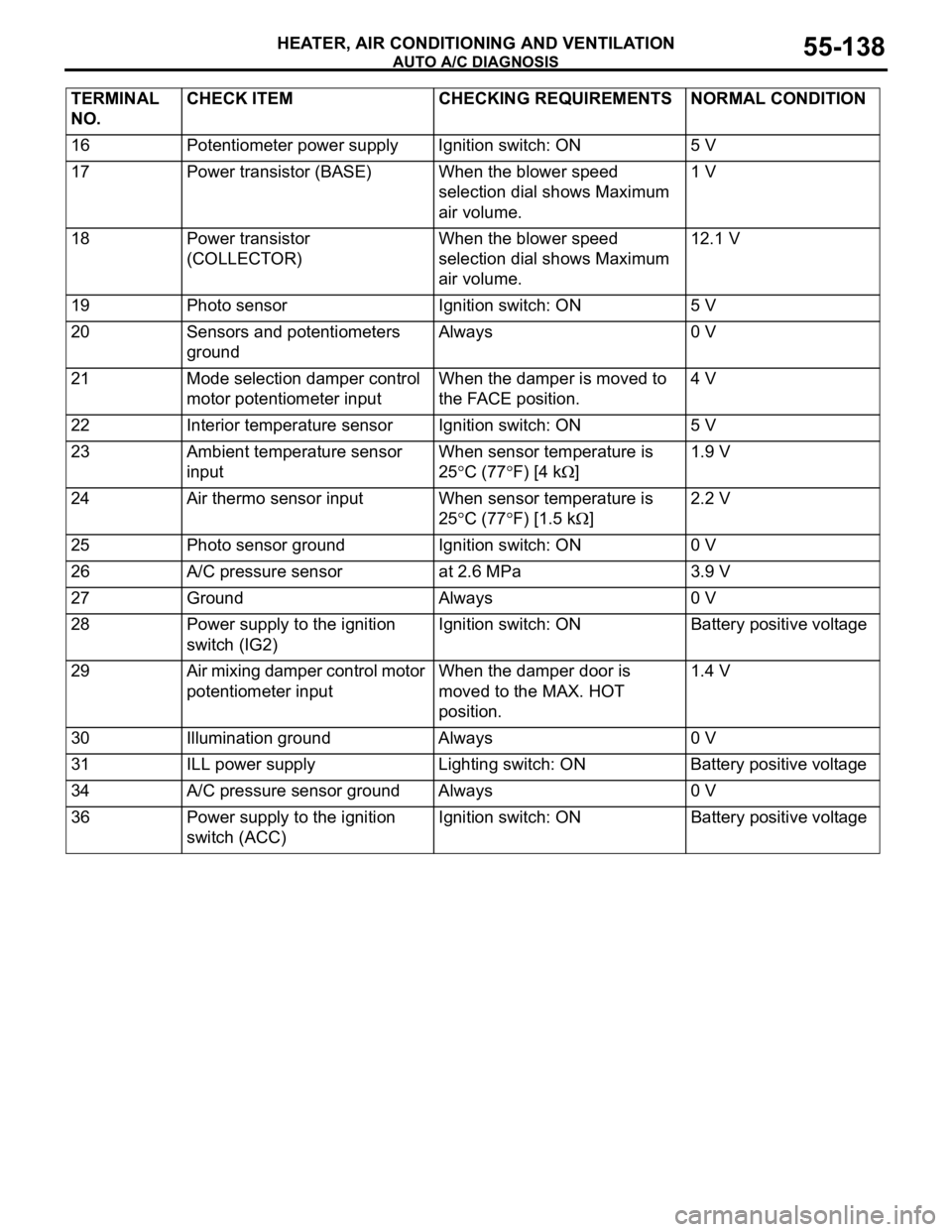

16 Potentiometer power supply Ignition switch: ON 5 V

17 Power transistor (BASE) When the blower speed

selection dial shows Maximum

air volume.1 V

18 Power transistor

(COLLECTOR)When the blower speed

selection dial shows Maximum

air volume.12.1 V

19 Photo sensor Ignition switch: ON 5 V

20 Sensors and potentiometers

groundAlways 0 V

21 Mode selection damper control

motor potentiometer inputWhen the damper is moved to

the FACE position. 4 V

22 Interior temperature sensor Ignition switch: ON 5 V

23 Ambient temperature sensor

inputWhen sensor temperature is

25

C (77F) [4 k]1.9 V

24 Air thermo sensor input When sensor temperature is

25

C (77F) [1.5 k]2.2 V

25 Photo sensor ground Ignition switch: ON 0 V

26 A/C pressure sensor at 2.6 MPa 3.9 V

27 Ground Always 0 V

28 Power supply to the ignition

switch (IG2)Ignition switch: ON Battery positive voltage

29 Air mixing damper control motor

potentiometer inputWhen the damper door is

moved to the MAX. HOT

position.1.4 V

30 Illumination ground Always 0 V

31 ILL power supply Lighting switch: ON Battery positive voltage

34 A/C pressure sensor ground Always 0 V

36 Power supply to the ignition

switch (ACC)Ignition switch: ON Battery positive voltage TERMINAL

NO.CHECK ITEM CHECKING REQUIREMENTS NORMAL CONDITION

Page 843 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-142

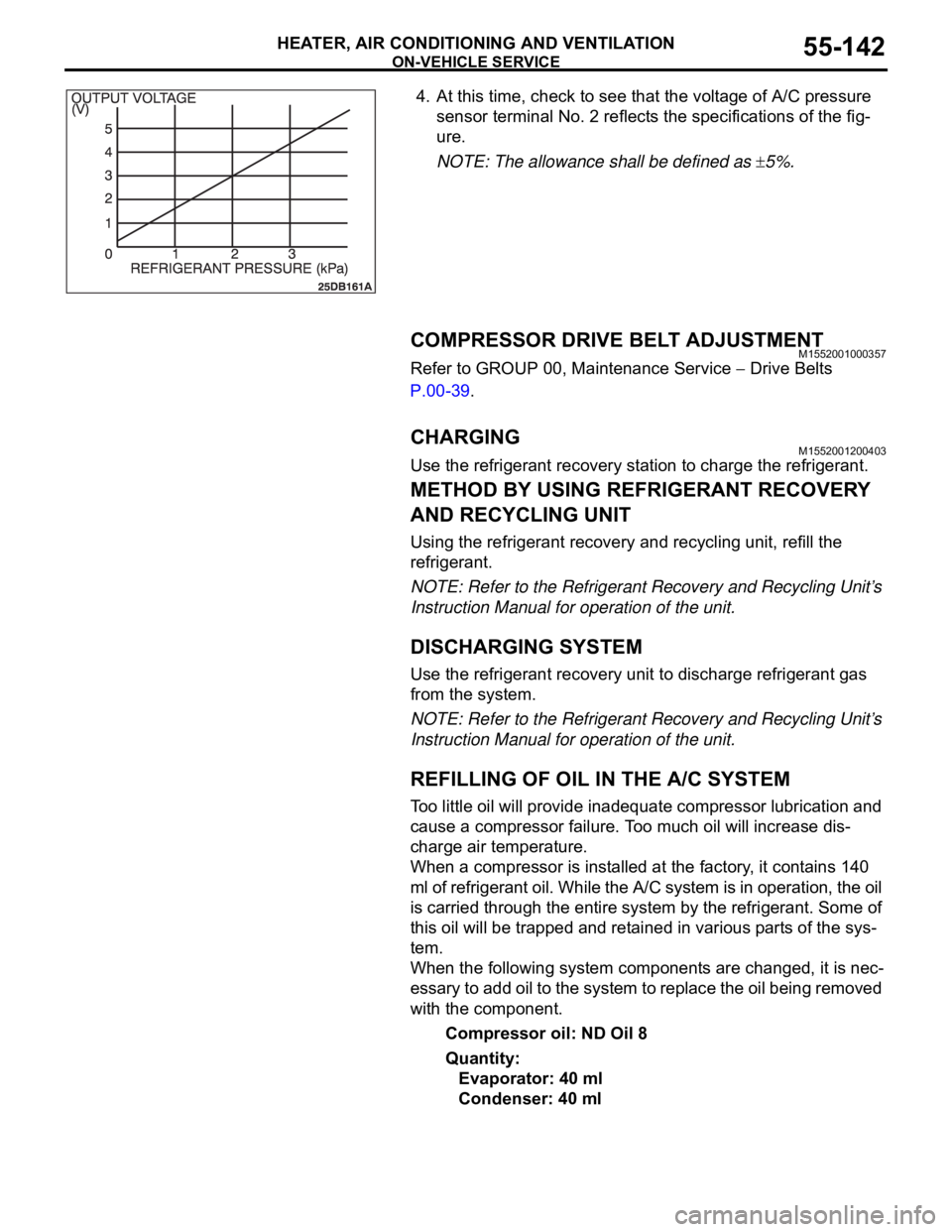

4. At this time, check to see that the voltage of A/C pressure

sensor terminal No. 2 reflects the specifications of the fig-

ure.

NOTE: The allowance shall be defined as

5%.

COMPRESSOR DRIVE BELT ADJUSTMENTM1552001000357

Refer to GROUP 00, Maintenance Service Drive Belts

P.00-39.

CHARGING M1552001200403

Use the refrigerant recovery station to charge the refrigerant.

METHOD BY USING REFRIGERANT RECOVERY

AND RECYCLING UNIT

Using the refrigerant recovery and recycling unit, refill the

refrigerant.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit’s

Instruction Manual for operation of the unit.

DISCHARGING SYSTEM

Use the refrigerant recovery unit to discharge refrigerant gas

from the system.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit’s

Instruction Manual for operation of the unit.

REFILLING OF OIL IN THE A/C SYSTEM

Too little oil will provide inadequate compressor lubrication and

cause a compressor failure. Too much oil will increase dis-

charge air temperature.

When a compressor is installed at the factory, it contains 140

ml of refrigerant oil. While the A/C system is in operation, the oil

is carried through the entire system by the refrigerant. Some of

this oil will be trapped and retained in various parts of the sys-

tem.

When the following system components are changed, it is nec-

essary to add oil to the system to replace the oil being removed

with the component.

Compressor oil: ND Oil 8

Quantity:

Evaporator: 40 ml

Condenser: 40 ml

Page 856 of 1500

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-155

INSPECTIONM1552014301157.

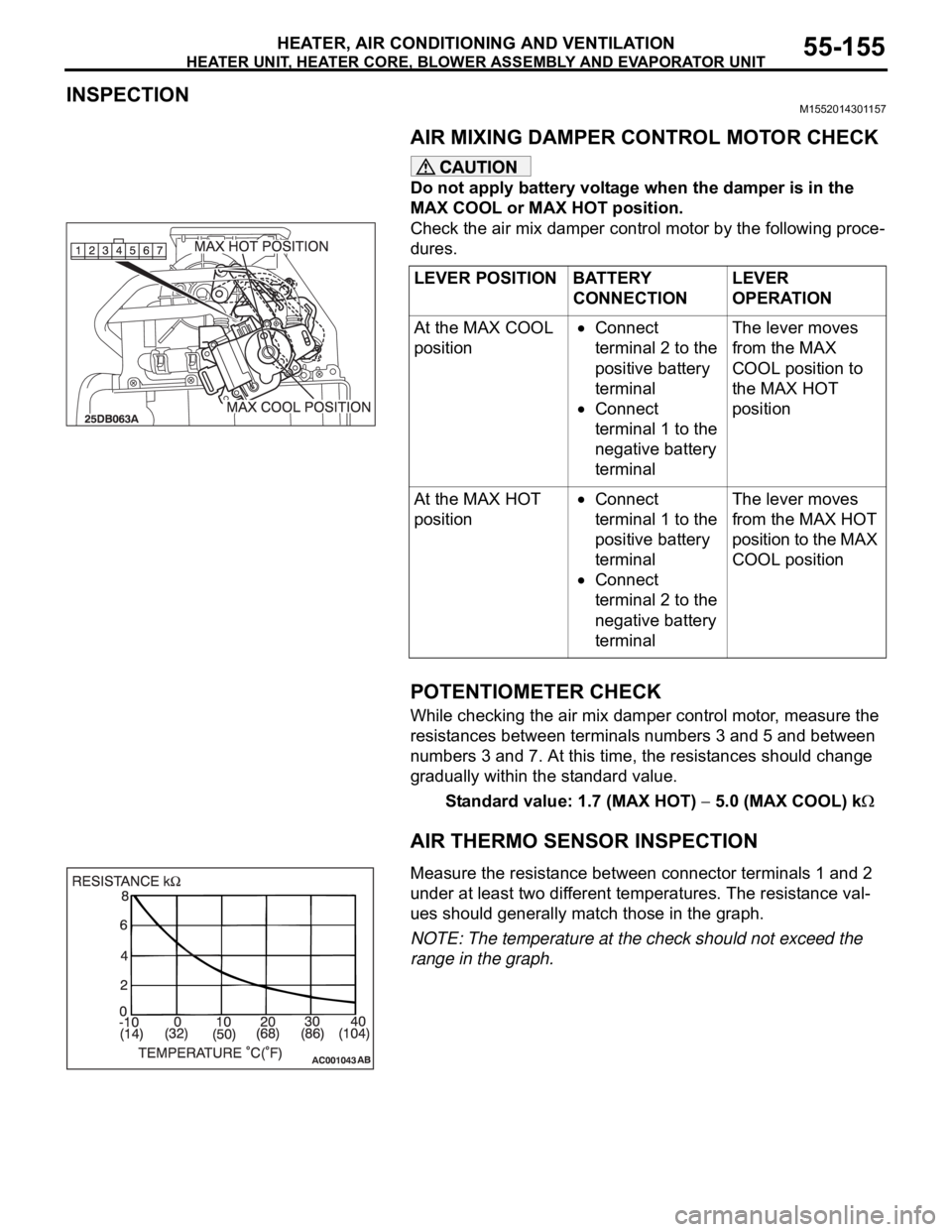

AIR MIXING DAMPER CONTROL MOTOR CHECK

Do not apply battery voltage when the damper is in the

MAX COOL or MAX HOT position.

Check the air mix damper control motor by the following proce-

dures.

.

POTENTIOMETER CHECK

While checking the air mix damper control motor, measure the

resistances between terminals numbers 3 and 5 and between

numbers 3 and 7. At this time, the resistances should change

gradually within the standard value.

Standard value: 1.7 (MAX HOT)

5.0 (MAX COOL) k

AIR THERMO SENSOR INSPECTION

.Measure the resistance between connector terminals 1 and 2

under at least two different temperatures. The resistance val-

ues should generally match those in the graph.

NOTE: The temperature at the check should not exceed the

range in the graph. LEVER POSITION BATTERY

CONNECTIONLEVER

OPERATION

At the MAX COOL

position

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 1 to the

negative battery

terminalThe lever moves

from the MAX

COOL position to

the MAX HOT

position

At the MAX HOT

position

Connect

terminal 1 to the

positive battery

terminal

Connect

terminal 2 to the

negative battery

terminalThe lever moves

from the MAX HOT

position to the MAX

COOL position

Page 861 of 1500

SENSORS

HEATER, AIR CONDITIONING AND VENTILATION55-160

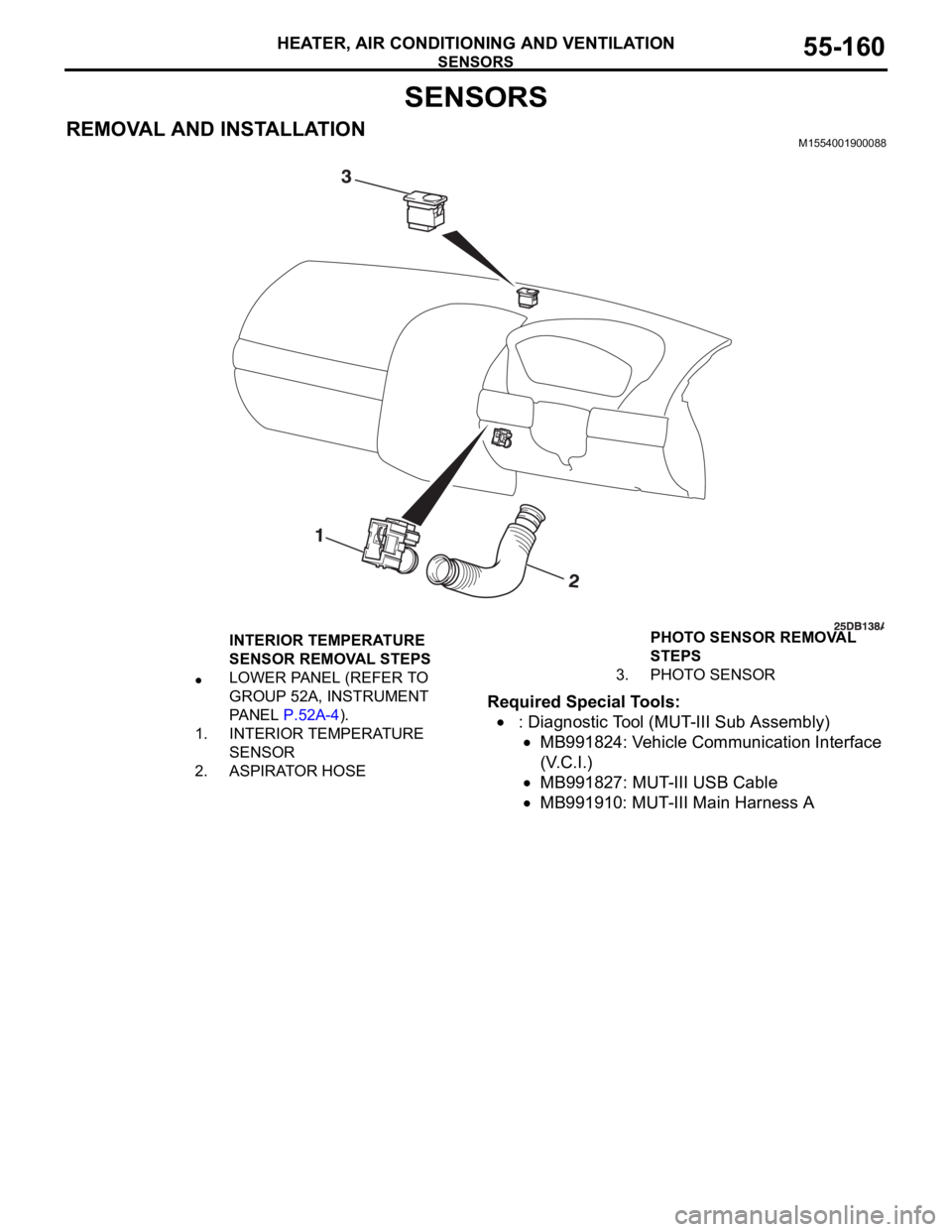

SENSORS

REMOVAL AND INSTALLATIONM1554001900088

Required Special Tools:

: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface

(V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

INTERIOR TEMPERATURE

SENSOR REMOVAL STEPS

LOWER PANEL (REFER TO

GROUP 52A, INSTRUMENT

PA N E L P.52A-4).

1. INTERIOR TEMPERATURE

SENSOR

2. ASPIRATOR HOSEPHOTO SENSOR REMOVAL

STEPS

3. PHOTO SENSOR

Page 862 of 1500

SENSORS

HEATER, AIR CONDITIONING AND VENTILATION55-161

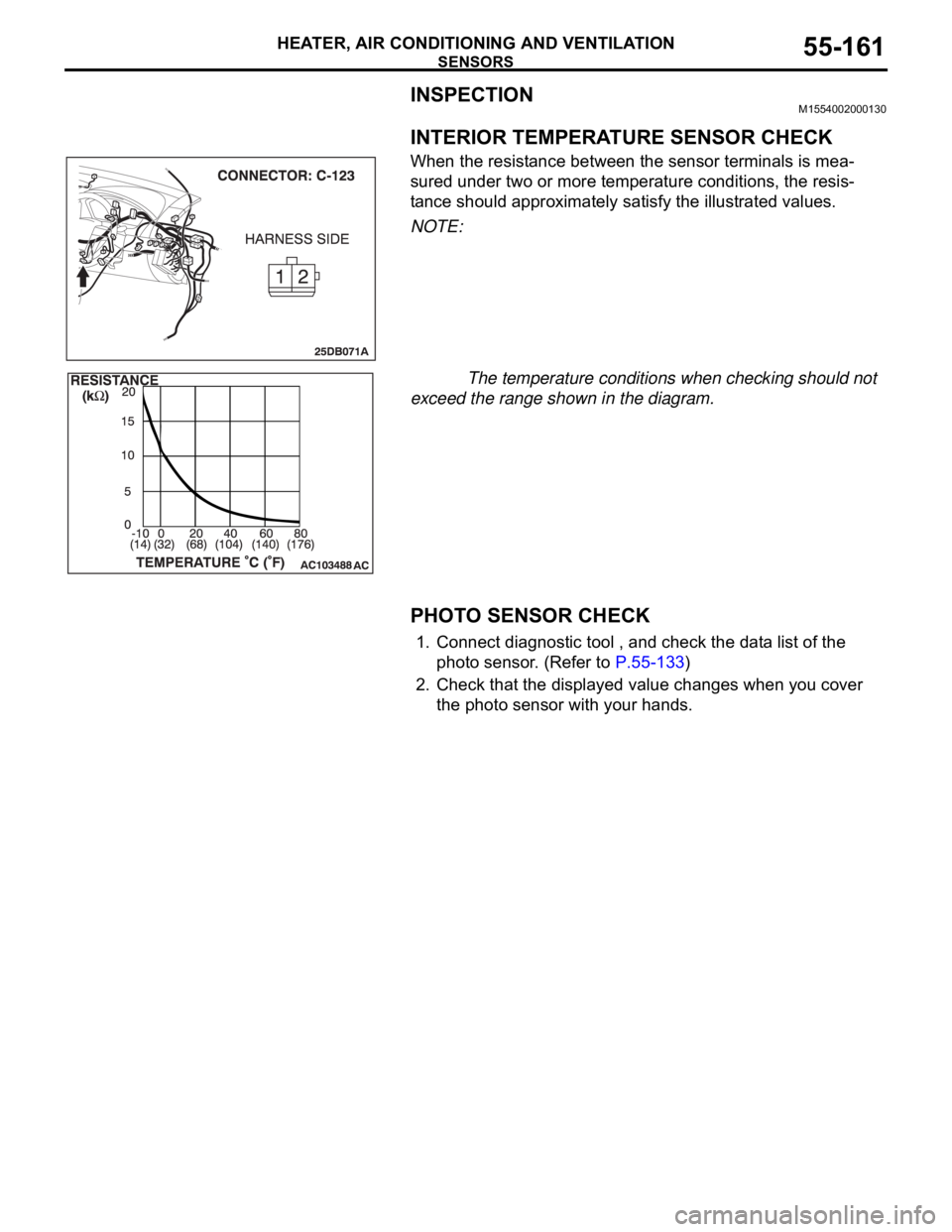

INSPECTIONM1554002000130.

INTERIOR TEMPERATURE SENSOR CHECK

When the resistance between the sensor terminals is mea-

sured under two or more temperature conditions, the resis-

tance should approximately satisfy the illustrated values.

NOTE:

The temperature conditions when checking should not

exceed the range shown in the diagram.

.

PHOTO SENSOR CHECK

1. Connect diagnostic tool , and check the data list of the

photo sensor. (Refer to P.55-133)

2. Check that the displayed value changes when you cover

the photo sensor with your hands.

Page 863 of 1500

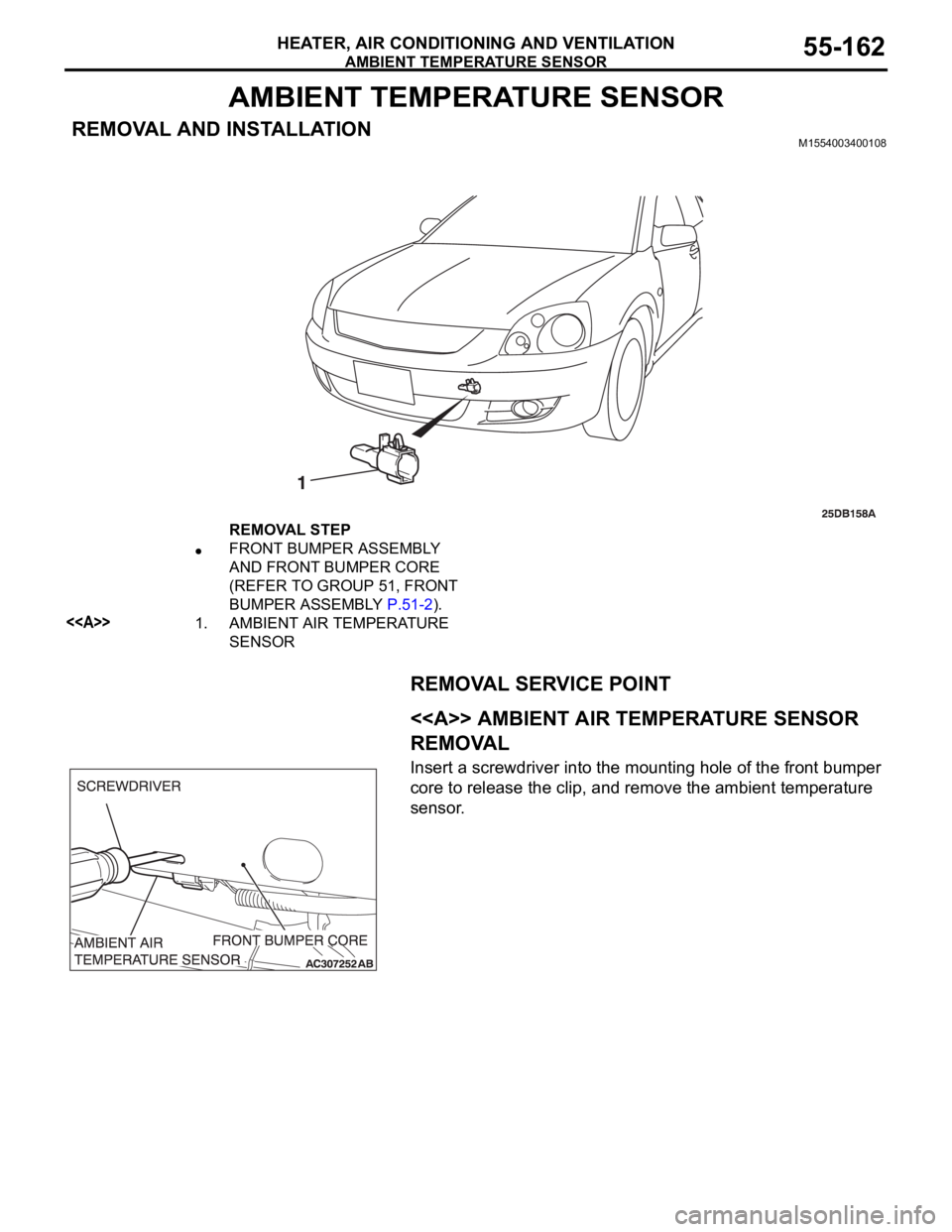

AMBIENT TEMPERATURE SENSOR

HEATER, AIR CONDITIONING AND VENTILATION55-162

AMBIENT TEMPERATURE SENSOR

REMOVAL AND INSTALLATIONM1554003400108

REMOVAL SERVICE POINT

.

<> AMBIENT AIR TEMPERATURE SENSOR

REMOVAL

Insert a screwdriver into the mounting hole of the front bumper

core to release the clip, and remove the ambient temperature

sensor.

REMOVAL STEP

FRONT BUMPER ASSEMBLY

AND FRONT BUMPER CORE

(REFER TO GROUP 51, FRONT

BUMPER ASSEMBLY P.51-2).

<>1. AMBIENT AIR TEMPERATURE

SENSOR

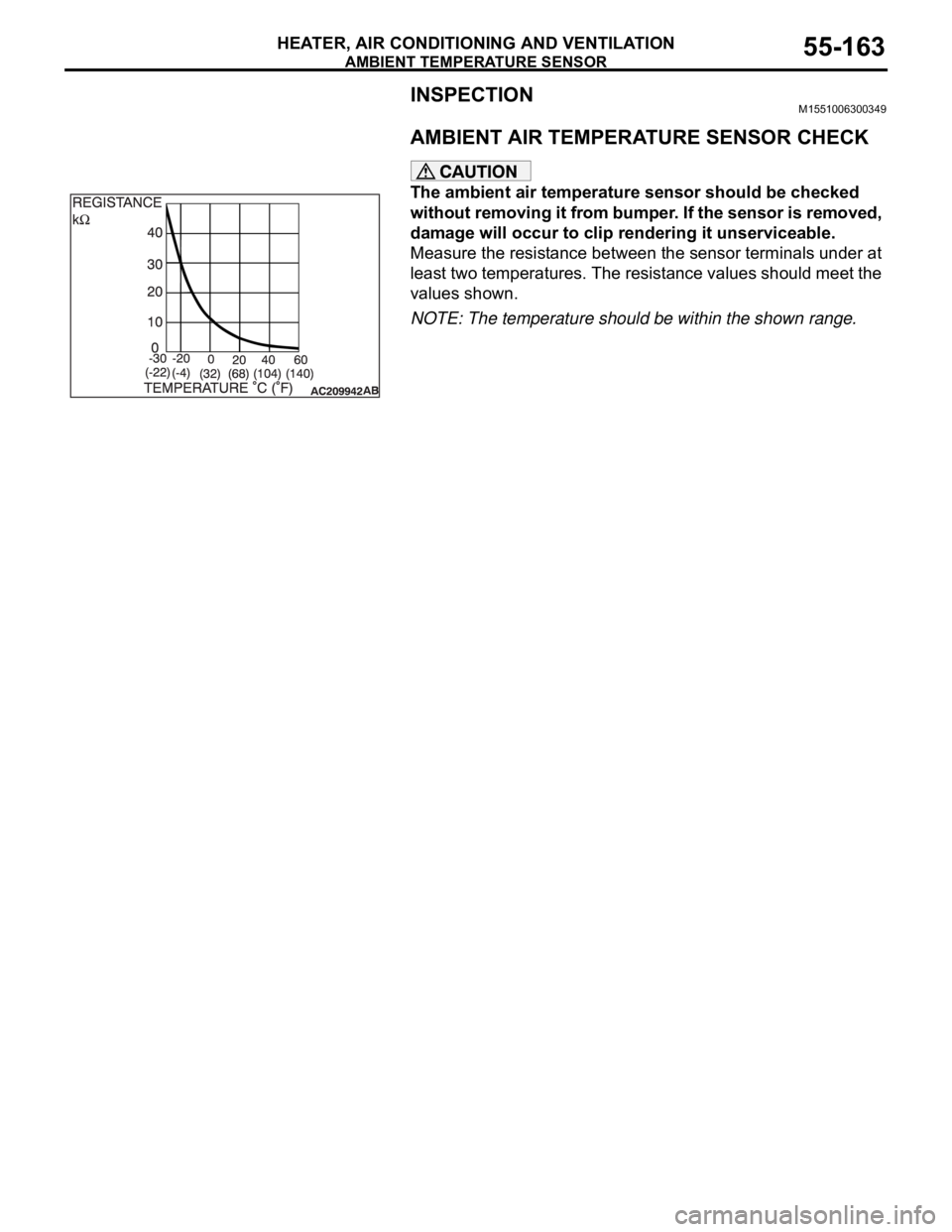

Page 864 of 1500

AMBIENT TEMPERATURE SENSOR

HEATER, AIR CONDITIONING AND VENTILATION55-163

INSPECTIONM1551006300349.

AMBIENT AIR TEMPERATURE SENSOR CHECK

The ambient air temperature sensor should be checked

without removing it from bumper. If the sensor is removed,

damage will occur to clip rendering it unserviceable.

Measure the resistance between the sensor terminals under at

least two temperatures. The resistance values should meet the

values shown.

NOTE: The temperature should be within the shown range.