AC temperature sensor MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 887 of 1500

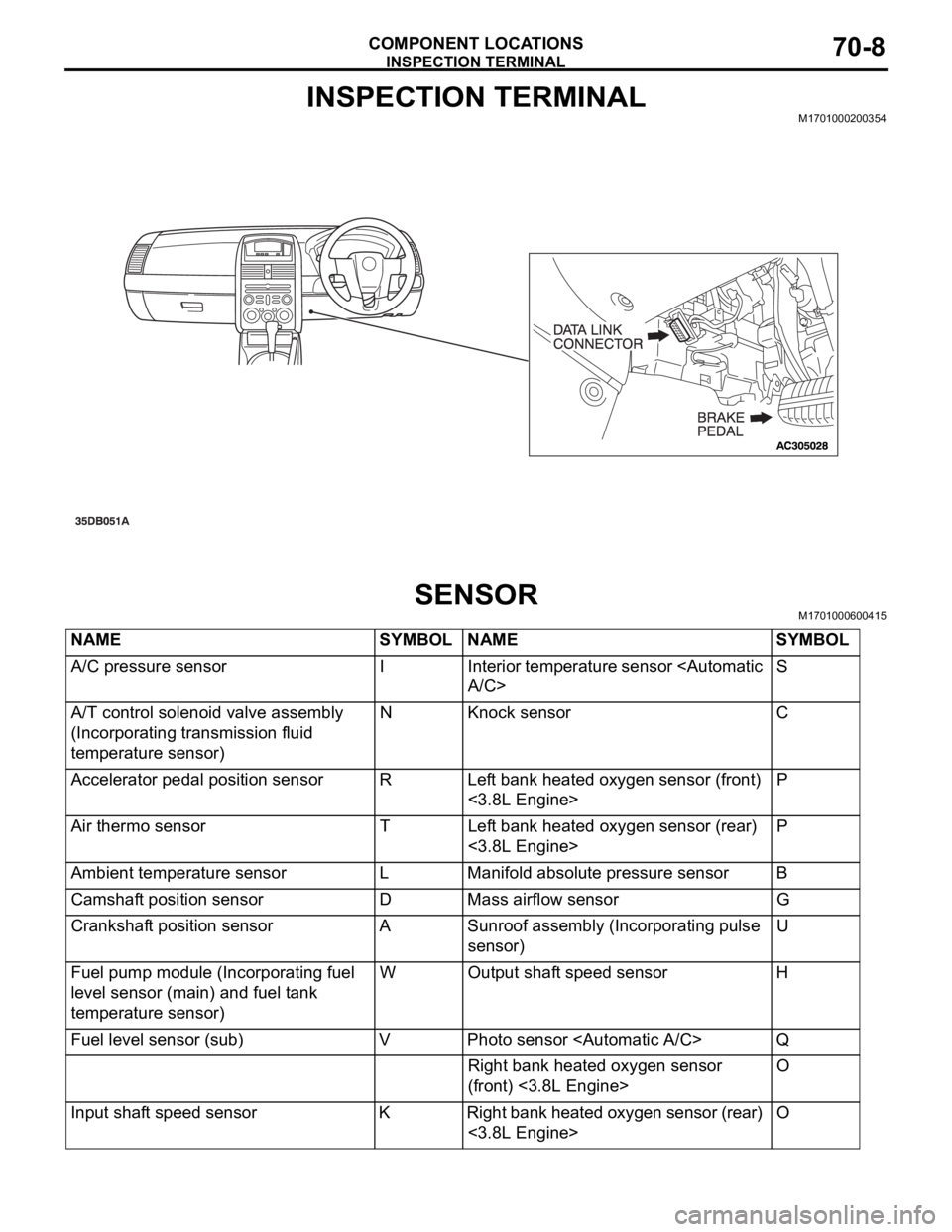

INSPECTION TERMINAL

COMPONENT LOCATIONS70-8

INSPECTION TERMINALM1701000200354

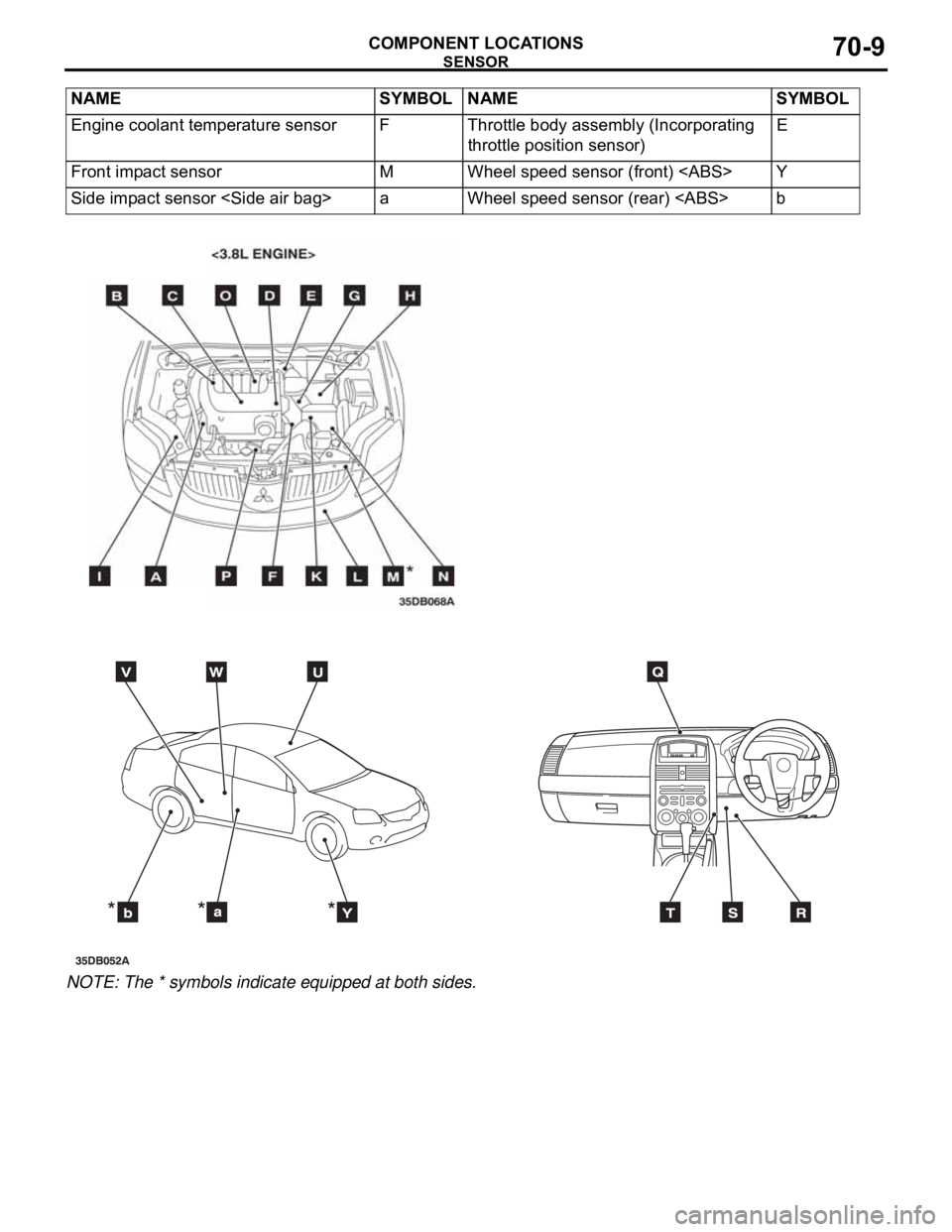

SENSORM1701000600415

NAME SYMBOL NAME SYMBOL

A/C pressure sensor I Interior temperature sensor

A/T control solenoid valve assembly

(Incorporating transmission fluid

temperature sensor)N Knock sensor C

Accelerator pedal position sensor R Left bank heated oxygen sensor (front)

<3.8L Engine>P

Air thermo sensor T Left bank heated oxygen sensor (rear)

<3.8L Engine>P

Ambient temperature sensor L Manifold absolute pressure sensor B

Camshaft position sensor D Mass airflow sensor G

Crankshaft position sensor A Sunroof assembly (Incorporating pulse

sensor)U

Fuel pump module (Incorporating fuel

level sensor (main) and fuel tank

temperature sensor)W Output shaft speed sensor H

Fuel level sensor (sub) V Photo sensor

Right bank heated oxygen sensor

(front) <3.8L Engine>O

Input shaft speed sensor K Right bank heated oxygen sensor (rear)

<3.8L Engine>O

Page 888 of 1500

SENSOR

COMPONENT LOCATIONS70-9

NOTE: The * symbols indicate equipped at both sides.Engine coolant temperature sensor F Throttle body assembly (Incorporating

throttle position sensor)E

Front impact sensor M Wheel speed sensor (front)

Side impact sensor

Page 920 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-5

INSPECTION PROCEDURE 3: Radiator Fan and Condenser Fan do not Operate

.

CIRCUIT OPERATION

The fan controller is powered from fusible link

No.2.

The engine-ECU uses input signals from the A/C

switch, the water temperature sensor unit and the

vehicle speed sensor

speed sensor to control the speed of the

radiator fan motor and the condenser fan motor.

The engine-ECU controls the fan controller to

activate the radiator fan motor and the condenser

fan motor.

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the fan con-

troller power supply or earth circuit.

If the communication line wiring harness between

the fan controller and the engine-ECU is

short-circuited to earth, the radiator fan motor

and the condenser fan motor will not rotate.

The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU.

The cause could also be a malfunction of the fan

controller or the engine-ECU.

.

TROUBLESHOOTING HINTS

Malfunction of fusible link No.2

Malfunction of fan control relay

Malfunction of cooling fan motor and fan control-

ler

Malfunction of engine-ECU.

Damaged wiring harness or connector

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

Page 935 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-20

STEP 23. MUT-III self-diag code

Check if an MPI system self-diag code is set. (Refer to GROUP

13A - Trouble shooting 13A-5).

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer to GROUP

13A - Trouble shooting 13A-17)

NO : Replace the engine-ECU (Refer to GROUP 13A,

Engine-ECU 13A-675 ). Then go to Step 24.

STEP 24. Check the symptoms.

Q: Does the radiator fan motor and the condenser fan

motor operate correctly?

YES : This symptom is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 4: Radiator Fan and Condenser Fan do not Change Speed or Stop

.

Radiator Fan and Condenser Fan Drive

Circuit

Refer to 5.

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the fan con-

troller power supply or earth circuit.

If the communication line wiring harness between

the fan controller and the engine-ECU is

short-circuited to earth, the radiator fan motor

and the condenser fan motor will not rotate.

The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU.

The cause could also be a malfunction of the fan

controller or the engine-ECU.

.

TROUBLESHOOTING HINTS

Malfunction of fusible link No.2

Malfunction of fan control relay

Malfunction of cooling fan motor

Malfunction of fan controller

Malfunction of engine-ECU

Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the fan control relay.

Refer to 14-31.

Q: Is the fan control relay in good condition?

YES : Go to Step 2.

NO : Replace the fan control relay. Then go to Step 8.

Page 951 of 1500

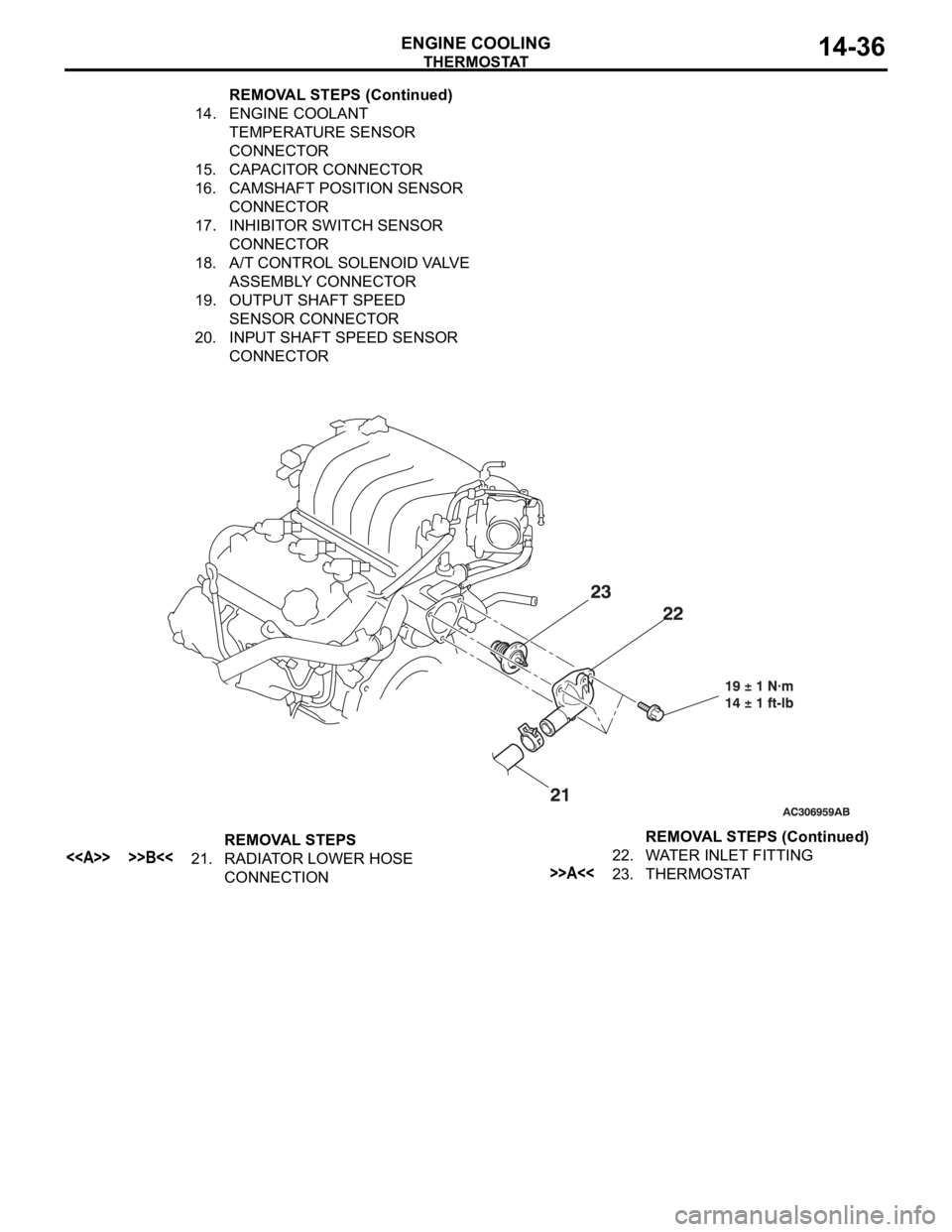

THERMOSTAT

ENGINE COOLING14-36

14. ENGINE COOLANT

TEMPERATURE SENSOR

CONNECTOR

15. CAPACITOR CONNECTOR

16. CAMSHAFT POSITION SENSOR

CONNECTOR

17. INHIBITOR SWITCH SENSOR

CONNECTOR

18. A/T CONTROL SOLENOID VALVE

ASSEMBLY CONNECTOR

19. OUTPUT SHAFT SPEED

SENSOR CONNECTOR

20. INPUT SHAFT SPEED SENSOR

CONNECTOR REMOVAL STEPS (Continued)

REMOVAL STEPS

<> >>B<<21. RADIATOR LOWER HOSE

CONNECTION22. WATER INLET FITTING>>A<<23. THERMOSTATREMOVAL STEPS (Continued)

Page 955 of 1500

WATER HOSE AND WATER PIPE

ENGINE COOLING14-40

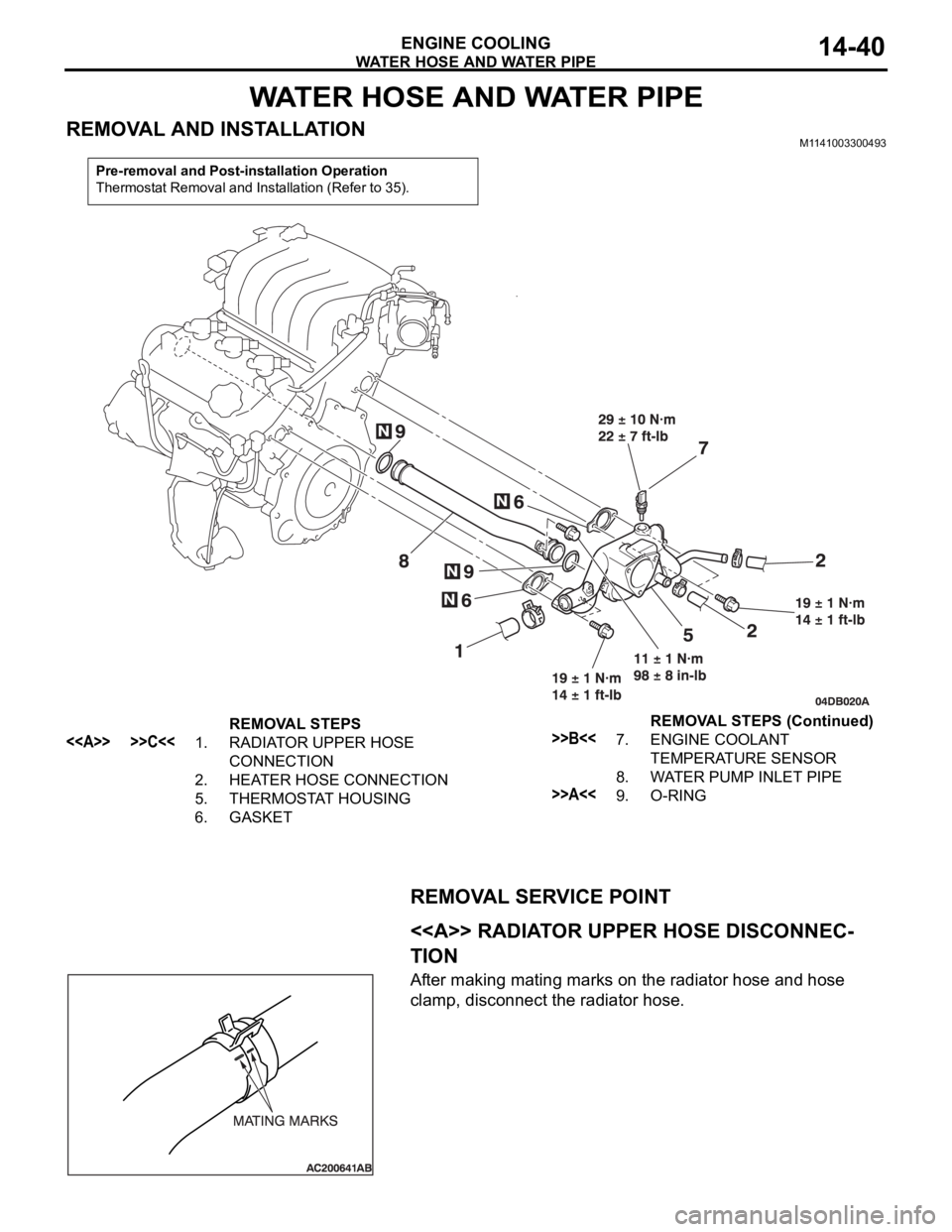

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATIONM1141003300493

REMOVAL SERVICE POINT

.

<> RADIATOR UPPER HOSE DISCONNEC-

TION

After making mating marks on the radiator hose and hose

clamp, disconnect the radiator hose.

Pre-removal and Post-installation Operation

Thermostat Removal and Installation (Refer to 35).

REMOVAL STEPS

<> >>C<<1. RADIATOR UPPER HOSE

CONNECTION

2. HEATER HOSE CONNECTION

5. THERMOSTAT HOUSING

6. GASKET>>B<<7. ENGINE COOLANT

TEMPERATURE SENSOR

8. WATER PUMP INLET PIPE

>>A<<9. O-RINGREMOVAL STEPS (Continued)

Page 956 of 1500

WATER HOSE AND WATER PIPE

ENGINE COOLING14-41

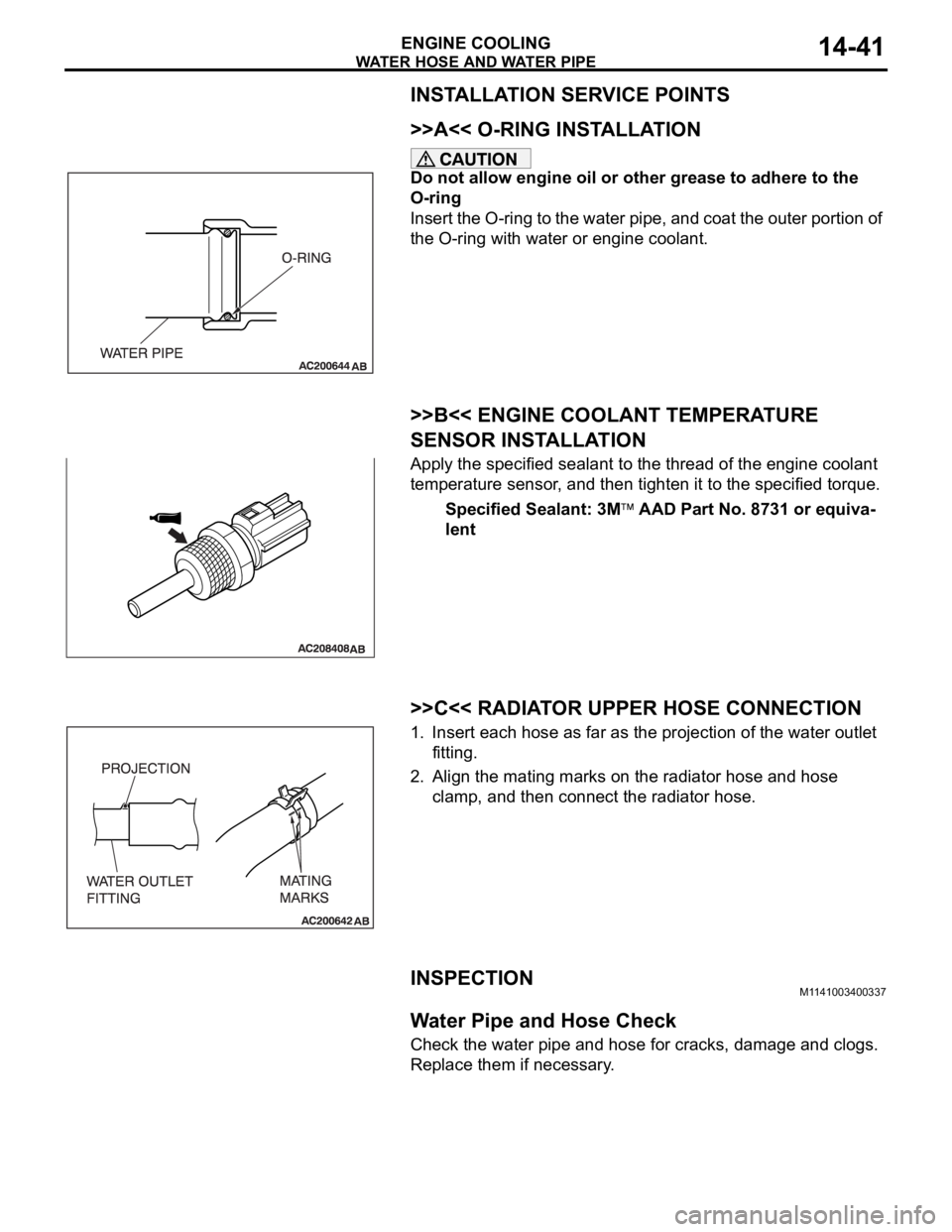

INSTALLATION SERVICE POINTS

.

>>A<< O-RING INSTALLATION

Do not allow engine oil or other grease to adhere to the

O-ring

Insert the O-ring to the water pipe, and coat the outer portion of

the O-ring with water or engine coolant.

.

>>B<< ENGINE COOLANT TEMPERATURE

SENSOR INSTALLATION

Apply the specified sealant to the thread of the engine coolant

temperature sensor, and then tighten it to the specified torque.

Specified Sealant: 3M

AAD Part No. 8731 or equiva-

lent

.

>>C<< RADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water outlet

fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTIONM1141003400337.

Water Pipe and Hose Check

Check the water pipe and hose for cracks, damage and clogs.

Replace them if necessary.

Page 957 of 1500

SPECIFICATIONS

ENGINE COOLING14-42

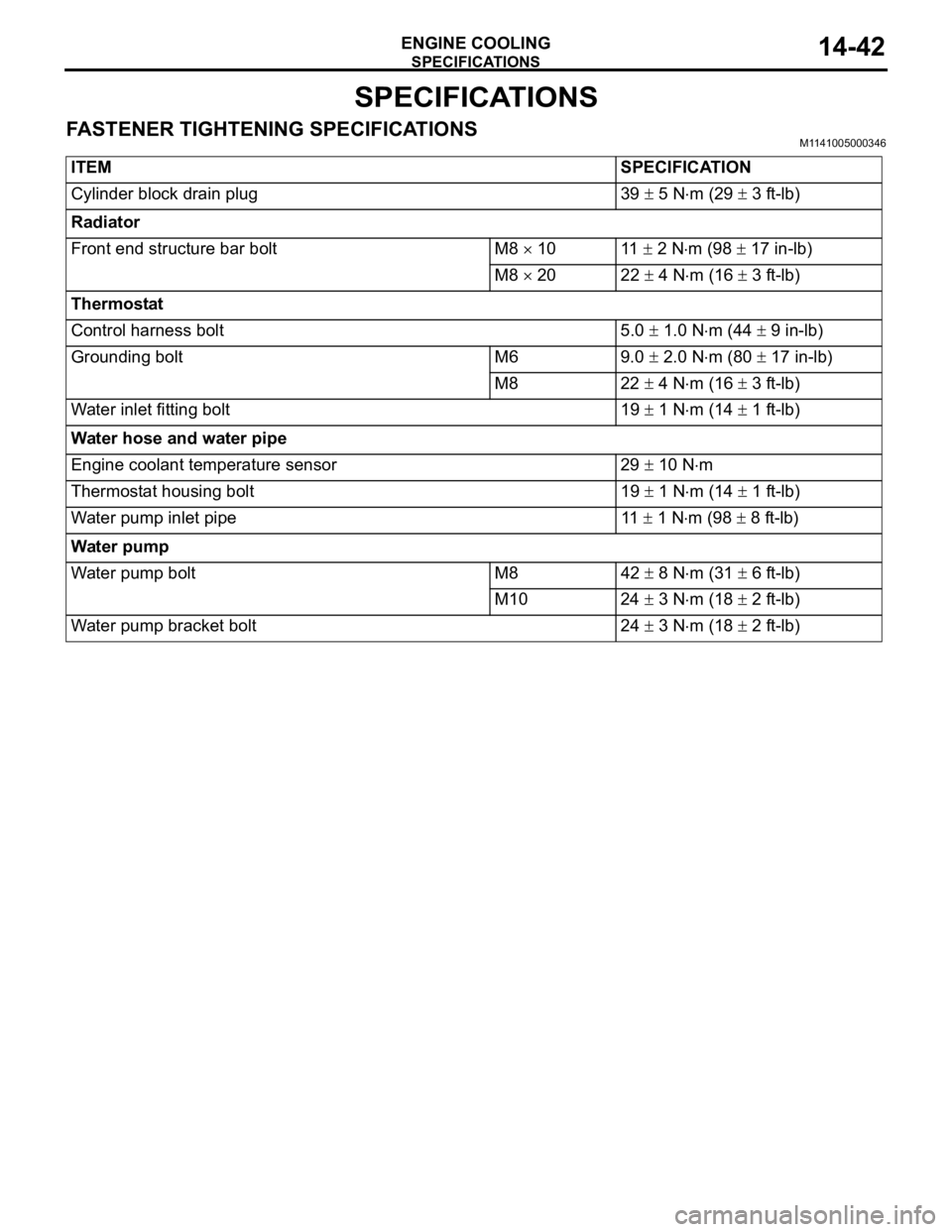

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1141005000346

ITEM SPECIFICATION

Cylinder block drain plug 39

5 Nm (29 3 ft-lb)

Radiator

Front end structure bar bolt M8

10 11 2 Nm (98 17 in-lb)

M8

20 22 4 Nm (16 3 ft-lb)

Thermostat

Control harness bolt 5.0

1.0 Nm (44 9 in-lb)

Grounding bolt M6 9.0

2.0 Nm (80 17 in-lb)

M8 22

4 Nm (16 3 ft-lb)

Water inlet fitting bolt 19

1 Nm (14 1 ft-lb)

Water hose and water pipe

Engine coolant temperature sensor 29

10 Nm

Thermostat housing bolt 19

1 Nm (14 1 ft-lb)

Water pump inlet pipe 11

1 Nm (98 8 ft-lb)

Water pump

Water pump bolt M8 42

8 Nm (31 6 ft-lb)

M10 24

3 Nm (18 2 ft-lb)

Water pump bracket bolt 24

3 Nm (18 2 ft-lb)

Page 958 of 1500

SPECIFICATIONS

ENGINE COOLING14-43

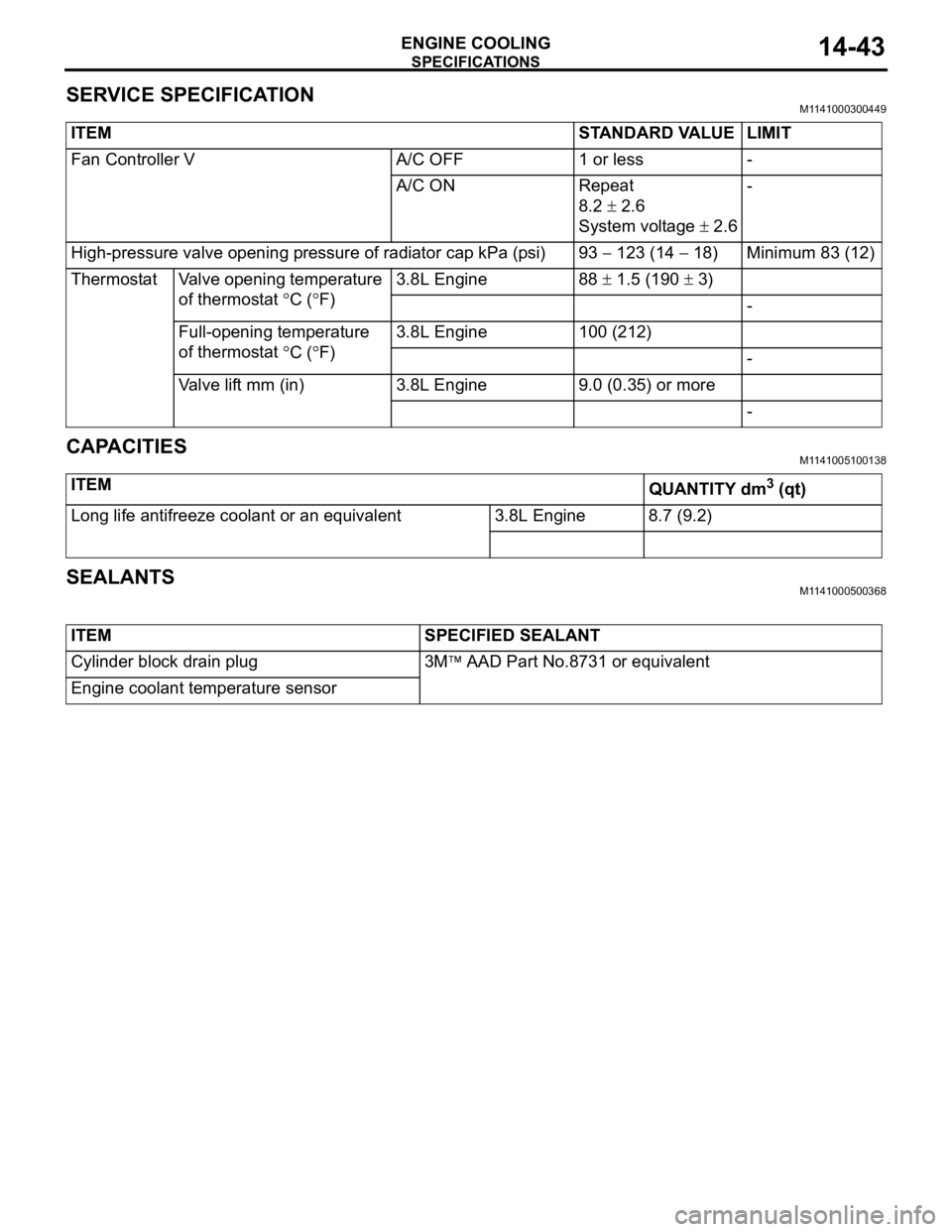

SERVICE SPECIFICATIONM1141000300449

CAPACITIESM1141005100138

SEALANTSM1141000500368

ITEM STANDARD VALUE LIMIT

Fan Controller V A/C OFF 1 or less -

A/C ON Repeat

8.2

2.6

System voltage

2.6-

High-pressure valve opening pressure of radiator cap kPa (psi) 93

123 (14 18) Minimum 83 (12)

Thermostat Valve opening temperature

of thermostat

C (F)3.8L Engine 88

1.5 (190 3)

-

Full-opening temperature

of thermostat

C (F)3.8L Engine 100 (212)

-

Valve lift mm (in) 3.8L Engine 9.0 (0.35) or more

-

ITEM

QUANTITY dm3 (qt)

Long life antifreeze coolant or an equivalent 3.8L Engine 8.7 (9.2)

ITEM SPECIFIED SEALANT

Cylinder block drain plug 3M

AAD Part No.8731 or equivalent

Engine coolant temperature sensor

Page 1333 of 1500

ENGINE AND EMISSION CONTROL17-2

EMISSION CONTROL . . . . . . . .17-76

GENERAL DESCRIPTION . . . . . .

17-76

DIAGNOSIS . . . . . . . . . . . . . . . . . .17-76

SPECIAL TOOLS. . . . . . . . . . . . . .17-76

VACUUM HOSES . . . . . . . . . . . . .17-77

VACUUM HOSE ROUTING. . . . . . . . . . 17-77

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-78

VACUUM HOSE INSTALLATION . . . . . 17-78

VACUUM HOSE CHECK. . . . . . . . . . . . 17-79

POSITIVE CRANKCASE VENTILATION

SYSTEM . . . . . . . . . . . . . . . . . . . . .

17-79

GENERAL DESCRIPTION (POSITIVE

CRANKCASE VENTILATION SYSTEM)17-79

COMPONENT LOCATION . . . . . . . . . . 17-80

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK. . . . . . . . . . . . . . . . . . 17-80

POSITIVE CRANKCASE VENTILATION

VALVE CHECK . . . . . . . . . . . . . . . . . . . 17-80

EVAPORATIVE EMISSION CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . .

17-81

GENERAL DESCRIPTION (EVAPORATIVE

EMISSION SYSTEM) . . . . . . . . . . . . . . . 17-81

COMPONENT LOCATION . . . . . . . . . . . 17-82

PURGE CONTROL SYSTEM CHECK

(PURGE FLOW CHECK) . . . . . . . . . . . . 17-82

EVAPORATIVE EMISSION PURGE

SOLENOID CHECK . . . . . . . . . . . . . . . . 17-83

MASS AIRFLOW SENSOR CHECK . . . 17-84

ENGINE COOLANT TEMPERATURE

SENSOR CHECK . . . . . . . . . . . . . . . . . . 17-84

INTAKE AIR TEMPERATURE SENSOR

CHECK. . . . . . . . . . . . . . . . . . . . . .17-84

EVAPORATIVE EMISSION CANISTER

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

17-81

REMOVAL AND INSTALLATION . . . . . . 17-81

INSPECTION . . . . . . . . . . . . . . . . . . . . . 17-81

CATALYTIC CONVERTER . . . . . .17-84

GENERAL DESCRIPTION (CATALYTIC

CONVERTER) . . . . . . . . . . . . . . . . . . . . 17-84

SPECIFICATIONS . . . . . . . . . . 17-85

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . . . . . . 17-85