air condition MITSUBISHI 380 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 92 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-92

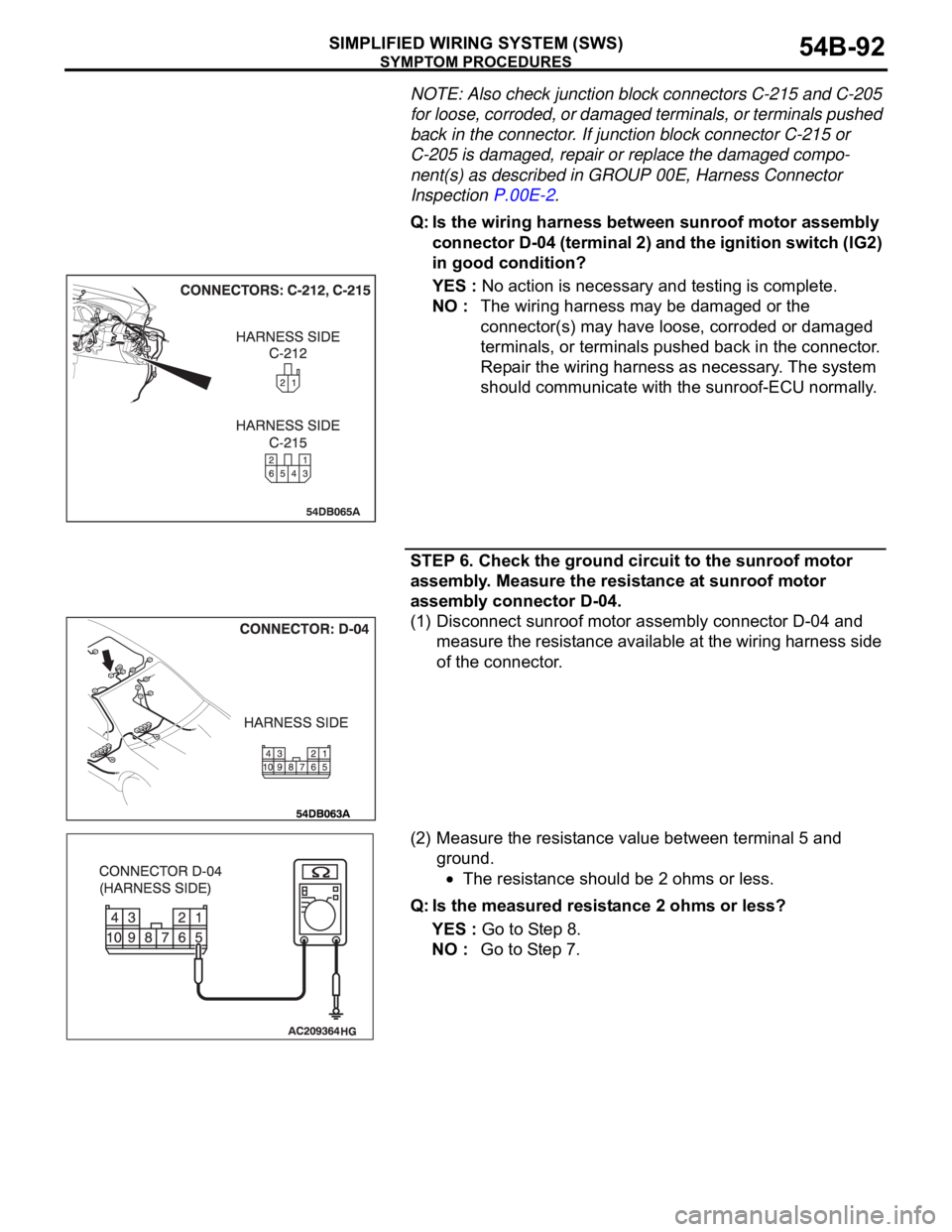

NOTE: Also check junction block connectors C-215 and C-205

for loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If junction block connector C-215 or

C-205 is damaged, repair or replace the damaged compo-

nent(s) as described in GROUP 00E, Harness Connector

Inspection P.00E-2.

Q: Is the wiring harness between sunroof motor assembly

connector D-04 (terminal 2) and the ignition switch (IG2)

in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the sunroof-ECU normally.

STEP 6. Check the ground circuit to the sunroof motor

assembly. Measure the resistance at sunroof motor

assembly connector D-04.

(1) Disconnect sunroof motor assembly connector D-04 and

measure the resistance available at the wiring harness side

of the connector.

(2) Measure the resistance value between terminal 5 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 8.

NO : Go to Step 7.

Page 93 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-93

STEP 7. Check the wiring harness between sunroof motor

assembly connector D-04 (terminal 5) and ground.

Q: Is the wiring harness between sunroof motor assembly

connector D-04 (terminal 5) and ground in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the sunroof-ECU normally.

STEP 8. Check ETACS-ECU connector C-218 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-218 in good condition?

YES : Go to Step 9.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

sunroof-ECU normally.

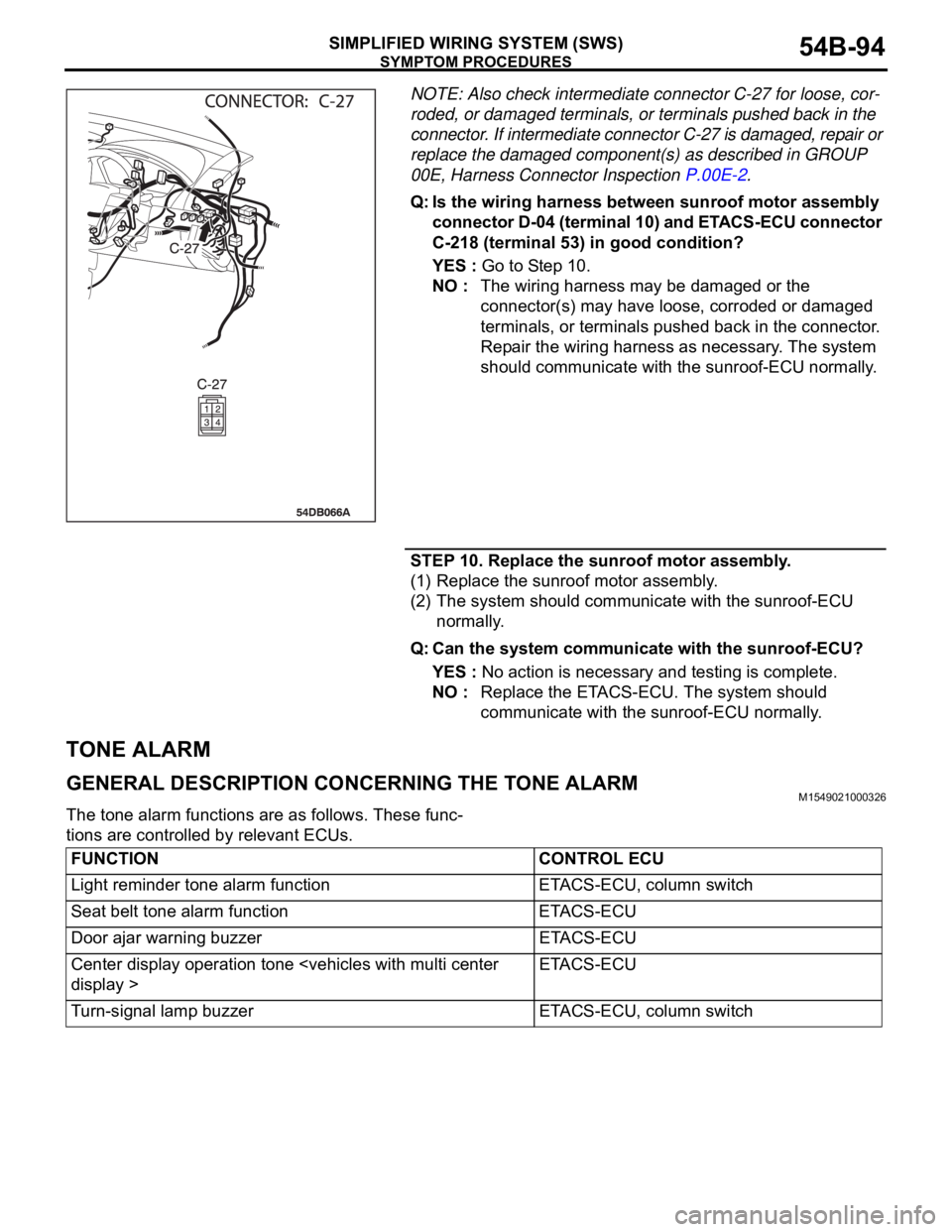

STEP 9. Check the wiring harness between sunroof motor

assembly connector D-04 (terminal 10) and ETACS-ECU

connector C-218 (terminal 53).

Page 94 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-94

NOTE: Also check intermediate connector C-27 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-27 is damaged, repair or

replace the damaged component(s) as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between sunroof motor assembly

connector D-04 (terminal 10) and ETACS-ECU connector

C-218 (terminal 53) in good condition?

YES : Go to Step 10.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the sunroof-ECU normally.

STEP 10. Replace the sunroof motor assembly.

(1) Replace the sunroof motor assembly.

(2) The system should communicate with the sunroof-ECU

normally.

Q: Can the system communicate with the sunroof-ECU?

YES : No action is necessary and testing is complete.

NO : Replace the ETACS-ECU. The system should

communicate with the sunroof-ECU normally.

TONE ALARM

GENERAL DESCRIPTION CONCERNING THE TONE ALARMM1549021000326

The tone alarm functions are as follows. These func-

tions are controlled by relevant ECUs.

FUNCTION CONTROL ECU

Light reminder tone alarm function ETACS-ECU, column switch

Seat belt tone alarm function ETACS-ECU

Door ajar warning buzzer ETACS-ECU

Center display operation tone

Turn-signal lamp buzzer ETACS-ECU, column switch

Page 117 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-117

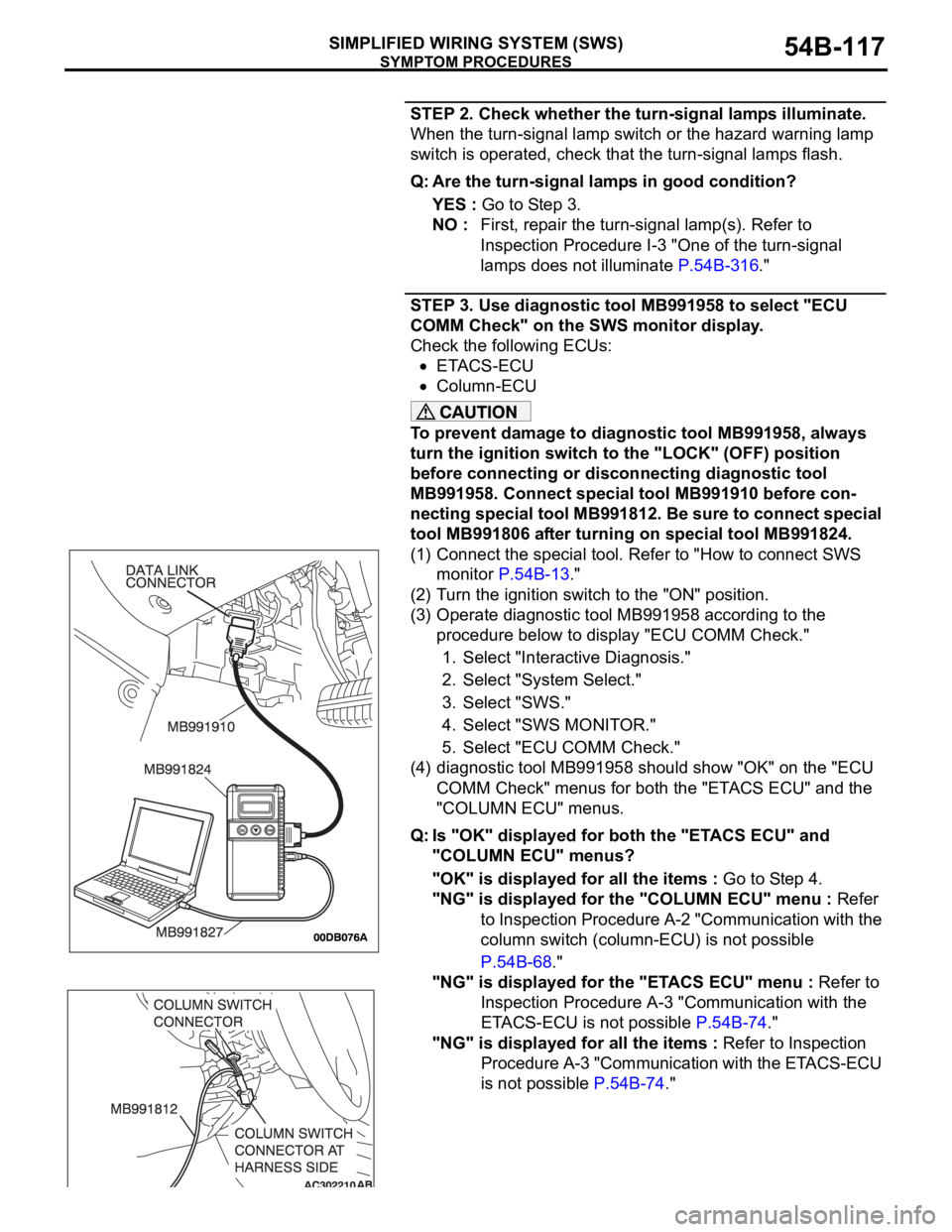

STEP 2. Check whether the turn-signal lamps illuminate.

When the turn-signal lamp switch or the hazard warning lamp

switch is operated, check that the turn-signal lamps flash.

Q: Are the turn-signal lamps in good condition?

YES : Go to Step 3.

NO : First, repair the turn-signal lamp(s). Refer to

Inspection Procedure I-3 "One of the turn-signal

lamps does not illuminate P.54B-316."

STEP 3. Use diagnostic tool MB991958 to select "ECU

COMM Check" on the SWS monitor display.

Check the following ECUs:

ETACS-ECU

Column-ECU

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958. Connect special tool MB991910 before con-

necting special tool MB991812. Be sure to connect special

tool MB991806 after turning on special tool MB991824.

(1) Connect the special tool. Refer to "How to connect SWS

monitor P.54B-13."

(2) Turn the ignition switch to the "ON" position.

(3) Operate diagnostic tool MB991958 according to the

procedure below to display "ECU COMM Check."

1. Select "Interactive Diagnosis."

2. Select "System Select."

3. Select "SWS."

4. Select "SWS MONITOR."

5. Select "ECU COMM Check."

(4) diagnostic tool MB991958 should show "OK" on the "ECU

COMM Check" menus for both the "ETACS ECU" and the

"COLUMN ECU" menus.

Q: Is "OK" displayed for both the "ETACS ECU" and

"COLUMN ECU" menus?

"OK" is displayed for all the items : Go to Step 4.

"NG" is displayed for the "COLUMN ECU" menu : Refer

to Inspection Procedure A-2 "Communication with the

column switch (column-ECU) is not possible

P.54B-68."

"NG" is displayed for the "ETACS ECU" menu : Refer to

Inspection Procedure A-3 "Communication with the

ETACS-ECU is not possible P.54B-74."

"NG" is displayed for all the items : Refer to Inspection

Procedure A-3 "Communication with the ETACS-ECU

is not possible P.54B-74."

Page 124 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-124

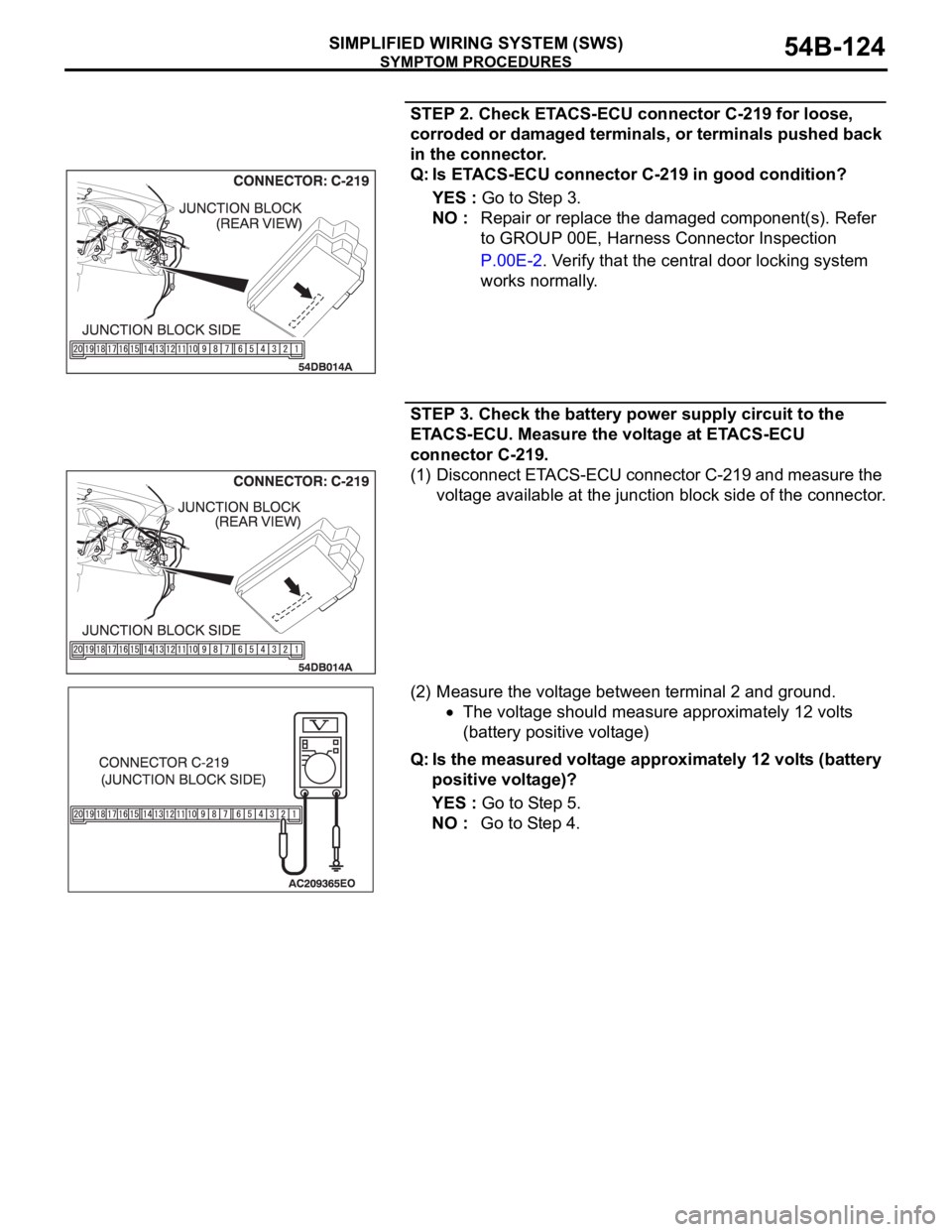

STEP 2. Check ETACS-ECU connector C-219 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-219 in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the central door locking system

works normally.

STEP 3. Check the battery power supply circuit to the

ETACS-ECU. Measure the voltage at ETACS-ECU

connector C-219.

(1) Disconnect ETACS-ECU connector C-219 and measure the

voltage available at the junction block side of the connector.

(2) Measure the voltage between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage)

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 5.

NO : Go to Step 4.

Page 125 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-125

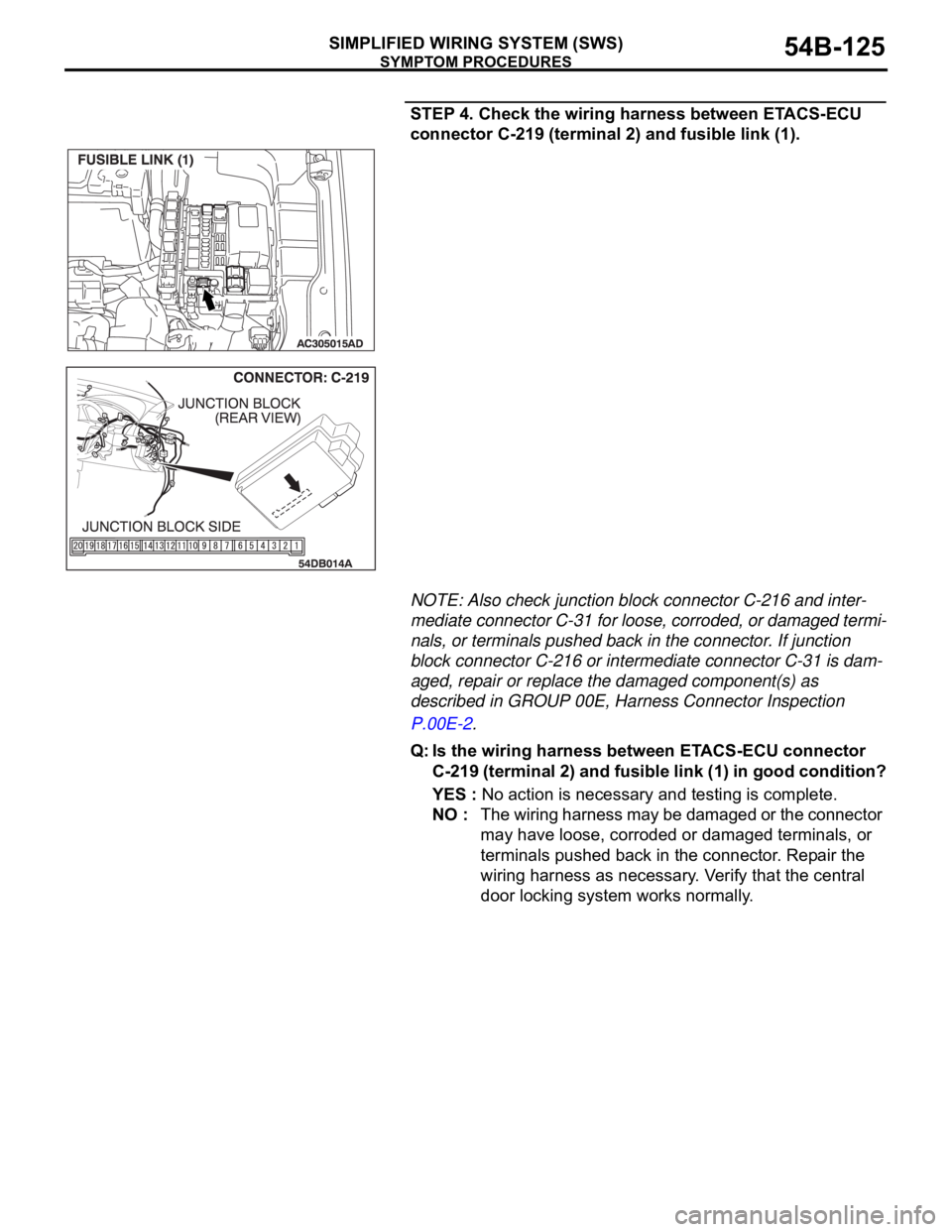

STEP 4. Check the wiring harness between ETACS-ECU

connector C-219 (terminal 2) and fusible link (1).

NOTE: Also check junction block connector C-216 and inter-

mediate connector C-31 for loose, corroded, or damaged termi-

nals, or terminals pushed back in the connector. If junction

block connector C-216 or intermediate connector C-31 is dam-

aged, repair or replace the damaged component(s) as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-219 (terminal 2) and fusible link (1) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the connector

may have loose, corroded or damaged terminals, or

terminals pushed back in the connector. Repair the

wiring harness as necessary. Verify that the central

door locking system works normally.

Page 126 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-126

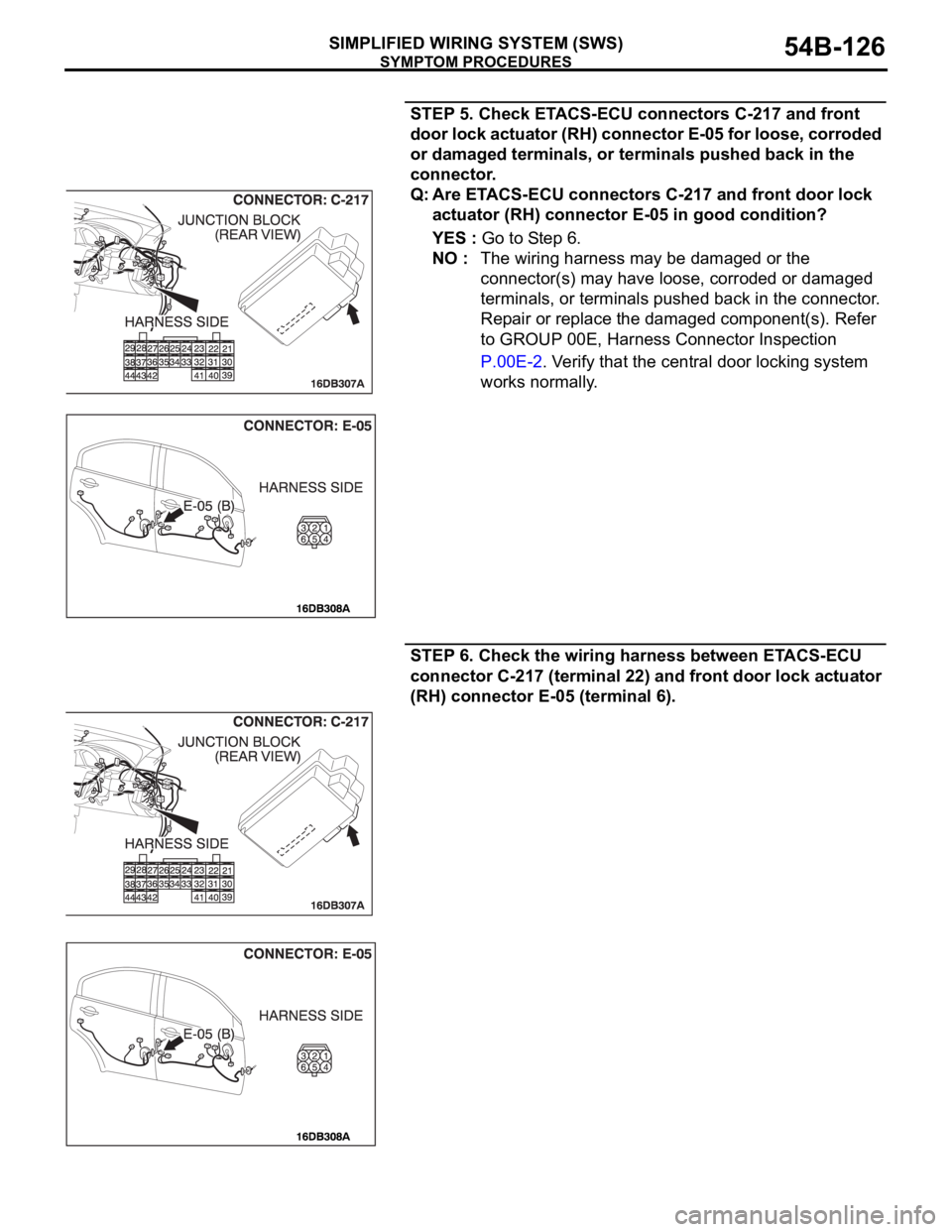

STEP 5. Check ETACS-ECU connectors C-217 and front

door lock actuator (RH) connector E-05 for loose, corroded

or damaged terminals, or terminals pushed back in the

connector.

Q: Are ETACS-ECU connectors C-217 and front door lock

actuator (RH) connector E-05 in good condition?

YES : Go to Step 6.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the central door locking system

works normally.

STEP 6. Check the wiring harness between ETACS-ECU

connector C-217 (terminal 22) and front door lock actuator

(RH) connector E-05 (terminal 6).

Page 127 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-127

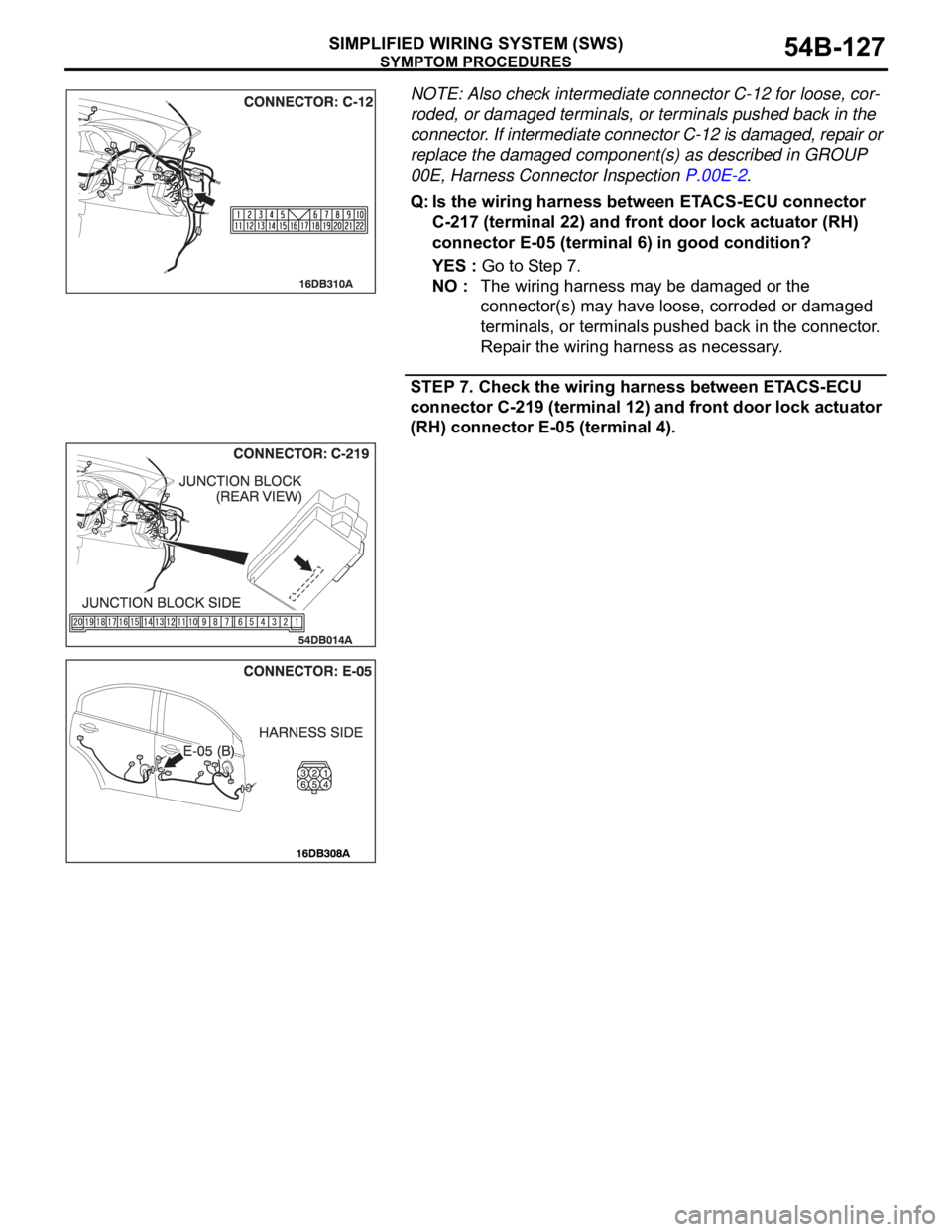

NOTE: Also check intermediate connector C-12 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-12 is damaged, repair or

replace the damaged component(s) as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-217 (terminal 22) and front door lock actuator (RH)

connector E-05 (terminal 6) in good condition?

YES : Go to Step 7.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary.

STEP 7. Check the wiring harness between ETACS-ECU

connector C-219 (terminal 12) and front door lock actuator

(RH) connector E-05 (terminal 4).

Page 128 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-128

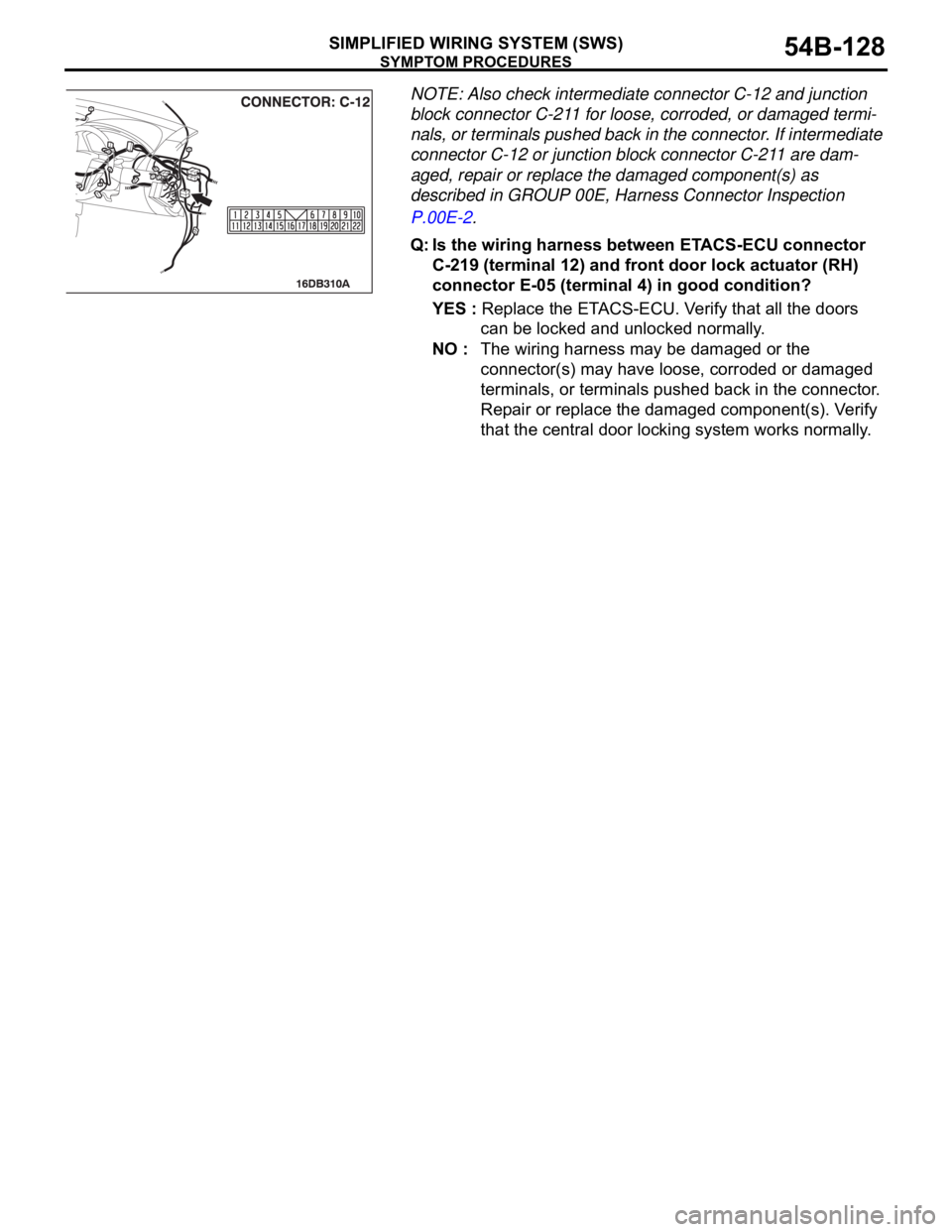

NOTE: Also check intermediate connector C-12 and junction

block connector C-211 for loose, corroded, or damaged termi-

nals, or terminals pushed back in the connector. If intermediate

connector C-12 or junction block connector C-211 are dam-

aged, repair or replace the damaged component(s) as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-219 (terminal 12) and front door lock actuator (RH)

connector E-05 (terminal 4) in good condition?

YES : Replace the ETACS-ECU. Verify that all the doors

can be locked and unlocked normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair or replace the damaged component(s). Verify

that the central door locking system works normally.

Page 130 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-130

.

TECHNICAL DESCRIPTION (COMMENT)

The wiring harness between the door lock actuator or

the ETACS-ECU and the door lock actuator may be

defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The front door lock actuator or rear door lock

actuator may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tool:

MB991223: Harness Set

STEP 1. Check which door lock is defective.

Q: Which of the door locks is defective?

Driver's door : Go to Step 2.

Front passenger's door : Go to Step 7.

Rear door (LH) : Go to Step 11.

Rear door (RH) : Go to Step 15.

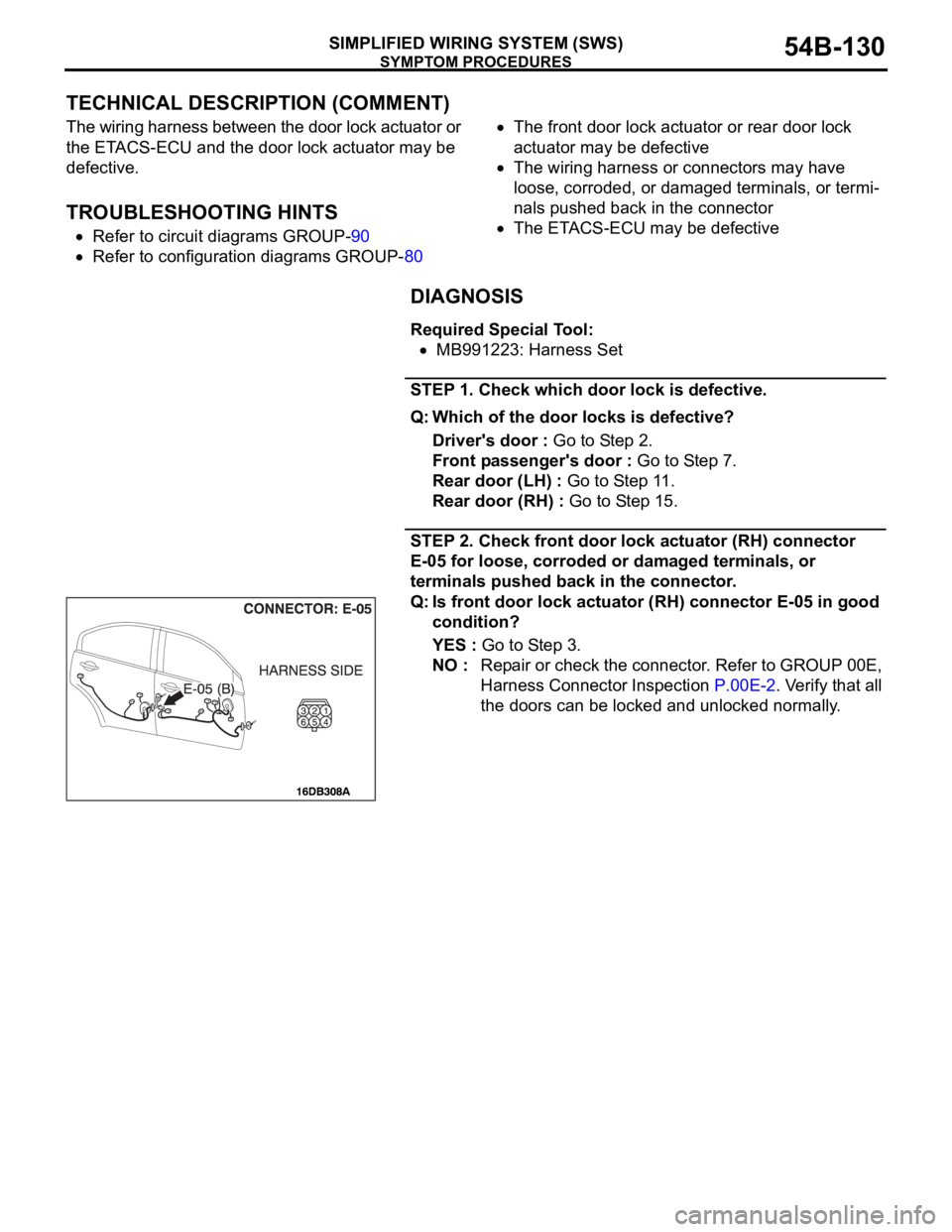

STEP 2. Check front door lock actuator (RH) connector

E-05 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is front door lock actuator (RH) connector E-05 in good

condition?

YES : Go to Step 3.

NO : Repair or check the connector. Refer to GROUP 00E,

Harness Connector Inspection P.00E-2. Verify that all

the doors can be locked and unlocked normally.