Oil MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 949 of 1500

Page 952 of 1500

Page 954 of 1500

WATE R P U M P

ENGINE COOLING14-39

WAT E R P U M P

REMOVAL AND INSTALLATIONM1141002700498

INSTALLATION SERVICE POINT

.

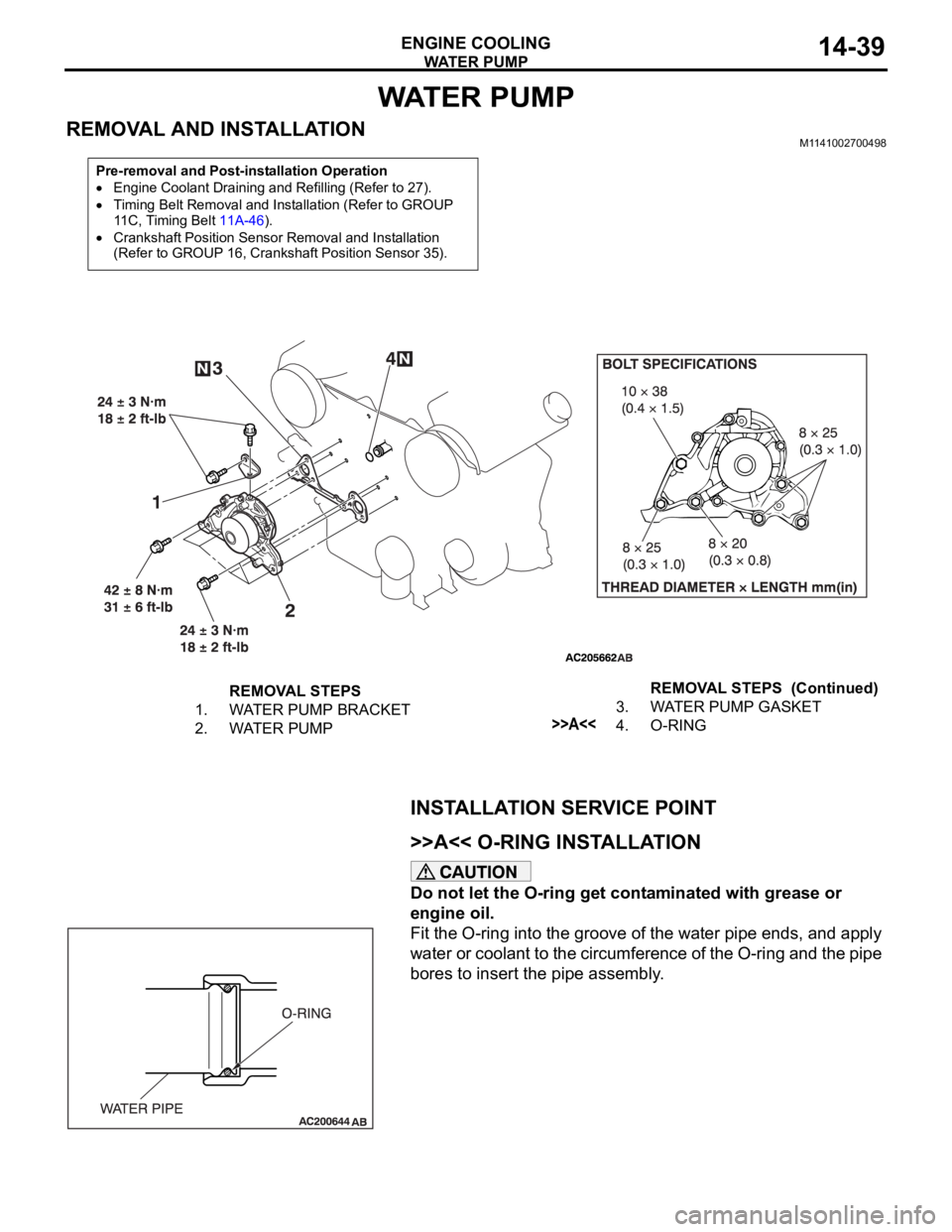

>>A<< O-RING INSTALLATION

Do not let the O-ring get contaminated with grease or

engine oil.

Fit the O-ring into the groove of the water pipe ends, and apply

water or coolant to the circumference of the O-ring and the pipe

bores to insert the pipe assembly.

Pre-removal and Post-installation Operation

Engine Coolant Draining and Refilling (Refer to 27).

Timing Belt Removal and Installation (Refer to GROUP

11C, Timing Belt 11A-46).

Crankshaft Position Sensor Removal and Installation

(Refer to GROUP 16, Crankshaft Position Sensor 35).

REMOVAL STEPS

1. WATER PUMP BRACKET

2. WATER PUMP3. WATER PUMP GASKET

>>A<<4. O-RINGREMOVAL STEPS (Continued)

Page 956 of 1500

WATER HOSE AND WATER PIPE

ENGINE COOLING14-41

INSTALLATION SERVICE POINTS

.

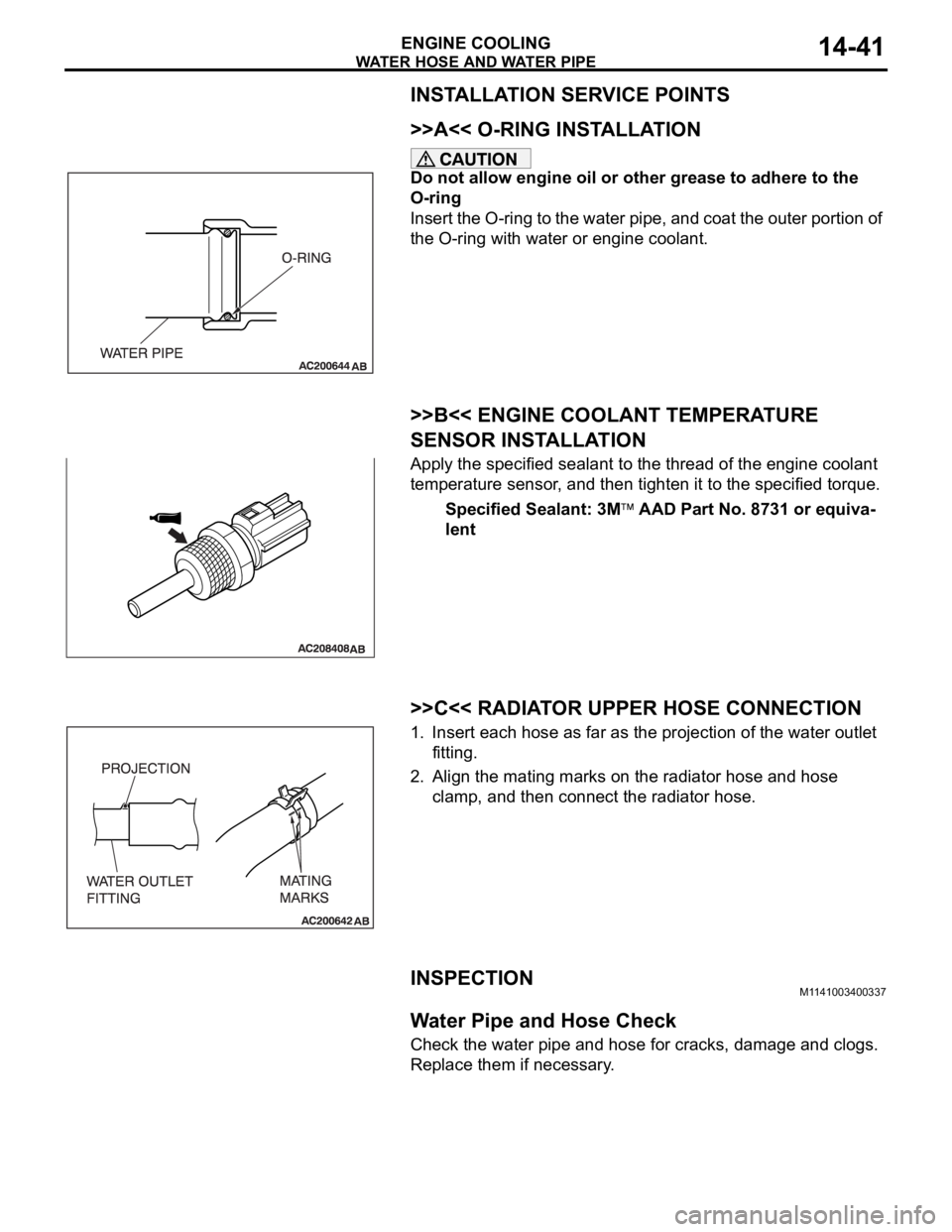

>>A<< O-RING INSTALLATION

Do not allow engine oil or other grease to adhere to the

O-ring

Insert the O-ring to the water pipe, and coat the outer portion of

the O-ring with water or engine coolant.

.

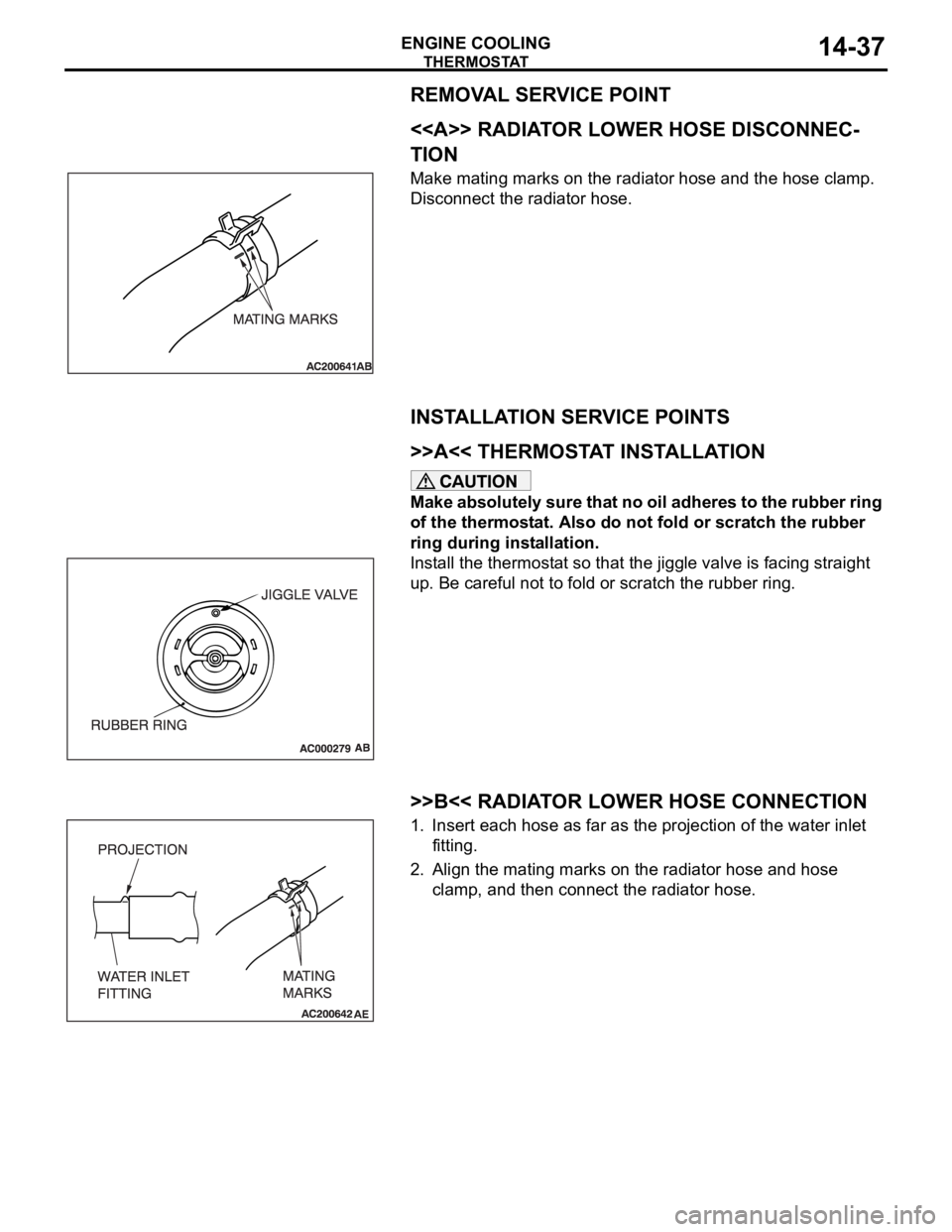

>>B<< ENGINE COOLANT TEMPERATURE

SENSOR INSTALLATION

Apply the specified sealant to the thread of the engine coolant

temperature sensor, and then tighten it to the specified torque.

Specified Sealant: 3M

AAD Part No. 8731 or equiva-

lent

.

>>C<< RADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water outlet

fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTIONM1141003400337.

Water Pipe and Hose Check

Check the water pipe and hose for cracks, damage and clogs.

Replace them if necessary.

Page 965 of 1500

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-6

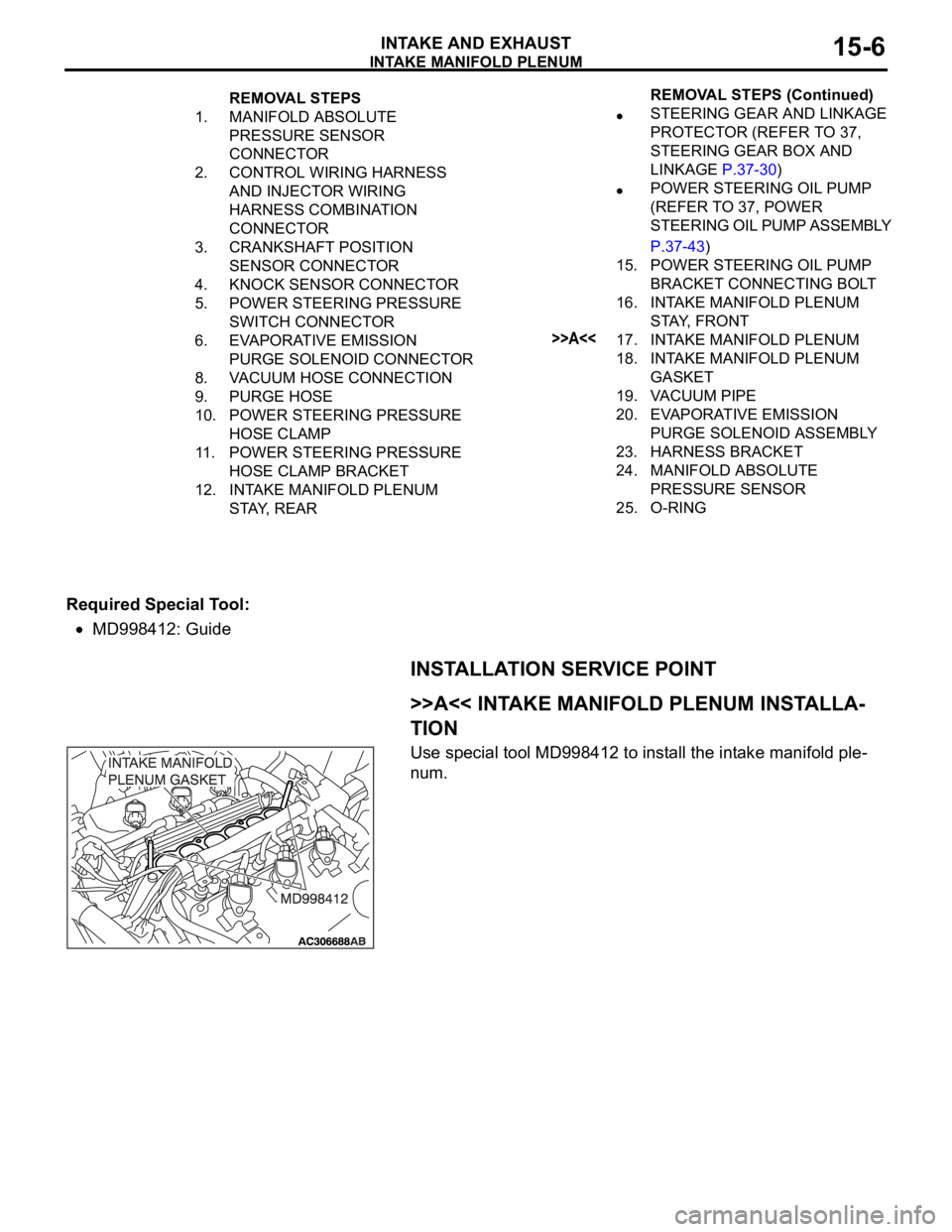

Required Special Tool:

MD998412: Guide

INSTALLATION SERVICE POINT

.

>>A<< INTAKE MANIFOLD PLENUM INSTALLA-

TION

Use special tool MD998412 to install the intake manifold ple-

num.

REMOVAL STEPS

1. MANIFOLD ABSOLUTE

PRESSURE SENSOR

CONNECTOR

2. CONTROL WIRING HARNESS

AND INJECTOR WIRING

HARNESS COMBINATION

CONNECTOR

3. CRANKSHAFT POSITION

SENSOR CONNECTOR

4. KNOCK SENSOR CONNECTOR

5. POWER STEERING PRESSURE

SWITCH CONNECTOR

6. EVAPORATIVE EMISSION

PURGE SOLENOID CONNECTOR

8. VACUUM HOSE CONNECTION

9. PURGE HOSE

10. POWER STEERING PRESSURE

HOSE CLAMP

11. POWER STEERING PRESSURE

HOSE CLAMP BRACKET

12. INTAKE MANIFOLD PLENUM

STAY, REARSTEERING GEAR AND LINKAGE

PROTECTOR (REFER TO 37,

STEERING GEAR BOX AND

LINKAGE P.37-30)

POWER STEERING OIL PUMP

(REFER TO 37, POWER

STEERING OIL PUMP ASSEMBLY

P.37-43)

15. POWER STEERING OIL PUMP

BRACKET CONNECTING BOLT

16. INTAKE MANIFOLD PLENUM

STAY, FRONT

>>A<<17. INTAKE MANIFOLD PLENUM

18. INTAKE MANIFOLD PLENUM

GASKET

19. VACUUM PIPE

20. EVAPORATIVE EMISSION

PURGE SOLENOID ASSEMBLY

23. HARNESS BRACKET

24. MANIFOLD ABSOLUTE

PRESSURE SENSOR

25. O-RINGREMOVAL STEPS (Continued)

Page 967 of 1500

Page 968 of 1500

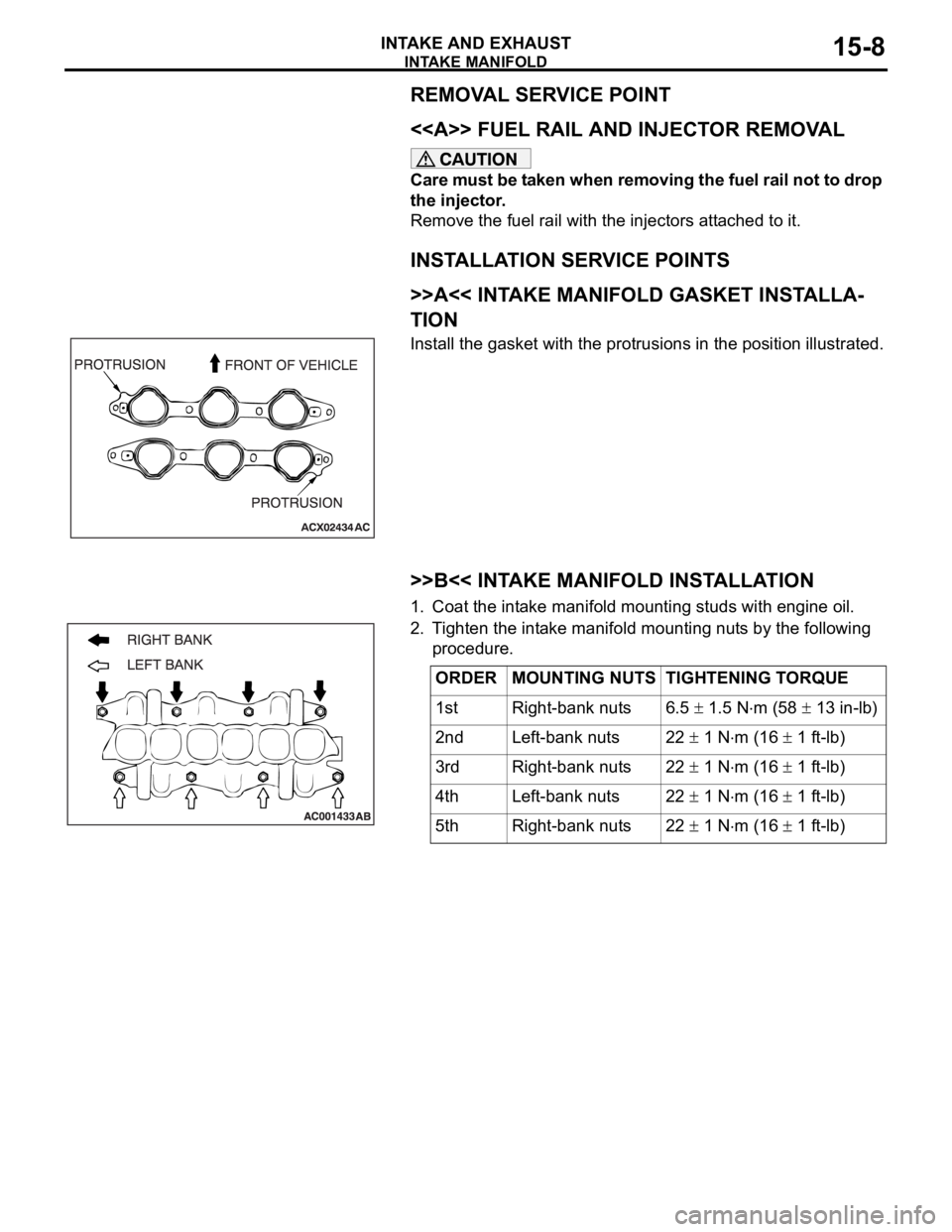

INTAKE MANIFOLD

INTAKE AND EXHAUST15-9

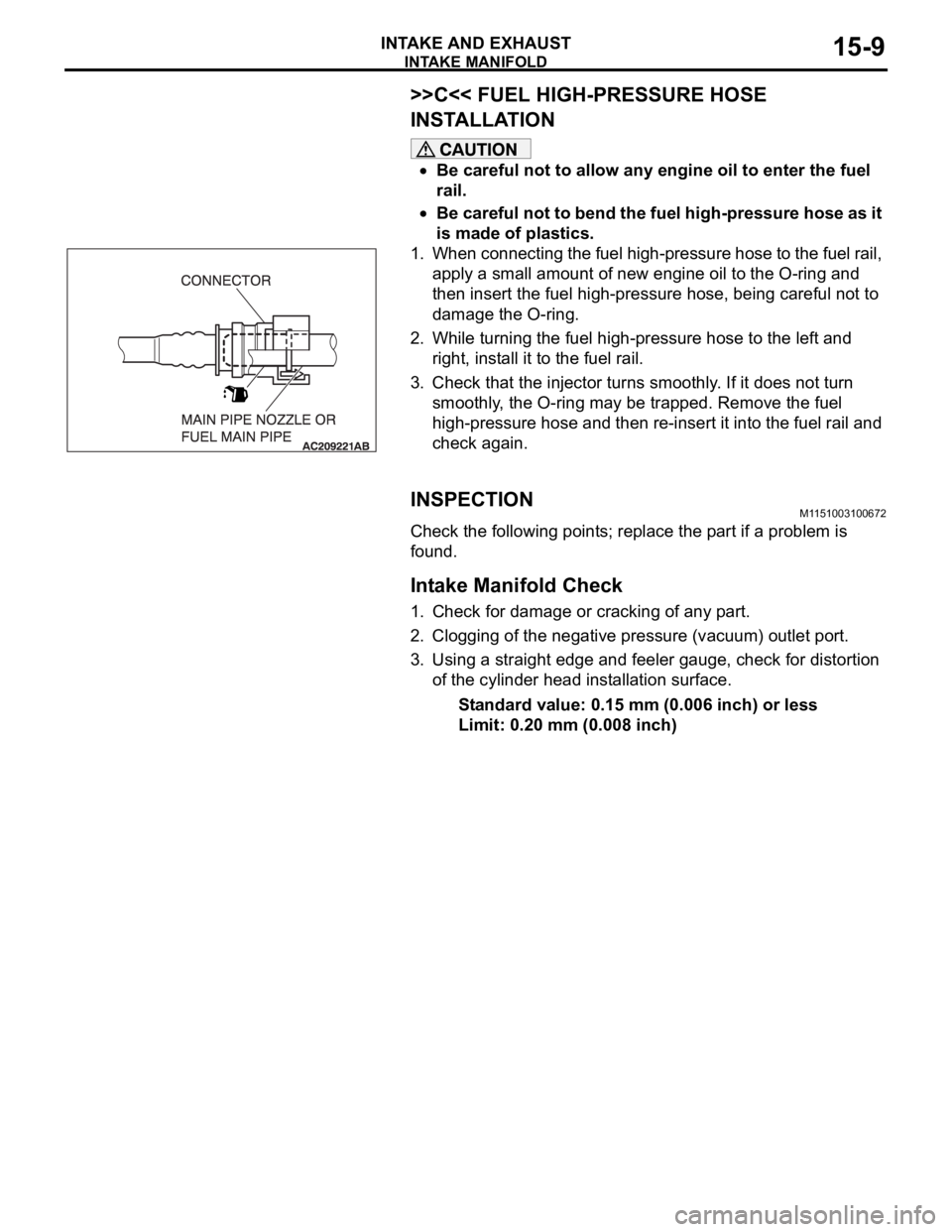

>>C<< FUEL HIGH-PRESSURE HOSE

INSTALLATION

Be careful not to allow any engine oil to enter the fuel

rail.

Be careful not to bend the fuel high-pressure hose as it

is made of plastics.

1. When connecting the fuel high-pressure hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the fuel high-pressure hose, being careful not to

damage the O-ring.

2. While turning the fuel high-pressure hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the fuel

high-pressure hose and then re-insert it into the fuel rail and

check again.

INSPECTIONM1151003100672

Check the following points; replace the part if a problem is

found.

.

Intake Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

Page 977 of 1500

SPECIFICATIONS

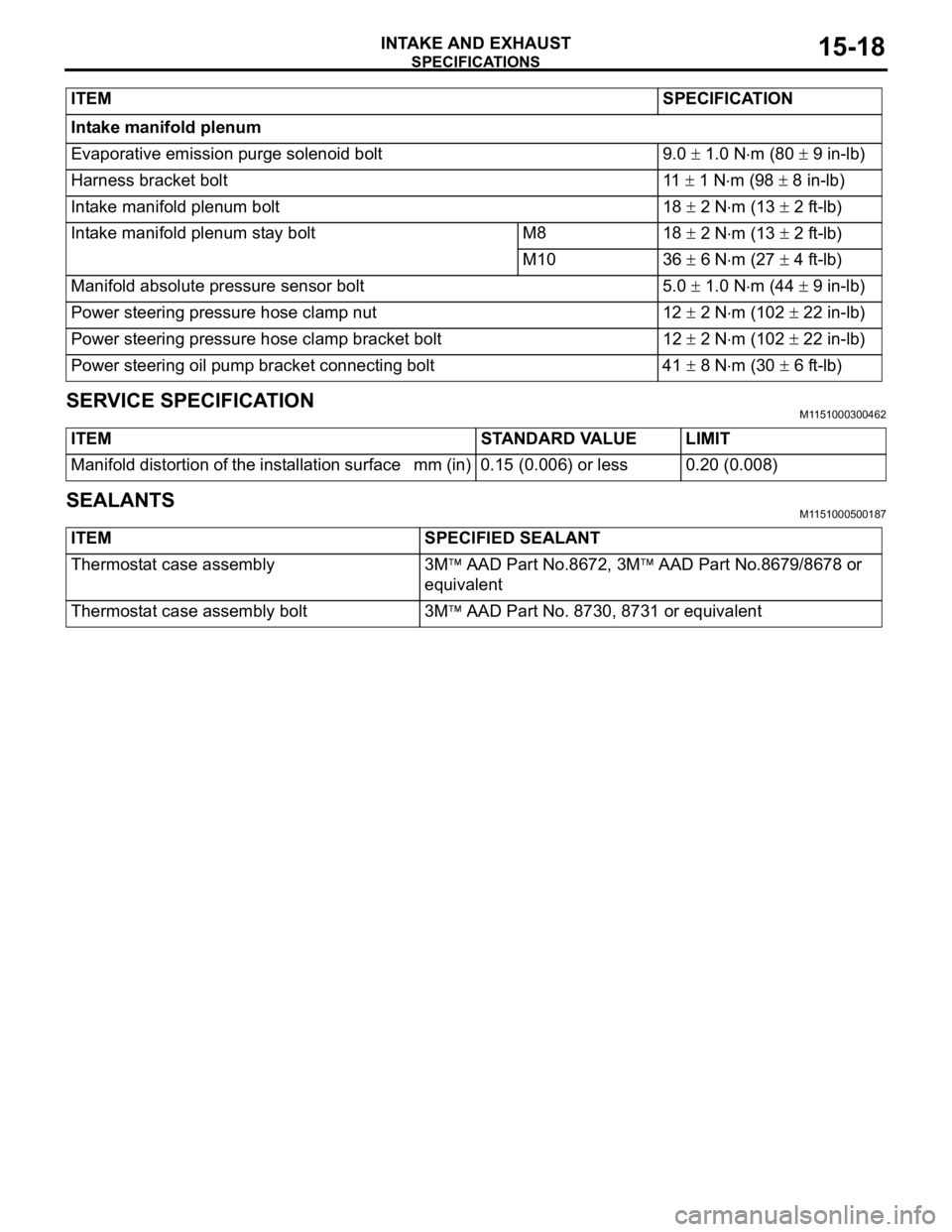

INTAKE AND EXHAUST15-18

SERVICE SPECIFICATIONM1151000300462

SEALANTSM1151000500187

Intake manifold plenum

Evaporative emission purge solenoid bolt 9.0

1.0 Nm (80 9 in-lb)

Harness bracket bolt 11

1 Nm (98 8 in-lb)

Intake manifold plenum bolt 18

2 Nm (13 2 ft-lb)

Intake manifold plenum stay bolt M8 18

2 Nm (13 2 ft-lb)

M10 36

6 Nm (27 4 ft-lb)

Manifold absolute pressure sensor bolt 5.0

1.0 Nm (44 9 in-lb)

Power steering pressure hose clamp nut 12

2 Nm (102 22 in-lb)

Power steering pressure hose clamp bracket bolt 12

2 Nm (102 22 in-lb)

Power steering oil pump bracket connecting bolt 41

8 Nm (30 6 ft-lb) ITEMSPECIFICATION

ITEM STANDARD VALUE LIMIT

Manifold distortion of the installation surface mm (in) 0.15 (0.006) or less 0.20 (0.008)

ITEM SPECIFIED SEALANT

Thermostat case assembly 3M

AAD Part No.8672, 3M AAD Part No.8679/8678 or

equivalent

Thermostat case assembly bolt 3M

AAD Part No. 8730, 8731 or equivalent

Page 978 of 1500

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .

16-2

GENERAL DESCRIPTION . . . . . .

16-2

CHARGING SYSTEM DIAGNOSIS16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-6

ON-VEHICLE SERVICE. . . . . . . . .16-7

ALTERNATOR OUTPUT WIRE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-7

OUTPUT CURRENT TEST . . . . . . . . . . 16-8

REGULATED VOLTAGE TEST . . . . . . . 16-10

WAVE PATTERN CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-11

ALTERNATOR ASSEMBLY . . . . .16-14

REMOVAL AND INSTALLATION . . . . . 16-14

DISASSEMBLY AND ASSEMBLY. . . . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-20

GENERAL DESCRIPTION . . . . . .

16-20

STARTING SYSTEM DIAGNOSIS . . . . 16-21

STARTER MOTOR ASSEMBLY . .16-23

REMOVAL AND INSTALLATION . . . . . 16-23

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-24

DISASSEMBLY AND ASSEMBLY. . . . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-28

IGNITION SYSTEM . . . . . . . . . . . . . .16-30GENERAL DESCRIPTION . . . . . . .

16-30

SPECIAL TOOLS . . . . . . . . . . . . . .16-30

ON-VEHICLE SERVICE . . . . . . . . .16-31

KNOCK CONTROL SYSTEM CHECK . . 16-31

IGNITION COIL CHECK. . . . . . . . . . . . . 16-31

SPARK PLUG TEST . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING16-32

CAMSHAFT POSITION SENSOR CHECK16-32

CRANKSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

IGNITION COIL . . . . . . . . . . . . . . . .16-33

REMOVAL AND INSTALLATION . . . . . 16-33

CAMSHAFT POSITION SENSOR .16-34

REMOVAL AND INSTALLATION . . . . . 16-34

CRANKSHAFT POSITION SENSOR16-35

REMOVAL AND INSTALLATION . . . . . 16-35

KNOCK SENSOR . . . . . . . . . . . . . .16-36

REMOVAL AND INSTALLATION . . . . . 16-36

SPECIFICATIONS . . . . . . . . . . 16-38

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . .

16-38

GENERAL SPECIFICATIONS . . . .16-38

SERVICE SPECIFICATIONS . . . . .16-39

Page 979 of 1500

16-2

CHARGING SYSTEM

GENERAL DESCRIPTIONM1161000100629

The charging system charges the battery with the

alternator output to keep the battery charged at a

constant level during varying electrical load.

OPERATION

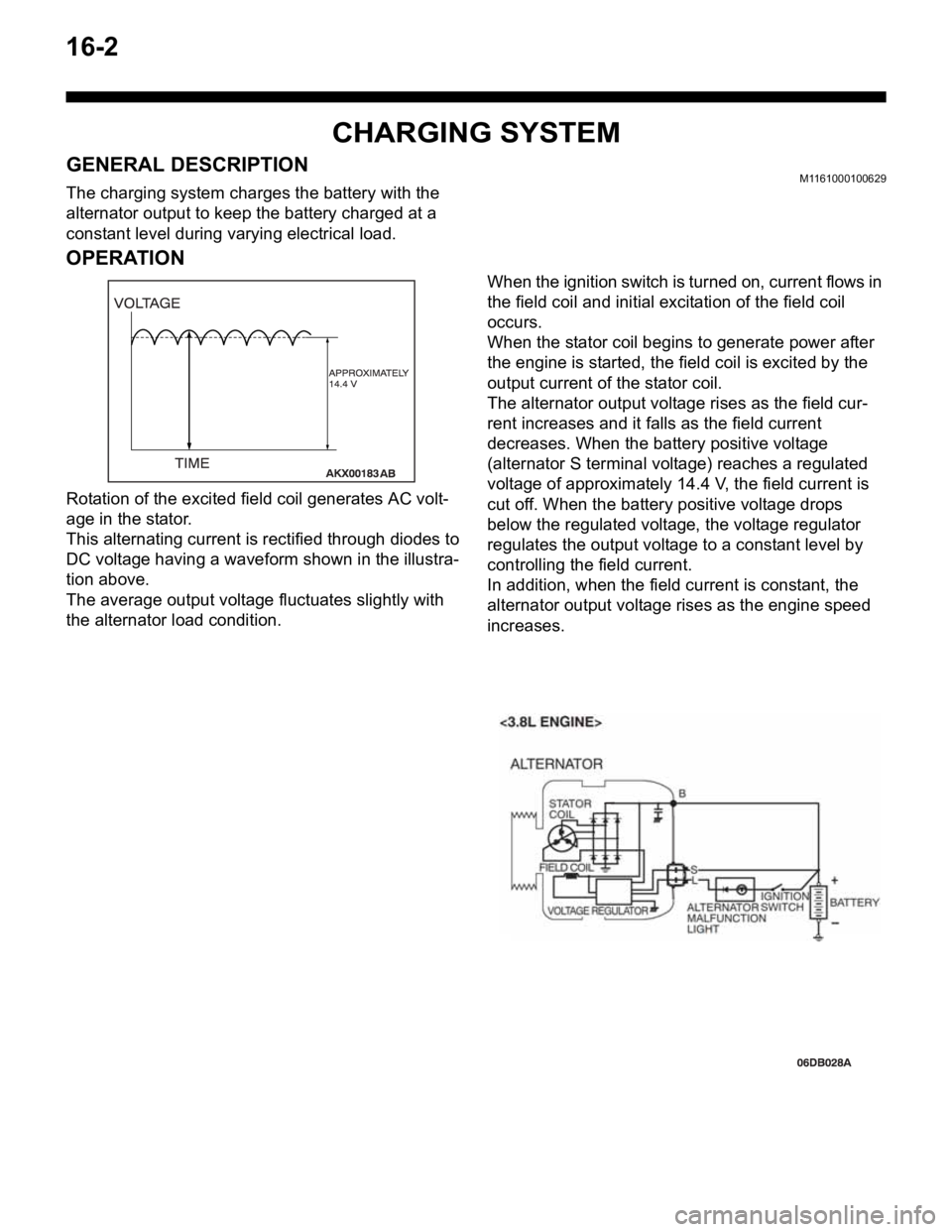

Rotation of the excited field coil generates AC volt-

age in the stator.

This alternating current is rectified through diodes to

DC voltage having a waveform shown in the illustra-

tion above.

The average output voltage fluctuates slightly with

the alternator load condition.When the ignition switch is turned on, current flows in

the field coil and initial excitation of the field coil

occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by the

output current of the stator coil.

The alternator output voltage rises as the field cur-

rent increases and it falls as the field current

decreases. When the battery positive voltage

(alternator S terminal voltage) reaches a regulated

voltage of approximately 14.4 V, the field current is

cut off. When the battery positive voltage drops

below the regulated voltage, the voltage regulator

regulates the output voltage to a constant level by

controlling the field current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.