relay MITSUBISHI 380 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 199 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-199

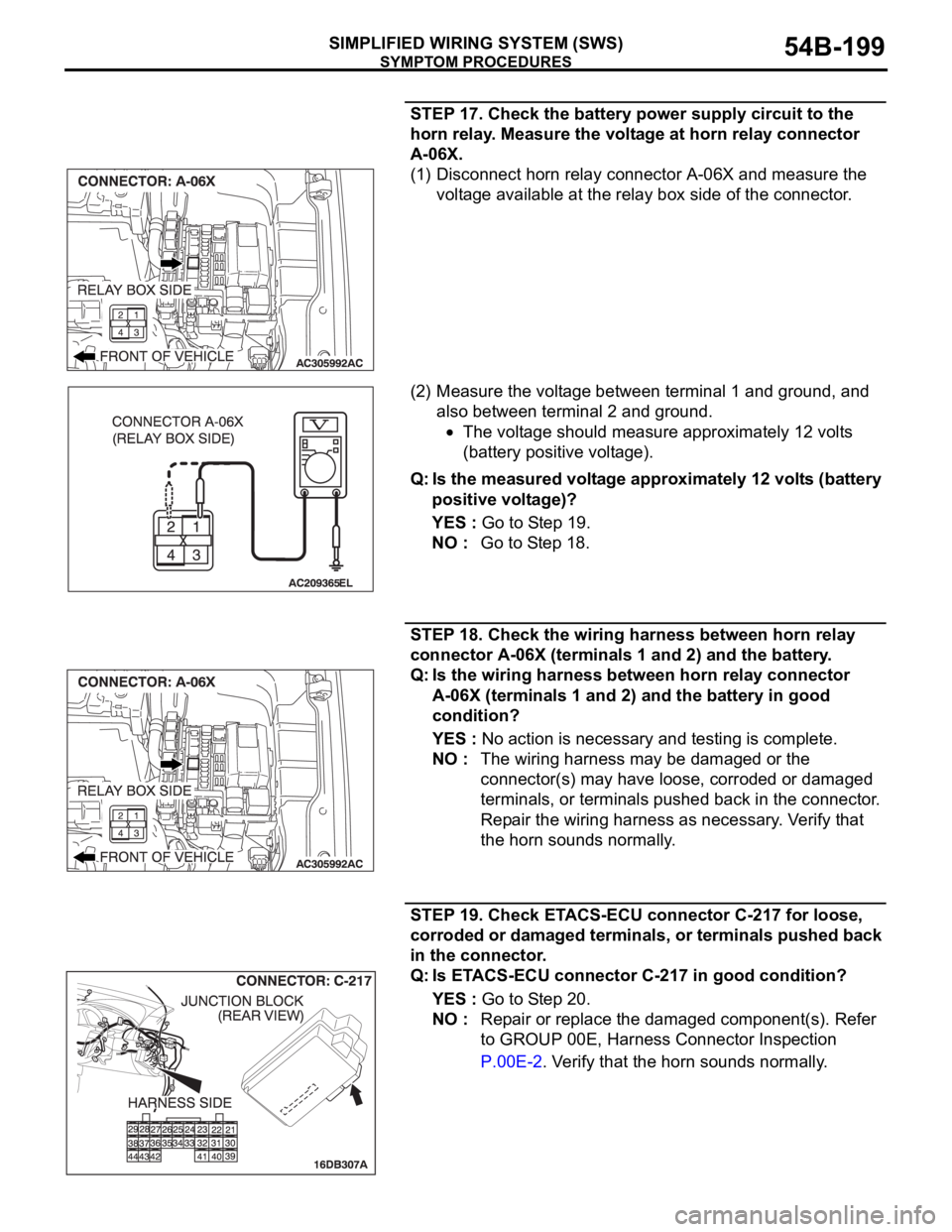

STEP 17. Check the battery power supply circuit to the

horn relay. Measure the voltage at horn relay connector

A-06X.

(1) Disconnect horn relay connector A-06X and measure the

voltage available at the relay box side of the connector.

(2) Measure the voltage between terminal 1 and ground, and

also between terminal 2 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 19.

NO : Go to Step 18.

STEP 18. Check the wiring harness between horn relay

connector A-06X (terminals 1 and 2) and the battery.

Q: Is the wiring harness between horn relay connector

A-06X (terminals 1 and 2) and the battery in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the horn sounds normally.

STEP 19. Check ETACS-ECU connector C-217 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-217 in good condition?

YES : Go to Step 20.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the horn sounds normally.

Page 200 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-200

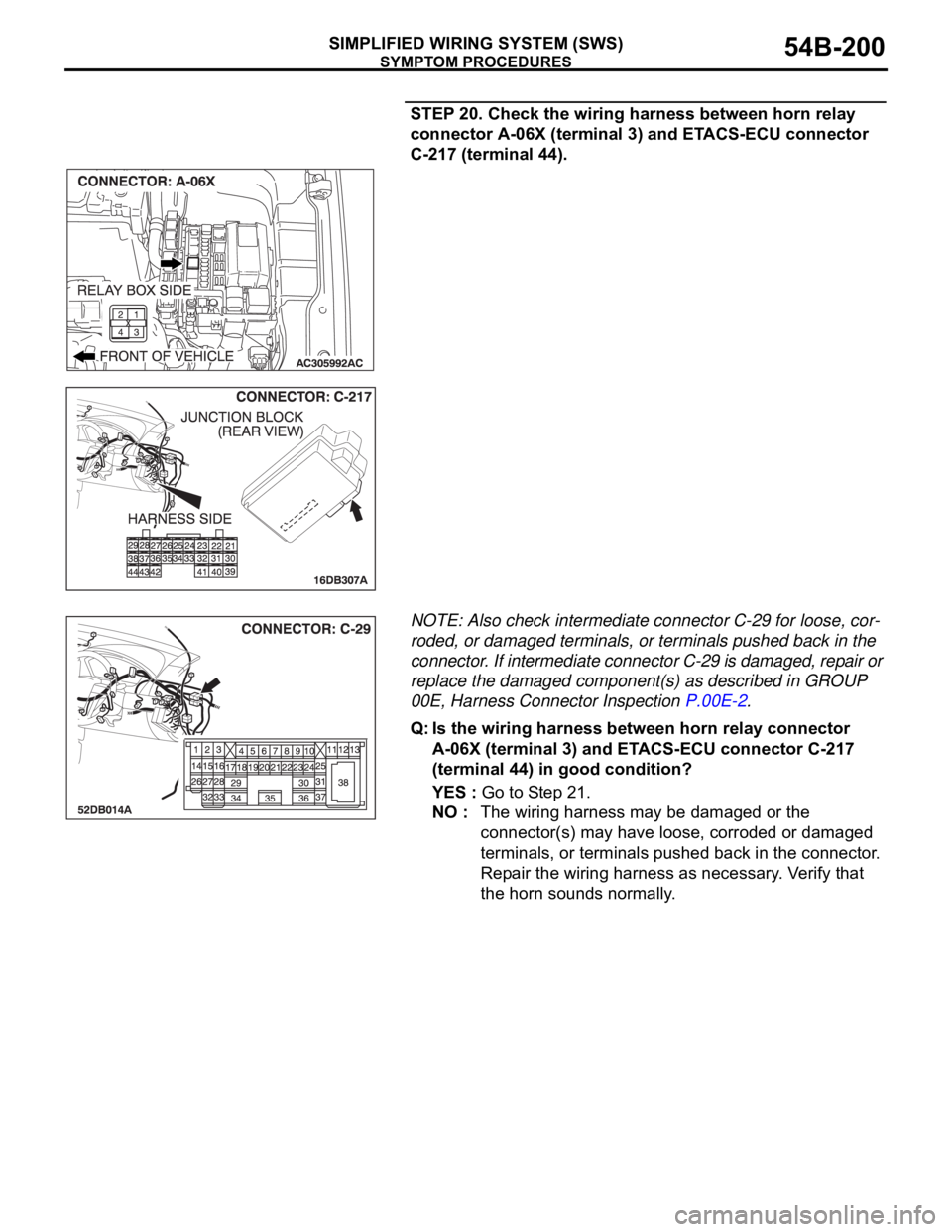

STEP 20. Check the wiring harness between horn relay

connector A-06X (terminal 3) and ETACS-ECU connector

C-217 (terminal 44).

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the damaged component(s) as described in GROUP

00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between horn relay connector

A-06X (terminal 3) and ETACS-ECU connector C-217

(terminal 44) in good condition?

YES : Go to Step 21.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the horn sounds normally.

Page 201 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-201

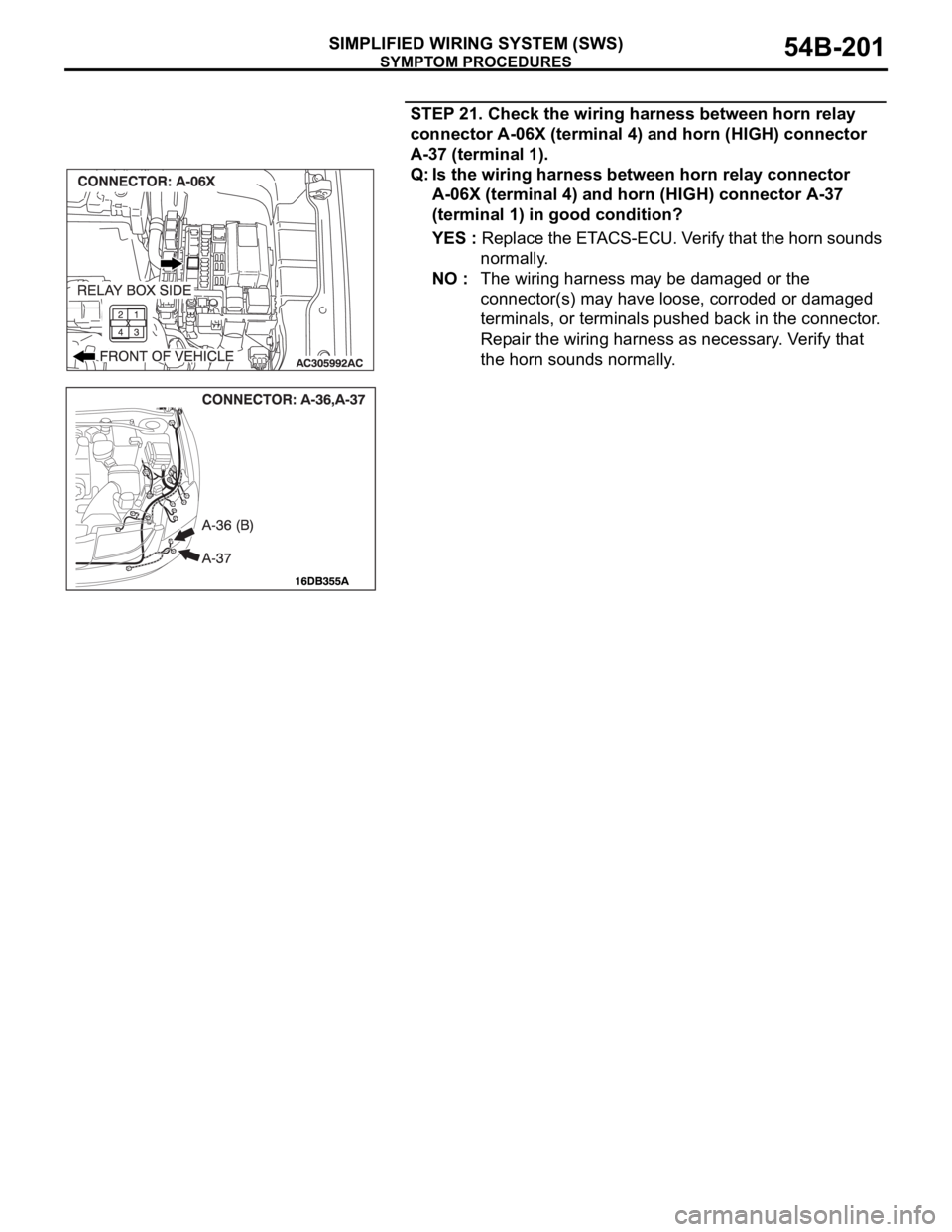

STEP 21. Check the wiring harness between horn relay

connector A-06X (terminal 4) and horn (HIGH) connector

A-37 (terminal 1).

Q: Is the wiring harness between horn relay connector

A-06X (terminal 4) and horn (HIGH) connector A-37

(terminal 1) in good condition?

YES : Replace the ETACS-ECU. Verify that the horn sounds

normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the horn sounds normally.

Page 224 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-224

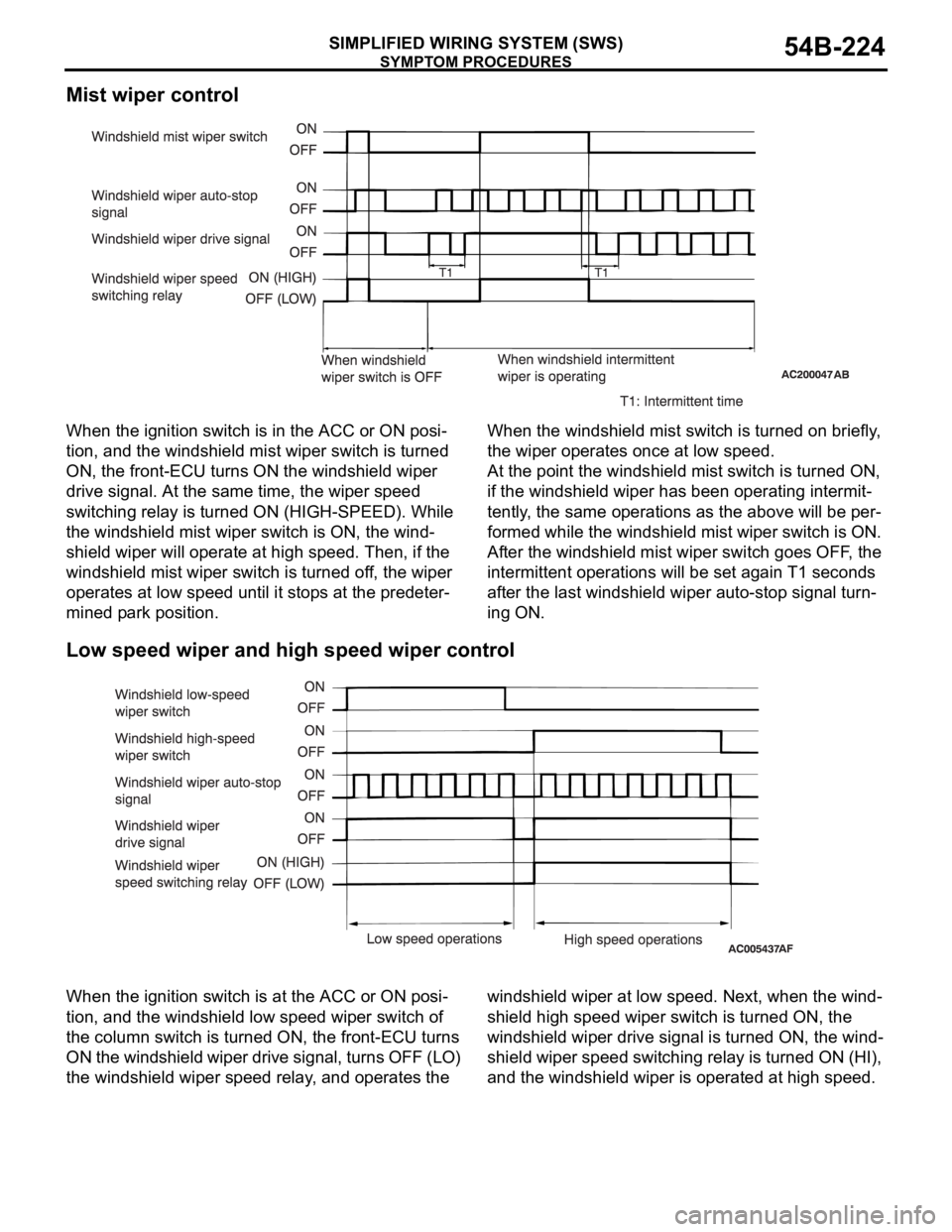

Mist wiper control

When the ignition switch is in the ACC or ON posi-

tion, and the windshield mist wiper switch is turned

ON, the front-ECU turns ON the windshield wiper

drive signal. At the same time, the wiper speed

switching relay is turned ON (HIGH-SPEED). While

the windshield mist wiper switch is ON, the wind-

shield wiper will operate at high speed. Then, if the

windshield mist wiper switch is turned off, the wiper

operates at low speed until it stops at the predeter-

mined park position.When the windshield mist switch is turned on briefly,

the wiper operates once at low speed.

At the point the windshield mist switch is turned ON,

if the windshield wiper has been operating intermit-

tently, the same operations as the above will be per-

formed while the windshield mist wiper switch is ON.

After the windshield mist wiper switch goes OFF, the

intermittent operations will be set again T1 seconds

after the last windshield wiper auto-stop signal turn-

ing ON.

.

Low speed wiper and high speed wiper control

When the ignition switch is at the ACC or ON posi-

tion, and the windshield low speed wiper switch of

the column switch is turned ON, the front-ECU turns

ON the windshield wiper drive signal, turns OFF (LO)

the windshield wiper speed relay, and operates the windshield wiper at low speed. Next, when the wind-

shield high speed wiper switch is turned ON, the

windshield wiper drive signal is turned ON, the wind-

shield wiper speed switching relay is turned ON (HI),

and the windshield wiper is operated at high speed.

.

Page 225 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-225

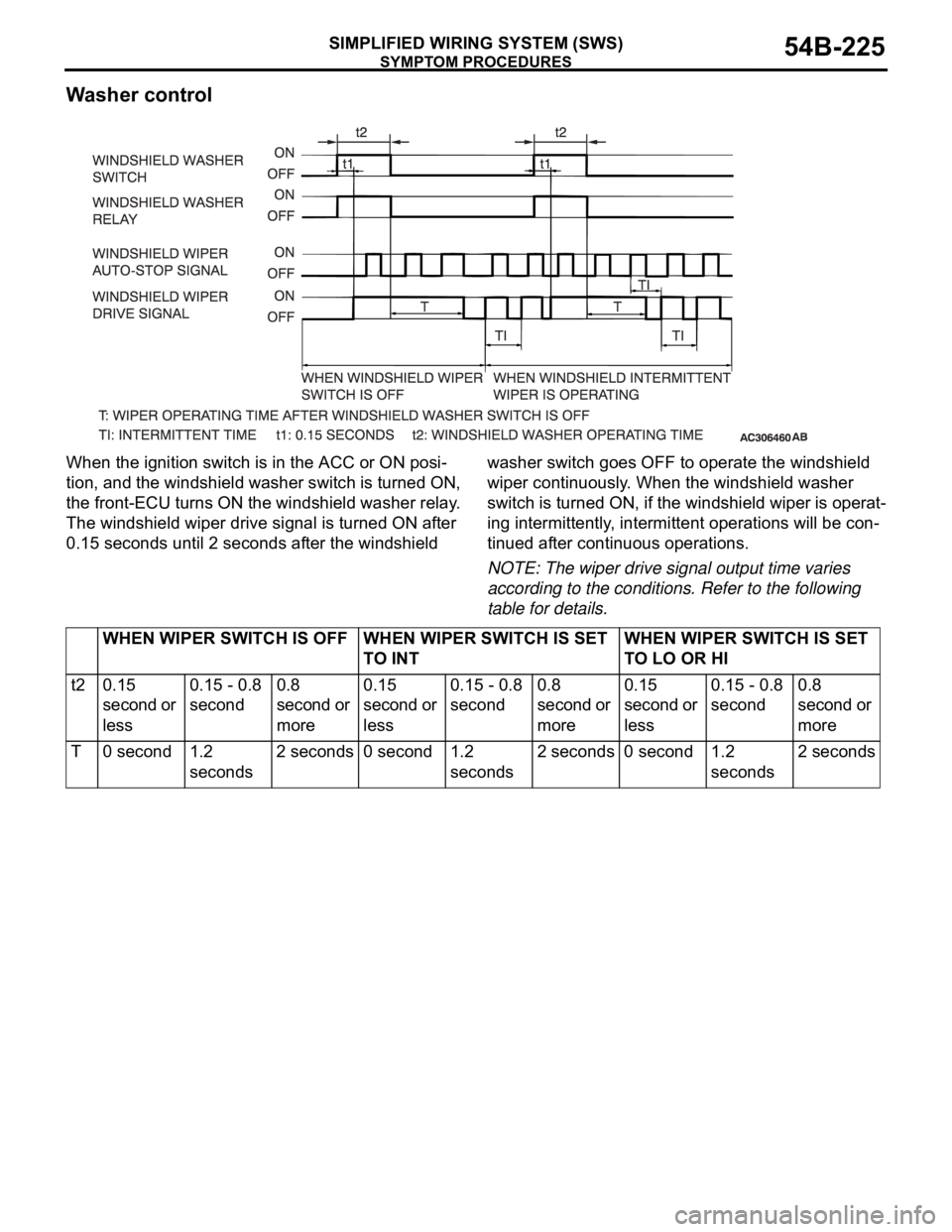

Washer control

When the ignition switch is in the ACC or ON posi-

tion, and the windshield washer switch is turned ON,

the front-ECU turns ON the windshield washer relay.

The windshield wiper drive signal is turned ON after

0.15 seconds until 2 seconds after the windshield washer switch goes OFF to operate the windshield

wiper continuously. When the windshield washer

switch is turned ON, if the windshield wiper is operat-

ing intermittently, intermittent operations will be con-

tinued after continuous operations.

NOTE: The wiper drive signal output time varies

according to the conditions. Refer to the following

table for details.

WHEN WIPER SWITCH IS OFF WHEN WIPER SWITCH IS SET

TO INTWHEN WIPER SWITCH IS SET

TO LO OR HI

t2 0.15

second or

less0.15 - 0.8

second0.8

second or

more0.15

second or

less0.15 - 0.8

second0.8

second or

more0.15

second or

less0.15 - 0.8

second0.8

second or

more

T0 second1.2

seconds2 seconds 0 second 1.2

seconds2 seconds 0 second 1.2

seconds2 seconds

Page 226 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-226

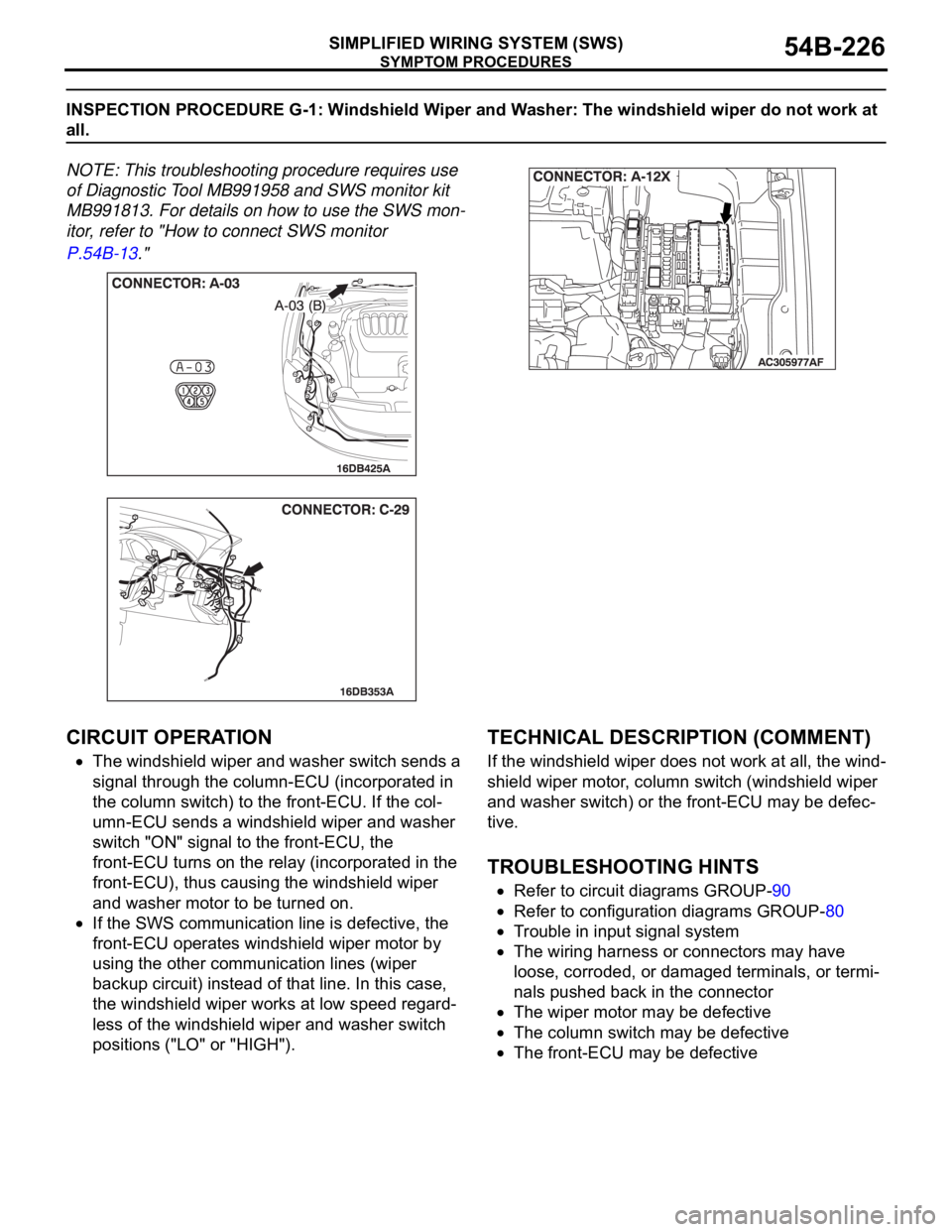

INSPECTION PROCEDURE G-1: Windshield Wiper and Washer: The windshield wiper do not work at

all.

NOTE: This troubleshooting procedure requires use

of Diagnostic Tool MB991958 and SWS monitor kit

MB991813. For details on how to use the SWS mon-

itor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The windshield wiper and washer switch sends a

signal through the column-ECU (incorporated in

the column switch) to the front-ECU. If the col-

umn-ECU sends a windshield wiper and washer

switch "ON" signal to the front-ECU, the

front-ECU turns on the relay (incorporated in the

front-ECU), thus causing the windshield wiper

and washer motor to be turned on.

If the SWS communication line is defective, the

front-ECU operates windshield wiper motor by

using the other communication lines (wiper

backup circuit) instead of that line. In this case,

the windshield wiper works at low speed regard-

less of the windshield wiper and washer switch

positions ("LO" or "HIGH").

.

TECHNICAL DESCRIPTION (COMMENT)

If the windshield wiper does not work at all, the wind-

shield wiper motor, column switch (windshield wiper

and washer switch) or the front-ECU may be defec-

tive.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The wiper motor may be defective

The column switch may be defective

The front-ECU may be defective

Page 232 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-232

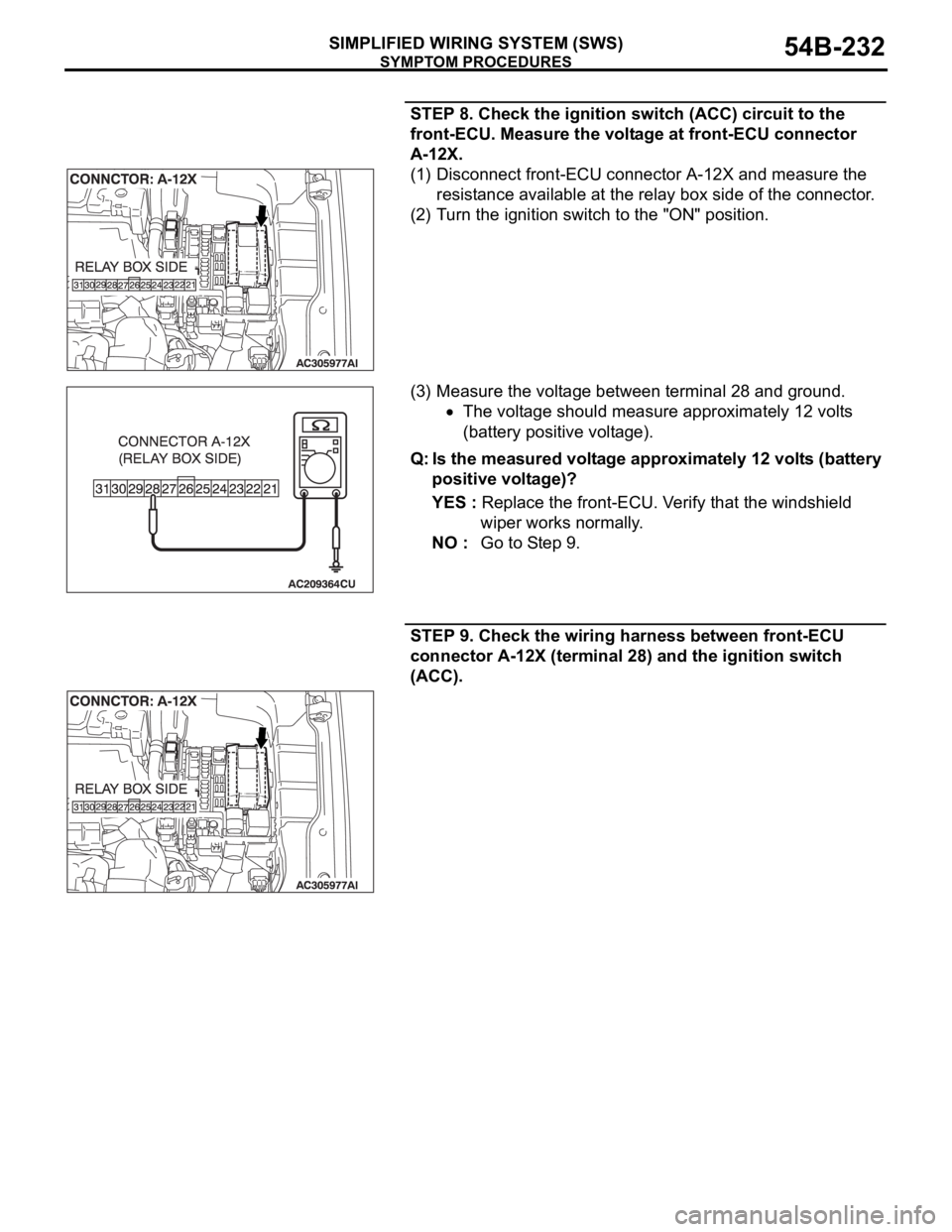

STEP 8. Check the ignition switch (ACC) circuit to the

front-ECU. Measure the voltage at front-ECU connector

A-12X.

(1) Disconnect front-ECU connector A-12X and measure the

resistance available at the relay box side of the connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 28 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Replace the front-ECU. Verify that the windshield

wiper works normally.

NO : Go to Step 9.

STEP 9. Check the wiring harness between front-ECU

connector A-12X (terminal 28) and the ignition switch

(ACC).

Page 251 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-251

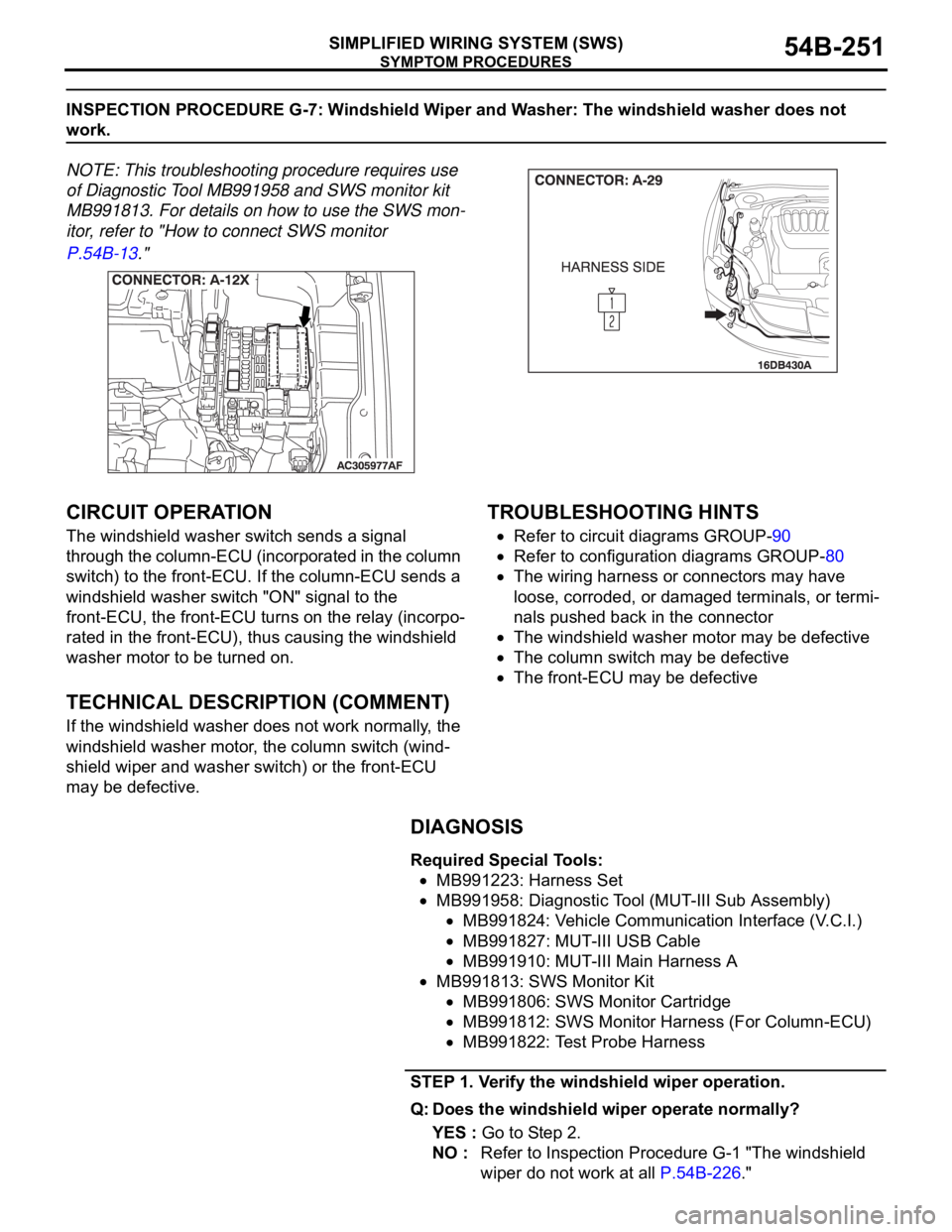

INSPECTION PROCEDURE G-7: Windshield Wiper and Washer: The windshield washer does not

work.

NOTE: This troubleshooting procedure requires use

of Diagnostic Tool MB991958 and SWS monitor kit

MB991813. For details on how to use the SWS mon-

itor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The windshield washer switch sends a signal

through the column-ECU (incorporated in the column

switch) to the front-ECU. If the column-ECU sends a

windshield washer switch "ON" signal to the

front-ECU, the front-ECU turns on the relay (incorpo-

rated in the front-ECU), thus causing the windshield

washer motor to be turned on.

.

TECHNICAL DESCRIPTION (COMMENT)

If the windshield washer does not work normally, the

windshield washer motor, the column switch (wind-

shield wiper and washer switch) or the front-ECU

may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The windshield washer motor may be defective

The column switch may be defective

The front-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness

STEP 1. Verify the windshield wiper operation.

Q: Does the windshield wiper operate normally?

YES : Go to Step 2.

NO : Refer to Inspection Procedure G-1 "The windshield

wiper do not work at all P.54B-226."

Page 258 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-258

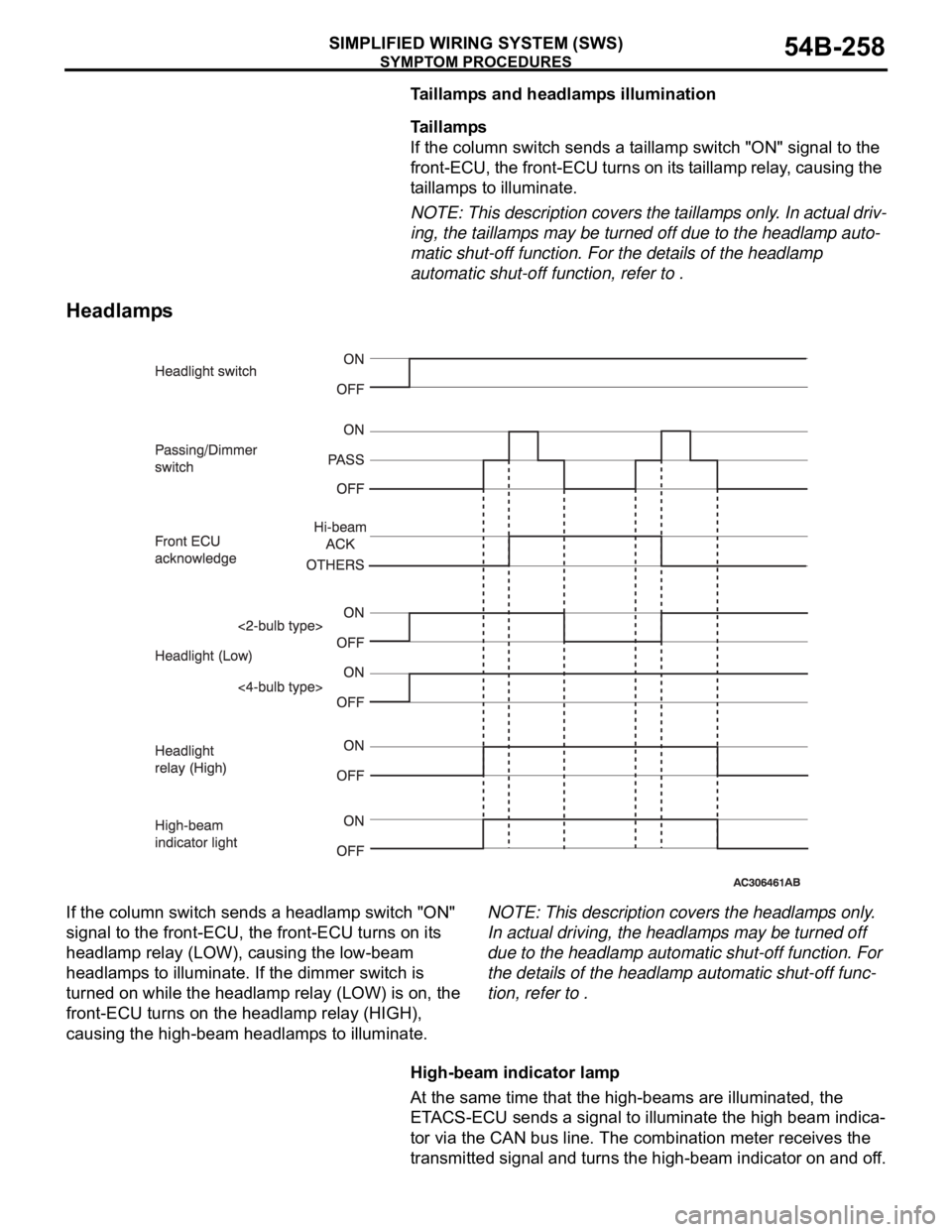

Taillamps and headlamps illumination

.

Taillamps

If the column switch sends a taillamp switch "ON" signal to the

front-ECU, the front-ECU turns on its taillamp relay, causing the

taillamps to illuminate.

NOTE: This description covers the taillamps only. In actual driv-

ing, the taillamps may be turned off due to the headlamp auto-

matic shut-off function. For the details of the headlamp

automatic shut-off function, refer to .

.

Headlamps

If the column switch sends a headlamp switch "ON"

signal to the front-ECU, the front-ECU turns on its

headlamp relay (LOW), causing the low-beam

headlamps to illuminate. If the dimmer switch is

turned on while the headlamp relay (LOW) is on, the

front-ECU turns on the headlamp relay (HIGH),

causing the high-beam headlamps to illuminate.NOTE: This description covers the headlamps only.

In actual driving, the headlamps may be turned off

due to the headlamp automatic shut-off function. For

the details of the headlamp automatic shut-off func-

tion, refer to .

High-beam indicator lamp

At the same time that the high-beams are illuminated, the

ETACS-ECU sends a signal to illuminate the high beam indica-

tor via the CAN bus line. The combination meter receives the

transmitted signal and turns the high-beam indicator on and off.

Page 260 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-260

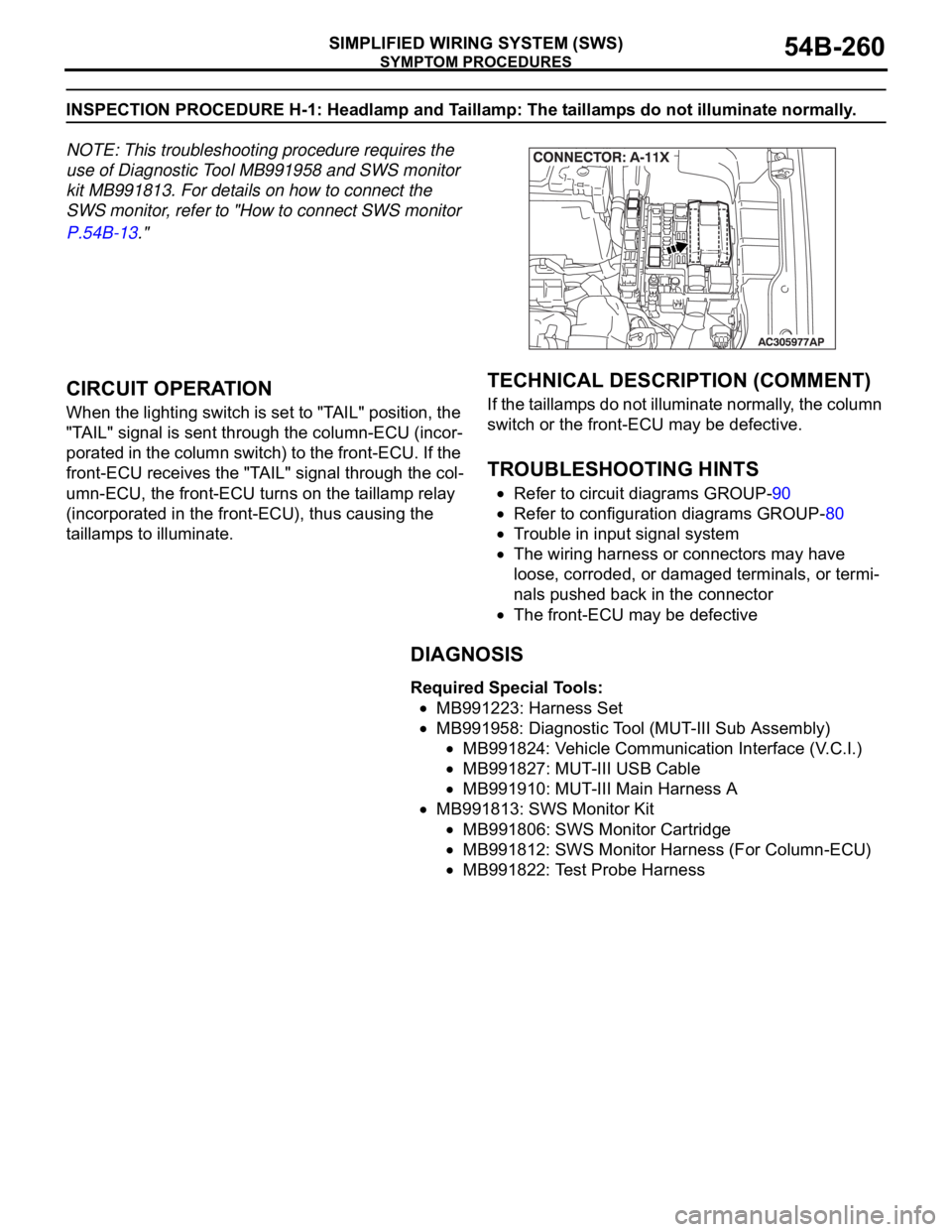

INSPECTION PROCEDURE H-1: Headlamp and Taillamp: The taillamps do not illuminate normally.

NOTE: This troubleshooting procedure requires the

use of Diagnostic Tool MB991958 and SWS monitor

kit MB991813. For details on how to connect the

SWS monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

When the lighting switch is set to "TAIL" position, the

"TAIL" signal is sent through the column-ECU (incor-

porated in the column switch) to the front-ECU. If the

front-ECU receives the "TAIL" signal through the col-

umn-ECU, the front-ECU turns on the taillamp relay

(incorporated in the front-ECU), thus causing the

taillamps to illuminate.

.

TECHNICAL DESCRIPTION (COMMENT)

If the taillamps do not illuminate normally, the column

switch or the front-ECU may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Trouble in input signal system

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The front-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness