relay MITSUBISHI 380 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 129 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-129

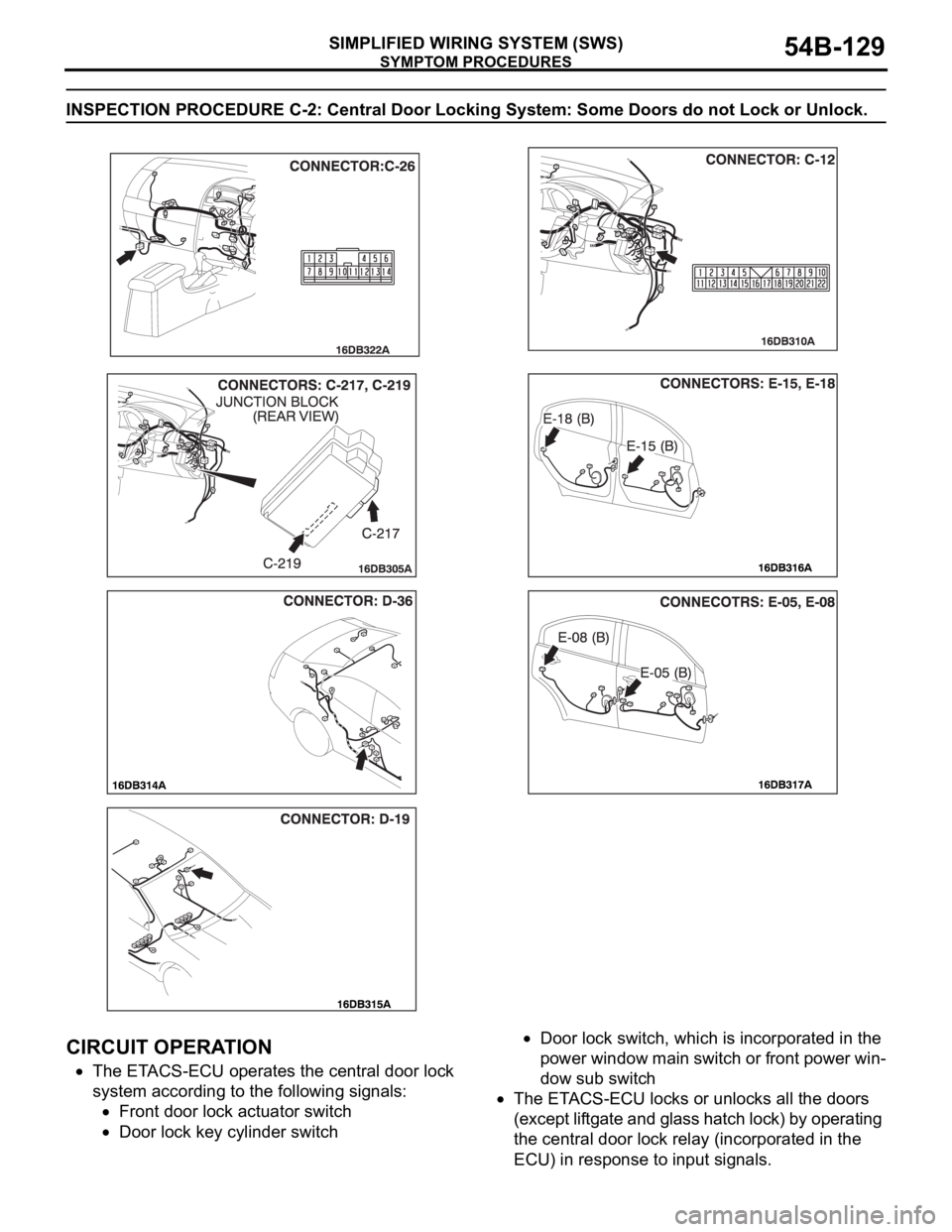

INSPECTION PROCEDURE C-2: Central Door Locking System: Some Doors do not Lock or Unlock.

.

CIRCUIT OPERATION

The ETACS-ECU operates the central door lock

system according to the following signals:

Front door lock actuator switch

Door lock key cylinder switch

Door lock switch, which is incorporated in the

power window main switch or front power win-

dow sub switch

The ETACS-ECU locks or unlocks all the doors

(except liftgate and glass hatch lock) by operating

the central door lock relay (incorporated in the

ECU) in response to input signals.

Page 150 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-150

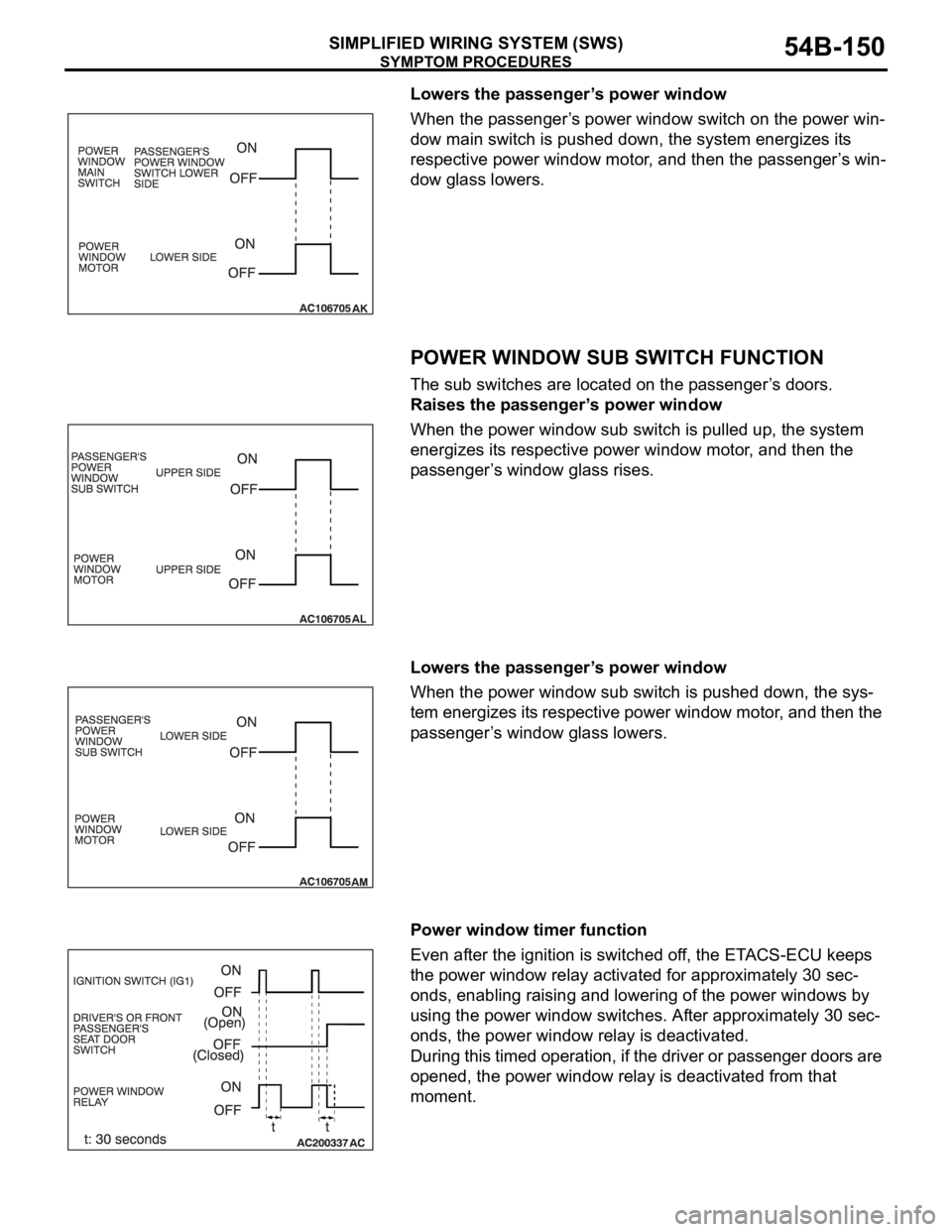

Lowers the passenger’s power window

When the passenger’s power window switch on the power win-

dow main switch is pushed down, the system energizes its

respective power window motor, and then the passenger’s win-

dow glass lowers.

POWER WINDOW SUB SWITCH FUNCTION

The sub switches are located on the passenger’s doors.

Raises the passenger’s power window

When the power window sub switch is pulled up, the system

energizes its respective power window motor, and then the

passenger’s window glass rises.

Lowers the passenger’s power window

When the power window sub switch is pushed down, the sys-

tem energizes its respective power window motor, and then the

passenger’s window glass lowers.

Power window timer function

Even after the ignition is switched off, the ETACS-ECU keeps

the power window relay activated for approximately 30 sec-

onds, enabling raising and lowering of the power windows by

using the power window switches. After approximately 30 sec-

onds, the power window relay is deactivated.

During this timed operation, if the driver or passenger doors are

opened, the power window relay is deactivated from that

moment.

Page 151 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-151

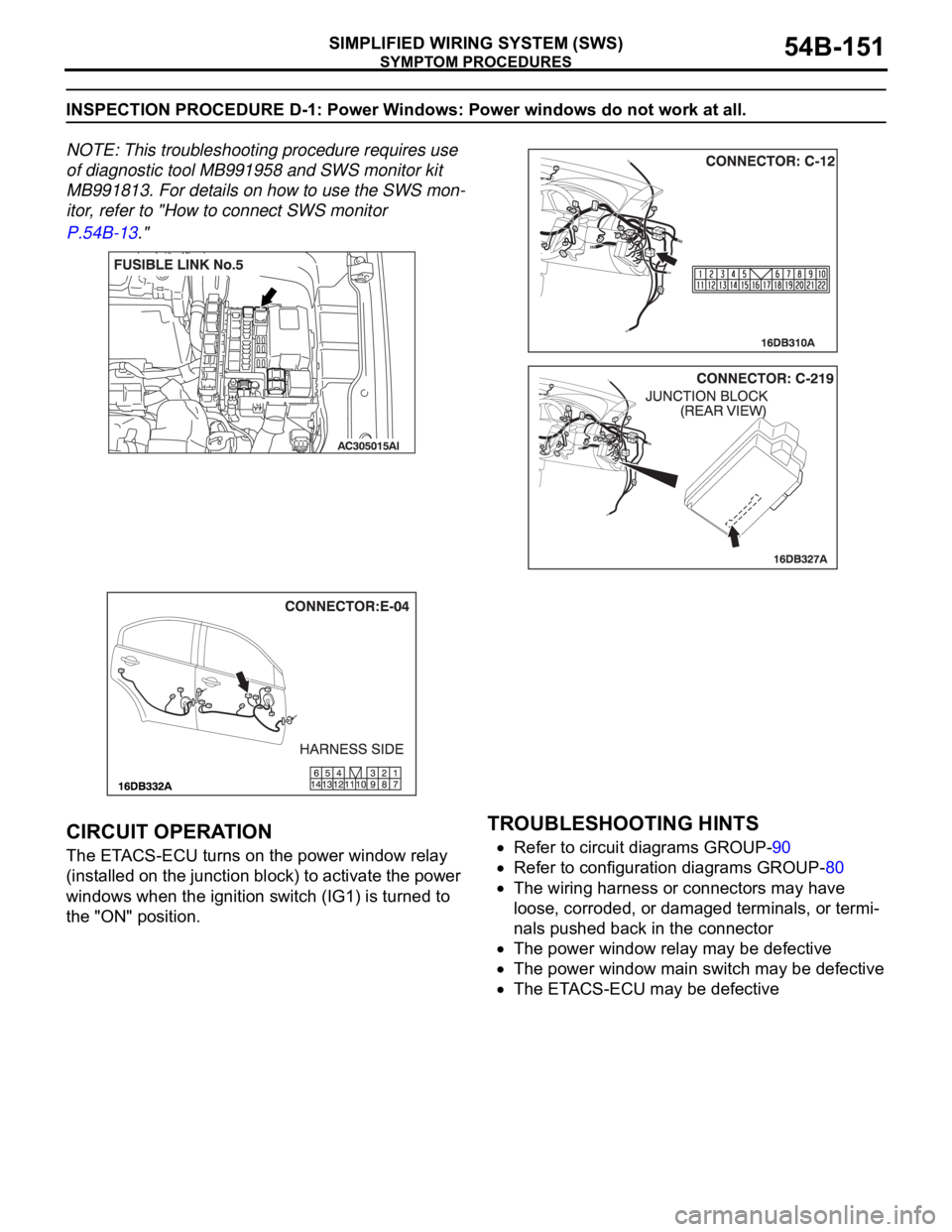

INSPECTION PROCEDURE D-1: Power Windows: Power windows do not work at all.

NOTE: This troubleshooting procedure requires use

of diagnostic tool MB991958 and SWS monitor kit

MB991813. For details on how to use the SWS mon-

itor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The ETACS-ECU turns on the power window relay

(installed on the junction block) to activate the power

windows when the ignition switch (IG1) is turned to

the "ON" position.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The power window relay may be defective

The power window main switch may be defective

The ETACS-ECU may be defective

Page 153 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-153

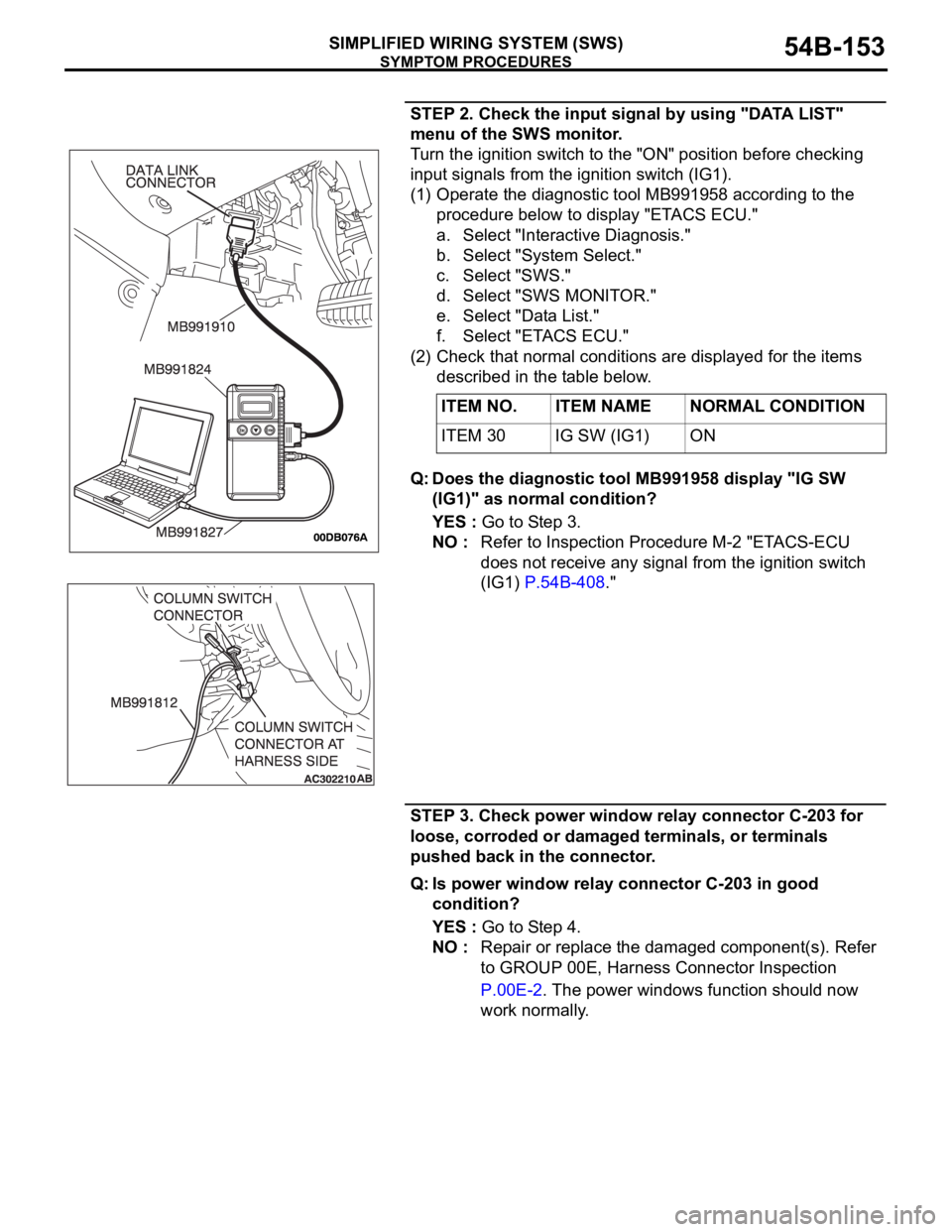

STEP 2. Check the input signal by using "DATA LIST"

menu of the SWS monitor.

Turn the ignition switch to the "ON" position before checking

input signals from the ignition switch (IG1).

(1) Operate the diagnostic tool MB991958 according to the

procedure below to display "ETACS ECU."

a. Select "Interactive Diagnosis."

b. Select "System Select."

c. Select "SWS."

d. Select "SWS MONITOR."

e. Select "Data List."

f. Select "ETACS ECU."

(2) Check that normal conditions are displayed for the items

described in the table below.

Q: Does the diagnostic tool MB991958 display "IG SW

(IG1)" as normal condition?

YES : Go to Step 3.

NO : Refer to Inspection Procedure M-2 "ETACS-ECU

does not receive any signal from the ignition switch

(IG1) P.54B-408."

STEP 3. Check power window relay connector C-203 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power window relay connector C-203 in good

condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The power windows function should now

work normally. ITEM NO. ITEM NAME NORMAL CONDITION

ITEM 30 IG SW (IG1) ON

Page 154 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-154

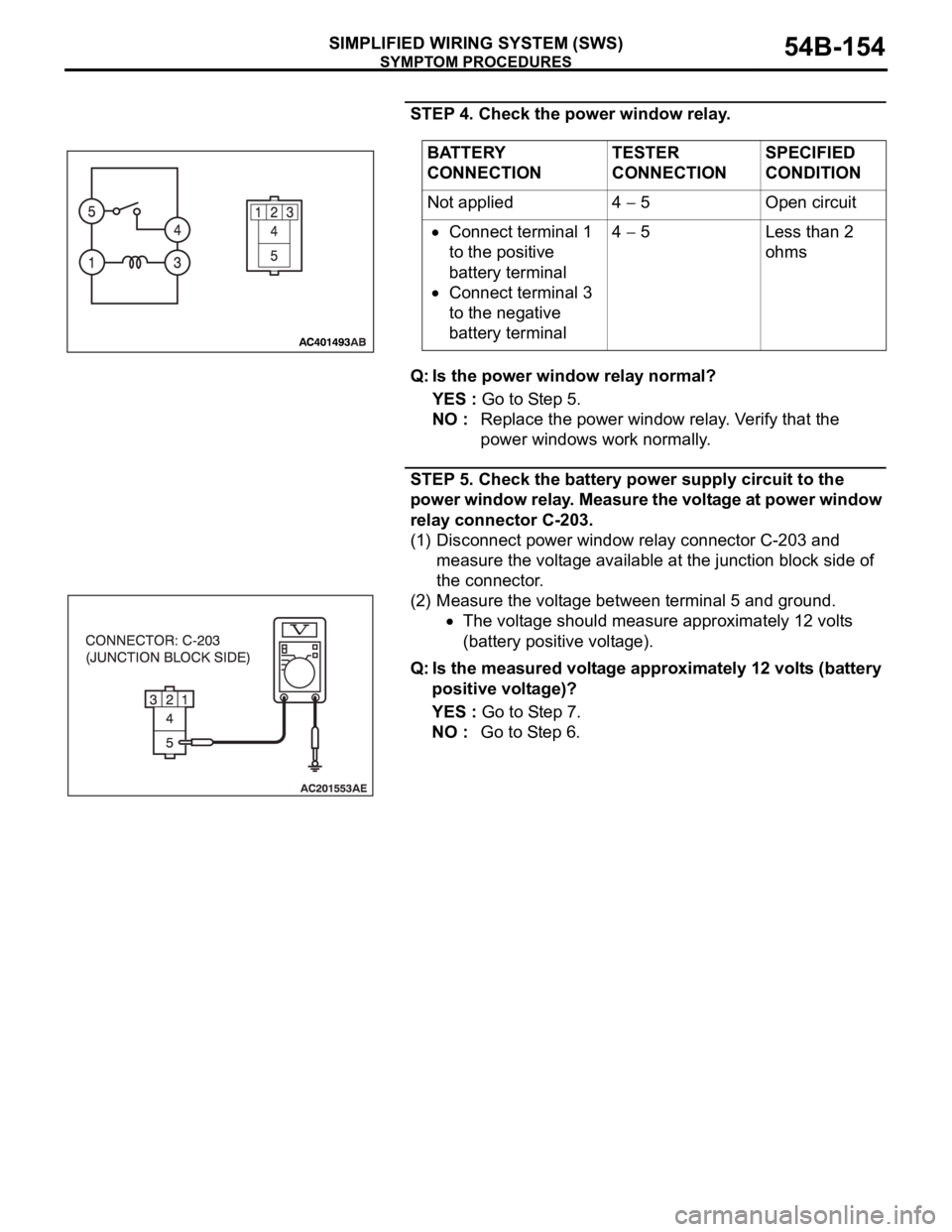

STEP 4. Check the power window relay.

Q: Is the power window relay normal?

YES : Go to Step 5.

NO : Replace the power window relay. Verify that the

power windows work normally.

STEP 5. Check the battery power supply circuit to the

power window relay. Measure the voltage at power window

relay connector C-203.

(1) Disconnect power window relay connector C-203 and

measure the voltage available at the junction block side of

the connector.

(2) Measure the voltage between terminal 5 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 7.

NO : Go to Step 6. BATTERY

CONNECTIONTESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect terminal 1

to the positive

battery terminal

Connect terminal 3

to the negative

battery terminal4

5 Less than 2

ohms

Page 155 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-155

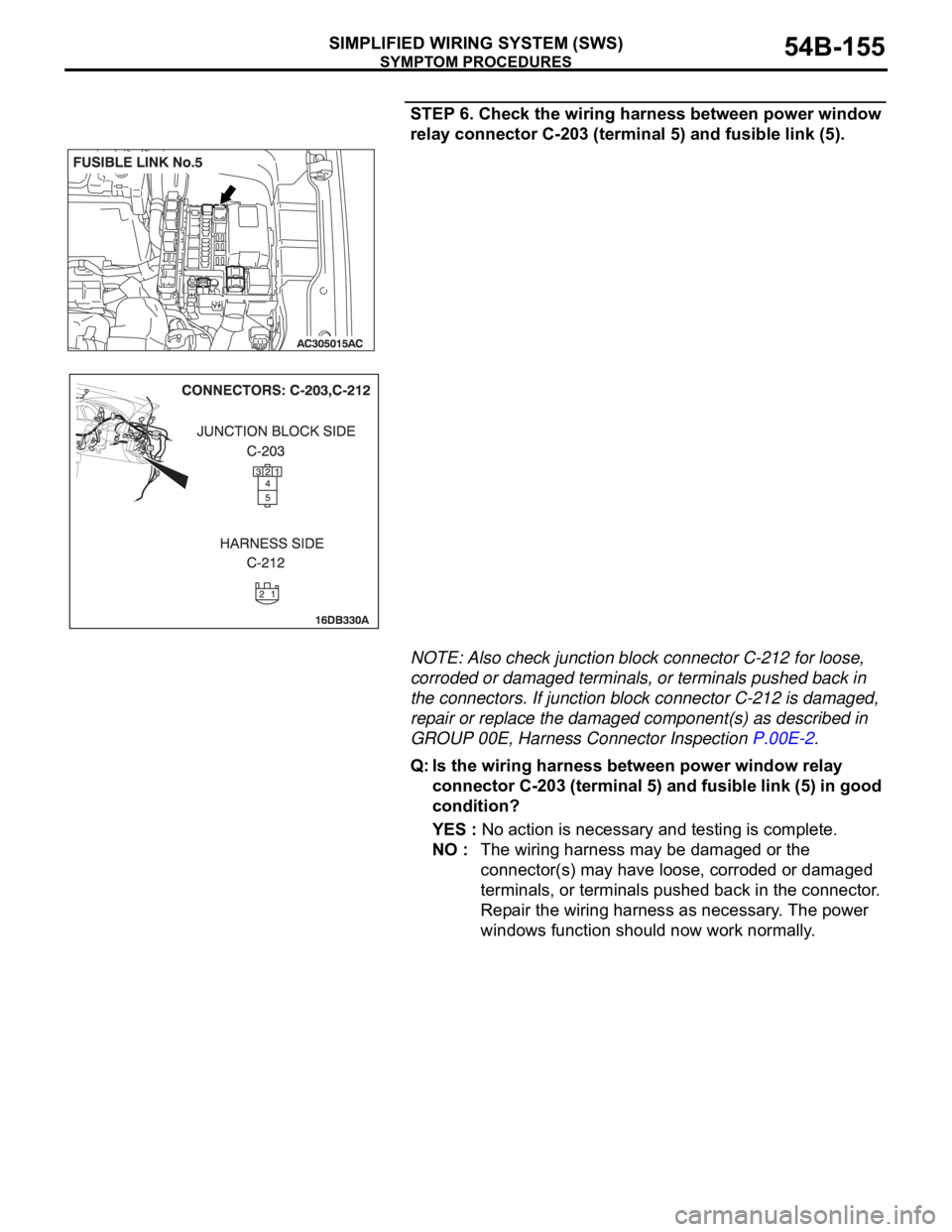

STEP 6. Check the wiring harness between power window

relay connector C-203 (terminal 5) and fusible link (5).

NOTE: Also check junction block connector C-212 for loose,

corroded or damaged terminals, or terminals pushed back in

the connectors. If junction block connector C-212 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 5) and fusible link (5) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The power

windows function should now work normally.

Page 156 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-156

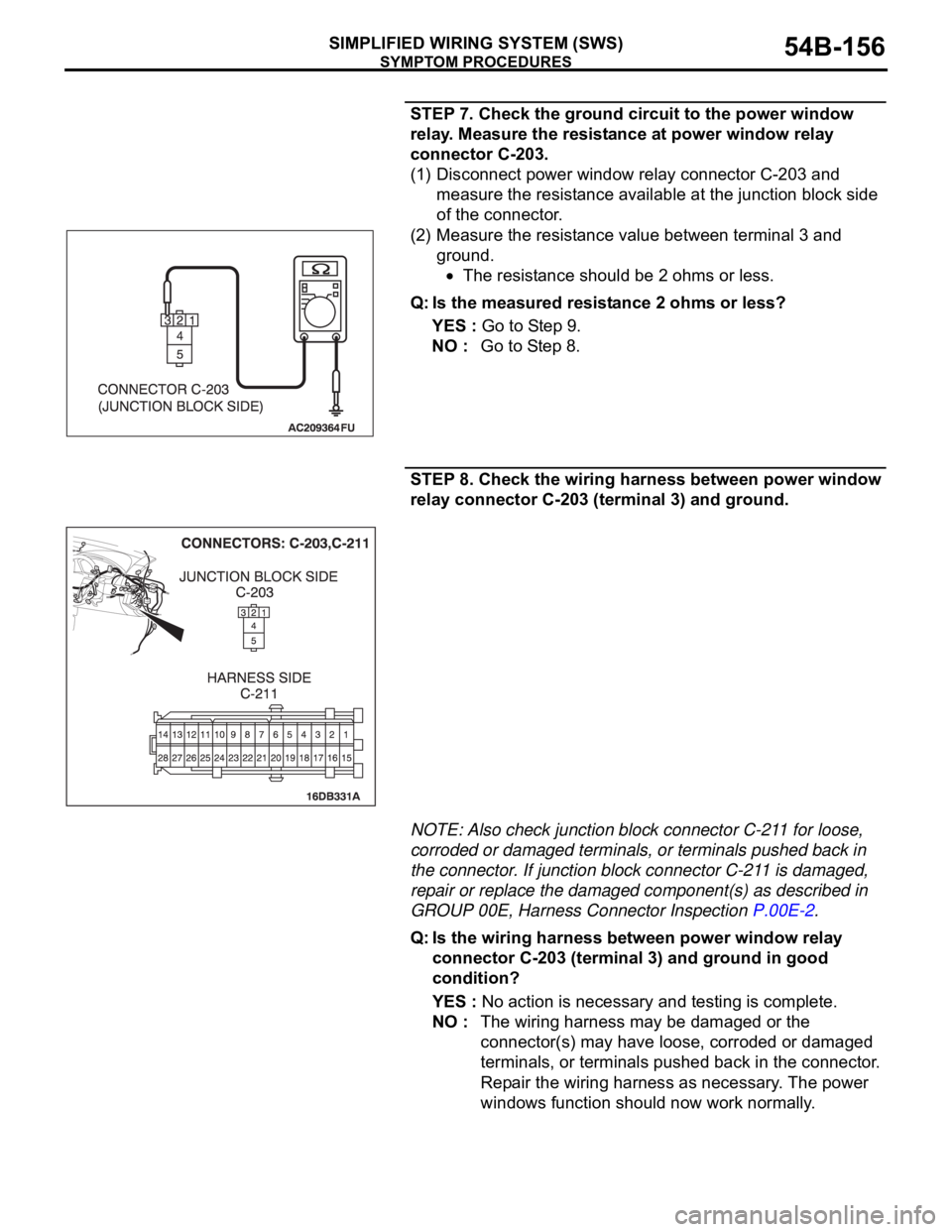

STEP 7. Check the ground circuit to the power window

relay. Measure the resistance at power window relay

connector C-203.

(1) Disconnect power window relay connector C-203 and

measure the resistance available at the junction block side

of the connector.

(2) Measure the resistance value between terminal 3 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 9.

NO : Go to Step 8.

STEP 8. Check the wiring harness between power window

relay connector C-203 (terminal 3) and ground.

NOTE: Also check junction block connector C-211 for loose,

corroded or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-211 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 3) and ground in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The power

windows function should now work normally.

Page 160 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-160

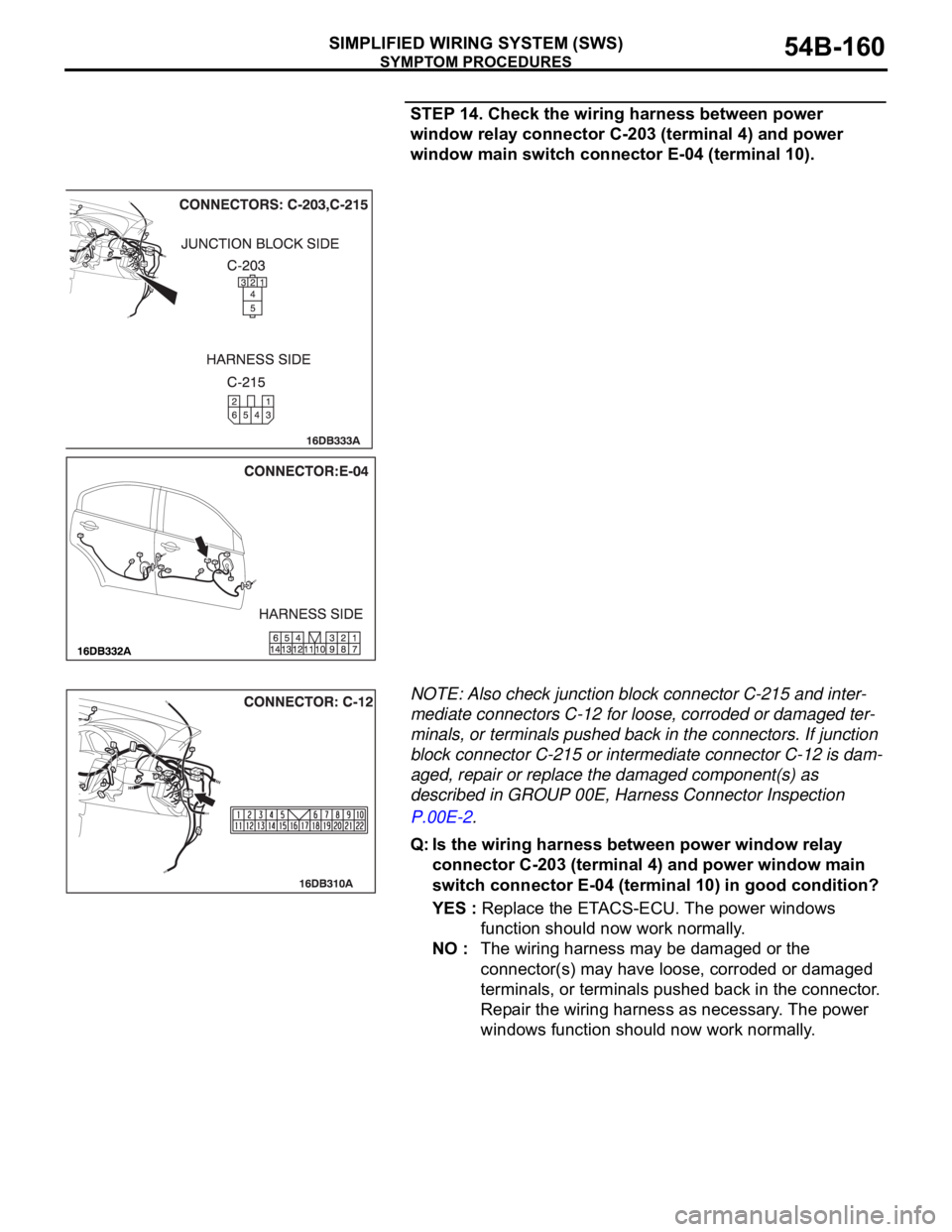

STEP 14. Check the wiring harness between power

window relay connector C-203 (terminal 4) and power

window main switch connector E-04 (terminal 10).

NOTE: Also check junction block connector C-215 and inter-

mediate connectors C-12 for loose, corroded or damaged ter-

minals, or terminals pushed back in the connectors. If junction

block connector C-215 or intermediate connector C-12 is dam-

aged, repair or replace the damaged component(s) as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and power window main

switch connector E-04 (terminal 10) in good condition?

YES : Replace the ETACS-ECU. The power windows

function should now work normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The power

windows function should now work normally.

Page 172 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-172

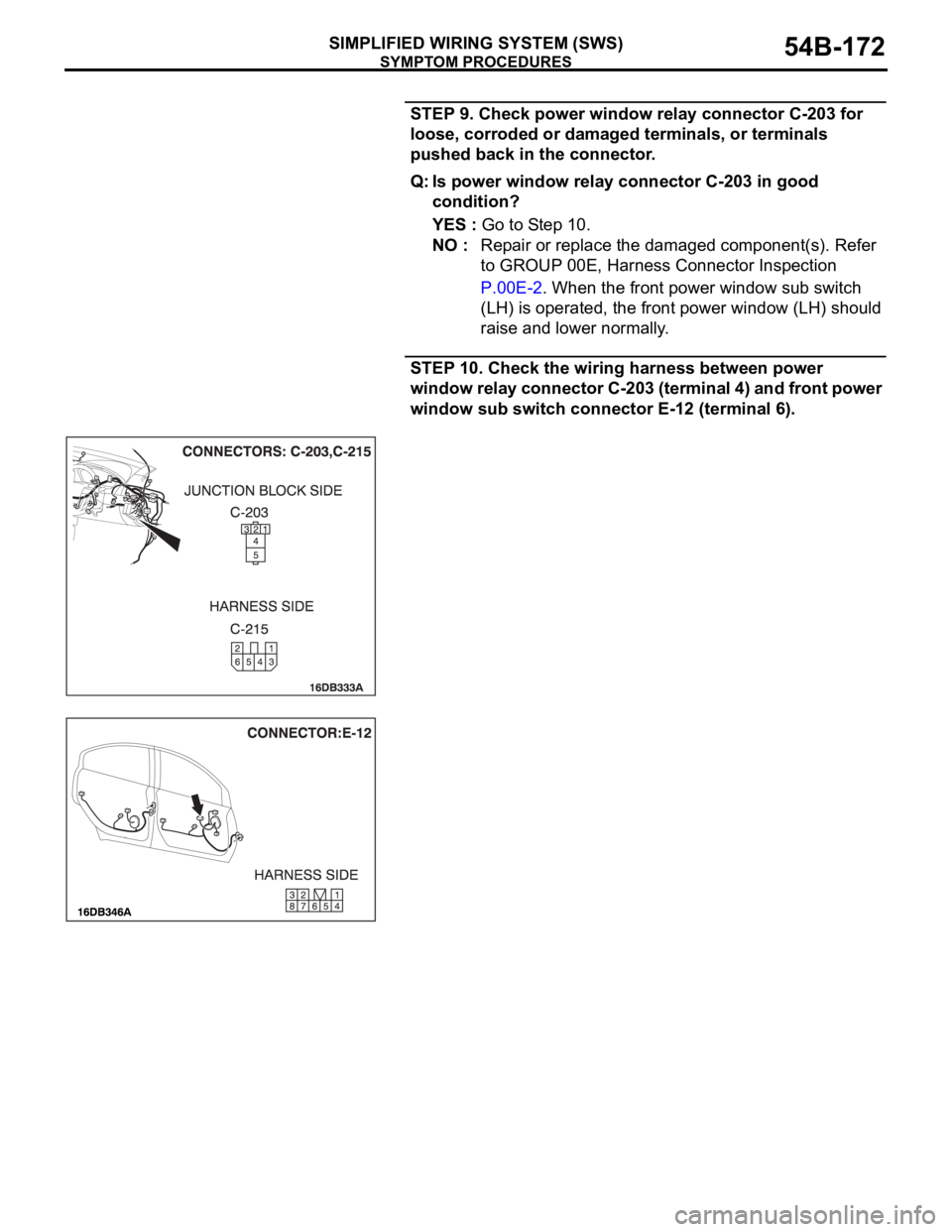

STEP 9. Check power window relay connector C-203 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is power window relay connector C-203 in good

condition?

YES : Go to Step 10.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. When the front power window sub switch

(LH) is operated, the front power window (LH) should

raise and lower normally.

STEP 10. Check the wiring harness between power

window relay connector C-203 (terminal 4) and front power

window sub switch connector E-12 (terminal 6).

Page 173 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-173

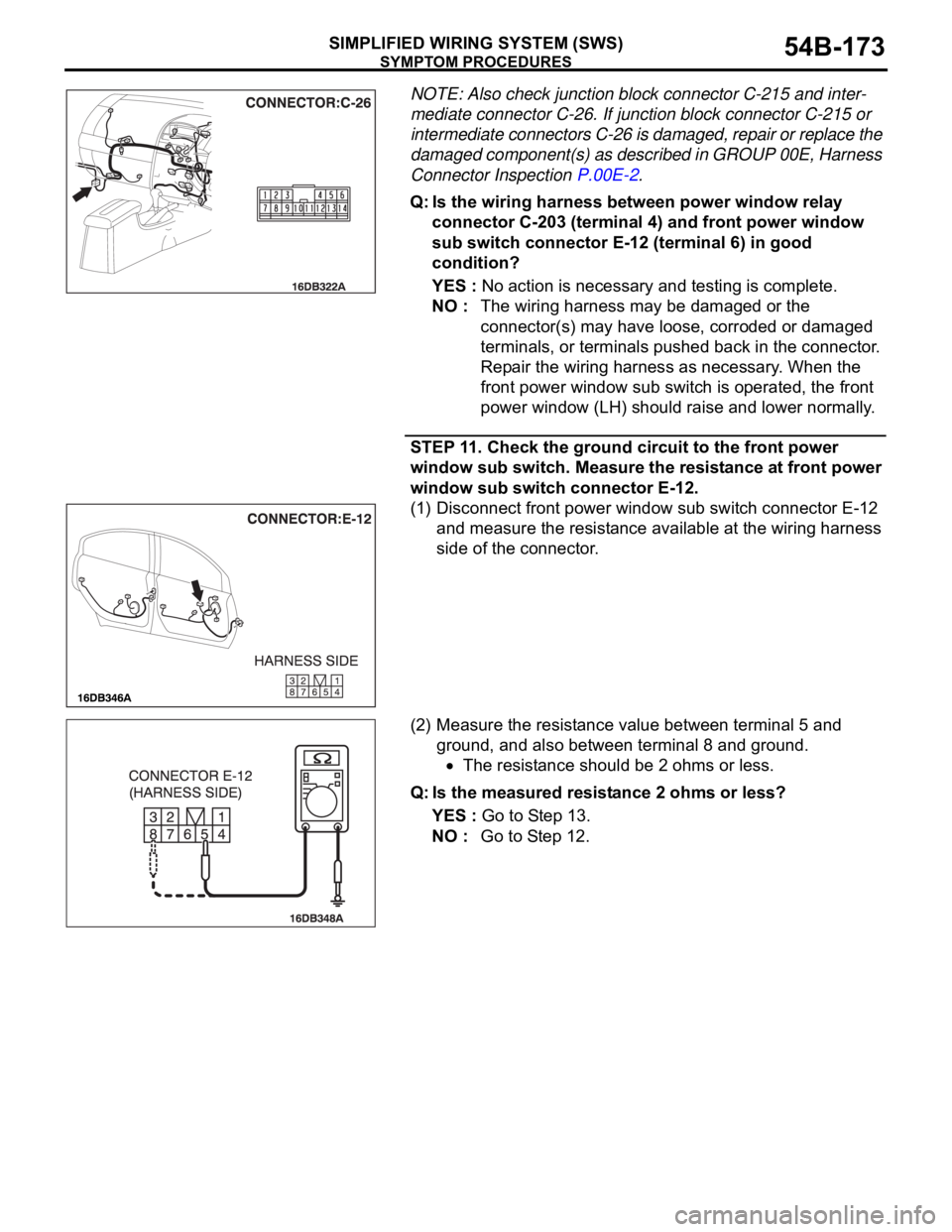

NOTE: Also check junction block connector C-215 and inter-

mediate connector C-26. If junction block connector C-215 or

intermediate connectors C-26 is damaged, repair or replace the

damaged component(s) as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between power window relay

connector C-203 (terminal 4) and front power window

sub switch connector E-12 (terminal 6) in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. When the

front power window sub switch is operated, the front

power window (LH) should raise and lower normally.

STEP 11. Check the ground circuit to the front power

window sub switch. Measure the resistance at front power

window sub switch connector E-12.

(1) Disconnect front power window sub switch connector E-12

and measure the resistance available at the wiring harness

side of the connector.

(2) Measure the resistance value between terminal 5 and

ground, and also between terminal 8 and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 13.

NO : Go to Step 12.