ECU MITSUBISHI COLT 2006 Service Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 211 of 364

TECHNICAL FEATURES

GENERAL00-26

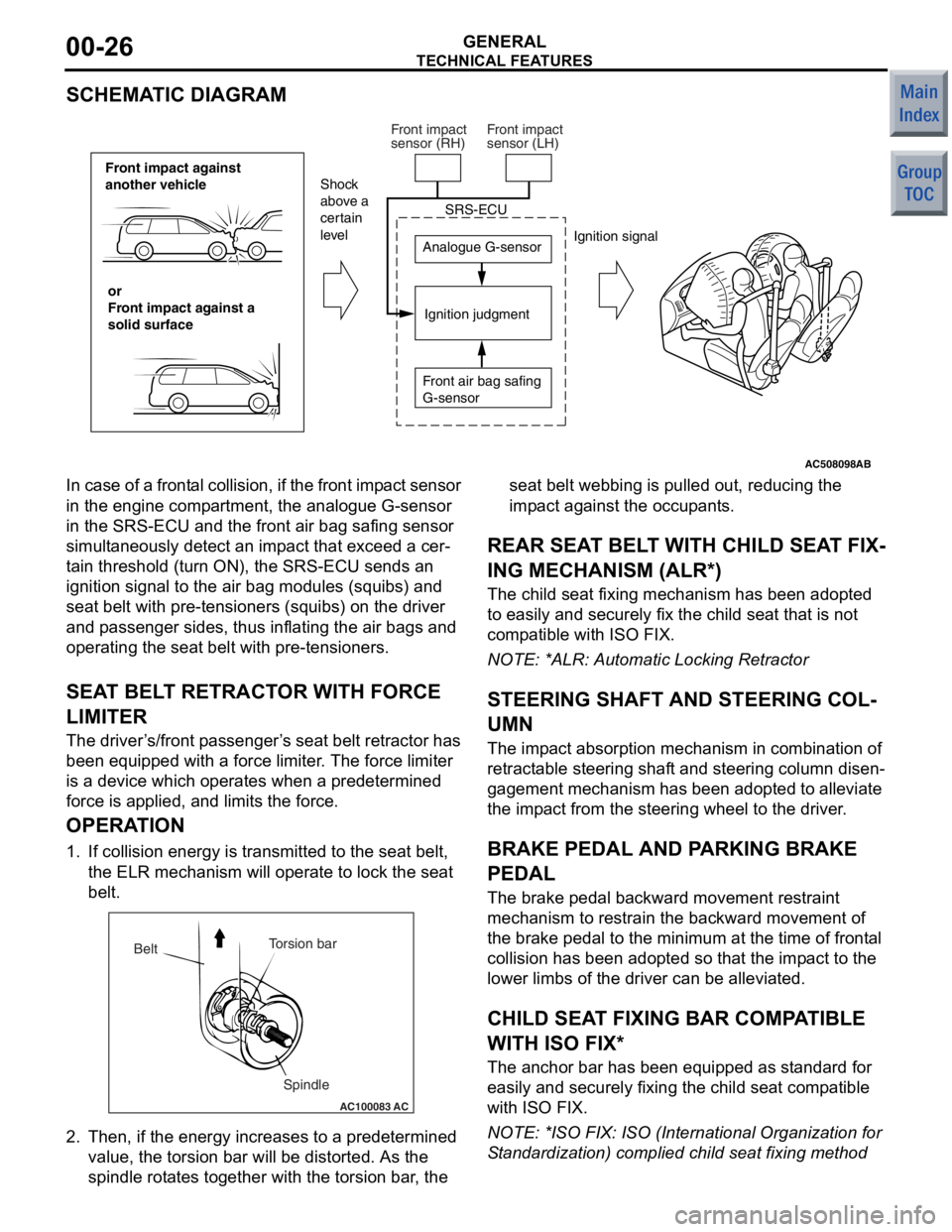

SCHEMATIC DIAGRAM

AC508098

Front impact against

another vehicleor

Front impact against a

solid surface Analogue G-sensor

Ignition judgment

Shock

above a

certain

level

Ignition signal

SRS-ECU

Front air bag safing

G-sensor

Front impact

sensor (RH)

Front impact

sensor (LH)

AB

In case of a

frontal collision, if the front imp act sensor

in the engine comp artment, the analogue G-sensor

in the SRS-ECU and t he front air bag safing sensor

simult aneously de tect an imp act th at excee d a cer

-

ta in threshold (turn ON), the SRS-ECU sen ds an

ignition signal to the air bag modules (squ ibs) and

seat belt with pre-te nsioners (squibs) on the driver

and p asseng er sides, thus inflating the air bag s and

operating the seat belt with pre -tensioner s.

SEAT BEL T RETRACT OR WITH FORCE

LIMITE R

The driver ’s /front p asseng er’s seat belt retractor has

been e quipped with a force limit er. The force limiter

is a device which operat es when a predetermined

force is applied, an d limits the for ce.

OPERA TION

1. If collision energy is transmit ted to the seat belt,

th e ELR mechanism will oper ate to lock the seat

be lt.

AC100083

Torsion bar

Spindle

Belt

AC

2.

Then, if the en ergy increase s to a prede termined

value , the to rsion bar will b e distorted . As th e

spind le rot ate s tog ether with the t orsion bar , the seat b

elt webb ing is p ulle d out, reducing th e

imp act against t he occupants.

REAR SEA T BELT WITH CHILD SEA T FIX-

ING MECHANISM (ALR*)

The child seat fixing mechanism h as b een ad opted

to easily and securely fix the child seat that is not

comp atible with ISO FIX.

NO TE: *ALR: Automatic Lockin g Retractor

STEERING SHAFT AND STEERING COL-

UMN

The impact ab sorption mech anism in combin ation of

retract able steerin g shaft and steering co lumn disen

-

gagement mecha nism has been ad opted t o alle viate

the imp act from th e steering wheel to the d rive r.

BRAKE PEDAL AND PA RKING BRAKE

PEDAL

The bra ke pe dal b ackward mo vement restraint

mechanism to restrain the backward movement of

the brake p edal to the minimum at the time o f f ront al

collision h as b een ad opted so that the impact to th e

lower limb s of the driver can be alleviated.

CHILD SEAT FIXING BAR COMP ATIBLE

WITH ISO FIX*

The an chor bar has been equipped a s st andard fo r

easily and secu rely fixing the child seat comp atible

with ISO FIX.

NO TE: *ISO F IX: ISO (In ternational Orga nization for

S tand ardizatio n) complied child se at fixing method

Page 212 of 364

TECHNICAL FEATURES

GENERAL00-27

POWER WINDOW WITH SAFETY MECHA-

NISM

The power window with safety mechanism has been

adopted to automatically roll down and stop the door

window glass as soon as the occurrence of jamming

is detected at the time of rolling up the door window

glass.

SUNROOF WITH SA FETY MECHANISM

The sunroof with safe ty mechanism has been

adopted so that the roof lid glass can move in the

reverse direction and stop when application of exter

-

nal force hinders the movement during the sliding to

close or tilt down operation.

TRIMS AND HEADLINING

The head impact absorption structure has been

adopted for the pillar trim, quarter trim, and headlin

-

ing so that impact towards the head of a passenger

can be reduced.

OTHER SAFETY FEATURES

•3-point ELR seat belts

•Child-protection rear door locks

•Front fog lamps

EQUIPMENTSM2000026000221

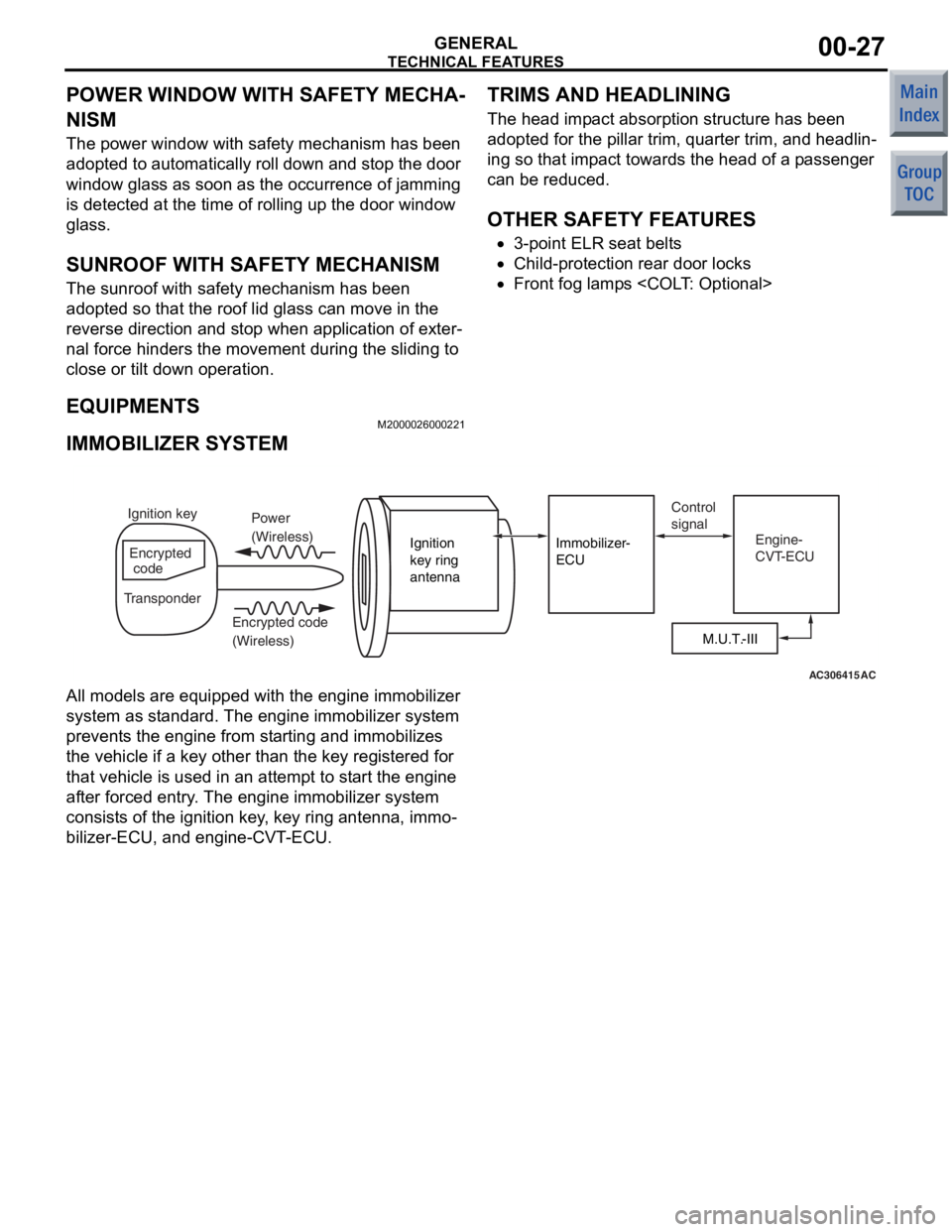

IMMOBILIZER SYSTEM

AC306415AC

M.U.T.-III

Ignition

key ring

antenna

Immobilizer-

ECU

Ignition key

Encrypted

code

Transponder Power

(Wireless)

Encrypted code

(Wireless) Control

signal

Engine-

CVT-ECU

All models are equipped with the e ngine immobilizer

system as st andard. The en gine immobilizer syst em

preve nts the engin e from starting and immobilizes

the vehicle if a key o ther tha n the key registered for

that vehicle is used in an attempt to start the e ngine

af te r forced entry . The en gine immobilizer syst em

consist s of the ignition key, key ring antenna, immo

-

bilizer-ECU, and engine-CVT-ECU.

Page 231 of 364

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M2140000100638

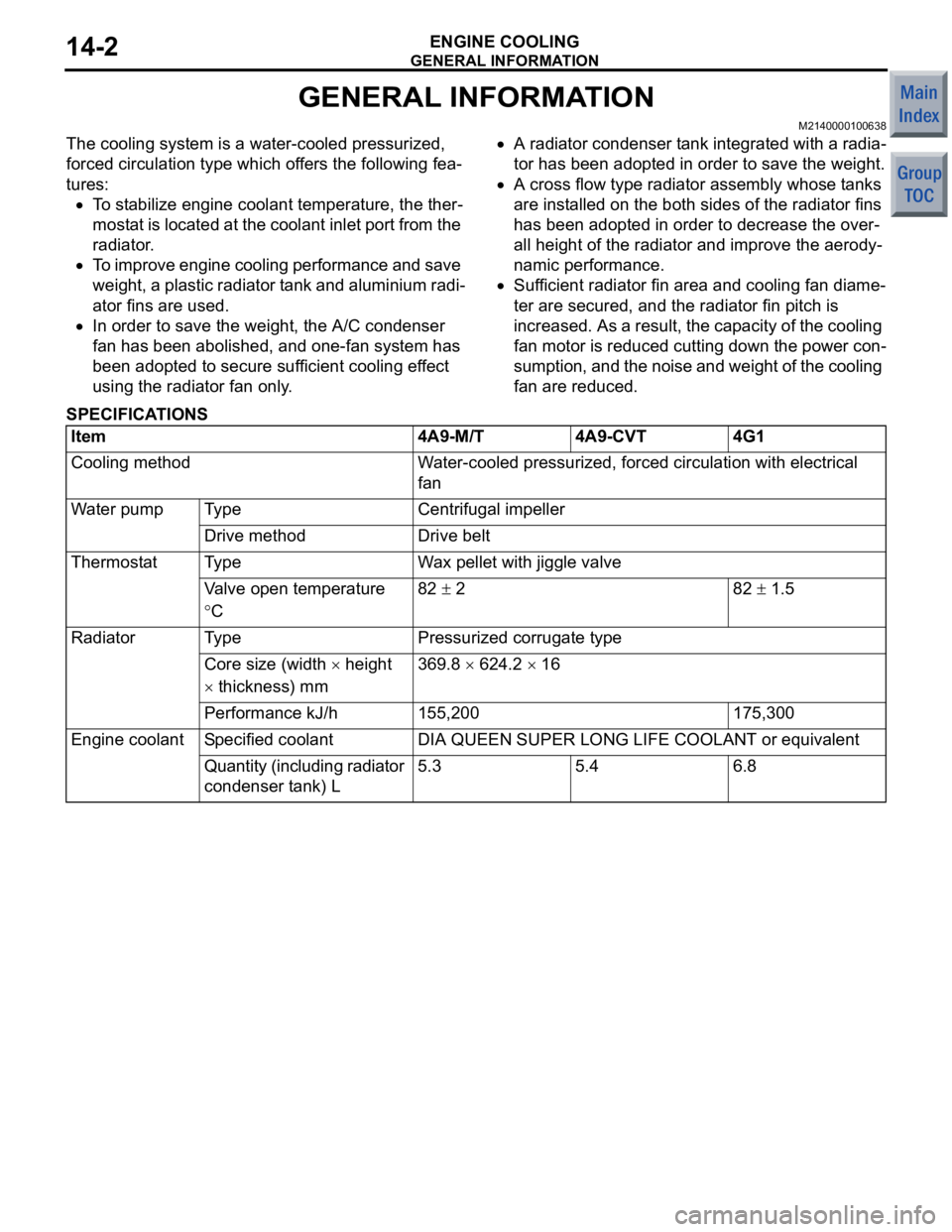

The cooling system is a water-cooled pressurized,

forced circulation type which offers the following fea

-

tures:

•To stabilize engine coolant temperature, the ther-

mostat is located at the coolant inlet port from the

radiator.

•To improve engine cooling performance and save

weight, a plastic radiator tank and aluminium radi

-

ator fins are used.

•In order to save the weight, the A/C condenser

fan has been abolished, and one-fan system has

been adopted to secure sufficient cooling effect

using the radiator fan only.

•A radiator condenser tank integrated with a radia-

tor has been adopted in order to save the weight.

•A cross flow type radiator assembly whose tanks

are installed on the both sides of the radiator fins

has been adopted in order to decrease the over

-

all height of the radiator and improve the aerody-

namic performance.

•Sufficient radiator fin area and cooling fan diame-

ter are secured, and the radiator fin pitch is

increased. As a result, the capacity of the cooling

fan motor is reduced cutting down the power con

-

sumption, and the noise and weight of the cooling

fan are reduced.

SPECIFICATIONS

Item4A9-M/T4A9-CVT4G1

Cooling methodWater-cooled pressurized, forced circulation with electrical

fan

Water pumpTy p eCentrifugal impeller

Drive methodDrive belt

ThermostatTy p eWax pellet with jiggle valve

Valve open temperature

°C

82 ± 282 ± 1.5

RadiatorTy p ePressurized corrugate type

Core size (width × height

× thickness) mm

369.8 × 624.2 × 16

Performance kJ/h155,200175,300

Engine coolantSpecified coolantDIA QUEEN SUPER LONG LIFE COOLANT or equivalent

Quantity (including radiator

condenser tank) L5.35.46.8

Page 234 of 364

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-2

CONSTRUCTION DESCRIPTION . . .37-5

STEERING WHEEL . . . . . . . . . . . . . . . . . . 37-5

STEERING SHAFT AND COLUMN . . . . . . 37-5

ELECTRICAL POWER STEERING . .37-7

GENERAL INFORMATION . . . . . . . . . . . . . 37-7

STEERING GEAR . . . . . . . . . . . . . . . . . . . . 37-9

MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-9

ELECTRIC POWER STEERING-ECU . . . . 37-10

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . 37-11

Page 236 of 364

GENERAL INFORMATION

POWER STEERING37-3

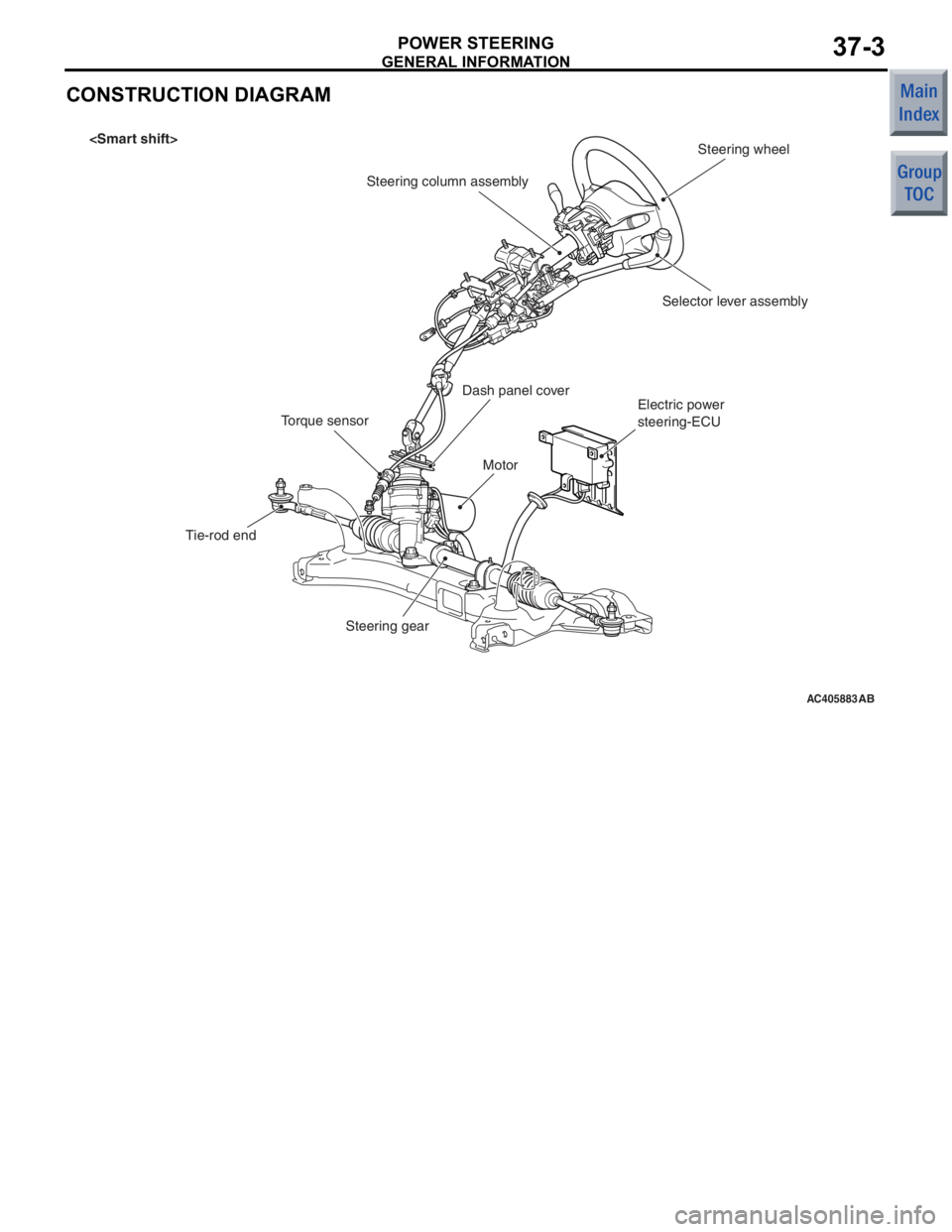

CONSTRUCTION DIAGRAM

AC405883AB

Steering wheel

Steering column assembly

Selector lever assembly

Electric power

steering-ECU

Motor

Torque sensor

Tie-rod end Steering gearDash panel cover

Page 237 of 364

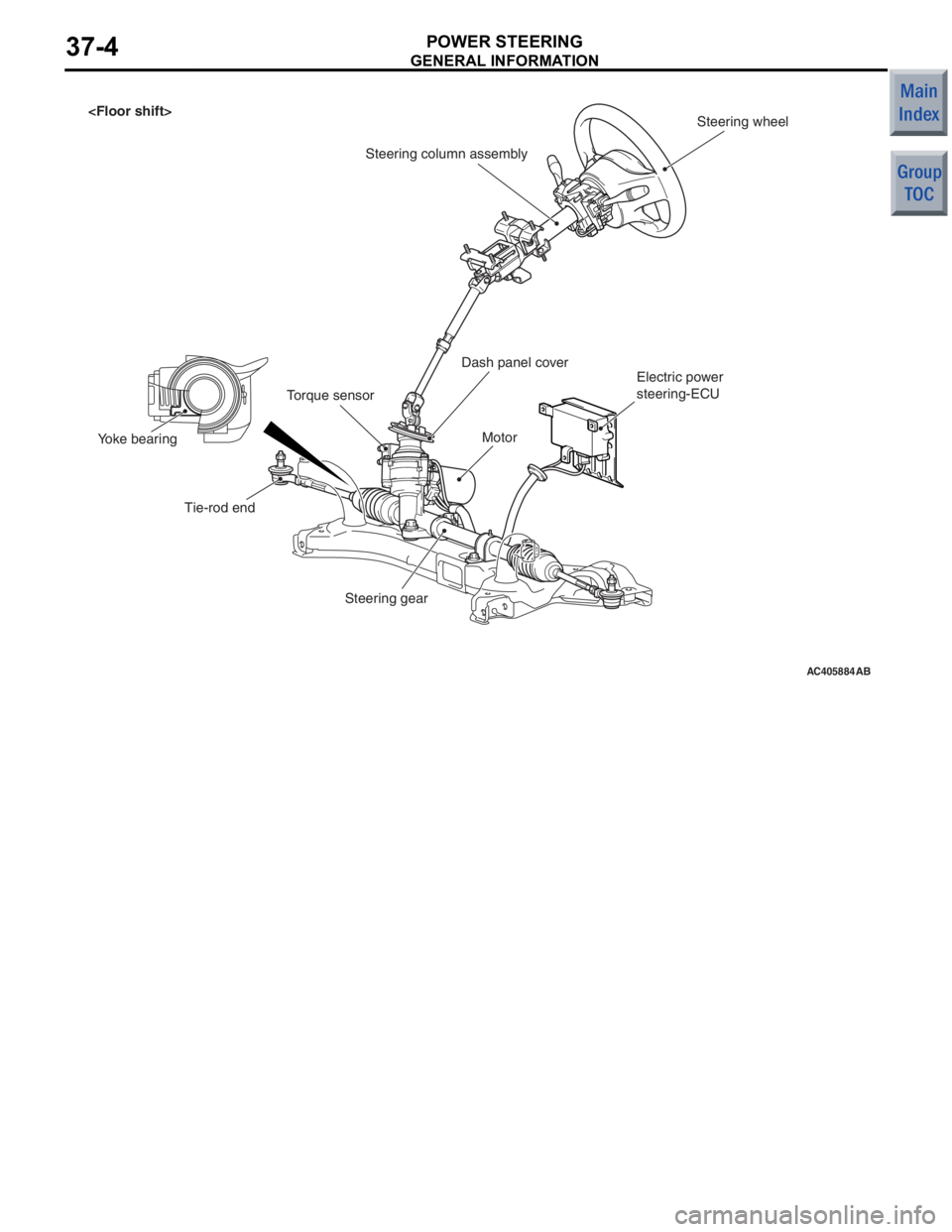

AC405884AB

Steering wheel

Steering column assembly

Electric power

steering-ECU

Motor

Torque sensor

Tie-rod end

Yoke bearing

Steering gearDash panel cover

GENER

A L IN FORMA T ION

POWER ST E E RING37-4

Page 240 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-7

ELECTRICAL POWER STEERING

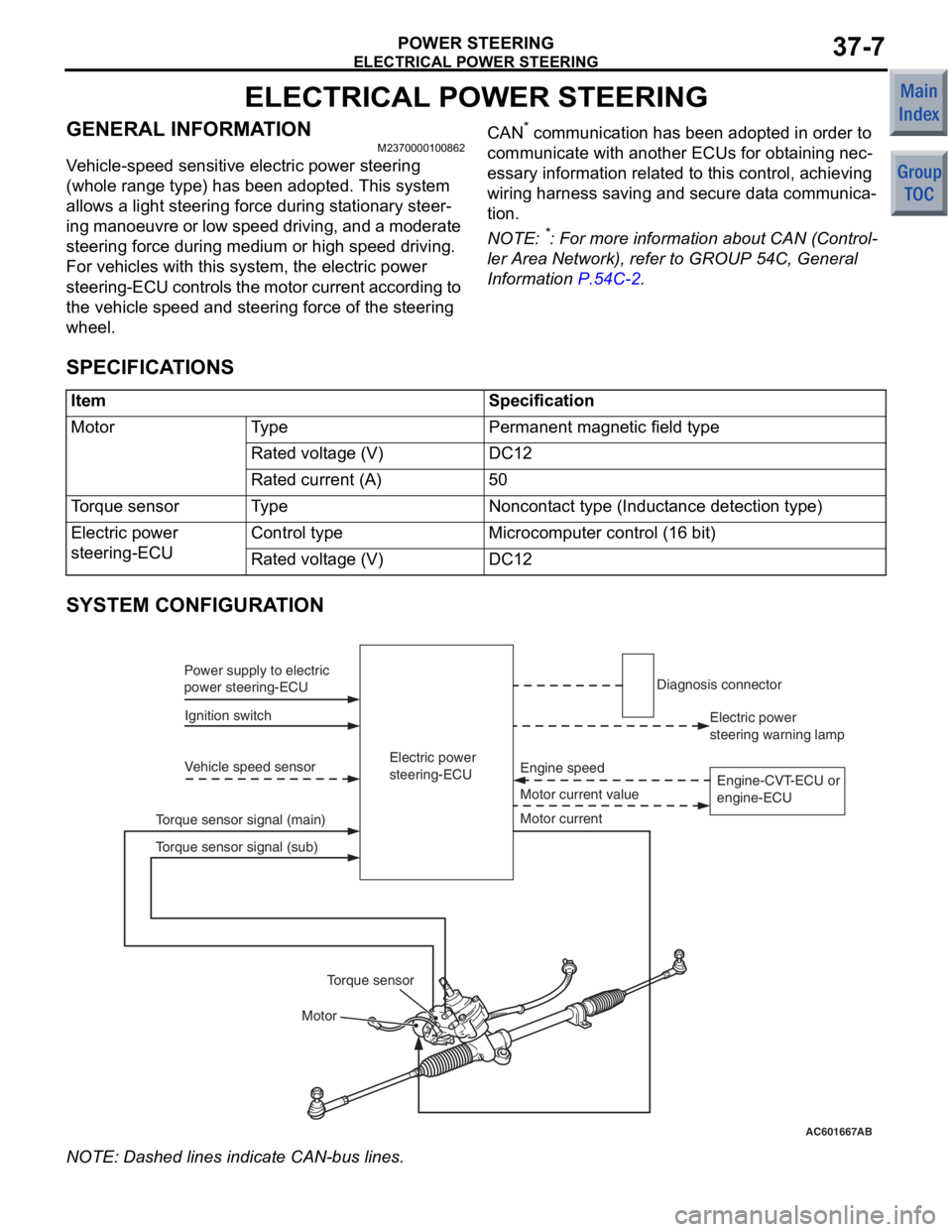

GENERAL INFORMATIONM2370000100862

Vehicle-speed sensitive electric power steering

(whole range type) has been adopted. This system

allows a light steering force during stationary steer

-

ing manoeuvre or low speed driving, and a moderate

steering force during medium or high speed driving.

For vehicles with this system, the electric power

steering-ECU controls the motor current according to

the vehicle speed and steering force of the steering

wheel.

CAN* communication has been adopted in order to

communicate with another ECUs for obtaining nec

-

essary information related to this control, achieving

wiring harness saving and secure data communica

-

tion.

NOTE: *: For more information about CAN (Control-

ler Area Network), refer to GROUP 54C, General

Information

P.54C-2.

SPECIFICATIONS

ItemSpecification

MotorTy p ePermanent magnetic field type

Rated voltage (V)DC12

Rated current (A)50

Torque sensorTy p eNoncontact type (Inductance detection type)

Electric power

steering-ECUControl typeMicrocomputer control (16 bit)

Rated voltage (V)DC12

SYSTEM CONFIGURATION

AC601667AB

Electric power

steering-ECU

Ignition switch

Power supply to electric

power steering-ECU

Vehicle speed sensor

Motor Motor current value Engine speed

Torque sensor signal (main) Electric power

steering warning lamp

Diagnosis connector

Motor current

Torque sensor

Torque sensor signal (sub) Engine-CVT-ECU or

engine-ECU

NO

TE: Dash ed lines indicat e CAN-bu s lines.

Page 241 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-8

ELECTRICAL PARTS AND FUNCTIONS

Parts nameDescription about function

SensorVehicle speed sensor (ABS-ECU)Sends the vehicle speed signal to the electric power

steering-ECU.

Torque sensorDetects a steering force, converts it into the voltage signal,

and then sends the signal to the electric power

steering-ECU.

ActuatorMotorGenerates assist torque by the steering operation to the

steering gear using the signals sent from the electric power

steering-ECU.

Electric power steering warning

lampWarns a driver of the system malfunction using the signal

sent from the electric power steering-ECU.

Electric power steering-ECUControl the actuator (motor) based on the signal sent from

sensor.

Controls the self-diagnostic fu nction and fail-safe function.

Controls diagnostic function (Compatible with M.U.T.-III).

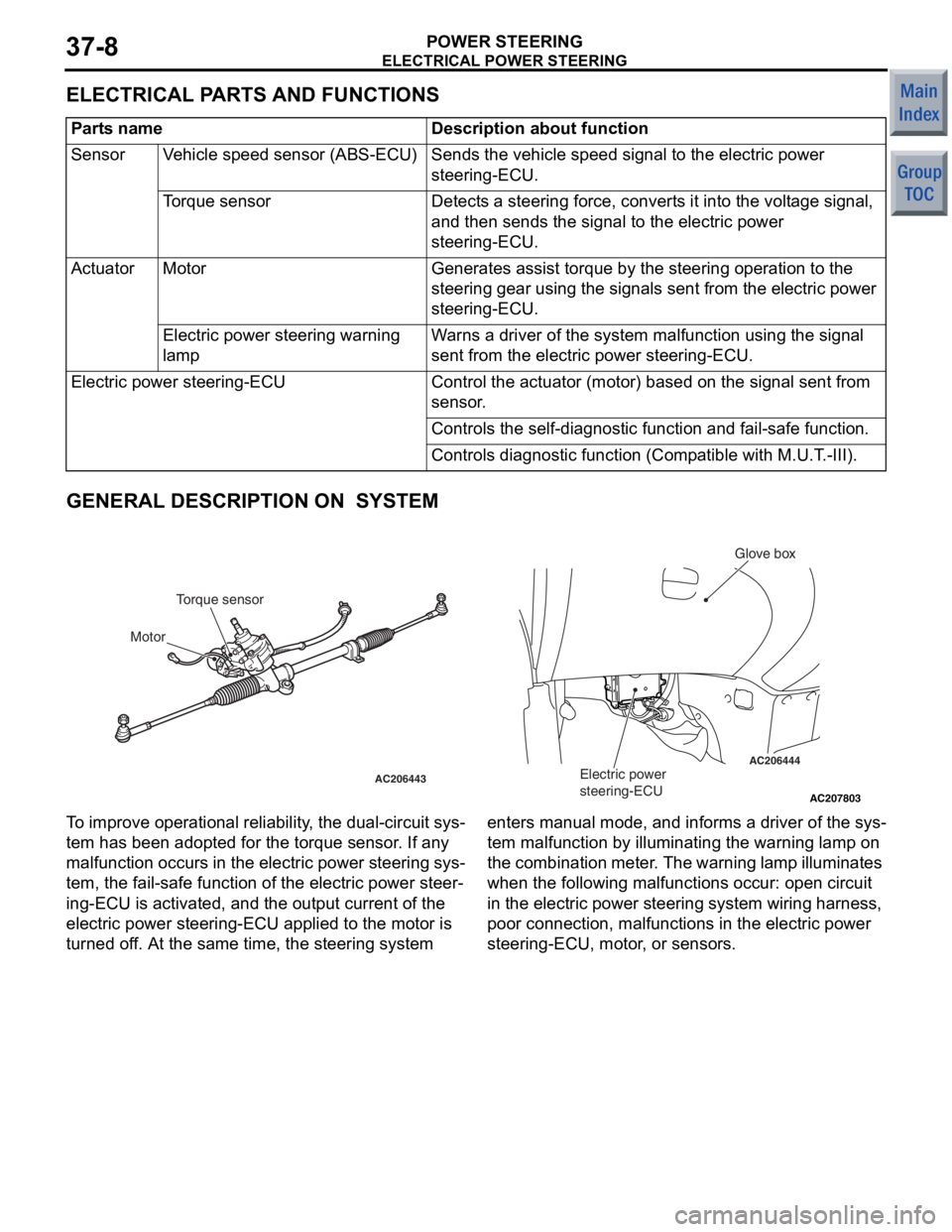

GENERAL DESCRIPTION ON SYSTEM

AC207803

AC206444

AC206443

AB

Electric power

steering-ECU

Glove box

Torque sensor

Motor

T o improve opera t iona l reliabi lity , th e dual-circuit sys-

tem ha s be en ad opted f o r the t o rque sensor . If a n y

malfunct

i on occurs in the electric power st eering sys

-

tem, the fail-sa f e fun c tio n of th e ele c tric power steer-

ing-ECU is activated, and the ou tput current of the

electric power steerin

g-ECU a pplied to the motor is

turned o

f f. At th e sa me time, the steerin g syste m enters man ual mode, and informs a dr iver of the sys

-

tem malfu

n ction by illuminating th e warnin g lamp on

the

comb in at io n me te r . Th e warn in g la mp il lu min a te s

wh

en the following malfu n ct ions occur: ope n circuit

in the

e l ectric power stee ring system wiring harness,

poor connectio

n , ma lfunction s in the e l ectric power

steering-ECU, mo

tor , or sensors.

Page 242 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-9

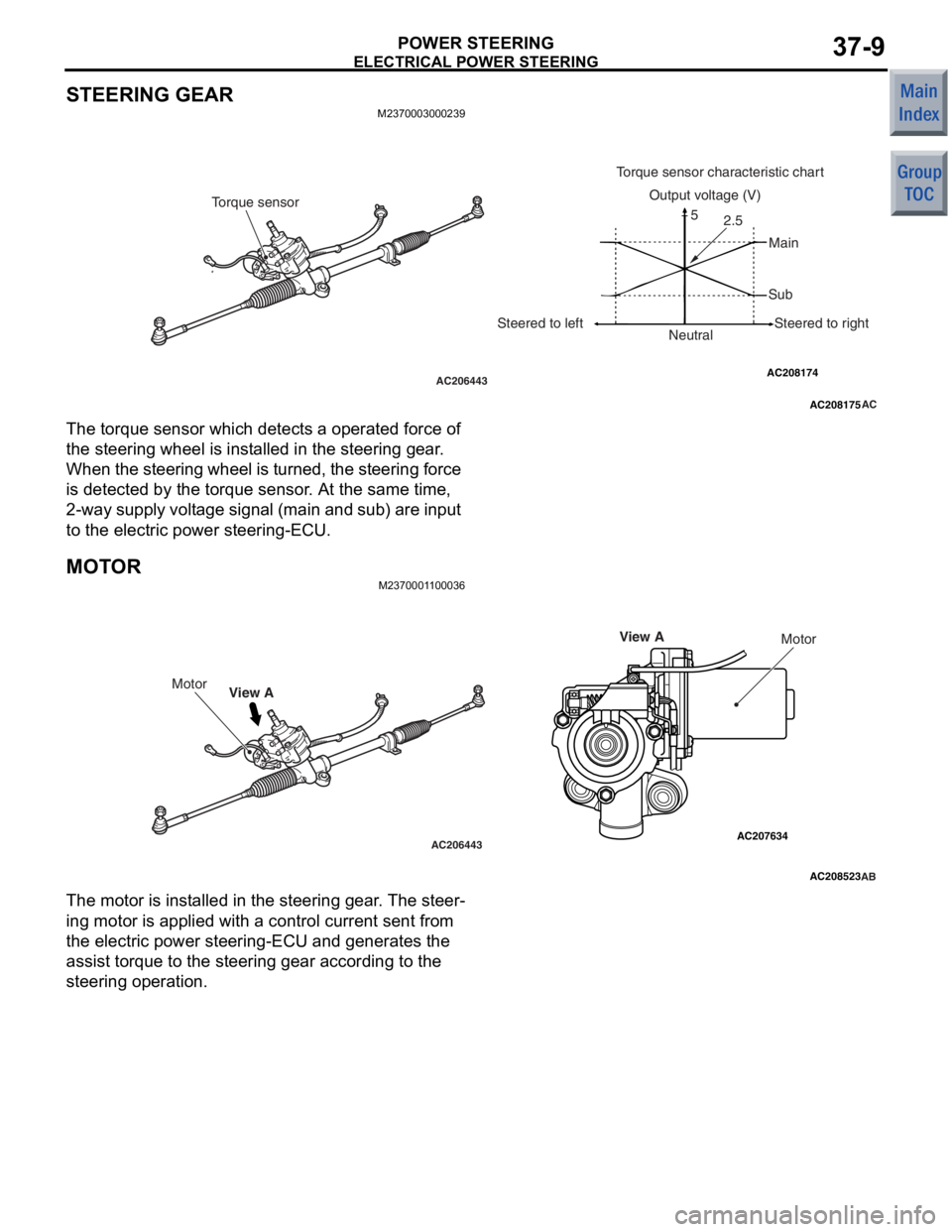

STEERING GEAR

M2370003000239

AC208175

AC208174AC206443AC

NeutralSub

Torque sensor

Steered to leftMain

Steered to right

Output voltage (V)

Torque sensor characteristic chart

52.5

The torqu e sensor which detect s a opera t ed force of

the steerin

g wheel is inst alled in the stee ring g ear .

Whe

n th e st eer in g whe e l is tu rn ed , t h e ste e ring f o rce

is d

e tected by the to rque sensor . At the same time,

2-way supp

ly volt a ge signa l (main and sub ) are input

to the e

l ectric power steerin g-ECU.

MOT O RM237000 1 1 0003 6

AC208523

AC206443

AC207634

AB

View AMotor

Motor

View A

The mot

o r is inst alled in th e steering gea r . The ste e r-

ing motor is applied with a con t rol current sent from

the electric po

we r stee ring-ECU and genera t es t he

assist

torque to the steering ge ar according to the

steering op

eratio n.

Page 243 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-10

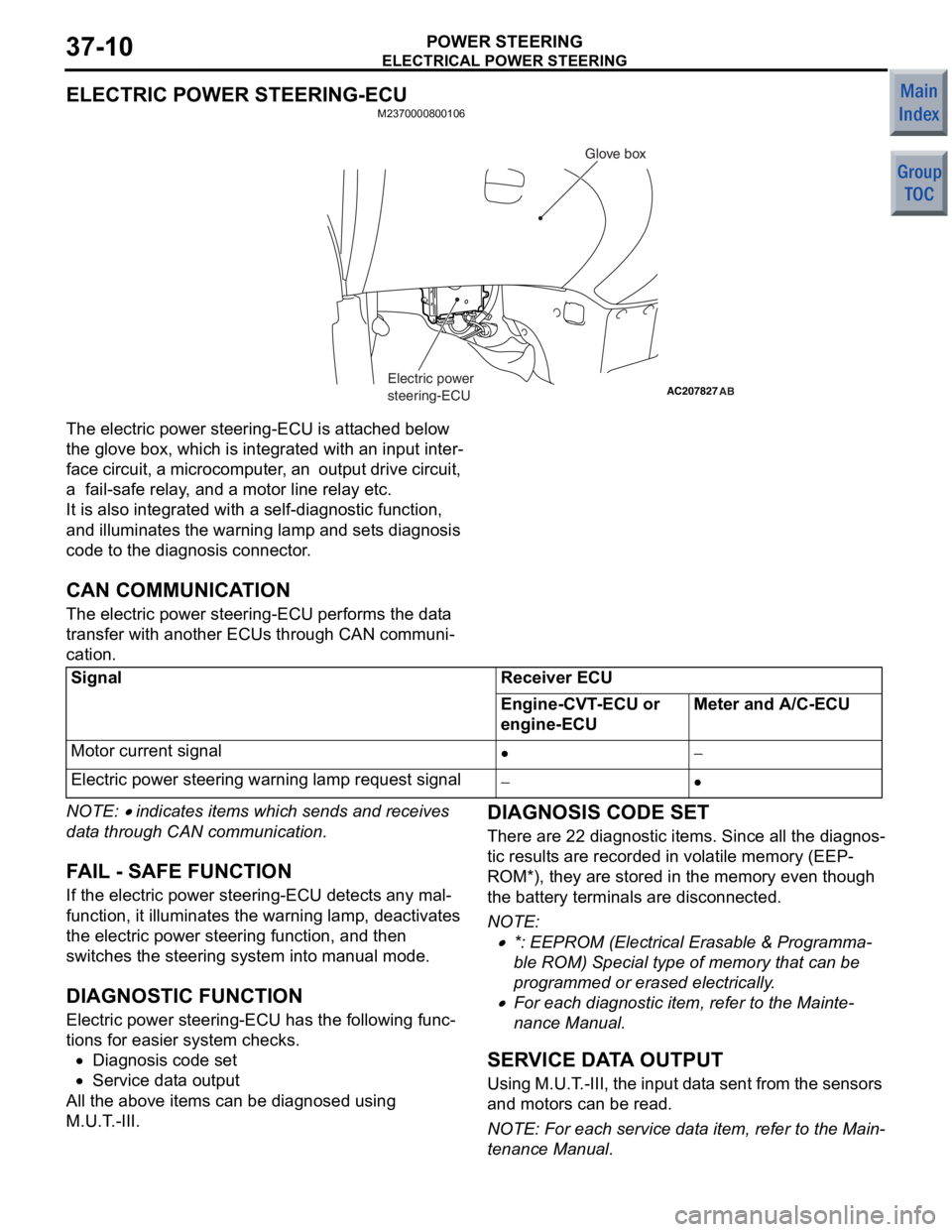

ELECTRIC POWER STEERING-ECU

M2370000800106

AC207827AB

Glove box

Electric power

steering-ECU

The electric powe r stee ring-ECU is att a ch ed below

the glove

box, wh ich is integ r ated wit h an input inter

-

face circu i t, a microco m p u ter , an outp u t d r ive circuit,

a fail-sa

f e rela y , and a mot o r line relay et c.

It is also integrated with a self-diag nostic fu nction,

and illuminate

s the warn ing lamp an d set s d i agno sis

code

to the diagn osis connector .

CAN COMMUNICATION

The electric powe r stee ring-ECU perfo rms the da t a

transf

e r with a nother ECUs through CAN communi

-

cation.

SignalReceiver ECU

Engine-CVT-ECU or

engine-ECUMeter and A/C-ECU

Motor current signal•−

Electric power steering warning lamp request signal−•

NOTE: • ind i ca tes items which sends and re ceives

dat

a throu gh CAN communicat i on.

FA IL - SAFE FUNCTION

If the e l ectric power st eering - ECU de tect s any mal-

functi on, it illuminat es th e warnin g lamp, de activate s

the electric po

we r stee ring f unct i on, a nd the n

switches

the steerin g system in to ma nual mode .

DIAGNOSTIC FUNCTION

Electric po wer ste e ring -ECU has the following fu nc-

tions for easie r system ch ecks.

•Diagnosis code set

•Service dat a outp u t

All the above ite m s can be diagnosed using

M.U.T

. -III.

DIAGNOSIS CODE SET

There a r e 22 d i agno stic ite m s. Since all the d i agn os-

tic result s are recorded in volatile memory (EEP-

ROM*), they a r e sto r ed in the memo ry even th ough

the bat

tery t e rminals are d i sconne cted.

NOTE: .

•*: EEPROM (E lectrical Erasable & Programma-

ble ROM) Special ty pe o f me mory that can b e

prog

rammed or erase d ele c trically .

•For each diag nostic item, refer to the Mainte-

nance Manua l.

SERV ICE DA T A OUTPUT

Usin g M. U. T . -II I , t h e i n p u t d a t a s e n t f r om t h e se ns ors

and motors can

be rea d .

NOTE: For e a ch service dat a it em, re fer to th e Ma in-

tenance Manual.