light MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 32 of 408

GENERALINFORMATIONAND MAINTENANC-E 1133

Used fluids such as engine oil, transaxle fluid, an-

tifreeze and brake fluid are hazardous wastes and

must be disposed of properly. Before draining any

fluids, consult with your local authorities; in many ar-

eas, waste oil, antifreeze, etc. is being accepted as a

part of recycling programs. A number of service sta-

tions and auto parts stores are also accepting waste

fluids for recycling.

Be sure of the recycling center’s policies before

draining any fluids, as many will not accept different

fluids that have been mixed together.

ENGINE OIL

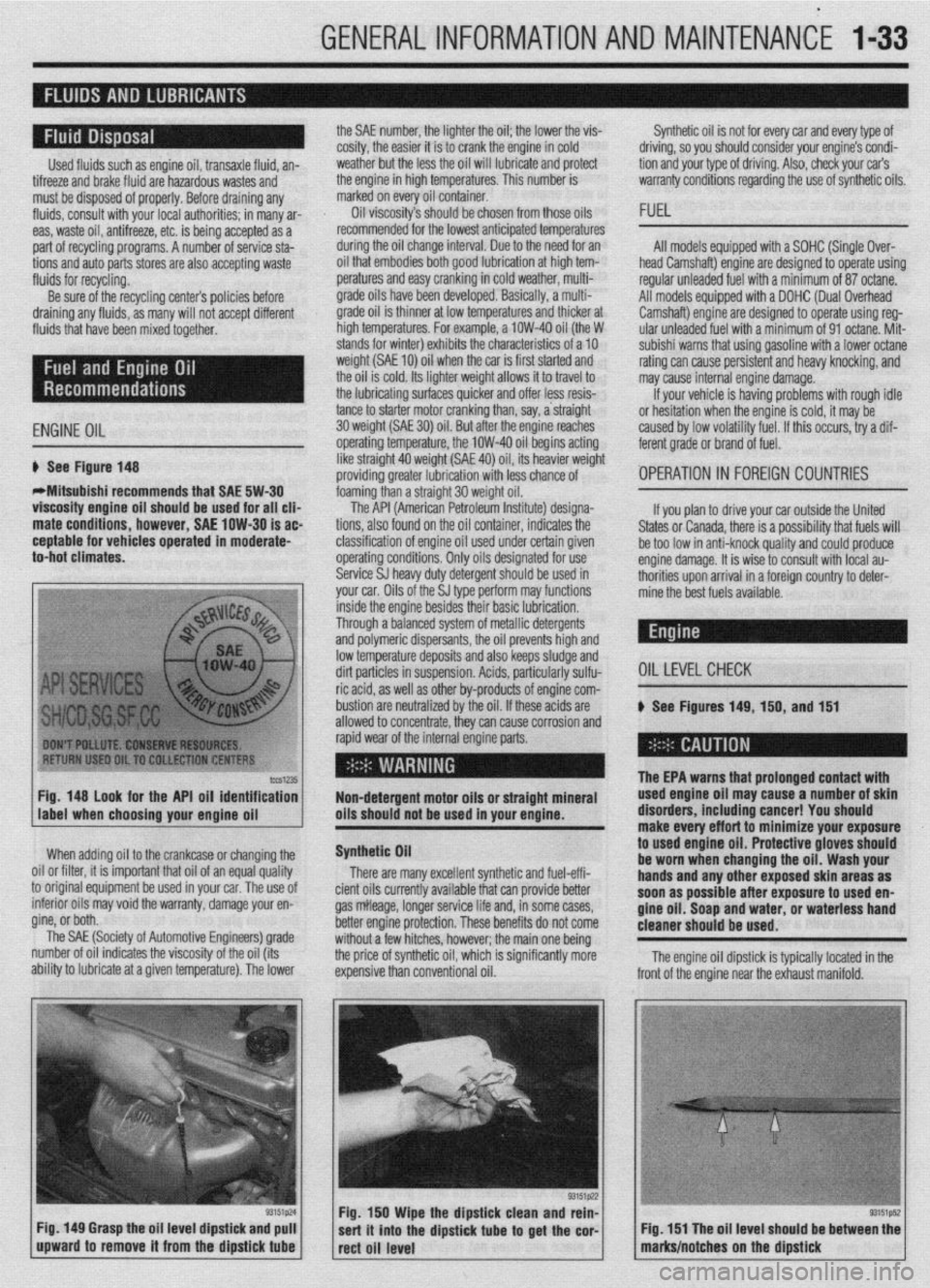

6 See Figure 148

WMitsubishi recommends that SAE 5W-30

viscosity engine oil should be used for all clia

mate conditions, however, SAE low-30 is ac

ceptable for vehicles operated in moderate-

to-hot climates. the SAE number, the lighter the oil; the lower the vis-

cosity, the easier it is to crank the engine in cold

weather but the less the oil will lubricate and protect

the engine in high temperatures. This number is

marked on every oil container.

Oil viscosity’s should be chosen from those oils

recommended for the lowest anticipated temperatures

during the oil change interval. Due to the need for an

oil that embodies both good lubrication at high tem-

peratures and easy cranking in cold weather, multi-

grade oils have been developed. Basically, a multi-

grade oil is thinner at low temperatures and thicker at

high temperatures. For example, a low-40 oil (the W

stands for winter) exhibits the characteristics of a 10

weight (SAE 10) oil when the car is first started and

the oil is cold. Its lighter weight allows it to travel to

the lubricating surfaces quicker and offer less resis-

tance to starter motor cranking than, say, a straight

30 weight (SAE 30) oil. But atier the ensine reaches

operating temperature, the low-40 oil begins acting

like straight 40 weight (SAE 40) oil, its heavier weight

providing greater lubrication with less chance of

foaming than a straight 30 weight oil. Synthetic oil is not for every car and every type of

driving, so you should consider your engine’s condi-

tion and your type of driving. Also, check your car’s

warranty conditions regarding the use of synthetic oils.

FUEL

All models equipped with a SOHC (Single Over-

head Camshaft) engine are designed to operate using

regular unleaded fuel with a minimum of 87 octane.

All models equipped with a DOHC (Dual Overhead

Camshaft) engine are designed to operate using reg-

ular unleaded fuel with a minimum of 91 octane. Mit-

subishi warns that using gasoline with a lower octane

rating can cause persistent and heavy knocking, and

may cause internal engine damage.

If your vehicle is having problems with rough idle

or hesitation when the enoine is cold, it mav be

caused by low volatility fuel. If this occurs, iry a dif-

ferent grade or brand of fuel.

'OPERATION 1~ FOREIGN COUNTRIES

lccS1235 Fig. 148 look for the API oil identification

Non-detergent motor oils or straight mineral

label when choosing your enaine oil oils should not be used in your engine.

When adding oil to the crankcase or changing the

0 Nil or filter, it is important that oil of an equal quality

I original equipment be used in your car. The use of

. tc mtenor 011s may void the warranty, damage your en-

gine, or both. __

The SAE (Society of Automotive Engineers) grade

number of oil indicates the viscosity of the oil (its

ability to lubricate at a given temperature). The lower

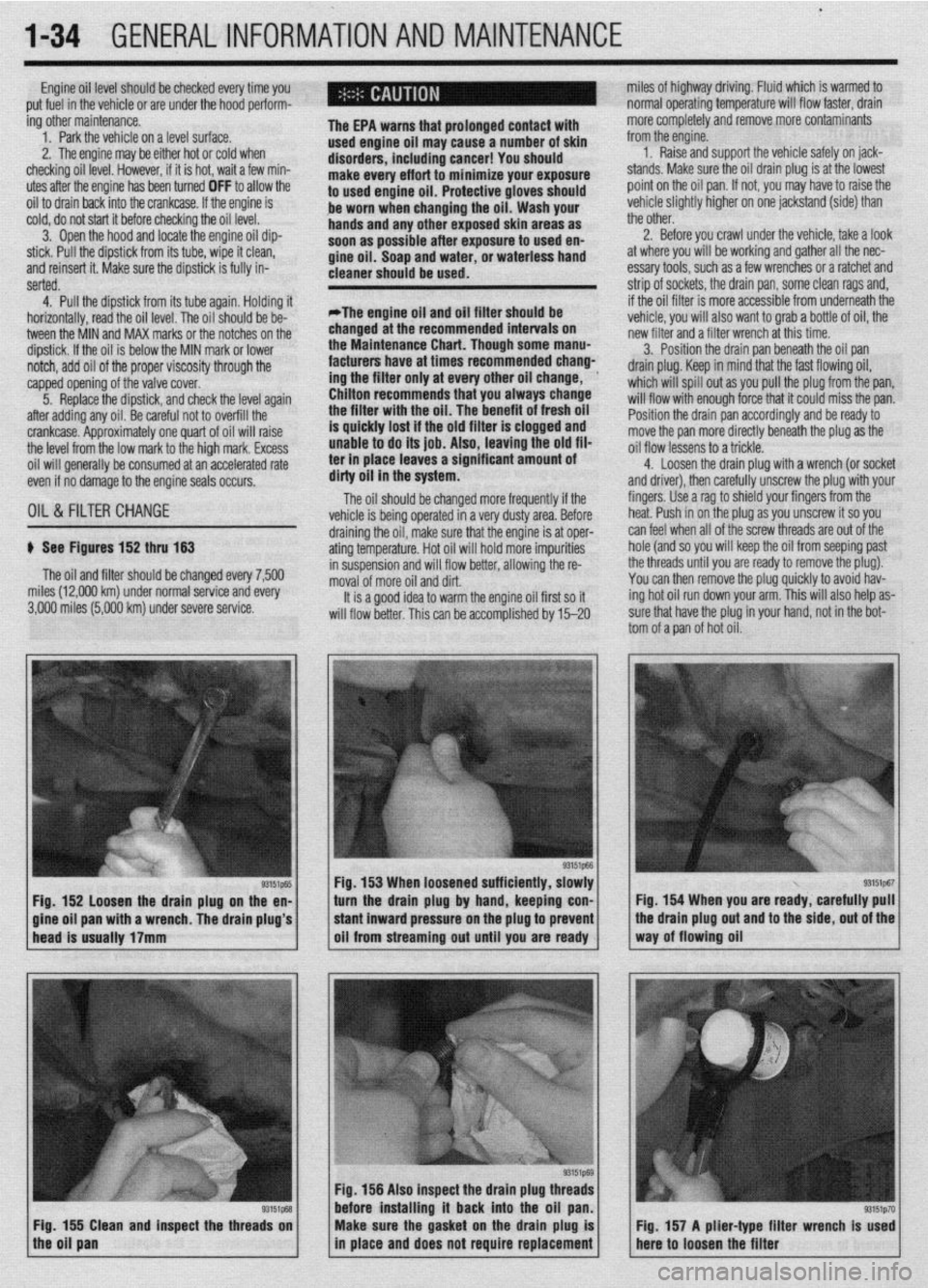

Fig. 149 Grasp the oil level dipstick and pull

upward to remove it from the dipstick

tube

The API (American Petroleum Institute) designa-

tions, also found on the oil container, indicates the

classification of engine oil used under certain given

operating conditions. Only oils designated for use

Service SJ heavy duty detergent should be used in

your car. Oils of the SJ type perform may functions If you plan to drive your car outside the United

States or Canada, there is a possibility that fuels will

be too low in anti-knock quality and could produce

engine damage. It is wise to consult with local au-

thorities upon arrival in a foreign country to deter-

mine the best fuels available.

inside the engine besides their basic lubrication.

Through a balanced system of metallic detergents

and polymeric dispersants, the oil prevents high and

low temperature deposits and also keeps sludge and

dirt particles in suspension. Acids, particularly sulfu-

OILLEVELCHECK ric acid, as well as other by-products of engine com-

bustion are neutralized by the oil. If these acids are

# See Figures 149, 150, and 151

allowed to concentrate, thev can cause corrosion and

rapid wear of the internal engine parts.

Synthetic Oil

There are many excellent synthetic and fuel-effi-

cient oils currently available that can provide better

gas mileage, longer service life and, in some cases,

better engine protection. These benefits do not come

without a few hitches, however; the main one being

the price of synthetic oil, which is significantly more

expensive than conventional oil.

.

The EPA warns that urolonoed contact with used engine oil ma; cause-a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to

used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

Fig. 150 Wipe the dipstick clean and rein-

sert it into the dipstick

tube to get the cor-

rect oil level The engine oil dipstick is typically located in the

Fig. 151 The oil level should be between the

marks/notches on the dipstick

Page 33 of 408

.

l-34 GENERALINFORMATIONAND MAINTENANCE

Engine oil level should be checked every time you

put fuel in the vehicle or are under the hood perform- miles of highway driving. Fluid which is warmed to

normal operating temperature will flow faster, drain

ing other maintenance.

1. Park the vehicle on a level surface.

2. The enaine mav be either hot or cold when

, if it is hot, wait a few min- checking oil level. The EPA warns that prolonged contact with

used engine oil may cause a num’ * * *

dianrAnrr inrldinn ranrnrl V#lll more completely and remove more contaminants

frnm tho clnnine

utes after the engine has been turned OFF to allow the

oil to drain back into the crankcase. If the engine is

cold, do not start it before checking the oil level. point on the oil pan. If not, you may have to raise the

vehicle slightly higher on one jackstand (side) than

3. Open the hood and locate the engine oil dip-

stick. Pull the dipstick from its tube, wipe it clean,

and reinsert it. Make sure the diDstick is fullv in-

serted.

4. Pull the dipstick from its tube again. Holding it to used engin

be worn whet

handsandan

so*m ..#a . . . . .

IDer 01 SKlll u,yu,u=,+, ,,,u,uu,,,u uu,,u=, i , vu should

uff art to minimize your exposure

le oil. Protective gloves should

1 changing the oil. Wash your

y other exposed skin areas as

111 aJ vv4ble after exposure to used en-

m nil St-mn mwl w&or nr umtarlncr hand gin Y “II. ““up “ll” .,U.“I, “rn W.Y.“. .““I .I....” cleaner should be used.

horizontally, read the oil level. The oilshould be be-

tween the MIN and MAX marks or the notches on the

dipstick. If the oil is below the MIN mark or lower

notch, add oil of the proper viscosity through the

capped opening of the valve cover. *The engine oil and oil filter should be

changed at the recommended intervals on

the Maintenance Chart. Though some manu-

facturers have at times recommended chang-

ing the filter only at every other oil change, ’

Chilton recommends that you always change

ll”,,, Cl>” ““y”‘“. 1. Raise and support the vehicle safely on jack-

stands. Make sure the oil drain olua is at the lowest

the other.

2. Before you crawl under the vehicle, take a look

at where you will be working and gather all the nec-

essary tools, such as a few wrenches or a ratchet and

strip of sockets, the drain pan, some clean rags and,

if the oil filter is more accessible from underneath the

vehicle, you will also want to grab a bottle of oil, the

new filter and a filter wrench at this time.

5. Reolace the diostick. and check the level aaain

. The benefit of fresh oil

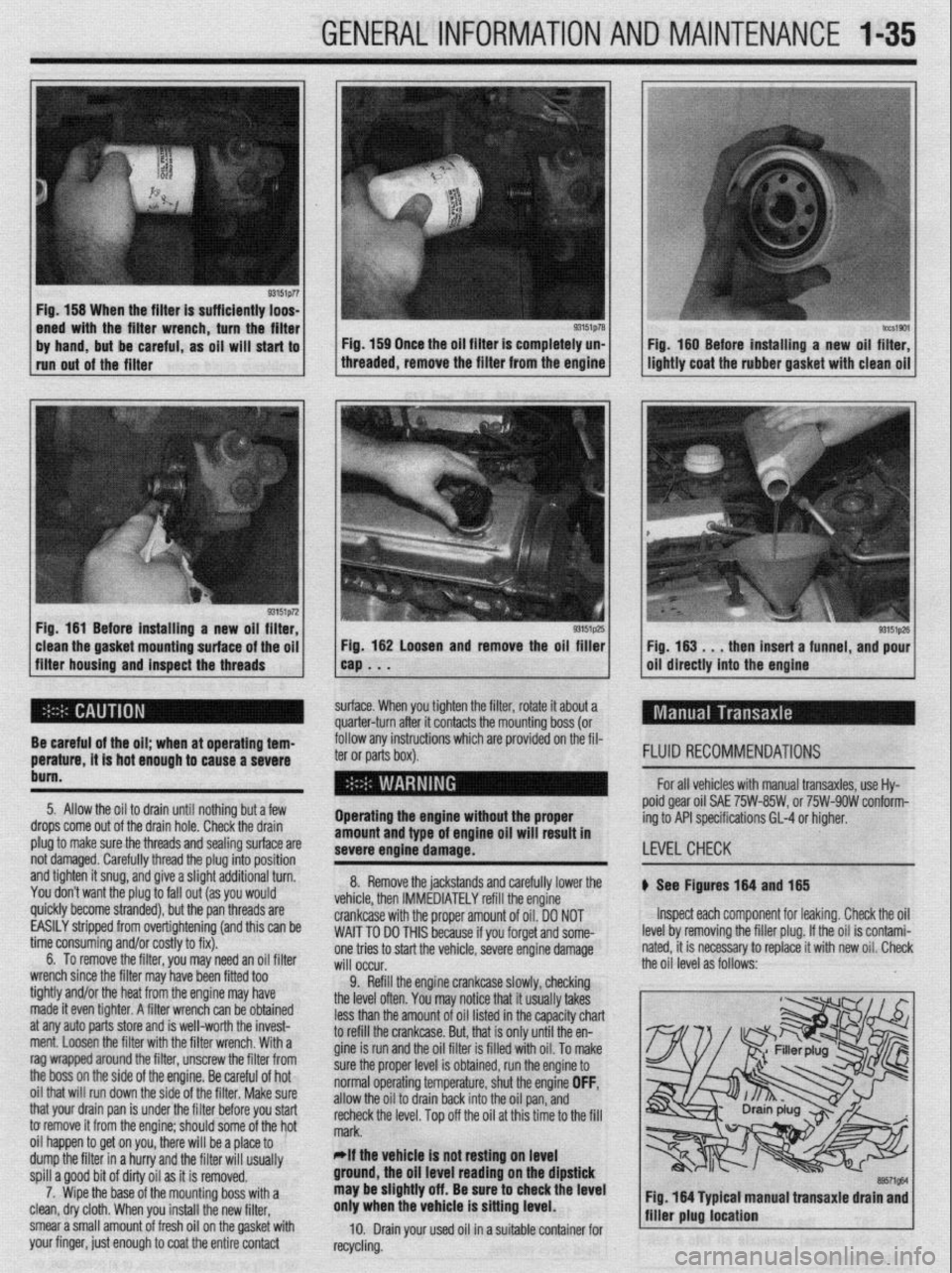

p See Figures 152 thru 153

The oil and filter should be changed every 7,500

miles (12,000 km) under normal service and every

3,000 miles (5,000 km) under severe service.

93151p-55 Fig. 152 loosen the drain plug on the en-

a wrench. The drain plug’s 3. Position the drain pan beneath the oil pan

drain plug. Keep in mind that the fast flowing oil,

which will spill out as you pull the plug from the pan,

will flow with enough force that it could miss the pan.

Position the drain pan accordingly and be ready to

move the pan more directly beneath the plug as the

oil flow lessens to a trickle.

4. Loosen the drain ~lua with a wrench (or socket

and driver), then carefuliy unscrew the plug with your

fingers. Use a rag to shield your fingers from the

heat. Push in on the plug as you unscrew it so you

draining the oil, make sure that the engine is at oper- can feel when all of the screw threads are out of the

ating temperature. Hot oil will hold more impurities hole (and so you will keep the oil from seeping past

in suspension and will flow better, allowing the re- the threads until you are ready to remove the plug).

moval of more oil and dirt. You can then remove the plug quickly to avoid hav-

It is a good idea to warm the engine oil first so it ing hot oil run down your arm. This will also help as-

will flow better. This can be accomolished bv 15-20 sure that have the plug in your hand, not in the bot-

tom of a pan of hot oil.

Fig. 153 When loosened sufficiently, slowly

turn the drain plug by hand, keeping con- Fig. 154 When you are ready, carefully pull

Fig. 156 Also inspect the drain plug th

before installing it back into the oil

Fig. 155 Clean and inspect the threads on

the oil pan Make sure the gasket on the drain plug is

in place and does not require replacement Fig. 157 A plier-type filter wrench Is used

here to loosen the filter

Page 34 of 408

GENERALINFORMATIONAND MAINTENANCE l-35

Fig. 158 When the filter is sufficiently loos-

Fig. 181 Before installing a new oil filter,

clean the gasket mounting surface of the oil

filter housing and inspect the threads Fig. 182 Loosen and remove the oil filler

cap . . .

surface. When you tighten the filter, rotate it about a

quarter-turn after it contacts the mounting boss (or Fig. 183 . , , then insert a funnel, and pour

oil directly into the engine

follow any instructions

which are provided on the fil-

ter or parts box).

Operating the engine without the proper

amount and type of engine oil will result In

severe engtne damage. FLUID RECOMMENDATIONS

For all vehicles with manual transaxles, use Hy-

poid gear oil SAE 75W-85W, or 75W-9OW conform-

ing to API specifications GL-4 or higher.

LEVELCHECK Be careful of the oil; when at operating tem-

perature, it is hot enough to cause a severe

bum.

5. Allow the oil to drain until nothing but a few

drops come out of the drain hole. Check the drain

plug to make sure the threads and sealing surface are

not damaged. Carefully thread the plug into position

and tighten it snug, and give a slight additional turn.

You don’t want the plug to fall out (as you would

quickly become stranded), but the pan threads are

EASILY stripped from overtightening (and this can be

time consuming and/or costly to fix).

6. To remove the filter, you may need an oil filter

wrench since the filter may have been fitted too

tightly and/or the heat from the engine may have

made it even tighter. A filter wrench can be obtained

at any auto parts store and is well-worth the invest-

ment. Loosen the filter with the filter wrench. With a

rag wrapped around the filter, unscrew the filter from

the boss on the side of the engine. Be careful of hot

oil that will run down the side of the filter. Make sure

that your drain pan is under the filter before you start

to remove it from the engine; should some of the hot

oil happen to get on you, there will be a place to

dump the filter in a hurry and the filter will usually

spill a good bit of dirty oil as it is removed.

7. Wipe the base of the mounting boss with a

clean, dry cloth. When you install the new filter,

smear a small amount of fresh oil on the gasket with

your finger, just enough to coat the entire contact 8. Remove the jackstands and carefully lower the

vehicle, then IMMEDIATELY refill the engine

crankcase with the proper amount of oil. DO NOT

WAIT TO DO THIS because if you forget and some-

one tries to start the vehicle, severe engine damage

will occur.

9. Refill the engine crankcase slowly, checking

the level oflen, you may r..‘:-- U.-1 :L ..-..” II.. .-L-e

lVL,VY II,UL II UUUU,,J ,“,\U.J

less than the amount of oil listed in the capacity chart

to refill the crankcase. But, that is only until the en-

gine is run and the oil filter is filled with oil. To make

sure the proper level is obtained, run the engine to

normal operating temperature, shut the engine OFF,

allow the oil to drain back into the oil pan, and

recheck the level. Top off the oil at this time to the fill

mark.

*If the vehicle Is not resting on level

ground, the oil level reading on the dipstick

may be slightly off. Be sure to check the level

only when the vehicle is sitting level.

10. Drain your used oil in a suitable container for

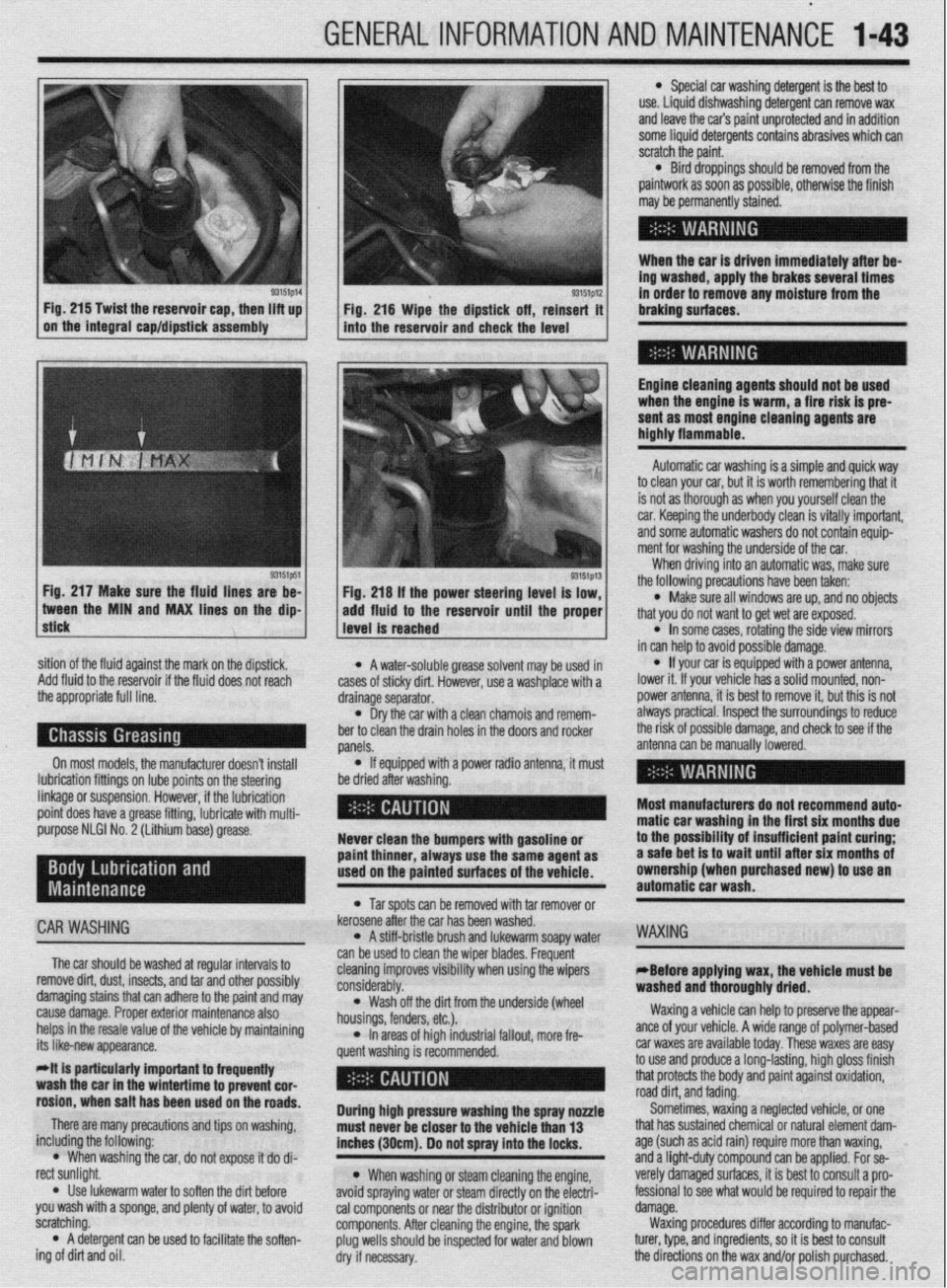

recycling. b See Flgures 184 and 185

Inspect each component for leaking. Check the oil

level by removing the filler plug. If the oil is contami-

nated, it is necessary to replace it with new oil. Check

the oil level as follows:

89571gM Fig. 164 Typtcal manual transaxle drain and

filler plug location

Page 42 of 408

GENERALINFORMATIONAND MAINTENANCE l-43

l Special car washing detergent is the best to

use. Liquid dishwashing detergent can remove wax

and leave the car’s paint unprotected and in addition

some liquid detergents contains abrasives which can

scratch the paint.

l Bird droppings should be removed from the

paintwork as soon as possible, otherwise the finish

may be permanently stained.

When the car is driven immediately after be-

ing washed, apply the brakes several times

93151p14 93151p12 Fig. 215 Twist the reservoir cap, then lift up

I I

in order to remove any moisture from the

Fig. 216 Wipe the dipstick off, reinsert it braking surfaces.

on the integral cap/dipstick assembly

into the reservoir and check the level

I

Engine cleaning agents should not be used

when the engine is warm, a fire risk is pre-

sent as most engine cleaning agents are

highly flammable.

sition of the fluid against the mark on the dipstick,

Add fluid to the reservoir if the fluid does not reach

the appropriate full line.

On most models, the manufacturer doesn’t install

lubrication fittings on lube points on the steering

linkage or suspension. However, if the lubrication

point does have a grease fitting, lubricate with multi-

purpose NLGI No. 2 (Lithium base) grease.

CAR WASHING

The car should be washed at regular intervals to

remove dirt, dust, insects, and tar and other possibly

damaging stains that can adhere to the paint and may

cause damage. Proper exterior maintenance also

helps in the resale value of the vehicle by maintaining

its like-new appearance.

Mt is particularly important ta frequentiy

wash the car in the wintertime to prevent cor-

rosion, when salt has been used on the roads.

There are many precautions and tips on washing,

including the following:

l When washing the car, do not expose it do di-

rect sunlight.

. Use lukewarm water to soften the dirt before

you wash with a sponge, and plenty of water, to avoid

scratching.

l A detergent can be used to facilitate the soften-

ing of dirt and oil. * A water-soluble grease solvent may be used in

cases of sticky dirt. However, use a washplace with a

drainage separator.

l Dry the car with a clean chamois and remem-

ber to clean the drain holes in the doors and rocker

panels.

l If equipped with a power radio antenna, it must

be dried after washing.

Never clean the bumpers with gasoline or

paint thinner, always use the same agent as

used on the painted surfaces of the vehicle.

l Tar spots can be removed with tar remover or

kerosene after the car has been washed.

l A stiff-bristle brush and lukewarm soapy water

can be used to clean the wiper blades. Frequent

cleaning improves visibility when using the wipers

considerably.

l Wash off the did from the underside (wheel

housings, fenders, etc.).

l In areas of high industrial fallout, more fre-

quent washing is recommended.

During high pressure washing the spray nonle

must never be closer to the vehicle than 13

inches (30cm). Do not spray into the locks.

l When washing or steam cleaning the engine,

avoid spraying water or steam directly on the electri-

cal components or near the distributor or ignition

components. After cleaning the engine, the spark

plug wells should be inspected for water and blown

dry if necessary. Automatic car washing is a simple and quick way

to clean your car, but it is worth remembering that it

is not as thorough as when you yourself clean the

car. Keeping the underbody clean is vitally important,

and some automatic washers do not contain equip-

ment for washing the underside of the car.

When driving into an automatic was, make sure

the following precautions have been taken:

l Make sure all windows are up, and no objects

that you do not want to get wet are exposed.

l In some cases, rotating the side view mirrors

in can help to avoid possible damage.

l If your car is equipped with a power antenna,

lower it. If your vehicle has a solid mounted, non-

power antenna, it is best to remove it, but this is not

always practical. Inspect the surroundings to reduce

the risk of possible damage, and check to see if the

antenna can be manually lowered.

Most manufacturers do not recommend auto-

matic car washing in the first six months due

to the possibility of insufficient paint curing;

a safe bet is to wait until after six months of

ownership (when purchased new) to use an

automatic car wash.

WAXING

eBefore applying wax, the vehicle must be

washed and thoroughly dried.

Waxing a vehicle can help to preserve the appear-

ante of your vehicle. A wide range of polymer-based

car waxes are available today. These waxes are easy

to use and produce a long-lasting, high gloss finish

that protects the body and paint against oxidation,

road dirt, and fading.

Sometimes, waxing a neglected vehicle, or one

that has sustained chemical or natural element dam-

age (such as acid rain) require more than waxing,

and a light-duty compound can be applied. For se-

verely damaged surfaces, it is best to consult a pro-

fessional to see what would be required to repair the

damage.

Waxing procedures differ according to manufac-

turer, type, and ingredients, so it is best to consult

the directions on the wax and/or polish purchased.

Page 43 of 408

1-44 GENERALINFORMATIONAND MAINTENANCE

INTERIOR CLEANING

Upholstery

Fabric can usually be cleaned with soapy water or

a proper detergent. For more difficult spots caused by

oil, ice cream, soda, etc., use a fabric cleaner avail-

able at most parts stores. Be sure when purchasing

the cleaner to read the label to ensure it is safe to use

on your type of fabric. A safe method of testing the

cleaner is to apply a small amount to an area usually

unseen, such as under a seat, or other areas. Wart a

while, perhaps even a day to check the spot for fad-

ing, discoloring, etc., as some cleaners will only

cause these problems after they have dried

Leather upholstery requrres special care, it can be

cleaned with a mild soap and a soft cloth. It is recom-

mended that a special leather cleaner be used to

clean but also treat the leather surfaces in your vehi-

cle. Leather surfaces can age quickly and can crack if

not properly taken care of, so it is vital that the leather

surfaces be maintained.

Floor Mats and Carpet

The floor mats and carpet should be vacuumed or

brushed regularly. They can be cleaned with a mild

soap and water. Special cleaners are available to

clean the carpeted surfaces of your vehicle, but take

care in choosing them, and again it is best to test

them in a usually unseen spot.

Dashboard, Console, Door Panels, Etc.

The dashboard, console, door panels, and other

plastic, vinyl, or wood surfaces can be cleaned using

a mild soap and water. Caution must be taken to keep

water out of electronic accessories and controls to

avoid shorts or ruining the components Again spe-

cial cleaners are available to clean these surfaces, as

with other cleaners care must taken in purchasmg

and using such cleaners.

There are protectants available which can treat the

various surfaces in your car giving them a “shiny new

look”, however some of these protectants can cause

more harm than good in the long run. The shine that

is placed on your dashboard attracts sunlight accel-

erating the aging, fading and possibly even cracking

the surfaces. These protectants also attract more dust

to stick to the surfaces they treat, Increasing the cleaning you must do to maintain the appearance of

your vehicle. Personal discretion is advised here.

On most models covered by this manual, the

wheel bearmgs used are sealed units and do not re-

quire routine maintenance. However on some Galant

and Mirage models, the rear wheel bearing do require

periodic repacking. For removal and installation in-

structions, please refer to Section 7 (for rear bear-

ings) or Section 8 (for front bearings).

REPACKING

*Sodium based grease is not compatible

with lithium based grease. Read the package

labels and be careful not to mix the two

types. If there is any doubt as to the type of

grease used, completely clean the old

grease from the bearing and hub before re-

placing.

Before handling the bearings, there are a few

things that you should remember to do and not to do.

DO the following: l Remove all outside dirt from the housing be-

fore exposing the bearing.

l Treat a used bearing as gently as you would a

new one.

l Work with clean tools in clean surroundings. l Use clean, dry gloves, or at least clean, dry

hands.

l Clean solvents and flushing fluids are a must. l Use clean paper when laying out the bearings

to dry.

l Protect drsassembled bearings from rust and

dirt. Cover them up.

l Use clean, lint-free rags to wipe the bearings. l Keep the bearings in oil-proof paper when they

are to be stored or are not in use.

l Clean the inside of the housing before replac-

ing the bearin

Do NOT do he followino: El, l Do not work in dirty sirroundings. l Do not use dirty, chipped or damaged tools. l Do not work on wooden work benches or use

wooden mallets.

l Do not handle bearings with dirty or moist

hands.

l Do not use gasoline for cleaning. Use a safe

solvent.

l Do not spin dry bearings with compressed air.

They will be damaged.

l Do not use cotton waste or dirty cloths to wipe

bearings.

l Do not scratch or nick bearing surfaces. l Do not allow the bearina to come in contact

” with dirt or rust at any time.

The rear wheel bearinas on some Galant and Mi-

rage models require periodic maintenance. A pre-

mium high melting point grease meeting Grade

Multipurpose Grease NLGI Grade #2 or equivalent

must be used. Long fiber type greases must not be

used. This service is recommended every 30,000

miles (48,000 km).

*For information on Wheel Bearing removal

and installation, refer to Section 7 of this

manual.

1. Remove the wheel bearing.

2. Clean all parts in a non-flammable solvent and

let them air dry.

*Only use lint-free rags to dry the bearings.

Never spin-dry a bearing with compressed

air, as this will damage the rollers.

3. Check for excessive wear and damage. Replace

the bearing as necessary.

*Packina wheel bearinos with arease is

best accomplished by u&g a wheel bearing

packer (available at most automotive parts

stores).

4. If a wheel bearing packer is not available, the

bearings may be packed by hand.

a. Place a “healthy’ glob of grease in the

palm of one hand.

b. Force the edge of the bearing into the

grease so that the grease fills the space between

the rollers and the bearing cage.

c. Keep rotating the bearing while continuing

to push the grease through.

d. Continue until the grease is forced out the

other side of the bearing.

5. Place the packed bearing on a clean surface

and cover it until it is time for installation.

6. Install the wheel bearing.

# See Figures 219 and 220

To prevent the bumper from deforming, these vehi-

cles cannot be towed by a wrecker using sling-type

equipment. If these vehicles require towing, use a

wheel lift or flat bed equipment. It is recommended

that the vehicle be towed from the front If a flat bed is

not available.

Manual transaxle vehicles may be towed from the

rear provided that the transaxle is in Neutral and the

driveline has not been damaged. The steering wheel

must be clamped in the straight-ahead positron with a

steering wheel clamping device designed for towing

service use.

Do not use the steering column lock to secure

the front wheel uosition for towina.

Automatic transaxle vehicles may be towed on the

front wheels at speeds not to exceed 30 mph (50

km/h) for a distance not to exceed 18 miles (30 km).

If these limits can not be met, then the front wheels

must be placed on a tow dolly.

# See Figure 221

All Wheel Drive (AWD) vehicles should only be

towed with all 4 wheels on the ground or lifted from

the road surface. This means that the vehicle is to be

towed either with flatbed equipment, with all wheels

on dollies or flat towed. Damage to the viscous cou-

pling may result if the vehicle is towed with only 2

wheels on the ground.

p See Figure 222

Whenever a vehicle is jump started, precautions

must be followed In order to prevent the possibility of

Page 45 of 408

.

I-46 GENERALINFORMATIONAND MAINTENANCE

2. Pull the jumping vehicle (with the good bat-

tery) into a position so the jumper cables can reach

the dead battery and that vehicle’s engine. Make sure

that the vehicles do NOT touch.

3. Place the transmissions/transaxles of both ve-

hicles in Neutral (MT) or P (AT), as applicable, then

firmly set their parking brakes.

*ff necessary for safety reasons, the hazard

lights on both vehicles may be operated

throughout the entire procedure without sig-

nificantiy increasing the diff icuity of jumping

the dead battery.

4. Turn all lights and accessories OFF on both

vehicles. Make sure the ignition switches on both ve-

hicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do

not cover the terminals.

6. Make sure the terminals on both batteries are

clean and free of corrosion or proper electrical con-

nection will be impeded. If necessary, clean the bat-

tery terminals before proceeding.

7. Identify the positive (+) and negative (-) termi-

nals on both batteries.

8. Connect the first jumper cable to the positive

(t) terminal of the dead battery, then connect the

other end of that cable to the positive (t) terminal of

the booster (good) battery.

9. Connect one end of the other jumper cable to

the negative (−) terminal on the booster bat-

tery and the final cable clamp to an engine bolt head,

alternator bracket or other solid, metallic point on the

engine with the dead battery. Try to pick a ground on

the engine that is positioned away from the battery in

order to minimize the possibility of the 2 clamps

touching should one loosen during the procedure.

DO NOT connect this clamp to the negative (-) termi-

nal of the bad battery. cable on the donor battery. Disconnect the positive

cable from the donor battery and finally, disconnect

the positive cable from the formerly dead battery. Be

careful when disconnecting the cables from the posi-

tive terminals not to allow the alligator clips to touch

any metal on either vehicle or a short and sparks will

occur.

I

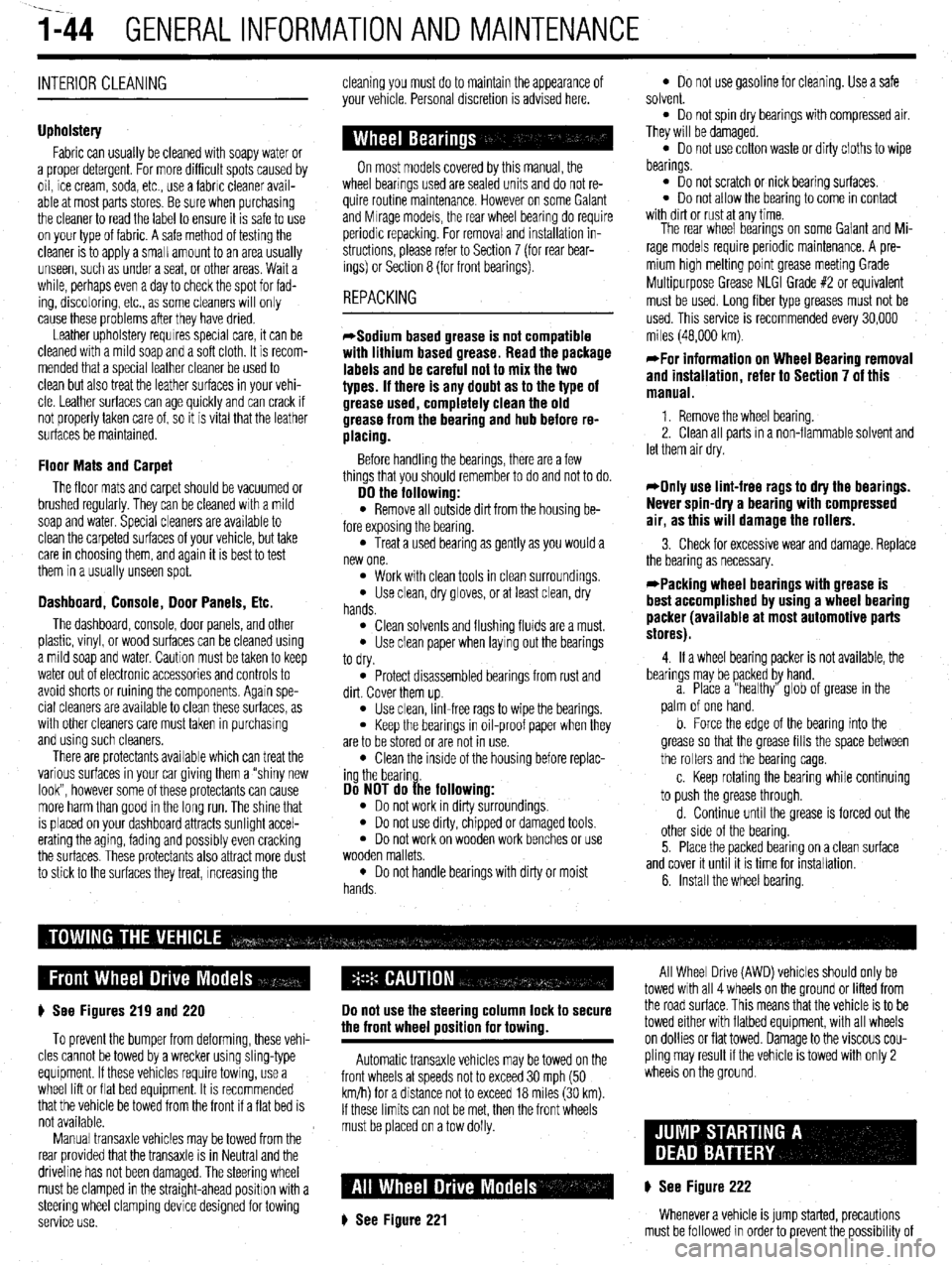

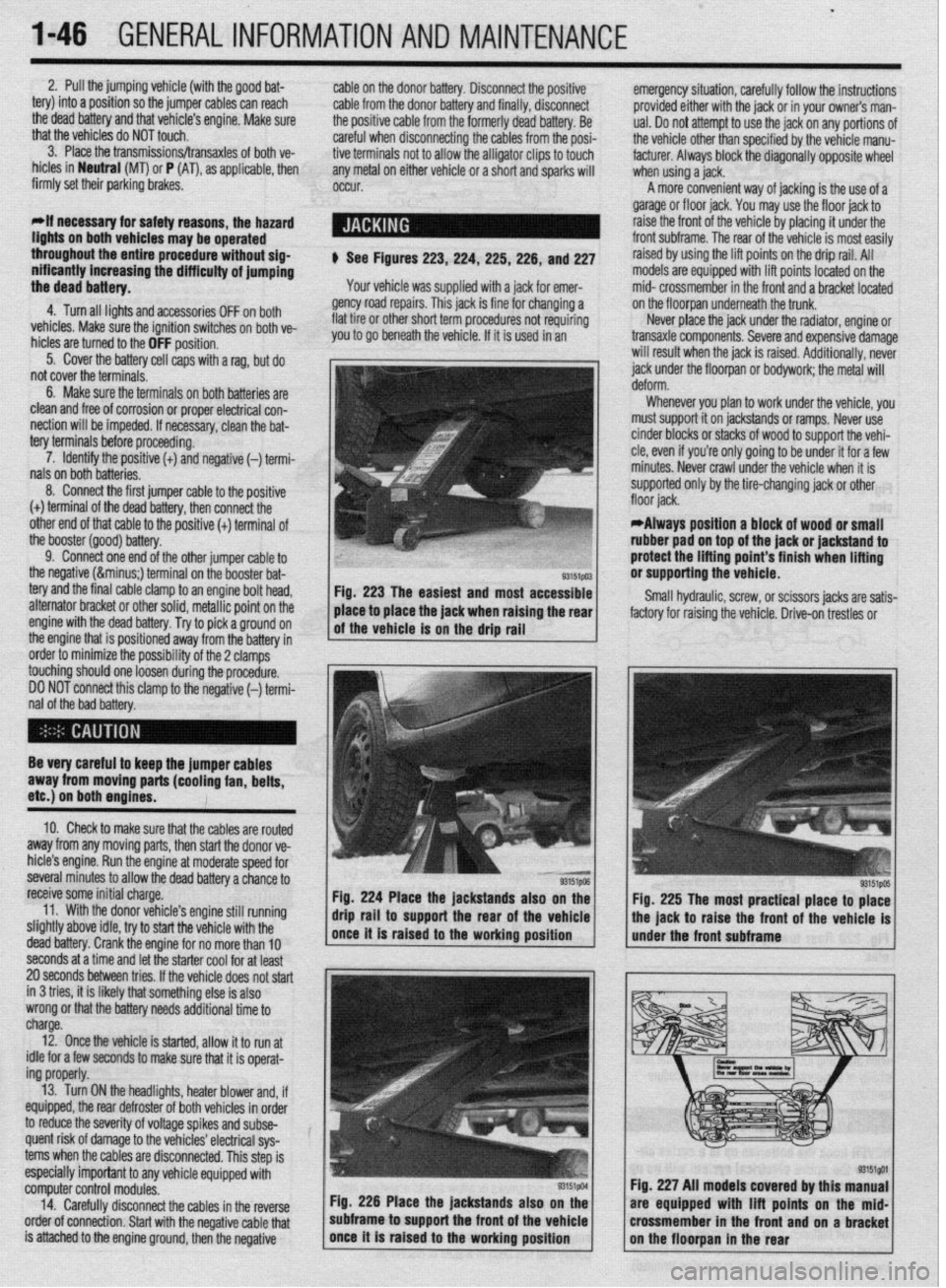

$ See Figures 223,224, 225,226, and 227

Your vehicle was supplied with a jack for emer-

gency road repairs. This jack is fine for changing a

flat tire or other short term procedures not requiring

you to go beneath the vehicle. If it is used in an emergency situation, carefully follow the instructions

provided either with the jack or in your owners man-

ual. Do not attempt to use the jack on any portions of

the vehicle other than specified by the vehicle manu-

facturer. Always block the diagonally opposite wheel

when using a jack.

A more convenient way of jacking is the use of a

garage or floor jack. You may use the floor jack to

raise the front of the vehicle by placing it under the

front subframe. The rear of the vehicle is most easily

raised by using the lift points on the drip rail. All

models are equipped with lift points located on the

mid- crossmember in the front and a bracket located

on the floorpan underneath the trunk.

Never place the jack under the radiator, engine or

transaxle components. Severe and expensive damage

will result when the jack is raised. Additionally, never

jack under the floorpan or

bodywork; the

metal will

Whenever you plan to work under the vehicle, you

must support it on jackstands or ramps. Never use

cinder blocks or stacks of wood to support the vehi-

cle, even if you’re only going to be under it for a few

minutes. Never crawl under the vehicle when it is

supported only by the tire-changing jack or other

*Always position a block of wood or small

rubber pad on top of the jack or jackstand to

protect the lifting point’s finish when lifting

or supporting the vehicle.

Small hydraulic, screw, or scissors jacks are satis-

factory for raising the vehicle. Drive-on trestles or

Be very careful to keep the jumper cables

away from moving parts (cooling fan, belts,

etc.) on both engines.

10. Check to make sure that the cables are routed

away from any moving parts, then start the donor ve-

hicle’s engine. Run the engine at moderate speed for

several minutes to allow the dead battery a chance to

receive some initial charge.

11. With the donor vehicle’s engine still running

slightly above idle, try to start the vehicle with the

dead battery. Crank the engine for no more than 10 &stands also on the

Fig. 225 The most practical place to place

front of the vehicle is

seconds at a time and let the starter cool for at least

20 seconds between tries. If the vehicle does not start

in 3 tries, it is likely thatsomething else is also

wrong or that the battery needs additional time to

charge.

12. Once the vehicle is started, allow it to run at

idle for a few seconds to make sure that it is operat-

ing properly.

13. Turn ON the headlights, heater blower and, if

equipped, the rear defroster of both vehicles in order

to reduce the severity of voltage spikes and subse-

quent risk of damage to the vehicles’ electrical sys-

tems when the cables are disconnected. This step is

especially important to any vehicle equipped with

computer control modules.

14. Carefully disconnect the cables in the’reverse

order of connection. Start with the negative cable that

is attached to the engine ground, then the negative Fig. 226 Place the jackstands also

subframe to support the front of the Fig. 227 All models covered by this

are equipped with lift points on t

crossmember in the front and on a

Page 55 of 408

.

2-8 ENGINEELECTRICAL

Front

of the

Vehicle

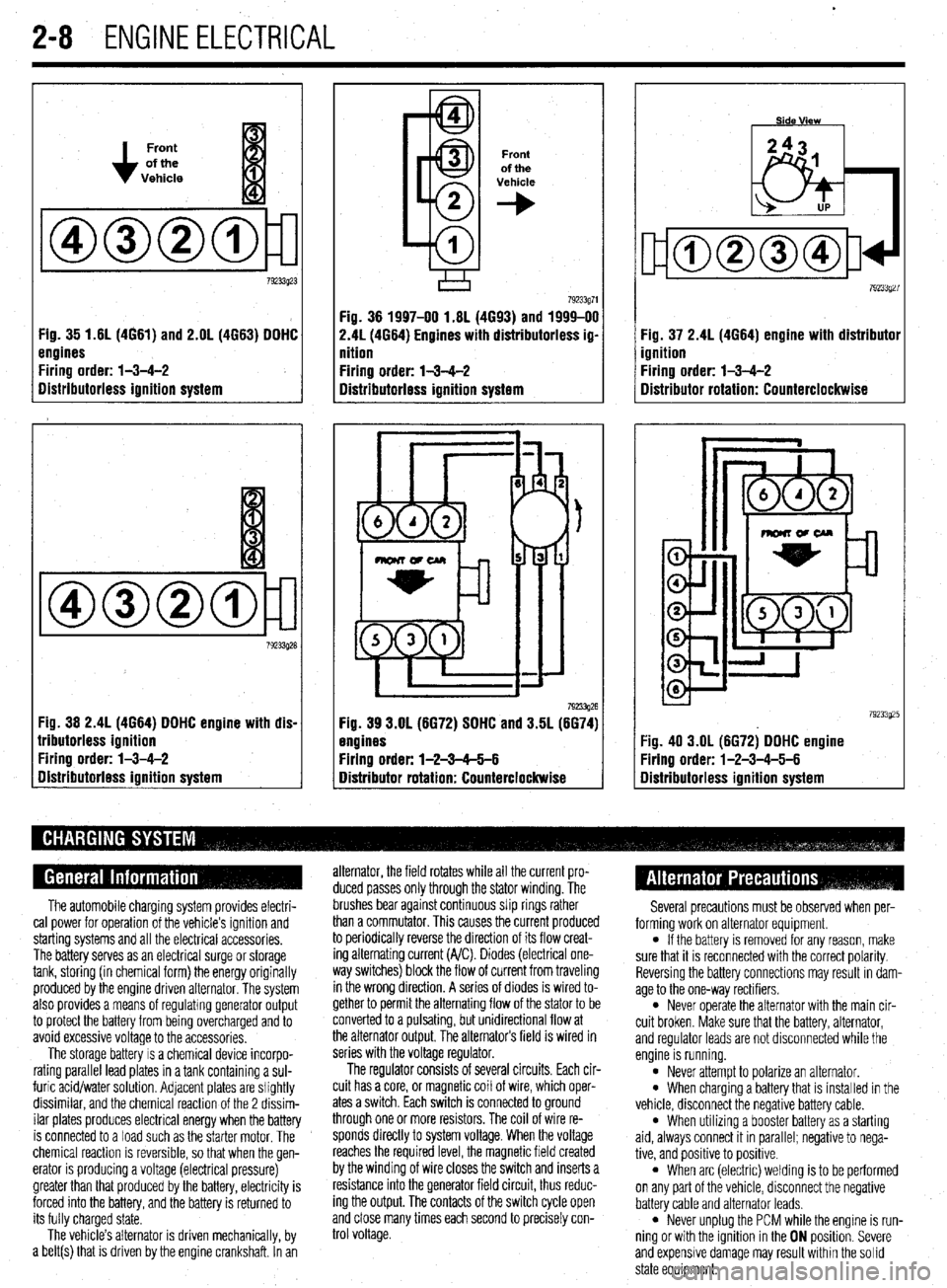

Fig. 35 1.61(4661) and 2.OL (4663) DDHC

engines

Firing order: l-3-4-2

Distributorless ignition system

Fig. 36 2.4L (4664) DDHC engine with dis-

lributorless ignition

Firing order: l-3-4-2

gistributorless ignition system

Front

of the

Vehicle

+

Fig. 36 1997-00 1.6L (4693) and 1999-00

2.41(4664) Engines with distributorless ig-

nition

Firing order: l-3-4-2

Distributorless ignition system

792!33g26 Fig. 39 3.OL (6672) SDHC and 3.5L (6674)

engines

Firing order: l-2-3-65-6

Distributor rotation: Counterclockwise Fig. 37 2.4L (4664) engine with distributor

ignition

Firing order: l-3-4-2

Distributor rotation: Counterclockwise

:ig. 40 3.OL (6672) DDHC engine

Yring order: l-2-3-4-5-6

Iistributorless ignition system

The automobile charging system provides electri-

cal power for operation of the vehicle’s ignition and

starting systems and all the electrical accessories.

The battery serves as an electrical surge or storage

tank, storing (in chemical form) the energy originally

produced by the engine driven alternator. The system

also provides a means of regulating generator output

to protect the battery from being overcharged and to

avoid excessive voltage to the accessories.

The storage battery IS a chemical device incorpo-

rating parallel lead plates in a tank containing a sul-

furic acid/water solution. Adjacent plates are slightly

dissimilar, and the chemical reaction of the 2 dissim-

ilar plates produces electrical energy when the battery

is connected to a load such as the starter motor. The

chemical reaction is reversible, so that when the gen-

erator IS producing a voltage (electrical pressure)

greater than that produced by the battery, electricity is

forced into the battery, and the battery is returned to

its fully charged state.

The vehicle’s alternator is driven mechanically, by

a belt(s) that is driven by the engine crankshaft. In an alternator, the field rotates while all the current pro-

duced passes only through the stator winding. The

brushes bear against continuous slip rings rather

than a commutator. This causes the current produced

to periodically reverse the direction of its flow creat-

ing alternating current (A/C). Diodes (electrical one-

way switches) block the flow of current from traveling

in the wrong direction. A series of diodes is wired to-

gether to permit the alternating flow of the stator to be

converted to a pulsating, but unidirectional flow at

the alternator output, The alternators field is wired in

series with the voltage regulator.

The regulator consists of several circuits. Each cir-

cuit has a core, or magnetic coil of wire, which oper-

ates a switch. Each switch is connected to ground

through one or more resistors. The coil of wire re-

sponds directly to system voltage. When the voltage

reaches the required level, the magnetic field created

by the winding of wire closes the switch and inserts a

resistance into the generator field circuit, thus reduc-

ing the output. The contacts of the switch cycle open

and close many times each second to precisely con-

trol voltage. Several precautions must be observed when per-

forming work on alternator equipment.

l If the battery is removed for any reason, make

sure that it is reconnected with the correct polarity.

Reversing the battery connections may result In dam-

age to the one-way rectifiers.

l Never operate the alternator with the main cir-

cuit broken. Make sure that the battery, alternator,

and regulator leads are not disconnected while the

engine is running.

l Never attempt to polarize an alternator. l When charging a battery that is installed in the

vehicle, disconnect the negative battery cable.

l When utilizing a booster battery as a starting

aid, always connect it in parallel; negatrve to nega-

tive, and positive to positrve.

l When arc (electric) welding is to be performed

on any part of the vehicle, disconnect the negative

battery cable and alternator leads.

l Never unplug the PCM while the engine is run-

ning or with the ignition in the ON position. Severe

and expensive damage may result within the solid

state equipment.

Page 56 of 408

ENGlNEELECTRldAL 2-9

TESTING

Voltage Test able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

REMOVAL&INSTALLATION

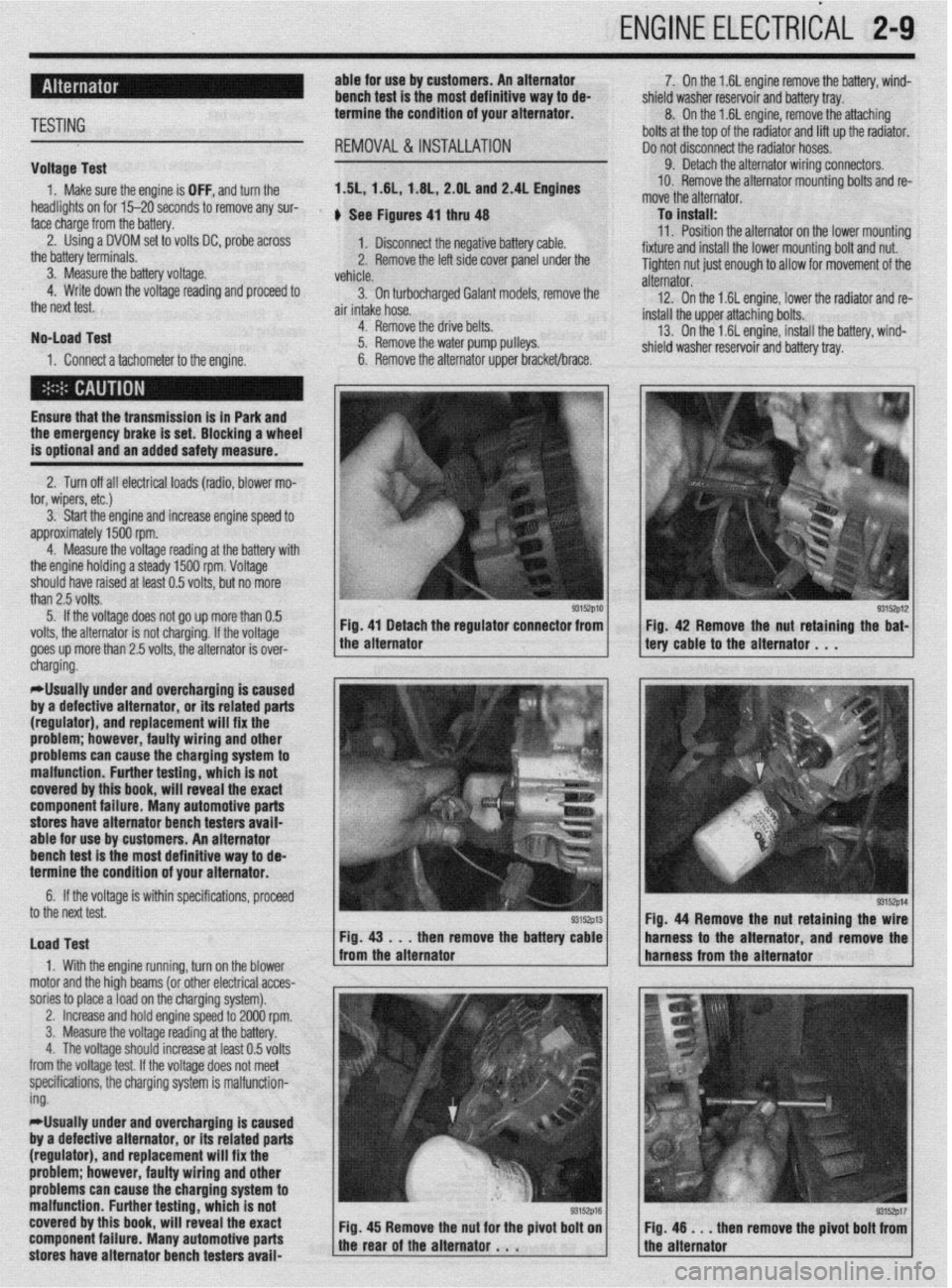

1. Make sure the engine is OFF, and turn the 1.51,1.61, 1.6L, 2.OL and 2.4L Engines

headlights on for 15-20 seconds to remove any sur-

face charge from the battery. , See Figures 4, thru 48

2. Using a DVOM set to volts DC, probe across

1. Disconnect the negative battery cable.

the battery terminals.

3. Measure the battery voltage. 2. Remove the left side cover panel under the

vehicle.

4. Write down the voltage reading and proceed to

3. On turbocharaed Galant models, remove the

the next test.

air intake hose. -

No-load Test

1. Connect a tachometer to the engine. 4. Remove the drive belts.

5. Remove the water pump pulleys.

6. Remove the alternator upper bracket/brace.

Ensure that the transmission

is in Park and the emergency brake is set. Blocking a wheel

is optional and an added safety measure.

2. Turn off all electrical loads (radio, blower mo-

tor, wipers, etc.)

3. Start the engine and increase engine speed to

approximately 1500 rpm.

4. Measure the voltage reading at the battery with

the engine holding a steady 1500 rpm. Voltage

should have raised at least 0.5 volts, but no more

than 2.5 volts.

5. If the voltage does not go up more than 0.5

volts, the alternator is not charging. If the voltage

goes up more than 2.5 volts, the alternator is over-

* 7. On the 1.6L engine remove the battery, wind-

shield washer reservoir and battery tray.

8. On the 1.6L engine, remove the attaching

bolts at the top of the radiator and lift up the radiator.

Do not disconnect the radiator hoses.

9. Detach the alternator wiring connectors.

10. Remove the alternator mounting bolts and re-

move the alternator.

To install:

11. Position the alternator on the lower mountina

fixture and install the lower mounting bolt and nut. U

Tighten nut just enough to allow for movement of the

alternator.

12. On the 1.6L engine, lower the radiator and re-

install the upper attaching bolts.

13. On the 1.6L engine, install the battery, wind-

shield washer reservoir and battery tray.

/ tery cable to the alternator . , . 93152p12 Fig 42 Remove the nut retaining the bat-

cnargmg.

*Usually under and overcharging is‘caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can

cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

6. If the voltage is within specifications, proceeU

to the next test.

Load Test

1. With the engine running, turn on the blower

motor and the hioh beams (or other electrical acces-

sories to place aioad on the charging system). Fig. 44 Remove the nut retaining the

then remove the batte harness to the alternator and remov

,

2. Increase and hold engine speed to 2000 rpm.

3. Measure the voltage reading at the battery.

4. The voltage should increase at least 0.5 volts

from the voltage test. If the voltage does not meet

specifications, the charging system is malfunction-

ing.

*Usually under and overcharging is caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

93152p17 en remove the pivot bolt from

Page 59 of 408

.

2-12 ENGINEELECTRICAL

*This section describes the operating prina

ciples of sending units, warning lights and

gauges. Sensors which provide information

to the Enafne Control Unit (ECU) or Electronic

or Power&in Control Module (FCM/PCM) are

covered in Section 4 of this manual.

Instrument panels contain a number of indicating

devices (gauges and warning lights). These devices

are composed of two separate components. One is

the sending unit, mounted on the engine or other re-

mote part of the vehicle, and the other is the actual

gauge or light in the instrument panel.

Several types of sending units exist, however most

can be characterized as being either a pressure type

or a resistance type. Pressure type sending units

convert liquid pressure into an electrical signal which

is sent to the gauge. Resistance type sending units

are most often used to measure temperature and use

variable resistance to control the current flow back to

the indicatinq device. Both types of sendinq units are

connected inseries by a wimto the batteryithiough

the ignition switch). When the ignition is turned ON,

current flows from the battery through the indicating

device and on to the sending unit.

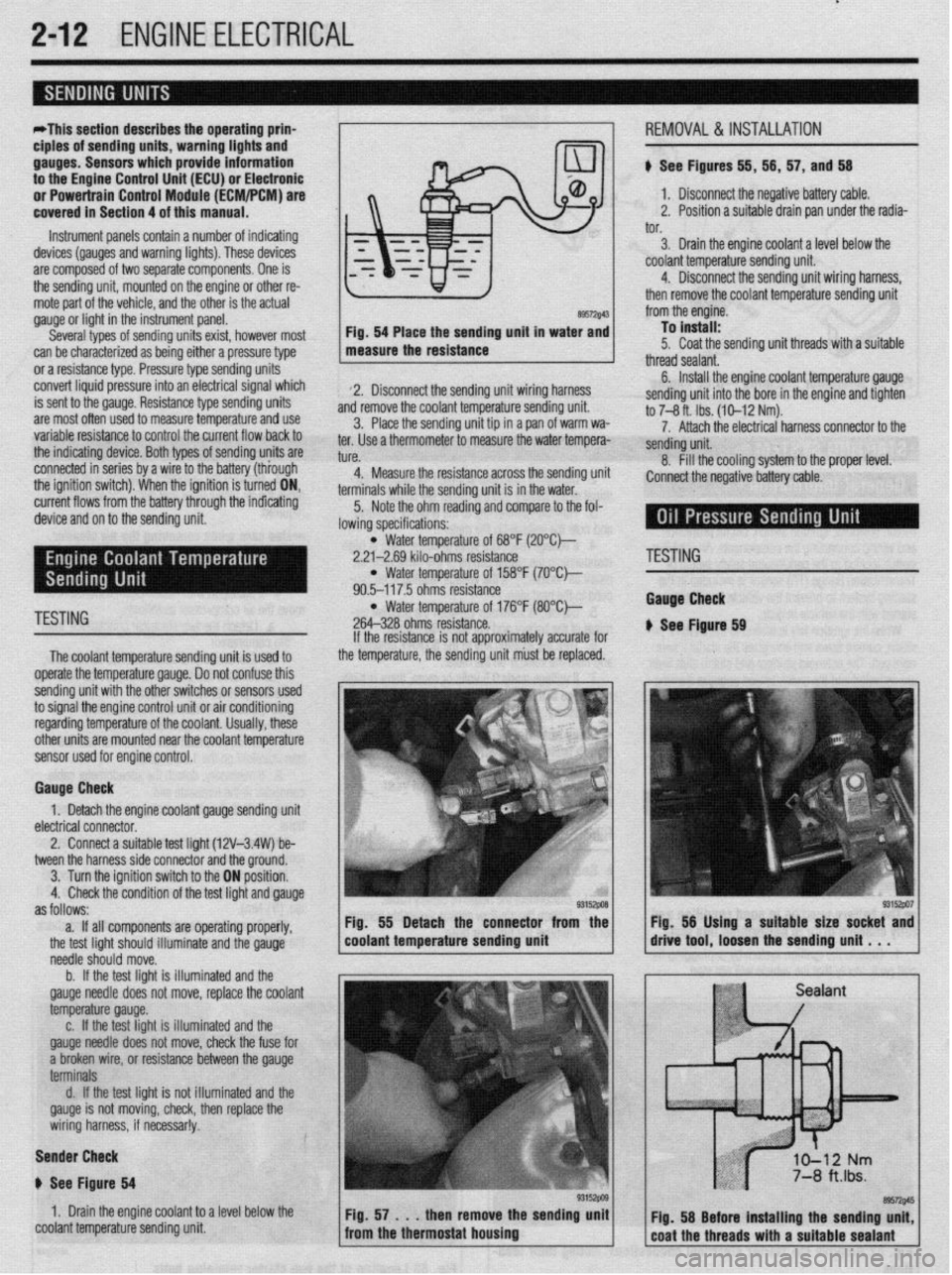

89572$43 Fig. 54 Place the sending unit in water and

measure the resistance

2. Disconnect the sending unit wiring harness

and remove the coolant temperature sending unit.

3. Place the sending unit tip in a pan of warm wa-

ter. Use a thermometer to measure the water tempera-

tl KP

L”,“.

4. Measure the resistance across the sending uni

terminals while the sending unit is in the water.

5. Note the ohm reading and compare to the fol-

lowing specifications: i, 56, 57, and 56

1. Disconnect the negative battery cable.

2. Position a suitable drain pan under the radia-

tor.

3. Drain the engine coolant a level below the

coolant temperature sending unit.

4. Disconnect the sending unit wiring harness,

then remove the coolant temperature sending unit

from the engine.

To install:

5. Coat the sending unit threads with a suitable

thread sealant.

6. Install the engine coolant temperature gauge

sending unit into the bore in the engine and tighten

to 7-8 ft. Ibs. (10-12 Nm).

7. Attach the electrical harness connector to the

sendina unit.

8. fill the cooling system to the proper level.

:onnect the negative battery cable.

l Water temperature of 68°F (2O”C)-

2.21-2.69 kilo-ohms resistance

l Water temperature of 158°F (7O’Ck

90.5-117.5 ohms resistance

TESTING l Water temperature of 176°F (8O”C)-

264-328 ohms resistance.

The coolant temperature sendina unit is used to

operate the temperature gauge. Donot confuse this

sending unit with the other switches or sensors used

to signal the engine control unit or air conditioning

regarding temperature of the coolant. Usually, these

other units are mounted near the coolant temoerature

sensor used for engine control. If the resistance is not approximately accurate for

the temperature, the sending unit must be replaced.

Gauge Check

1. Detach the engine coolant gauge sending unit

electrical connector.

2. Connect a suitable test liaht (12V-3.4W) be-

tween the harness side connector and the around.

I

3. Turn the ignition switch to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light should illuminate and the gauge

needle should move.

b. If the test light is illuminated and the

gauge needle does not move, replace the coolant

temperature gauge.

c. If the test light is illuminated and the

gauge needle does not move, check the fuse for

a broken wire, or resistance between the gauge

terminals

d. If the test light is not illuminated and the

gauge is not moving, check, then replace the

wiring harness, if necessar!y.

Sender Check

p See Figure 64

1. Drain the engine coolant to a level below the

coolant temperature sending unit Fig. 55 Detach the connector from the

coolant temperature sending unit

'ESTING

tauga Check

See Ftgure 69

Page 60 of 408

ENGINE ELECTRlCiL 2-13

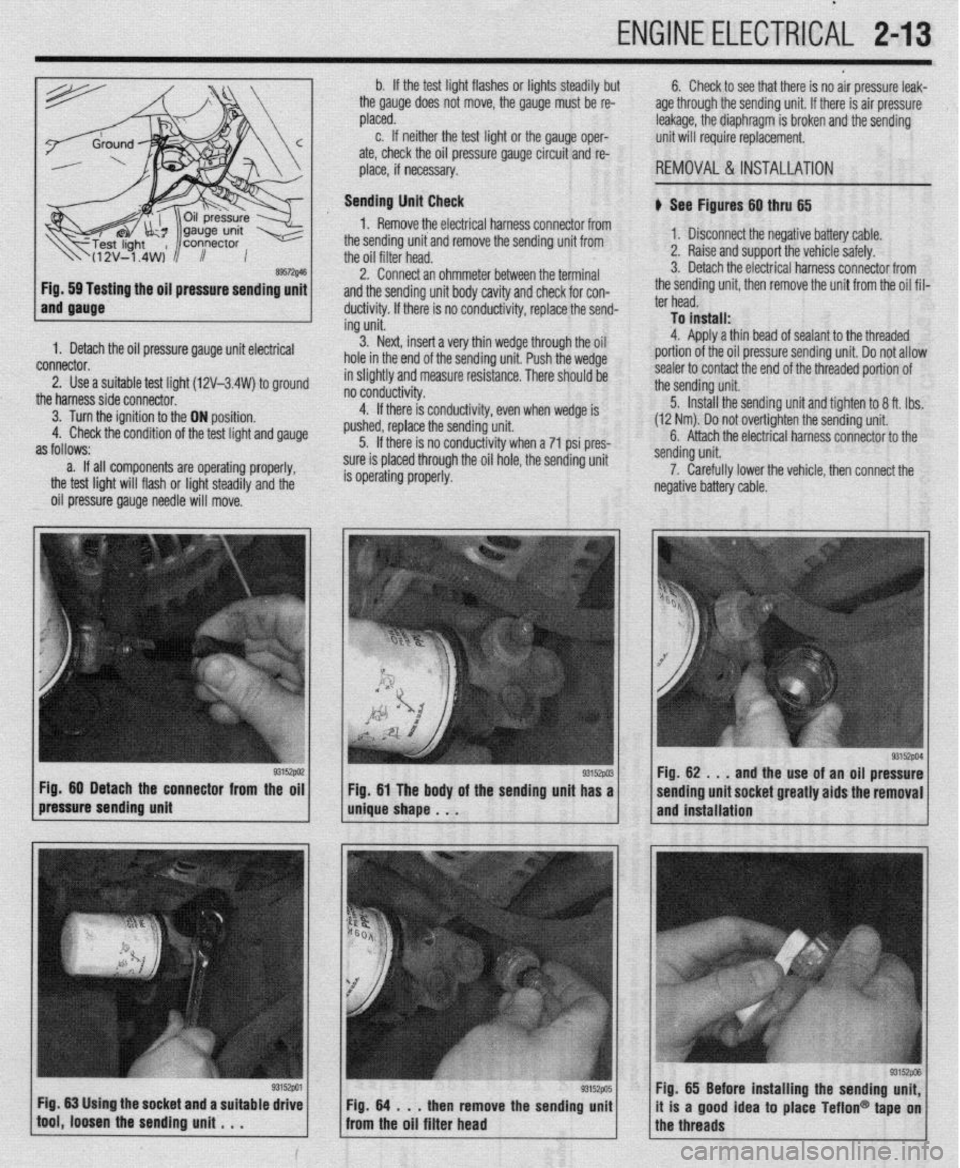

ing the oil pressure sending unit

1. Detach the oil pressure gauge unit electrical

connector.

2. Use a suitable test lioht (12V-3.4W) to around

the harnesssideconnecto~ ’ ’ -

3. Turn the ignition to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light will flash or light steadily and the

oil pressure gauge needle will move. b. If the test light flashes or lights steadily but

the gauge does not move, the gauge must be re-

placed.

c. If neither the test light or the gauge oper-

ate, check the oil pressure gauge circuit and re-

place, if necessary.

Sending Unit Check

1. Remove the electrical harness connector from

the sending unit and remove the sending unit from

the oil filter head.

2. Connect an ohmmeter between the terminal

and the sending unit body cavity and check for con-

ductivity. If there is no conductivity, replace the send-

ing unit.

3. Next, insert a very thin wedge through the oil

hole in the end of the sending unit. Push the wedge

in slightly and measure resistance. There should be

- - -- d . . . .

no conoucovey.

4. If there is conductivity, even when wedge is

pushed, replace the sending unit.

5. If there is no conductivity when a 71 psi pres-

sure is placed through the oil hole, the sending unit

is operating properly. 6. Check to see that there is no air pressure leak-

age through the sending unit. If there is air pressure

leakage, the diaphragm is broken and the sending

unit will require replacement.

REMOVAL &INSTALLATION

b See Figures 60 thru 65

1. Disconnect the negative battery cable.

2. Raise and support the vehicle safely.

3. Detach the electrical harness connector from

the sending unit, then remove the unit from the oil fil-

ter head.

To install:

4. Aoolv a thin bead of sealant to the threaded

portion of the oil pressure sending unit. Do not allow

sealer to contact the end of the threaded portion of

the sending unit.

5. Install the sending unit and tighten to 8 ft. tbs.

(12 Nm). Do not over-tighten the sending unit.

6. Attach the electrical harness connector to the

/pressure sending unit g3’9wi / m&e shape . . . Fig 60 Detach the connector from the oil

g3152w Fig 61 The body of the sending unit has a sending unit.

7. Carefully lower the vehicle, then connect the

negative battery cable.

93152PM Fig. 62 . , .

and the use of an oil pressure

sending unit socket greatly aids the removal

and installation

Fig. 65 Before installing the sending unit,

it is a good idea to place Teflon@ tape on

the threads