headlamp MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 57 of 408

.

2-10 ENGINEELECTRICAL 1

2. Disconnect and remove the air intake hose.

3. Loosen the tensioner pulley and remove the

alternator drive belt.

4. On California models, remove the rear bank

converter assembly.

5. Remove the engine roll stopper stay bracket

assembly.

6. On the 3.OL SDHC engine, disconneCt the

EGR temperature sensor wire and remove the EGR

pipe assembly.

7. On the 3.OL SOHC engine, remove the intake

plenum stay bracket assembly.

8. Detach the alternator wiring harness connec-

tors.

Fig, 47 Remove the alternator adjusting bolt

. a a 9. Remove the alternator upper and lower

mounting bolts.

10. From beneath the vehicle, remove the alterna-‘

I^”

._. To install:

11. Position the alternator on the lower mountino

fixture. Install and tighten the mounting bolt and nu<

to M-18 ft. Ibs. (20-25 Nm).

12. Connect the alternator wiring harness.

13. On the 3.OL SOHC engine, install the intake

plenum stay bracket and tighten the mounting bolt to

13 ft. Ibs. (18 Nm).

14. On the 3.OL SOHC engine, install the EGR

pipe and tighten the fitting connections to 43 ft. Ibs.

(60 Nm).

93152015

12. Position the alternator on the mour

sting hmrkd lnrtnll rmr( tinhtnn thn mm dim L VIUVI,VL. lllcllUll Ully llylllvll LltU ,,tvuln,,ly volt and nut

to 17 ft. Ibs. (24 Nm).

13. Reinstall the drive belt and adjust the ten-

pinnor fmtil the nmnor hdt toncinn ic art-:--~

15. On the 3.OL SOHC enoine. connect the EGR

- temperature sensor wire.

16. Connect the engine roll stopper stay and

tighten the mountina bolt to 35 ft. Ibs. (45 Nm) and

the nut to 36-43 ft. Tbs. (50-60 Nm).

’

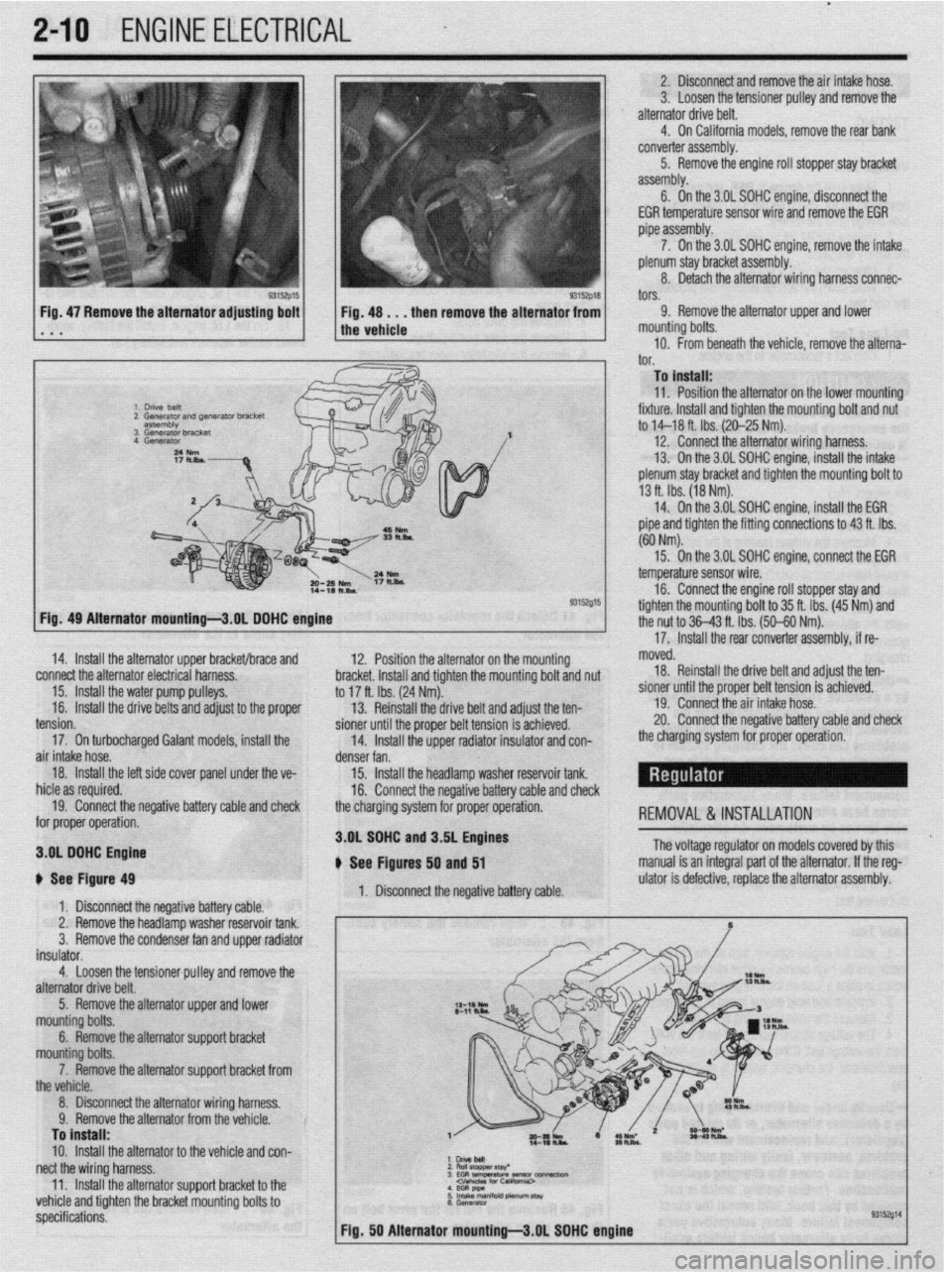

17. Install the rear converter assembly, if re- Fia. 49 Alternator mountinu-3.0L DOHC enoine

14. Install the alternator upper bracket/brace and

connect the alternator electrical harness.

15. Install the water pump pulleys.

16.

Install the drive belts and adjust to the proper moved.

18. Reinstall the drive belt and adjust the ten-

sioner until the proper belt tension is achieved.

19. Connect the air intake hose.

20. Connect the neoativa hatterv rzahle and check -_. -_. __. _. _=-__

_ _-.._. , ___ _ _. _ _ _ _

the charoina system for orooer ooeration. - - _ -rr- -- - I Ull” Yvll air intake hose.

denser fan.

18.

Install the left side cover panel unde

r the ve-

15. Install the headlamp washer reservoir tank.

hid@ zx ran~kwl 1IIVI” YY ‘“~“““Y.

16. Connect the negative battery cable and check

19. Connect the negative battery cable and check

the charging svstem for proper operation.

-,-.- for proper operation. REMOVAL &INSTALLATION

3.OL SOHC n C, n---I_--

3.OL DOHC Engine

i fhs Itin** tension.

17. On turbocharged Galant models, install the

b See Figure 49

1. Disconnect the negative battery cable.

2. Remove the headlamp washer reservoir tank.

3.

Remove the condenser fan and upper radiator

insulator.

4.

Loosen the tensioner pulley and remove the

alternator drive belt. and J.DL engines

, - , lyures 50 and 51

1. Disconnect the negative battery cable. The voltage regulator on models covered by this

manual is an integral part of the alternator. If the reg-

ulator is defective, replace the alternator assembly.

5. Remove the alternator upper and lower

mounting bolts.

6. Remove the alternator support bracket

mn~lntinn h&c

_ _ _ _ -. ._ ,_._

--TT-.. -.--..-. ..-...

the vehicle.

8. Disconnect the alternator wiring harness.

Q Romnm thn slternatnr frnm thn mhirln V. llYlll”“Y LI1”“I~Y1IIU,“I II”,,, Lll” ,“,,,“,“. To install:

10.

Install the alternator to the vehicle and con-

nect the wiring harness. :z

E$llaf 3EG RtEWtiW~-~ 11

Install the alternatnr wnnnrt hrxket tn thp .._. -.. .._ - .._..._._.

--rT-.. -.--..-. .- I.._ .P _ vehicle and tighten the bracket mounting bolts to

specifications.

Page 223 of 408

.

6-20 CHASSIS ELECTRICAL

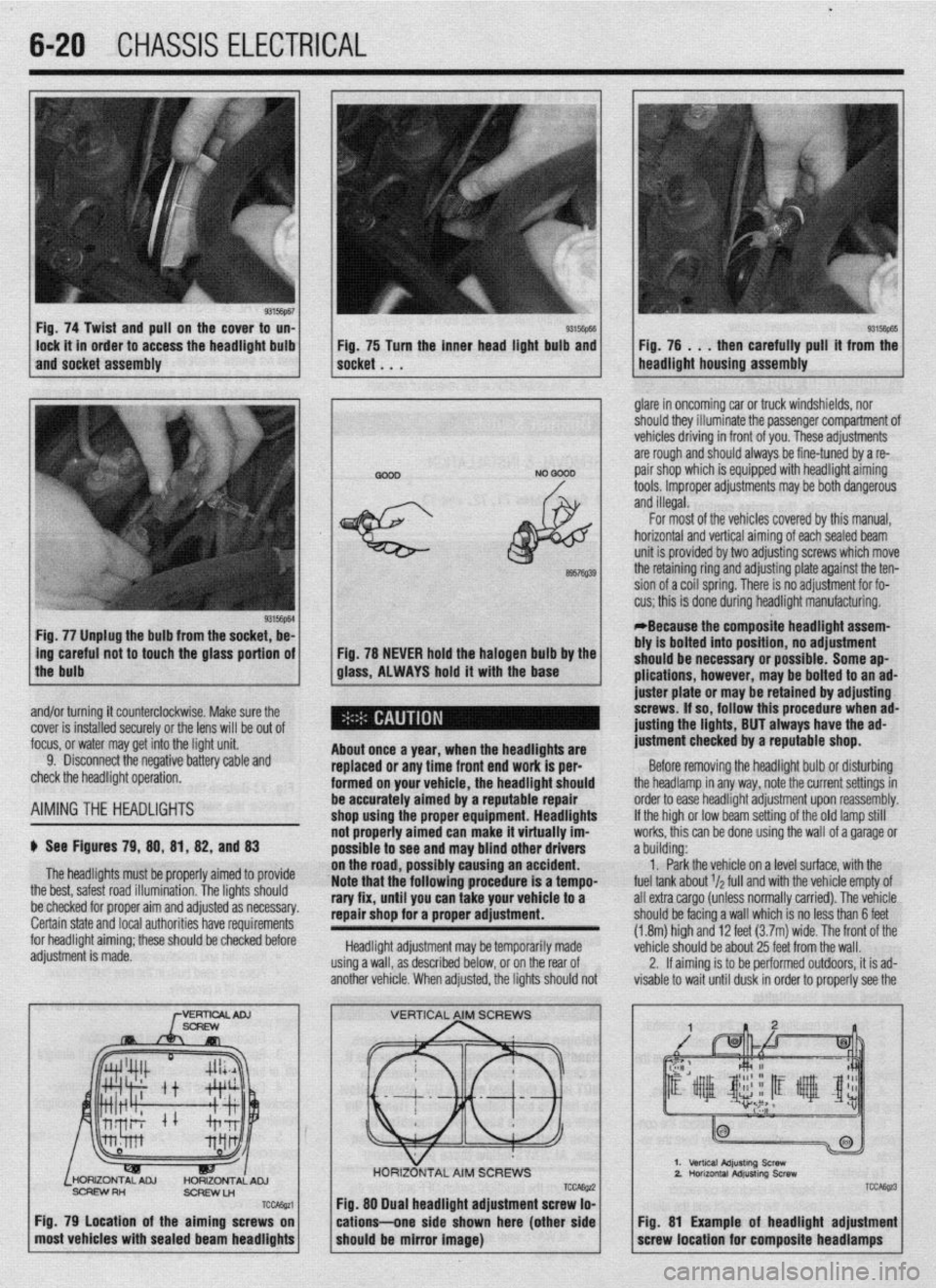

Fig. 74 Twist and pull on the cover to un-

lock it in order to access the headlight bulb

and socket assembly 93Mm Fig, 75 Turn the inner head light bulb and then carefully pull’ it from the

NO 0000 . glare in oncoming car or truck windshields, nor

should they illuminate the passenger compartment of

vehicles driving in front of you. These adjustments

are rough and should always be fine-tuned by a re-

pair shop which is equipped with headlight aiming

tools. Improper adjustments may be both dangerous

and illegal.

Fig. 77 Unplug the bulb from the socket, be-

L

ing careful not to touch the glass portion of

the bulb

I

6957Q39

Fig. 78 NEVER hold the halogen bulb by the

glass, ALWAYS hold it with the base

,

About once a year, when the headllgftts are

replaced or any time front end work is per-

formed on your vehicle, the headlight should

be accurately aimed by a reputable repair

shop uslng the proper equipment. Headlights

not properly aimed can make it virtually im-

possible to see ar Id may blind other drivers

ibly causing an accident.

Note that the’following procedure is a tempo-

rary fix, until you can take your vehicle to a

repair shop for a proper adjustment.

Headlight adjustment may be temporarily made

using a wall, as described below, or on the rear of

another vehicle. When adjusted, the lights should not For most of the vehicles covered by this manual,

horizontal and vertical aiming of eachsealed beam

unit is provided by two adjusting screws which move

the retaining ring and adjusting plate against the ten-

sion of a coil spring. There is no adjustment for fo-

cus; this is done during headlight manufacturing.

*Because the composite headlight assem-

bly is bolted into position, no adjustment

should be necessary or possible. Some ap-

plications, however, may be bolted to an ad-

juster plate or may be retained by adjusting

screws. If so, follow this procedure when ad-

@sting the lights, BUT always have the ad-

justment checked by a reputable shop.

Before removing the headlight bulb or disturbing

the headlamp in any way, note the current settings in

order to ease headlight adjustment upon reassembly.

If the high or low beam setting of the old lamp still

works, this can be done using the wall of a garage or

a building:

1. Park the vehicle on a level surface, with the

fuel tank about r/a full and with the vehicle empty of

all extra cargo (unless normally carried). The vehicle

should be facing a wall which is no less than 6 feet

(1.8m) high and 12 feet (3.7m) wide. The front of the

vehicle should be about 25 feet from the wall.

2. If aiming is to be performed outdoors, it is ad-

visable to wait until dusk in order to properly see the

% and/or turning it counterclockwise. Make sure the

cover is installed securely or the lens will be out of

focus, or water may get into the light unit.

9. Disconnect the negative battery cable and

check the headlight operation.

AIMINGTHE HEADLIGHTS

$ See Figures 79, 88, 81, 82, and 83

The headlights must be proper’ ’ ’ ’

the best, safest road illumination. ’ ’

ly armea IO provrae

The lights should

:.__1__1 __ - -___-_-. on the road, POSSI

be checked for proper aim and adfusreu as IlweSYdly. Certain state and local authorities have requirements

for headlight aiming; these should be checked before

adjustment is made.

SCFEWRH

ScFlEwLn

TCcAssa

Fig. 79 Location of the aiming screws on

most vehicles with sealed beam headlights

TCCAE@ Fig. 88 Dual headlight adjustment screw lo-

cations--one side shown here (other side

should be mirror image)

2.

TCC&z3

Fig. 81 Example of headlight adjustment

screw location for composite headlamps

Page 374 of 408

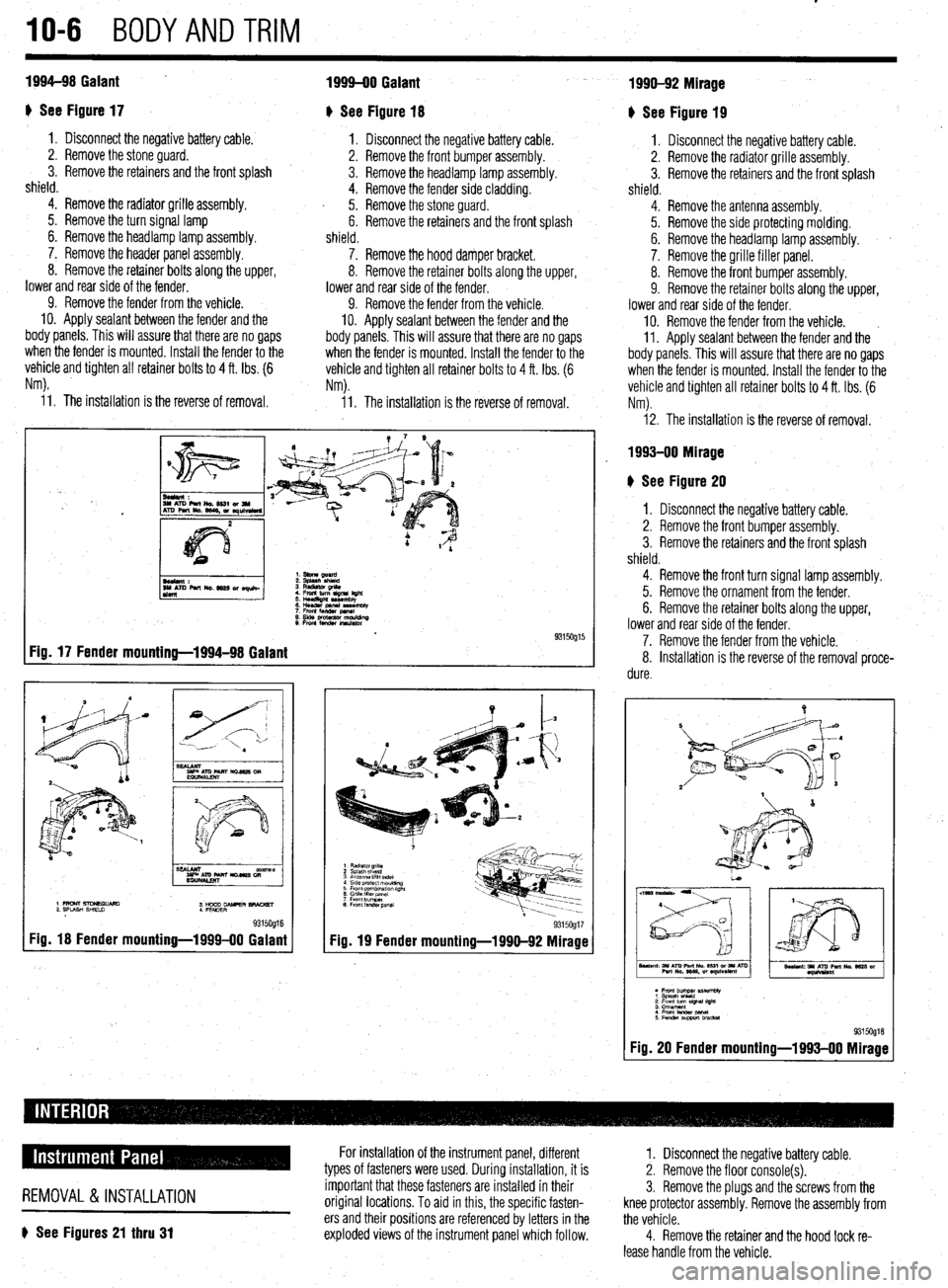

IO-6 BODYANDTRIM

1994-98 Galant .

I) See Figure 17

1. Disconnect the negative battery cable.

2. Remove the stone guard. -

3. Remove the retainers and the front splash

shield.

4. Remove the radiator grille assembly.

5. Remove the turn signal lamp

6. Remove the headlamp lamp assembly.

7. Remove the header panel assembly.

8. Remove the retainer bolts along the upper,

lower and rear side of the fender.

9. Remove the fender from the vehicle.

10. Apply sealant between the fender and the

body panels, This will assure that there are no gaps

when the fender is mounted. Install the fender to the

vehicle and tighten all retainer bolts to 4 ft. Ibs. (6

Nm).

I

L

1999-00 Galant

I) See Figure 18

1. Disconnect the negative battery cable.

2. Remove the front bumper assembly.

3. Remove the headlamp lamp assembly.

4. Remove the fender side cladding.

I 5. Remove the stone guard.

6. Remove the retainers and the front splash

shield.

7. Remove the hood damper bracket.

8. Remove the retainer bolts along the upper,

lower and rear side of the fender.

9. Remove the fender from the vehicle.

10. Apply sealant between the fender and the

body panels. This will assure that there are no gaps

when the fender is mounted. Install the fender to the

vehicle and tighten all retainer bolts to 4 ft. Ibs. (6

Nm).

i 1. The installation is the reverse of removal. 11. The installation is the reverse of removal.

Fig. 17 Fender mounting-1994-98 Galant

9315Og16 Fig. 18 Fender mounting-1999-00 Galant

Fig. 19 Fender mounting-1990-92 Mirage 93150917

1990-92 Mirage

+ See Figure 19

1. Disconnect the negative battery cable.

2. Remove the radiator grille assembly.

3. Remove the retainers and the front splash

shield.

4. Remove the antenna assembly.

5. Remove the side protecting molding.

6. Remove the headlamp lamp assembly. a

7. Remove the grille filler panel.

8. Remove the front bumper assembly.

9. Remove the retainer bolts along the upper,

lower and rear side of the fender.

IO. Remove the fender from the vehicle. ~

11. Apply sealant between the fender

and the

body panels. This will assure that there are no gaps

when the fender is mounted. Install the fender to the

vehicle and tighten all retainer bolts to 4 ft. Ibs. (6

Nm).

12. The installation is the reverse of removal.

1993-00 Mirage

b See Figure 20

I. Disconnect the negative battery cable.

2. Remove the front bumper assembly.

3. Remove the retainers and the front splash

shield.

4. Remove the front turn signal lamp assembly.

5. Remove the ornament from the fender.

6. Remove the retainer bolts along the upper,

lower and rear side of the fender.

7. Remove the fender from the vehicle.

8. Installation is the reverse of the removal proce-

dure.

l Font bummer pISeWtbly 1 Splash shield

; !$yum~ slgwl l!gM 4. From lander panal

5Fenderswtlbracket 93150918 Fig. 20 Fender mounting-1993-00 Mirage

REMOVAL &INSTALLATION

6 See Figures 21 thru 31

For installation of the instrument panel, different

types of fasteners were used. During installation, it is

important that these fasteners are installed in their

original locations. To aid in this, the specific fasten-

ers and their positions are referenced by letters in the

exploded views of the instrument panel which follow. 1. Disconnect the negative battery cable.

2. Remove the floor console(s).

3. Remove the plugs and the screws from the

knee protector assembly. Remove the assembly from

the vehicle.

4. Remove the retainer and the hood lock re-

lease handle from the vehicle.

Page 395 of 408

TROUBLESHOOTING 11-13

NOTE: When one shock fails, ft is recommended to replace front or rear

units as pairs.

3. Vehicle leans excessively in turns

a. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

b. Check for missing, damaged, or worn stabilizer links or bushings, and replace or in-

stall as necessary.

4. Vehicle ride quality seems excessively ha&h

a. Check for seized shock absorbers or strut assemblies and replace as necessary.

b. Check for excessively high tire pressures and adjust pressures to vehicle recommen-

dations.

5. Vehicle seems low or leans to one side

a. Check for a damaged, broken or weak spring. Replace defective parts and check for a

needed alignment.

b. Check for seized shock absorbers or strut assemblies and replace as necessary.

c. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

Noises 1. Vehicle makes a clicking noises when driven

a. Check the noise to see if it varies with road speed. Verify if the noise is present when

coasting or with steering or throttle input. If the clicking noise frequency changes with

road speed and is not affected by steering or throttle input, check the tire treads for a

stone, piece of glass, nail or another hard object imbedded into the tire or tire tread.

Stones rarely cause a tire puncture and are easily removed. Other objects may create

an air leak when removed. Consider having these objects removed immediately at a

facility equipped to repair tire punctures.

b. If the clicking noise varies with throttle input and steering, check for a worn Constant

Velocity (CV-joint) joint, universal (U- joint) or flex joint.

2. Vehicle makes a clunking or knocking noise over bumps

a. A clunking noise over bumps is most often caused by excessive movement or clear-

ance in a suspension component. Check the suspension for soft, cracked, damaged or

worn bushings. Replace the bushings and check the vehicle’s alignment.

b. Check for loose suspension mounting bolts. Check the tightness on subframe bolts,

pivot bolts and suspension mounting bolts, and torque to specification.

c. Check the vehicle for a loose wheel bearing. Some wheel bearings can be adjusted for

looseness, while others must be replaced if loose. Adjust or replace the bearings as

recommended by the manufacturer.

d. Check the door latch adjustment. If the door is slightly loose, or the latch adjustment

is not centered, the door assembly may create noises over bumps and rough surfaces.

Properly adjust the door latches to secure the door. 3. Vehicle makes a low pitched rumbling noise when driven

a. A low pitched rumbling noise is usually caused by a drive train related bearing and is

most often associated with a wheel bearing which has been damaged or worn. The

damage can be caused by excessive brake temperatures or physical contact with a pot

hole or curb. Sometimes the noise will vary when turning. Left hand turns increase the

load on the vehicle’s right side, and right turns load the left side. A failed front wheel

bearing may also cause a slight steering wheel vibration when turning. A bearing

which exhibits noise must be replaced.

b. Check the tire condition and balance. An internally damaged tire may cause failure

symptoms similar to failed suspension parts. For diagnostic purposes, try a known

good set of tires and replace defective tires.

4. Vehicle makes a squeaking noise over bumps

a. Check the vehicle’s ball joints for wear, damaged or leaking boots. Replace a ball joint

if it is loose, the boot is damaged and leaking, or the ball joint is binding. When re-

placing suspension parts, check the vehicle for alignment.

b. Check for seized or deteriorated bushings. Replace bushings that are worn or dam-

aged and check the vehicle for alignment.

c. Check for the presence of sway bar or stabilizer bar bushings which wrap around the

bar. Inspect the condition of the bushings and replace if worn or damaged. Remove

the bushing bracket and apply a thin layer of suspension grease to the area where the

bushings wrap around the bar and reinstall the bushing brackets. ~

5. Vehicle vibrates when driven

a. Check the road surface. Roads which have rough or uneven surfaces may cause un-

usual vi brations.

b. Check the tire condition and balance. An internally damaged tire may cause failure

symptoms similar to failed suspension parts. For diagnostic purposes, try a known

good set of tires and replace defective tires immediately.

c. Check for a worn Constant Velocity (CV-joint) joint, universal (U- joint) or flex joint

and replace if loose, damaged or binding.

d. Check for a loose, bent, or out-of-balance axle or drive shaft. Replace damaged or

failed components.

NOTE: Diagnosing failures related to wheels, tires, steering and the sus-

pension system can often times be accomplished with a careful and thor-

ough test drive. Bearing noises are isolated by noting whether the noises

or symptoms vary when turning left or right, or occur while driving a

straight line. During a teft hand turn, the vehicle’s weight shifts to the

right, placing more force on the right side bearings, such that if a right side

wheel bearing is worn or damaged, the noise or vibration should increase

during light-to-heavy acceleration. Conversely, on right hand turns, the ve-

hicle tends to lean to the left, loading the left side bearings.

Knocking noises in the suspension when the vehicle is driven over rough roads, rail-

road tracks and speed bumps indicate worn suspension components such as bushings,

ball joints or tie rod ends, or a worn steering system.

1. One headlight only works on high or low beam

a. Check for battery voltage at headlight electrical connector. If battery voltage is present,

replace the headlight assembly or bulb if available separately. If battery voltage is not

present, refer to the headlight wiring diagram to troubleshoot.

2. Headlight does not work on high or low beam

a. Check for battery voltage and ground at headlight electrical connector. If battery volt-

age is present, check the headlight connector ground terminal for a proper ground. If

battery voltage and ground are present at the headlight connector, replace the head-

light assembly or bulb if available separately. If battery voltage or ground is not pre-

sent, refer to the headlight wiring diagram to troubleshoot.

b. Check the headlight switch operation. Replace the switch if the switch is defective or

ooerates intermittentlv. 1. Tail light, running light or side marker light inoperative

a. Check for battery voltage and ground at light’s electrical connector. If battery voltage is

present, check the bulb socket and electrical connector ground terminal for a proper

ground. If battery voltage and ground are present at the light connector, but not in the

socket, clean the socket and the ground terminal connector. If battery voltage and

ground are present in the bulb socket, replace the bulb. If battery voltage or ground is

not present, refer to the wiring diagram to troubleshoot for an open circuit.

b. Check the light switch operation and replace if necessary.

2. Tall light, running light or side marker light works intermittently

a. Check the bulb for a damaged filament, and replace if damaged.

b. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

w 3. Headlight(s) very dim

a. Check for battery voltage and ground at headlight electrical connector. If battery volt-

age is present, trace the ground circuit for the headlamp electrical connector, then

clean and repair as necessary. If the voltage at the headlight electrical connector is

significantly less than the voltage at the battery, refer to the headlight wiring diagram

to troubleshoot and locate the voltage drop. c. Check for loose, damaged or corroded wires and electrical terminals, and repair as

necessary.

d. Check the light switch operation and replace if necessary.

3. Tail light, running light or side marker light very dim

a. Check the bulb and bulb socket for corrosion and clean or replace the bulb and

socket.