warning MITSUBISHI DIAMANTE 1900 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 361 of 408

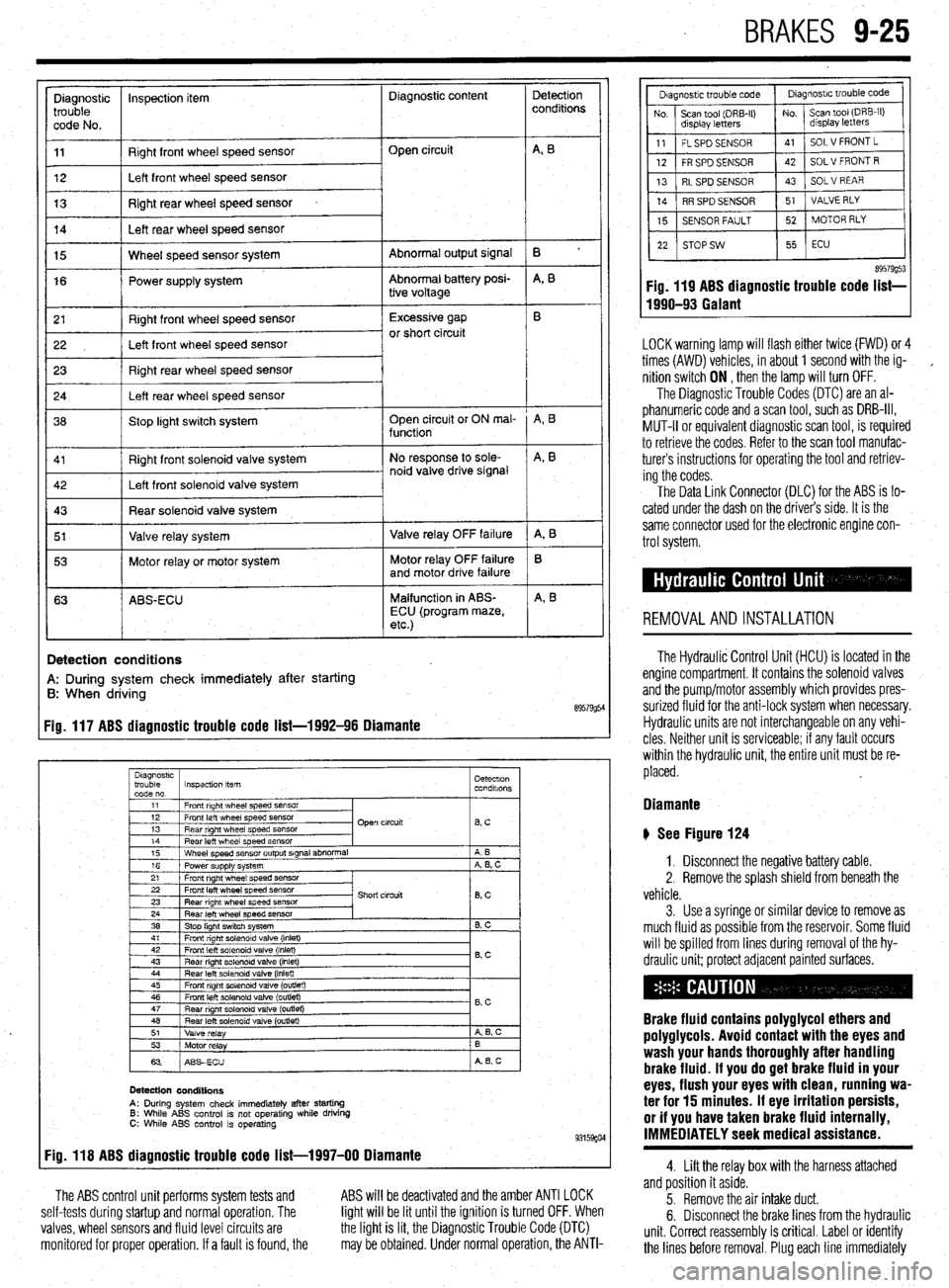

BRAKES 9-25

Diagnostic inspection item Diagnostic content

trouble

code No.

11 Right front wheel speed sensor

12 Left front wheel speed sensor Open circuit

13 Right rear wheel speed sensor

14 Left rear wheel speed sensor

Abnormal output signal

Abnormal battery posi-

tive voltage 15 Wheel speed sensor system

16 Power supply system

r 21

I Right front wheel speed sensor 1 Excessive gap

22 I Left front wheel speed sensor or short circuit

23 Right rear wheel speed sensor

24 Left rear wheel speed sensor

36 Stop light switch system Open circuit or ON mal-

function

Right front solenoid valve system

I 5’ I Valve relay system 1 Valve relay OFF failure

I 53 1 Motor relay or motor system Motor relay OFF failure

and motor drive failure

63 ABS-ECU Malfunction in ABS-

ECU (program maze,

etc.)

I

!

Detection

conditions

B ’

A, B

A, B

A, B

A, 8

B

A, B

Detection conditions

A: During system check immediately after starting

B: When driving

89579954 Fig. 117 ABS diagnostic trouble code list-1992-96 Diamante

Diagnostrc

trouble Inspection item Detectron

code no. condalons

1

11 1 Front right wheel speed SensOr

I

I I

12 1 Front left wheel speed sensor

13 1 Rear right wheel speed sensor Open circuit

lBsC I

14

Rear left wheel speed sensor

15 Wheel speed sensor output signal abnormal

16 Power supply system

21 Front right wheel speed sensor A B

A, B, C

22 Front left wheel speed sensor

23 Rear right wheel speed sensor

24 Rear left wheel speed sensor

38 Stop light switch system Short circuit

8, c

B. C

41 1 Front right solenoid valve (inlet)

I I

42

Front left solenoid valve (inlet)

43 Rear right solenord valve (inlet) 0.c

44 Rear left solenoid valve (inlet)

45 Front right solenoid valve (outlet)

46 Front left solenoid valve (outlet)

47

Rear nght solenoid valve (outret) - B,C

48 Rear left solenoid valve (outlet)

51

Valve relay A 6, c

53

Motor relay B

63 ABSECU A B, c

Detection conditions

A: During system check immediately after starting 6: While ABS control is not operating while driving C: While ABS control is operating 93159go4 Fig. 118 ABS diagnostic trouble code list-1997-00 Diamante

The ABS control unit performs system tests and

self-tests during startup and normal operation. The

valves, wheel sensors and fluid level circuits are

monitored for proper operation. If a fault is found, the ABS will be deactivated and the amber ANTI LOCK

light will be lit until the ignition is turned OFF. When

the light is lit, the Diagnostic Trouble Code (DTC)

may be obtained. Under normal operation, the ANTI-

89579g53 Fig. 119 ABS diagnostic trouble code list-

1990-93 Galant

LOCK warning lamp will flash either twice (FWD) or 4

times (AWD) vehicles, in about 1 second with the ig-

,

nition switch ON , then the lamp will turn OFF.

The Diagnostic Trouble Codes (DTC) are an al-

phanumeric code and a scan tool, such as DRB-III,

MUT-II or equivalent diagnostic scan tool, is required

to retrieve the codes. Refer to the scan tool manufac-

turers instructions for operating the tool and retriev-

ing the codes.

The Data Link Connector (DLC) for the ABS is lo-

cated under the dash on the driver’s side. It is the

same connector used for the electronic engine con-

trol system.

REMOVALANDINSTALLATION

The Hydraulic Control Unit (HCU) is located in the

engine compartment. It contains the solenoid valves

and the pump/motor assembly which provides pres-

surized fluid for the anti-lock system when necessary.

Hydraulic units are not interchangeable on any vehi-

cles Neither unit is serviceable; if any fault occurs

within the hydraulic unit, the entire unit must be re-

placed.

Diamante

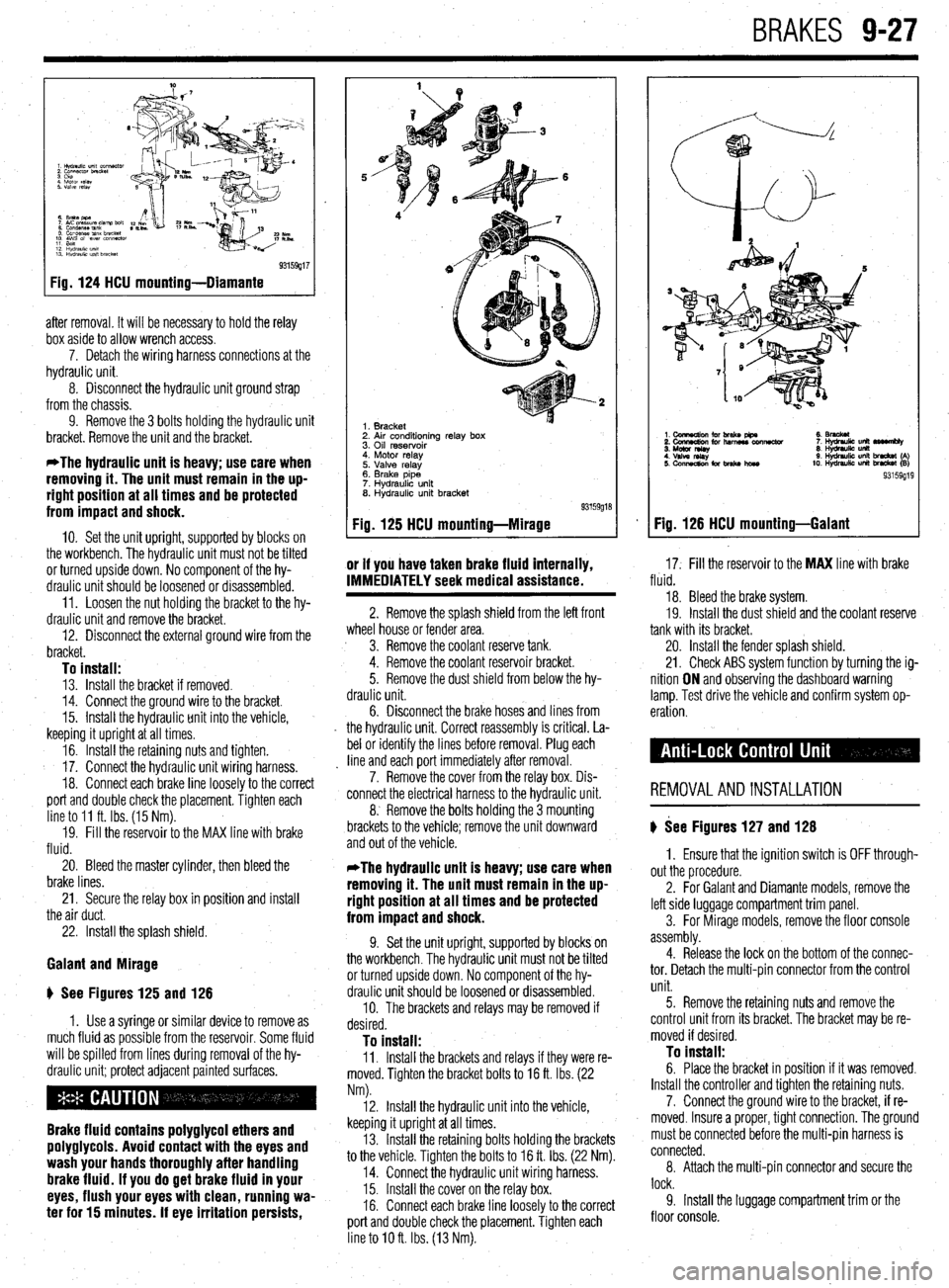

b See Figure 124

1. Disconnect the negative battery cable.

2. Remove the splash shield from beneath the

vehicle.

3. Use a syringe or similar device to remove as

much fluid as possible from the reservoir. Some fluid

will be spilled from lines during removal of the hy-

draulic unit; protect adjacent painted surfaces.

Brake fluid contains polyglycol ethers and

poly9lycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brake fluid. If you do 9et brake fluid in your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

4. Lift the relay box with the harness attached

and position it aside.

5. Remove the air intake duct.

6. Disconnect the brake lines from the hydraulic

unit. Correct reassembly is critical. Label or identify

the lines before removal. Plug each line immediately

Page 363 of 408

BRAKES 9-27

93159g17

Fig. 124 HCU mounting-Diamante

after removal. It will be necessary to hold the relay

box aside to allow wrench access.

7. Detach the wiring harness connections at the

hydraulic unit.

8. Disconnect the hydraulic unit ground strap

from the chassis.

9. Remove the 3 bolts holding the hydraulic unit

bracket. Remove the unit and the bracket.

*The hydraulic unit is heavy; use care when

removing it. The unit must remain in the up-

right position at all times and be protected

from impact and shock.

IO. Set the unit upright, supported by blocks on

the workbench. The hydraulic unit must not be tilted

or turned upside down. No component of the hy-

draulic unit should be loosened or disassembled.

11. Loosen the nut holding the bracket to the hy-

draulic unit and remove the bracket.

12. Disconnect the external ground wire from the

bracket.

To install: 13. Install the bracket if removed.

14. Connect the ground wire to the bracket.

15. Install the hydraulic unit into the vehicle,

keeping it upright at all times.

16. Install the retaining nuts and tighten.

17. Connect the hydraulic unit wiring harness.

18. Connect each brake line loosely to the correct

port and double check the placement. Tighten each

line to 11 ft. Ibs. (15 Nm).

19. Fill the reservoir to the MAX line with brake

fluid.

20. Bleed the master cylinder, then bleed the

brake lines.

21. Secure the relay box in position and install

the air duct.

22. Install the splash shield.

Galant and Mirage

ti See Figures 125 and 126

1. Use a syringe or similar device to remove as

much fluid as possible from the reservoir. Some fluid

will be spilled from lines during removal of the hy-

draulic unit; protect adjacent painted surfaces.

Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brake fluid. If you do get brake fluid in your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

1. Bracket

2. Air conditioning relay box

3. Oil reservoir

4. Motor relay

5. Valve relay

6. Brake pipe

7. Hydraulic unit

8. Hydraulic unit bracket

Fig. 125 HCU mounting-Mirage

or if you have taken brake fluid internally,

17. Fill the reservoir to the MAX line with brake IMMEDIATELY seek medical assistance. fluid.

2. Remove the splash shield from the left front

wheel house or fender area.

3. Remove the coolant reserve tank.

4. Remove the coolant reservoir bracket.

5. Remove the dust shield from below the hy-

draulic unit.

6. Disconnect the

brake hoses and lines from

the hydraulic unit. Correct reassembly is critical. La-

bel or identify the lines before removal. Plug each

line and each port immediately after removal.

7. Remove the cover from the relay box. Dis-

connect the electrical harness to the hydraulic unit.

8. Remove the bolts holding the 3 mounting

brackets to the vehicle; remove the unit downward

and out of the vehicle. 18. Bleed the brake system.

19. Install the dust shield and the coolant reserve

tank with its bracket.

20. Install the fender splash shield.

21. Check ABS system function by turning the ig-

nition ON and observing the dashboard warning

lamp. Test drive the vehicle and confirm system op-

eration.

REMOVALANDINSTALLATION

) See Figures 127 and 128

*The hydraulic unit is heavy; use care when

removing it. The unit must remain in the up-

right position at all times and be protected

from impact and shock.

9. Set the unit upright, supported by blocks on

the workbench. The hydraulic unit must not be tilted

or turned upside down. No component of the hy-

draulic unit should be loosened or disassembled.

10. The brackets and relays may be removed if

desired.

To install: 11. Install the brackets and relays if they were re-

moved. Tighten the bracket bolts to 16 ft. Ibs. (22

Nm). 1. Ensure that the ignition switch is OFF through-

out the procedure.

2. For Galant and Diamante models, remove the

left side luggage compartment trim panel.

3. For Mirage models, remove the floor console

assembly.

4. Release the lock on the bottom of the connec-

tor. Detach the multi-pin connector from the control

unit.

12. Install the hydraulic unit into the vehicle,

keeping it upright at all times.

13. Install the retaining bolts holding the brackets

to the vehicle. Tighten the bolts to 16 ft. Ibs. (22 Nm).

14. Connect the hydraulic unit wiring harness.

15. Install the cover on the relay box.

16. Connect each brake line loosely to the correct

port and double check the placement. Tighten each

line to IO ft. Ibs. (13 Nm). 5. Remove the retaining nuts and remove the

control unit from its bracket. The bracket may be re-

moved if desired. To install: 6. Place the bracket in position if it was removed.

Install the controller and tighten the retaining nuts.

7. Connect the ground wire to the bracket, if re-

moved. Insure a proper, tight connection. The ground

must be connected before the multi-pin harness is

connected.

8. Attach the multi-pin connector and secure the

lock.

9. Install the luggage compartment trim or the

floor console.

Fig. 126 HCU mounting-Galant

Page 376 of 408

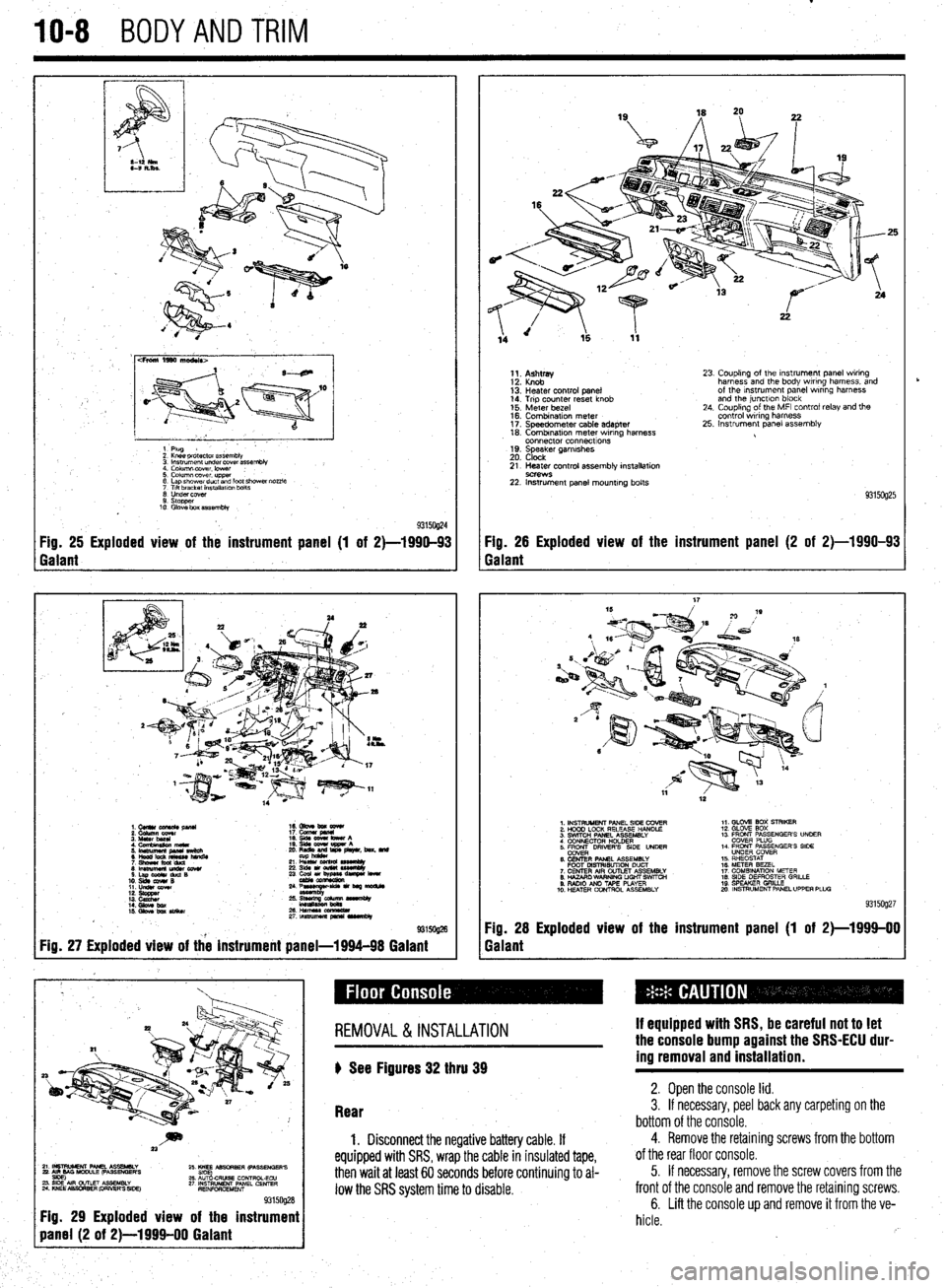

IO-8 BODYANDTRIM

cFroni 1990 ma&Is>

1 Plug

2 Knee pr&ctor assembb

3 lnsuumen~ under covet assembly

4. Column lxwer. lower :

5. Column cover upper

6 Lap shower duct and foot shcwai nozzle

7 Ttlt bracket installalm bolts

0 Undercover

9. stopper

10 Glove box assembly

93150@4 Fig. 25 Exploded view of the instrument panel (1 of 2)-1990-93 Fig. 26 Exploded view of the instrument panel (2 of 2)-1990-93

Galant Galant

1.CUllUCU+RC&pllU 16. Gbve bm eewr

i: iiiikz!!T 17. cucw gmnl

4. Cfnnbinuion meta 19. qds cww bww A

5 ‘~fiJzg%L L: ,“zr&, beat. md

21 L% sssemuy

8lmwmemu&cowr 236&1ou(W~

S.LapOdrduQB

10. slds cw4# B 23 ~u,~e-

11. LIdsI corn

::: s%ZZ

14. Gbw bx / ;:+q-=:-

kmasa

IS. Gkw ba SIiikw 2&HWSSCCl!ZL

2rtnsmlmuapr*lrvrnbly

@ma

Fig. 27 Exploded view of the instrument panel-1994-98 Galant

1;. p;;w

13: Heater control panel

14. Trip counter reset knob

15. Meter bezel

16. Combination meter

17. Speedometer cable adapter

18. Combrnatron meter wiring harness

connector connecttons

19. Speaker garnrshes

20. Clock 23. Coupling of the Instrument panel wiring

harness and the body wiring harness, and

of the Instrument panel wrring harness

and the junctlon block

24. Coupling of the MFI control relay and the

control wiring harness

25. Instrument panel assembly

21. Heater control assembly installation

9C?WS 22. Instrument panel mounting bolts

93150925

1. INSTRUMENT PANEL SIDE COVER

2. HOOD LOCK RELEASE HANDLE

3. SWITCH PANEL ASSEMBLY

4 CONNECTOR H+DER

5. ER DRIVERS SIDE UNDER

6. CENTER PANEL ASSEMBLY

FOOT MSTRISUTION DUCT

7. CENTER AIR OUTLET ASSEMBLY

8. HAZARO WARNING LIGHT SWfTCti

9. RADIO AN0 TAPE PLAYER

10. H!ZATER CONTROL ASSEMBLY 1,. GLOV2 BOX STRIKER

12. GLOVE SOX

13 FRONT PASSENGER’S UNOER

COVER PLUG

14. FRONT PASSENGER’S SIDE

UNDER COVER

15. RHEOSTAT

16. METER BEZEL

17. COMBINATION METER

18. SIDE DEFROSTER GRILLE

19 SPEAKER GRILLE

mo. INSTRUMENT PANEL UPPER PLUG

93159927

Fig. 28 Exploded view of the instrument panel (1 of 2)-1999-00

Galant

~~~~~~~~~

Fig. 29 Exploded view of the instrument

REMOVAL &INSTALLATION

) See Figures 32 thru 39 If equipped with SRS, be careful not to let

the console bump against the SRS-ECU dur-

ing removal and installation.

Rear 2. Open the console lid. 3. If necessary, peel back any carpeting on the

bottom of the console.

1. Disconnect the negative battery cable. If

equipped with SRS, wrap the cable in insulated tape,

then wait at least 60 seconds before continuing to al-

low the SRS system time to disable.

4. Remove the retaining screws from the bottom

of the rear floor console.

5. If necessary, remove the screw covers from the

front of the console and remove the retaining screws.

6. Lift the console up and remove it from the ve-

hicle.

rb

Page 383 of 408

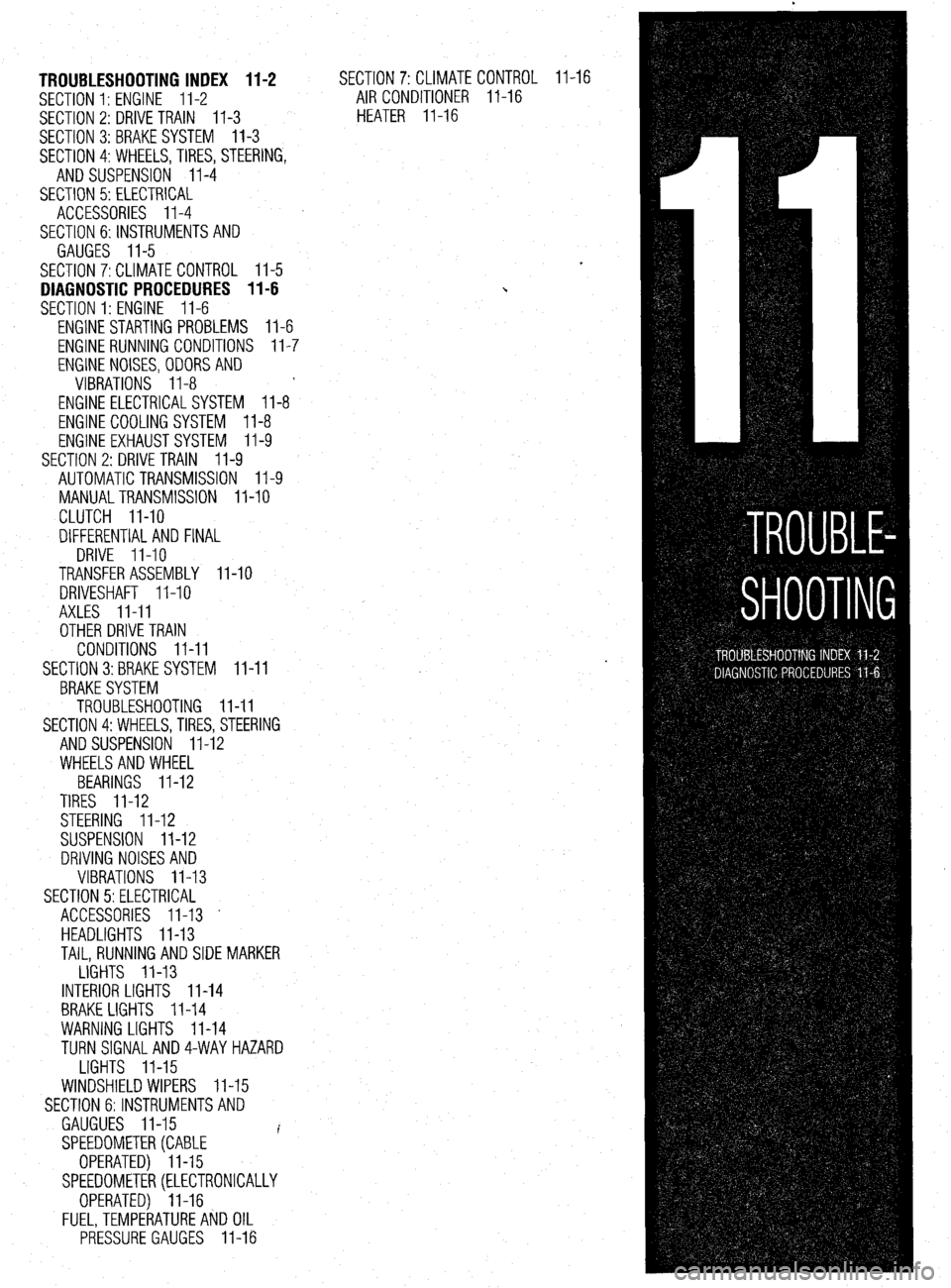

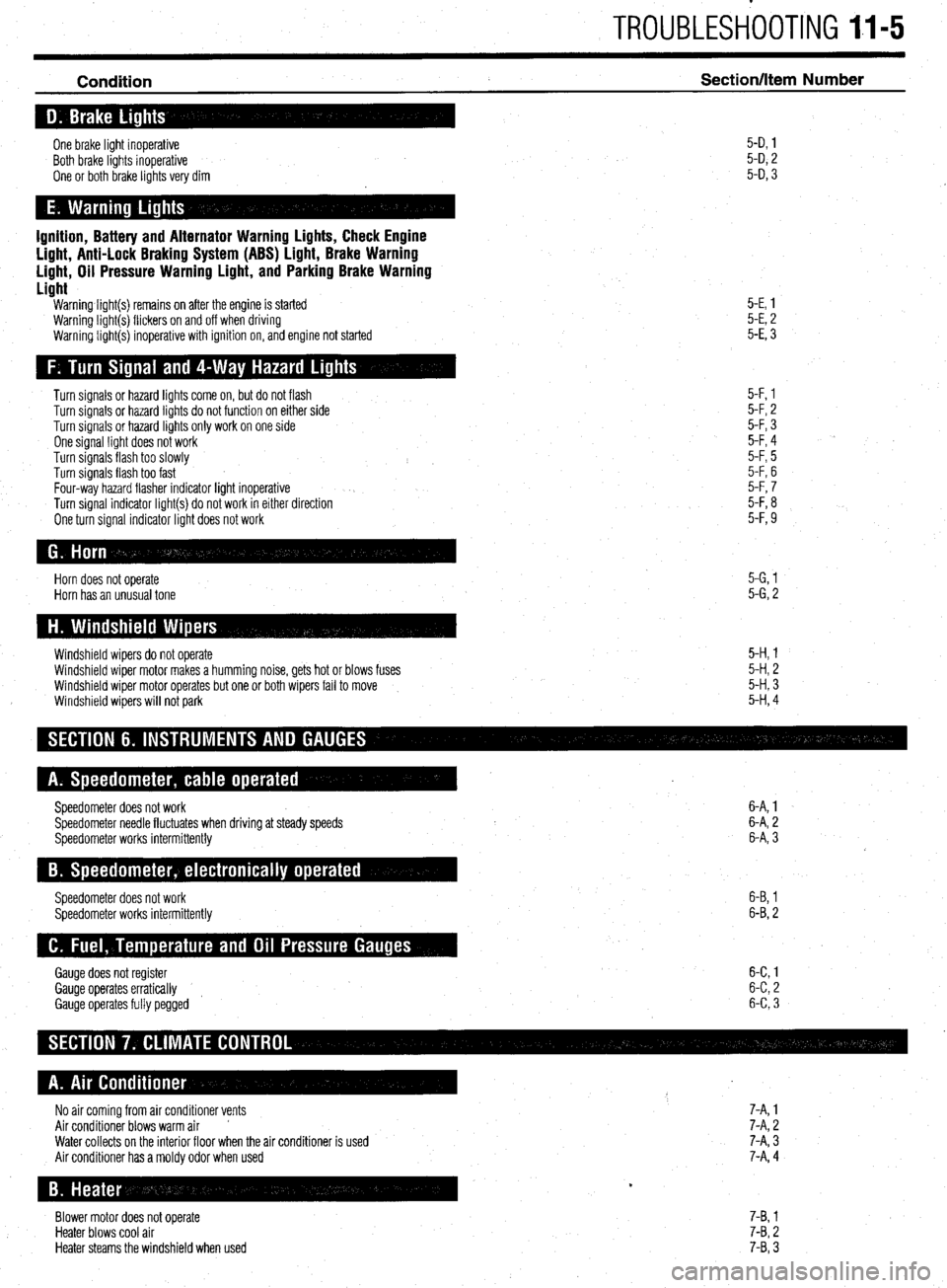

TROUBLESHOOTING INDEX 11-2

SECTION 1: ENGINE 11-2

SECTION 2: DRIVE TRAIN

11-3

SECTION 3:BRAKESYSTEM 11-3

SECTION 4:WHEELS,TIRES, STEERING,

AND SUSPENSION II-4

SECTION 5: ELECTRICAL

ACCESSORIES II-4

SECTION 6:lNSTRUMENTSAND

GAUGES II-5

SECTION 7:CLlMATE CONTROL II-5

DIAGNOSTIC PROCEDURES II-6

SECTION 1: ENGINE II-6

ENGINE STARTING PROBLEMS II-6

ENGINE RUNNING CONDITIONS II-7

ENGINE NOISES,ODORSAND

VIBRATIONS II-8

ENGINE ELECTRICALSYSTEM 11-8

ENGINE COOLING SYSTEM II-8

ENGINE EXHAUSTSYSTEM II-9

SECTION 2: DRIVE TRAIN

II-9

AUTOMATIC TRANSMISSION II-9

MANUALTRANSMISSION II-10

CLUTCH II-10

DIFFERENTIAL AND FINAL

DRIVE II-10

TRANSFER ASSEMBLY II-10

DRIVESHAFT II-10

AXLES II-II

OTHER DRIVE TRAIN

CONDITIONS II-II

SECTION 3:BRAKE SYSTEM II-II

BRAKESYSTEM

TROUBLESHOOTING II-II

SECTION 4:WHEELS, TIRES, STEERING

AND SUSPENSION II-12

WHEELSAND WHEEL

BEARINGS II-12

TIRES II-12

STEERING II-12

SUSPENSION II-12

DRIVING NOISES AND

VIBRATIONS II-13

SECTION 5:ELECTRlCAL

ACCESSORIES II-13 -

HEADLIGHTS II-13

TAIL, RUNNING AND SIDE MARKER

LIGHTS II-13

INTERIOR LIGHTS II-14

BRAKE LIGHTS II-14

WARNING LIGHTS II-14

TURN SlGNALAND4-WAYHAZARD

LIGHTS II-15

WINDSHIELD WIPERS II-15

SECTION 6:lNSTRUMENTSAND

GAUGUES II-15

I

SPEEDOMETER(CABLE

OPERATED) II-15

SPEEDOMETER(ELECTRONICALLY

OPERATED) II-16

FUEL,TEMPERATUREAkJD OIL

PRESSURE GAUGES II-16 SECTION 7:CLlMATECON

AIR CONDITIONER ll-

HEATER II-16 TR(

-16 IL II-16

Page 387 of 408

.

TROUBLESHOOTING II-5

Condition Section/Item Number

One brake light inoperative

Both brake lights inoperative

One or both brake lights very dim 5-D, 1

5-D, 2

5-D, 3

Ignition, Battery and Alternator Warning Lights, Check Engine

Light, Anti-Lock Braking System (ABS) Light, Brake Warning

Light, Oil Pressure Warning Light, and Parking Brake Warning

Light

Warning light(s) remains on after the engine is started

Warning light(s) flickers on and off when driving

Warning light(s) inoperative with ignition on, and engine not started 5-E, 1

5-E, 2

5-E, 3

Turn signals or hazard lights come on, but do not flash

Turn signals or hazard lights do not function on either side

Turn signals or hazard lights only work on one side

One signal light does not work

Turn signals flash too slowly

Turn signals flash too fast

Four-way hazard flasher indicator light inoperative

Turn signal indicator light(s) do not work in either direction

One turn signal indicator light does not work 5-F, 1

5-F, 2

5-F, 3

5-F, 4

5-F, 5

5-F, 6

5-F, 7

5-F, 8

5-F, 9

Horn does not operate

Horn has an unusual tone 5-G, 1

5-G, 2

Windshield wipers do not operate

Windshield wiper motor makes a humming noise, gets hot or blows fuses

Windshield wiper motor operates but one or both wipers fail to move

Windshield wipers will not park 5-H, 1

5-H, 2

5-H, 3

5-H, 4

Speedometer does not work

Speedometer needle fluctuates when driving at steady speeds

Speedometer works intermittently 6-A, 1

6-A, 2

6-A, 3

Speedometer does not work

Speedometer works intermittently 6-B, 1

6-B, 2

Gauge does not register 6-C 1

Gauge operates erratically 6-C 2

’

Gauge operates fully pegged 6-C 3

No air coming from air conditioner vents 7-A, 1

Air conditioner blows warm air ’ 7-A, 2

Water collects on the interior floor when the air conditioner is used

Air conditioner has a moldy odor when used 7-A, 3

7-A, 4

Blower motor does not operate

Heater blows cool air

Heater steams the windshield when used 7-B, 1

7-B, 2

7-B, 3

Page 390 of 408

11-8 TROUBLESHOOTING

Ignition systems may be controlled by, or linked to, the engine fuel management sys-

tem. Similar to the fuel injection system, these ignition systems rely on electronic sen-

sors for information to determine the optimum ignition timing for a given engine speed

and load. Some ignition systems no longer allow the ignition timing to be adjusted.

Feedback from low voltage electrical sensors provide information to the control unit to

determine the amount of ignition advance. On these systems, if a failure occurs the failed

component must be replaced. Before replacing suspected failed electrical components,

carefully inspect the wiring and electrical connectors to the related components. Make

sure the electrical connectors are fully connected, clean and not physically damaged. If

necessary, clean the electrical contacts using electrical contact cleaner. The use of clean-

ing agents not specifically designed for electrical contacts should be avoided, as they

could leave a surface film or damage the insulation of the wiring.

1. Engine makes a knocking or pinging noise when accelerating

a. Check the octane rating of the fuel being used. Depending on the type of driving or

driving conditions, it may be necessary to use a higher octane fuel.

b. Verify the ignition system settings and operation. Improperly adjusted ignition timing

or a failed component, such as a knock sensor, may cause the ignition timing to ad-

vance excessively or prematurely. Check the ignition system operation and adjust, or

replace components as needed.

c. Check the spark plug gap, heat range and condition. If the vehicle is operated in se-

vere operating conditions or at continuous high speeds, use a colder heat range spark

plug. Adjust the spark plug gap to the manufacturer’s recommended specification and

replace worn or damaged spark plugs.

2. Sfarter motor grinds when used

a. Examine the starter pinion gear and the engine ring gear for damage, and replace dam-

aged parts.

b. Check the starter mounting bolts and housing. If the housing is cracked or damaged

replace the starter motor and check the mounting bolts for tightness.

3. Engine makes a screeching noise

a. Check the accessory drive belts for looseness and adjust as necessary.

b. Check the accessory drive belt tensioners for seizing or excessive bearing noises and

replace if loose, binding, or excessively noisy.

c. Check for a seizing water pump. The pump may not be leaking; however, the bearing

may be faulty or the impeller loose and jammed. Replace the water pump.

4. Engine makes a growling noise

a. Check for a loose or failing water pump. Replace the pump and engine coolant.

b. Check the accessory drive belt tensioners for excessive bearing noises and replace if

loose or excessively noisy.

5. Engine makes a ticking or tapping noise

a. On vehicles with hydraulic lash adjusters, check for low or dirty engine oil and top off

or replace the engine oil and filter.

b. On vehicles with hydraulic lash adjusters, check for collapsed lifters and replace failed

components.

c. On vehicles with hydraulic lash adjusters, check for low oil pressure caused by a re-

stricted oil filter, worn engine oil pump, or oil pressure relief valve.

d. On vehicles with manually adjusted valves, check for excessive valve clearance or

worn valve train parts. Adjust the valves to specification or replace worn and defective

parts.

e. Check for a loose or improperly tensioned timing belt or timing chain and adjust or re-

place parts as necessary.

f. Check for a bent or sticking exhaust or intake valve. Remove the engine cylinder head

to access and replace.

6. Engine makes a heavy knocking noise

a. Check for a loose crankshaft pulley or flywheel; replace and torque the mounting

bolt(s) to specification.

b. Check for a bent connecting rod caused by a hydro-lock condition. Engine disassem-

bly is necessary to inspect for damaged and needed replacement parts.

c. Check for excessive engine rod bearing wear or damage. This condition is also asso-

ciated with low engine oil pressure and will require engine disassembly to inspect for

damaged and needed replacement parts,

7. Vehicle has a fuel odor when driven ’ a. Check the fuel gauge level. If the fuel gauge registers full, it is possible that the odor is

caused by being filled beyond capacity, or some spillage occurred during refueling.

The odor should clear after driving an hour, or twenty miles, allowing the vapor canis-

ter to purge.

b. Check the fuel filler cap for looseness or seepage. Check the cap tightness and, if

loose, properly secure. If seepage is noted, replace the filler cap.

c. Check for loose hose clamps, cracked or damaged fuel delivery and return lines, or

leaking components or seals, and replace or repair as necessary. d. Check the vehicle’s fuel economy. If fuel consumption has increased due to a failed

component, or if the fuel is not properly ignited due to an ignition related failure, the

catalytic converter may become contaminated. This condition may also trigger the

check engine warning light. Check the spark plugs for a dark, rich condition or verify

the condition by testing the vehicle’s emissions. Replace fuel fouled spark plugs, and

test and replace failed components as necessary.

5. Vehicle has a rotten egg odor when driven

a. Check for a leaking intake gasket or vacuum leak causing a lean running condition. A

lean mixture may result in increased exhaust temperatures, causing the catalytic con-

verter to run hotter than normal. This condition may also trigger the check engine

warning light. Check and repair the vacuum leaks as necessary.

b. Check the vehicle’s alternator and battery condition. If the alternator is overcharging,

the battery electrolyte can be boiled from the battery, and the battery casing may begin

to crack, swell or bulge, damaging or shorting the battery internally. If this has oc-

curred, neutralize the battery mounting area with a suitable baking soda and water

mixture or equivalent, and replace the alternator or voltage regulator. Inspect, service,

and load test the battery, and replace if necessary.

9. Vehicle has a sweet odor when driven

a. Check for an engine coolant leak caused by a seeping radiator cap, loose hose clamp,

weeping cooling system seal, gasket or cooling system hose and replace or repair as

needed.

b. Check for a coolant leak from the radiator, coolant reservoir, heater control valve or

under the dashboard from the heater core, and replace the failed part as necessary.

c. Check the engine’s exhaust for white smoke in addition to a sweet odor. The presence

of white, steamy smoke with a sweet odor indicates coolant leaking into the combus-

tion chamber. Possible causes include a failed head gasket, cracked engine block or

cylinder head. Other symptoms of this condition include a white paste build-up on the

inside of the oil filler cap, and softened, deformed or bulging radiator hoses.

19. Engine vibraies when idling

a. Check for loose, collapsed, or damaged engine or transmission mounts and repair or

replace as necessary.

b. Check for loose or damaged engine covers or shields and secure or replace as neces-

sary.

11. Engine vibrates during acceleration

a. Check for missing, loose or damaged exhaust system hangers and mounts; replace or

repair as necessary.

b. Check the exhaust system routing and fit for adequate clearance or potential rubbing;

repair or adjust as necessary.

7. Battery goes dead while driving

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test. If the battery loses fluid while driving, check for an overcharg-

ing condition. If the alternator is overcharging, replace the alternator or voltage regula-

tor. (A voltage regulator is typically built into the alternator, necessitating alternator re-

placement or overhaul.)

b. Check the battery cable condition. Clean or replace corroded cables and clean the bat-

tery terminals.

c. Check the alternator and voltage regulator operation. If the charging system is over or

undercharging, replace the alternator or voltage regulator, or both.

d. Inspect the wiring and wire connectors at the alternator for looseness, a missing .

ground or defective terminal, and repair as necessary.

e. Inspect the alternator drive belt tension, tensioners and condition. Properly tension the

drive belt, replace weak or broken tensioners, and replace the drive belt if worn or

cracked.

2. Battery goes dead overnight

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test.

b. Check for a voltage draw, such as a trunk light, interior light or glove box light staying

on. Check light switch position and operation, and replace if defective.

c. Check the alternator for an internally failed diode, and replace the alternator if defec-

tive.

1. Engine overheats

a. Check the coolant level. Set the heater temperature to full hot and check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture.

b. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.

Page 396 of 408

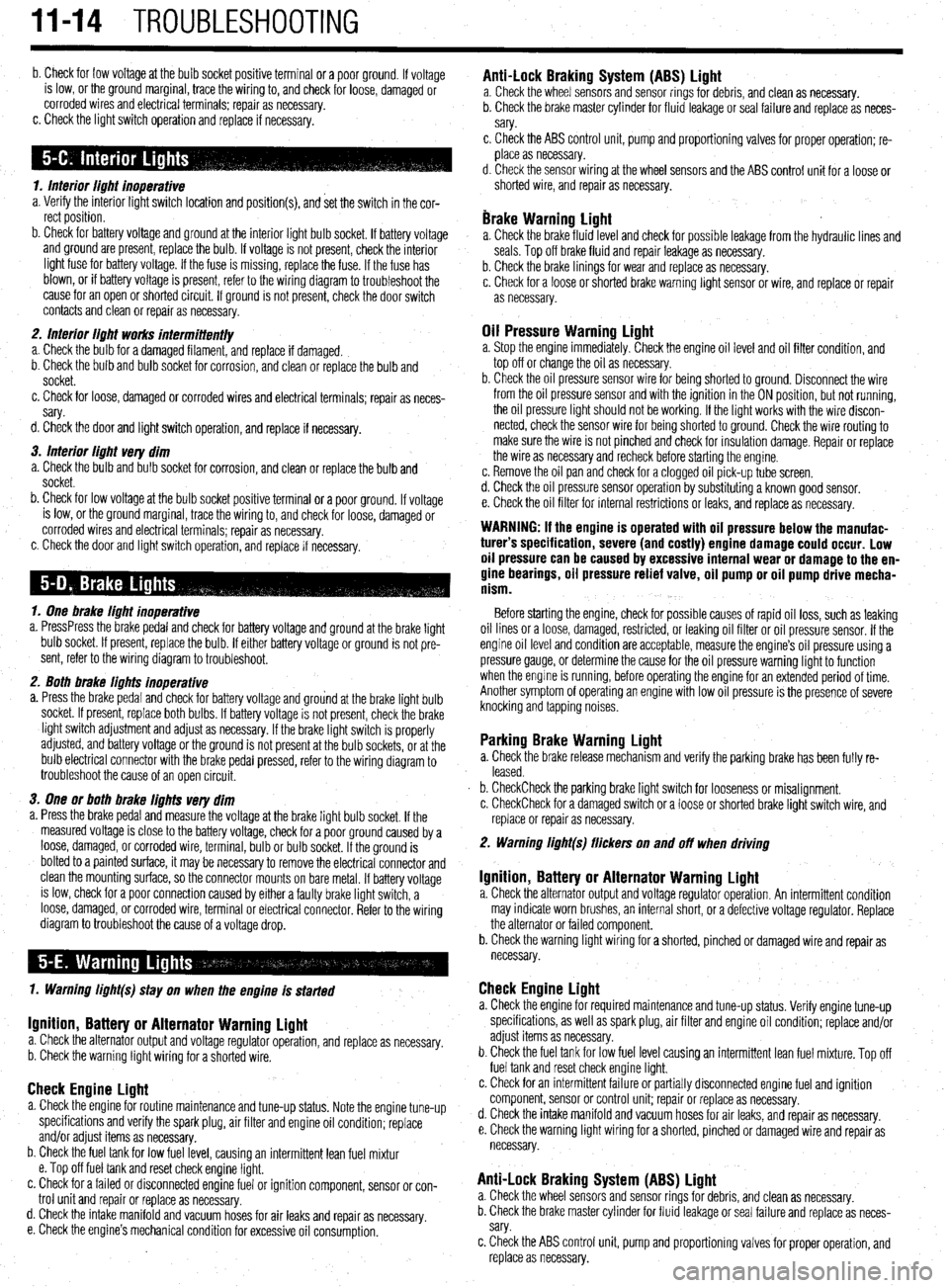

II-14 TROUBLESHOOTING

b. Check for low voltage at the bulb socket positive terminal or a poor ground. If voltage

is low, or the ground marginal, trace the wiring to, and check for loose, damaged or

corroded wires and electrical terminals; repair as necessary.

c. Check the light switch operation and replace if necessary.

1. Interior light inoperative

a. Verify the interior light switch location and position(s), and set the switch in the cor-

rect position.

b. Check for battery voltage and ground at the interior light bulb socket. If battery voltage

and ground are present, replace the bulb. If voltage is not present, check the interior

light fuse for battery voltage. If the fuse is missing, replace the fuse. If the fuse has

blown, or if battery voltage is present, refer to the wiring diagram to troubleshoot the

cause for an open or shorted circuit. If ground is not present, check the door switch

contacts and clean or repair as necessary.

2. Interior light works intermittent/y

a. Check the bulb for a damaged filament, and replace if damaged.

b. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

c. Check for loose, damaged or corroded wires and electrical terminals; repair as neces-

sary.

d. Check the door and light switch operation, and replace if necessary.

3. Interior light very dim

a. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

b. Check for low voltage at the bulb socket positive terminal or a poor ground. If voltage

is low, or the ground marginal, trace the wiring to, and check for loose, damaged or

corroded wires and electrical terminals; repair as necessary.

c. Check the door and light switch operation, and replace if necessary.

1. One brake light inoperative

a. PressPress the brake pedal and check for battery voltage and ground at the brake light

bulb socket. If present, replace the bulb. If either battery voltage or ground is not pre-

sent, refer to the wiring diagram to troubleshoot.

2. Both brake lights inoperative

a. Press the brake pedal and check for battery voltage and grou’nd at the brake light bulb

socket. If present, replace both bulbs. If battery voltage is not present, check the brake

light switch adjustment and adjust as necessary. If the brake light switch is properly

adjusted, and battery voltage or the ground is not present at the bulb sockets, or at the

bulb electrical connector with the brake pedal pressed, refer to the wiring diagram to

troubleshoot the cause of an open circuit.

3. One or both brake lights very dim

a. Press the brake pedal and measure the voltage at the brake light bulb socket. If the

measured voltage is close to the battery voltage, check for a poor ground caused by a

loose, damaged, or corroded wire, terminal, bulb or bulb socket. If the ground is

bolted to a painted surface, it may be necessary to remove the electrical connector and

clean the mounting surface, so the connector mounts on bare metal. If battery voltage

is low, check for a poor connection caused by either a faulty brake light switch, a

loose, damaged, or corroded wire, terminal or electrical connector. Refer to the wiring

diagram to troubleshoot the cause of a voltage drop.

1. Warning light(s) stay on when the engine is started

Ignition, Battery or Alternator Warning light a. Check the alternator output and voltage regulator operation, and replace as necessary.

b. Check the warning light wiring for a shorted wire.

Check Engine Light a. Check the engine for routine maintenance and tune-up status. Note the engine tune-up

specifications and verify the spark plug, air filter and engine oil condition; replace

and/or adjust items as necessary.

b. Check the fuel tank for low fuel level, causing an intermittent lean fuel mixtur

e. Top off fuel tank and reset check engine light.

c. Check for a failed or disconnected engine fuel or ignition component, sensor or con-

trol unit and repair or replace as necessary.

d. Check the intake manifold and vacuum hoses for air leaks and repair as

necessary.

e. Check the engine’s mechanical condition for excessive oil consumption.

Anti-Lock Braking System (ABS) Light a. Check the wheel sensors and sensor rings for debris, and clean as necessary.

b. Check the brake master cylinder for fluid leakage or seal failure and replace as neces-

sary.

c, Check the ABS control unit, pump and proportioning valves for proper operation; re-

place as necessary.

d. Check the sensor wiring at the wheel sensors and the ABS control unit for a loose or

shorted wire, and repair as necessary.

brake Warning Light a. Check the brake fluid level and check for possible leakage from the hydraulic lines and

seals. Top off brake fluid and repair leakage as necessary.

b. Check the brake linings for wear and replace as necessary.

c. Check for a loose or shot-ted brake warning light sensor or wire, and replace or repair

as necessary.

Oil Pressure Warning Light a. Stop the engine immediately. Check the engine oil level and oil filter condition, and

top off or change the oil as necessary.

b. Check the oil pressure sensor wire for being shorted to ground. Disconnect the wire

from the oil pressure sensor and with the ignition in the ON position, but not running,

the oil pressure light should not be working. If the light works with the wire discon-

nected, check the sensor wire for being shorted to ground. Check the wire routing to

make sure the wire is not pinched and check for insulation damage. Repair or replace

the wire as necessary and recheck before starting the engine.

c. Remove the oil pan and check for a clogged oil pick-up tube screen.

d. Check the oil pressure sensor operation by substituting a known good sensor.

e. Check the oil filter for internal restrictions or leaks, and replace as necessary.

WARNING: If the engine is operated with oil pressure below the manufac-

turer’s specification, severe (and costly) engine damage could occur. Low

oil pressure can be caused by excessive internal wear or damage to the en-

gine bearings, oil pressure relief valve, oil pump or oil pump drive mecha-

nism.

Before starting the engine, check for possible causes of rapid oil loss, such as leaking

oil lines or a loose, damaged, restricted, or leaking oil filter or oil pressure sensor. If the

engine oil level and condition are acceptable, measure the engine’s oil pressure using a

pressure gauge, or determine the cause for the oil pressure warning light to function

when the engine is running, before operating the engine for an extended period of time.

Another symptom of operating an engine with low oil pressure is the presence of severe

knocking and tapping noises.

Parking Brake Warning Light a. Check the brake release mechanism and verify the parking brake has been fully re-

leased.

b. CheckCheck the parking brake light switch for looseness or misalignment.

c. CheckCheck for a damaged switch or a loose or shorted brake light switch wire, and

replace or repair as necessary.

2. Warning light(s) flickers on and off when driving

Ignition, Battery or Alternator Warning Light a. Check the alternator output and voltage regulator operation. An intermittent condition

may indicate worn brushes, an internal short, or a defective voltage regulator. Replace

the alternator or failed component.

b. Check the warning light wiring for a shorted, pinched or damaged wire and repair as

necessary.

Check Engine Light a. Check the engine for required maintenance and tune-up status. Verify engine tune-up

specifications, as well as spark plug, air filter and engine oil condition; replace and/or

adjust items as necessary.

b. Check the fuel tank for low fuel level causing an intermittent lean fuel mixture. Top off

fuel tank and reset check engine light.

c. Check for an intermittent failure or partially disconnected engine fuel and ignition

component, sensor or control unit; repair or replace as necessary.

d. Check the intake manifold and vacuum hoses for air leaks, and repair as necessary.

e. Check the warning light wiring for a shorted, pinched or damaged wire and repair as

necessary.

Anti-Lock Braking System (ABS) Light a. Check the wheel sensors and sensor rings for debris, and clean as necessary.

b. Check the brake master cylinder for fluid leakage or seal failure and replace as neces-

sary.

c. Check the ABS control unit, pump and proportioning valves for proper operation, and

replace as necessary.

Page 397 of 408

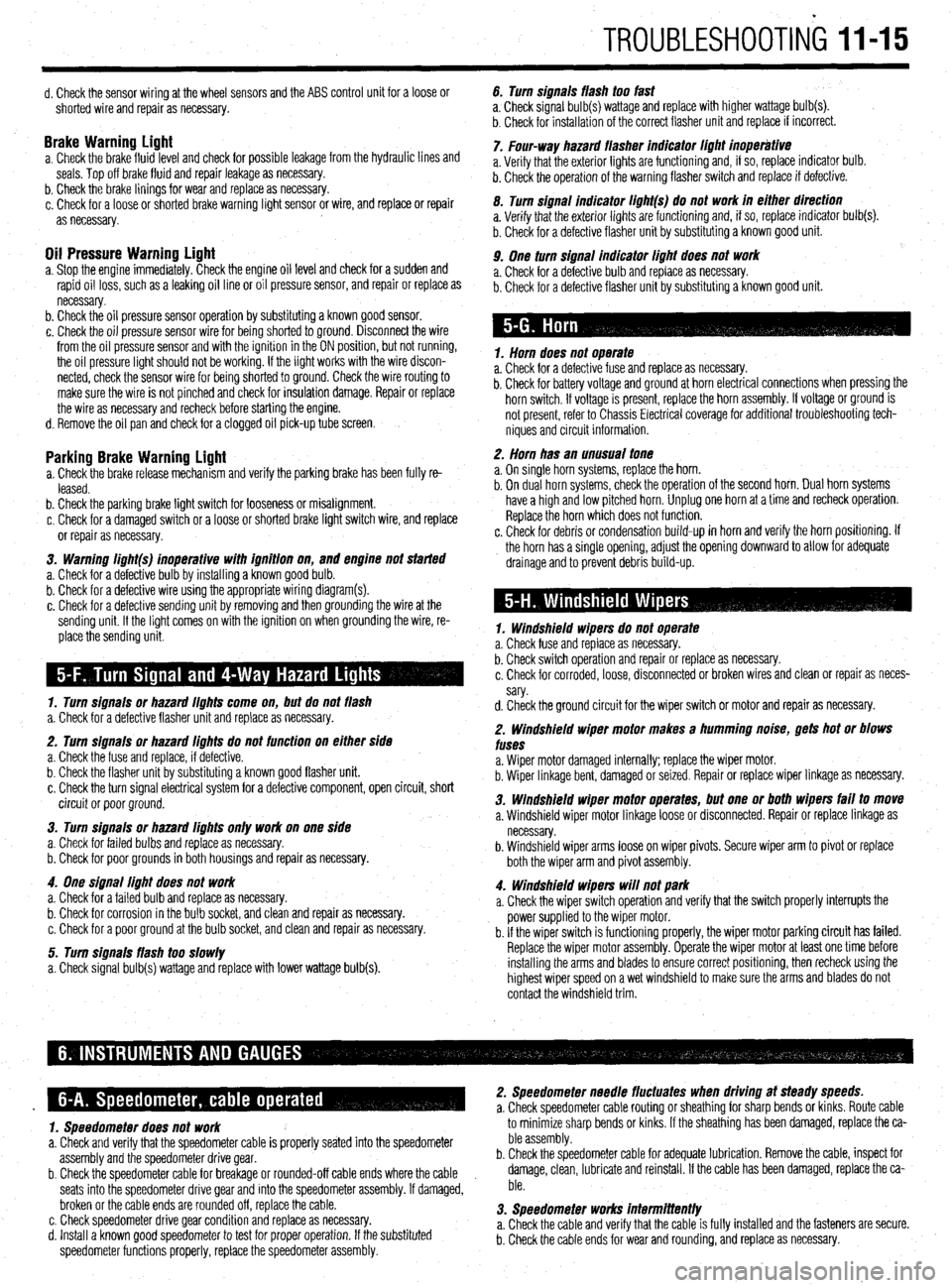

TROUBLESHOOTING 1145

d. Check the sensor wiring at the wheel sensors and the ABS control unit for a loose or

shorted wire and repair as necessary.

Brake Warninu Liaht a. Check the brakefluid~evel and check for possible leakage from the hydraulic lines and

seals. Top off brake fluid and repair leakage as necessary.

b. Check the brake linings for wear and replace as necessary.

c. Check for a loose or shorted brake warning light sensor or wire, and replace or repair

as necessary.

Oil Pressure Warning Light a. Stop the engine immediately. Check the engine oil level and check for a sudden and

rapid oil loss, such as a leaking oil line or oil pressure sensor, and repair or replace as

necessary.

b. Check the oil pressure sensor operation by substituting a known good sensor.

c. Check the oil pressure sensor wire for being shorted to ground. Disconnect the wire

from the oil pressure sensor and with the ignition in the ON position, but not running,

the oil pressure light should not be working. If the light works with the wire discon-

nected, check the sensor wire for being shorted to ground. Check the wire routing to

make sure the wire is not pinched and check for insulation damage. Repair or replace

the wire as necessary and recheck before starting the engine.

d. Remove the oil pan and check for a clogged oil pick-up tube screen.

Parking Brake Warning Light a. Check the brake release mechanism and verify the parking brake has been fully re-

leased.

b. Check the parking brake light switch for looseness or misalignment.

c. Check for a damaged switch or a loose or shorted brake light switch wire, and replace

or repair as necessary.

3. Warning li#ht(s) inoperative with iflnition on,

and engine not started

a. Check for a defective bulb by installing a known good bulb.

b. Check for a defective wire using the appropriate wiring diagram(s).

c. Check for a defective sending unit by removing and then grounding the wire at the

sending unit. If the light comes on with the ignition on when grounding the wire, re-

place the sending unit.

1. Turn siflnais or hazard iiflhts come on, but do not flash

a. Check for a defective flasher unit and replace as necessary.

2. Turn signals or hazard iiflhts do not function on either side

a. Check the fuse and replace, if defective.

b. Check the flasher unit by substituting a known good flasher unit.

c. Check the turn signal electrical system for a defective component, open circuit, short

circuit or poor ground.

3. Turn siflnais or hazard lights only work on one side

a. Check for failed bulbs and replace as necessary.

b. Check for poor grounds in both housings and repair as necessary.

4. One siflnai light does not work

a. Check for a failed bulb and replace as necessary.

b. Check for corrosion in the bulb socket, and clean and repair as necessary.

c. Check for a poor ground at the bulb socket, and clean and repair as necessary.

5. Turn signals flash too slowly

a. Check signal bulb(s) wattage and replace with lower wattage bulb(s). 6. Turn signals flash too fast

a, Check signal bulb(s) wattage and replace with higher wattage bulb(s).

b. Check for installation of the correct flasher unit and replace if incorrect.

7. Four-way hazard flasher indicator iiflhi inoperative

a. Verify that the exterior lights are functioning and, if so, replace indicator bulb.

b. Check the operation of the warning flasher switch and replace if defective.

0. Turn signal indicator ii#ht(s) do not work in either direction

a. Verify that the exterior lights are functioning and, if so, replace indicator bulb(s).

b. Check for a defective flasher unit by substituting a known good unit.

9. One turn signal indicator liflht does not work

a. Check for a defective bulb and replace as necessary.

b. Check for a defective flasher unit by substituting a known good unit.

1. Horn does not operate

a. Check for a defective fuse and replace as necessary.

b. Check for battery voltage and ground at horn electrical connections when pressing the

horn switch. If voltage is present, replace the horn assembly. If voltage or ground is

not present, refer to Chassis Electrical coverage for additional troubleshooting tech-

niques and circuit information.

2. Horn has an unusual tone

a. On single horn systems, replace the horn.

b. On dual horn systems, check the operation of the second horn. Dual horn systems

have a high and low pitched horn. Unplug one horn at a time and recheck operation.

Replace the horn which does not function.

c. Check for debris or condensation build-up in horn and verify the horn positioning. If

the horn has a single opening, adjust the opening downward to allow for adequate

drainage and to prevent debris build-up.

1. Windshield wipers do not operate

a. Check fuse and replace as necessary.

b. Check switch operation and repair or replace as necessary.

c. Check for corroded, loose, disconnected or broken wires and clean or repair as neces-

sary.

d. Check the ground circuit for the wiper switch or motor and repair as necessary.

2. Windshield wiper motor makes a humming noise, gets hot or blows

fuses

a. Wiper motor damaged internally; replace the wiper motor.

b. Wiper linkage bent, damaged or seized. Repair or replace wiper linkage as necessary.

3. Windshield wiper motor operates, but one or both wipers fail to move

a. Windshield wiper motor linkage loose or disconnected. Repair or replace linkage as

necessary.

b. Windshield wiper arms loose on wiper pivots. Secure wiper arm to pivot or replace

both the wiper arm and pivot assembly.

4. Windshield wipers will not park

a. Check the wiper switch operation and verify that the switch properly interrupts the

power supplied to the wiper motor.

b. If the wiper switch is functioning properly, the wiper motor parking circuit has failed.

Replace the wiper motor assembly. Operate the wiper motor at least one time before

installing the arms and blades to ensure correct positioning, then recheck using the

highest wiper speed on a wet windshield to make sure the arms and blades do not

contact the windshield trim.

1. Speedometer does not work to minimize sharp bends or kinks.

If the sheathing has been

damaged, replace the ca-

a. Check and verify that the speedometer cable is properly seated into the speedometer ble assembly.

assembly and the speedometer drive gear. b. Check the speedometer cable for adequate lubrication. Remove the cable, inspect for

b. Check the speedometer cable for breakage or rounded-off cable ends where the cable damage, clean, lubricate and reinstall. If the cable has been damaged, replace the ca-

seats into the speedometer drive gear and into the speedometer assembly. If damaged, ble.

broken or the cable ends are rounded off, replace the cable.

c. Check speedometer drive gear condition and replace as necessary. 3. Speedometer works intermittently

d. Install a known good speedometer to test for proper operation. If the substituted a. Check the cable and verify that the cable is fully installed and the fasteners are secure.

speedometer functions properly, replace the speedometer assembly. b. Check the cable ends for wear and rounding, and replace as necessary.

Page 399 of 408

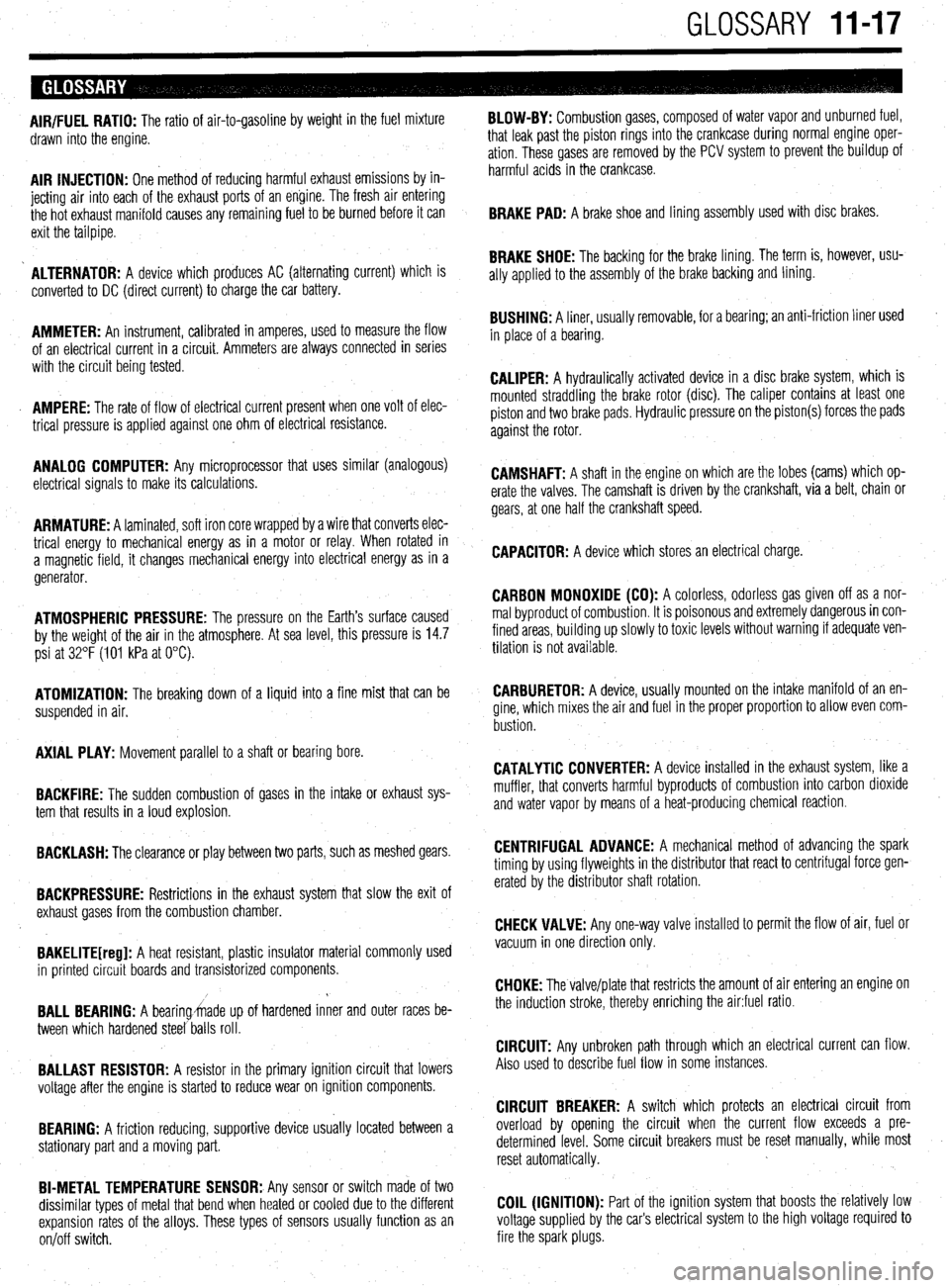

GLOSSARY 11-17

AIR/FUEL RATIO: The ratio of air-to-gasoline by weight in the fuel mixture

drawn into the engine.

AIR INJECTION: One method of reducing harmful exhaust emissions by in-

jecting air into each of the exhaust ports of an engine. The fresh air entering

the hot exhaust manifold causes any remaining fuel to be burned before it can

exit the tailpipe.

ALTERNATOR: A device which produces AC (alternating current) which is

converted to DC (direct current) to charge the car battery.

AMMETER: An instrument, calibrated in amperes, used to measure the flow

of an electrical current in a circuit. Ammeters are always connected in series

with the circuit being tested.

AMPERE: The rate of flow of electrical current present when one volt of elec-

trical pressure is applied against one ohm of electrical resistance.

ANALOG COMPUTER: Any microprocessor that uses similar (analogous)

electrical signals to make its calculations.

ARMATURE: A laminated, soft iron core wrapped by a wire that converts elec-

trical energy to mechanical energy as in a motor or relay. When rotated in

a magnetic field, it changes mechanical energy into electrical energy as in a

generator.

ATMOSPHERIC PRESSURE: The pressure on the Earth’s surface caused

by the weight of the air in the atmosphere. At sea level, this pressure is 14.7

psi at 32°F (101 kPa at OOC).

ATOMIZATION: The breaking down of a liquid into a fine mist that can be

suspended in air.

AXIAL PLAY: Movement parallel to a shaft or bearing bore.

BACKFIRE: The sudden combustion of gases in the intake or exhaust sys-

tem that results in a loud explosion.

BACKLASH: The clearance or play between two parts, such as meshed gears.

BACKPRESSURE: Restrictions in the exhaust system that slow the exit of

exhaust gases from the combustion chamber.

BAKELITE[reg]: A heat resistant, plastic insulator material commonly used

in printed circuit boards and transistorized components.

BALL BEARING: A bearingmade up of hardened inner and outer races be-

tween which hardened steel’balls roll.

BALLAST RESISTOR: A resistor in the primary ignition circuit that lowers

voltage after the engine is started to reduce wear on ignition components.

BEARING: A friction reducing, supportive device usually located between a

stationary part and a moving part.

BI-METAL TEMPERATURE SENSOR: Anv sensor or switch made of two

dissimilar types of metal that bend when heated or cooled due to the different

expansion rates of the alloys. These types of sensors usually function as an

on/off switch. BLOW-BY: Combustion gases, composed of water vapor and unburned fuel,

that leak past the piston rings into the crankcase during normal engine oper-

ation. These gases are removed by the PCV system to prevent the buildup of

harmful acids in the crankcase.

BRAKE PAD: A brake shoe and lining assembly used with disc brakes.

BRAKE SHOE: The backing for the brake lining. The term is, however, usu-

ally applied to the assembly of the brake backing and lining.

BUSHING: A liner, usually removable, for a bearing; an anti-friction liner used

in place of a bearing.

CALIPER: A hydraulically activated device in a disc brake system, which is

mounted straddling the brake rotor (disc). The caliper contains at least one

piston and two brake pads. Hydraulic pressure on the piston(s) forces the pads

against the rotor.

CAMSHAFT: A shaft in the engine on which are the lobes (cams) which op-

erate the valves. The camshaft is driven by the crankshaft, via a belt, chain or

gears, at one half the crankshaft speed.

CAPACITOR: A device which stores an electrical charge.

CARBON MONOXIDE (CO): A colorless, odorless gas given off as a nor-

mal byproduct of combustion. It is poisonous and extremely dangerous in con-

fined areas, building up slowly to toxic levels without warning if adequate ven-

tilation is not available.

CARBURETOR: A device, usually mounted on the intake manifold of an en-

gine, which mixes the air and fuel in the proper proportion to allow even com-

bustion

CATALYTIC CONVERTER: A device installed in the exhaust system, like a

muffler, that converts harmful byproducts of combustion into carbon dioxide

and water vapor by means of a heat-producing chemical reaction.

CENTRIFUGAL ADVANCE: A mechanical method of advancing the spark

timing by using flyweights in the distributor that react to centrifugal force gen-

erated by the distributor shaft rotation.

CHECK VALVE: Any one-way valve installed to permit the flow of air, fuel or

vacuum in one direction only.

CHOKE: The valve/plate that restricts the amount of air entering an engine on

the induction stroke, thereby enriching the air:fuel ratio.

CIRCUIT: Any unbroken path through which an electrical current can flow.

Also used to describe fuel flow in some instances.

CIRCUIT BREAKER: A switch which protects an electrical circuit from

overload by opening the circuit when the current flow exceeds a pre-

determined level. Some circuit breakers must be reset manually, while most

reset automatically.

COIL (IGNITION): Part of the ignition system that boosts the relatively low

voltage supplied by the car’s electrical system to the high voltage required to

fire the spark plugs.