engine MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 292 of 408

DRIVETRAIN 7-13

27. Shde the transaxle rearward and carefully

lower it from the vehicle.

To install: 28. After the torque converter has been mounted

on the transaxle, install the transaxle assembly to the

engine. Install the mounting bolts and tighten to 35

ft. Ibs. (48 Nm).

29. Install the transaxle lower coupling bolt and

tighten to 21-25 ft Ibs. (29-34 Nm).

30. Connect the torque converter to the flexplate

and tighten the bolts to 33-38 ft. Ibs. (45-52 Nm).

31. Install the cover to the transaxle bellhous-

ing and tighten the mounting bolts to 7 ft. Ibs. (9

Nm).

32 Install the crossmember and tighten the front

mounting bolts to 65 ft. Ibs (88 Nm) and the rear

bolt to 54 ft. Ibs. (73 Nm) Install the front engine roll

stopper through-bolt and lightly tighten. Once the full

weight of the engine is on the mounts, tighten the ’

bolt to 42 ft. Ibs. (57 Nm),

33. Install the triangular stay bracket and tighten

the mounting bolts to 65 ft. Ibs. (88 Nm).

34. Install the halfshafts, using new circlips on

the axle ends.

When installing the axleshaft, keep the in-

board joint straight in relation to the axle, so

as not to damage the oil seal lip of the

transaxle with the serrated part of the half-

shaft.

35. Connect the tie rod and ball joints to the

steering knuckle. Tighten the ball joint self-locking

nuts to 48 ft. Ibs. (65 Nm). Tighten the tie rod end nut

to 21 ft. Ibs. (28 Nm) and secure with a new cotter

pin.

36. Connect the damper fork to the lower control

arm and tighten the through-bolt to 65 ft Ibs. (88

Nm).

37. Connect the stabilizer link to the damper fork,

and tighten the self-locking nut to 29 ft. Ibs. (39 Nm).

38. Install the undercover.

39. Install the wheels and carefully lower the ve-

hicle

40. Install the transaxle mount bracket to the

transaxle, and tighten the mounting nuts to 32 ft. Ibs.

(43 Nm).

41. Install the rear roll stopper mounting bracket.

42. Remove the engine support. Tighten the

transaxle mount through-bolt to 51 ft. Ibs. (69 Nm)

and tighten the front engine roll stopper through-bolt.

43. Install the upper transaxle mounting bolts

and tighten to 35 fl. Ibs. (48 Nm).

44. Install the starter motor.

45. Install the dipstick tube and the dipstick

46. Install the shifter cable mounting bracket.

47. Connect the shifter lever and tighten the re-

taining nut to 14 ft. Ibs. (19 Nm).

48. Connect the oil cooler lines and secure with

clamps.

49. Attach the electrical connectors for the

speedometer, solenoid, neutral safety switch (in-,

hibitor switch), the pulse generator, kickdown servo

switch and oil temperature sensor.

50. Install the air cleaner and the air intake hose.

51. Connect the negative battery cable.

52. Make sure the vehicle is level, and refill the

transaxle. Start the engine and allow to idle for 2 minutes. Apply parking brake and move selector

through each gear position, ending in N. Recheck

fluid level and add if necessary. Fluid level should be

between the marks in the HOT range.

53. Check the transaxle for proper operation.

Make sure the reverse lights come on when in re-

verse and the engine starts only in

P or N.

Mirage

*If the vehicle is going to be rolled on its

wheels while the halfshafts are out of the ve-

hicle, obtain two outer CV-joints or proper

equivalent tools and install to the hubs. If the

vehicle is rolled without the proper torque

applied to the front wheel bearings, the bear-

ings will no longer be usable.

1. Disconnect the negative battery cable then

the positive battery cable.

2. Remove the battery and battery tray.

3. Remove the air hose and air cleaner assem-

bly.

4. Raise the vehicle and support safely.

5. Remove the under guard pan.

6. Drain the transaxle oil into a suitable con-

tainer.

7. If equipped with 1.6L engine, remove the ten-

sion rod.

8. Disconnect the control cable and cooler

lines.

9. On 3-speed transaxles, disconnect the throt-

tle control cable.

10. On 4-speed transaxles, perform the following:

a. Detach the shift control solenoid valve

connector.

b. Disconnect the inhibitor switch and kick-

down servo switch.

c. Disconnect the pulse generator and oil

temperature sensor.

11. Disconnect the speedometer cable and re-

move the starter.

12. Remove the transaxle mounting bolts and

bracket.

13. Disconnect the stabilizer bar from the lower

control arm.

14. Disconnect the steering tie rod end and the

ball joint from the steering arm.

15. Remove the halfshafts at the inboard side

from the transaxle. Tie the joint assembly aside.

*It is not necessary to disconnect the half-

shafts from the wheel hubs.

16. Support the engine and remove the center

member.

17. Remove the bellhousing cover and remove

the driveplate bolts.

18 Remove the transaxle assembly lower con-

necting bolt, located just over the halfshaft opening.

19. Properly support the transaxle assembly, then

lower it, moving it to the right for clearance.

To install: 20. After the torque converter has been mounted

on the transaxle, install the transaxle assembly on the

engine. Install the mounting bolts and tighten to

31-40 ft. Ibs. (43-55 Nm) on 1990-92 models and

35 ft. Ibs. (48 Nm) on 1993-00 models.

21. Tighten the driveplate bolts to 33-38 ft. Ibs.

(46-53 Nm). Install the bellhousing cover.

22. Install the center member. 23. Replace the circlips and install the halfshafts

to the transaxle.

24. Install the tie rods, ball joints and stabilizer

links to the steering arm

25. Install the transaxle mounting bracket and

bolts.

26. Install the starter.

27. Connect the speedometer cable.

28. Connect the inhibitor switch, kickdown servo

switch, the pulse generator and oil temperature sen-

sor, if disconnected.

29. Connect the shift control solenoid valve con-

nector.

30. Connect the control cables and oil cooler

lines.

31. Install the tension rod, if removed.

32. Install the air cleaner assembly.

33. Install the battery tray and battery.

34. Connect the positive then the negative termi-

nal.

35. Refill with Dexron@ II, Mopar ATF Plus type

7176 or equivalent, automatic transaxle fluid.

36. Start the engine and allow to idle for two min-

utes. Apply parking brake and move selector through

each gear position, ending in N. Recheck fluid level

and add if necessary. Fluid level should be between

the marks in the HOT range.

ADJUSTMENTS

Shifter Control Cable Adjustment

1. The shifter cable adjustment is done at the

neutral safety switch (inhibitor switch). Locate the

switch on the transaxle and note the alignment holes

in the arm and the body of the switch. Place the se-

lector lever in N. Place the manual lever of the

transaxle in the neutral position.

2. Check alignment of the hole in the manual

control lever to the hole in the inhibitor switch body.

If the holes do not align, adjustment is required.

3. To adjust, loosen the nut on the cable end and

pull the cable end by hand until the alignment holes

match. Tighten the nut. Check that the transaxle

shifts and conforms to the positions of the selector

lever.

Throttle Valve Cable

The throttle valve adjustment applies only to the

1990-96 Mirage.

1. Place selector lever and manual control lever

in N position.

2. Loosen adjusting nut. While lightly pulling on

control cable tighten mounting nut to 7-10 ft. Ibs.

(X-14 Nm).

3. When adjustment is complete, be sure selector

lever is still in the N position. Verify all functions

correspond to the position indicated on the selector

lever.

The halfshaft removal and installation and over-

haul are the same as a manual transaxle Please refer

to Manual Transaxle in this Section

Page 307 of 408

8-12 SUSPENSION AND STEERING

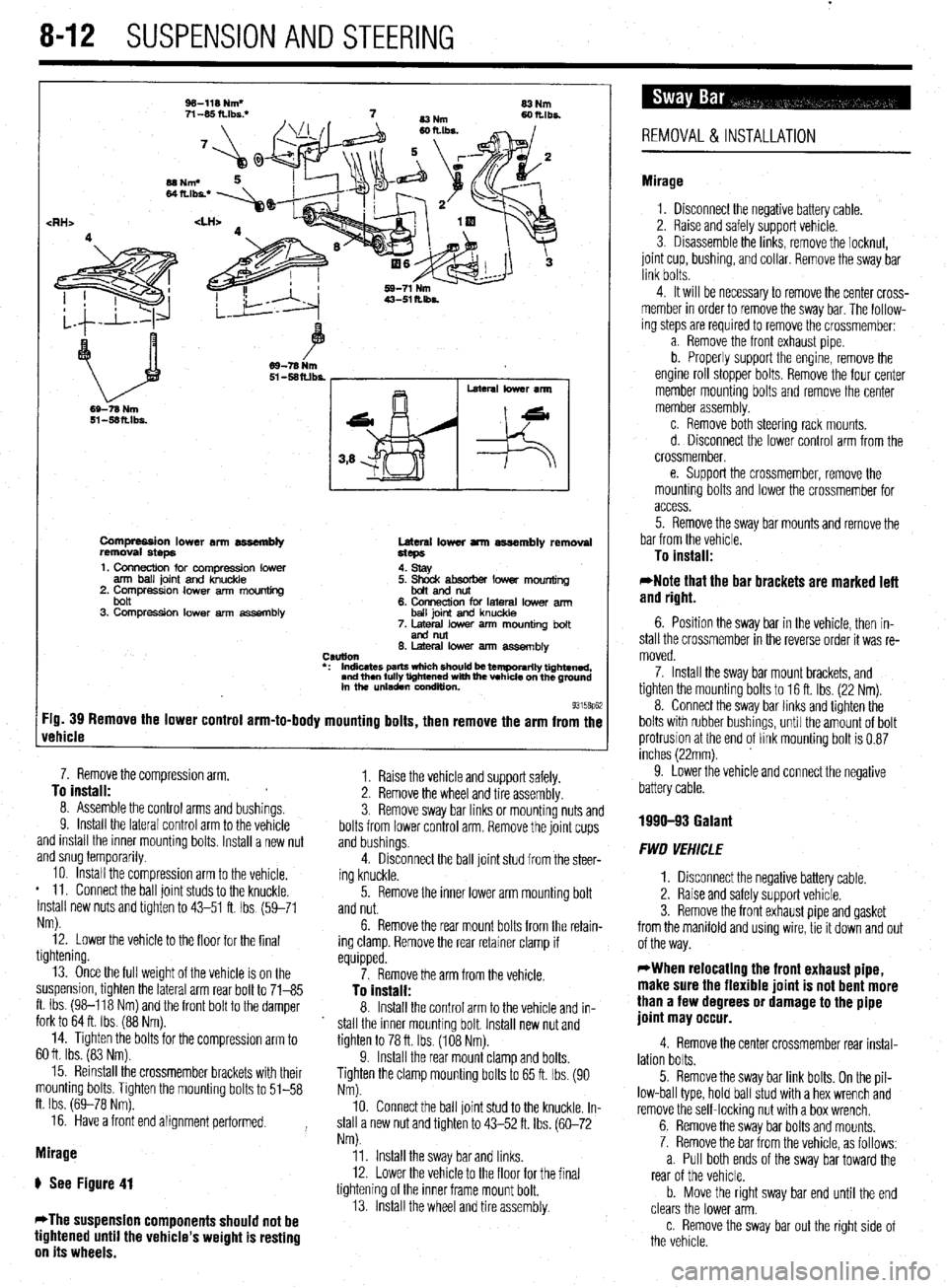

Compression lower an assembly

removal steps Lateral lower arm assembly removal

Hcps

1. Connection for compression lower

arm ball joint and knuckle

2. Compressron lower arm mounting

bolt

3. Compression lower arm assembly 4. stay

5. ~mdtsoorber lower mounting

6. Connection for lateral lower arm

ball joint and knuckle

7. Metal lower arm mounting bolt

end nut

6. Lateral low% arm assemblv

CSUtlOll

l : Indicates parts wfdch should k temporarily tightened,

and then fully tightened with fhe vehicle on the ground

in the unladen wndluon.

93158p62 :ig. 39 Remove the lower control arm-to-body mounting bolts, then remove the arm from the

rehicle

8. Assemole me control arms and bushmgs. 7. Remove the compression arm,

^. To install:

Y. Install the lateral control arm to the vehicle

and install the inner mounting bolts. Install a new nut

and snug temporarily. -. .*.. a.

10. Install the compression arm to the vehicle.

* 11. Connect the ball joint studs to the knuckle.

Install new nuts and tighten to 43-51 ft. Ibs (59-71

Nm).

12. Lower the vehicle to the floor for the final

tightening. 3. Remove sway bar links or mounting nuts and

bolts from lower control arm. Remove the joint cups 1.

and bushings.

4. Raise the vehicle and support safely.

Disconnect the ball joint stud from the steer-

ing knuckle. 2. Remove the wheel and tire assembly

13. Once the full weight of the vehicle is on the

suspension, tighten the lateral arm rear bolt to 71-85

ft. Ibs. (98-118 Nm) and the front bolt to the damper

fork to 64 ft. Ibs. (88 Nm).

14. Tighten the bolts for the compresslon arm to

60 ft. Ibs. (83 Nm).

15. Reinstall the crossmember brackets with their

mounting bolts. Tighten the mounting bolts to 51-58

ft. Ibs. (69-78 Nm).

16. Have a front end alignment performed.

Mirage

ti See Figure 41

*The suspension components should not be

tightened until the vehicle’s weight is resting

on its wheels. 5. Remove the inner lower arm mounting bolt

and nut.

6. Remove the rear mount bolts from the retain-

ing clamp. Remove the rear retainer clamp if

equipped.

7. Remove the arm from the vehicle.

To install:

8. Install the control arm to the vehicle and in-

stall the inner mounting bolt. Install new nut and

tighten to 78 ft. Ibs. (108 Nm).

9. Install the rear mount clamp and bolts.

Tighten the clamp mounting bolts to 65 ft. Ibs. (90

Nm).

10. Connect the ball joint stud to the knuckle. In-

stall a new nut and tighten to 43-52 ft. Ibs. (60-72

Nm).

11. Install the sway bar and links.

12. Lower the vehicle to the floor for the final

tightening of the inner frame mount bolt.

13. Install the wheel and tire assembly.

REMOVAL&INSTALLATION

Mirage

1. Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Disassemble the links, remove the locknut,

joint cup, bushing, and collar. Remove the sway bar

link bolts.

4. It will be necessary to remove the center cross-

member in order to remove the sway bar. The follow-

ing steps are required to remove the crossmember:

a. Remove the front exhaust pipe

b. Properly support the engine, remove the

engine roll stopper bolts. Remove the four center

member mounting bolts and remove the center

member assembly.

c. Remove both steering rack mounts.

d. Disconnect the lower control arm from the

crossmember,

e. Support the crossmember, remove the

mounting bolts and lower the crossmember for

access.

5. Remove the sway bar mounts and remove the

bar from the vehicle.

To install:

*Note that the bar brackets are marked left

and right.

6. Position the sway bar in the vehicle, then in-

stall the crossmember in the reverse order it was re-

moved.

7. Install the sway bar mount brackets, and

tighten the mounting bolts to 16 ft. Ibs. (22 Nm).

8. Connect the sway bar links and tighten the

bolts with rubber bushings, until the amount of bolt

protrusion at the end of link mounting bolt is 0.87

inches (22mm).

9. Lower the vehicle and connect the negative

battery cable.

1990-93 Galant

FWD VEHICLE

1. Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Remove the front exhaust pipe and gasket

from the manifold and using wire, tie it down and out

of the way.

WWhen relocating the front exhaust pipe,

make sure the flexible joint is not bent more

than a few degrees or damage to the pipe

joint may occur.

4. Remove the center crossmember rear instal-

lation bolts.

5. Remove the sway bar link bolts. On the pil-

low-ball type, hold ball stud with a hex wrench and

remove the self-locking nut with a box wrench.

6. Remove the sway bar bolts and mounts.

7. Remove the bar from the vehicle, as follows:

a. Pull both ends of the sway bar toward the

rear of the vehicle.

b. Move the right sway bar end until the end

clears the lower arm.

c. Remove the sway bar out the right side of

the vehicle.

Page 308 of 408

SUSPENSION AND STEERING 8-13

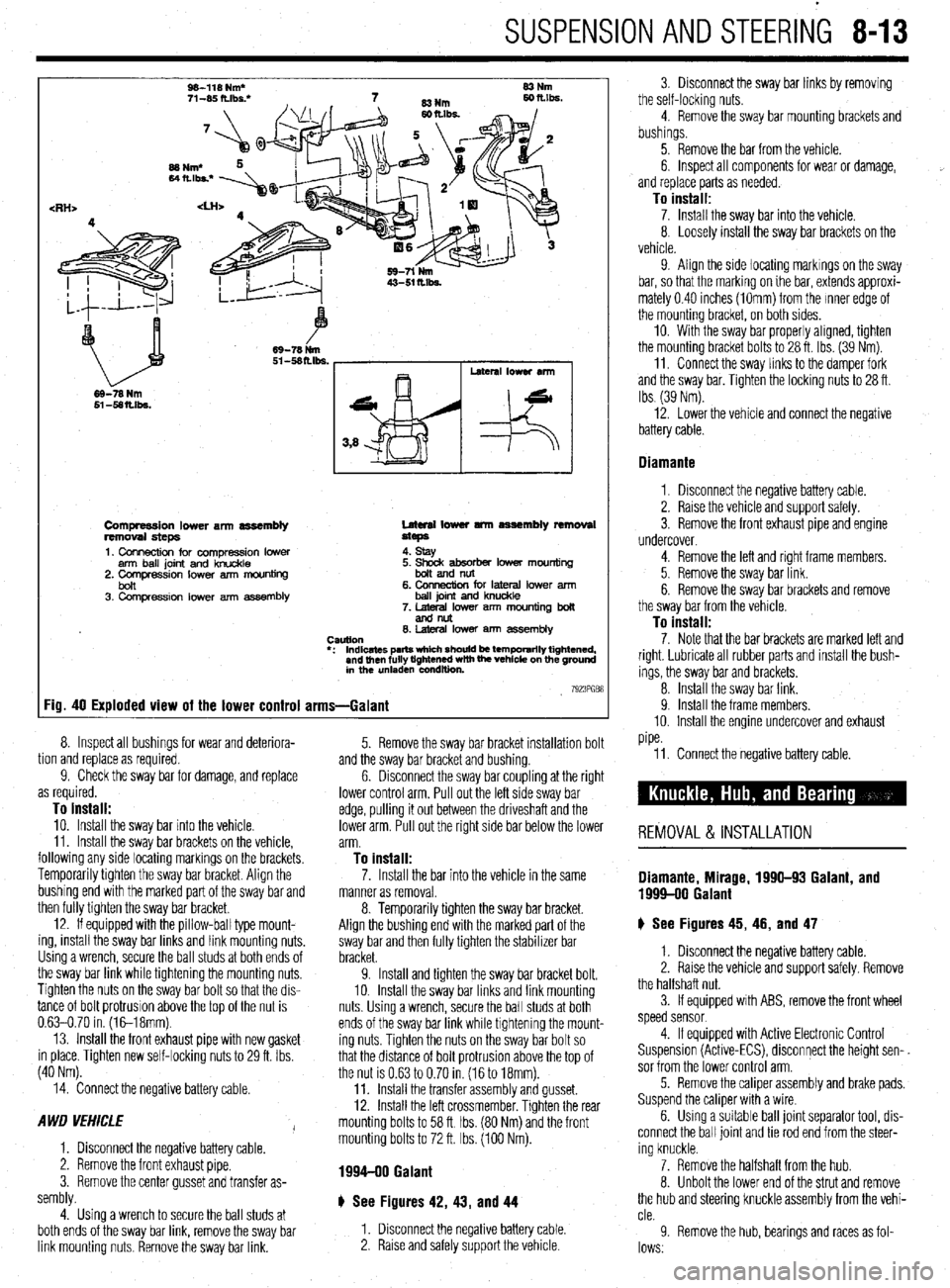

W-118 Nm*

71-W ft.lbs: 83Nm

69-78 Nm

Compression lower arm assembly

removal steps

1. Connection for compression lower

arm ball joint and knuckle

2. Comoression lower arm mouniina Lateral lower tmn assembly removal

steps

4. stay

bon ’ 3. Compression lower arm assembly 6. CMlnection for lateral lower arm

ball joint and knuckle

7. lateral lower arm mounting boll

andnllt

0. hleral lower am7 assembly

CWtlOtl

l : Indicates parts which should be temporarily tightened,

and then fully tightened with the vehicle on the ground

in the unladen condition

7923PGB8 Fig. 40 Exploded view of the lower control arms-Galant

tion and replace as required. 8.

9. Inspect all bushings for wear and deteriora-

Check the sway bar for damage, and replace

as required.

To install: 10. Install the sway bar into the vehicle.

11. Install the sway bar brackets on the vehicle,

following any side locating markings on the brackets.

Temporarily tighten the sway bar bracket. Align the

bushing end with the marked part of the sway bar and

then fully tighten the sway bar bracket.

12. If equipped with the pillow-ball type mount-

ing, install the sway bar links and link mounting nuts.

Using a wrench, secure the ball studs at both ends of

the sway bar link while tightening the mounting nuts.

Tighten the nuts on the sway bar bolt so that the dis-

tance of bolt protrusion above the top of the nut is

0.63-0.70 in. (1&18mm).

13. Install the front exhaust pipe with new gasket

in place. Tighten new self-locking nuts to 29 ft. Ibs.

(40 Nm). and the sway bar bracket and bushing.

6. 5. Remove the sway bar bracket installation bolt

Disconnect the sway bar coupling at the right

lower control arm. Pull out the left side sway bar

edge, pulling it out between the driveshaft and the

lower arm. Pull out the right side bar below the lower

arm.

To install:

14. Connect the negative battery cable.

A WD VEHICLE

I

1. Disconnect the negative battery cable.

2. Remove the front exhaust pipe.

3. Remove the center gusset and transfer as-

sembly.

4. Using a wrench to secure the ball studs at

both ends of the sway bar link, remove the sway bar

link mounting nuts. Remove the sway bar link. 11. Connect the negative battery cable.

REMOVAL & INSTALLATION

7. Install the bar into the vehicle in the same Diamante, Mirage, 1996-93 Galant, and manner as removal. 1999-00 Galant 8. Temporarily tighten the sway bar bracket.

Align the bushing end with the marked part of the

sway bar and then fully tighten the stabilizer bar

bracket.

9. Install and tighten the sway bar bracket bolt.

10. Install the sway bar links and link mounting

nuts Using a wrench, secure the ball studs at both

ends of the sway bar link while tightening the mount-

ing nuts. Tighten the nuts on the sway bar bolt so

that the distance of bolt protrusion above the top of

the nut is 0.63 to 0.70 in. (16 to 18mm).

11. Install the transfer assembly and gusset.

12. Install the left crossmember. Tighten the rear

mounting bolts to 58 ft Ibs. (80 Nm) and the front

mounting bolts to 72 ft. Ibs. (100 Nm). ) See Figures 45, 46, and 47

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely. Remove

the halfshaft nut.

3. If equipped with ABS, remove the front wheel

speed sensor

1994-90 Galant

4. If equipped with Active Electronic Control

Suspension (Active-ECS), disconnect the height sen-.

sor from the lower control arm.

5. Remove the caliper assembly and brake pads.

Suspend the caliper with a wire

6. Using a suitable ball joint separator tool, dis-

connect the ball joint and tie rod end from the steer-

ing knuckle.

7. Remove the halfshaft from the hub.

8. Unbolt the lower end of the strut and remove

the hub and steering knuckle assembly from the vehi-

cle.

9 Remove the hub, bearings and races as fol-

lows.

# See Figures 42, 43, and 44

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle 3. Disconnect the sway bar links by removing

the self-locking nuts.

4. Remove the sway bar mounting brackets and

bushings.

5. Remove the bar from the vehicle.

6. Inspect all components for wear or damage,

and replace parts as needed.

To install: 7. Install the sway bar into the vehicle.

8. Loosely install the sway bar brackets on the

vehicle.

9. Align the side locating markings on the sway

bar, so that the marking on ihe bar, extends approxi-

mately 0.40 inches (1Omm) from the Inner edge of

the mounting bracket, on both sides.

10. With the sway bar properly aligned, tighten

the mounting bracket bolts to 28 ft. Ibs. (39 Nm).

11. Connect the sway links to the damper fork

and the sway bar. Tighten the locking nuts to 28 ft.

Ibs (39 Nm).

12. Lower the vehicle and connect the negative

battery cable.

Diamante

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the front exhaust pipe and engine

undercover.

4. Remove the left and right frame members.

5. Remove the sway bar link.

6. Remove the sway bar brackets and remove

the sway bar from the vehicle.

To install: 7. Note that the bar brackets are marked left and

right. Lubricate all rubber parts and install the bush-

ings, the sway bar and brackets.

8. Install the sway bar link.

9. Install the frame members.

10. Install the engine undercover and exhaust

pipe.

Page 316 of 408

.

SUSPENSION AND STEERING 8-21

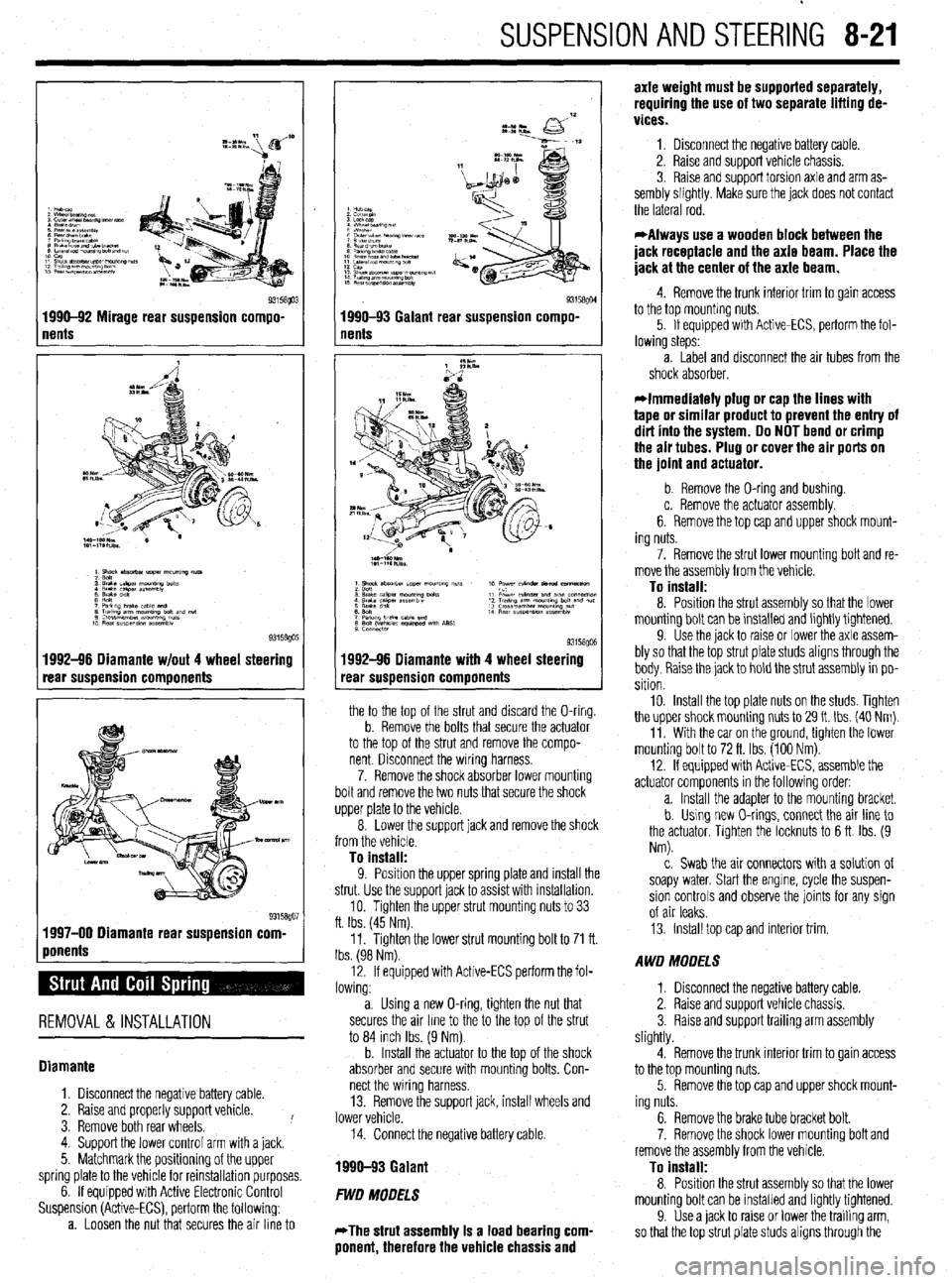

1 nents Q3158!@3 1990-92 Mirage rear suspension compo-

1992-96 Diamante w/out 4 wheel steering

rear suspension components

1 ponents %” 1997-00 Diamante rear suspension corn

REMOVAL & INSTALLATION

Diamante

1. Disconnect the negative battery cable.

2. Raise and properly support vehicle.

3. Remove both rear wheels. !

4. Support the lower control arm with a jack.

5. Matchmark the positioning of the upper

spring plate to the vehicle for reinstallation purposes.

6. If equipped with Active Electronic Control

Suspension (Active-ECS), perform the following:

a. Loosen the nut that secures the air line to

I

93158QM 1990-93 Galant rear suspension compo-

nents

1992-96 Diamante with 4 wheel steering

rear suspension components

the to the top of the strut and discard the O-ring.

b. Remove the bolts that secure the actuator

to the top of the strut and remove the compo-

nent Disconnect the wiring harness.

7. Remove the shock absorber lower mounting

bolt and remove the two nuts that secure the shock

upper plate to the vehicle.

8. Lower the support jack and remove the shock

from the vehicle.

To install:

9. Position the uooer sprina elate and install the

strut. Use the support’jack to as% with installation.

10. Tighten the upper strut mounting nuts to 33

ft. Ibs. (45 Nm).

11. Tighten the lower strut mounting bolt to 71 ft.

Ibs. (98 Nm).

12. If equipped with Active-ECS perform the fol-

lowing:

a. Using a new O-ring, tighten the nut that

secures the air line to the to the top of the strut

to 84 inch Ibs. (9 Nm).

b. Install the actuator to the top of the shock

absorber and secure with mounting bolts. Con-

nect the wiring harness.

13. Remove the support jack, install wheels and

lower vehicle.

14. Connect the negative battery cable.

1990-93 Galant

FWD MODELS

*The strut assembly Is a load bearing com-

ponent, therefore the vehicle chassis and axle weight must be supported separately,

requiring the use of two separate lifting de-

vices.

1. Disconnect the negative battery cable.

2. Raise and support vehicle chassis.

3. Raise and support torsion axle and arm as-

sembly slightly. Make sure the jack does not contact

the lateral rod.

*Always use a wooden block between the

jack receptacle and the axle beam. Place the

jack at the center of the axle beam.

4. Remove the trunk interior trim to gain access

to the top mounting nuts.

5. If equipped with Active-ECS, perform the fol-

lowing steps:

a. Label and disconnect the air tubes from the

shock absorber.

*Immediately plug or cap the lines with

tape or similar product to prevent the entry of

dirt into the system. Do NOT bend or crimp

the air tubes. Plug or cover the air ports on

the joint and actuator.

b. Remove the O-ring and bushing.

c. Remove the actuator assembly.

6. Remove the top cap and upper shock mount-

ing nuts.

7. Remove the strut lower mounting bolt and re-

move the assembly from the vehicle.

To install:

8. Position the strut assembly so that the lower

mounting bolt can be installed and lightly tightened.

9. Use the jack to raise or lower the axle assem-

bly so that the top strut plate studs aligns through the

body. Raise the jack to hold the strut assembly in po-

sition

10. Install the top plate nuts on the studs. Tighten

the upper shock mounting nuts to 29 It. Ibs. (40 Nm).

11. With the car on the ground, tighten the lower

mounting bolt to 72 ft. Ibs. (100 Nm).

12. If equipped with Active-ECS, assemble the

actuator components in the following order:

a. Install the adapter to the mounting bracket.

b. Using new O-rings, connect the air line to

the actuator, Tighten the locknuts to 6 ft Ibs. (9

Nm).

c. Swab the air connectors with a solution of

soapy water. Start the engine, cycle the suspen-

sion controls and observe the joints for any sign

of air leaks.

13. Install top cap and interior trim.

AWD MODELS

1. Disconnect the negative battery cable.

2. Raise and support vehicle chassis.

3. Raise and support trailing arm assembly

slightly.

4. Remove the trunk interior trim to gain access

to the top mounting nuts.

5. Remove the top cap and upper shock mount-

ing nuts.

6. Remove the brake tube bracket bolt.

7. Remove the shock lower mounting bolt and

remove the assembly from the vehicle.

To install:

8. Position the strut assembly so that the lower

mounting bolt can be installed and lightly tightened.

9. Use a jack to raise or lower the trailing arm,

so that the top strut plate studs aligns through the

Page 328 of 408

.

8132 SUSPENSION AND STEERING

(42 Nm) on Mirage and 36-39 ft. tbs. (49-53 Nm)

on Galant and Diamante models.

19. Have the front end alignment checked, and

adjusted if necessary.

Inner Tie Rods

11. Loosen the inner tie rod end nut from the

steering gear and remove the inner tie rod end.

To install: 12. Using a new lock plate, install the tie rod end

and tighten the tie rod to 65 ft. Ibs. (90 Nm). REMOVAL &INSTALLATION 13. Bend the tabs of the new lock plate to secure

1. Raise the front of the vehicle and support it

on jackstands.

2. Remove the wheel.

3. Remove the cotter pin and the outer tie rod

ball joint stud nut. Note the position of the steering

linkage.

4. Wire brush the threads on the tie rod shaft

and lubricate with penetrating oil.

5. Using a suitable ball joint separator tool, re-

move the tie rod ball joint from the steering knuckle.

6. Loosen the locknut and remove the tie rod

end from the tie rod. Count the number of complete

turns it takes to completely remove it.

7. Remove the tie rod-to-steering gear locknut.

8. Remove the clamps that secure the flexible

boot to the steering gear.

9. Slide the boot from the inner tie rod and re-

move the boot.

IO. Bend the lock plate tabs from the inner tie rod

end nut. the inner tie rod end.

14. Slide the boot onto the steering gear and se-

cure it with new clamps.

15. Install the outer tie rod end to the steering

gear locknut.

16. Install the outer tie rod end, turning it in ex-

actly as many turns as it was to remove the old one.

Make sure it is correctly positioned in relationship to

the steering linkage.

22. Have a front end alignment performed. 17. Connect the outer tie rod end to the steering

knuckle and install the castle nut. Tighten the nut to

25 ft. Ibs. (34 Nm,) on the Mirage and 21 ft. Ibs. (29

Nm) on the Galant and Diamante models.

18. Install a new cotter pin to the castle nut.

19. Tighten the tie rod end locking nut to 30 ft.

Ibs. (42 Nm) on the Mirage and 36-39 ft. Ibs. (49-53

Nm) on the Galant and Diamante models.

20. Install the wheel and tire assembly.

21. Lower the vehicle.

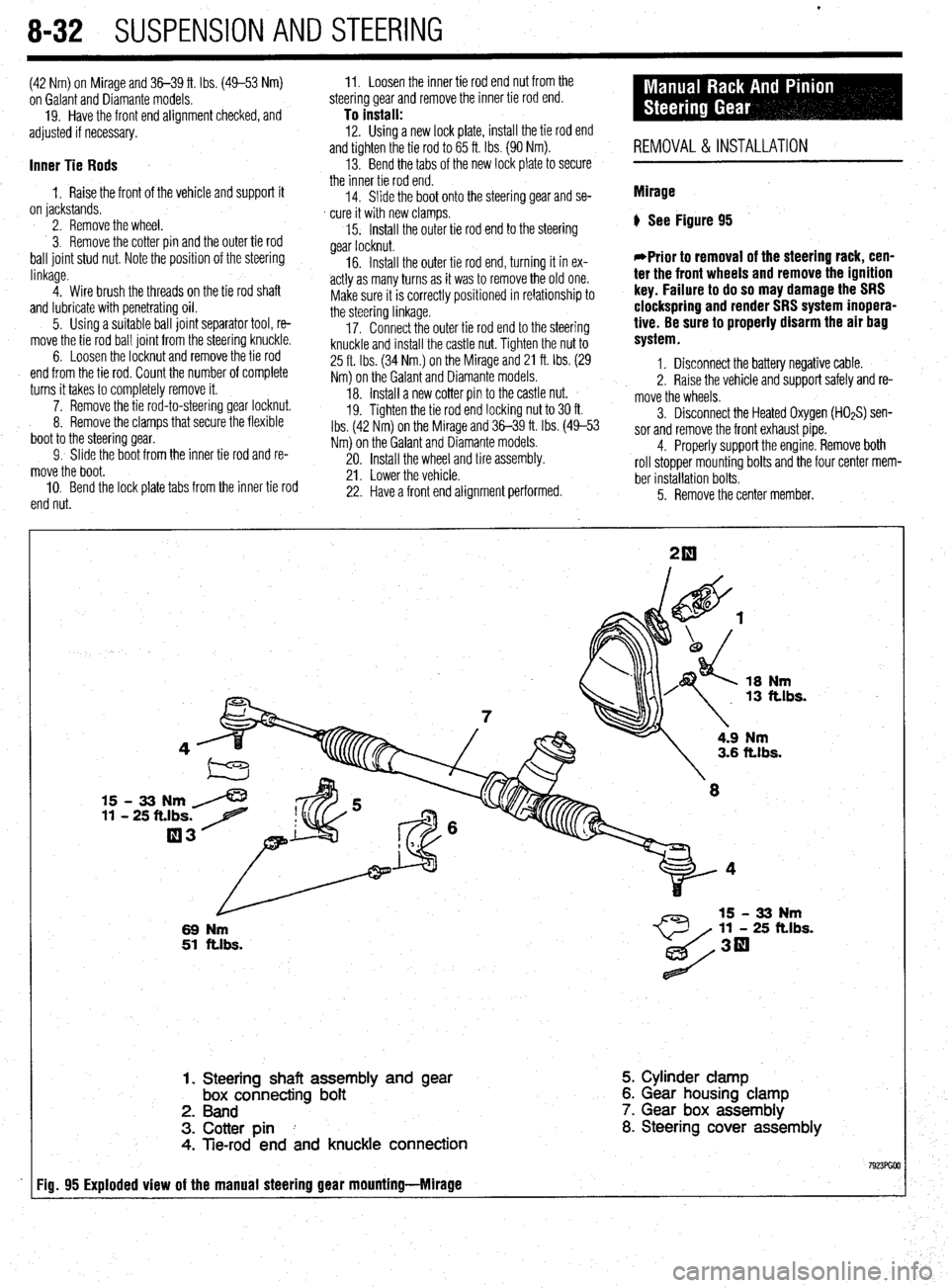

Mirage

) See Figure 95

*Prior to removal of the steering rack, cen-

ter the front wheels and remove the ignition

key. Failure to do so may damage the SRS

clockspring and render SRS system inopera-

tive. Be sure to properly disarm the air bag

system.

1. Disconnect the battery negative cable.

2. Raise the vehicle and support safely and re-

move the wheels.

5. Remove the center member. 3. Disconnect the Heated Oxygen (HOzS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine. Remove both

roll stopper mounting bolts and the four center mem-

ber installation bolts.

18

Nm 13 ft.lbs.

15 - 33 Nm /

11 - 25 ft.lbs. 7

03

L

69 Nm

51 ftlbs.

4.9 Nm 3.6 ft.lbs.

11 - 25 ft.lbs.

1. Steering shaft assembly and

gear box connecting bolt

2. Band

3. Cotter pin I

4. Tie-rod end and knuckle connection 5. Cylinder clamp

6. Gear housing clamp

7. Gear box assembly

8. Steering cover assembly

Fig. 95 Exploded view of the manual steering gear mounting-Mlrage

Page 329 of 408

SUSPENSION AND STEERING 8-33

*Matchmark the pinion input shaft of the

rack to the lower steering column joint for in-

stallation purposes.

6. Remove the pinch bolt holding the lower

steering column joint to the rack and pinion input

shaft.

7. Remove the cotter pins and disconnect the tie

rod ends from the steering knuckle.

8. Remove the rack and pinion steering assem-

bly and its rubber mounts from the right side of the

vehicle.

To install: 9. Align the matchmarks of the input shaft and

install the rack to the vehicle.

10. Secure the rack using the retainer clamps and

bolts. Tighten the bolts to 51 ft. Ibs. (70 Nm).

11. Tighten the steering column pinch bolt to 13

ft. Ibs. (18 Nm).

12. Install the center member.

13. Install the front exhaust pipe.

14. Connect the HO$ sensor.

15. Connect the tie rod ends to the steering

knuckles and tighten the castle nuts to 25 ft. Ibs. (34

Nm). Install new cotter pins.

16. Install the wheels and connect the negative

battery cable.

17. Have a front end alignment performed.

REMOVAL &INSTALLATION

Diamante

FRONT

*Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clock spring and render SRS system in-

operative.

1. Disconnect the negative battery cable.

2. Disconnect the front exhaust pipe.

3. If equipped with AWD, remove the transfer

case assembly.

4. Remove the bolt holding the lower steering

column joint to the rack and pinion input shaft.

5. Remove the cotter pins and disconnect the tie

rod ends.

6. Remove the left and right frame members.

7. Remove the stabilizer bar bracket.

8. If equipped with four-wheel steering, discon-

nect the lines going to the rear pump.

9. Remove the rack and pinion steering assem-

bly and its rubber mounts. Move the rack to the right

to remove it from the crossmember.

To install: IO. Install the rack and mounting bolts. Tighten

the bolts to 51 ft. Ibs. (70 Nm). When installing the

rubber rack mounts, align the projection of the

mounting rubber with the indentation in the cross:

member. Install the pinch bolt.

11. Connect the pressure and return lines to the

rack and to the rear pump, if equipped.

12. Install the frame members and tighten the

bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Connect the tie rods and install new cotter

pins. 14. Install the transfer case and front exhaust

pipe.

15. Refill the reservoir and bleed the system.

16. Have a front end alignment performed.

REAR

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Drain the power steering fluid.

4. Remove the main muffler assembly.

5. Remove the rear shock absorber lower

mounting bolts.

6. Using the proper equipment, support the

weight of the rear differential. Remove the 2 small

crossmember brackets.

7. Remove the large self-locking crossmember

mounting nuts on the differential side.

8. Remove the oil line clamp bolts.

9. Remove the pressure tubes.

IO. Hold the tie rod ends stationary and remove

the tie rod end nuts. Remove the tie rod ends from

the trailing arms.

11. Remove the mounting bolts and remove the

rear steering gear.

To install: 12. Secure the unit to the crossmember. Move

the power cylinder piston rod over its full stroke to

determine its neutral position.

13. Align the tie rod ends with the holes in the

trailing arms and install the nuts. Adjust the length of

the tie rods with the nuts if necessary. The difference

in length between the 2 tie rod ends should not ex-

ceed 0.04 in. (1 mm). The nuts’ torque specification is

42 ft. Ibs. (58 Nm).

14. Replace the O-rings and install the pressure

tubes. Clamp in place.

15. Install the large self-locking crossmember

mounting nuts on the differential side. Tighten to

80-94 ft. Ibs. (110-130 Nm).

16. Remove the support equipment.

17. Install the 2 small crossmember brackets.

18. Install the shock mounting bolts.

19. Install the muffler assembly.

20. Refill the reservoir and bleed the system.

21. Have a front end alignment performed. _

Galant

1990-93 MODELS

1. Disconnect the negative battery cable.

2. Drain the power steering fluid.

3. Raise the vehicle and support safely.

4. Remove the bolt holding lower steering col-

umn joint to the rack and pinion input shaft.

5. Remove the transfer case, if equipped.

6. Remove the cotter pins and using the proper

tools, separate the tie rod ends from the steering

knuckle.

7. Locate the triangular brace near the stabilizer

bar brackets on the crossmember and remove both

the brace and the stabilizer bar bracket.

8. Support the center crossmember.

9. Remove the through-bolt from the round roll

stopper and remove the rear bolts from the center

crossmember.

10. Disconnect the front exhaust pipe, if

equipped with FWD.

11. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings. Plug the

fittings to prevent excess fluid leakage. 12. Lower the crossmember slightly.

13. Remove the rack and pinion steering assem-

bly and its rubber mounts. Move the rack to the right

to remove from the crossmember. Tilt the assembly

downward and remove from the left side of the vehi-

cle. Use caution to avoid damaging the boots.

To install: 14. Install the rack and install the mounting bolts. Tighten the mounting bolts to 43-58 ft. Ibs. (60-80

Nm). When installing the rubber rack mounts, align

the projection of the mounting rubber with the inden-

tation in the crossmember.

15. Connect the power steering fluid lines to the

rack.

16. Connect the exhaust pipe, if removed.

17. Raise the crossmember into position. Install

the center member mounting bolts and tighten to 72

ft. Ibs. (100 Nm). Install the roll stopper bolt and new

nut. Tighten nut to 47 ft. Ibs. (65 Nm).

18. Install the stabilizer bar brackets and brace.

19. Connect the tie rod ends and tighten nuts to

25 ft. Ibs. (34 Nm).

20. Install the transfer case, if removed. Check

and fill fluid.

21. Refill the reservoir with power steering fluid

and bleed the system.

22. Have a front end alignment performed.

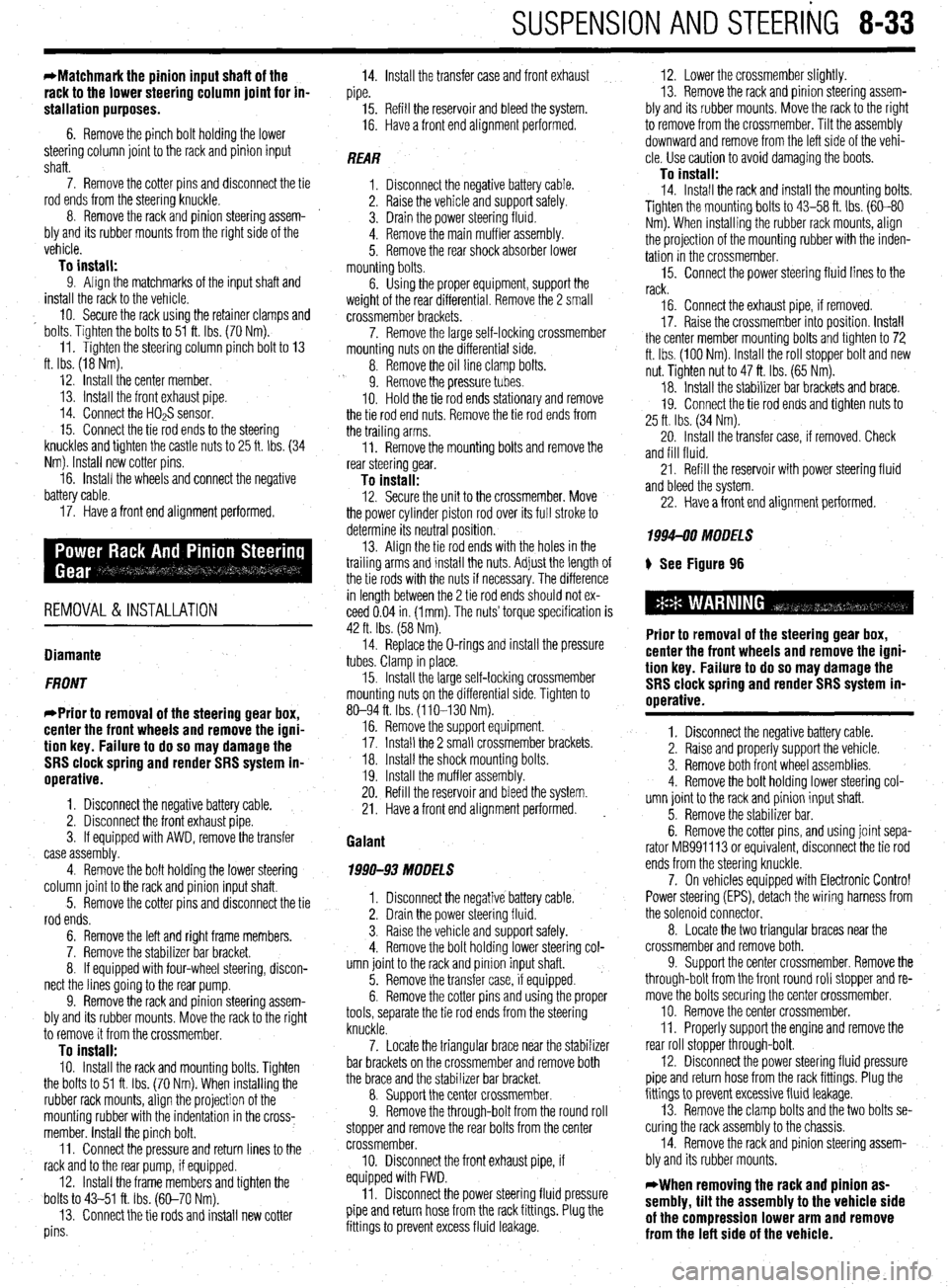

1994-M MODELS

+ See Figure 96

Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clock spring and render SRS system in-

operative.

1. Disconnect the negative battery cable.

2. Raise and properly support the vehicle.

3. Remove both front wheel assemblies.

4. Remove the bolt holding lower steering col-

umn joint to the rack and pinion input shaft.

5. Remove the stabilizer bar.

6. Remove the cotter pins, and using joint sepa-

rator MB991 113 or equivalent, disconnect the tie rod

ends from the steering knuckle.

7. On vehicles equipped with Electronic Control

Power steering (EPS), detach the wiring harness from

the solenoid connector.

8. Locate the two triangular braces near the

crossmember and remove both.

9. Support the center crossmember. Remove the

through-bolt from the front round roll stopper and re-

move the bolts securing the center crossmember.

10. Remove the center crossmember. ,

Il. Properly support the engine and remove the

rear roll stopper through-bolt.

12. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings. Plug the

fittings to prevent excessive fluid leakage.

13. Remove the clamp bolts and the two bolts se-

curing the rack assembly to the chassis.

14. Remove the rack and pinion steering assem-

bly and its rubber mounts.

*When removing the rack and pinion as-

sembly, tilt the assembly to the vehicle side

of the compression lower arm and remove

from the left side of the vehicle.

Page 330 of 408

8-34 SUSPENSION AND STEERING'

Fig. 96 Exploded view of the power steering gear removal procedure- -Galant 43 Nm*

7 18 Nm

24-33 Nm

18-24 ttlbs.

15 Nm . 11 ftlbs. 6

57 Nm

42 ft.lbs.

\1- 69 Nm

51 ft.lbs. 24-33 Nm

18-24

ft.1 bs.

’ 78-86 Nm

58-65 ft.lbs.

69-78

Nm 51-58 ftlbs.

1. Joint assembly and gear box con-

necting bolt

2. Cotter pin

3. Connection for tie rod end and

knuckle

4. Stay

5. Center member assembly

6. Clamp

7. Bott

I 8. Gear box assembly

Caution

The fasteners marked * should be temporarily

tightened before they are finally tightened once

the total weight of the engine has been placed

on the vehicle

body.

7923PGAl

To install:

15. Center the rack assembly and insert the pin-

ion into the steering column shaft.

16. Install the rack and mounting bolts. Tighten

the mounting bolts to 51 ft. Ibs. (69 Nm).

17. Install the pinch bolt and tighten the bolt to

13 ft. Ibs. (18 Nm).

18. Connect the power steering fluid lines to the

rack and tighten the pressure hose fitting to 11 ft. Ibs.

(15 Nm). Secure the return hose with the clamp.

19. Raise the engine into position.

20. Install the rear roll stopper through-bolt and I

tighten to 32 ft. Ibs. (43 Nm).

21. Raise the crossmember into position. Install

_ the center member mounting bolts; tighten the front

bolts to 58-65 ft. Ibs. (78-88 Nm) and the rear bolt

to 51-58 ft. Ibs. (69-78 Nm).

22. Install the front roll stopper bolt and tighten

the nut to 32 ft. Ibs. (43 Nm).

23. Install the two triangular braces and tighten

the mounting bolts to 50-56 ft. Ibs. (69-78 Nm). 24. Install the stabilizer bar.

25. Connect the tie rod ends and tighten the nuts

to 20 ft. Ibs. (27 Nm).

26. On vehicles equipped with EPS, connect the

wiring harness to the solenoid connector.

27. Install the wheel assemblies and lower the

vehicle.

28. Refill the reservoir with power steering fluid

and bleed the system.

29. Have a front end alignment performed.

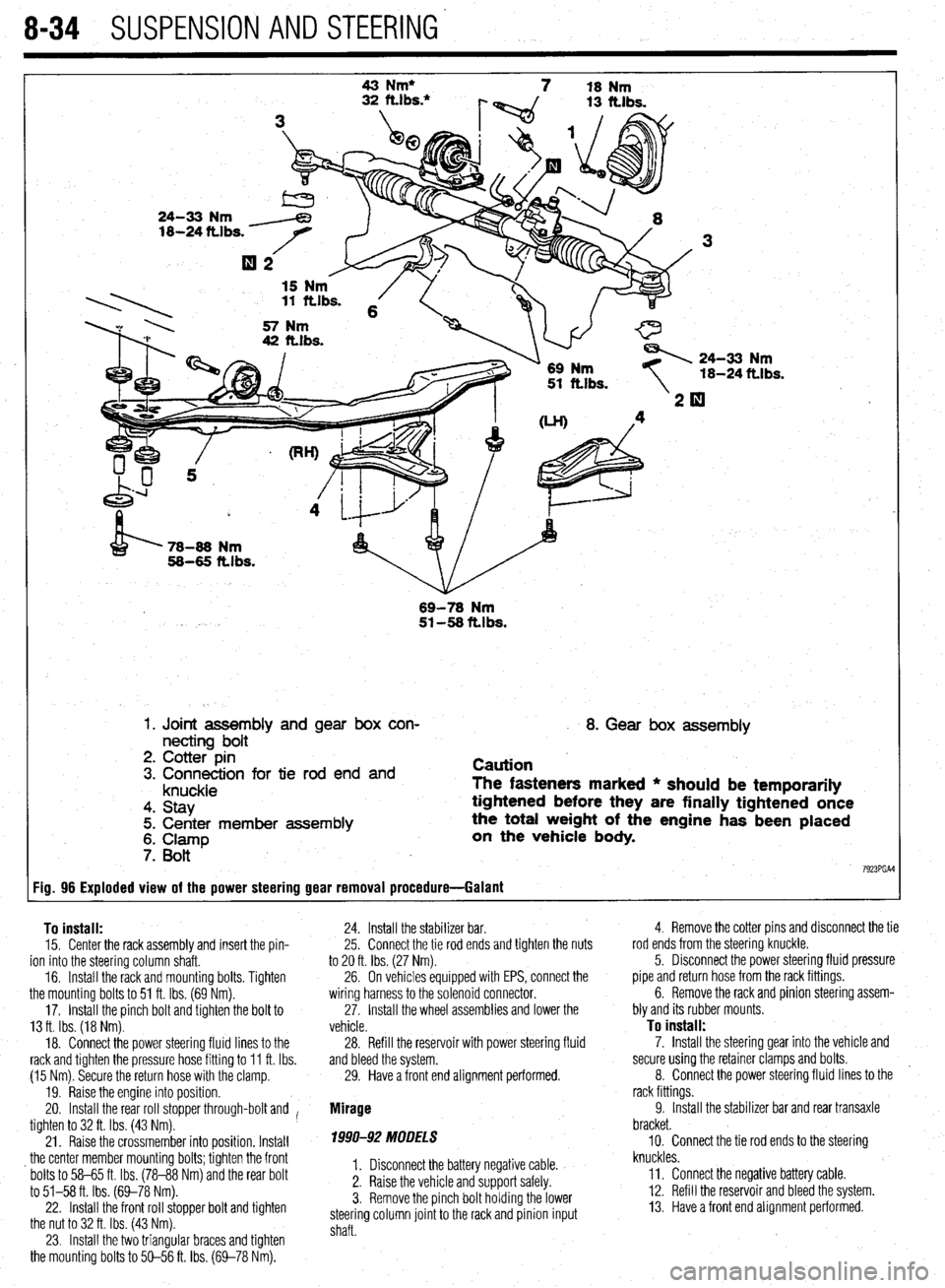

Mirage

1990-92 MODELS

I. Disconnect the battery negative cable.

2. Raise the vehicle and support safely.

3. Remove the pinch bolt holding the lower

steering column joint to the rack and pinion input

shaft. 4. Remove the cotter pins and disconnect the tie

rod ends from the steering’knuckle.

5. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings.

6. Remove the rack and pinion steering assem-

bly and its rubber mounts.

To install:

7. Install the steering gear into the vehicle and

secure using the retainer clamps and bolts.

8. Connect the power steering fluid lines to the

rack fittings.

9. Install the stabilizer bar and rear transaxle

bracket.

10. Connect the tie rod ends to the steering

knuckles.

ll= Connect the negative battery cable.

12. Refill the reservoir and bleed the system.

13. Have a front end alignment performed.

Page 331 of 408

SUSPENSION AND STEERING 8-35

1. Steering shaft assembly and gear

box connecting bolt

2. Band

3. Cotter pin

4. Tie-rod end and knuckle connection

5. Return tube connection 6. Pressure tube connection

7. Cylinder clamp

8. Gear housing clamp

9. Gear box assembly 10. Steering cover assembly

7923PGAl FiD= 97 Exploded view of the power steering gear assembly-Mirage

1993-90 MODELS To install:

) See Figure 97

*Prior to removal of the steering gear box,

center the front wheels and remove the igni-

tion key. Failure to do so may damage the

SRS clockspring and render SRS system in-

operative.

,mr;iin thepower steering system.

2. Disconnect the battery negative cable. Raise

the vehicle and support safely.

3. Disconnect the Heated Oxygen (HOPS) sen-

sor and remove the front exhaust pipe.

4. Properly support the engine.

5. Remove both roll stopper mounting bolts and

the four center member installation bolts. Remove the

center member.

6. Remove the center member. 11. Align the matchmarks of the input shaft and

install the rack to the vehicle.

12. Secure the rack using the retainer clamps and

bolts. Tighten the bolts to 51 ft. Ibs. (70 Nm).

13. Tighten the steering column pinch bolt to 13

ft. Ibs. (18 Nm).

14. Using new O-rings, connect the power steer-

ing fluid lines to the rack fittings.

15. Install the center member.

16. Install the front exhaust pipe.

17. Connect the H02S sensor.

18. Connect the tie rod ends to the steering

knuckles and tighten the castle nuts to 25 ft. Ibs. (34

Nm). Install new cotter pins.

19. Install the wheels and connect the negative

battery cable.

20. Refill ‘the reservoir and bleed the system.

21. Have a front end alignment performed.

stallation purposes. -

7. Remove the pinch bolt holding the lower REMOVALANDINSTALLATION

steering column joint to the rack and pinion input

shaft.

8. Remove the cotter pins and disconnect the tie

rod ends from the steering knuckle.

9. Disconnect the power steering fluid pressure

pipe and return hose from the rack fittings.

IO. Remove the rack and pinion steering assem-

bly and its rubber mounts from the right side of the

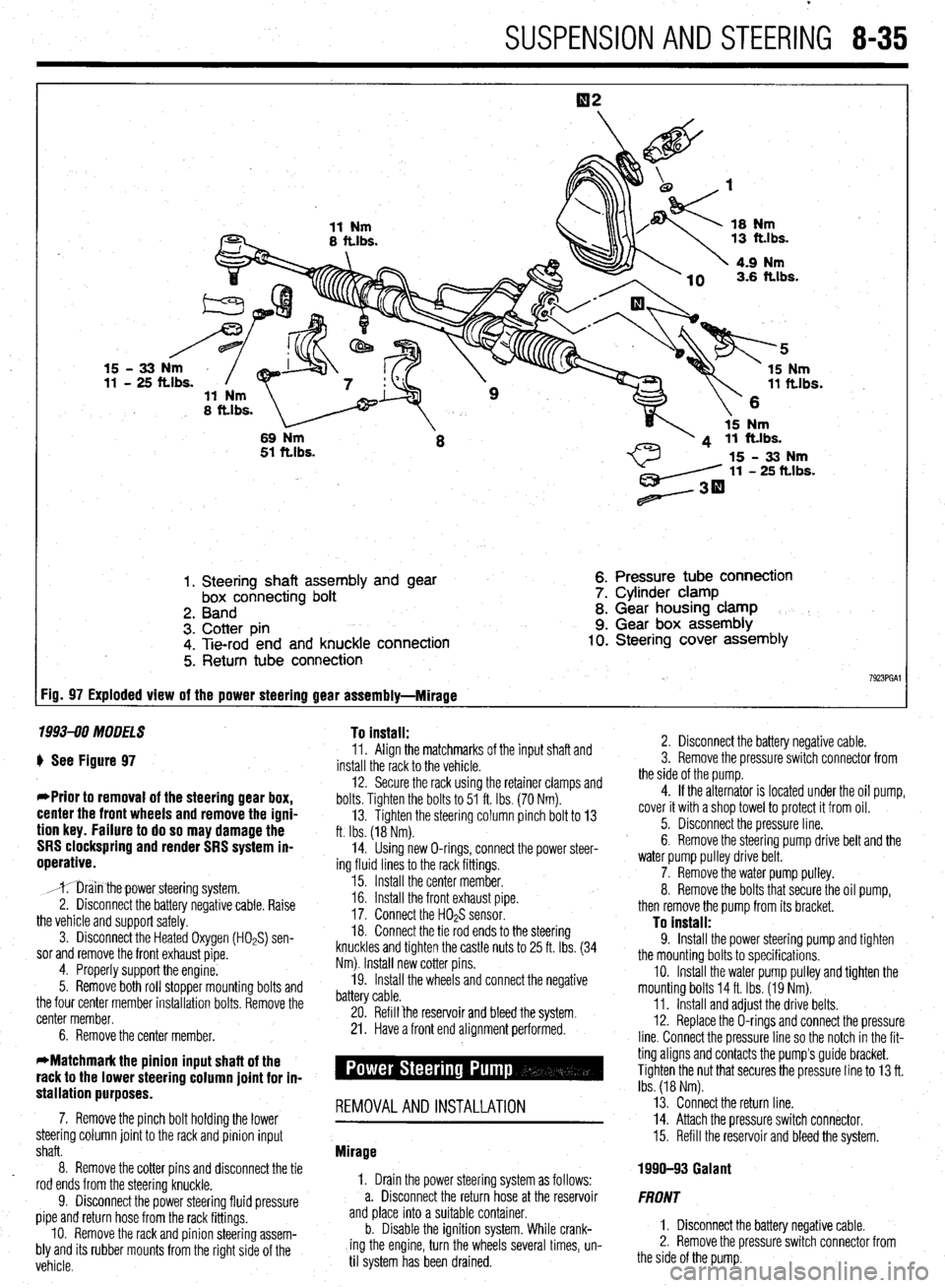

vehicle. Mirage

1, Drain the power steering system as follows:

a. Disconnect the return hose at the reservoir

and place into a suitable container.

b. Disable the ignition system. While crank-

ing the engine, turn the wheels several times, un-

til system has been drained. 2. Disconnect the battery negative cable.

3. Remove the pressure switch connector from

the side of the pump.

4. If the alternator is located under the oil pump,

cover it with a shop towel to protect it from oil.

5. Disconnect the pressure line.

6. Remove the steering pump drive belt and the

water pump pulley drive belt.

7. Remove the water pump pulley.

8. Remove the bolts that secure the oil pump,

then remove the pump from its bracket.

To install: 9. Install the power steering pump and tighten

the mounting bolts to specifications.

IO. Install the water pump pulley and tighten the

mounting bolts 14 ft. Ibs. (19 Nm).

11. Install and adjust the drive belts.

12. Replace the O-rings and connect the pressure

line. Connect the pressure line so the notch in the fit-

ting aligns and contacts the pump’s guide bracket.

Tighten the nut that secures the pressure line to 13 ft.

Ibs. (18 Nm).

13. Connect the return line.

14. Attach the pressure switch connector.

15. Refill the reservoir and bleed the system.

1990-93 Galant

FRONT

1. Disconnect the battery negative cable.

2. Remove the pressure switch connector from

the side of the pump.

Page 332 of 408

8-36 SUSPENSION AND STEERING

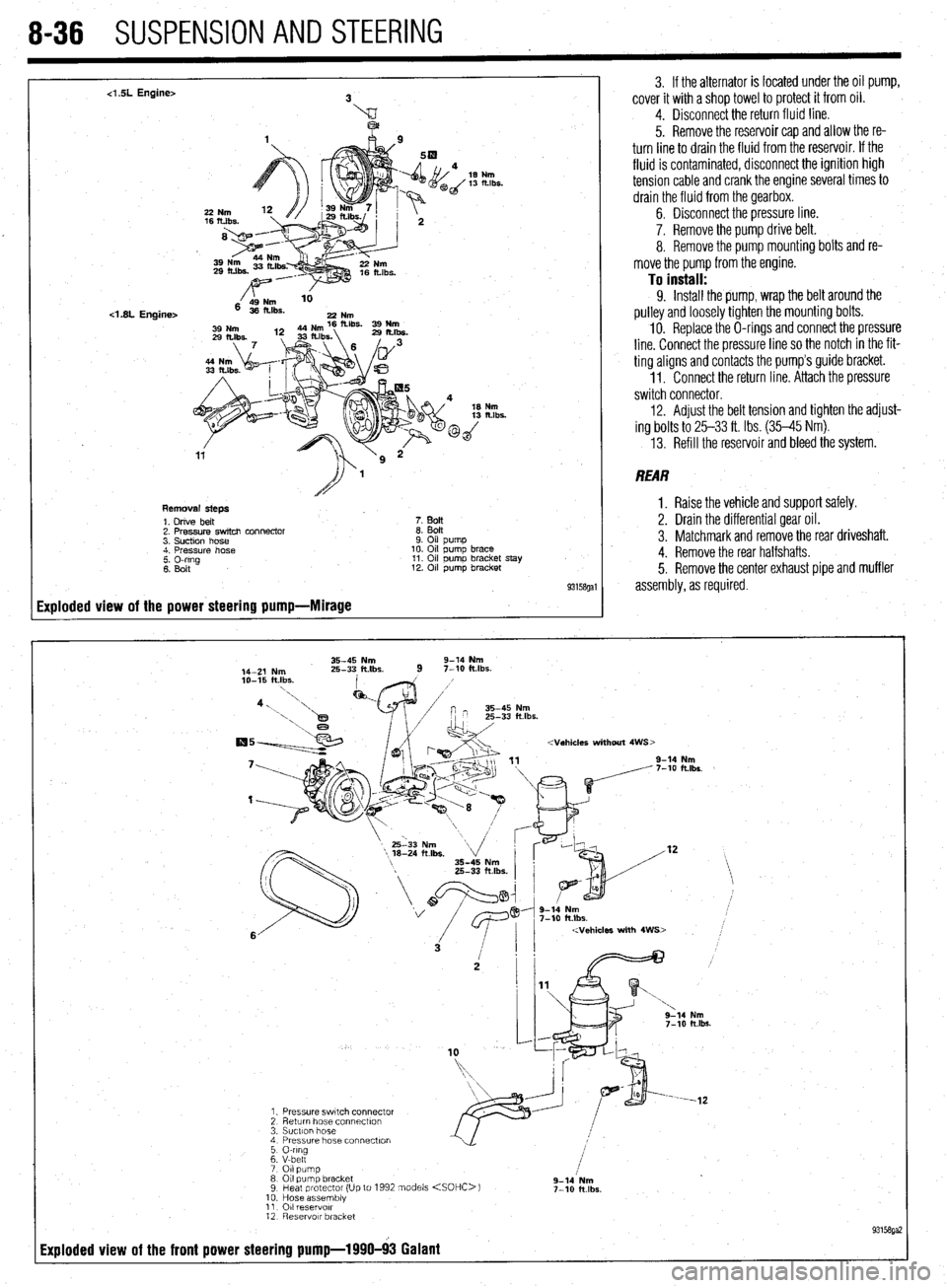

4 SL Engine>

<1.8L Engine>

Removal steps

1. Drive belt

7. BoIt

2. Pressure switch connector

8. Bolt

3. Suction hose

9. Oil pump

4. Pressure hose

10. Oil pump brace

2 Elrg

11. Oil pumo bracket stay

12. Oil pump bracket

93158gal

Exploded view of the power steering pump-Mirage

3. If the alternator is located under the oil pump,

cover it with a shop towel to protect it from oil.

4. Disconnect the return fluid line.

5. Remove the reservoir cap and allow the re-

turn line to drain the fluid from the reservoir. If the

fluid is contaminated, disconnect the ignition high

tension cable and crank the engine several times to

drain the fluid from the gearbox.

6. Disconnect the pressure line.

7. Remove the pump drive belt.

8. Remove the pump mounting bolts and re-

move the pump from the engine.

To install: 9. Install the pump, wrap the belt around the

pulley and loosely tighten the mounting bolts.

10. Replace the O-rings and connect the pressure

line. Connect the pressure line so the notch in the fit-

ting aligns and contacts the pump’s guide bracket.

1 I. Connect the return line. Attach the pressure

switch connector.

12. Adjust the belt tension and tighten the adjust-

ing bolts to 25-33 ft. Ibs. (35-45 Nm).

13. Refill the reservoir and bleed the system.

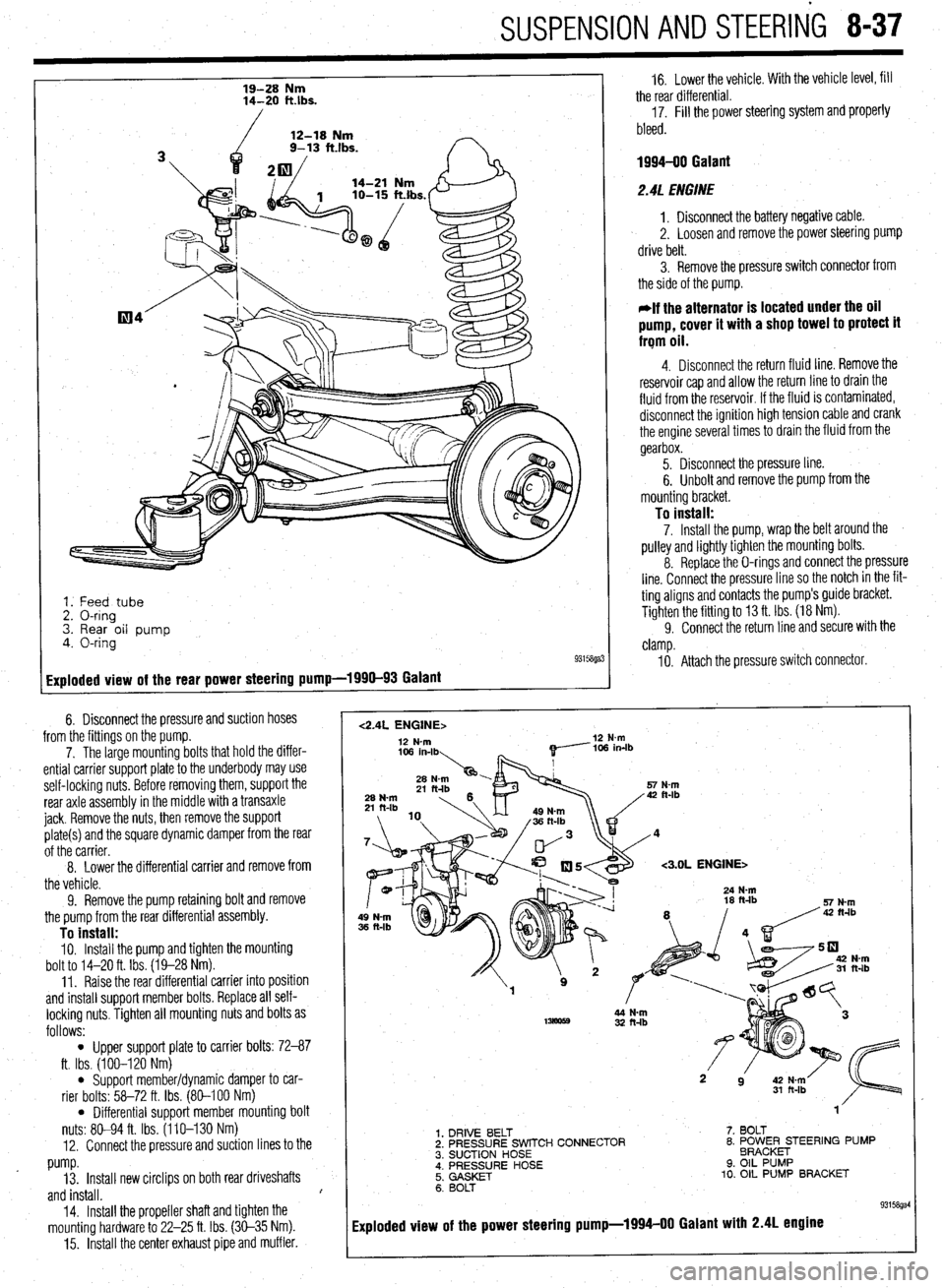

REAR

1. Raise the vehicle and support safely.

2. Drain the differential gear oil.

3. Matchmark and remove the rear driveshaft.

4. Remove the rear halfshafts.

5. Remove the center exhaust pipe and muffler

assembly, as required.

35-45 Nm 9-14 Nm

14-Z Nm 25-33 ft.lbs.

9 7-10 klbs.

2 g-lb Nm

7-10 ft.lbs.

Page 333 of 408

SUSPENSION AND STEERING 8-37

19-28 Nm

14-20 klbs.

/

12-18 Nm

9- 13 ft.lbs.

2rd

,

1. Feed tube

2. O-ring

3. Rear oil pump

4. O-ring

93158ga:

Exploded view of the rear power steering pump-1990-93 Galant

6. Disconnect the pressure and suction hoses

from the fittings on the pump.

7. The large mounting bolts that hold the differ-

ential carrier support plate to the underbody may use

self-locking nuts. Before removing them, support the

rear axle assembly in the middle with a transaxle

jack. Remove the nuts, then remove the support

plate(s) and the square dynamic damper from the rear

of the carrier.

8. Lower the differential carrier

and remove from

the vehicle.

9. Remove the pump retaining bolt and remove

the pump from the rear differential assembly.

To install: IO. Install the pump and tighten the mounting

bolt to 14-20 ft. Ibs. (19-28 Nm).

11. Raise the rear differential carrier into position

and install support member bolts. Replace all self-

locking nuts. Tighten all mounting nuts and bolts as

follows:

l Upper support plate to carrier bolts: 72-87

ft. Ibs. (100-120 Nm)

l Support member/dynamic damper to car-

rier bolts: 58-72 ft. Ibs. (80-100 Nm)

l Differential support member mounting bolt

nuts: 80-94 ft. Ibs. (110-130 Nm)

12. Connect the pressure and suction lines to the

pump.

13. Install new circlips on both rear driveshafts

and install. I

14.

Install the propeller shaft and tighten the

mounting hardware to 22-25 ft. Ibs. (30-35 Nm).

15. Install the center exhaust pipe and muffler.

1

16. Lower the vehicle. With the vehicle level, fill

the rear differential.

17. Fill the power steering system and properly

bleed.

1994-00 Galant

2.4L ENGINE

1. Disconnect the battery negative cable.

2. Loosen and remove the power steering pump

drive belt.

3. Remove the pressure switch connector from

the side of the pump.

*If the alternator is located under the oil

pump, cover it with a shop towel to protect it

frqm oil.

4. Disconnect the return fluid line. Remove the

reservoir cap and allow the return line to drain the

fluid from the reservoir. If the fluid is contaminated,

disconnect the ignition high tension cable and crank

the engine several times to drain the fluid from the

gearbox.

5. Disconnect the pressure line.

6. Unbolt and remove the pump from the

mounting bracket.

To install: 7. Install the pump, wrap the belt around the

pulley and lightly tighten the mounting bolts.

8. Replace the O-rings and connect the pressure

line. Connect the pressure line so the notch in the fit-

ting aligns and contacts the pump’s guide bracket.

Tighten the fitting to 13 ft. Ibs. (18 Nm).

9. Connect the return line and secure with the

clamp.

IO. Attach the pressure switch connector.

<2.4L ENGINE> 12 N-m 12 N-m

<3.OL ENGINE>

32 ft-lb

1. DRIVE BELT

2. PRESSURE SWITCH CONNECTOR

3. SUCTION HOSE

; i’;;‘;;RE HOSE 7. BOLT

8. ~O~~~E;TEER’NG PUMP

9. OIL PUMP

10. OIL PUMP BRACKET

6. BOLT

93158gal

Exploded view of the power steering pump-1994-00 Galant with 2.4L engine