engine MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 185 of 408

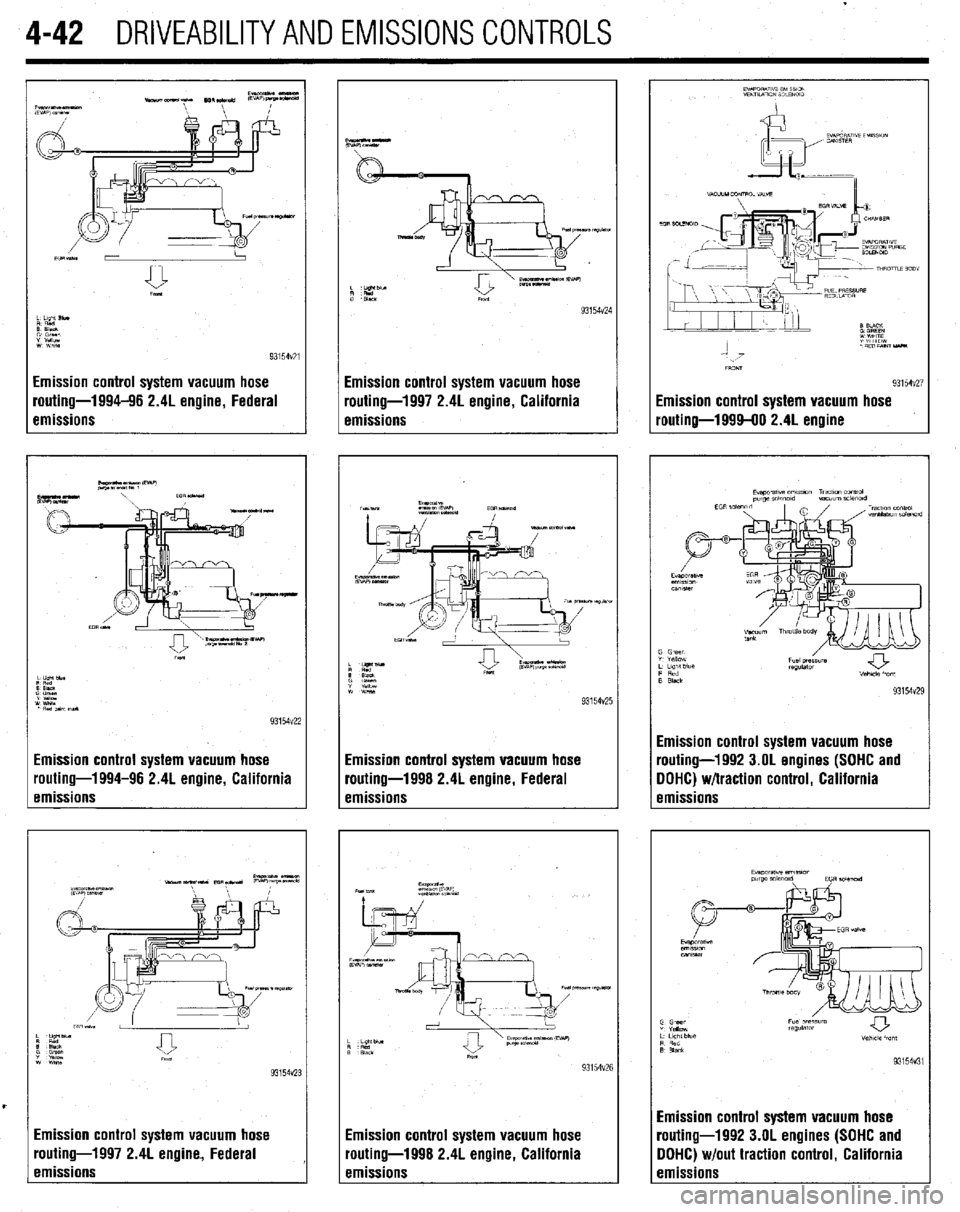

4-42 DRIVEABILITYAND EMISSIONS CONTROLS

Emission control system vacuum hose

routing-1994-96 2.4L engine, Federal

emissions

Emission control system vacuum hose

routing-1994-96 2.4L engine, California

emissions

Emission control system vacuum hose

routing-1997 2.4L engine, Federal

emissions I Emission control system vacuum hose I routing-1997 2.4L engine, California I emissions

TV TbE

93154v25

I Emission control system vacuum hose I routing-1998 2.4L engine, Federal I emissions

93154v26

El

ro

el nission control system vacuum hose

uting-1998 2.4L engine, California

nissions

93154v24

Emission control system vacuum hose

routing-1999-00 2.4L engine

93154~26

Emission control system vacuum hose

routing-1992 3.OL engines (SOHC and

DDHC) w/traction control, California

emissions

93154v31

Imission control system vacuum hose

-outing-l992 3.OL engines (SOHC and

IOHC) w/out traction control, California

:missions

Page 186 of 408

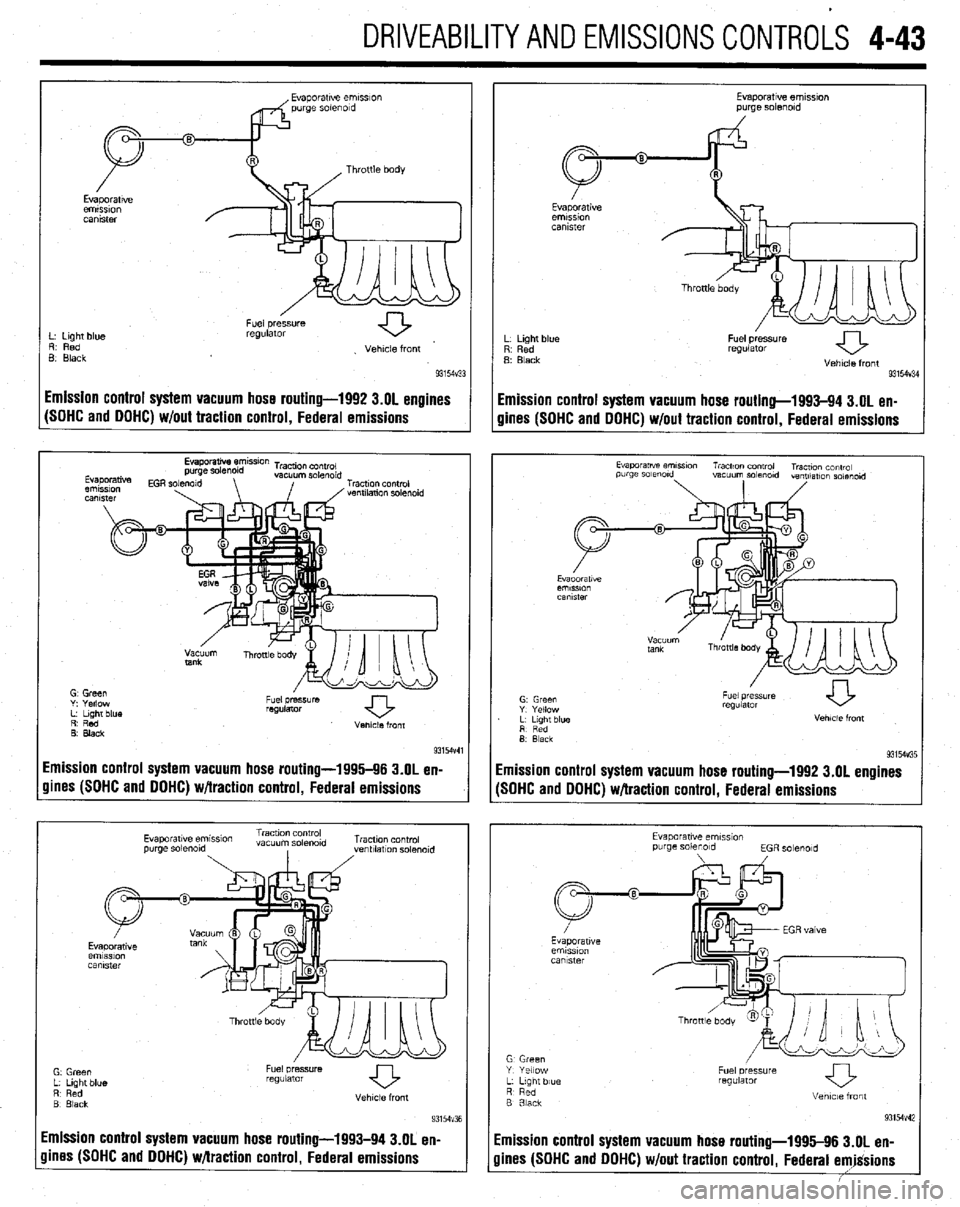

DRIVEABILITYAND EMISSIONSCONTROL-S 4-43

L. Light blue

R. Red

B Black Fuel pressure

regulator

. Vehicle front

93154~33

I Fuel pressure

regulator

Vehicle front

93154V34

Emission control system vacuum hose routing-1992 3.01 engines

Emission control system vacuum hose routing-1993-94 3.OL en-

(SOHC and OOHC) w/out traction control, Federal emissions

gines (SOHC and DOHC) w/out traction control, Federal emissions

R’ Red

0. Black Venlcle front

9315-M

Emission control system vacuum hose routing-1996-96 3.OL en-

gines (SOHC and DOHC) w/traction control, Federal emissions

Evaporatwe em~smn Traction control

vacuum so&old Tracuon control

purge solmold

, ,ventllatlon solmold

Emission control system vacuum hose routing-1993-94 3.OL en-

Evaporatwe ernmon

purge solenoid

L Light blue

R Red

B Black

Fuel pressure

regulator

Vehicle front

931W3E

imission control system vacuum hose routing-1992 3.OL engines

SOHC and DOHC) w/traction control, Federal emissions

Evaporawe emss~on

purge solenoid

EGR solmold

G Green

Y Yellow

L L,gnt blue

R Red

B 3lack Fuel oressure

regUlatOr

Vetme front

93154v42

imission control system vacuum hose routing-1995-96 3.OL en-

lines (SOHC and DOHC) w/out traction control, Federal emjgsions

Page 187 of 408

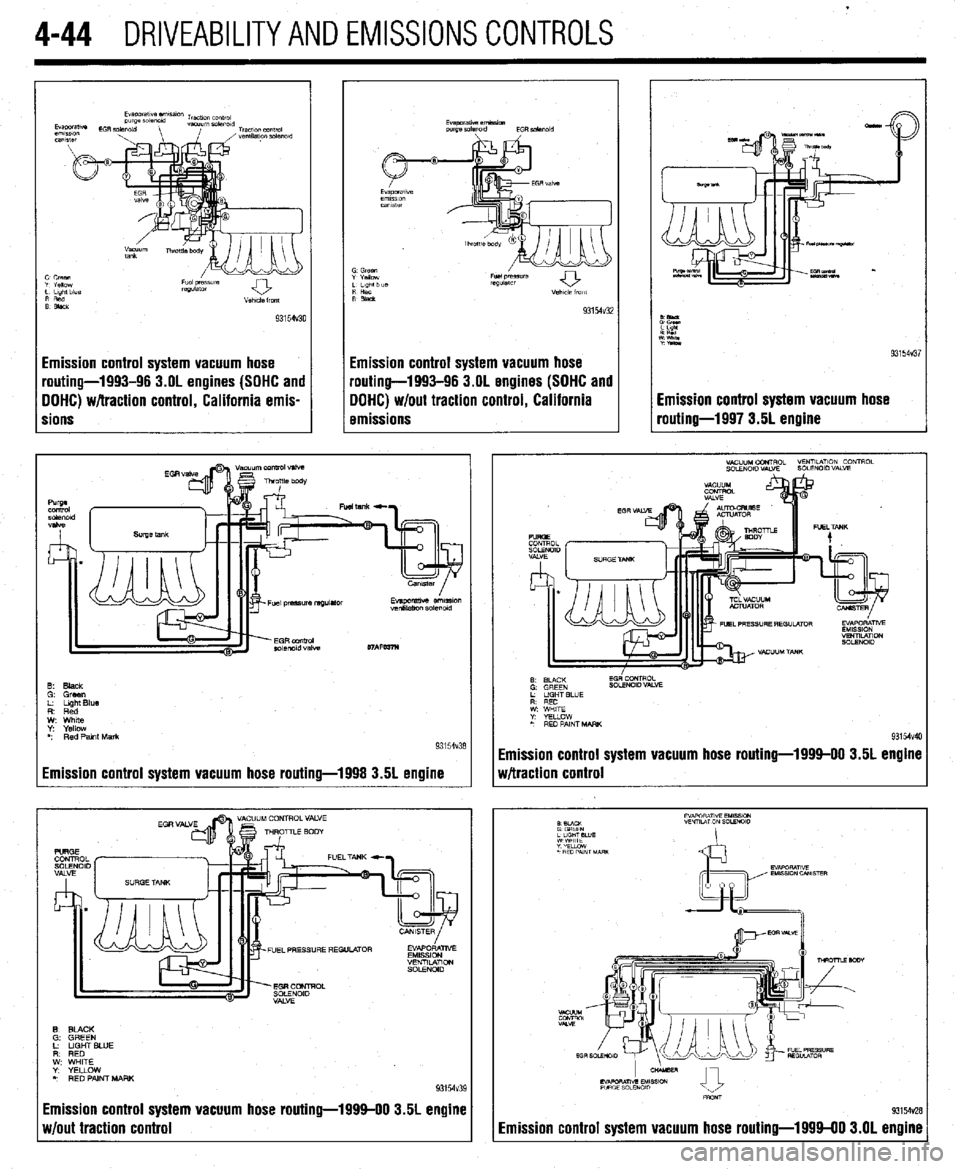

4-44 DRIVEABILITYAND EMISSIONS CONTROLS

Emission control system vacuum hose

pouting-1993-96 3.OL engines (SOHC and

DOHC) w/traction control, California emis-

rions Emission control system vacuum hose

routing-1993-96 3.OL engines (SOHC and

DOHC) w/out traction control, California

emissions

Emission control system vacuum hose routing-1998 3.5L engine

Emission control system vacuum hose routing-199%00 3.5L engine

w/out traction control Emission control system vacuum hose

routing-1997 3.5L engine

Emission control system vacuum hose routing-1999-00 3.5L engim

Mtraction control

Emission control system vacuum hose routing-199940 3.OL engine

Page 189 of 408

I

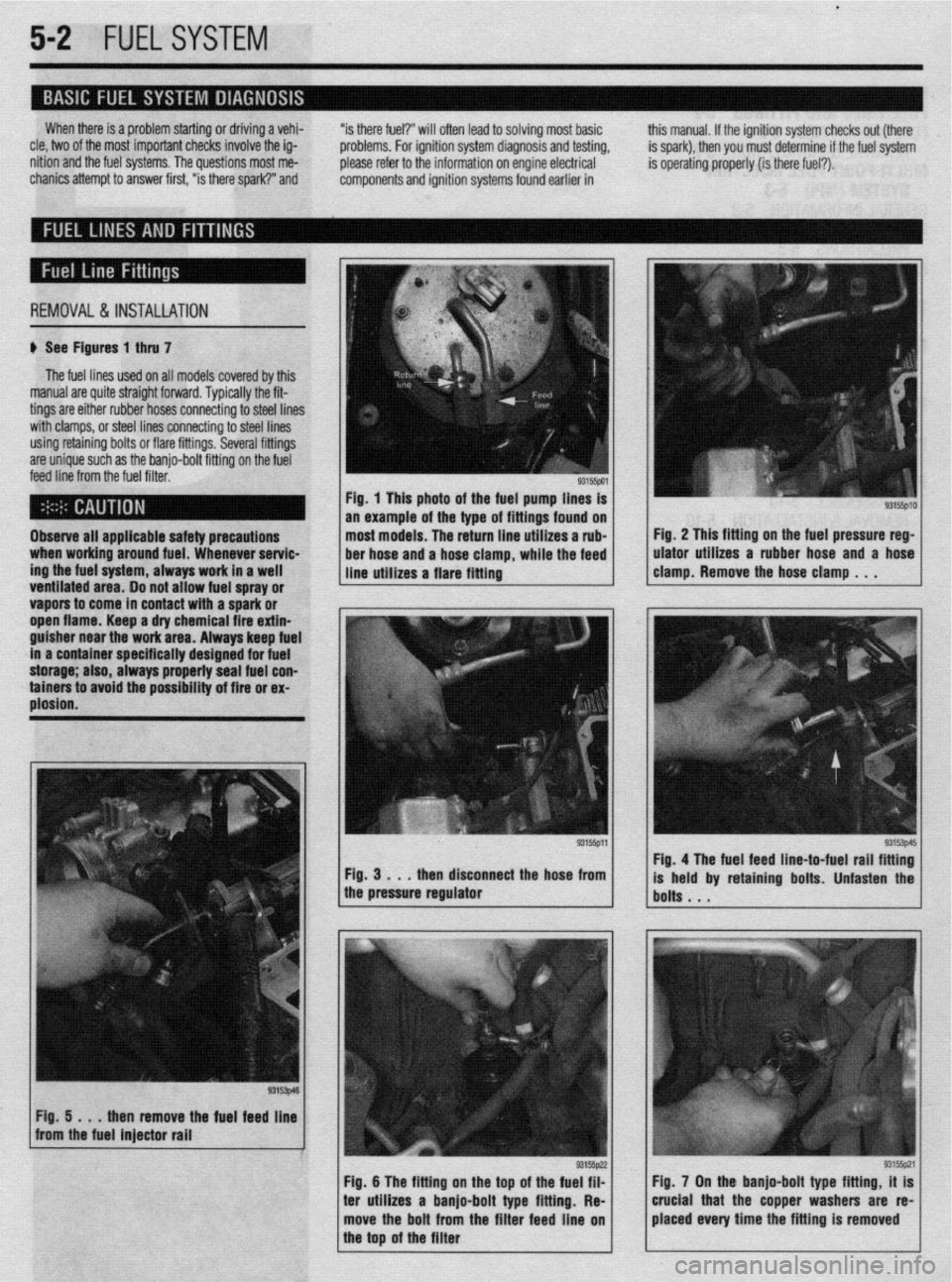

5-2, FUELSYSTEM

When there is a problem starting or driving a vehi-

“is there fuel? will often lead to solving most basic

cle, two of the most important checks involve the ig- problems. For ignition system diagnosis and testing,

nition and the fuel systems. The questions most me-

please refer to the information on engine electrical

chanics attempt to answer first, “is there spark?” and

components and ignition systems found earlier in this manual. If the ignition system checks out (there

is spark), then you must determine if the fuel system

is operating properly (is there fuel?).

REMOVAL&INSTALLATION

# See Figures 1 thru 7

The fuel lines used on all models covered by this

manual are quite straight forward. Typically the fit-

tings are either rubber hoses connecting to steel lines

with clamps, or steel lines connecting to steel lines

using retaining bolts or flare fittings. Several fittings

are unique such as the banjo-bolt fitting on the fuel

feed line from the fuel filter.

ventitateu area. Do not allow fuel spray or

vapors to come in contact with a spark or

ooen flame. Keen a drv chemical fire extin- Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

___ _ . . . _

guisher near the’work &ea. Always keep fuel

in a container specifically designed for fuel

storage; also, always pmperly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion. Fig. 1 This photo of the fuel pump lines is

an example of the type of fittings found on

most models. The return line utilizes a rub-

ber hose and a hose clamp, while the feed

line utilizes a flare fitting

ren disconnect the hose from

1 the pressure regulator Fig. 2 This fitting on the fuel pressure reg-

ulator utilizes a rubber hose and a hose

clamp. Remove the hose clamp . . .

93153p45 Fig. 4 The fuel feed line-to-fuel rail fitting

is held by retaining bolts. Unfasten the

bolts . . .

Fig. 5 . . .

then remove the fuel feed line

from the fuel injector rail

I

1 Fig. 6 The fitting on the too of the fueg;?lz

I I

93155pzl Fig. 7 On the banjo-bolt type fitting, it is

ter utilizes a banjo-bolt type fitting. Re-

I I crucial that the copper washers are re-

move the bolt from the filter feed line on placed every time the fitting is removed

the top of the filter

Page 190 of 408

FUELSYSTEM 513

l Always replace worn fuel fitting O-rings with

new. Do not substitute fuel hose or equivalent, where

I

The Multi-Point Injection (MPI) system is electroni-

rally controlled by the Engine Control Module (ECM),

based on data from various sensors. The ECM controls

the fuel flow, idle speed and ignition timing. fuel pipe is installed.

Fuel is supplied to the injectors by an electric in-

tank fuel pump and is distributed to the respective in-

jectors via the main fuel pipe. The fuel pressure ap-

plied to the injector is constant and higher than the

pressure in the intake manifold. The pressure is con-

trolled by the fuel pressure regulator. The excess fuel

is returned to the fuel tank through the fuel return pipe.

When an electric current flows in the injector, the

injector valve is fully opened to supply fuel. Since the

fuel pressure is constant, the amount of the fuel in-

jetted from the injector into the manifold is increased

or decreased in proportion to the time the electric

current flows. Based on ECU signals, the injectors in-

ject fuel to the cylinder manifold ports in firing order. Fuel injection systems remain under pres-

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

neeting any fuel lines. Failure to do so may

result in fire or personal injury.

1. Turn the ignition to the OFF position.

2. Loosen the fuel filler cap to release fuel tank

pressure.

I

The flow rate of the air drawn through the air

cleaner is measured by the air flow sensor. The air

enters the air intake plenum or manifold through the

throttle body. In the intake manifold, the air is mixed

with the fuel from the injectors and is drawn into the

cylinder, The air flow rate is controlled according to

the degree of the throttle valve and the servo motor

openings. The system is monitored through a num-

ber of sensors which feed information on engine con-

ditions and requirements to the ECM. The ECM cal-

culates the injection time and rate according to the

signals from the sensors,

Safety is the most important factor when perform-

ing not only fuel system maintenance but any type of

maintenance. Failure to conduct maintenance and re-

pairs in a safe manner may result in serious personal

injury or death. Maintenance and testing of the vehi-

cle’s fuel system components can be accomplished

safely and effectively by adhering to the following

rules and guidelines.

l To avoid the possibility of fire and personal in-

jury, always disconnect the negative battery cable un-

less the repair or test procedure requires that battery

voltage be applied.

l Always relieve the fuel system pressure prior to

disconnecting any fuel system component (injector,

fuel rail, pressure regulator, etc.), fitting or fuel line

connection. Exercise extreme caution whenever re- Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or va-

pors to come in contact with a spark or open

flame. Keep a dry chemical fire extinguisher

near the work area. Always keep fuel in a con-

tainer specifically designed for fuel storage;

also, always properly seal fuel containers to

avoid the possibility of fire or explosion.

3. For the Mirage, Diamante, and 1994-00

Galant, remove the rear seat cushion, then remove

the service cover and detach the fuel pump harness

connector.

4. For the 1990-93 FWD Galant, detach the fuel

pump harness connector located in the area of the

fuel tank. It may be necessary to raise the vehicle to

access the connector.

5. For the 1990-93 AWD Galant, remove the car-

pet from the trunk, locate the fuel tank wiring at the

pump access cover, then detach the wiring.

6. Start the vehicle and allow it to run until it

stalls from lack of fuel. Turn the key to the OFF posi-

tion.

7. Disconnect the negative battery cable, then at-

tach the fuel pump connector. Install the access .

cover, cushion or carpet as necessary.

8. Wrap shop towels around the fitting that is be-

ing disconnected to absorb residual fuel in the lines.

9. Place shop towels into proper safety container. Fig, 8 Detach the connector for the throttle

position (TP) sensor

93153ps5 Fig, 9 Remove the accelerator cable end

from the throttle lever

Fig. IO Remove the hose shown here from

lieving fuel system pressure to avoid exposing skin,

face and eyes to fuel spray. Please be advised that

fuel under pressure may penetrate the skin or any

part of the body that it contacts.

l Always place a shop towel or cloth around the

fitting or connection prior to loosening to absorb any

excess fuel due to spillage. Ensure that all fuel

spillage (should it occur) is quickly removed from

enginesurfaces. Ensure that all fuel soaked cloths or

towels are deposited into a suitable waste container.

l Always keep a dry chemical (Class B) fire ex-

tinguisher near the work area.

l Do not allow fuel spray or fuel vapors to come

into contact with a spark or open flame.

l Always use a backup wrench when loosening’

and tightening fuel line connection fittings. This will

prevent unnecessary stress and torsion to fuel line

piping. Always follow the proper torque specifica-

tions. REMOVAL &INSTALLATION

p See Figures 8 thru 18

1. Properly relieve the fuel system pressure as

outlined earlier in this section.

2. Drain the engine cooling system into a suit-

able container.

3. Matchmark the jocation of the adjuster bolt

on the accelerator cable mounting flange. This will

assure that the cable is installed in its original loca-

tion. Remove the throttle cable adjusting bolt and

disconnect the cable from the lever on the throttle

body. Position cable aside.

Page 191 of 408

5-4 FUELSYSTEM

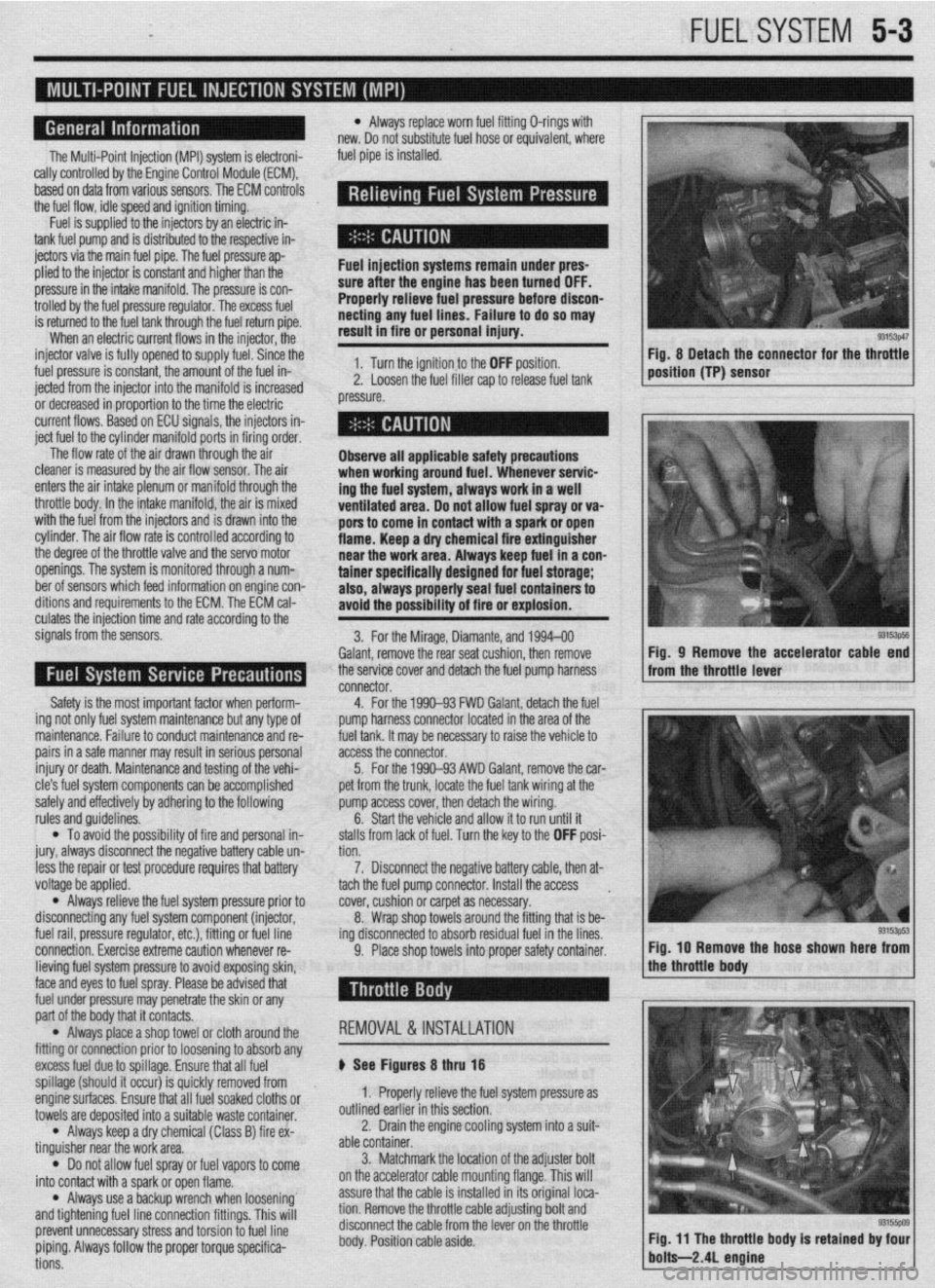

93155422 Fig. 12 Exploded view of the throttle body

and related components-l .5L engine

15-Z Nm

11-16 lt.lbs. 15-22 Nm 11-16 ft.lbr.

1. Connectnn for accelerator cable

2. Connection for breather hose

3 Connection for au intake hose

4 Connectton for au hose C

5. Connectton for vacuum hose

6 Connectton for IAC motor connector and

closed throttle posItIon swtch connector

7 ConnectIon for TPS connector

8 Connectton for water hose

9 Connectnon for water by-pass hose

10 Ground plate mounting screw

11. Throttle body stay and ground plate

12 Au flttlng

13 Gasket

14 Throttle body

15 Gasket ’

89575422 :ig. 14 Exploded view of the throttle body and related components-l.61 and 2.OL DOHC en-

line

93155g24 Yg. 15 Exploded view of the throttle body and related components- :ig. 16 Exploded view of the throttle body and related components-

1.OL SOHC engine, DOHC similar

1.5L engine

4. Remove the connection for the breather hose

10. Unfasten the throttle body mounting bolts, 14. If equipped, install the throttle body stay and

and the air intake hose from the throttle body and po-

then remove the throttle body from the engine. Re- QrOUnd plate. Secure with retainers tightened to

sition aside.

move and discard the gasket. 11-16 ft. Ibs. (15-22 Nm).

5. Tag and disconnect the necessary vacuum

To install: 15. Install the ground plate mounting screw.

hoses.

11. Clean all old gasket material from the both 16. Connect the water hoses to the throttle body.

6. Label and detach the electrical connectors at throttle body mounting surfaces. Install new gasket Install new hose clamps if required.

the throttle body, as necessary.

1 onto the intake manifold plenum mounting surface. 17. Attach the electrical and vacuum connectors

7. Disconnect the water and water by-pass

*Poor idling quality and poor performance to the throttle body, as tagged during removal.

hoses at the base of the throttle body.

may be experienced if the gasket is installed 18 Connect the accelerator cable to the throttle

8. If equipped, unfasten the ground plate

incorrectly. body and install the adjusting bolt in original posi-

mounting screws, then remove the throttle body stay

tion. Check adjustment of cable.

and QrOUnd plate from the engine.

12. Install the throttle body to the intake manifold 19 Install the air intake and breather hoses.

9. Remove the air fitting and

gasket. plenum and tighten the mounting bolts. 20. If removed, install the battery and connect the

13. Install the air fitting, if equipped, making sure positive cable.

new gasket iS in place.

Page 192 of 408

FUEL SYSTEM 5-5,

21. Connect the negative battery cable. Refill the

cooling system.

REMOVAL & INSTALLATION

1.5L, 1.8L, And 2.OL SOHC Engines

ti See Figures 17, 18, and 19

1. Relieve the fuel system pressure as described

in this section.

2. Disconnect the PCV hose from the valve

cover. Also disconnect the breather hose at the oppo-

site end of the valve cover.

3. Remove the bolts holding the high pressure

fuel line to the fuel rail and disconnect the line. Be

prepared to contain fuel spillage; plug the line to

keep out dirt and debris.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. 00 not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

4. Remove the vacuum hose from the fuel pres-

sure regulator.

5. Disconnect the fuel return hose from the

pressure regulator.

6. Label and detach the electrical connectors

from each injector.

7. Remove the bolt(s) holding the fuel rail to the

manifold. Carefully lift the rail up and remove it with

the injectors attached. Take great care not to drop an

injector Place the rail and Injectors in a safe location

on the workbench; protect the tips of the injectors

from dirt and/or Impact.

8. Remove and discard the injector rnsulators

from the intake manifold. The insulators are not

reusable.

9. Remove the injectors from the fuel rail by

pulling gently in a straight outward motion. Make

certain the grommet and O-ring come off with the in-

jector.

To install: 10. Install a new insulator in each injector port in

the manifold.

11. Remove the old grommet and O-ring from

each injector Install a new grommet and O-ring; coat

the O-ring lightly with clean, thin oil.

12. If the fuel pressure regulator was removed,

replace the O-ring with a new one and coat it lightly

with clean, thin oil Insert the regulator straight into

the rail, then check that it can be rotated freely. If It

does not rotate smoothly, remove it and inspect the

O-ring for deformation or jamming. When properly

installed, align the mounting holes and tighten the

retaining bolts to 7 ft. Ibs. (9 Nm). This procedure

must be followed even if the fuel rail was not re-

moved.

13. Install the injector into the fuel rail, constantly

turning the injector left and right during installation.

1Hilt4naunfu(norc e Fu(l

:E%!,,.,.- 1: IEE

: Efgz tz!z? :: %%I

;P&.xmeaw 13 m

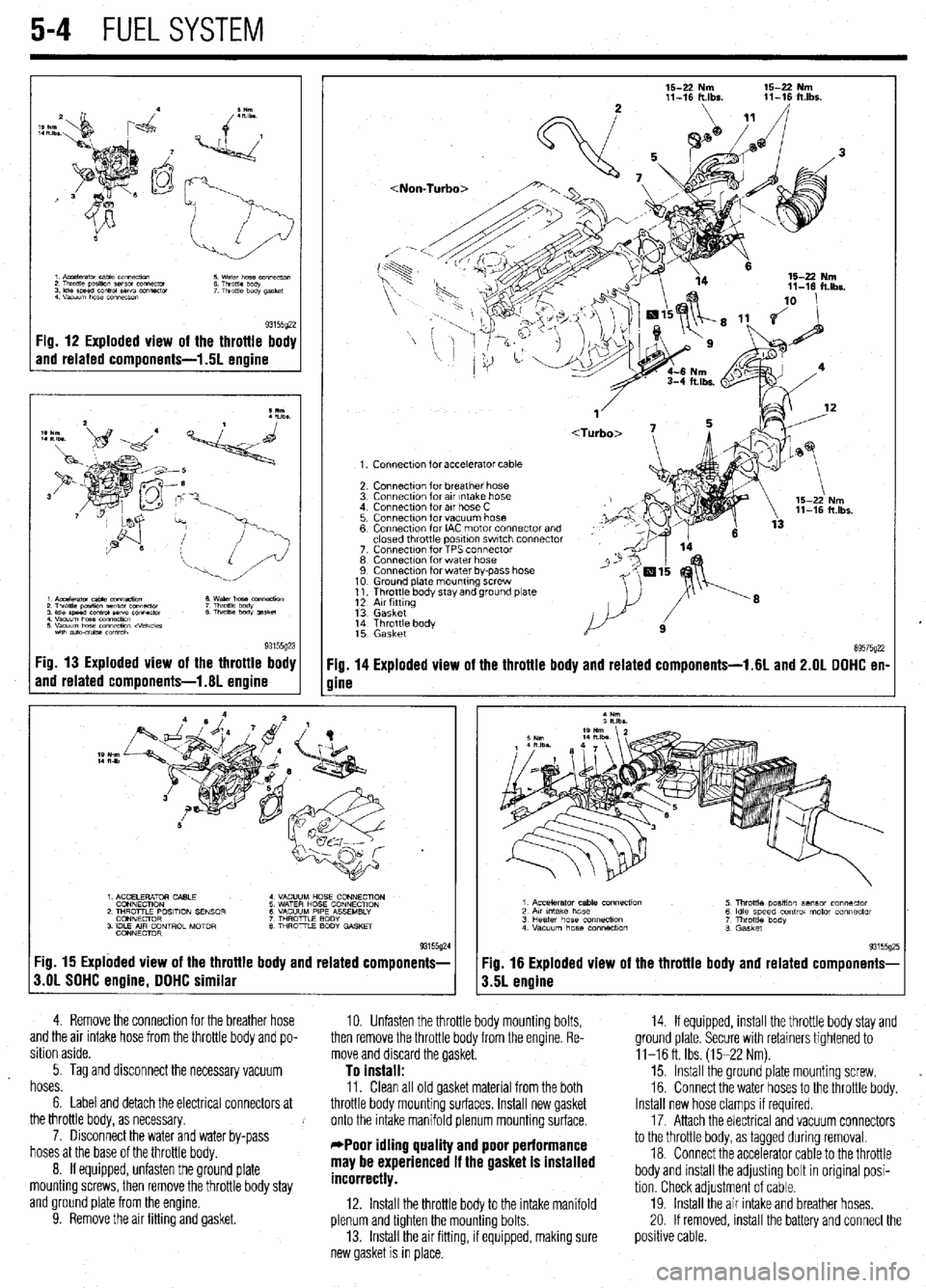

Fig. 17 Exploded view of the fuel injectors and related components-l .5L engine

I

.xs.

1 Connection for breather hose

2 Connection for PCV hose

3 Connection for high tm?ss”re fuel hose

4 0-ring

5 Connection for vacuum hose

6 Connecr~on for fuel return hose

7 Fuel pressure regulator

8 0-ring

9 Connection for control harness

10 Fuel ml

11 Insulator

12 insulator

13 lnlector

14 O-ring

15 Grommet

89575026

Fig. 19 Exploded view of the fuel injectors and related components-2.01 SOHC engine

When fully installed, the injector should still turn

freely in the rail. If it does not, remove the injector

and inspect the O-ring for deformation or damage.

14. Install the delivery pipe and injectors to the

engine. Make certain that each injector fits correctly

into its port and that the rubber insulators for the fuel

rail mounts are in position. 15. Install the fuel rail retaining bolts and tighten

* them to 9 ft. Ibs. (12 Nm).

16. Connect the wiring harnesses to the appro-

priate injector.

17. Connect the fuel return hose to the pressure

regulator, then connect the vacuum hose.

18. Replace the O-ring on the high pressure fuel

line, coat the O-ring lightly with clean, thin oil and

Page 193 of 408

install the line to the fuel rail. Tighten the mounting

bolts,

19. Attach the PCV hose and the breather hose if

thev were disconnected.

20. Connect the negative battery cable. Pressur-

ize the fuel system and inspect all connections for

I

leaks.

1.6L and 2.01 DOHC Engines

b See Figure 20

1. Relieve the fuel system pressure as described

in this section.

2. Disconnect the negative battery cable.

3. Wrap the connection with a shop towel and

disconnect the high pressure fuel line at the fuel rail.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

* tainers to avoid the possibility of fire or ex-

plosion.

4. Disconnect the fuel return hose and remove

the O-ring.

5. Disconnect the vacuum hose from the fuel

pressure regulator.

6. Disconnect the PCV hose. On 2.OL engine,

remove the center cover.

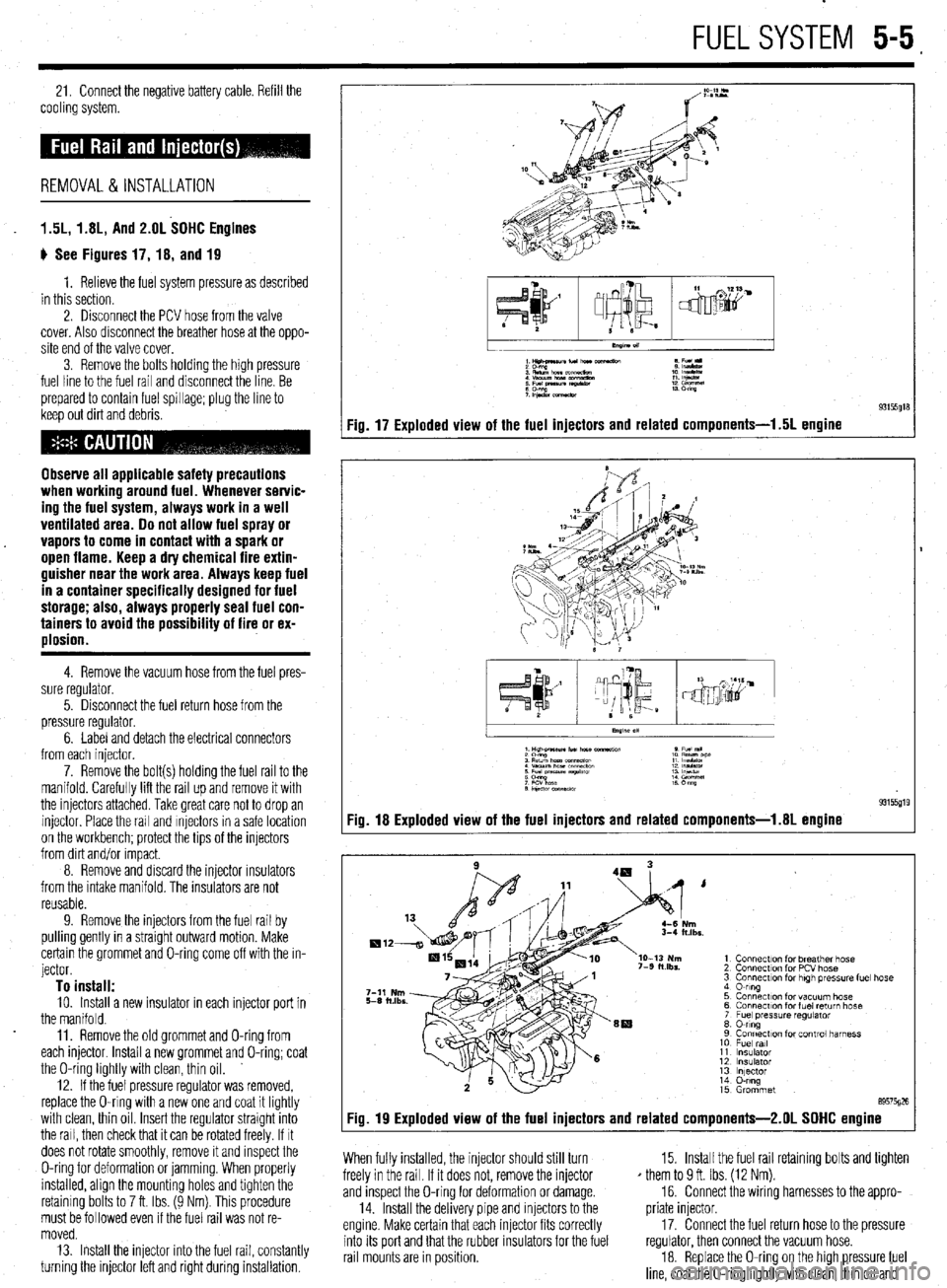

1 x Connection for PCV hose

2. Connection for high pressure fuel hose

3. O-ring

4. Connection for vacuum hose

5. Connection for fuel return hose

&2 I=, 1c.1 nrncc*.ra regu,ator

lble clamD

7. Label and detach the electrical connectors

from each iniector.

8. Accelerator ca

9. Center cover . 10. Connection for control harness

11 Fuel rail

12. Insulator

13. Insulator

14. Injector

15. O-ring

16. Grommet

89575g27 Exploded view of the fuel injectors and related

components -1.6L and 2.QL DOHC

5-6 FUELSYSTEM

8. Remove the injector rail retaining bolts, Make

sure the rubber mounting bushings do not get lost.

9. Lift the rail assembly up and away from the

engine.

10. Remove the injectors from the rail by pulling

gently. Discard the lower insulator. Check the resis-

tance through the injector. The specification for 2.OL

turbocharged engine is 2-3 ohms at 70°F (20°C).

The specification for the others is 13-15 ohms at

70°F (20°C). To install:

11. Install a new grommet and O-ring to the in-

jector. Coat the O-ring with light oil.

12. install the injector to the fuel rail.

13. Replace the seats in the intake manifold. In-

stall the fuel rail and injectors to the manifold. Make

sure the rubber bushings are in place before tighten-

ing the mounting bolts.

14. Tighten the retaining bolts to 72 inch lbs. (11

Nm).

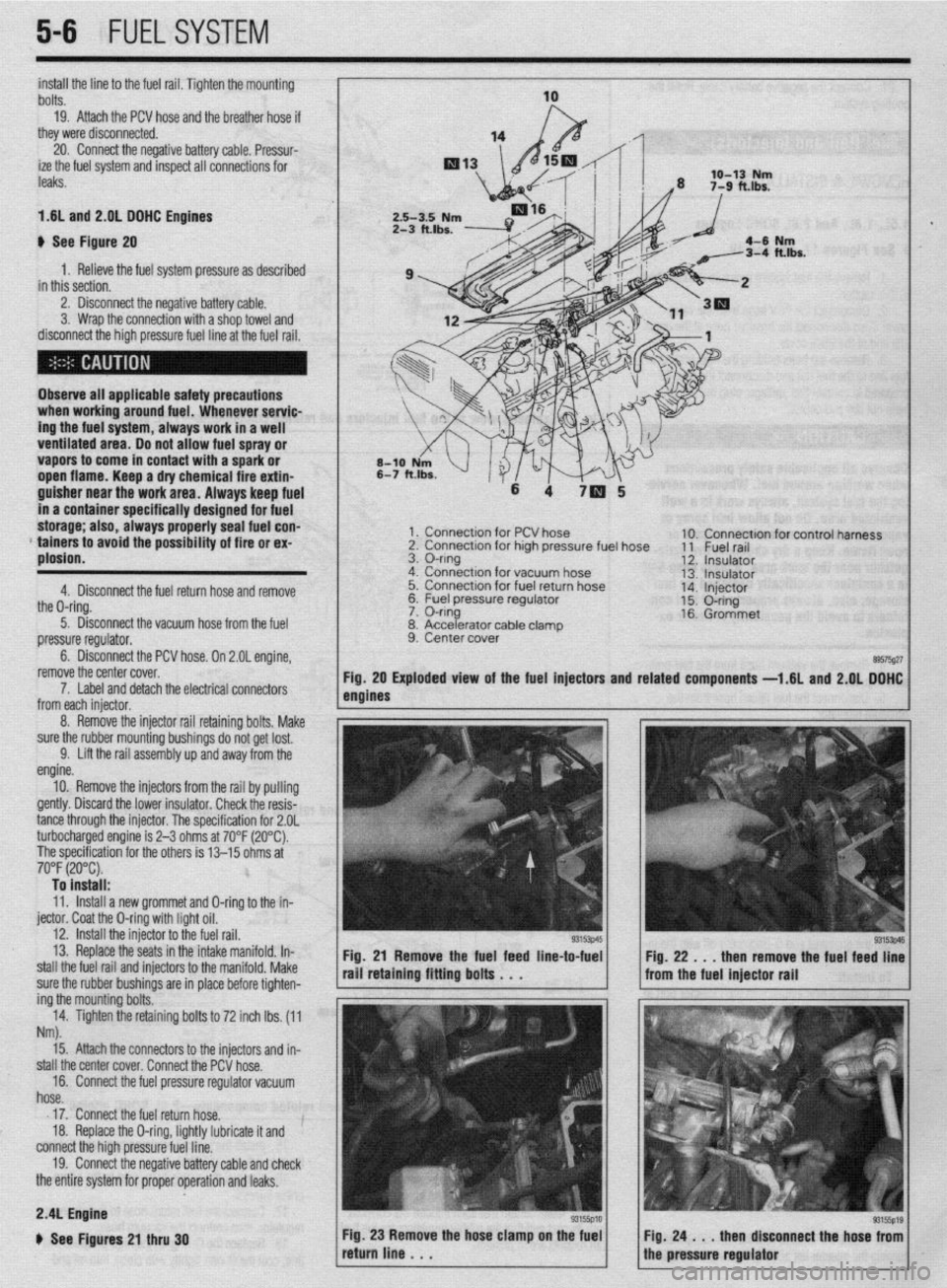

Fig. 21 Remove the fuel feed line-to-fuel

rail retaining fitting bolts . . .

15. Attach the connectors to the injectors and in-

stall the center cover. Connect the PCV hose.

16. Connect the fuel pressure regulator vacuum

hose.

17. Connect the fuel return hose.

18. Replace the O-ring, lightly lubricate it and

connect the high pressure fuel line.

19. Connect the negative battery cable and check

the entire system for proper operation and leaks. Fig. 22 . . . then remove the fuel feed line

from the fuel injector rail

2.4L Engine

b See Figures 21 thru 30

Page 194 of 408

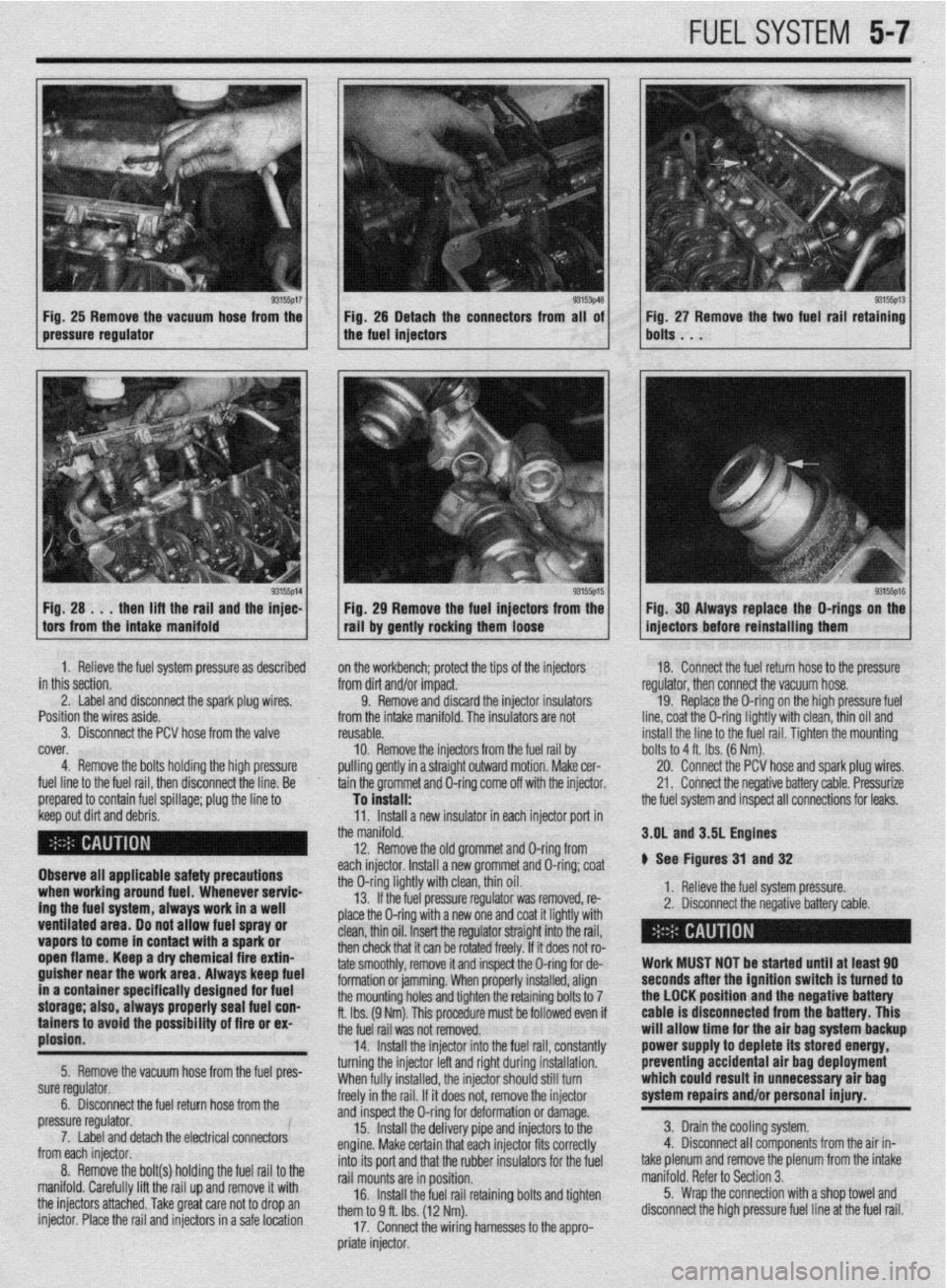

FUELSYSTEM 5-7

Fig, 25 Remove the vacuum hose from the Fig. 25 Detach the connectors from all of

pressure regulator the fuel injectors

1 H; :A ..;lt;;aft~rgi,i~;yl the ;F: 1 / . 93155p15 1 Fig 29 Remove the fuel injectors from the

tall by gently rocking them loose Fig. 27 Remove the two fuel rail retaining

bolts . . .

93155ps Fig. 30 Always replace the O-rings on the

injectors before reinstalling them

1. Relieve the fuel system pressure as described

in this section.

2. Label and disconnect the spark plug wires. ’

Position the wires aside.

3. Disconnect the PCV hose from the valve

cover,

4. Remove the bolts holding the high pressure

fuel line to the fuel rail, then disconnect the line. Be

prepared to contain fuel spillage; plug the line to on the workbench; protect the tips of the injectors

from dirt and/or impact.

9. Remove and discard the injector insulators

from the intake manifold. The insulators are not

reusable.

10. Remove the injectors from

pulling gently in a straight outwarc the fuel rail by

I motion. Make cer-

tain the grommet and O-ring come off with the injector. 18. Connect the fuel return hose to the pressure

regulator, then connect the vacuum hose.

19. Replace the O-ring on the high pressure fuel

line, coat the O-ring lightly with clean, thin oil and

install the line to the fuel rail. Tiahten the mountina

To install: -

the fuel system and inspect all connections for leaks. bolts to 4 ft. Ibs. (6 Nm).

20. Connect the PCV hose and spark plug wires.

21. Connect the negative battery cable. Pressurize

1. neneve me rueI system pressure.

2. Disconnect the negative battery cable. 3.OL and 3.5L Engines

# See Figures 31 and 32

> - ,. .* , ,

I

I

Work MUST NOT be started until at least 90

seconds after the ignition switch is turned to

the LOCK position and the negative battery

cable is disconnected from the battery. This

will allow time for the air bag system backup

power supply to deplete its stored energy,

preventing accidental air bag deployment

which could result in unnecessary air bag

system repairs and/or personal injury.

3. Drain the cooling system.

4. Disconnect all components from the air in-

take plenum and remove the plenum from the intake

manifold. Refer to Section 3.

5. Wrap the connection with a shop towel and

disconnect the high pressure fuel line at the fuel rail. keep out dirt and debris.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possfbility of fire or ex-

plosion.

5. Remove the vacuum hose from the fuel pres-

sure regulator.

6. Disconnect the fuel return hose from the

pressure regulator.

7. Label and detach the electrical connectors

from each injector.

8. Remove the bolt(s) holding the fuel rail to the

manifold. Carefully lift the rail up and remove it with

the injectors attached. Take great care not to drop an

injector. Place the rail and injectors in a safe location 11. Install a new insulator in each injector port in

the manifold.

12. Remove the old grommet and D-ring from

each injector. Install a new grommet and O-ring; coat

the O-ring lightly with clean, thin oil.

13. If the fuel pressure regulator was removed, re-

place the O-ring with a new one and coat it lightly with

clean, thin oil. Insert the regulator straight into the rail,

then check that it can be rotated freely. If it does not ro-

tate smoothly, remove it and inspect the O-ring for de-

formation or jamming. When properly installed, align

the mounting holes and tighten the retaining bolts to 7

ft. Ibs. (9 Nm). This procedure must be followed even if

the fuel rail was not removed.

14. Install the injector into the fuel rail, constantly

turning the injector left and right during installation.

When fully installed, the injector should still turn

freely in the rail. If it does not, remove the injector

and inspect the O-ring for deformation or damage.

15. Install the delivery pipe and injectors to the

engine. Make certain that each injector fits correctly

into its port and that the rubber insulators for the fuel

rail mounts are in position.

16. Install the fuel rail retaining bolts and tighten

them to 9 ff. Ibs. (12 Nm).

17. Connect the wiring harnesses to the appro-

priate injector.

Page 195 of 408

5-8 FUELSYSTEM

9 ,npimr w1m.m

1: i”“L,

1: 82”w

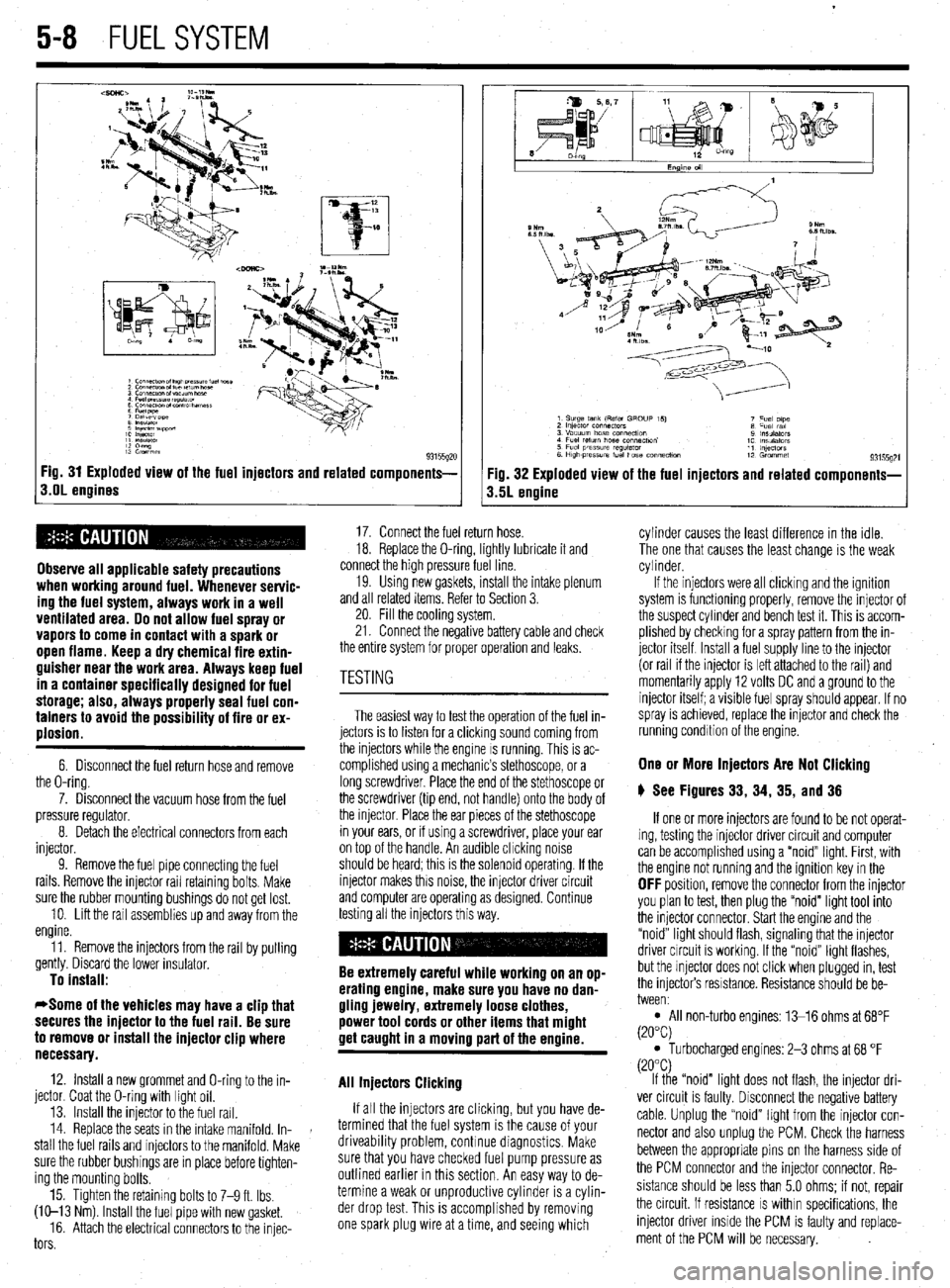

93155gx Fig. 31 Exploded view of the fuel injectors and related components-

s.OL engines

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

6. Disconnect the fuel return hose and remove

the O-ring.

7. Disconnect the vacuum hose from the fuel

pressure regulator.

8. Detach the electrical connectors from each

injector.

9. Remove the fuel pipe connectmg the fuel

rails. Remove the injector rail retaining bolts. Make

sure the rubber mounting bushings do not get lost.

10. Lift the rail assemblies up and away from the

engine.

11. Remove the injectors from the rail by pulling

gently. Discard the lower insulator.

To install:

*Some of the vehicles may have a clip that

secures the injector to the fuel rail. Be sure

to remove or install the injector clip where

necessary.

12. Install a new grommet and O-ring to the in-

jector. Coat the O-ring with light oil.

13. Install the injector to the fuel rail.

14. Replace the seats in the intake manifold. In-

stall the fuel rails and injectors to the manifold. Make

sure the rubber bushings are in place before tighten-

ing the mounting bolts.

15. Tighten the retaining bolts to 7-9 ft. Ibs.

(W-13 Nm) Install the fuel pipe with new gasket.

16. Attach the electrical connectors to the injec-

tors

Fig. 32 Exploded view of the fuel injectors and related components-

3.5L engine

17. Connect the fuel return hose.

18. Replace the O-ring, lightly lubricate it and

connect the high pressure fuel line.

19. Usmg new gaskets, install the intake plenum

and all related items. Refer to Section 3.

20. Fill the cooling system.

21. Connect the negative battery cable and check

the entire system for proper operation and leaks.

The easiest way to test the operation of the fuel in-

jectors is to listen for a clicking sound coming from

the injectors while the engine IS running. This is ac-

complished using a mechanic’s stethoscope, or a

long screwdriver. Place the end of the stethoscope or

the screwdriver (tip end, not handle) onto the body of

the injector. Place the ear pieces of the stethoscope

in your ears, or if using a screwdriver, place your ear

on top of the handle. An audible chcking noise

should be heard; this is the solenoid operating. If the

injector makes this noise, the injector driver circuit

and computer are operating as designed. Continue

testing all the injectors this way.

Be extremely careful while working on an op-

erating engine, make sure you have no dan-

gling jewelry, extremely loose clothes,

power tool cords or other items that might

get caught in a moving part of the ermine.

All Injectors Clicking

If all the injectors are clicking, but you have de-

termined that the fuel system is the cause of your

driveability problem, continue diagnostics. Make

sure that you have checked fuel pump pressure as

outlined earlier in this section. An easy way to de-

termine a weak or unproductive cylinder is a cylin-

der drop test. This is accomplished by removing

one spark plug wire at a time, and seeing which cylinder causes the least difference in the idle.

The one that causes the least change is the weak

cylinder.

If the injectors were all clicking and the ignition

system is functioning properly, remove the injector of

the suspect cylinder and bench test it. This is accom-

plished by checking for a spray pattern from the in-

jector itself Install a fuel supply line to the injector

(or rail if the injector is left attached to the rail) and

momentarily apply 12 volts DC and a ground to the

injector itself; a visible fuel spray should appear. If no

spray is achieved, replace the injector and check the

running condition of the engine.

One or More Injectors Are Not Clicking

6 See Figures 33, 34, 35, and 36

If one or more injectors are found to be not operat-

ing, testing the injector driver circuit and computer

can be accomplished using a “noid” light. First, with

the engine not running and the ignition key in the

OFF position, remove the connector from the injector

you plan to test, then plug the “noid” light tool into

the injector connector. Start the engine and the

“noid” light should flash, signaling that the injector

driver circuit is working. If the “noid” light flashes,

but the injector does not click when plugged in, test

the injectors resistance. Resistance should be be-

tween:

l All non-turbo engines: 13-16 ohms at 68°F

(20°C)

l Turbocharged engines: 2-3 ohms at 68 “F

(20°C)

If the “noid” light does not flash, the injector dri-

ver circuit is faulty. Disconnect the negative battery

cable. Unplug the “noid” light from the injector con-

nector and also unplug the PCM. Check the harness

between the appropriate pins on the harness side of

the PCM connector and the injector connector. Re-

sistance should be less than 5.0 ohms; if not, repair

the circuit. If resistance

IS within specifications, the

injector driver inside the PCM is faulty and replace-

ment of the PCM will be necessary.