radio MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 42 of 408

GENERALINFORMATIONAND MAINTENANCE l-43

l Special car washing detergent is the best to

use. Liquid dishwashing detergent can remove wax

and leave the car’s paint unprotected and in addition

some liquid detergents contains abrasives which can

scratch the paint.

l Bird droppings should be removed from the

paintwork as soon as possible, otherwise the finish

may be permanently stained.

When the car is driven immediately after be-

ing washed, apply the brakes several times

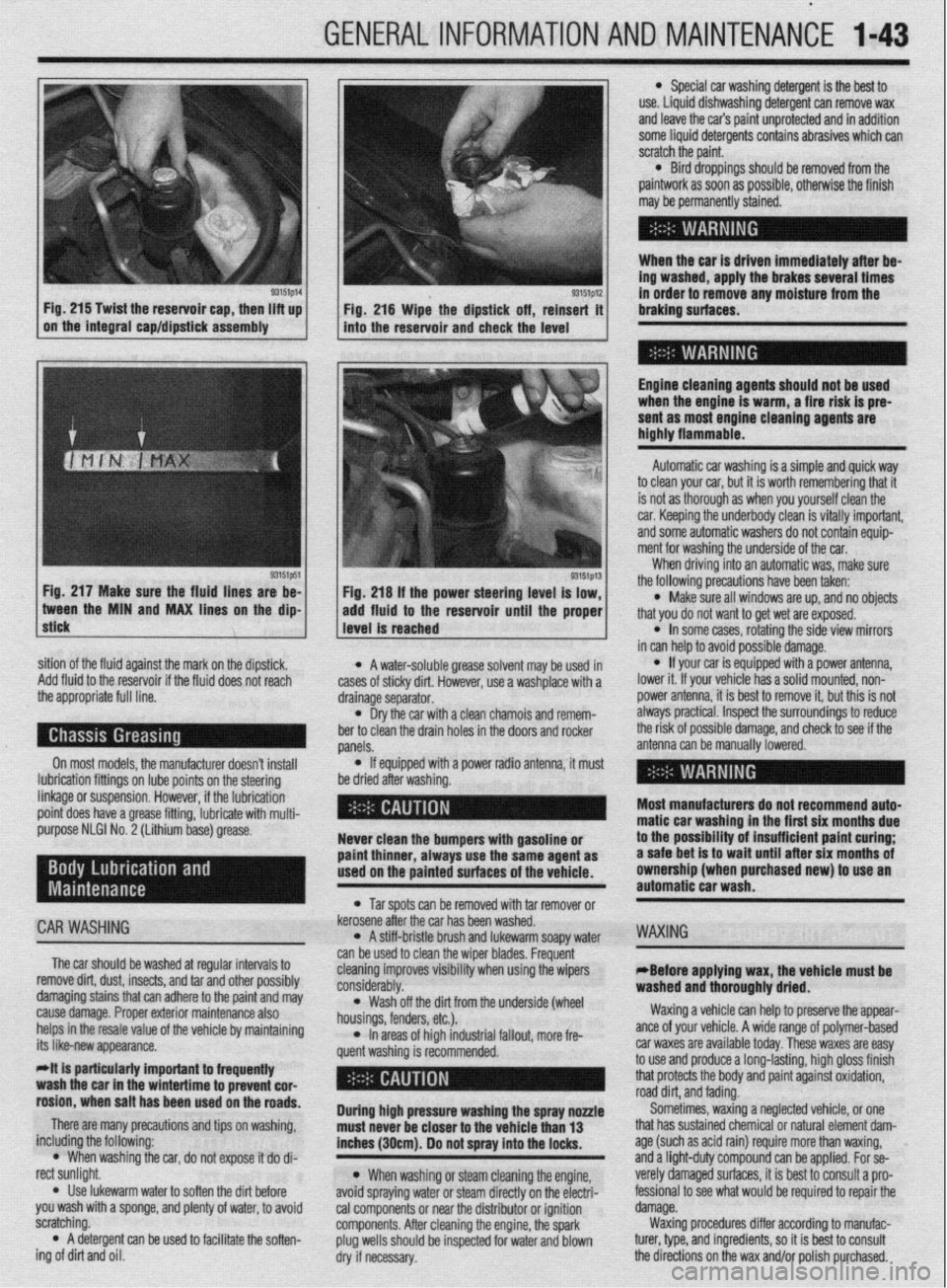

93151p14 93151p12 Fig. 215 Twist the reservoir cap, then lift up

I I

in order to remove any moisture from the

Fig. 216 Wipe the dipstick off, reinsert it braking surfaces.

on the integral cap/dipstick assembly

into the reservoir and check the level

I

Engine cleaning agents should not be used

when the engine is warm, a fire risk is pre-

sent as most engine cleaning agents are

highly flammable.

sition of the fluid against the mark on the dipstick,

Add fluid to the reservoir if the fluid does not reach

the appropriate full line.

On most models, the manufacturer doesn’t install

lubrication fittings on lube points on the steering

linkage or suspension. However, if the lubrication

point does have a grease fitting, lubricate with multi-

purpose NLGI No. 2 (Lithium base) grease.

CAR WASHING

The car should be washed at regular intervals to

remove dirt, dust, insects, and tar and other possibly

damaging stains that can adhere to the paint and may

cause damage. Proper exterior maintenance also

helps in the resale value of the vehicle by maintaining

its like-new appearance.

Mt is particularly important ta frequentiy

wash the car in the wintertime to prevent cor-

rosion, when salt has been used on the roads.

There are many precautions and tips on washing,

including the following:

l When washing the car, do not expose it do di-

rect sunlight.

. Use lukewarm water to soften the dirt before

you wash with a sponge, and plenty of water, to avoid

scratching.

l A detergent can be used to facilitate the soften-

ing of dirt and oil. * A water-soluble grease solvent may be used in

cases of sticky dirt. However, use a washplace with a

drainage separator.

l Dry the car with a clean chamois and remem-

ber to clean the drain holes in the doors and rocker

panels.

l If equipped with a power radio antenna, it must

be dried after washing.

Never clean the bumpers with gasoline or

paint thinner, always use the same agent as

used on the painted surfaces of the vehicle.

l Tar spots can be removed with tar remover or

kerosene after the car has been washed.

l A stiff-bristle brush and lukewarm soapy water

can be used to clean the wiper blades. Frequent

cleaning improves visibility when using the wipers

considerably.

l Wash off the did from the underside (wheel

housings, fenders, etc.).

l In areas of high industrial fallout, more fre-

quent washing is recommended.

During high pressure washing the spray nonle

must never be closer to the vehicle than 13

inches (30cm). Do not spray into the locks.

l When washing or steam cleaning the engine,

avoid spraying water or steam directly on the electri-

cal components or near the distributor or ignition

components. After cleaning the engine, the spark

plug wells should be inspected for water and blown

dry if necessary. Automatic car washing is a simple and quick way

to clean your car, but it is worth remembering that it

is not as thorough as when you yourself clean the

car. Keeping the underbody clean is vitally important,

and some automatic washers do not contain equip-

ment for washing the underside of the car.

When driving into an automatic was, make sure

the following precautions have been taken:

l Make sure all windows are up, and no objects

that you do not want to get wet are exposed.

l In some cases, rotating the side view mirrors

in can help to avoid possible damage.

l If your car is equipped with a power antenna,

lower it. If your vehicle has a solid mounted, non-

power antenna, it is best to remove it, but this is not

always practical. Inspect the surroundings to reduce

the risk of possible damage, and check to see if the

antenna can be manually lowered.

Most manufacturers do not recommend auto-

matic car washing in the first six months due

to the possibility of insufficient paint curing;

a safe bet is to wait until after six months of

ownership (when purchased new) to use an

automatic car wash.

WAXING

eBefore applying wax, the vehicle must be

washed and thoroughly dried.

Waxing a vehicle can help to preserve the appear-

ante of your vehicle. A wide range of polymer-based

car waxes are available today. These waxes are easy

to use and produce a long-lasting, high gloss finish

that protects the body and paint against oxidation,

road dirt, and fading.

Sometimes, waxing a neglected vehicle, or one

that has sustained chemical or natural element dam-

age (such as acid rain) require more than waxing,

and a light-duty compound can be applied. For se-

verely damaged surfaces, it is best to consult a pro-

fessional to see what would be required to repair the

damage.

Waxing procedures differ according to manufac-

turer, type, and ingredients, so it is best to consult

the directions on the wax and/or polish purchased.

Page 56 of 408

ENGlNEELECTRldAL 2-9

TESTING

Voltage Test able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

REMOVAL&INSTALLATION

1. Make sure the engine is OFF, and turn the 1.51,1.61, 1.6L, 2.OL and 2.4L Engines

headlights on for 15-20 seconds to remove any sur-

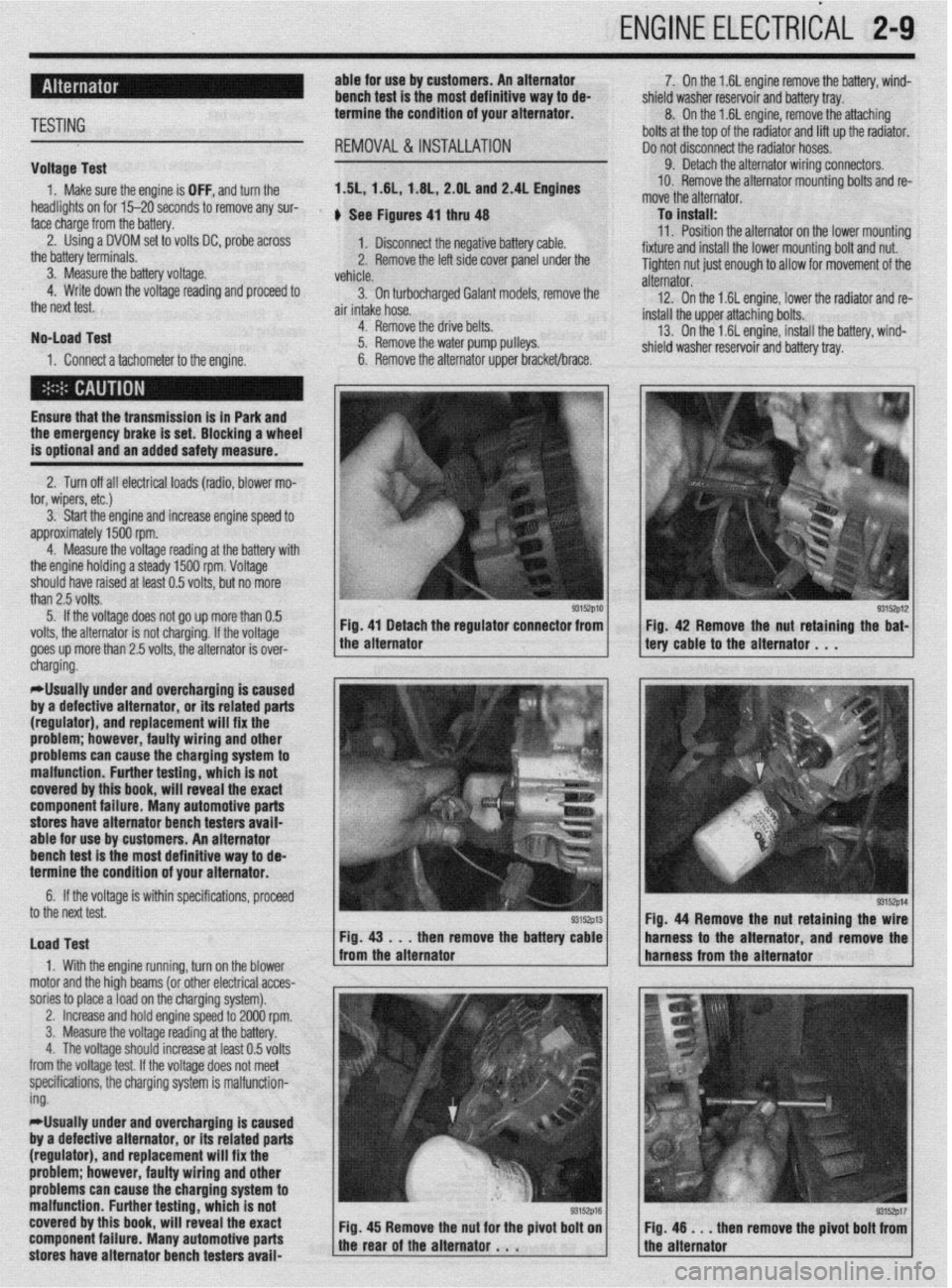

face charge from the battery. , See Figures 4, thru 48

2. Using a DVOM set to volts DC, probe across

1. Disconnect the negative battery cable.

the battery terminals.

3. Measure the battery voltage. 2. Remove the left side cover panel under the

vehicle.

4. Write down the voltage reading and proceed to

3. On turbocharaed Galant models, remove the

the next test.

air intake hose. -

No-load Test

1. Connect a tachometer to the engine. 4. Remove the drive belts.

5. Remove the water pump pulleys.

6. Remove the alternator upper bracket/brace.

Ensure that the transmission

is in Park and the emergency brake is set. Blocking a wheel

is optional and an added safety measure.

2. Turn off all electrical loads (radio, blower mo-

tor, wipers, etc.)

3. Start the engine and increase engine speed to

approximately 1500 rpm.

4. Measure the voltage reading at the battery with

the engine holding a steady 1500 rpm. Voltage

should have raised at least 0.5 volts, but no more

than 2.5 volts.

5. If the voltage does not go up more than 0.5

volts, the alternator is not charging. If the voltage

goes up more than 2.5 volts, the alternator is over-

* 7. On the 1.6L engine remove the battery, wind-

shield washer reservoir and battery tray.

8. On the 1.6L engine, remove the attaching

bolts at the top of the radiator and lift up the radiator.

Do not disconnect the radiator hoses.

9. Detach the alternator wiring connectors.

10. Remove the alternator mounting bolts and re-

move the alternator.

To install:

11. Position the alternator on the lower mountina

fixture and install the lower mounting bolt and nut. U

Tighten nut just enough to allow for movement of the

alternator.

12. On the 1.6L engine, lower the radiator and re-

install the upper attaching bolts.

13. On the 1.6L engine, install the battery, wind-

shield washer reservoir and battery tray.

/ tery cable to the alternator . , . 93152p12 Fig 42 Remove the nut retaining the bat-

cnargmg.

*Usually under and overcharging is‘caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can

cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

6. If the voltage is within specifications, proceeU

to the next test.

Load Test

1. With the engine running, turn on the blower

motor and the hioh beams (or other electrical acces-

sories to place aioad on the charging system). Fig. 44 Remove the nut retaining the

then remove the batte harness to the alternator and remov

,

2. Increase and hold engine speed to 2000 rpm.

3. Measure the voltage reading at the battery.

4. The voltage should increase at least 0.5 volts

from the voltage test. If the voltage does not meet

specifications, the charging system is malfunction-

ing.

*Usually under and overcharging is caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

93152p17 en remove the pivot bolt from

Page 204 of 408

UNDERSTANDING AND

TROUBLESHOOTING

ELECTRICAL SYSTEMS 6-2

BASIC ELECTRICALTHEORY 6-2

HOW DOES ELECTRICITY WORK:

THEWATERANALOGY 6-2

OHM'S LAW 6-2

ELECTRICALCOMPONENTS 6-2

POWERSOURCE 6-2

GROUND 6-3

PROTECTIVE DEVICES 6-3

SWITCHES&RELAYS 6-3

LOAD 6-3

WIRING & HARNESSES 6-3

CONNECTORS 6-4

TEST EQUIPMENT 6-4

JUMPER WIRES 6-4

TEST LIGHTS 6-4

MULTIMETERS 6-5

TROUBLESHOOTING ELECTRICAL

SYSTEMS 6-5

TESTING 6-5

OPEN CIRCUITS 6-5

SHORT CIRCUITS 6-6

VOLTAGE 6-6

VOLTAGE DROP 6-6

RESISTANCE 6-8

WIRE AND CONNECTORREPAIR 6-6

BATTERY CABLES 6-7

DISCONNECTING THE CABLES 6-7

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 6-7

GENERALINFORMATION 6-7

SERVICE PRECAUTIONS 6-7

DISARMING 6-7

REARMING 6-7

HEATING AND AIR

CONDITIONING 6-7

BLOWER MOTOR 6-7

REMOVAL &INSTALLATION 6-7

HEATER CORE 6-9 INSTRUMENTS AND SWITCHES 6-17

INSTRUMENTCLUSTER 6-17

REMOVAL &INSTALLATION 6-17

GAUGES 6-18

REMOVAL&INSTALLATION 6-18

WINDSHIELD WIPER SWITCH 6-19

REMOVAL&INSTALLATION 6-19

REARWINDOWWIPERSWITCH 6-19

REMOVAL &INSTALLATION 6-19

DIMMER SWITCH 6-19

REMOVAL & INSTALLATION 6-19 .

HEADLIGHT SWITCH 6-19

REMOVAL & INSTALLATION 6-19

LIGHTING 6-19

HEADLIGHTS 6-19

REMOVAL &INSTALLATION 6-19

AIMINGTHEHEADLIGHTS 6-20

SIGNAL AND MARKER LIGHTS 6-21

REMOVAL &INSTALLATION 6-21

CIRCUIT PROTECTION 6-27

FUSES 6-27

REPLACEMENT 6-27

FUSIBLE LINKS 6-27

CIRCUIT BREAKERS 6-28

RESETTING AND/OR

REPLACEMENT 6-28

FLASHERS 6-28

REPLACEMENT 6-28

WIRING DIAGRAMS 6-31

REMOVAL & INSTALLATION 6-9

AIR CONDITIONING COMPONENTS 6-11

REMOVAL & INSTALLATION 6-11

CONTROLCABLES 6-12

ADJUSTMENT 6-12

CONTROL PANEL 6-12

REMOVAL & INSTALLATION 6-12

CRUISE CONTROL 6-13

ENTERTAINMENT SYSTEMS 6-14

RADIO RECEIVER/AMPLIFIER/TAPE

PLAYER/CD PLAYER 6-14

SPEAKERS 6-14

REMOVAL & INSTALLATION 6-14

WINDSHIELD WIPERS AND

WASHERS 6-15

WINDSHIELD WIPER BLADE AND

ARM 6-15

REMOVAL & INSTALLATION 6-15

WINDSHIELD WIPER MOTOR 6-16 _

REMOVAL &INSTALLATION 6-16

WINDSHIELD WASHER PUMP 6-17

REMOVAL &INSTALLATION 6-17

Page 210 of 408

I I

CHASSIS ELECTRICAL 6-7

When working on any electrical component on the

vehicle, it is always a good idea to disconnect the

negative (-) battery cable. This will prevent potential

damage to many sensitive electrical components

such as the Powertrain Control Module (PCM), radio,

alternator, etc.

*Any time you disengage the battery cables,

it is recommended that you disconnect the negative (-) battery cable first. This will pre-

vent your accidentally grounding the positive

(+) terminal to the body of the vehicle when

disconnecting it, thereby preventing damage

to the above mentioned components.

Before you disconnect the cable(s), first turn the

ignition to the OFF position. This will prevent a draw

on the battery which could cause arcing (electricity

trying to ground itself to the body of a vehicle, just

like a spark plug jumping the gap) and, of course, damaging some components such as the alternator

diodes.

When the battery cable(s) are reconnected (nega-

tive cable last), be sure to check that your lights,

windshield wipers and other electrically operated

safety components are all working correctly. If your

vehicle contains an Electronically Tuned Radio (ETR),

don’t forget to also reset your radio stations. Ditto for

the clock.

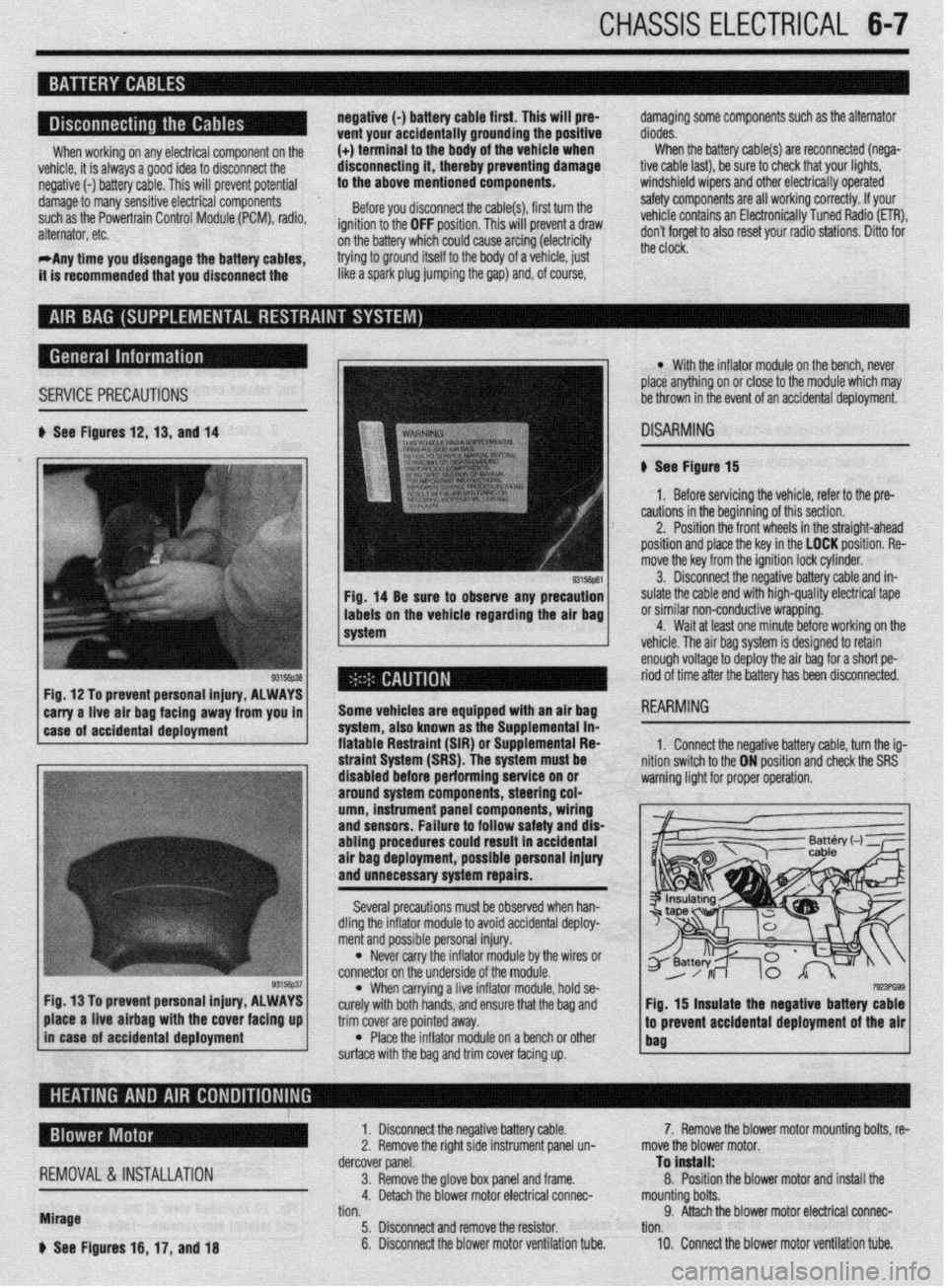

SERVICE PRECAUTIONS

b See Figures 12,13, and 14

Fig, 14 Be sure to observe any precaution

labels on the vehicle regarding the air bag

system

Fig. 12 To prevent personal injury, ALWAYS

*

carry a-live -ah bag fac!ng away from you in 1

1 case of accidental deployment Some vehicles are equipped wtth an air bag

-.-‘--

syr1em, aiscl Known as I11 -I-- ‘------- -- sLe Supplemental in- fiatable Restraint (SIR) o r Suouiementai Fiea

l With the inflator module on the bench, never

place anything on or close to the module which may

be thrown in the event of an accidental deployment.

DISARMING

# See Figure 15

1. Before servicing the vehicle, refer to the pre-

cautions in the beginning of this section.

2. Position the front wheels in the straight-ahead

position and place the key in the LOCK position. Re-

move the key from the ignition lock cylinder.

3. Disconnect the negative battery cable and in-

sulate the cable end with high-quality electrical tape

or similar non-conductive wrapping.

4. Wait at least one minute before working on the

vehicle. The air baa svstem is desianed to retain

enough voltage to deploy the air bag for a short pe-

riod of time after the battery has been disconnected.

1. Connect the neoative batters cable. turn the ia-

3, hold se-

e bag and

trim cover are pointed away.

l Place the inflator module on a bench or other

surface with the bag and trim cover facing up.

7!r!3PG93 Fig. 15 insulate the negative battery cable

.I

to prevent accidental deployment of the air

bag place a live airbag with the cover facing up

in case of accidental deployment

REMOVAL &INSTALLATION

Mirage

b See Figures 16, 17, and 18 1. Disconnect the negative battery cable.

2. Remove the right side instrument panel un-

dercover panel.

3. Remove the glove box panel and frame.

4. Detach the blower motor electrical connec-

tion.

5. Disconnect and remove the resistor.

6. Disconnect the blower motor ventilation tube. 7. Remove the blower motor mounting bolts, re-

move the blower motor.

To install:

8. Position the blower motor and install the

mounting bolts.

9. Attach the blower motor electrical connec-

tion.

10. Connect the blower motor ventilation tube.

Page 212 of 408

CHASSIS ELECtRldAL 6-9

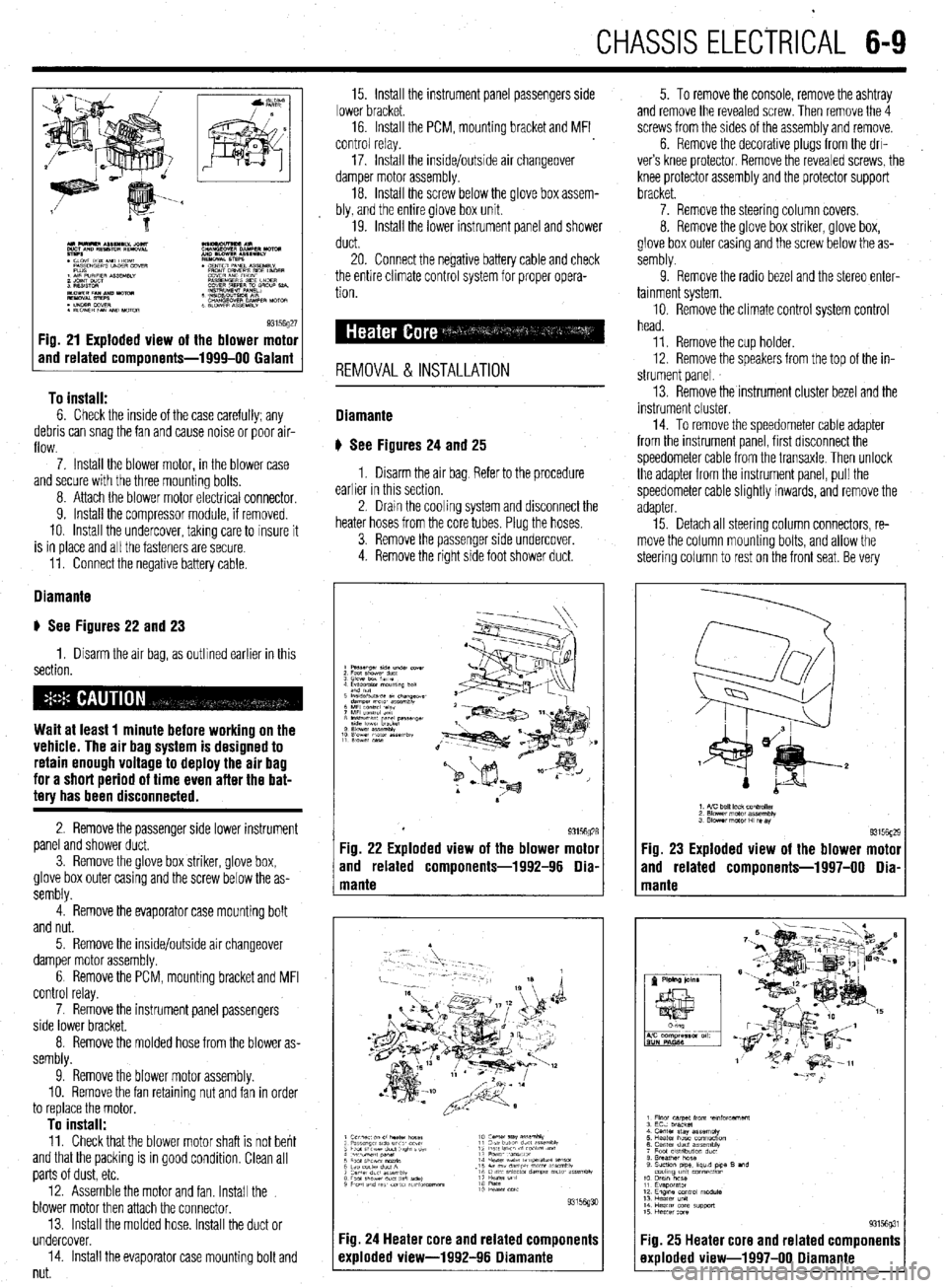

93156g27 Fig. 21 Exploded view of the blower motor

and related components-1999-00 Galant

To install:

6. Check the inside of the case carefully; any

debris can snag the fan and cause noise or poor air-

flow.

7. Install the blower motor, in the blower case

and secure with the three mounting bolts,

8. Attach the blower motor electrlcal connector,

9. Install the compressor module, if removed.

10. Install the undercover, takmg care to insure it

is in place and all the fasteners are secure.

11. Connect the negative battery cable.

Diamante

u See Figures 22 and 23

1. Disarm the air bag, as outlined earlier in this

section.

Wait at least 1 minute before working on the

vehicle. The air bag system is designed to

retain enough voltage to deploy the air bag

for a short period of time even after the bat-

tery has been disconnected.

2. Remove the passenger side lower instrument

panel and shower duct,

3. Remove the glove box striker, glove box,

glove box outer casing and the screw below the as-

sembly.

4. Remove the evaporator case mounting bolt

and nut.

5. Remove the inside/outside air changeover

damper motor assembly.

6 Remove the PCM, mounting bracket and MFI

control relay.

7. Remove the instrument panel passengers

side lower bracket.

8. Remove the molded hose from the blower as-

sembly.

9. Remove the blower motor assembly.

10. Remove the fan retaining nut and fan in order

to replace the motor,

To install: 11. Check that the blower motor shaft is not bent

and that the packing is in good condition, Clean all

parts of dust, etc.

12. Assemble the motor and fan. Install the

blower motor then attach the connector.

13. Install the molded hose. Install the duct or

undercover.

14. Install the evaporator case mounting bolt and

nut. 15. Install the instrument panel passengers side

lower bracket.

16. Install the PCM, mounting bracket and MFI

control relay.

17. Install the inside/outside air changeover

damper motor assembly.

18. Install the screw below the glove box assem-

bly, and the entire glove box unit.

19. Install the lower instrument panel and shower

duct.

20. Connect the negative battery cable and check

the entire climate control system for proper opera-

tion.

REMOVAL & INSTALLATION

Diamante

u See Figures 24

and 25

1. Disarm the air bag Refer to the procedure

earlier in this section.

2. Dram the cooling system and disconnect the

heater hoses from the core tubes. Plug the hoses.

3. Remove the passenger side undercover.

4. Remove the right side foot shower duct. 5. To remove the console, remove the ashtray

and remove the revealed screw. Then remove the 4

screws from the sides of the assembly and remove.

6. Remove the decorative plugs from the drl-

ver’s knee protector. Remove the revealed screws, the

knee protector assembly and the protector support

bracket.

7. Remove the steering column covers.

8. Remove the glove box striker, glove box,

glove box outer casing and the screw below the as-

sembly.

9. Remove the radio bezel and the stereo enter-

tainment system.

10. Remove the climate control system control

head.

11. Remove the cup holder.

12. Remove the speakers from the top of the in-

strument panel.

13. Remove the instrument cluster bezel and the

instrument cluster.

14. To remove the speedometer cable adapter

from the instrument panel, first disconnect the

speedometer cable from the transaxle. Then unlock

the adapter from the instrument panel, pull the

speedometer cable slightly inwards, and remove the

adapter

15. Detach all steering column connectors, re-

move the column mounting bolts, and allow the

steering column to rest on the front seat. Be very

Fig. 23 Exploded view of the blower motor

and related components-1997-00 Dia-

Fig. 25 Heater core and related components

exploded view-1997-00 Diamante

Page 214 of 408

CHASSIS ELECTRICAL 6-11

45. Install the heater hoses under the hood.

46. Install the mstrument panel by reversing its

removal procedure.

47. Install the center console.

48. install the upper and lower steering column

covers.

49. Install the center panel undercover.

50. Install the small column panel.

51. Install the steering wheel.

52. Fill the cooling system.

53. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

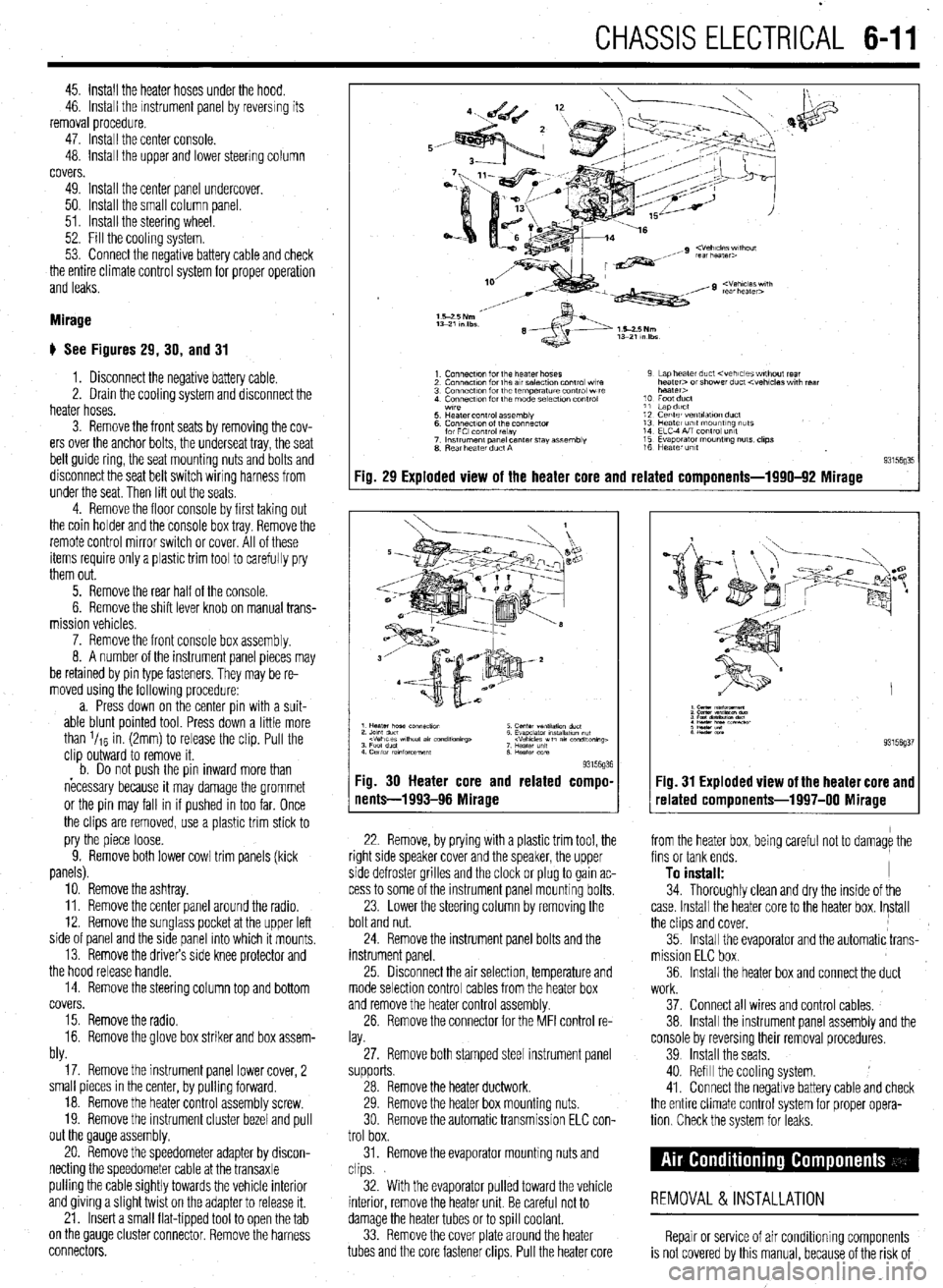

Mirage

# See Figures 29, 30, and 31

1. Disconnect the negative battery cable.

2. Drain the cooling system and disconnect the

heater hoses.

3. Remove the front seats by removing the cov-

ers over the anchor bolts, the underseat tray, the seat

belt guide ring, the seat mounting nuts and bolts and

disconnect the seat belt switch wiring harness from

under the seat. Then lift out the seats

4. Remove the floor console by first taking out

the coin holder and the console box tray. Remove the

remote control mirror switch or cover. All of these

items require only a plastic trim tool to carefully pry

them out.

5. Remove the rear half of the console.

6. Remove the shift lever knob on manual trans-

mission vehicles.

7. Remove the front console box assembly.

8. A number of the instrument panel pieces may

be retamed by pin type fasteners. They may be re-

moved using the following procedure:

a. Press down on the center pin with a suit-

able blunt pointed tool. Press down a little more

than l/re in. (2mm) to release the clip. Pull the

clip outward to remove it.

b. Do not oush the oin inward more than

necessary because it may damage the grommet

or the pin may fall in if pushed in too far. Once

the clips are removed, use a plastic trim stick to

pry the piece loose.

9. Remove both lower cowl trim panels (kick

panels).

10. Remove the ashtray.

11. Remove the center panel around the radio.

12. Remove the sunglass pocket at the upper left

side of panel and the side panel into which it mounts,

13. Remove the drivers side knee protector and

the hood release handle.

14. Remove the steering column top and bottom

covers.

15. Remove the radio.

16. Remove the glove box striker and box assem-

bly.

17. Remove the instrument panel lower cover, 2

small pieces in the center, by pulling forward.

18. Remove the heater control assembly screw.

19. Remove the instrument cluster bezel and pull

out the Qauge assembly.

20. Remove the speedometer adapter by discon-

necting the speedometer cable at the transaxle

pulling the cable Sightly towards the vehicle interior

and giving a Slight twist on the adapter to release it.

21. Insert a small flat-tipped tool to open the tab

on the QauQe cluster connector. Remove the harness

connectors.

Fig. 29 Exploded view of the heater core and related components-1990-92 Mirage

93l%Q% Fig. 30 Heater core and related compo-

nents-1993-96 Mirage

22. Remove, by prying with a plastic trim tool, the

right side speaker cover and the speaker, the upper

side defroster grilles and the clock or plug to gain ac-

cess to some of the instrument panel mounting bolts.

23. Lower the steering column by removing the

bolt and nut.

24. Remove the instrument panel bolts and the

instrument panel.

25 Drsconnect the air selection, temperature and

mode selection control cables from the heater box

and remove the heater control assembly.

26. Remove the connector for the MFI control re-

lay.

27. Remove both stamped steel instrument panel

supports.

28. Remove the heater ductwork.

29. Remove the heater box mounting nuts.

30 Remove the automatic transmission ELC con-

trol box.

31. Remove the evaporator mounting nuts and

clips.

32. With the evaporator pulled toward the vehicle

interior, remove the heater unit. Be careful not to

damage the heater tubes or to spill coolant.

33. Remove the cover plate around the heater

tubes and the core fastener clips. Pull the heater core 34. Thoroughly clean and dry the inside of the

case. Install the heater core to the heater box. Install

the clips and cover,

35. Install the evaporator and the automatic trans-

mission ELC box.

36. Install the heater box and connect the duct

Fig. 31 Exploded view of the heater core and

related components-1997-00 Mirage

from the heater box, being careful not to damage the

fins or tank ends.

To install: I

work.

37. Connect all wires and control cables,

38. Install the instrument panel assembly and the

console by reversmg their removal procedures.

39 Install the seats.

40. Refill the cooling system.

41. Connect the negative battery cable and check

the entire climate control system for proper opera-

tion Check the system for leaks.

REMOVAL &INSTALLATION

Repair or service of air Conditioning components

is not covered by this manual, because of the risk of

Page 215 of 408

6-12 CHASSIS ELECTRICAL

personal injury or death, and because of the legal

ramifications of servicing these components without

the proper EPA certification and experience. Cost,

personal injury or death, environmental damage, and

legal considerations (such as the fact that it is a fed-

eral crime to vent refrigerant into the atmosphere),

dictate that the A/C comoonents on your vehicle 4. Move the air selection controi lever to the RE-

CIRC position. Move the air selection damper FULLY

INWARD and connect the cable to the lever. Adjust as

required. C. Push the outer cable in the direction of the

arrow so that there is no looseness, then secure

should be serviced only’by a Motor Vehicle Air Con-

ditioning (MVAC) trained, and EPA certified automo-

REMOVAL&INSTALLATION tive technician. with the clip.

d. Set the knob for the air outlet changeover

on the control to the DEF position.

e. Set the air outlet changeover damper lever

of the heater unit to the DEF position, then attach

the cable to the lever pin.

f. Push the outer cable in the direction of the

arrow so there is no loosen&s, then secure it

with the clip. *If your vehicle’s A/C system uses R-12 re-

frlgerant and is in need of recharging, the

AK system can be converted over to R-Ma

refrigerant (less environmentally harmful

and expensive). Refer to Section 1 for addi-

tional information on R-12 to R-134a eonver-

sions, and for additional considerations

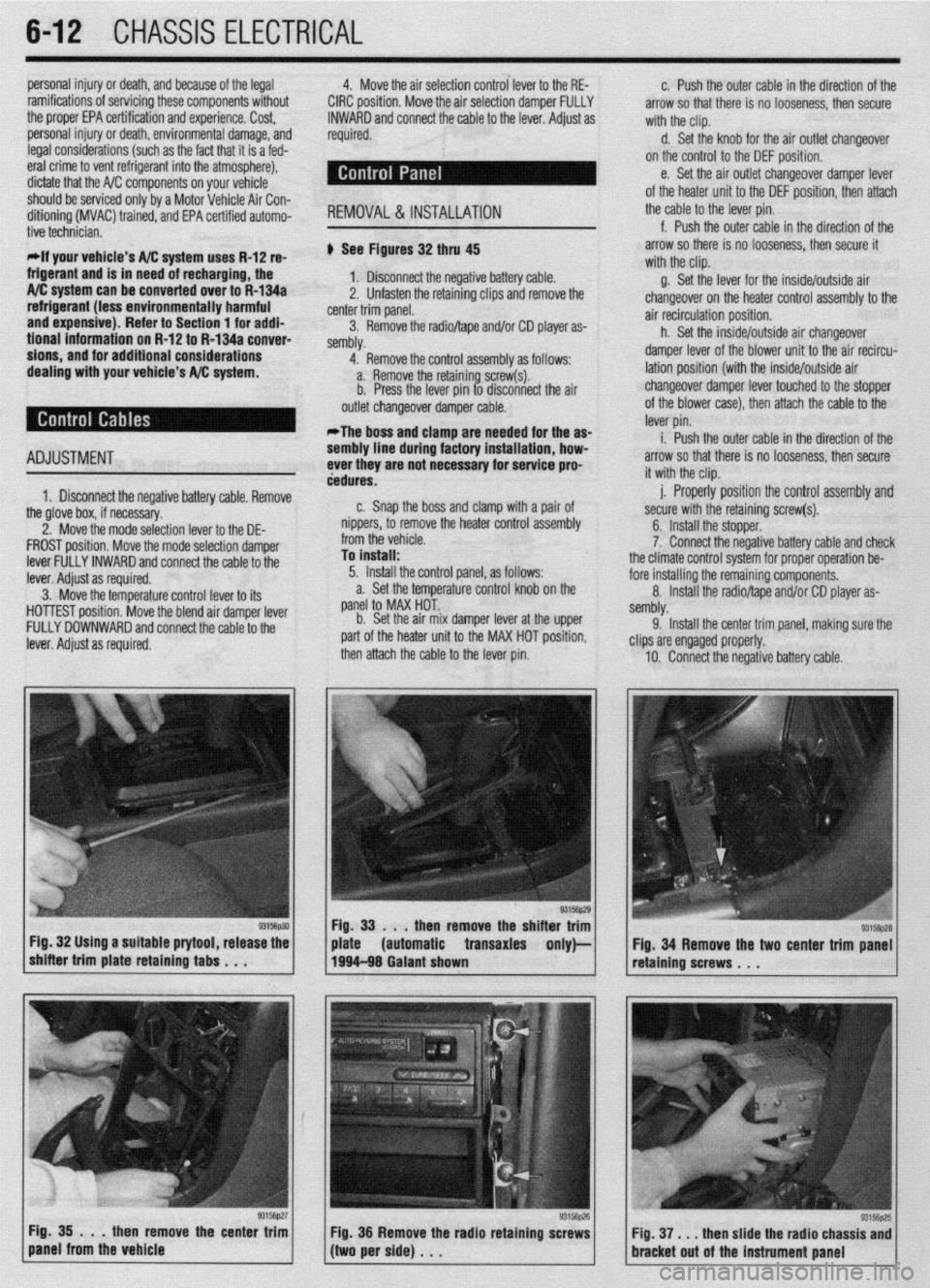

dealing with your vehicle’s A/C system. ti See Figures 32 thru 45

1. Disconnect the negative battery cable.

2, Unfasten the retaining clips and remove the

center trim panel.

3. Remove the radioltape and/or CD player as-

sembly,

4. Remove the control assembly as follows:

a. Remove the retaining screw(s).

b. Press the lever pin to disconnect the air

outlet changeover damper cable.

*The boss and clamp are needed for the as-

ADJUSTMENT

1. Disconnect the negative battery cable. Remove sembly line d

ever they are

dedures.

n Cnan i luring factory installation, how-

not necessary for service pro-

the glove box, if necessary,

2. Move the mode selection lever to the DE-

FROST position. Move the mode selection damper

lever FULLY INWARD and connect the cable to the

lever. Adiust as required.

3. M&e tht

3 temperature control lever to its

HOlli

5ST position. Move the blend air damper lever

FULL’t

’ DOWNWARD and connect the cable to the

lever. i

4djust as required. b,. dIIal, the boss and clamp with a pair of

nippers, to remove the heater control assembly

from the vehicle.

To install:

5. Install the control panel, as follows:

a. Set the temperature control knob on the

panel to MAX HOT..

b. Set the air mix damper lever at the upper

part of the heater unit to the MAX HOT position,

then attach the cable to the lever pin.

then remove the shi

Fig. 32 Using a suitable prytool, release the

automatic transaxles

93156p27 Fig. 35 . . .

then remove the center trim

panel from the vehicle

/(twiperside)... y Fig 36 Remove the radio retaining screws g. Set the lever for the inside/outside air

changeover on the heater control assemblv to the

air recirculation position.

h. Set the inside/outside air changeover

damper lever of the blower unit to the air recircu-

lation position (with the inside/outside air

changeover damper lever touched to the stopper

of the blower case), then attach the cable to the

lever pin.

i. Push the outer cable in the direction of the

arrow so that there is no looseness, then secure

it with the clip.

j. Properly position the control assembly and

secure with the retaining screw(s).

6. Install the stopper.

7. Connect the negative battery cable and check

the climate control system for proper operation be-

fore installing the remaining components.

8. Install the radio/tape and/or CD player as-

sembly.

9. Install the center trim oanel, makina sure the

clips are engaged properly. -

10. Connect the negative battery cable.

Fig. 34 Remove the two center trim panel

retaining screws . . .

Fig. 37, . . then slide the radio chassis and

bracket out of the instrument Dane1

Page 216 of 408

CHASSIS ELECTRICiL 6-13

.

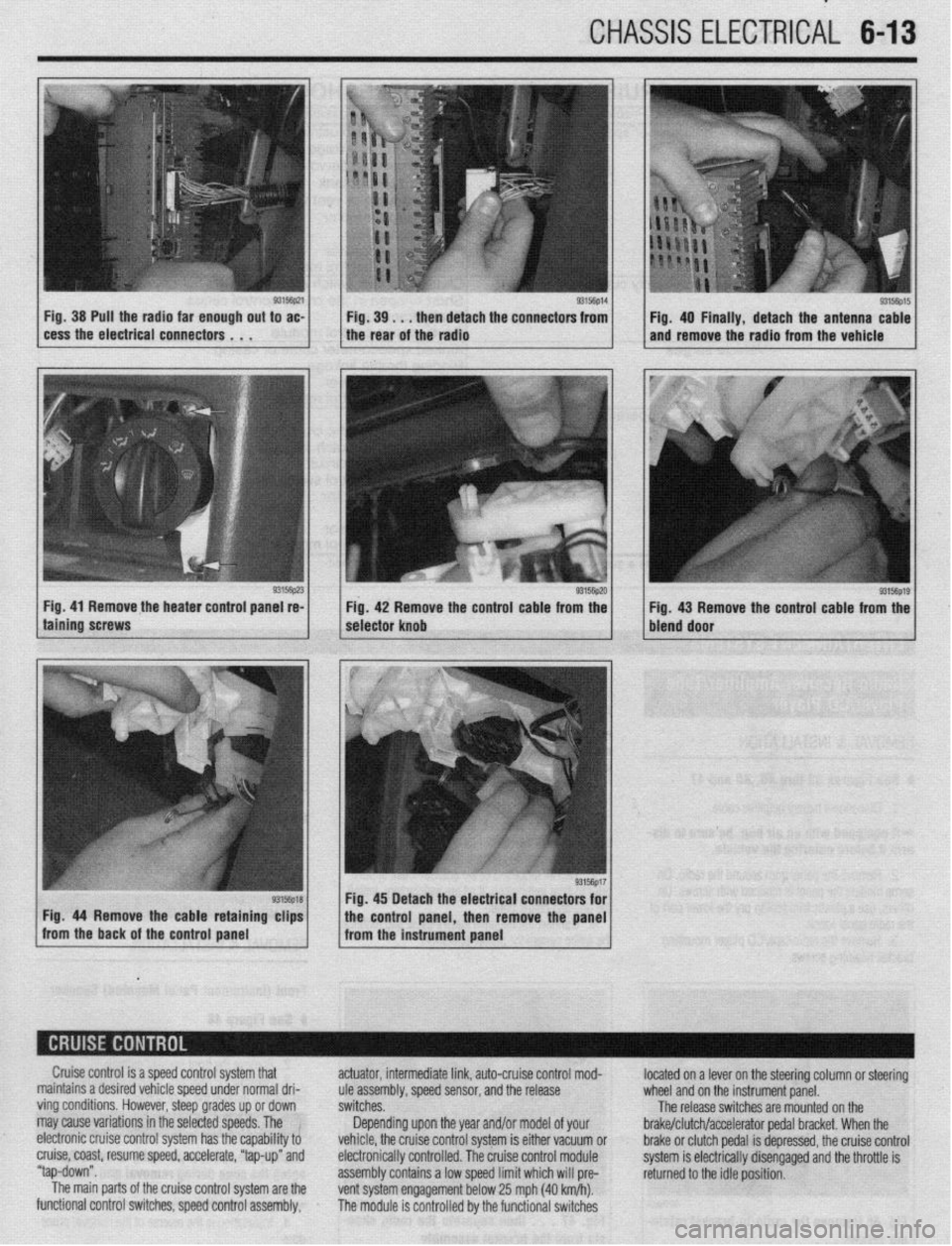

Fig. 38 Pull the radia far enough out to ac-

cess the electrical connectors . . . 9315fip14 Fig. 39. . . then detach the connectors from

I I Fig. 40 Finally, detach the antenna cable

the rear of the radio and remove the radio from the vehicle

Fig. 41 Remove the heater control panel re-

Fig. 42 Remove the control cable from the

g3156p1g / Fig 43 Remove the control cable from the

bleid door

Cruise control is a speed control system that

maintains a desired vehicle speed under normal dri-

ving conditions. However, steep grades up or down

may cause variations in the selected speeds. The !

electronic cruise control system has the capability to

cruise, coast, resume speed, accelerate, “tap-up” and

“tap-down”.

The main parts of the cruise control system are the

functional control switches, speed control assembly, actuator, intermediate link, auto-cruise control mod-

ule assembly, speed sensor, and the release

switches.

Depending upon the year and/or model of your

vehicle, the cruise control system is either vacuum or

electronically controlled. The cruise control module

assembly contains a low speed limit which will pre-

vent system engagement below 25 mph (40 km/h).

The module is controlled by the functional switches located on a lever on the steering column or steering

wheel and on the instrument panel.

The release switches are mounted on the

brake/clutch/accelerator pedal bracket. When the

brake or clutch pedal is depressed, the cruise control

system is electrically disengaged and the throttle is

returned to the idle position.

Page 217 of 408

6-14 CHASSIS ELECTRICAL

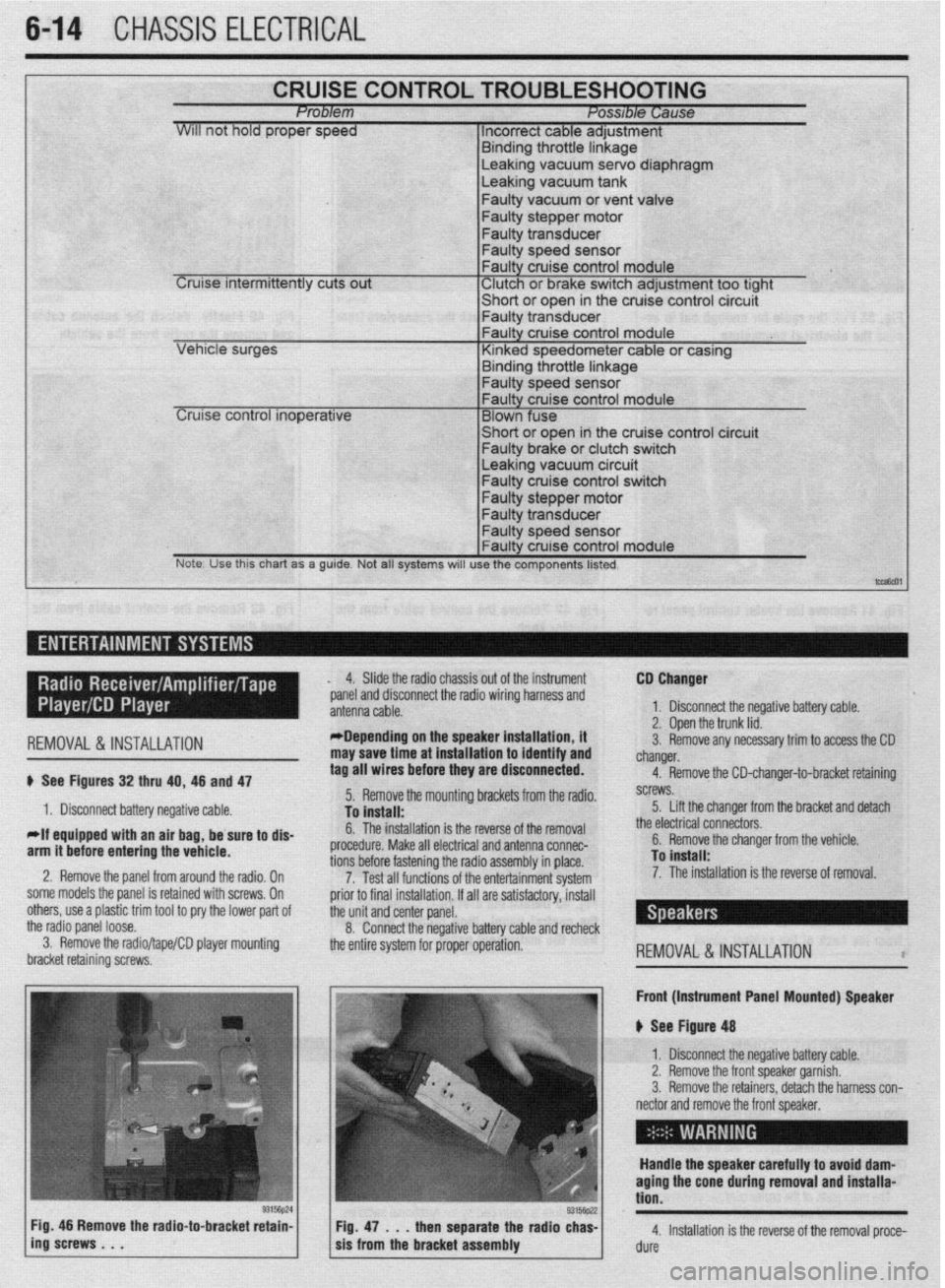

CRUISE CONTROL TROUBLESHOOTING Problem Posable Cause

WIII not hold proper speed 1 Incorrect cable adjustment

F.~. _I.~_ - 1L .-AL‘- I. I -

Cruise intermittently cuts out

trrnarng Inrome nnKage Leaking vacuum servo diaphragm

Leaking vacuum tank

Faulty vacuum or vent valve

Faulty stepper motor

Faulty transducer

Faulty speed sensor

Faulty cruise control module

‘ Clutch or brake switch adjustment too tight -chnrt *r nna* in the cruise control circuit

cer VI I”, . vt “y”‘,

I- Faulty transdu

Leaking vacuum circuit Faulty cruise control switch

Faulty stepper motor

Note. Use this chart as a guide. Not all systems will use the components listed.

t-,

I ,-- ,

REMOVAL&INSTALLATION

# See Figures 32 thru 40, 46 and 47

1. Disconnect battery negative cable.

*If equipped with an air bag, be sure to dis-

arm it before entering the vehicle.

2. Remove the panel from around the radio, On

some models the panel is retained with screws, On

others, use a plastic trim tool to pry the lower pad of

the radio panel loose.

3. Remove the radio/tape/CD player mounting

bracket retaining screws, 4. Slide the radio chassis out of the instrument

*panel and disconnect the radio wiring harness and

*Depending on the speaker installation, it

may save time at installation to identify and

tag all wires before they are disconnected.

5. Remove the mounting brackets from the radio.

To install:

6. The installation is the reverse of the removal

procedure. Make all electrical and antenna connec-

tions before fastening the radio assembly in place.

7. Test all functions of the entertainment system

prior to final installation. If all are satisfactory, install

the unit and center panel.

8. Connect the negative battery cable and recheck

the entire system for proper operation. CD Changer

1. Disconnect the negative battery cable.

2. Open the trunk lid.

3. Remove any necessary trim to access the CD

changer.

4. Remove the CD-changer-to-bracket retaining

screws.

5. Lift the changer from the bracket and detach

the electrical connectors.

6. Remove the changer from the vehicle.

To install:

7. The installation is the reverse of removal.

REMOVAL&INSTALLATION l

Front (Instrument Panel Mounted) Speaker

u See Figure 48

1. Disconnect the negative battery cable.

2. Remove the front speaker garnish.

3. Remove the retainers, detach the harness con-

nector and remove the front speaker,

Handle the speaker carefully to avoid dam-

aging the cone during removal and installa-

tion.

4. Installation is the reverse of the removal proce-

dure

Page 233 of 408

6-30 CHASSIS ELECTRICAL

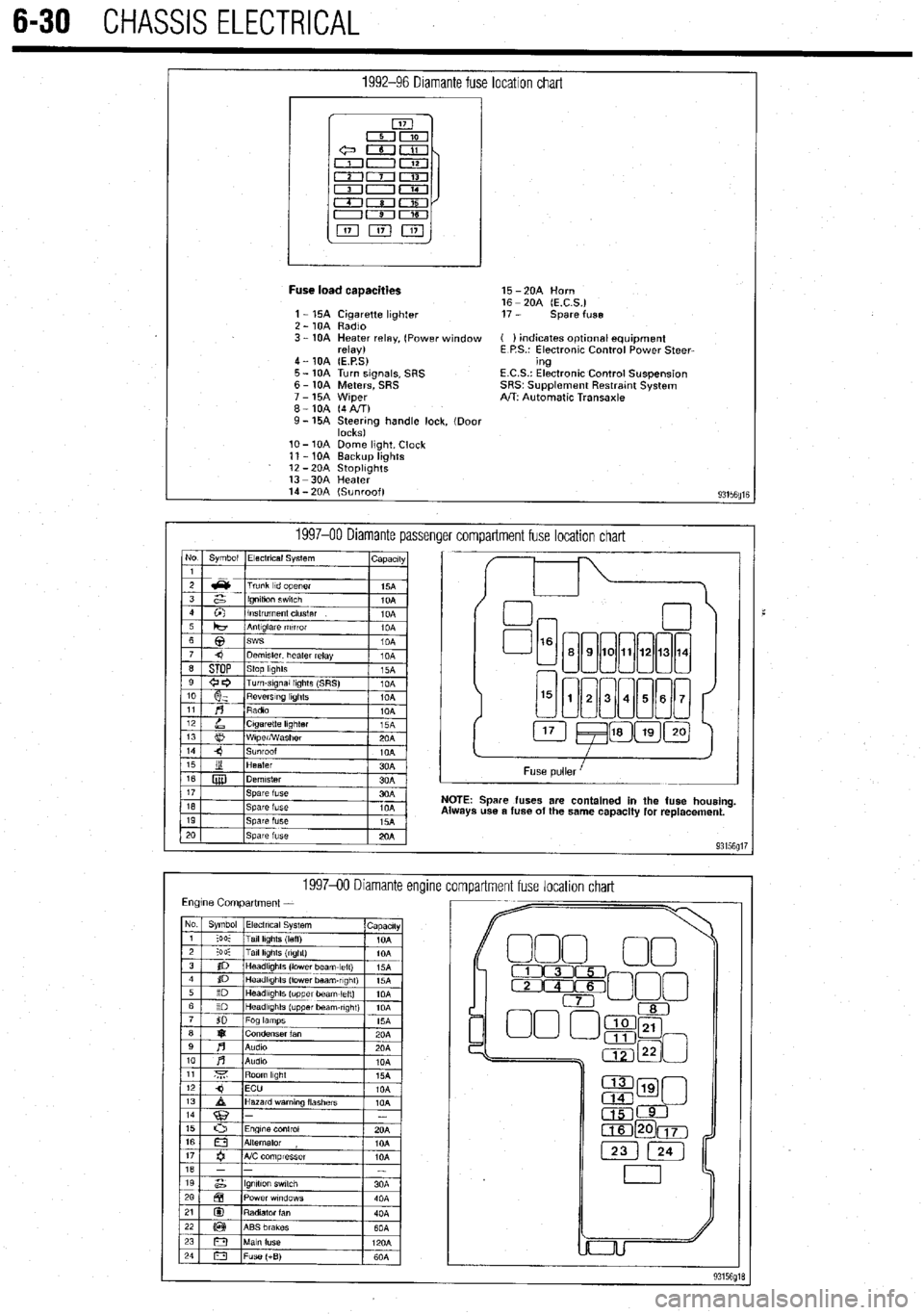

1992-96 Diamante fuse location chart

I

Fuse load caaacities 15 -2OA Horn

16 - 20A (E.C.S.)

1 - 15A Cigarette lighter 17 - spare fuse

2 - 10A Radio

3 - 10A Heater relay, (Power window ( ) indicates optlonal equipment

relay) E P.S.: Electronic Control Power Steer-

4 - 10A (E.P.S) ing

5 - 10A Turn signals, SRS E.C.S.: Electronic Control Suspension

6 - 10A Meters, SRS SRS~ Supplement Restratnt System

7 - 15A Wiper A/T: Automatic Transaxle

8-10A (4AIT)

9- 15A Steering handle lock, (Door

locks)

lo- 10A Dome light, Clock

11 - 10A Backup lights

12 -2OA StoplIghts

13 -3OA Heater

14 - 20A (Sunroof)

93156fllE

1997-00 Diamante passenger compartment fuse location chart No Symbol Electrical System

I capactty

I

Spare fuses are contained in the fuse housing

use a fuse of the same capacity for replacement.

199740 Diamante encline

compartment fuse location chart