center console MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 151 of 408

.

4-8 DRIVEABILITYAND EMISSIONS CONTROLS

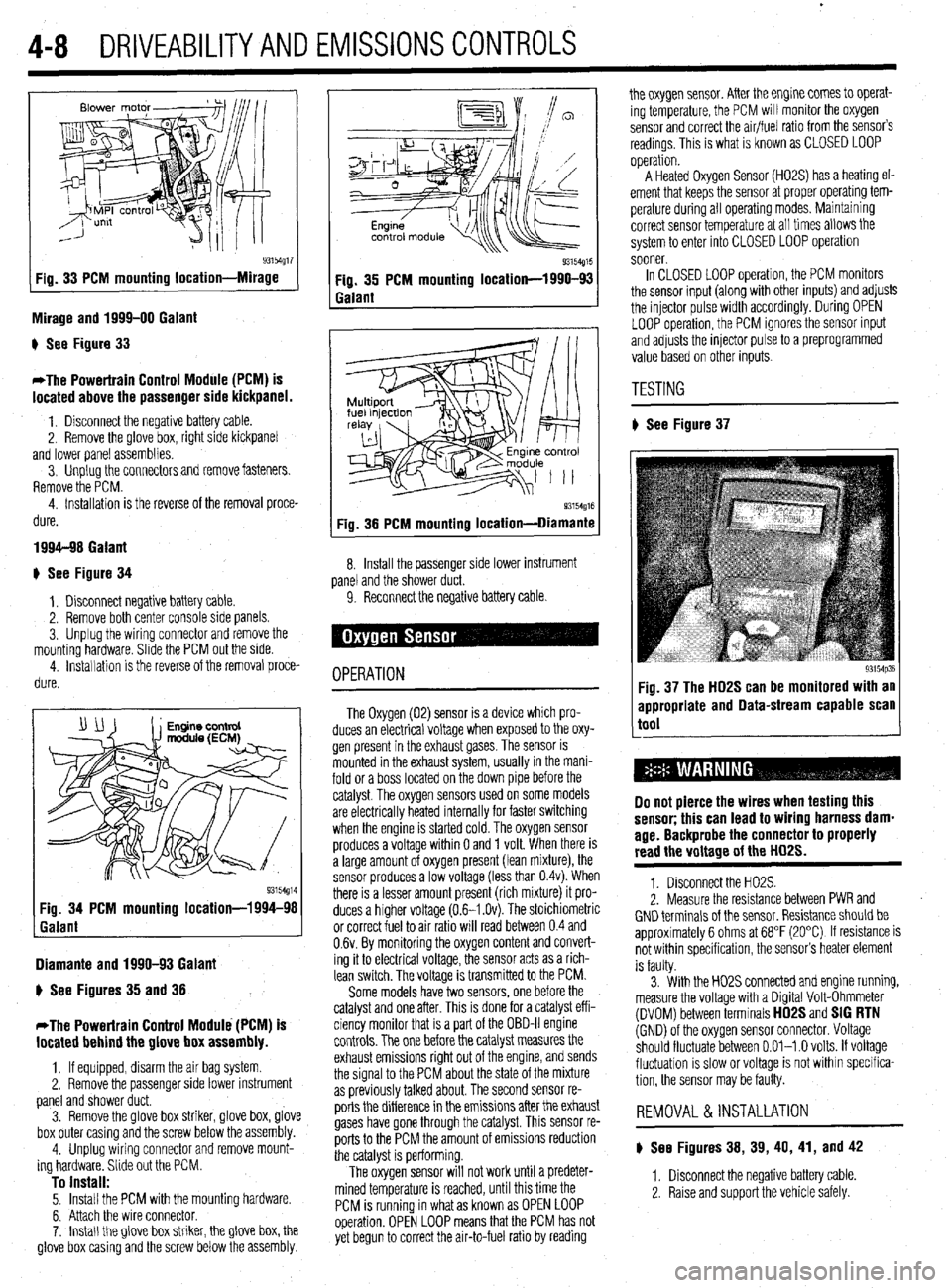

93154g17 Fig. 33 PCM mounting location-Mirage

Mirage and 1999-00 Galant

) See Figure 33

*The Powertrain Control Module (PCM) is

located above the passenger side kickpanel.

1. Disconnect the negative battery cable.

2. Remove the @love box, right side kickpanel

and lower panel assemblies.

3. Unplug the connectors and remove fasteners.

Remove the PCM.

4. Installation is the reverse of the removal proce-

dure.

1994-98 Galant

+ See Figure 34

1, Disconnect negative battery cable.

2. Remove both center console side panels.

3. Unplug the wiring connector and remove the

mounting hardware. Slide the PCM out the side.

4. installation is the reverse of the removal proce-

dure.

Diamante and 1990-93 Galant

) See Figures 35 and 38

*The Powertrain Control Module (PCM) is

located behind the glove box assembly.

1, If equipped, disarm the air bag system

2. Remove the passenger side lower instrument

panel and shower duct.

3. Remove the glove box striker, glove box, glove

box outer casing and the screw below the assembly.

4. Unplug wiring connector and remove mount-

ing hardware. Slide out the PCM.

To install: 5. Install the PCM with the mounting hardware.

6. Attach the wire connector.

7. Install the glove box striker, the glove box, the

glove box casing and the screw below the assembly.

Q3154g15 Fig. 35 PCM mounting location-1990-93

Galant

93154g16 Fig. 38 PCM mounting location-Diamante

8. Install the passenger side lower instrument

panel and the shower duct.

9. Reconnect the negative battery cable

OPERATION

The Oxygen (02) sensor is a device which pro-

duces an electrical voltage when exposed to the oxy-

gen present in the exhaust gases. The sensor is

mounted in the exhaust system, usually in the mani-

fold or a boss located on the down pipe before the

catalyst. The oxygen sensors used on some models

are electrically heated internally for faster switching

when the engine is started cold. The oxygen sensor

produces a voltage within 0 and 1 volt. When there is

a large amount of oxygen present (lean mixture), the

sensor produces a low voltage (less than 0.4~). When

there is a lesser amount present (rich mixture) it pro-

duces a higher voltage (0.6-I .Ov). The stoichiometric

or correct fuel to air ratio will read between 0.4 and

0.6~. By monitoring the oxygen content and convert-

ing it to electrical voltage, the sensor acts as a rich-

lean switch. The voltage is transmitted to the PCM.

Some models have two sensors, one before the

catalyst and one after. This is done for a catalyst eff i-

ciency monitor that is a part of the OBD-II engine

controls. The one before the catalyst measures the

exhaust emissions right out of the engine, and sends

the signal to the PCM about the state of the mixture

as previously talked about. The second sensor re-

ports the difference in the emissions after the exhaust

gases have gone through the catalyst. This sensor re-

ports to the PCM the amount of emissions reduction

the catalyst is performing.

The oxygen sensor will not work until a predeter-

mined temperature is reached, until this time the

PCM is running in what as known as OPEN LOOP

operation. OPEN LOOP means that the PCM has not

yet begun to correct the air-to-fuel ratio by reading the oxygen sensor. After the engine comes to operat-

ing temperature, the PCM will monitor the oxygen

sensor and correct the air/fuel ratio from the sensor’s

readings. This is what is known as CLOSED LOOP

operation.

A Heated Oxygen Sensor (H02S) has a heating el-

ement that keeps the sensor at proper operatmg tem-

perature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into CLOSED LOOP operation

sooner.

In CLOSED LOOP operation, the PCM monitors

the sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During OPEN

LOOP operation, the PCM ignores the sensor input

and adjusts the injector pulse to a preprogrammed

value based on other inputs.

TESTING

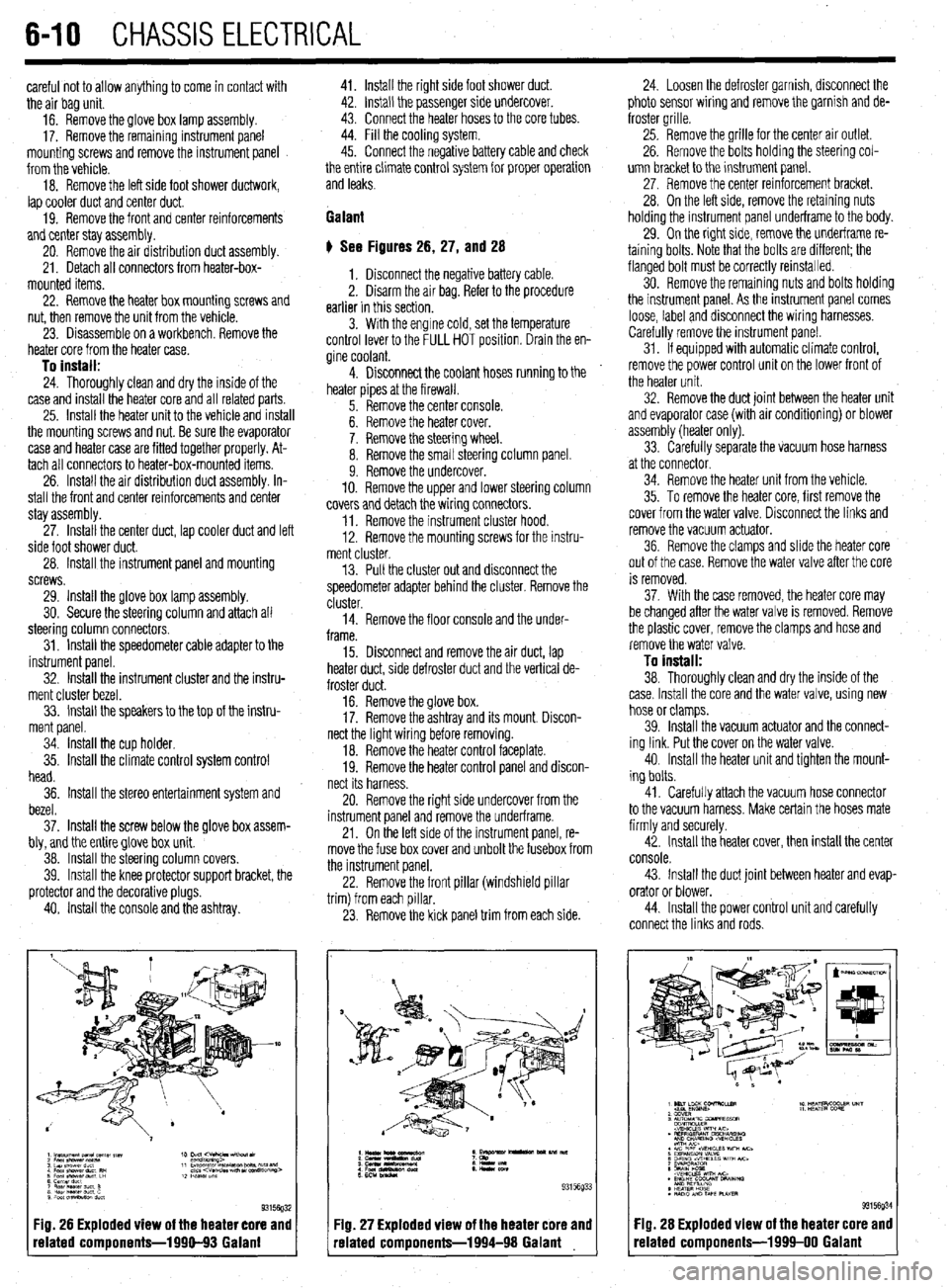

# See Figure 37

93154p36 Fig. 37 The HD2S can be monitored with an

appropriate and Data-stream capable scan

tool

Do not pierce the wires when testing this

sensor; this can lead to wiring harness dam-

age. Backprobe the connector to properly

read the voltage of the HD2S.

1. Disconnect the H02S.

2. Measure the resistance between PWR and

GND terminals of the sensor. Resistance should be

approximately 6 ohms at 68°F (20°C) If resistance is

not within specification, the sensor’s heater element

is faulty.

3. With the H02S connected and engine running,

measure the voltage with a Digital Volt-Ohmmeter

(DVOM) between terminals

HD2S and SIG RTN (GND) of the oxygen sensor connector. Voltage

should fluctuate between 0.01-l .O volts. If voltage

fluctuation is slow or voltage is not within specifica-

tion, the sensor may be faulty.

REMOVAL &INSTALLATION

) See Figures 38, 39, 40, 41, and 42

1. Disconnect the negative battery cable

2. Raise and support the vehicle safely.

Page 213 of 408

640 CHASSIS ELECTRICAL

careful not to allow anything to come in contact with

the air bag unit.

16. Remove the glove box lamp assembly.

17. Remove the remaining instrument panel

mounting screws and remove the instrument panel

from the vehicle.

18. Remove the left side foot shower ductwork,

lap cooler duct and center duct.

19. Remove the front and center reinforcements

and center stay assembly.

20. Remove the air distribution duct assembly.

21. Detach all connectors from heater-box-

mounted items.

22. Remove the heater box mounting screws and

nut, then remove the unit from the vehicle.

23. Disassemble on a workbench. Remove the

heater core from the heater case.

To install:

24. Thoroughly clean and dry the inside of the

case and install the heater core and all related parts.

25. Install the heater unit to the vehicle and install

the mounting screws and nut. Be sure the evaporator

case and heater case are fitted together properly. At-

tach all connectors to heater-box-mounted items.

26. Install the air distribution duct assembly. In-

stall the front and center reinforcements and center

stay assembly.

27. Install the center duct, lap cooler duct and left

side foot shower duct.

28. Install the instrument panel and mounting

screws.

29. Install the glove box lamp assembly.

30. Secure the steering column and attach all

steering column connectors.

31. Install the speedometer cable adapter to the

instrument panel.

32. Install the instrument cluster and the instru-

ment cluster bezel.

33. Install the speakers to the top of the instru-

ment panel.

34. Install the cup holder.

35. Install the climate control system control

head.

36. Install the stereo entertainment system and

bezel.

37. Install the screw below the glove box assem-

bly, and the entire glove box unit.

38. Install the steering column covers.

39. Install the knee protector support bracket, the

protector and the decorative plugs.

40. Install the console and the ashtray. 41. Install the right side foot shower duct.

42. Install the passenger side undercover.

43. Connect the heater hoses to the core tubes.

44. Fill the cooling system.

45. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Galant

# See Figures 26, 27, and 28

1. Disconnect the negative battery cable.

2. Disarm the air bag. Refer to the procedure

earlier in this section.

3. With the engine cold, set the temperature

control lever to the FULL HOT position. Drain the en-

gine coolant.

4. Disconnect the coolant hoses running to the

heater pipes at the firewall.

5. Remove the center console.

6. Remove the heater cover.

7. Remove the steering wheel.

8. Remove the small steering column panel.

9. Remove the undercover.

10. Remove the upper and lower steering column

covers and detach the wiring connectors.

11. Remove the instrument cluster hood.

12. Remove the mounting screws for the instru-

ment cluster.

13. Pull the cluster out and disconnect the

speedometer adapter behind the cluster. Remove the

cluster.

14. Remove the floor console and the under-

frame.

15. Disconnect and remove the air duct, lap

heater duct, side defroster duct and the vertical de-

froster duct.

16. Remove the glove box.

17. Remove the ashtray and its mount. Discon-

nect the light wiring before removing.

18. Remove the heater control faceplate.

19. Remove the heater control panel and discon-

nect its harness.

20. Remove the right side undercover from the

instrument panel and remove the underframe.

21. On the left side of the instrument panel, re-

move the fuse box cover and unbolt the fusebox from

the instrument panel.

22. Remove the front pillar (windshield pillar

trim) from each pillar.

23. Remove the kick panel trim from each side.

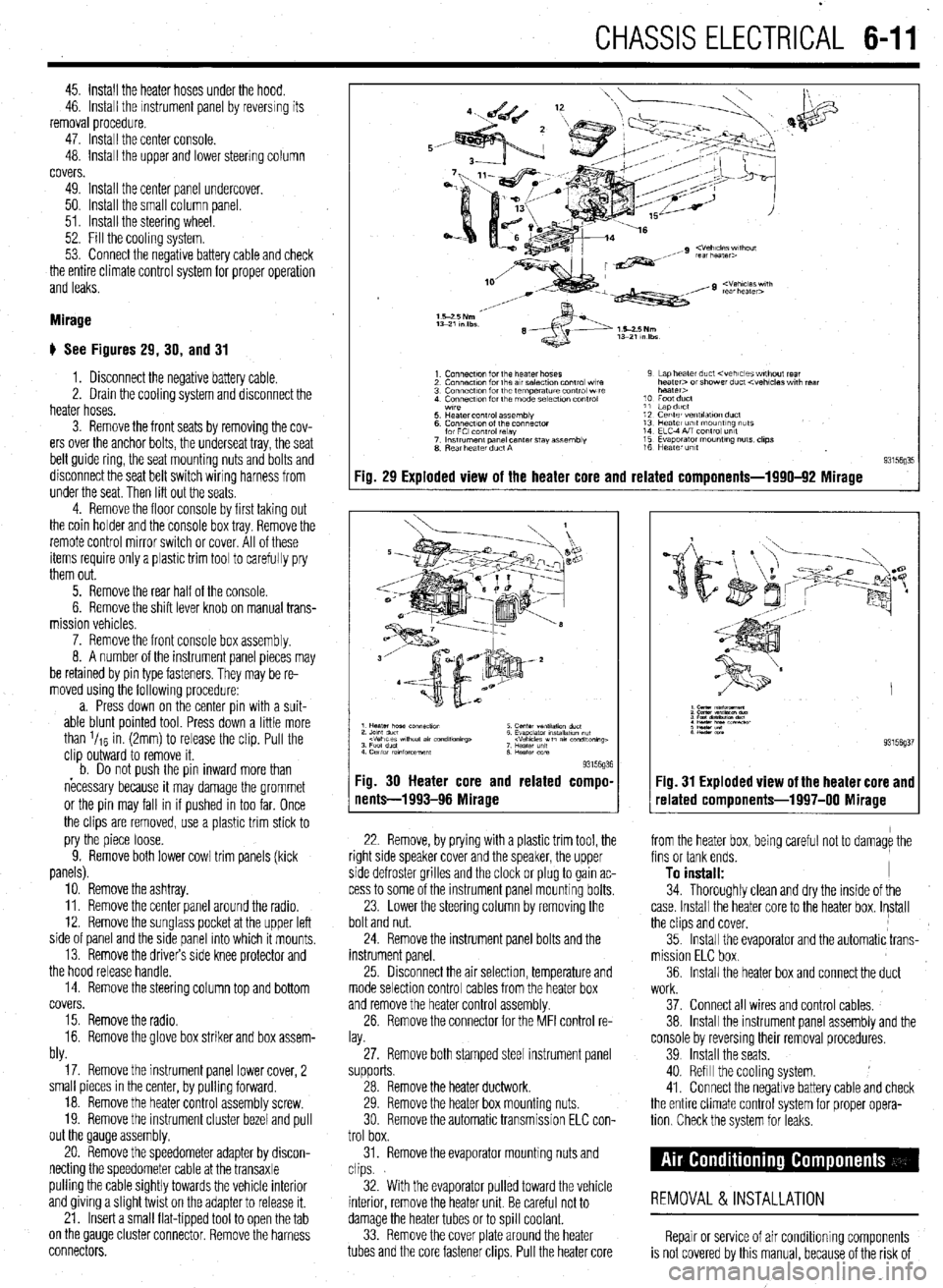

Fig. 26 Exploded view of the heater core and

related components-1990-93 Galant

:IQ. 27 Exploded view of the heater core and

-elated components-1994-98 Galant 24. Loosen the defroster garnish, disconnect the

photo sensor wiring and remove the garnish and de-

froster grille.

25. Remove the grille for the center air outlet.

26. Remove the bolts holding the steering col-

umn bracket to the instrument panel.

27, Remove the center reinforcement bracket.

28. On the left side, remove the retaining nuts

holding the instrument panel underframe to the body.

29. On the right side, remove the underframe re-

taining bolts. Note that the bolts are different; the

flanged bolt must be correctly reinstalled.

30. Remove the remaining nuts and bolts holding

the instrument panel. As the instrument panel comes

loose, label and disconnect the wiring harnesses.

Carefully remove the instrument panel.

31. If equipped with automatic climate control,

remove the power control unit on the lower front of

the heater unit.

32. Remove the duct joint between the heater unit

and evaporator case (with air conditioning) or blower

assembly (heater only).

33. Carefully separate the vacuum hose harness

at the connector.

34. Remove the heater unit from the vehicle.

35. To remove the heater core, first remove the

cover from the water valve. Disconnect the links and

remove the vacuum actuator.

36. Remove the clamps and slide the heater core

out of the case. Remove the water valve after the core

is removed.

37. With the case removed, the heater core may

be changed after the water valve is removed. Remove

the plastic cover, remove the clamps and hose and

remove the water valve.

To install:

38. Thoroughly clean and dry the inside of the

case. Install the core and the water valve, using new

hose or clamps.

39. Install the vacuum actuator and the connect-

ing link. Put the cover on the water valve.

40. Install the heater unit and tighten the mount-

ing bolts.

41. Carefully attach the vacuum hose connector

to the vacuum harness. Make certain the hoses mate

firmly and securely.

42. Install the heater cover, then install the center

console.

43. Install the duct joint between heater and evap-

orator or blower.

44. Install the power control unit and carefully

connect the links and rods.

Fig. 28 Exploded view of the heater core and

related components-1999-00 Galant

Page 214 of 408

CHASSIS ELECTRICAL 6-11

45. Install the heater hoses under the hood.

46. Install the mstrument panel by reversing its

removal procedure.

47. Install the center console.

48. install the upper and lower steering column

covers.

49. Install the center panel undercover.

50. Install the small column panel.

51. Install the steering wheel.

52. Fill the cooling system.

53. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Mirage

# See Figures 29, 30, and 31

1. Disconnect the negative battery cable.

2. Drain the cooling system and disconnect the

heater hoses.

3. Remove the front seats by removing the cov-

ers over the anchor bolts, the underseat tray, the seat

belt guide ring, the seat mounting nuts and bolts and

disconnect the seat belt switch wiring harness from

under the seat. Then lift out the seats

4. Remove the floor console by first taking out

the coin holder and the console box tray. Remove the

remote control mirror switch or cover. All of these

items require only a plastic trim tool to carefully pry

them out.

5. Remove the rear half of the console.

6. Remove the shift lever knob on manual trans-

mission vehicles.

7. Remove the front console box assembly.

8. A number of the instrument panel pieces may

be retamed by pin type fasteners. They may be re-

moved using the following procedure:

a. Press down on the center pin with a suit-

able blunt pointed tool. Press down a little more

than l/re in. (2mm) to release the clip. Pull the

clip outward to remove it.

b. Do not oush the oin inward more than

necessary because it may damage the grommet

or the pin may fall in if pushed in too far. Once

the clips are removed, use a plastic trim stick to

pry the piece loose.

9. Remove both lower cowl trim panels (kick

panels).

10. Remove the ashtray.

11. Remove the center panel around the radio.

12. Remove the sunglass pocket at the upper left

side of panel and the side panel into which it mounts,

13. Remove the drivers side knee protector and

the hood release handle.

14. Remove the steering column top and bottom

covers.

15. Remove the radio.

16. Remove the glove box striker and box assem-

bly.

17. Remove the instrument panel lower cover, 2

small pieces in the center, by pulling forward.

18. Remove the heater control assembly screw.

19. Remove the instrument cluster bezel and pull

out the Qauge assembly.

20. Remove the speedometer adapter by discon-

necting the speedometer cable at the transaxle

pulling the cable Sightly towards the vehicle interior

and giving a Slight twist on the adapter to release it.

21. Insert a small flat-tipped tool to open the tab

on the QauQe cluster connector. Remove the harness

connectors.

Fig. 29 Exploded view of the heater core and related components-1990-92 Mirage

93l%Q% Fig. 30 Heater core and related compo-

nents-1993-96 Mirage

22. Remove, by prying with a plastic trim tool, the

right side speaker cover and the speaker, the upper

side defroster grilles and the clock or plug to gain ac-

cess to some of the instrument panel mounting bolts.

23. Lower the steering column by removing the

bolt and nut.

24. Remove the instrument panel bolts and the

instrument panel.

25 Drsconnect the air selection, temperature and

mode selection control cables from the heater box

and remove the heater control assembly.

26. Remove the connector for the MFI control re-

lay.

27. Remove both stamped steel instrument panel

supports.

28. Remove the heater ductwork.

29. Remove the heater box mounting nuts.

30 Remove the automatic transmission ELC con-

trol box.

31. Remove the evaporator mounting nuts and

clips.

32. With the evaporator pulled toward the vehicle

interior, remove the heater unit. Be careful not to

damage the heater tubes or to spill coolant.

33. Remove the cover plate around the heater

tubes and the core fastener clips. Pull the heater core 34. Thoroughly clean and dry the inside of the

case. Install the heater core to the heater box. Install

the clips and cover,

35. Install the evaporator and the automatic trans-

mission ELC box.

36. Install the heater box and connect the duct

Fig. 31 Exploded view of the heater core and

related components-1997-00 Mirage

from the heater box, being careful not to damage the

fins or tank ends.

To install: I

work.

37. Connect all wires and control cables,

38. Install the instrument panel assembly and the

console by reversmg their removal procedures.

39 Install the seats.

40. Refill the cooling system.

41. Connect the negative battery cable and check

the entire climate control system for proper opera-

tion Check the system for leaks.

REMOVAL &INSTALLATION

Repair or service of air Conditioning components

is not covered by this manual, because of the risk of

Page 356 of 408

‘I

9-20 ,BRAKES

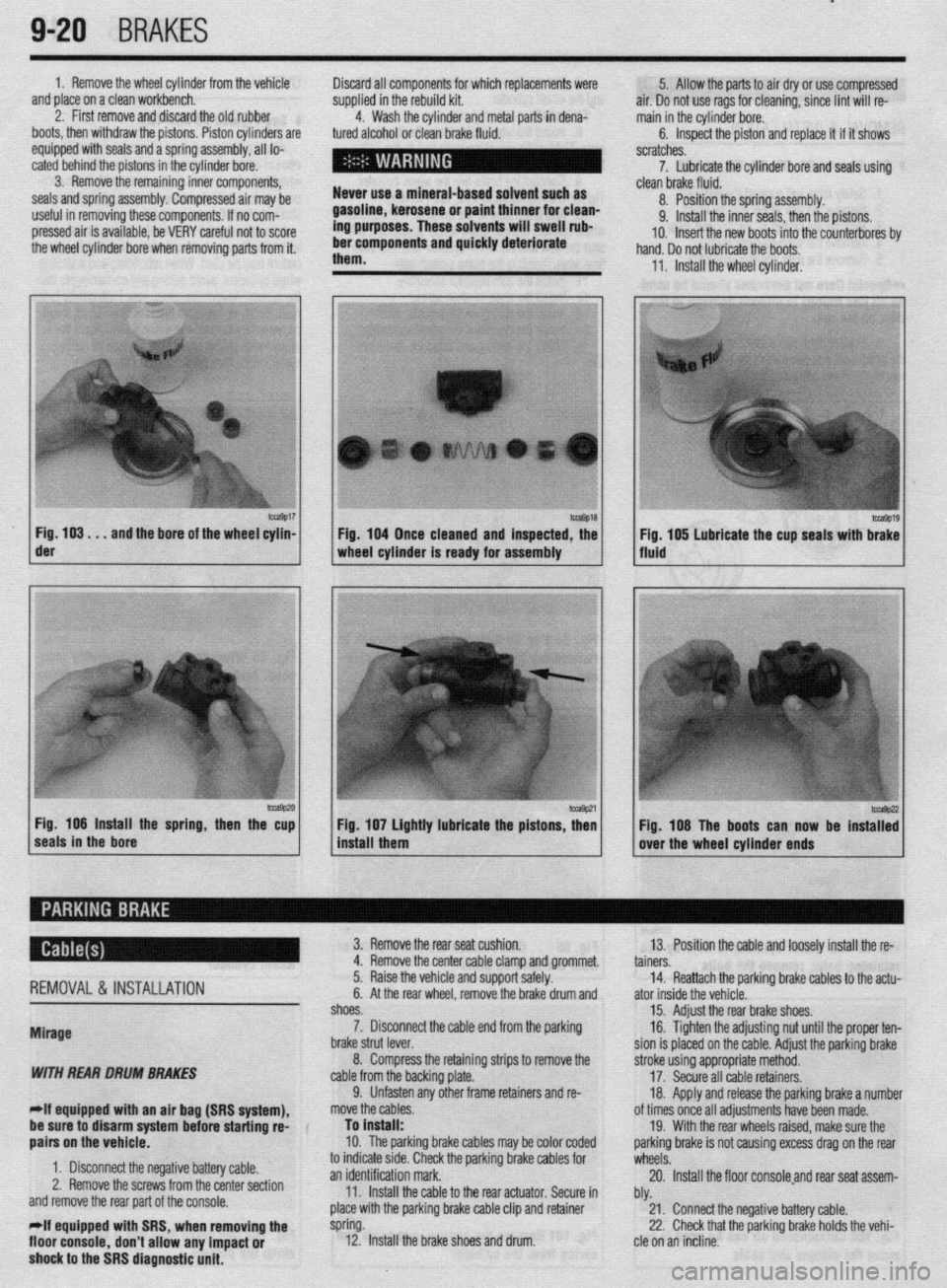

1. Remove the wheel cylinder from the vehicle

and place on a clean workbench.

2. First remove and discard the old rubber

boots, then withdraw the pistons. Piston cylinders are

equipped with seals and a spring assembly, all lo-

cated behind the pistons in the cylinder bore.

3. Remove the remaining inner components,

seals and spring assembly. Compressed air may be

useful in removing these components. If no com-

pressed air is available, be VERY careful not to score

the wheel cylinder bore when removing parts from it. Discard all components for which replacements were

supplied in the rebuild kit.

4. Wash the cylinder and metal parts in dena-

tured alcohol or clean brake fluid.

Never use a mineral-based solvent such as

gasoline, kerosene or paint thinner for clean-

ing purposes. These solvents will swell rub-

ber components and quickly deteriorate

them. 5. Allow the parts to air dry or use compressed

air. Do not use rags for cleaning, since lint will re-

main in the cylinder bore.

6. Inspect the piston and replace it if it shows

scratches.

7. Lubricate the cylinder bore and seals using

- clean brake fluid.

8. Position the spring assembly.

9. Install the inner seals, then the pistons.

IO. Insert the new boots into the counterbores bv

hand. Do not lubricate the boots,

11, Install the wheel cylinder,

m9017 Fig. 103. . .

and the bore of the wheel cylin- der

-9P20 Fig. 106 Install the spring, then the cup

seals in the bore 1 Fig. 104 Once cleaned and inspected, the

1 wheel cylinder Is ready for assembly

1 install them Fig 107 Lightly lubricate the pistons z

’ Fig. 108 The boots can now be instaT:

over the wheel cylinder ends

REMOVAL& INSTALLATION

Mirage

WITH REAR DRUM BRAKES

-If equipped witti an air bag (SRS system), 3. Remove the rear seat cushion.

13. Position the cable and loosely install the re-

4. Remove the center cable clamp and grommet.

tainers.

5. Raise the vehicle and support safely.

14. Reattach the parking brake cables to the actu-

6. At the rear wheel, remove the brake drum and

ator inside the vehicle.

shoes.

15. Adjust the rear brake shoes.

7. Disconnect the cable end from the parking

16. Tighten the adjusting nut until the proper ten-

brake strut lever.

sion is placed on the cable. Adjust the parking brake

8. Compress the retaining strips to remove the

stroke using appropriate method.

cable from the backing plate.

17. Secure all cable retainers,

9. Unfasten any other frame retainers and re-

18. Apply and release the parking brake a number

move the cables.

of times once all adjustments have been made.

be sure to disarm system

befok starting rd-

aairs on the vehicle. To install:

10. The parkinq brake cables mav be color coded 19. With the rear wheels raised, make sure the

oarkino brake is not causina excess draa on the rear

1. Disconnect the negative battery cable.

2. Remove the screws from the center section

and remove the rear part of the console.

*If equipped with SRS, when removing the

floor console,

don’t allow any impact or

shock to the SRS diagnostic unit. to indicate stde. Check the parking brake cables for

wheels: .A

an identification mark.

20. Install the floor consoleand rear seat assem-

11. Install the cable to the rear actuator. Secure in

bly.

place with the parking brake cable clip and retainer

21. Connect the negative battery cable.

spring.

22. Check that the parking brake holds the vehi-

12. Install the brake shoes and drum.

cle on an incline.

Page 357 of 408

BRAKES 9-21

WITH REAR DISC BRAKES

*If equipped with an air bag (SRS system),

be sure to disarm the system before starting

repairs on the vehicle.

1. Disconnect the negative battery cable.

2. Remove the screws from the center section

and remove the rear part of the console.

*If equipped with SRS, when removing the

floor console, don’t allow any impact or

shock to the SRS diagnostic unit.

3. Remove the rear seat cushion.

4. Loosen the cable adjusting nut and discon-

nect the rear brake cables from the actuator.

5. Remove the center cable clamp and grommet.

6. Raise the vehicle and support safely.

7. Remove the parking brake cable clip and re-

tainer spring.

8. Disconnect the cable end from the parking

brake assembly.

9. Unfasten any remaining frame retainers and

remove the cables from the vehicle.

To install: IO. The parking brake cables may be color coded

to indicate side. Check the parking brake cables for

an identification mark.

11. Install the cable to the rear actuator. Secure in

place with the parking brake cable clip and retainer

spring.

12. Position the cable and loosely install the re-

tainers.

13. Reattach the parking brake cables to the actu-

ator inside the vehicle.

14. Tighten the adjusting nut until the proper ten-

sion is placed on the cable. Adjust the parking brake

. stroke using appropriate method.

15. Secure all cable retainers.

16. Apply and release the parking brake a number

of times once all adjustments have been made.

17. With the rear wheels raised, make sure the

parking brake is not causing excess drag on the rear

wheels.

18. Install the floor console and rear seat assem-

bly.

19. Connect the negative battery cable.

20. Check console electrical components for

proper operation.

21. Road test the vehicle and check for proper

brake operation.

22. Check that the parking brake holds the vehi-

cle on an incline.

1990-93 Galant

WITH REAR DRUM BRAKES

1. Disconnect the negative battery cable.

2. Remove the center console as follows:

a. Remove both side cover panels.

b. Remove the shifter knob on manual

transaxle models. Remove the spacer trim piece

on automatic transaxle models.

c. Remove the switch panel/box and remove

the two screws beneath the panel/box.

d. Remove the radio trim panel.

e. Remove the radio and tape player.

f. Remove the console inner panel and re-

move the two screws for beneath the panel.

g. Remove the remaining screws from the

sides of the console. h. Remove the console assembly from the ve-

hicle.

3. While pressing downward on the front of the

rear seat cushion, release the locking levers and re-

move the seat cushion.

4. Loosen the cable adjustment at the cable

equalizer.

5. Remove the center cable clamp and grommet.

6. Raise the vehicle and support safely.

7. At the rear wheel, remove the brake drum and

shoes.

8. Disconnect the cable end from the parking

brake strut lever.

9. Remove the snapring securing the cable to

the backing plate.

IO. Unfasten any other frame retainers and re-

move the cables.

To install:

*The parking brake cables may be color

coded to indicate side. Check the parking

brake cables for an identification mark.

11. Install the cable to the rear actuator. Secure in

place with the parking brake cable clip and snapring.

12. Install the brake shoes and drum.

13. Position the cable and loosely install the re-

tainers

14. Reattach the parking brake cables to the actu-

ator inside the vehicle. Tighten the adjusting nut until

the proper tension is placed on the cable. Adjust the

parking brake stroke using appropriate method.

15. Secure all cable retainers.

16. Apply and release the parking brake a number

of times once all adjustments have been made.

17. Adjust the rear brakes and parking brake ca-

bles.

18. Check the rear wheels to confirm that the rear

brakes are not dragging.

19. Install the center console and rear seat cush-

ion.

20. Connect the negative battery cable.

21. Check console electrical components for

proper operation.

22. Check that the parking brake holds the vehi-

cle on an incline.

WITH REAR DISC BRAKES

1. Disconnect the negative battery cable.

2. Remove the center console as follows:

a. Remove both side cover panels.

b. Remove the shifter knob on manual

transaxle models. Remove the spacer trim piece

on automatic transaxle models.

c. Remove the switch panel/box and remove

the two screws beneath the panel/box.

d. Remove the radio trim panel.

e. Remove the radio and tape player.

f. Remove the console inner panel and re-

move the two screws from beneath the panel.

g. Remove the remaining screws from the

sides of the console.

h. Remove the console assembly from the ve-

hicle.

3. While pressing downward on the front of the

rear seat cushion, release the locking levers and re-

move the seat cushion.

4. Loosen the cable adjusting nut and discon-

nect the rear brake cables from the actuator.

5. Remove the center cable clamp and grommet.

6. Raise the vehicle and support it safely. 7. At the rear caliper assembly, remove the

parking brake cable clip and retainer spring.

8. Disconnect the cable end from the caliper.

9. Unfasten any remaining frame retainers and

remove the cables from the vehicle.

To install:

*The parking brake cables may be color

coded to indicate side. Check the parking

brake cables for an identification mark.

IO. Connect the cable to the actuator at the brake

caliper. Secure in place with the parking brake cable

clip and retainer spring.

11. Position the cable and loosely install the re-

tainers.

12. Reattach the parking brake cables to the actu-

ator inside the vehicle. Tighten the adjusting nut until

the proper tension is placed on the cable.

13. Adjust the parking brake stroke using appro-

priate method.

14. Secure all cable retainers.

15. Apply and release the parking brake a number

of times once all adjustments have been made.

16. With the rear wheels raised, make sure the

parking brake is not causing excess drag on the rear

wheels.

17. Install the floor console assembly and rear

seat cushion.

18. Connect the negative battery cable.

19. Check console electrical components for

proper operation.

20. Road test the vehicle and check for proper

brake operation.

21. Check that the parking brake holds the vehi-

cle on an incline.

1994-00 Galant

WITH REAR DRUM BRAKES

1. Disconnect the negative battery cable.

The SRS control unit is mounted beneath the

center console. Use care when working with

the center console assembly not to impact or

shock the control unit.

2. Remove the center floor console assembly as

follows:

a. Remove the shifter knob on models

equipped with a manual transaxle.

b. Remove the shifter trim panel.

c. Remove the center instrument panel.

d. Remove the panel box from the console

assembly.

e. Remove the two screws from the center of

the console.

f. Remove the four side panel screws and re-

move the console from the vehicle.

3. Loosen the cable adjuster nut, then remove

the parking brake cable by pulling it from the passen-

ger compartment.

4. Raise the vehicle and support safely.

5. At the rear wheel, remove the brake drum and

shoes.

6. Disconnect the cable end from the parking

brake strut lever. Compress the retaining strips to re-

move the cable from the backing plate.

Page 358 of 408

--7 9-22

BRAKES

7. Unfasten any other frame retainers and re-

move the cables.

To install: 8. Install the cable to the rear actuator. Secure in ’

place with the parking brake cable clip and retainer

spring. b. Remove the shifter trim panel.

c. Remove the center instrument panel.

d. Remove the panel box from the console

assembly.

e. Remove the two screws from the center of

the console.

9. Install the brake shoes and drum.

10. Position the cable and loosely install the re-

tainers.

Il. Reattach the parking brake cables to the actu-

ator inside the vehicle.

12. Tighten the adjusting nut until the proper ten-

sion is placed on the cable.

13. Adjust the parking brake stroke using appro-

priate method.

14. Secure all cable retainers. Apply and release

the parking brake a number of times once all adjust-

ments have been made.

15. Assemble the interior components which

were removed.

16. Adjust the rear brakes and parking brake ca-

bles.

17. Connect the negative battery cable.

18. Check the rear wheels to confirm that the rear

brakes are not dragging.

19. Check that the parking brake holds the vehi-

cle on an incline.

WITH REAR DISC BRAKES

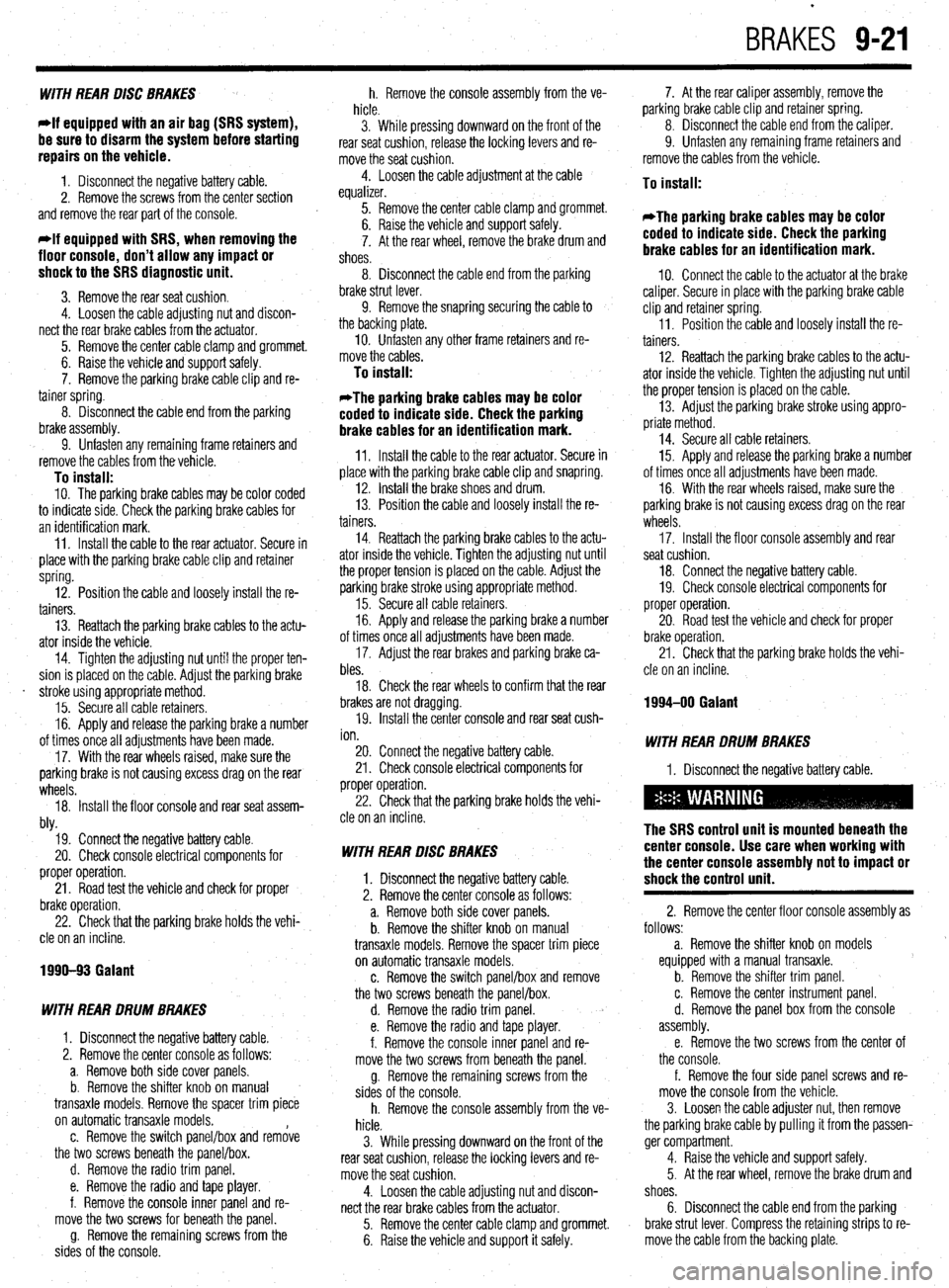

) See Figure 109

Unlike conventional rear disc brake systems, the

parking brake operation is NOT incorporated into the

brake caliper. This system, uses a separate set of

brake shoes, located behind the brake rotor.

1. Disconnect the negative battery cable.

The SRS control unit is mounted beneath the

center console. Use care when working with

17. Secure all cable retainers.

18. Apply and release the parking brake a number

of times once all adjustments have been made.

19. Assemble the interior components which

were removed.

l the center console assembly not to impact or 20. Adjust the parking brake shoes and parking shock the control unit. brake cables.

2. Remove the center floor console assembly as

follows:

a. Remove the shifter knob on models

equipped with a manual transaxle. 21. Connect the negative battery cable.

22. Check the rear wheels to confirm that the rear

brakes are not dragging.

23. Check that the parking brake holds the vehi-

cle on an incline.

8. Stnd return aring

0 Shwhdd-downcup

10. shna hchd-dPwn SpnnQ

11. Shm hold-dcwn pm

12. shoe and lllllnp us*mbly

13.

14 cap

PwkilvJbnko~

93159g24 Fig. 109 Exploded view of parking brake

components (with disc brake rear system)-

1994-95 Galant

f. Remove the four side panel screws and re-

d move the console from the vehicle.

3. Loosen the cable adjuster nut, then remove

the parking brake cable by pulling it from the passen-

ger compartment.

4. Raise the vehicle and support safely.

5. At the rear wheel, remove the brake caliper

and rotor.

6. Remove the parking brake shoes. Refer to the

procedure in this section.

7. Disconnect the cable end from the parking

brake strut lever.

8. Compress the retaining strips to remove the

cable from the backing plate.

9. Unfasten any other frame retainers and re-

move the cables.

To install: IO. Install the cable to the rear actuator. Secure in

place with the parking brake cable clip and retainer

spring.

Il. Install the parking brake shoes.

12. Install the brake rotor and caliper assembly.

13. Position the cable and loosely install the re-

tainers.

14. Reattach the parking brake cables to the actu-

ator inside the vehicle.

15. Tighten the adjusting nut until the proper ten-

sion is placed on the cable.

16. Adjust the parking brake stroke using appro-

priate method.

Diamante

Unlike conventional rear disc brake systems, the

parking brake operation is NOT incorporated into the

brake caliper. This system, uses a separate set of

brake shoes, located behind the brake rotor.

1. Disconnect the negative battery cable.

Work must be started after 90 seconds from

the time the ignition switch is turned to the

LOCK position and the negative battery cable

is disconnected.

*If equipped with an air bag, be sure to dis-

arm it before starting repairs on the vehicle.

2. Remove the center floor console assembly as

follows:

a. Remove the ashtray or console switch

panel from the console assembly.

b. Remove the two screws from the center of

the console. c. Remove the four side panel screws and re-

move the console from the vehicle.

*If equipped with SRS, don’t allow any im-

pact or shock to the SRS diagnostic unit

when removing the floor console.

3. Loosen the cable adjuster nut, then remove

the parking brake cable by pulling it from the passen-

ger compartment.

4. Raise the vehicle and support it safely.

5. At the rear wheel, remove the brake caliper

and rotor.

6. Remove the parking brake shoes.

7. Disconnect the cable end from the parking

brake strut lever.

8. Compress the retaining strips to remove the

cable from the backing plate.

9. Unfasten any other frame retainers and re-

move the cables.

To install: 10. Install the cable to the rear actuator. Secure in

place with the parking brake cable clip and retainer

spring.

11. Install the parking brake shoes.

12. Install the brake rotor and caliper assembly.

13. Position the cable and loosely install the re-

tainers.

14. Reattach the parking brake cables to the actu-

ator inside the vehicle.

15. Tighten the adjusting nut until the proper ten-

sion is placed on the cable.

16. Adjust the parking brake stroke using appro-

priate method.

17. Secure all cable retainers.

18. Apply and release the parking brake a number

of times once all adjustments have been made.

19. Assemble the interior components which

were removed.

20. Adjust the parking brake shoes and parking

brake cables.

21. Connect the negative battery cable.

22. Check the rear wheels to confirm that the rear

brakes are not dragging.

23. Check that the parking brake holds the vehi-

cle on an incline.

ADJUSTMENT

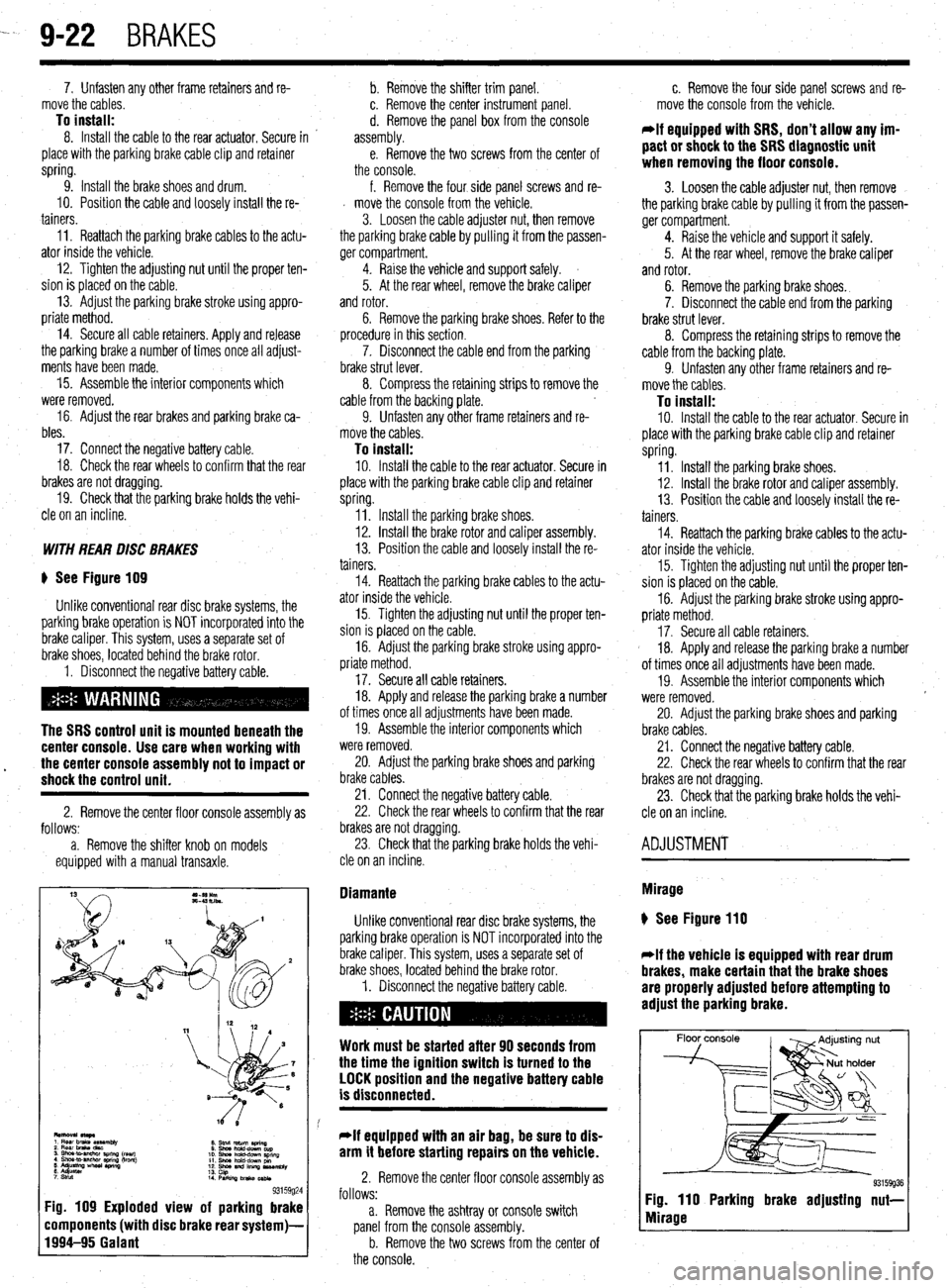

Mirage

) See Figure 110

*If the vehicle is equipped with rear drum

brakes, make certain that the brake shoes

are properly adjusted before attempting to

adjust the parking brake.

Floor console

93159936 Fig. 110 Parking brake adjusting nut-

Mirage

Page 365 of 408

BRAKES 9-29

8. Reinstall the sensor harness with its clamps

and bolts.

9. Reconnect the speed sensor connector.

IO. Install the fender splash shield.

11. Reinstall the tire and wheel, safely lower the

vehicle, and reconnect the negative battery cable. To install: 7. Install the speed sensor and torque to 9 ft.

Ibs. (12 Nm).

8. Install the clips holding the sensor harness.

9. Connect the speed sensor connector.

IO. Connect the negative battery cable.

REAR REAR

) See Figure 131 and 132

1. Disconnect the negative battery cable. Wait at

least 90 seconds before performing any work.

2. Raise and safely support the vehicle. Remove

the necessary tire and wheel assembly.

3. Detach the ABS speed sensor connector.

4. Remove the sensor harness clamp bolts and

clamps.

I) See Figure 133

1. Disconnect the negative battery cable.

5. Remove the ABS speed sensor mounting bolt

and the sensor.

Work must be started after 90 seconds from

the time the ignition switch is turned to the

LOCK position and the negative battery cable

is disconnected.

To install:

6. Install the ABS speed sensor with its mounting

bolt.

*The clearance between the wheel speed

sensor and the rotor’s toothed surface is not

adjustable, but measure the distance be-

tween the sensor installation surface and the

rotor’s toothed surface. Standard value is:

1.11-l .I2 in. (28.2-28.4mm). If not within

specifications, replace the speed sensor or

the toothed rotor.

2. Raise and safely support the vehicle.

3. Detach the speed sensor connector.

4. Remove the clips holding the sensor harness.

5. On AWD models, remove the cable band.

6. Remove the mounting bolt and the speed

sensor with the O-ring.

To install: 7. Install the speed sensor with the O-ring and

torque to 9 ft. Ibs. (12 Nm).

8. Install the clips holding the sensor harness.

9. Install the cable band.

10. Install the sensor wire harness and connect

the connector.

7. Reinstall the sensor harness with its clamps

and bolts.

8. Reconnect the speed sensor connector.

9. Reinstall the tire and wheel, safely lower the

vehicle, and reconnect the negative battery cable.

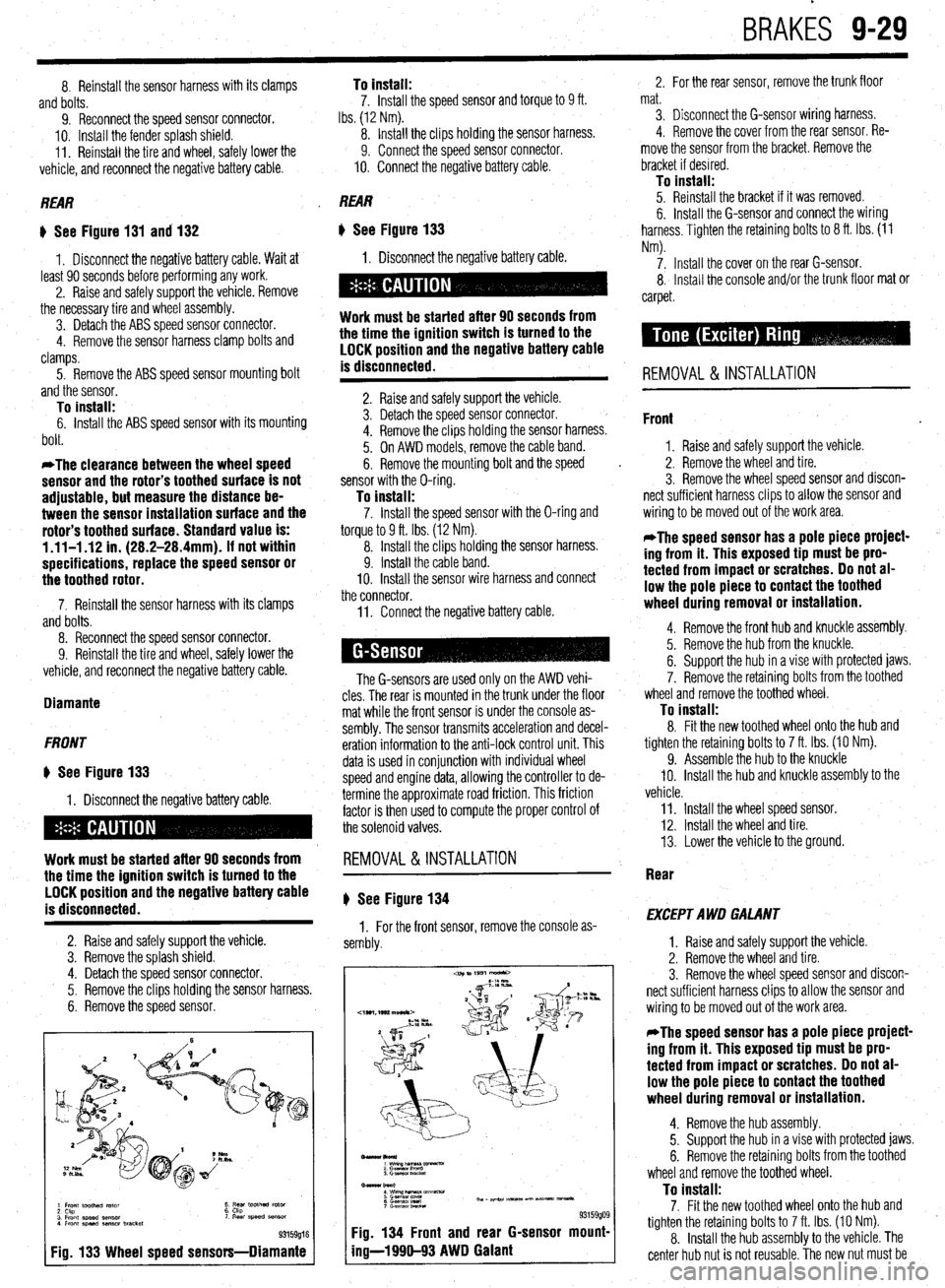

Diamante

FRONT

* See Figure 133

1. Disconnect the negative battery cable.

Work must be started after 90 seconds from

the time the ignition switch is turned to the

LOCK position and the negative battery cable

is disconnected.

2. Raise and safely support the vehicle.

3. Remove the splash shield.

4. Detach the speed sensor connector.

5. Remove the clips holding the sensor harness.

6. Remove the speed sensor.

1 Front toothed rotor

2 Ckp

3 Front speed sensor

4 Front speed aenmr bracket t ;5’ toothed rotor ‘I Rear speed SB"SO,

93159016

Fig. 133 Wheel speed sensors-Diamante

11. Connect the negative battery cable.

The G-sensors are used only on the AWD vehi-

cles. The rear is mounted in the trunk under the floor

mat while the front sensor is under the console as-

sembly. The sensor transmits acceleration and decel-

eration information to the anti-lock control unit. This

data is used in conjunction with individual wheel

speed and engine data, allowing the controller to de-

termine the approximate road friction. This friction

factor is then used to compute the proper control of

the solenoid valves.

REMOVAL&INSTALLATION

# See Figure 134

1. For the front sensor, remove the console as-

sembly.

-lkol*)

1 wimp--vx

2 Gasnan I‘m”0

3. Gmwor LmcM

Bmar burl

: wwzh&T&m~mm-

6 G.smsol Ired Th, - ape.24 m-5 un Nt- vmsa*.

7 c-.elwnbRcta

93159909 Fig. 134 Front and rear G-sensor mount-

ing-l 990-93 AWD Galant

2. For the rear sensor, remove the trunk floor

mat.

3. Disconnect the G-sensor wiring harness.

4. Remove the cover from the rear sensor. Re-

move the sensor from the bracket. Remove the

bracket if desired.

To install: 5. Reinstall the bracket if it was removed.

6. Install the G-sensor and connect the wiring

harness. Tighten the retaining bolts to 8 ft. Ibs. (11

Nm).

7. Install the cover on the rear G-sensor.

8, Install the console and/or the trunk floor mat or

carpet.

REMOVAL & INSTALLATION

Front

1. Raise and safely support the vehicle.

2. Remove the wheel and tire.

3. Remove the wheel speed sensor and discon-

nect sufficient harness clips to allow the sensor and

wiring to be moved out of the work area.

*The speed sensor has a pole piece project-

ing from it. This exposed tip must be pro-

tected from impact or scratches. Do not al-

low the pole piece to contact the toothed

wheel during removal or installation.

4. Remove the front hub and knuckle assembly.

5. Remove the hub from the knuckle.

6. Support the hub in a vise with protected jaws.

7. Remove the retaining bolts from the toothed

wheel and remove the toothed wheel.

To install: 8. Fit the new toothed wheel onto the hub and

tighten the retaining bolts to 7 ft. Ibs. (10 Nm).

9. Assemble the hub to the knuckle

IO. Install the hub and knuckle assembly to the

vehicle.

11. Install the wheel speed sensor.

12. Install the wheel and tire.

13. Lower the vehicle to the ground.

Rear

EXCEPT AWD GALANT

1. Raise and safely support the vehicle.

2. Remove the wheel and tire.

3. Remove the wheel speed sensor and discon-

nect sufficient harness clips to allow the sensor and

wiring to be moved out of the work area.

*The speed sensor has a pole piece project-

ing from it. This exposed tip must be pro-

tected from impact or scratches. Do not al-

low the pole piece to contact the toothed

wheel during removal or installation.

4. Remove the hub assembly.

5. Support the hub in a vise with protected jaws.

6. Remove the retaining bolts from the toothed

wheel and remove the toothed wheel.

To install: 7. Fit the new toothed wheel onto the hub and

tighten the retaining bolts to 7 ft. Ibs. (10 Nm).

8. Install the hub assembly to the vehicle. The

center hub nut is not reusable. The new nut must be

Page 375 of 408

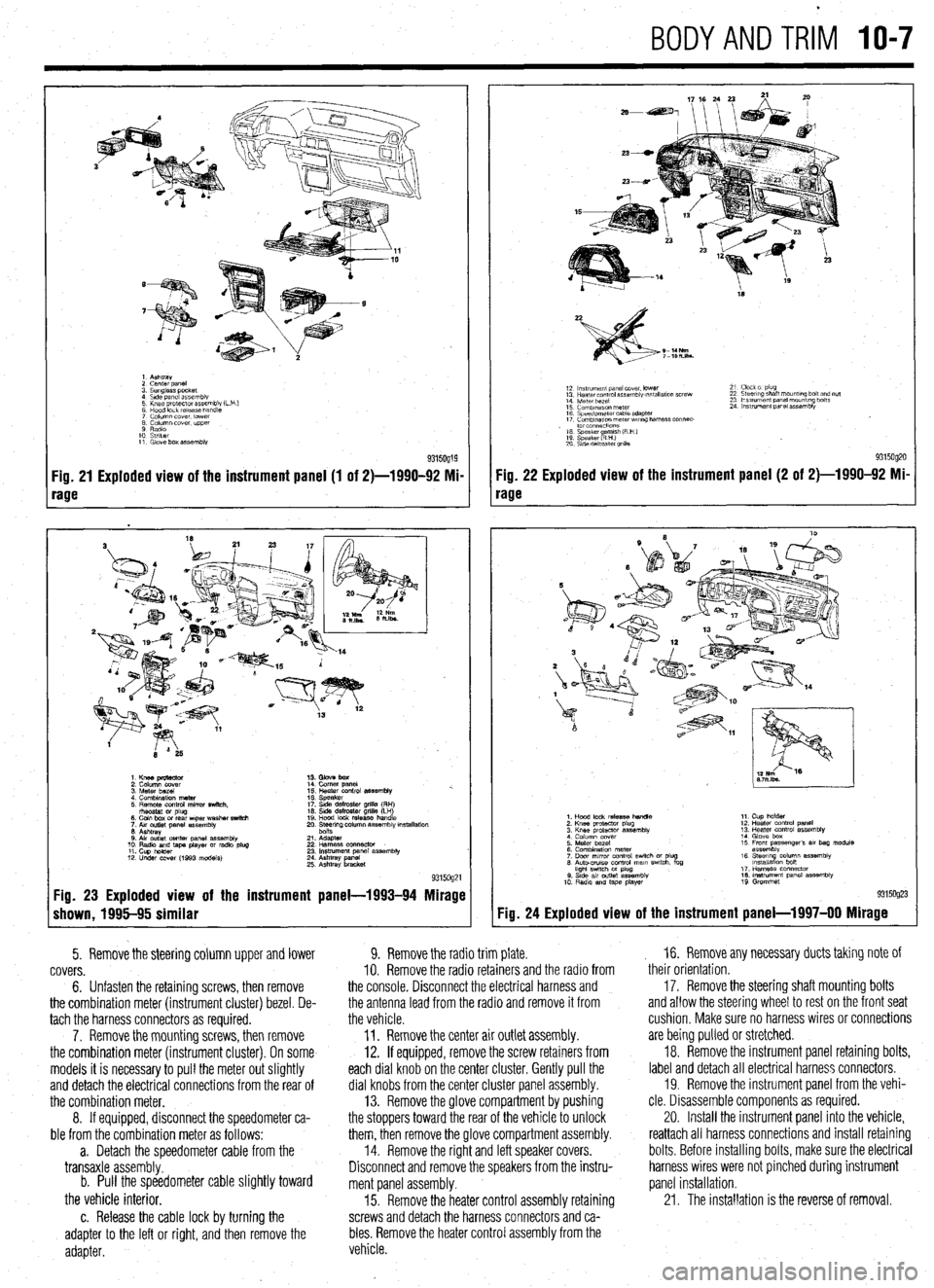

BODYANDTRIM IO-7

1. Ashtray

2 cenrer DaneI

3. Sunglass pocket

4 Side panel assembly

5 Knee protector assembly (L

6 Hood lock release handle

7 Column cover. lower

8 Column cover. upper

9 Radio

10 Striker

11. Glove box assembly

Fig. 21 Exploded view of the instrument panel (1 of 2)-1990-92 Mi-

rage

1. Knee pmtector

2. Column cover

3. Meter bezel

4. Combination meter

5. Remote control mirror switch.

rhsostat or plug

6. Coin box or rear wper washer switch

7. Aw outlet panel assembly

6. Ashtray

0. Air outlet center panel assembly

10. Radio and tape player or radio plug

11. Cup holder

12. Under COW (1993 models) 14. Comer panel

15. Heater control assembly %.

16. Speaker

17. Side defroster grille (RH)

16. Side defroster grille (LH)

19. Hood lock release handle

20. Ee$ng column assembly mstallation

21. Adapter

22 Harness oonnector

23. Instrument panel assembly

24. Ashtray panel

25. Ashtray bracket

9315og21 Fig. 23 Exploded view of the instrument panel-1993-94 Mirage

shown, 1995-95 similar

5. Remove the steering column upper and lower

covers.

6. Unfasten the retaining screws, then remove

the combination meter (instrument cluster) bezel. De-

tach the harness connectors as required.

7. Remove the mounting screws, then remove

the combination meter (instrument cluster). On some

models it is necessary to pull the meter out slightly

and detach the electrical connections from the rear of

the combination meter.

8. If equipped, disconnect the speedometer ca-

ble from the combination meter as follows:

a. Detach the speedometer cable from the

transaxle assembly.

b. Pull the speedometer cable slightly toward

the vehicle interior.

c. Release the cable lock by turning the

adapter to the left or right, and then remove the

adapter.

18

S-14Nm

7-lOh.lbs.

12 ln~v~rnent panel cover. lower

13 Hearer control assembly w,tallatlon screw

14 Meter bezel

15 Combination meter

16 Speedometer cable adapter

17 Comblnawn meterwr~ng harness connec-

. to1 co”“ectlo”s

16 Speaker amlsh (R H )

19 Speaker RHI e

20 S\de defroster grllla 21 Clock 01 plug

22 Steering shaft mount,ng bolt and nut

23 Ins!rument panel mounting bolts

24 Instrument panel assembly

9315og20 Fig. 22 Exploded view of the instrument panel (2 of 2)-1990-92 Mi-

rage

Fig. 24

1. Hood lock release handle

2. Knee protactor plug

3. Knee protector assembly

4 Column cover

5. Meter bezel

6. Combination meter

7. Door mrror control swich or plug

6. Auto-CNISO control mam swtch. fog

hght swtch M plug

0. Stde av outlet assembly

10 Radio and tape player 11. Cup holder

12. Heater control panel

13. Heater control assembly

14. Glove box

15 Front passenger’s 81, bag module

assembly

16. Steerq column assembly

lnstallatlon bon

17. Harness connector

16. Instrument panel assembly

19 Grommet

Exploded view of the instrument panel-l 997-00 Mirage

9. Remove the radio trim plate.

IO. Remove the radio retainers and the radio from

the console. Disconnect the electrical harness and

the antenna lead from the radio and remove it from

the vehicle.

11. Remove the center air outlet assembly.

12. If equipped, remove the screw retainers from

each dial knob on the center cluster. Gently pull the

dial knobs from the center cluster panel assembly.

13. Remove the glove compartment by pushing

the stoppers toward the rear of the vehicle to unlock

them, then remove the glove compartment assembly.

14. Remove the right and left speaker covers.

Disconnect and remove the speakers from the instru-

ment panel assembly.

15. Remove the heater control assembly retaining

screws and detach the harness connectors and ca-

bles. Remove the heater control assembly from the

vehicle. , 16. Remove any necessary ducts taking note of

their orientation,

17. Remove the steering shaft mounting bolts

and allow the steering wheel to rest on the front seat

cushion, Make sure no harness wires or connections

are being pulled or stretched.

18. Remove the instrument panel retaining bolts,

label and detach all electrical harness connectors.

19. Remove the instrument panel from the vehi-

cle. Disassemble components as required.

20. Install the instrument panel into the vehicle,

reattach all harness connections and install retaining

bolts. Before installing bolts, make sure the electrical

harness wires were not pinched during instrument

panel installation.

21. The installation is the reverse of removal.

Page 376 of 408

IO-8 BODYANDTRIM

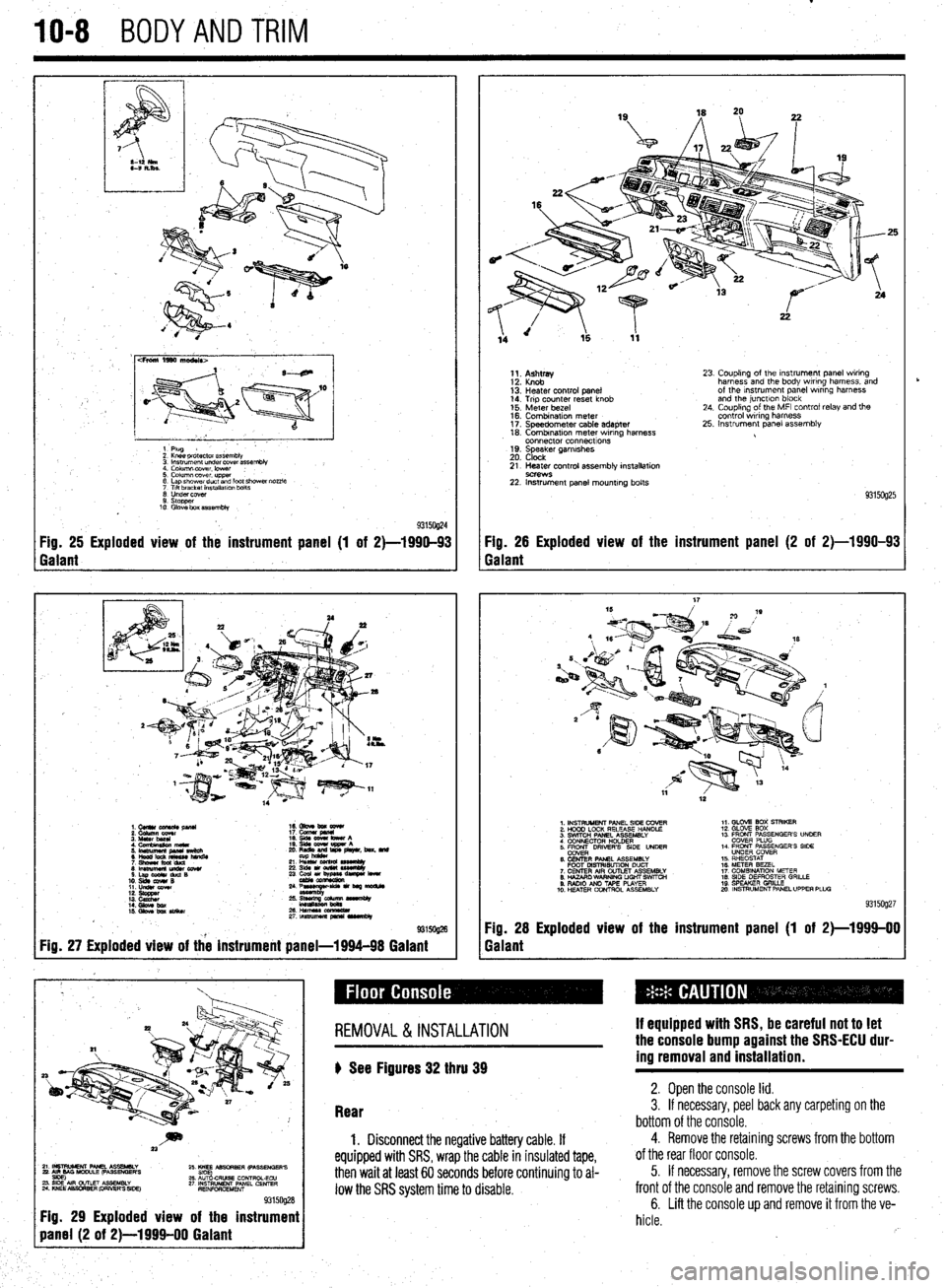

cFroni 1990 ma&Is>

1 Plug

2 Knee pr&ctor assembb

3 lnsuumen~ under covet assembly

4. Column lxwer. lower :

5. Column cover upper

6 Lap shower duct and foot shcwai nozzle

7 Ttlt bracket installalm bolts

0 Undercover

9. stopper

10 Glove box assembly

93150@4 Fig. 25 Exploded view of the instrument panel (1 of 2)-1990-93 Fig. 26 Exploded view of the instrument panel (2 of 2)-1990-93

Galant Galant

1.CUllUCU+RC&pllU 16. Gbve bm eewr

i: iiiikz!!T 17. cucw gmnl

4. Cfnnbinuion meta 19. qds cww bww A

5 ‘~fiJzg%L L: ,“zr&, beat. md

21 L% sssemuy

8lmwmemu&cowr 236&1ou(W~

S.LapOdrduQB

10. slds cw4# B 23 ~u,~e-

11. LIdsI corn

::: s%ZZ

14. Gbw bx / ;:+q-=:-

kmasa

IS. Gkw ba SIiikw 2&HWSSCCl!ZL

2rtnsmlmuapr*lrvrnbly

@ma

Fig. 27 Exploded view of the instrument panel-1994-98 Galant

1;. p;;w

13: Heater control panel

14. Trip counter reset knob

15. Meter bezel

16. Combination meter

17. Speedometer cable adapter

18. Combrnatron meter wiring harness

connector connecttons

19. Speaker garnrshes

20. Clock 23. Coupling of the Instrument panel wiring

harness and the body wiring harness, and

of the Instrument panel wrring harness

and the junctlon block

24. Coupling of the MFI control relay and the

control wiring harness

25. Instrument panel assembly

21. Heater control assembly installation

9C?WS 22. Instrument panel mounting bolts

93150925

1. INSTRUMENT PANEL SIDE COVER

2. HOOD LOCK RELEASE HANDLE

3. SWITCH PANEL ASSEMBLY

4 CONNECTOR H+DER

5. ER DRIVERS SIDE UNDER

6. CENTER PANEL ASSEMBLY

FOOT MSTRISUTION DUCT

7. CENTER AIR OUTLET ASSEMBLY

8. HAZARO WARNING LIGHT SWfTCti

9. RADIO AN0 TAPE PLAYER

10. H!ZATER CONTROL ASSEMBLY 1,. GLOV2 BOX STRIKER

12. GLOVE SOX

13 FRONT PASSENGER’S UNOER

COVER PLUG

14. FRONT PASSENGER’S SIDE

UNDER COVER

15. RHEOSTAT

16. METER BEZEL

17. COMBINATION METER

18. SIDE DEFROSTER GRILLE

19 SPEAKER GRILLE

mo. INSTRUMENT PANEL UPPER PLUG

93159927

Fig. 28 Exploded view of the instrument panel (1 of 2)-1999-00

Galant

~~~~~~~~~

Fig. 29 Exploded view of the instrument

REMOVAL &INSTALLATION

) See Figures 32 thru 39 If equipped with SRS, be careful not to let

the console bump against the SRS-ECU dur-

ing removal and installation.

Rear 2. Open the console lid. 3. If necessary, peel back any carpeting on the

bottom of the console.

1. Disconnect the negative battery cable. If

equipped with SRS, wrap the cable in insulated tape,

then wait at least 60 seconds before continuing to al-

low the SRS system time to disable.

4. Remove the retaining screws from the bottom

of the rear floor console.

5. If necessary, remove the screw covers from the

front of the console and remove the retaining screws.

6. Lift the console up and remove it from the ve-

hicle.

rb

Page 377 of 408

c BODYANDTRi'l IO-9

:: k% protector assembly

3. Knee protector support bracket

4. Column cover

5 Glove box striker

6 Glove box and glove box outer case

7 Under cover mstallatmn screw

8. Audio panel

9 Radio and tape player

10 Heater control panel

assembly 11 Cup holder

12. Speaker

13 Meter bezel

14 Combination meter

15 Speeoometer cable adapter

16 %&rrng column assembly rnstallatioh

17 Harness connector

18. Glove box kght swatch

19. Instrument panel assembly

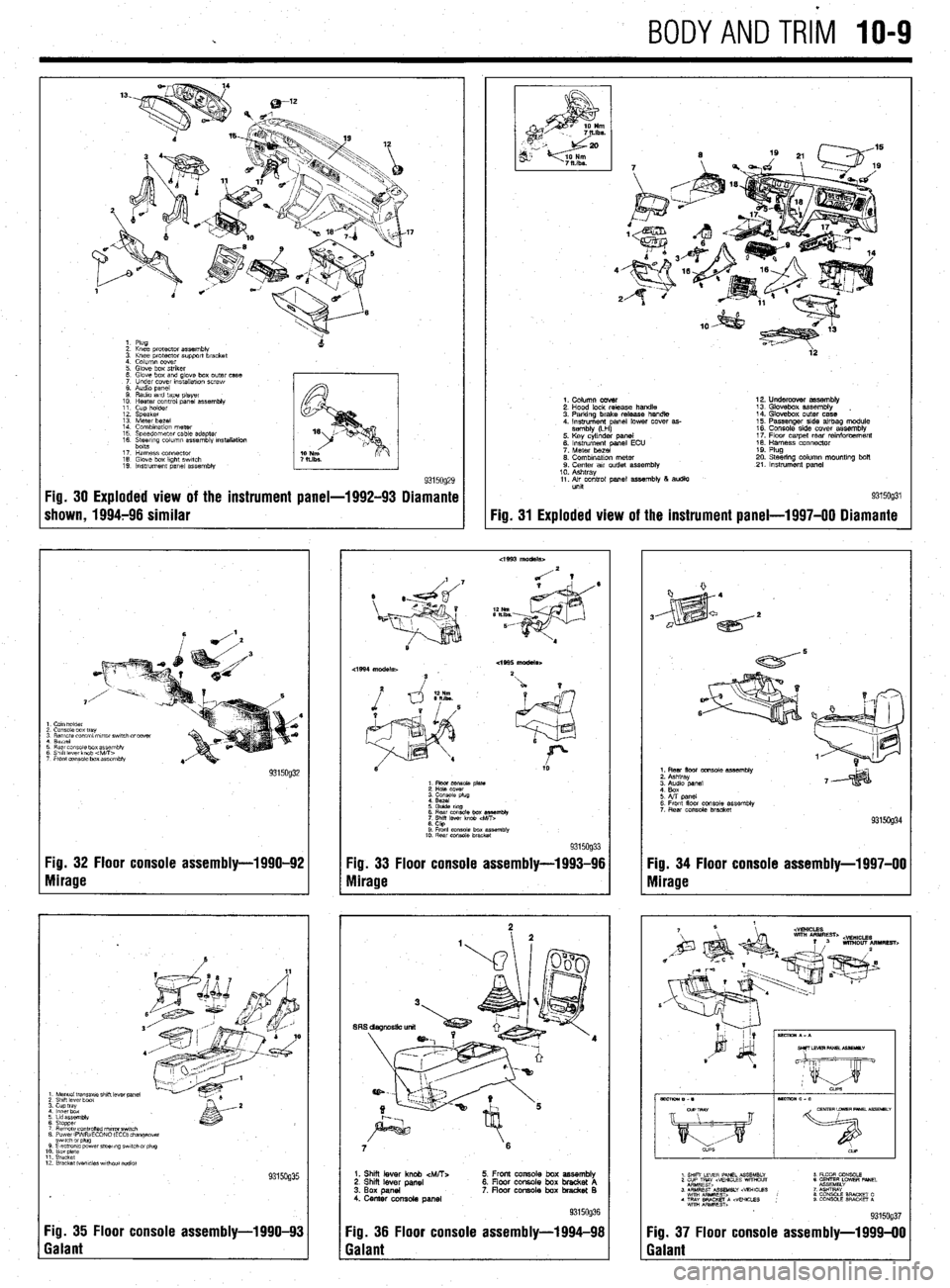

9315og29 Fig. 30 Exploded view of the instrument panel-1992-93 Diamante

shown, 1994796 similar

I Cam holder

2 Console box tray

3 Remote control mrror swatch drcover

1 Berrel

3 Rear cms~ie box assembly

3 Shift lever knob 4vitT>

7 Front eonsale box assembly

Fig. 32 Floor console assembly-1990-92

Yg. 33 Floor console assembly-1993-96

Nlirage

Mirage

1 Manual tmnsaxle shrft lever panel 2 Shrft lever boat 3. cup tray 4 lnnerbdx

6 Lrd assembly

6 Stopper 7 Remote cO”trOned nl,rrorSwl,Ch 8 PowerlFVWECONO (EC01 changeover

12 Bracket Wvcles wrthout addlo)

Fig. 35 Floor console assembly-l 990-93

Galant

4’

2

ia

9315og31 Fig. 31

Exploded view of the instrument

panel-l 997-00 Diamante

1. Column cover

2. Hood lock release handle

3. Parking brake release handle

4. Instrument anal lower cover as-

sembly (LH

P 5. Key cylinder panel

6. instrument panel ECU

7. Meter bezel

0. Combination meter 9. Center air outlet assembly

10. Ashtray

11. Air control panel assembly 8 audio

unit 12. Undercover assembly

13. Glovebox assembly

14. Glovebox outer case

15. Passenger side airbag module

16. Console side cover assemblv

17. Flow carpet rear rainforcem&t

18. Harness connector

19. Plug

20. Steering column mountlng bolt

21. Instrument panel

6 Rear cmsole box es%mbly

7

Shrff lever knob

6. CtQ 9 Front console box assembfk

10. Rear console bracket 9315og33

7 6

1. Shii lever knob &ATT:.

2. Shi lever panel

3. Box panel

4. Center console panel 5. Front console box assembly

6. Floor console box bracket A

7. floar console box bradret B

Fig. 36 Floor console assembly-1994-98

Galant

1. Rear floor console assembly

2. Ashtray

6. Front floor console assembly

7 Rear console bracket

Fig. 34 Floor console assembly-1997-00

Mirage

Fig. 37 Floor console assembly-l 999-00

Galant