high beam MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 4 of 408

I-4 GENERALINFORMATIONAND MAINTENANCE

Fig. 12 A screw-in type compression gauge- Fig. 13 A vacuum/pressure tester is neces-

is recommended for compression testing sary for many testing procedures

Fig. 14 Most modern automotive multime-

ters incorporate many helpful features

your workbench. Some useful household items are: a

large turkey baster or siphon, empty coffee cans and

ice trays (to store parts), ball of twine, electrical tape

for wiring, small rolls of colored tape for tagging lines

or hoses, markers and pens, a note pad, golf tees (for

plugging vacuum lines), metal coat hangers or a roll

of mechanic’s wire (to hold things out of the way),

dental pick or similar long, pointed probe, a strong

magnet, and a small mirror (to see into recesses and

under manifolds).

A more advanced set of tools, suitable for tune-up

work, can be drawn up easily. While the tools are

lmvl Fig. 15 Proper information is vital, so at

ways have a Chiiton Total Car Care manua

handy

l Feeler aauoes for valve adiustment

* Timing-light.

The choice of a timing fight should be made

carefully. A light which works on the DC current

supplied by the vehicle’s battery is the best choice;

it should have a xenon tube for brightness. On any

vehicle with an electronic ignition system, a timing

light with an inductive pickup that clamps around

the No. 1 spark plug cable is preferred.

In addition to these basic tools, there are several

other tools and gauges you may find useful. These

include:

l Compression gauge. The screw-in type is

slower to use, but eliminates the possibility of a

fauliy reading due to escaping pressure.

l Manifold vacuum gauge. l 12V test light. l A combination volt/ohmmeter l induction Ammeter. This is used for determin-

ing whether or not there is current in a wire. These

are handy for use if a wire is broken somewhere in a

wiring harness.

As a final note, vou will orobablv find a torque

wrench necessary for all but the most basic work.

The beam type models are perfectly adequate, al-

though the newer click types (breakaway) are easier

to use. The click type torque wrenches tend to be

more expensive. Also keep in mind that all types of

torque wrenches should be periodically checked

and/or recalibrated. You will have to decide for your-

self which better fits your pocketbook, and purpose.

ilightly more sophisticated, they need not be outra-

feously expensive. There are several inexpensive

achldwell meters on the market that are every bit as

Toad for the average mechanic as a professional

nodel. Just be sure that it goes to a least 1200-1500

pm on the tach scale and that it works on 4,6 and 8-

:ylinder engines. The key to these purchases is to

nake them with an eye towards adaptability and wide

ange. A basic list of tune-up tools could include:

l Tach/dwell meter. l Spark plug wrench and gapping tool. Normally, the use of special factory tools is

avoided for repair procedures, since these are not

readily available for the do-it-yourself mechanic.

When it is possible to perform the job with more

commonly available tools, it will be pointed out, but

occasionally, a special tool was designed to perform

a specific function and should be used. Before sub-

stituting another tool, you should be convinced that

neither your safety nor the performance of the vehicle

will be compromised.

Special tools can usually be purchased from an

automotive parts store or from your dealer. In some

cases special tools may be available directly from the

tool manufacturer.

p See Figures 16, 17, 16, and 19

It is virtually impossible to anticipate all of the haz-

ards involved with automotive maintenance and ser-

vice, but care and common sense will prevent most

accidents.

The rules of safety for mechanics range from “don’t

smoke around gasoline,” to “use the proper tool(s) for

the job.” The trick to avoiding injuries is to develop

safe work habits and to take every possible precaution.

Do keep a fire extinguisher and first aid kit

l handy.

Do wear safety glasses or goggles when cut- l ting, drilling, grinding or prying, even if you have

20-20 vision. If you wear glasses for the sake of vi-

sion, wear safety goggles over your regular glasses.

l Do shield your eyes whenever you work around

the battery. Batteries contain sulfuric acid. In case of

contact with the eyes or skin, flush the area with water

or a mixture of water and baking soda, then seek im-

mediate medical attention.

l Do use safety stands (jackstands) for any un-

dervehicle service. Jacks are for raising vehicles;

jackstands are for making sure the vehicle stays

raised until you want it to come down. Whenever the

vehicle is raised, block the wheels remaining on the

ground and set the parking brake.

l Do use adequate ventilation when working

with any chemicals or hazardous materials, Like car-

bon monoxide, the asbestos dust resulting from

some brake lining wear can be hazardous in suffi-

cient quantities.

l Do disconnect the negative battery cable when

working on the electrical system. The secondary ig- nition system contains EXTREMELY HIGH VOLT-

AGE. In some cases it can even exceed 50,000 volts.

l Do follow manufacturer’s directions whenever

working with potentially hazardous materials. Most

chemicals and fluids are poisonous if taken inter-

nally.

l Do properly maintain your tools. Loose ham-

merheads, mushroomed punches and chisels, frayed

or poorly grounded electrical cords, excessively

worn screwdrivers, spread wrenches (open end),

cracked sockets, slipping ratchets, or faulty droplight

sockets can cause accidents.

* Likewise, keep your tools clean; a greasy

wrench can slip off a bolt head, ruining the bolt and

often harming your knuckles in the process.

l Do use the proper size and type of tool for the

job at hand. Do select a wrench or socket that fits the

nut or bolt. The wrench or socket should sit straight,

not cocked.

Page 200 of 408

FUELSYSTiM 5-13

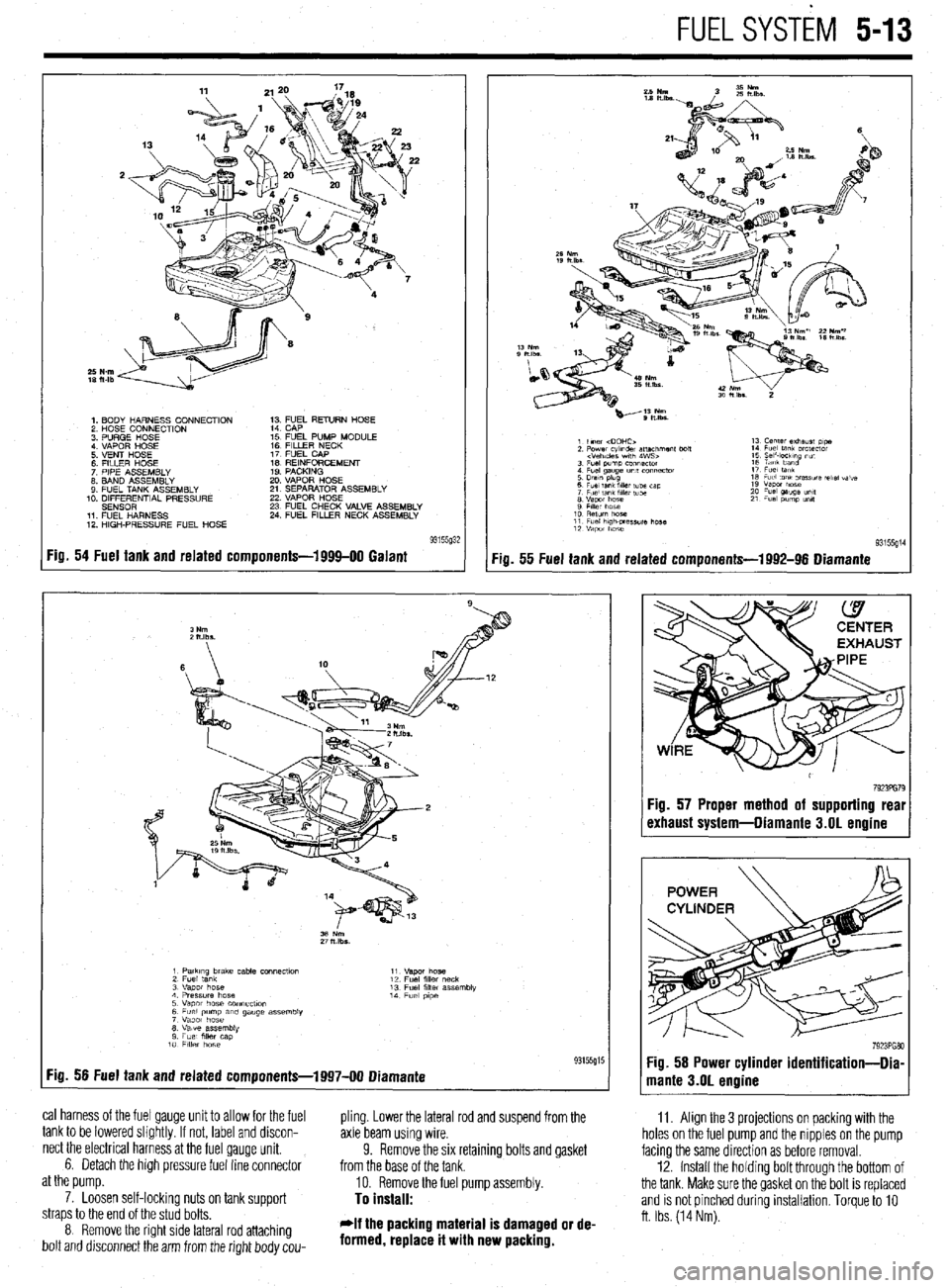

1. BODY HARNESS CONNECTION

2 HOSE CONNECTION

3 PURGE HOSE

4 VAPOR HOSE

5 VENT HOSE

6 FllLER HOSE

7 PIPE ASSEMBLY

8. BAND ASSEMBLY

9 FUEL TANK ASSEMBLY

10. DIFFERENTIAL PRESSURE

SENSOR

11 FUEL HARNESS

12 HIGH-PRESSURE FUEL HOSE 1; ;;JL RETURN HOSE

15 FUEL PUMP MODULE

16 FILLER NECK

17 FUEL CAP

IS REINFORCEMENT

19 PACKING

20 VAPOR HOSE

21 SEPARATOR ASSEMBLY

22 VAPOR HOSE

23 FUEL CHECK VALVE ASSEMBLY

24 FUEL FILLER NECK ASSEMBLY

Fig. 54 Fuel tank and related components-1999-00 Galant

:ia. 55 Fuel tank and related components-1992-96 Diamante

11. Align the 3 projections on packing with the

holes on the fuel pump and the nipples on the pump

facing the same direction as before removal.

12. Install the holdrng bolt through the bottom of

the tank. Make sure the gasket on the bolt is replaced

and is not pinched during installation. Torque to 10

ft. Ibs. (14 Nm).

1 PatkIng brake cable COnneCtlo” 11

2 Fuel tank “.qm hose

12 Fuel fllk, neck

3 “apot hose 13 Fuel filler assembly

4 Pressure hose 14

5 Vapor hose COnneCflOn Fuel p,pe

6 Fuel pump am gauge assembly

7 Vapor hose

8 Valve assembly

9 Fuel mer cap

10 FllkY hose

:ig. 56 Fuel tank and related components-1997-00 Diamante 93155g15

cal harness of the fuel gauge unit to allow for the fuel

pling. Lower the lateral rod and suspend from the

tank to be lowered slightly. If not, label and discon-

axle beam using wire.

nect the electrical harness at the fuel gauge unit.

6. Detach the high pressure fuel line connector 9. Remove the six retaining bolts and gasket

from the base of the tank.

at the pump.

10. Remove the fuel pump assembly.

7. Loosen self-lockinq nuts on tank suooort

To install: straps to the end of the stud bolts.

8 Remove the right side lateral rod attaching

bolt and drsconnect the arm from the right body cou- *If the packing material is damaged or de-

formed, replace it with new packing.

7923PG79 :ig. 57 Proper method of supporting real

rxhaust system-Diamante 3.01 engine

Page 223 of 408

.

6-20 CHASSIS ELECTRICAL

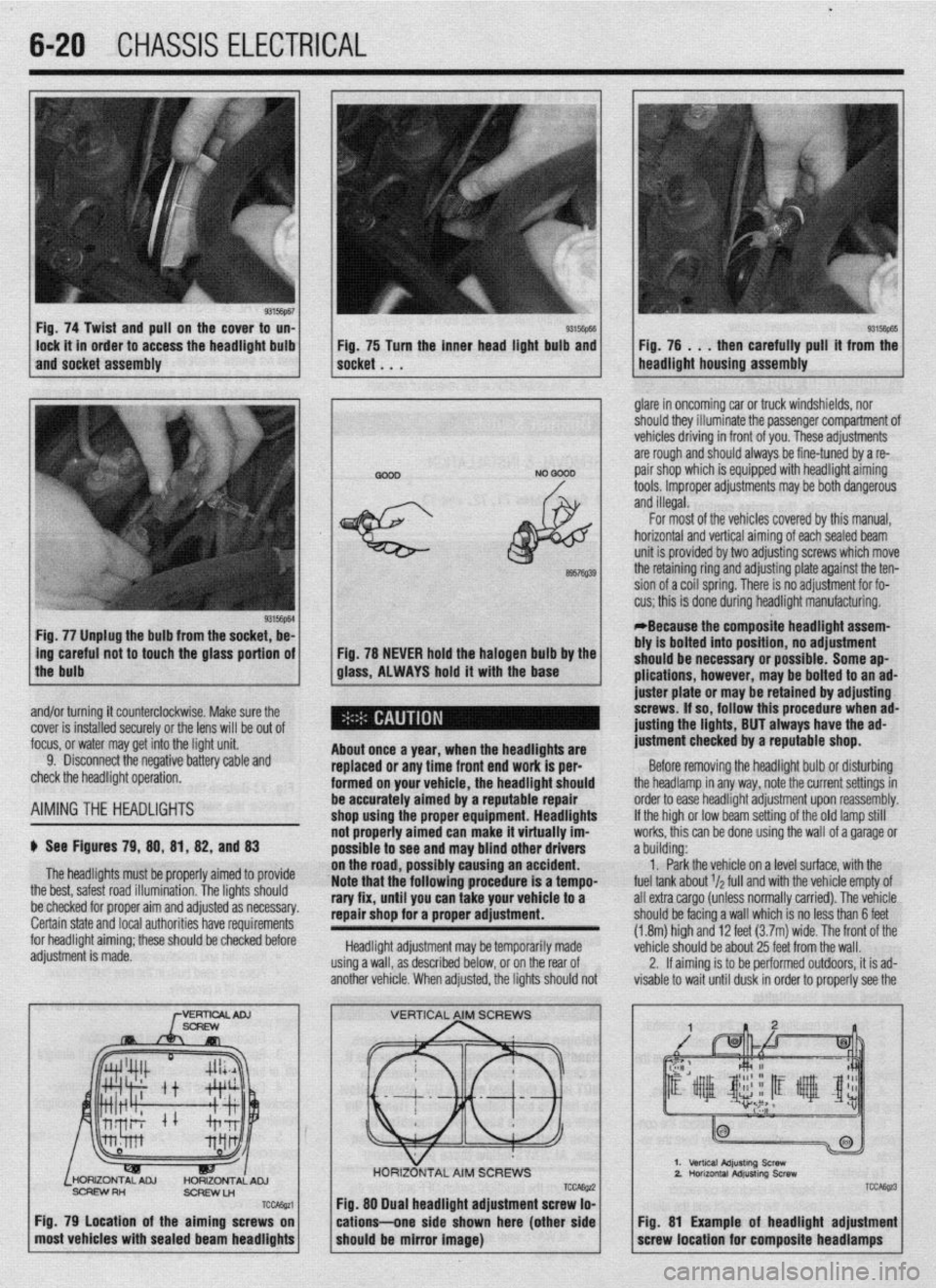

Fig. 74 Twist and pull on the cover to un-

lock it in order to access the headlight bulb

and socket assembly 93Mm Fig, 75 Turn the inner head light bulb and then carefully pull’ it from the

NO 0000 . glare in oncoming car or truck windshields, nor

should they illuminate the passenger compartment of

vehicles driving in front of you. These adjustments

are rough and should always be fine-tuned by a re-

pair shop which is equipped with headlight aiming

tools. Improper adjustments may be both dangerous

and illegal.

Fig. 77 Unplug the bulb from the socket, be-

L

ing careful not to touch the glass portion of

the bulb

I

6957Q39

Fig. 78 NEVER hold the halogen bulb by the

glass, ALWAYS hold it with the base

,

About once a year, when the headllgftts are

replaced or any time front end work is per-

formed on your vehicle, the headlight should

be accurately aimed by a reputable repair

shop uslng the proper equipment. Headlights

not properly aimed can make it virtually im-

possible to see ar Id may blind other drivers

ibly causing an accident.

Note that the’following procedure is a tempo-

rary fix, until you can take your vehicle to a

repair shop for a proper adjustment.

Headlight adjustment may be temporarily made

using a wall, as described below, or on the rear of

another vehicle. When adjusted, the lights should not For most of the vehicles covered by this manual,

horizontal and vertical aiming of eachsealed beam

unit is provided by two adjusting screws which move

the retaining ring and adjusting plate against the ten-

sion of a coil spring. There is no adjustment for fo-

cus; this is done during headlight manufacturing.

*Because the composite headlight assem-

bly is bolted into position, no adjustment

should be necessary or possible. Some ap-

plications, however, may be bolted to an ad-

juster plate or may be retained by adjusting

screws. If so, follow this procedure when ad-

@sting the lights, BUT always have the ad-

justment checked by a reputable shop.

Before removing the headlight bulb or disturbing

the headlamp in any way, note the current settings in

order to ease headlight adjustment upon reassembly.

If the high or low beam setting of the old lamp still

works, this can be done using the wall of a garage or

a building:

1. Park the vehicle on a level surface, with the

fuel tank about r/a full and with the vehicle empty of

all extra cargo (unless normally carried). The vehicle

should be facing a wall which is no less than 6 feet

(1.8m) high and 12 feet (3.7m) wide. The front of the

vehicle should be about 25 feet from the wall.

2. If aiming is to be performed outdoors, it is ad-

visable to wait until dusk in order to properly see the

% and/or turning it counterclockwise. Make sure the

cover is installed securely or the lens will be out of

focus, or water may get into the light unit.

9. Disconnect the negative battery cable and

check the headlight operation.

AIMINGTHE HEADLIGHTS

$ See Figures 79, 88, 81, 82, and 83

The headlights must be proper’ ’ ’ ’

the best, safest road illumination. ’ ’

ly armea IO provrae

The lights should

:.__1__1 __ - -___-_-. on the road, POSSI

be checked for proper aim and adfusreu as IlweSYdly. Certain state and local authorities have requirements

for headlight aiming; these should be checked before

adjustment is made.

SCFEWRH

ScFlEwLn

TCcAssa

Fig. 79 Location of the aiming screws on

most vehicles with sealed beam headlights

TCCAE@ Fig. 88 Dual headlight adjustment screw lo-

cations--one side shown here (other side

should be mirror image)

2.

TCC&z3

Fig. 81 Example of headlight adjustment

screw location for composite headlamps

Page 224 of 408

CHASSIS ELECTRICAL 6-21

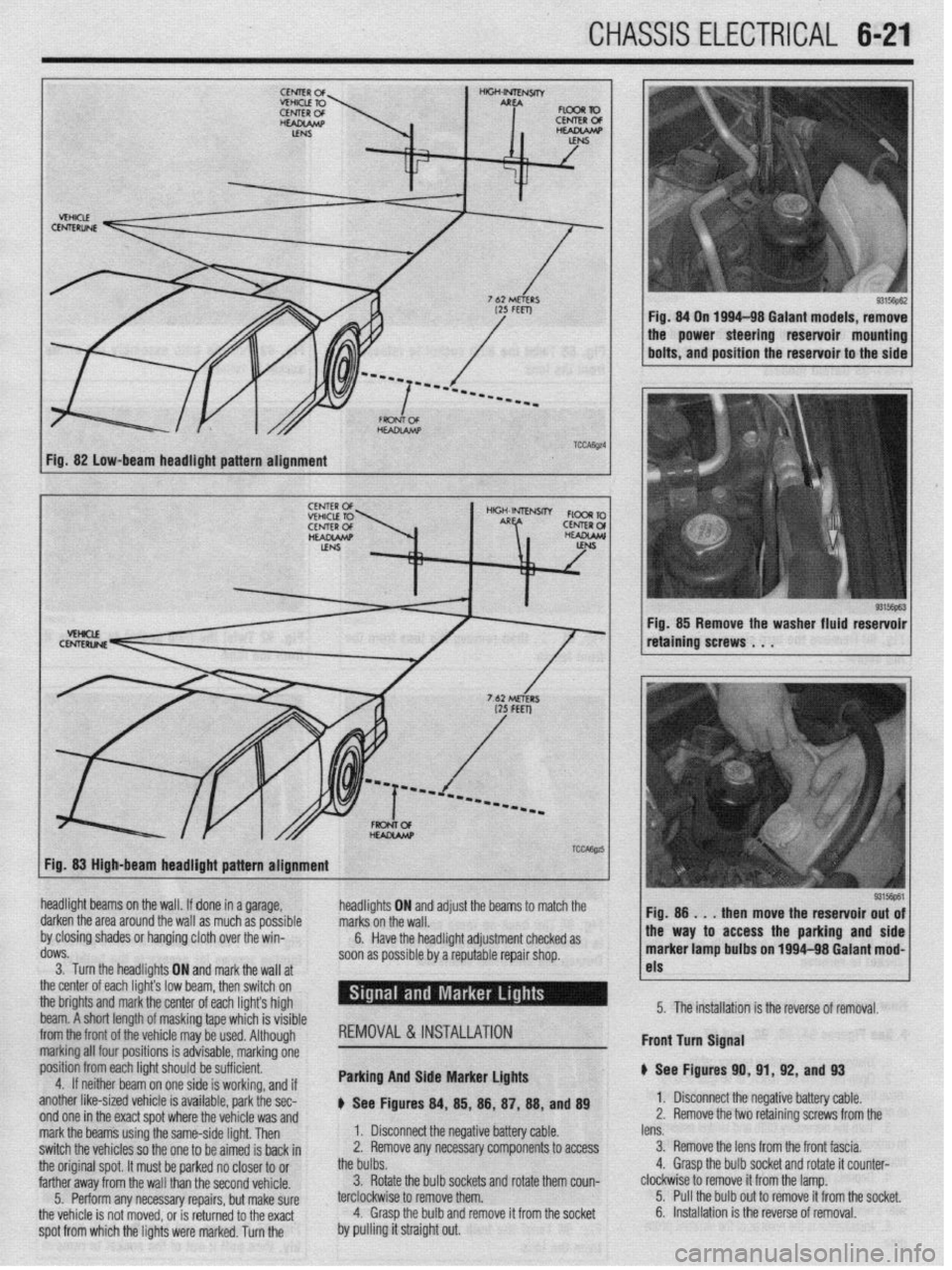

Fig. 82 low-beam headlight pattern alignment

93156pE.3 Fig. 85 Remove the washer fluid reservoir

retaining screws . . .

Fig. 83 High-beam headlight pattern alignment

headlight beams on the wall. If done in a garage,

darken the area around the wall as much as possible

by closing shades or hanging cloth over the win-

dows.

3. Turn the headlights ON and markthe wall at

the center of each light’s low br ram, then switch on

the brights and mark the center of each lights high

beam. A short length of maskin g tape which is visible

from the front of the

whir+ ma . ._..._._ . .._ y be used. Although

marking all four po:

sitions is advisable, marking one

position from each

light should be sufficient.

4. If neithar he; ~. __

Irn on one side is working, and if

another like-sized vehicle is available, park the sec-

nnri nm in the wart cnnt whrw the whirlo um md

headli! jhts ON and adjust the beams to marcn me

I. Disconnect the negative battery cable. marks on the wall.

2. Remove any necessary components to access 6.

the bulbs. Have the headlight adjustment checked as

soon as possible by a reputable repair shop.

3. Rotate the bulb sockets and rotate them coun-

terclockwise to remove them.

4. Grasp the bulb and remove it from the socket REMOVAL&INSTALLATION

Parking And Side Marker Lights

p See Figures 84, 85, 88, 87, 88, and 89 !ss the parking and side

1~ nn loo4-98 Galant mod-

I

1 I-

5315@61

lens. 1 Fio. 8

then move the reservoir out of

3. Remove the lens from the front fascia.

4. Grasp the bulb socket and rotate it counter- marker lamp bult, _.. ._“~-

clockwise to remove it from the lamp.

5. Pull the bulb out to remove it from the socket. 5. The installation is the reverse of removal.

6. Installation is the reverse of removal. Front turn Signal

p See Figures 91

1. Disconnect tl

2. Remove the t 0, 91, 92, and 93

I(? n,-.nn+:.m b.Hnn, nnL.L

z Ill7yau”e “allcly ul”IC. 10 retainino screws from the

spot from which the lights were marked. Turn the . ..I_ WIIY I.8 %,I” V”UVL”fdYI T.II”IU Lll” “VlllUlY ,.UU U,,” mark the beams using the same-side light. Then

switch the vehicles so the one to be aimed is back in

the original spot. It must be parked no closer to or

farther away from the wall than the second vehicle.

5. Perform any necessary repairs, but make sure

the vehicle is not moved, or is returned to the exact

by pulling it straight out.

Page 232 of 408

CHASSIS ELECTRlCiL 6-29

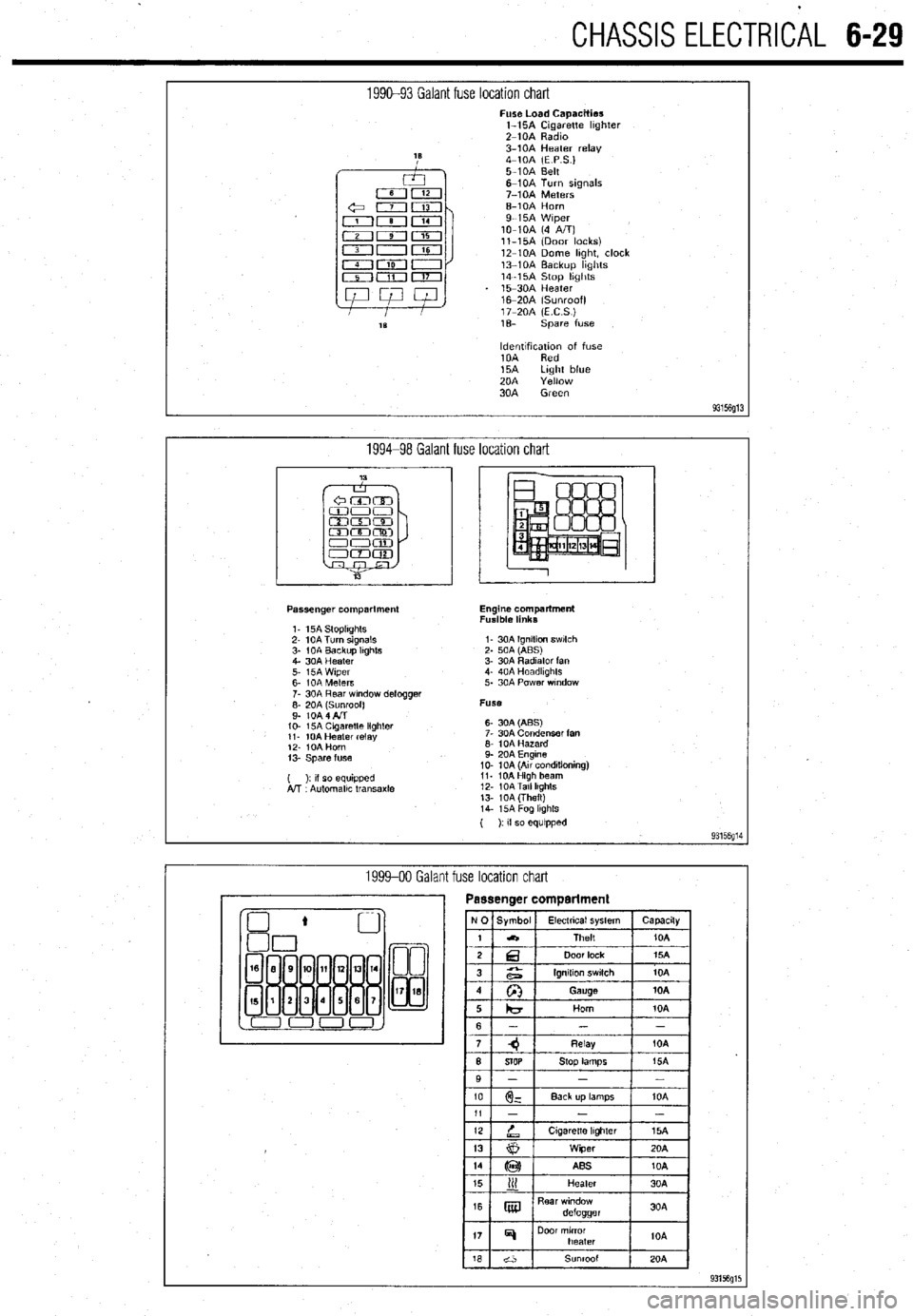

1990-93 Galant fuse location chart Fuse Load Capacities

l-15A Cigarette hghter

Z-10A Radm

3-10A Heater relay

4-10A (E P S.)

5-10A Belt

6-10A Turn signals

7-10A Meters

6-10A Horn

9-15A Wiper

lo-10A (4 A/T)

ll-15A (Door locks)

12-10A Dome hght, clock

13-10A Backup hghts

14-15A Stop hghts

15-30A Heater

16m20A (Sunroof)

17-20A (ECS)

1% spare fuse

ldentlfxation of fuse

10A Red

15A Light blue

20A Yellow

30A Green

93156g13

1994-98 Galant fuse location chart

Passenger compartment

1. 15A StoplIghts

2- 10A Turn signals

3- 1 OA Backup Itghts

4. 30A Heater

5. i5A Wiper

6- IOA Meters

7. 30A Rear wndow defogger

;: fo& fl$oof)

IO- 15A Cagaretle lighler

11. 10A Heater relay

12. IOA Horn

13. Spare fuse

( ): II so equipped

A!T Automallc transaxle Engine compartment

Fusible links

I- 30A Ignition swlch

2. 50A (ABS)

3. 30A Radiator fan

4. 40A Headkghts

5. 30A Power wndow

Fuse

6- 30A (ABS)

7. 30A Condenser fan

6. 10A Hazard

9. 20A Engine

10. 10A (Au conditioning)

11. 10AHigh beam

12. 10ATall lkghts

13. 10A (Theft)

14. i5A Fog lkghls

( ): If so equipped

93156g14

1999-00 Galant fuse location chart

Page 386 of 408

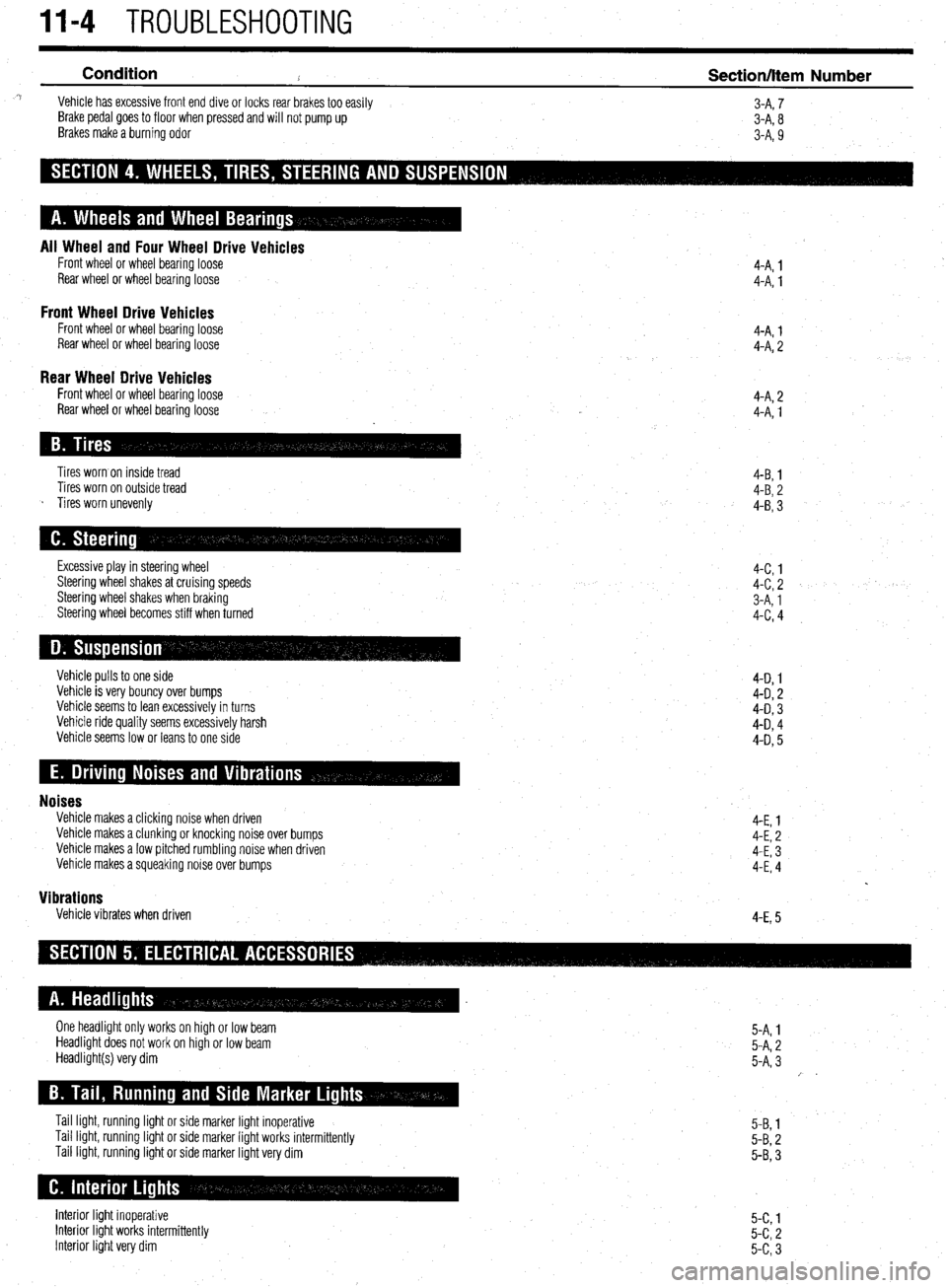

11-4 TROUBLESHOOTING

Condition

2 Section/Item Number ^i Vehicle has excessive front end dive or locks rear brakes too easily

3-A, 7

Brake pedal goes to floor when pressed and will not pump up

3-A, 8

Brakes make a burning odor

3-A, 9

All Wheel and Four Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearingloose

Front Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearing loose 4-A. 1

4-A: 1

4-A, 1

4-A, 2

Rear Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearing loose 4-A, 2

4-A, 1

Tires worn on inside tread

Tires worn on outside tread

s Tires worn unevenly 4-B, 1

4-B, 2

4-B, 3

Excessive play in steering wheel

Steering wheel shakes at cruising speeds

Steering wheel shakes when braking

Steering wheel becomes stiff when turned 4-c, 1

4-c, 2

3-A, 1

4-c, 4

Vehicle pulls to one side

Vehicle is very bouncy over bumps

Vehicle seems to lean excessively in turns

Vehicle ride quality seems excessively harsh

Vehicle seems low or leans to one side 4-D 1

4-D, 2

4-D, 3

4-D, 4

4-D, 5

Noises Vehicle makes a clicking noise when driven

Vehicle makes a clunking or knocking noise over bumps

Vehicle makes a low pitched rumbling noise when driven

Vehicle makes a squeaking noise over bumps

Vibrations Vehicle vibrates when driven 4-E, 1

4-E, 2

4-E, 3

4-E, 4

4-E, 5

One headlight only works on high or low beam

Headlight does not work on high or low beam

Headlight(s) very dim

Tail light, running light or side marker light inoperative

Tail light, running light or side marker light works intermittently

Tail light, running light or side marker light very dim 5-A, 1

5-A, 2

5-A, 3

/ .

5-B, 1

5-B, 2

5-B, 3

Interior light inoperative

Interior light works intermittently

Interior light very dim 5-c, 1

5-c, 2

5-c, 3

Page 395 of 408

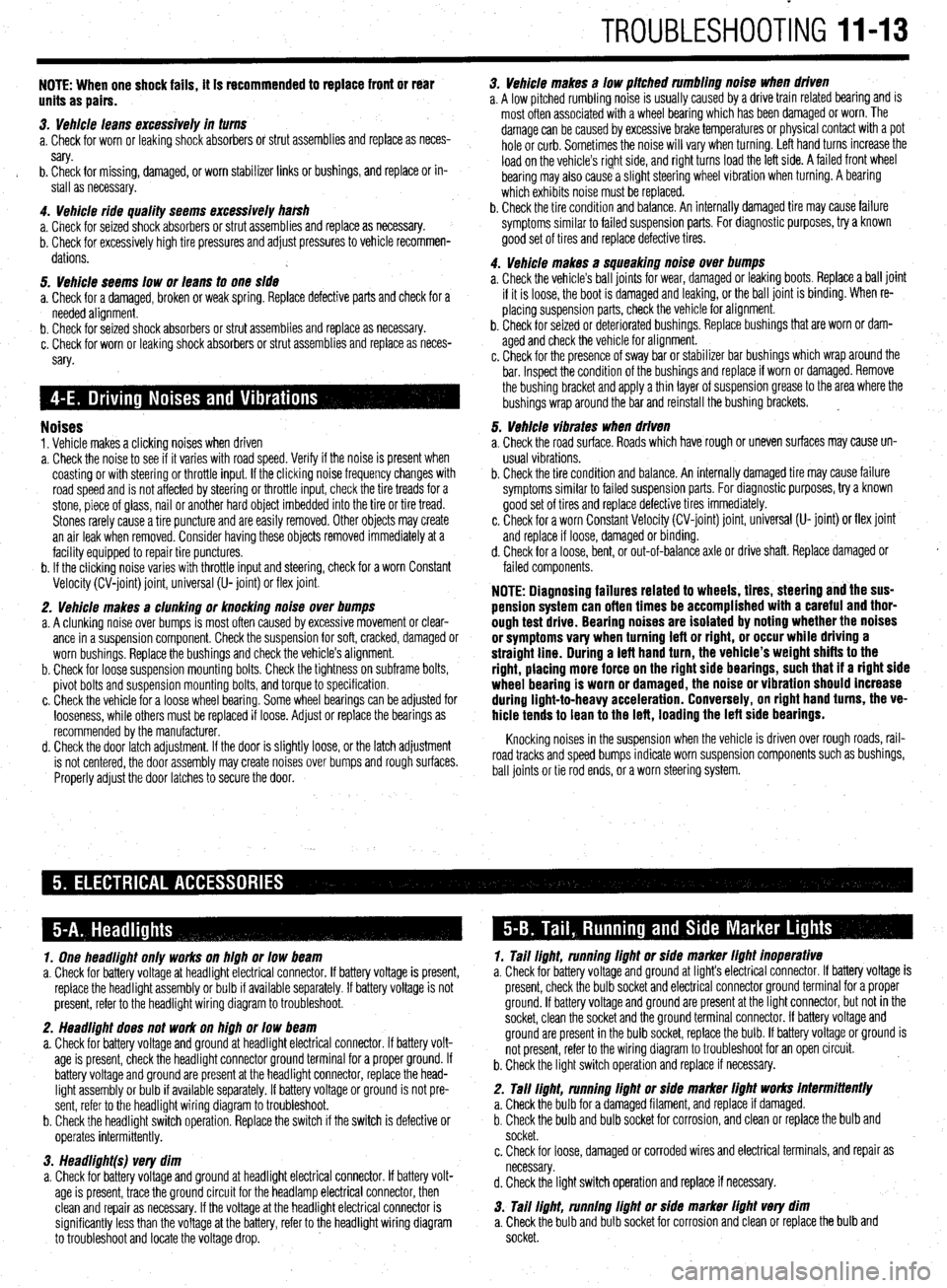

TROUBLESHOOTING 11-13

NOTE: When one shock fails, ft is recommended to replace front or rear

units as pairs.

3. Vehicle leans excessively in turns

a. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

b. Check for missing, damaged, or worn stabilizer links or bushings, and replace or in-

stall as necessary.

4. Vehicle ride quality seems excessively ha&h

a. Check for seized shock absorbers or strut assemblies and replace as necessary.

b. Check for excessively high tire pressures and adjust pressures to vehicle recommen-

dations.

5. Vehicle seems low or leans to one side

a. Check for a damaged, broken or weak spring. Replace defective parts and check for a

needed alignment.

b. Check for seized shock absorbers or strut assemblies and replace as necessary.

c. Check for worn or leaking shock absorbers or strut assemblies and replace as neces-

sary.

Noises 1. Vehicle makes a clicking noises when driven

a. Check the noise to see if it varies with road speed. Verify if the noise is present when

coasting or with steering or throttle input. If the clicking noise frequency changes with

road speed and is not affected by steering or throttle input, check the tire treads for a

stone, piece of glass, nail or another hard object imbedded into the tire or tire tread.

Stones rarely cause a tire puncture and are easily removed. Other objects may create

an air leak when removed. Consider having these objects removed immediately at a

facility equipped to repair tire punctures.

b. If the clicking noise varies with throttle input and steering, check for a worn Constant

Velocity (CV-joint) joint, universal (U- joint) or flex joint.

2. Vehicle makes a clunking or knocking noise over bumps

a. A clunking noise over bumps is most often caused by excessive movement or clear-

ance in a suspension component. Check the suspension for soft, cracked, damaged or

worn bushings. Replace the bushings and check the vehicle’s alignment.

b. Check for loose suspension mounting bolts. Check the tightness on subframe bolts,

pivot bolts and suspension mounting bolts, and torque to specification.

c. Check the vehicle for a loose wheel bearing. Some wheel bearings can be adjusted for

looseness, while others must be replaced if loose. Adjust or replace the bearings as

recommended by the manufacturer.

d. Check the door latch adjustment. If the door is slightly loose, or the latch adjustment

is not centered, the door assembly may create noises over bumps and rough surfaces.

Properly adjust the door latches to secure the door. 3. Vehicle makes a low pitched rumbling noise when driven

a. A low pitched rumbling noise is usually caused by a drive train related bearing and is

most often associated with a wheel bearing which has been damaged or worn. The

damage can be caused by excessive brake temperatures or physical contact with a pot

hole or curb. Sometimes the noise will vary when turning. Left hand turns increase the

load on the vehicle’s right side, and right turns load the left side. A failed front wheel

bearing may also cause a slight steering wheel vibration when turning. A bearing

which exhibits noise must be replaced.

b. Check the tire condition and balance. An internally damaged tire may cause failure

symptoms similar to failed suspension parts. For diagnostic purposes, try a known

good set of tires and replace defective tires.

4. Vehicle makes a squeaking noise over bumps

a. Check the vehicle’s ball joints for wear, damaged or leaking boots. Replace a ball joint

if it is loose, the boot is damaged and leaking, or the ball joint is binding. When re-

placing suspension parts, check the vehicle for alignment.

b. Check for seized or deteriorated bushings. Replace bushings that are worn or dam-

aged and check the vehicle for alignment.

c. Check for the presence of sway bar or stabilizer bar bushings which wrap around the

bar. Inspect the condition of the bushings and replace if worn or damaged. Remove

the bushing bracket and apply a thin layer of suspension grease to the area where the

bushings wrap around the bar and reinstall the bushing brackets. ~

5. Vehicle vibrates when driven

a. Check the road surface. Roads which have rough or uneven surfaces may cause un-

usual vi brations.

b. Check the tire condition and balance. An internally damaged tire may cause failure

symptoms similar to failed suspension parts. For diagnostic purposes, try a known

good set of tires and replace defective tires immediately.

c. Check for a worn Constant Velocity (CV-joint) joint, universal (U- joint) or flex joint

and replace if loose, damaged or binding.

d. Check for a loose, bent, or out-of-balance axle or drive shaft. Replace damaged or

failed components.

NOTE: Diagnosing failures related to wheels, tires, steering and the sus-

pension system can often times be accomplished with a careful and thor-

ough test drive. Bearing noises are isolated by noting whether the noises

or symptoms vary when turning left or right, or occur while driving a

straight line. During a teft hand turn, the vehicle’s weight shifts to the

right, placing more force on the right side bearings, such that if a right side

wheel bearing is worn or damaged, the noise or vibration should increase

during light-to-heavy acceleration. Conversely, on right hand turns, the ve-

hicle tends to lean to the left, loading the left side bearings.

Knocking noises in the suspension when the vehicle is driven over rough roads, rail-

road tracks and speed bumps indicate worn suspension components such as bushings,

ball joints or tie rod ends, or a worn steering system.

1. One headlight only works on high or low beam

a. Check for battery voltage at headlight electrical connector. If battery voltage is present,

replace the headlight assembly or bulb if available separately. If battery voltage is not

present, refer to the headlight wiring diagram to troubleshoot.

2. Headlight does not work on high or low beam

a. Check for battery voltage and ground at headlight electrical connector. If battery volt-

age is present, check the headlight connector ground terminal for a proper ground. If

battery voltage and ground are present at the headlight connector, replace the head-

light assembly or bulb if available separately. If battery voltage or ground is not pre-

sent, refer to the headlight wiring diagram to troubleshoot.

b. Check the headlight switch operation. Replace the switch if the switch is defective or

ooerates intermittentlv. 1. Tail light, running light or side marker light inoperative

a. Check for battery voltage and ground at light’s electrical connector. If battery voltage is

present, check the bulb socket and electrical connector ground terminal for a proper

ground. If battery voltage and ground are present at the light connector, but not in the

socket, clean the socket and the ground terminal connector. If battery voltage and

ground are present in the bulb socket, replace the bulb. If battery voltage or ground is

not present, refer to the wiring diagram to troubleshoot for an open circuit.

b. Check the light switch operation and replace if necessary.

2. Tall light, running light or side marker light works intermittently

a. Check the bulb for a damaged filament, and replace if damaged.

b. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

w 3. Headlight(s) very dim

a. Check for battery voltage and ground at headlight electrical connector. If battery volt-

age is present, trace the ground circuit for the headlamp electrical connector, then

clean and repair as necessary. If the voltage at the headlight electrical connector is

significantly less than the voltage at the battery, refer to the headlight wiring diagram

to troubleshoot and locate the voltage drop. c. Check for loose, damaged or corroded wires and electrical terminals, and repair as

necessary.

d. Check the light switch operation and replace if necessary.

3. Tail light, running light or side marker light very dim

a. Check the bulb and bulb socket for corrosion and clean or replace the bulb and

socket.