service MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 2 of 408

.

1-2 GENERALINFORMATIONAND MAINTENANCE

Chitton’s Total Car Care manual for the 199M10

Mitsubishi Mirage, Galant and Diamante is intended

to help you learn more about the inner workings of

your vehicle while saving you money on its upkeep

and operation.

The beginning of the book will likely be referred to

the most, since that is where you will find information

for maintenance and tune-up. The other sections deal

with the more complex systems of your vehicle. Oper-

ating systems from engine through brakes are cov-

ered to the extent that the average do-it-yourselfer be-

comes mechanically involved. This book will not

explain such things as rebuilding a differential for the

simple reason that the expertise required and the in-

vestment in special tools make this task uneconomi-

cal. It will, however, give you detailed instructions to

help you change your own brake pads and shoes, re-

place spark plugs, and perform many more jobs that

can save you money, give you personal satisfaction

and help you avoid expensive problems.

A secondary purpose of this book is a reference for

owners who want to understand their vehicle and/or

their mechanics better. In this case, no tools at all are

required.

Before removing any bolts, read through the entire

procedure. This will give you the overall view of what

tools and supplies will be required. There is nothing

more frustrating than having to walk to the bus stop

on Monday morning because you were short one bolt

on Sunday afternoon. So read ahead and plan ahead.

Each operation should be approached logically and

all procedures thoroughly understood before attempt-

ing any work.

All sections contain adjustments, maintenance, re-

moval and installation procedures, and in some cases,

repair or overhaul procedures. When repair is not con-

sidered practical, we tell you how to remove the part

and then how to install the new or rebuilt replacement.

In this way, you at least save labor costs. “Backyard”

repair of some components is just not practical.

Many procedures in this book require you to “label

and disconnect. . ” a group of lines, hoses or wires.

Don’t be lulled into thinking you can remember where

everything goes-you won’t. If you hook up vacuum

or fuel lines incorrectly, the vehicle may run poorly, if

at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don’t need to know the official or engineering

name for each hose or line. A piece of masking tape

on the hose and a piece on its fitting will allow you to

assign your own label such as the letter A or a short name. As long as you remember your own code, the

lines can be reconnected by matching similar letters

or names. Do remember that tape will dissolve in

gasolrne or other fluids; if a component is to be

washed or cleaned, use another method of identifica-

tion. A permanent felt-tipped marker or a metal scribe

can be very handy for marking metal parts. Remove

any tape or paper labels after assembly.

It’s necessary to mention the difference between

maintenance and repair Maintenance includes rou-

tine inspections, adjustments, and replacement of

parts which show signs of normal wear Maintenance

compensates for wear or deterioration. Repair implies

that something has broken or is not working. A need

for repair is often caused by lack of maintenance. Ex-

ample, draining and refilling the automatic transaxle

fluid is maintenance recommended by the manufac-

turer at specific mileage intervals. Failure to do this

can shorten the life of the transmission/transaxle, re-

quiring very expensive repairs. While no maintenance

program can prevent items from breaking or wearing

out, a general rule can be stated: MAINTENANCE IS

CHEAPER THAN REPAIR.

Two basic mechanrc’s rules should be mentioned

here. First, whenever the left side of the vehicle or en-

gine is referred to, it is meant to specify the drivers

side. Conversely, the right side of the vehicle means

the passengers side. Second, screws and bolts are

removed by turning counterclockwise, and tightened

by turning clockwrse unless specifically noted.

Safety is always the most important rule. Con-

stantly be aware of the dangers involved in working

on an automobile and take the proper precautions.

See the informatron in this section regarding SER-

VICING YOUR VEHICLE SAFELY and the SAFETY

NOTICE on the acknowledgment page.

Pay attention to the instructions provided. There

are 3 common mistakes in mechanical work:

1. Incorrect order of assembly, disassembly or

adjustment. When taking something apart or putting

it together, performing steps in the wrong order usu-

ally just costs you extra time; however, it CAN break

something. Read the entire procedure before begin-

ning disassembly. Perform everything in the order in

which the instructions say you should, even if you

can’t immedrately see a reason for it. When you’re

taking apart something that is very intricate, you

might want to draw a picture of how it looks when as-

sembled at one point in order to make sure you get everything back in its proper position. We will supply

exploded views whenever possible. When making

adjustments, perform them in the proper order. One

adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is

more common for overtorquing to cause damage,

undertorquing may allow a fastener to vibrate loose

causing serious damage. Especially when dealing

with aluminum parts, pay attention to torque specifi-

cations and utilize a torque wrench in assembly. If a

torque figure is not available, remember that if you

are using the right tool to perform the job, you will

probably not have to strain yourself to get a fastener

tight enough. The pitch of most threads is so slight

that the tension you put on the wrench will be multi-

plied many times in actual force on what you are

tightening. A good example of how critical torque is

can be seen in the case of spark plug installation, es-

pecially where you are putting the plug into an alu-

minum cylinder head. Too little torque can fail to

crush the gasket, causing leakage of combustion

gases and consequent overheating of the plug and

engine parts. Too much torque can damage the

threads or distort the plug, changing the spark gap.

There are many commercial products available for

ensuring that fasteners won’t come loose, even if they

are not torqued just right (a very common brand is

Loctite? If you’re worried

about getting something

together tight enough to hold, but loose enough to

avoid mechanical damage during assembly, one of

these products might offer substantial insurance. Be-

fore choosing a threadlocking compound, read the

label on the package and make sure the product is

compatible with the materials, fluids, etc. involved.

3. Crossthreading. This occurs when a part such

as a bolt is screwed into a nut or casting at the wrong

angle and forced. Crossthreading is more likely to

occur if access is difficult. It helps to clean and lubri-

cate fasteners, then to start threading the bolt, spark

plug, etc. with your fingers If you encounter resis-

tance, unscrew the part and start over again at a dif-

ferent angle until it can be inserted and turned several

times without much effort. Keep in mind that many

parts, especially spark plugs, have tapered threads,

so that gentle turning will automatically bring the part

you’re threading to the proper angle. Don’t put a

wrench on the part until its been tightened a couple

of turns by hand. If you suddenly encounter resis-

tance, and the part has not seated fully, don’t force it.

Pull it back out to make sure it’s clean and threading

properly.

Be sure to take your time and be patient, and al-

ways plan ahead. Allow yourself ample time to per-

form repairs and maintenance You may find main-

taining your car a satisfying and enjoyable

experience.

b See Figures 1 thru 15

Naturally, without the proper tools and equipment

it is impossible to properly service your vehicle. It

would also be virtually impossible

to catalog every

tool that you would need to perform all of the opera-

tions in this book. Of course, It would be unwise for

the amateur to rush out and buy an expensive set of

tools on the theory that he/she may need one or more

of them at some time, The best approach is to proceed slowly, gathering savings will

be far outweighed by frustration and

a good quality set of those tools that are used most mangled knuckles.

frequently Don’t be misled by the low cost of bargain Begin accumulating those tools that are used most

tools. It is far better to spend a little more for better frequently: those associated with routine maintenance

quality. Forged wrenches, 6 or 12-point sockets and and tune-up. In addition to the normal assortment of

fine tooth ratchets are by far preferable to their less screwdrivers and pliers, you should have the follow-

expensive counterparts. As any good mechanic can ing tools:

tell you, there are few worse experiences than trying

l Wrenches/sockets and combination open

to work on a vehicle with bad tools. Your monetary end/box end wrenches in sizes from %-% in. or

Page 4 of 408

I-4 GENERALINFORMATIONAND MAINTENANCE

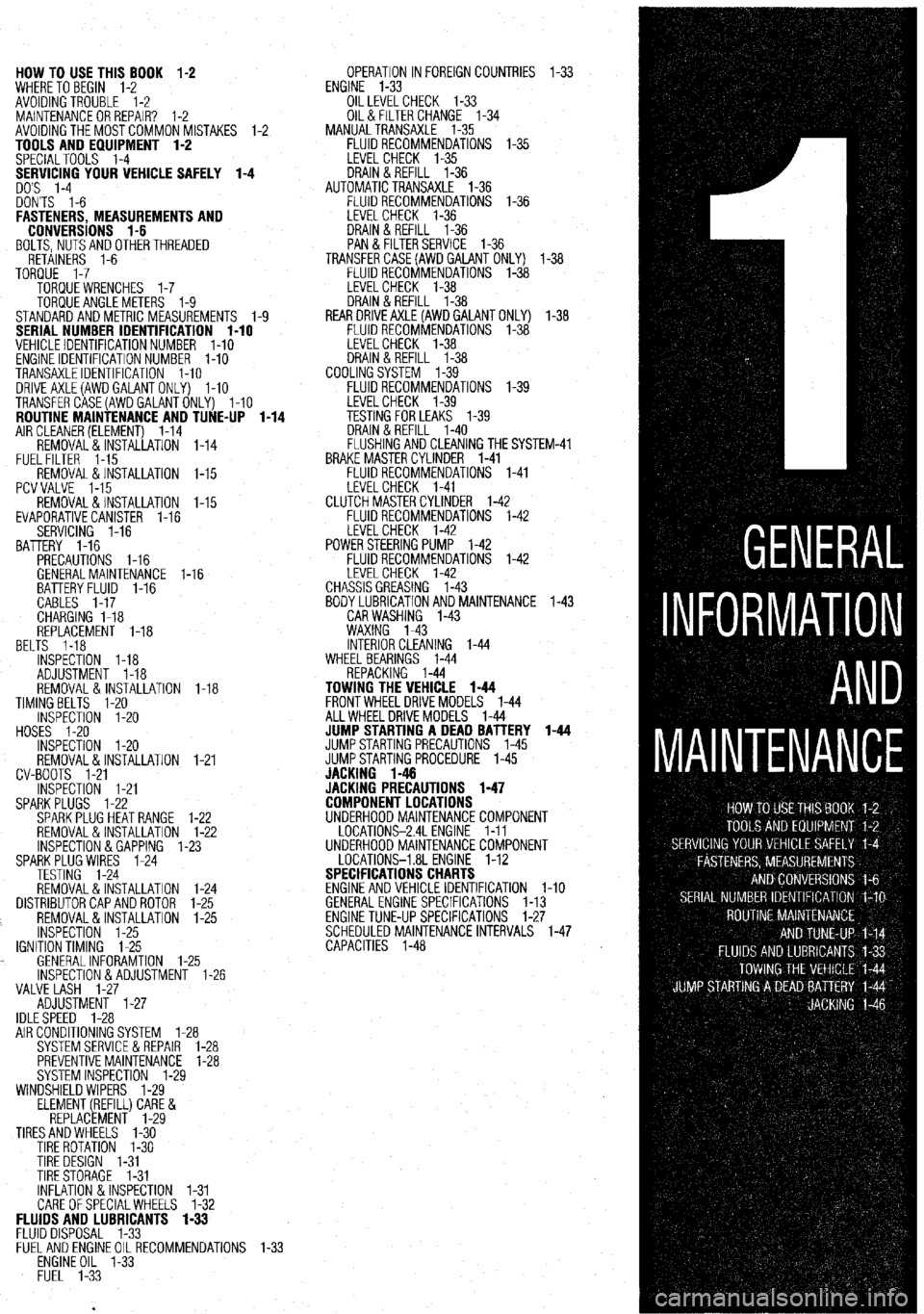

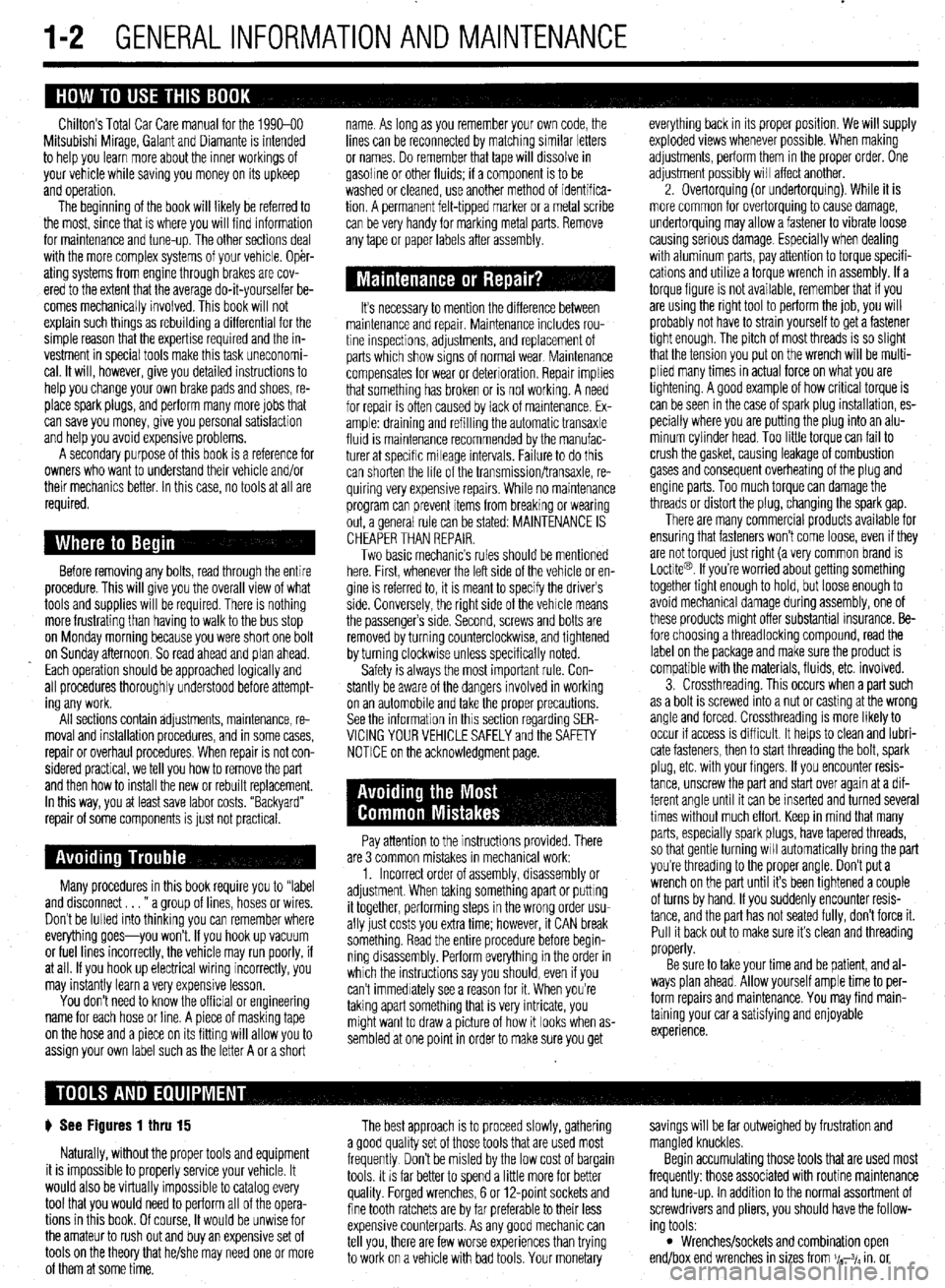

Fig. 12 A screw-in type compression gauge- Fig. 13 A vacuum/pressure tester is neces-

is recommended for compression testing sary for many testing procedures

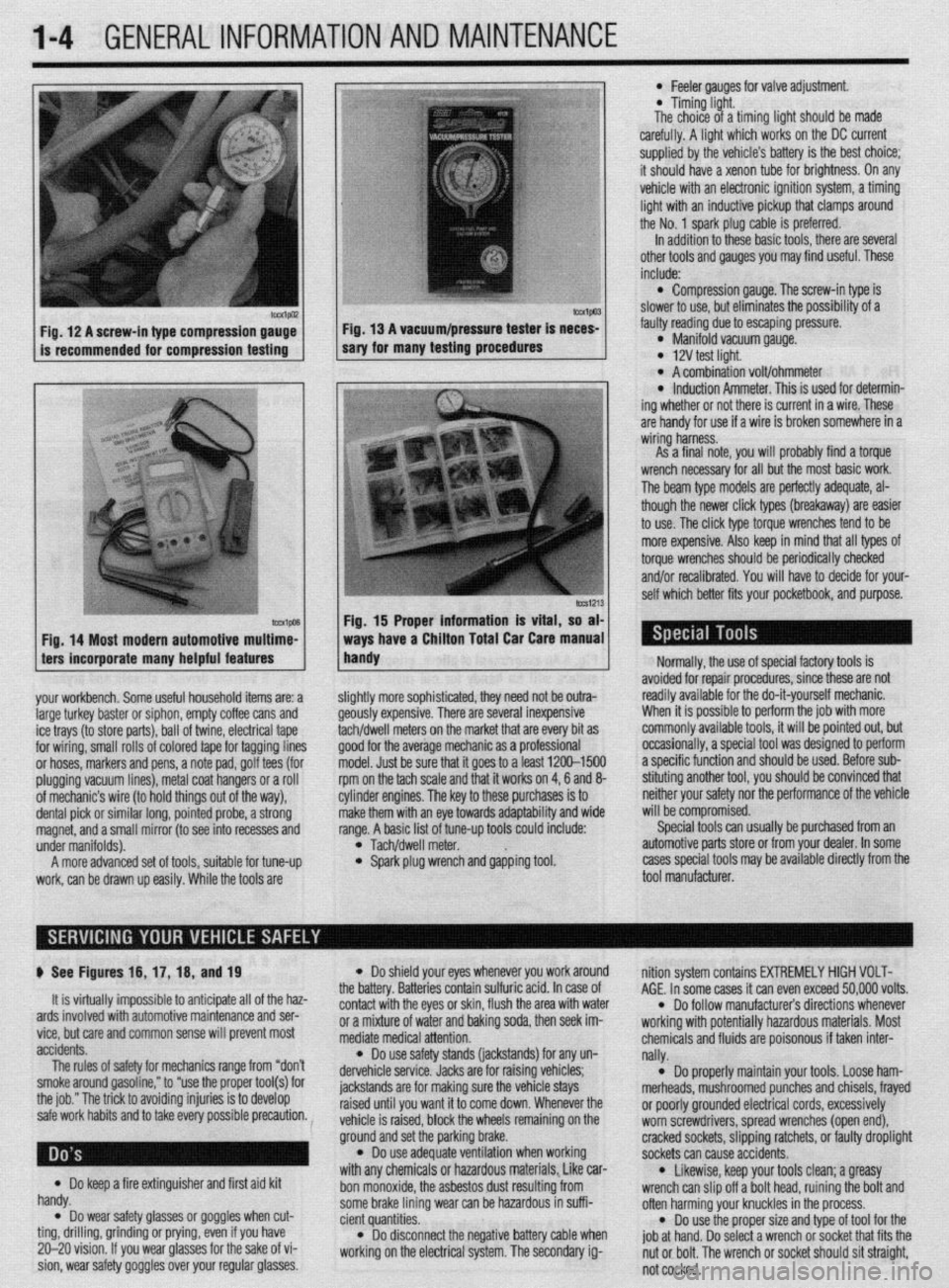

Fig. 14 Most modern automotive multime-

ters incorporate many helpful features

your workbench. Some useful household items are: a

large turkey baster or siphon, empty coffee cans and

ice trays (to store parts), ball of twine, electrical tape

for wiring, small rolls of colored tape for tagging lines

or hoses, markers and pens, a note pad, golf tees (for

plugging vacuum lines), metal coat hangers or a roll

of mechanic’s wire (to hold things out of the way),

dental pick or similar long, pointed probe, a strong

magnet, and a small mirror (to see into recesses and

under manifolds).

A more advanced set of tools, suitable for tune-up

work, can be drawn up easily. While the tools are

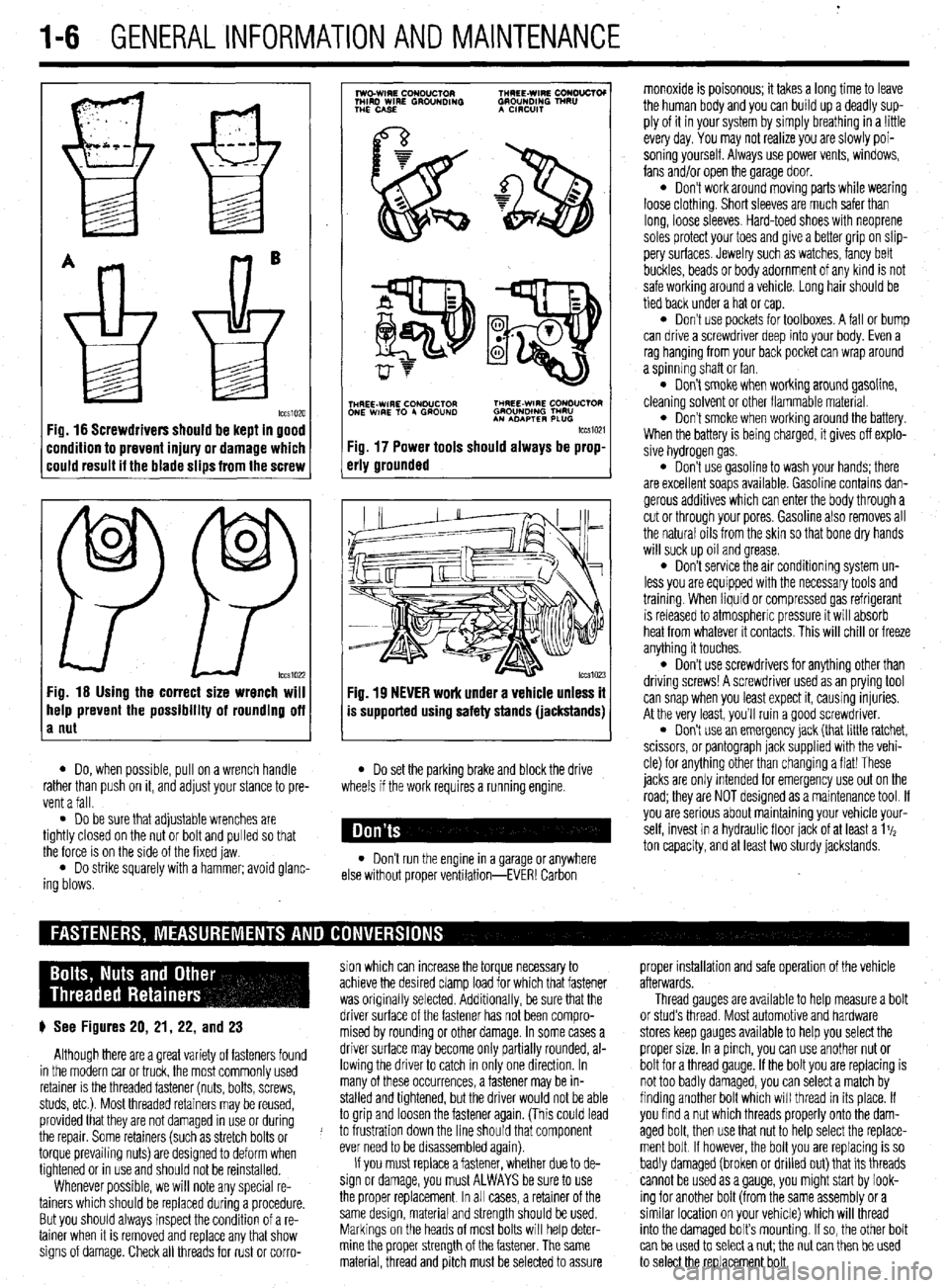

lmvl Fig. 15 Proper information is vital, so at

ways have a Chiiton Total Car Care manua

handy

l Feeler aauoes for valve adiustment

* Timing-light.

The choice of a timing fight should be made

carefully. A light which works on the DC current

supplied by the vehicle’s battery is the best choice;

it should have a xenon tube for brightness. On any

vehicle with an electronic ignition system, a timing

light with an inductive pickup that clamps around

the No. 1 spark plug cable is preferred.

In addition to these basic tools, there are several

other tools and gauges you may find useful. These

include:

l Compression gauge. The screw-in type is

slower to use, but eliminates the possibility of a

fauliy reading due to escaping pressure.

l Manifold vacuum gauge. l 12V test light. l A combination volt/ohmmeter l induction Ammeter. This is used for determin-

ing whether or not there is current in a wire. These

are handy for use if a wire is broken somewhere in a

wiring harness.

As a final note, vou will orobablv find a torque

wrench necessary for all but the most basic work.

The beam type models are perfectly adequate, al-

though the newer click types (breakaway) are easier

to use. The click type torque wrenches tend to be

more expensive. Also keep in mind that all types of

torque wrenches should be periodically checked

and/or recalibrated. You will have to decide for your-

self which better fits your pocketbook, and purpose.

ilightly more sophisticated, they need not be outra-

feously expensive. There are several inexpensive

achldwell meters on the market that are every bit as

Toad for the average mechanic as a professional

nodel. Just be sure that it goes to a least 1200-1500

pm on the tach scale and that it works on 4,6 and 8-

:ylinder engines. The key to these purchases is to

nake them with an eye towards adaptability and wide

ange. A basic list of tune-up tools could include:

l Tach/dwell meter. l Spark plug wrench and gapping tool. Normally, the use of special factory tools is

avoided for repair procedures, since these are not

readily available for the do-it-yourself mechanic.

When it is possible to perform the job with more

commonly available tools, it will be pointed out, but

occasionally, a special tool was designed to perform

a specific function and should be used. Before sub-

stituting another tool, you should be convinced that

neither your safety nor the performance of the vehicle

will be compromised.

Special tools can usually be purchased from an

automotive parts store or from your dealer. In some

cases special tools may be available directly from the

tool manufacturer.

p See Figures 16, 17, 16, and 19

It is virtually impossible to anticipate all of the haz-

ards involved with automotive maintenance and ser-

vice, but care and common sense will prevent most

accidents.

The rules of safety for mechanics range from “don’t

smoke around gasoline,” to “use the proper tool(s) for

the job.” The trick to avoiding injuries is to develop

safe work habits and to take every possible precaution.

Do keep a fire extinguisher and first aid kit

l handy.

Do wear safety glasses or goggles when cut- l ting, drilling, grinding or prying, even if you have

20-20 vision. If you wear glasses for the sake of vi-

sion, wear safety goggles over your regular glasses.

l Do shield your eyes whenever you work around

the battery. Batteries contain sulfuric acid. In case of

contact with the eyes or skin, flush the area with water

or a mixture of water and baking soda, then seek im-

mediate medical attention.

l Do use safety stands (jackstands) for any un-

dervehicle service. Jacks are for raising vehicles;

jackstands are for making sure the vehicle stays

raised until you want it to come down. Whenever the

vehicle is raised, block the wheels remaining on the

ground and set the parking brake.

l Do use adequate ventilation when working

with any chemicals or hazardous materials, Like car-

bon monoxide, the asbestos dust resulting from

some brake lining wear can be hazardous in suffi-

cient quantities.

l Do disconnect the negative battery cable when

working on the electrical system. The secondary ig- nition system contains EXTREMELY HIGH VOLT-

AGE. In some cases it can even exceed 50,000 volts.

l Do follow manufacturer’s directions whenever

working with potentially hazardous materials. Most

chemicals and fluids are poisonous if taken inter-

nally.

l Do properly maintain your tools. Loose ham-

merheads, mushroomed punches and chisels, frayed

or poorly grounded electrical cords, excessively

worn screwdrivers, spread wrenches (open end),

cracked sockets, slipping ratchets, or faulty droplight

sockets can cause accidents.

* Likewise, keep your tools clean; a greasy

wrench can slip off a bolt head, ruining the bolt and

often harming your knuckles in the process.

l Do use the proper size and type of tool for the

job at hand. Do select a wrench or socket that fits the

nut or bolt. The wrench or socket should sit straight,

not cocked.

Page 5 of 408

1-6 GENERALINFORMATIONAND MAINTENANCE

Fig. 16 Screwdrivers should be kept in good

:ondition to prevent injury or damage which

:ould result it the blade slips from the screw

0

0

PP tccs1022 Fig. 16 Using the correct size wrench will

help prevent the possibility of rounding off

a nut

7

lwo.WIRE CouDuClOR TMREE-WIRE CONO”CTOI

MIRD WIRE GROUNDING GROUNDING TNRU

THE CASE A CmxlIT

.

i$Y$$pQ

p-+

TNHREE-WIRE CONDUCTOR THREE-WIRE CONDUCTOR

ONE WIRE TO 4 GROUND GROUNOlNG TMRU

AN ADAPTER PLUG

tccm21

Fig. 17 Power tools should always be prop-

erly grounded

Fig. 19 NEVER work under a vehicle unless it

is supported using safety stands (jackstands)

l Do, when possible, pull on a wrench handle l Do set the parking brake and block the drive

rather than push on it, and adjust your stance to pre-

vent a fall. wheels if the work requires a running engine.

l Do be sure that adjustable wrenches are

tightly closed on the nut or bolt and pulled so that

the force is on the side of the fixed jaw.

l Do strike squarely with a hammer; avoid glanc-

ing blows. l Don’t run the engine in a garage or anywhere

else without proper ventilation-EVER! Carbon monoxide is poisonous; it takes a long time to leave

the human body and you can build up a deadly sup-

ply of it in your system by simply breathing in a !ittle

every day. You may not realize you are slowly poi-

soning yourself. Always use power vents, windows,

fans and/or open the garage door.

l Don’t work around moving parts while wearing

loose clothing. Short sleeves are much safer than

long, loose sleeves. Hard-toed shoes with neoprene

soles protect your toes and give a better grip on slip-

pery surfaces. Jewelry such as watches, fancy belt

buckles, beads or body adornment of any kind is not

safe working around a vehicle. Long hair should be

tied back under a hat or cap.

l Don’t use pockets for toolboxes. A fall or bump

can drive a screwdriver deep into your body. Even a

rag hanging from your back pocket can wrap around

a spinning shaft or fan.

l Don’t smoke when working around gasoline,

cleaning solvent or other flammable material.

l Don’t smoke when workrng around the battery.

When the battery is being charged, it gives off explo-

sive hydrogen gas.

l Don’t use gasoline to wash your hands; there

are excellent soaps available. Gasoline contains dan-

gerous additives which can enter the body through a

cut or through your pores. Gasoline also removes all

the natural oils from the skin so that bone dry hands

will suck up oil and grease.

l Don’t service the air conditioning system un-

less you are equipped with the necessary tools and

trainmg. When liquid or compressed gas refrigerant

is released to atmospheric pressure it will absorb

heat from whatever it contacts. This will chill or freeze

anything it touches.

l Don’t use screwdrivers for anything other than

driving screws! A screwdriver used as an prying tool

can snap when you least expect it, causing injuries.

At the very least, you’ll ruin a good screwdriver.

. Don’t use an emergency jack (that little ratchet,

scissors, or pantograph jack supplied with the vehi-

cle) for anything other than changing a flat! These

jacks are only Intended for emergency use out on the

road; they are NOT designed as a maintenance tool. If

you are serious about mamtaining your vehicle your-

self, invest in a hydraulic floor jack of at least a 1%

ton capacity, and at least two sturdy jackstands.

sion which can increase the torque necessary to proper installation and safe operation of the vehicle

achieve the desired clamp load for which that fastener afterwards.

was originally selected. Additionally, be sure that the Thread gauges are available to help measure a bolt

p See Figures 20, 21, 22, and 23 driver surface of the fastener has not been compro- or stud’s thread. Most automotive and hardware

mised by rounding or other damage. In some cases a stores keep gauges available to help you select the

Although there are a great variety of fasteners found driver surface may become only partially rounded, al- proper size. In a pinch, you can use another nut or

in the modern car or truck, the most commonly used lowing the driver to catch in only one direction. In bolt for a thread gauge. If the bolt you are replacing is

retainer is the threaded fastener (nuts, bolts, screws, many of these occurrences, a fastener may be in- not too badly damaged, you can select a match by

studs, etc.). Most threaded retainers may be reused, stalled and tightened, but the driver would not be able finding another bolt which will thread in its place. If

provided that they are not damaged in use or during to grip and loosen the fastener again. (This could lead you find a nut which threads properly onto the dam-

the repair. Some retainers (such as stretch bolts or J to frustration down the line should that component aged bolt, then use that nut to help select the replace-

torque prevailing nuts) are designed to deform when ever need to be disassembled again). ment bolt If however, the bolt you are replacing is so

tightened or in use and should not be reinstalled. If you must replace a fastener, whether due to de- badly damaged (broken or drilled out) that its threads

Whenever possible, we will note any special re- sign or damage, you must ALWAYS be sure to use cannot be used as a gauge, you might start by look-

tainers which should be replaced during a procedure. the proper replacement In all cases, a retainer of the ing for another bolt (from the same assembly or a

But you should always inspect the condition of a re- same design, material and strength should be used. similar location on your vehicle) which will thread

tainer when It is removed and replace any that show Markings on the heads of most bolts will help deter- into the damaged bolt’s mounting. If so, the other bolt

signs of damage. Check all threads for rust or corro- mine the proper strength of the fastener. The same

can be used to select a nut; the nut can then be used

material, thread and pitch must be selected to assure

to select the replacement bolt.

Page 13 of 408

l

l-14 GENERALINFORMATIONAND MAINTENANCE

Proper maintenance and tune-up is the key to long

and trouble-free vehicle life, and the work can yield

its own rewards. Studies have shown that a properly

tuned and maintained vehicle can achieve better gas

mileage than an out-of-tune vehicle. As a conscien-

tious owner and driver, set aside a Saturday morning,

say once a month, to check or replace items which

could cause major problems later. Keep your own

personal log to jot down which services you per-

formed, how much the parts cost you, the date, and

the exact odometer reading at the time. Keep all re-

selfer, these receipts are the only proof you have that ceipts for such items as engine oil and filters, so that

they may be referred tp in case of related problems or

to determine operating expenses. As a do-it-your- the required maintenance was performed. In the event

of a warranty problem, these receipts will be invalu-

able.

The literature provided with your vehicle when it

was originally delivered includes the factory recom-

mended maintenance schedule. If you no longer have

this literature, replacement copies are usually avail-

able from the dealer. A maintenance schedule is pro-

vided later in this section, in case you do not have

the factory literature. *

REMOVAL &INSTALLATION

Except 2.gL Turbocharged Engine

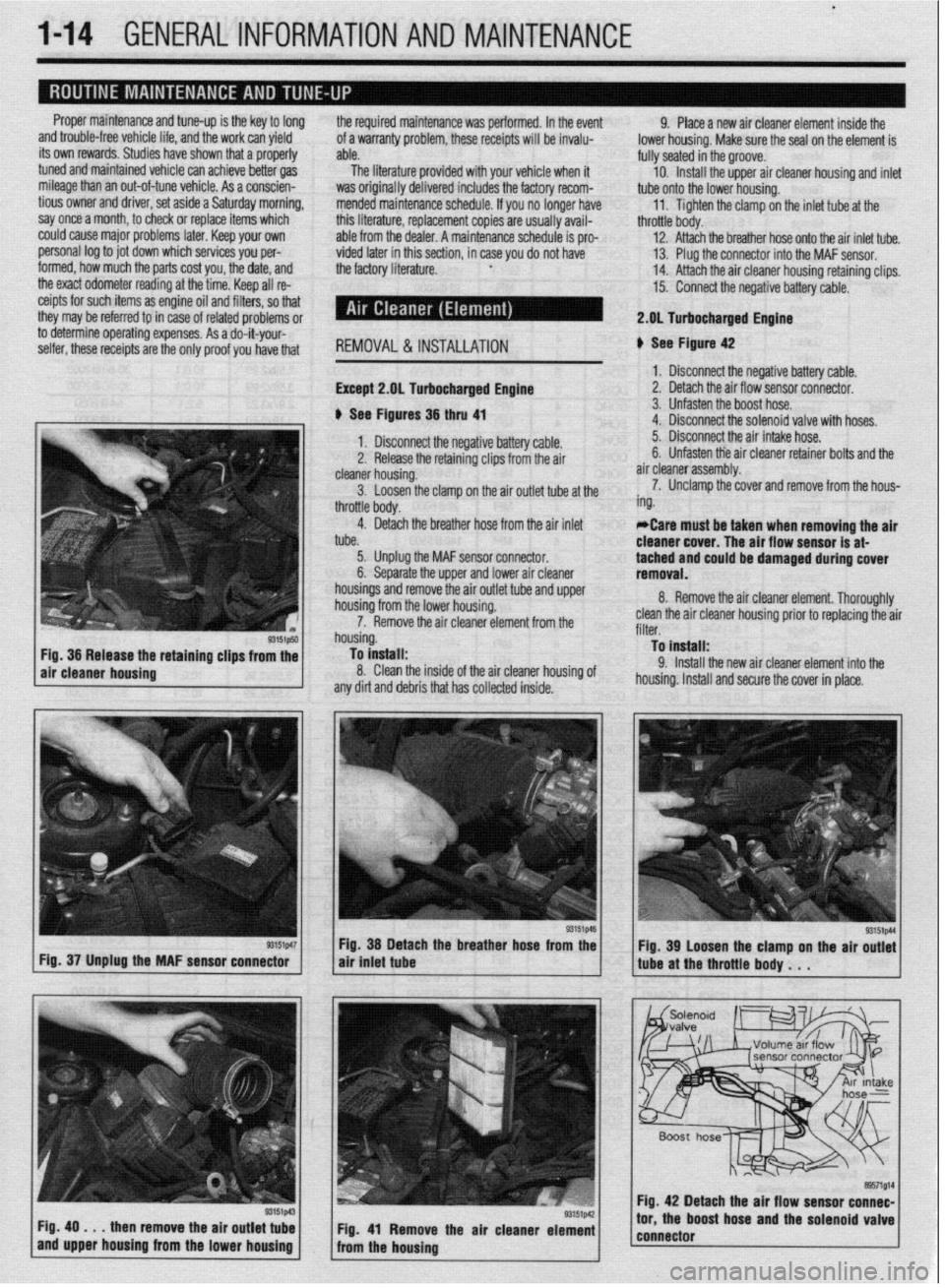

b See Figures 36 thru 41 9. Place a new air cleaner element inside the

lower housing. Make sure the seal on the element is

fully seated in the groove.

10. Install the upper air cleaner housing and inlet

tube onto the lower housing.

11. Tighten the clamp on the inlet tube at the

throttle body.

12. Attach the breather hose onto the air inlet tube.

13. Plug the connector into the MAF sensor.

14. Attach the air cleaner housing retaining clips.

15. Connect the negative battery cable.

2.DL Turbocharged Engine

b See Figure 42

1. Disconnect the negative battery cable.

2. Detach the air flow sensor connector.

3. Unfasten the boost hose.

4. Disconnect the solenoid valve with hoses.

93151p50 Fig. 36 Release the retaining clips from the

air cleaner housing

r3151p47 Fig. 37 Unplug the MAF sensor connector

Fig. 49

. . . then remove the air outlet tube

and upper housing from the lower housing 1. Disconnect the negative battery cable. 5. Disconnect the air intake hose.

2. Release the retaining clips from the air 6. Unfasten tie air cleaner retainer bolts and the

cleaner housing. air cleaner assembly.

3. Loosen the clamp on the air outlet tube at the 7. Unclamp the cover and remove from the hous-

throttle body. ing.

4. Detach the breather hose from the air inlet

tube. *Care must be taken when removing the air

cleaner cover. The air flow sensor is at-

5. Unplug the MAF sensor connector.

6. Separate the upper and lower air cleaner tached and could be damaged during cover

removal.

housings and remove the air outlet tube and upper

housing from the lower housing.

7. Remove the air cleaner element from the

housing.

To install:

8. Clean the inside of the air cleaner housing of

any dirt and debris that has collected inside. 8. Remove the air cleaner element. Thoroughly

clean the air cleaner housing prior to replacing the air

filter.

To install:

9. Install the new air cleaner element into the

housing. Install and secure the cover in place.

Fig. 38 Detach the breather hose from the

air tniet tube

Fig. 41 Remove the air cleaner element

from the housing Fig. 39 Loosen the clamp on the air outlet

tube at the throttle body . . .

Fig. 42 Detach the air flow sensor connec-

tor, the boost hose and the solenoid valve

connector

Page 17 of 408

l

1-18 GENERALINFORMATIONAND MAINTENANCE

the clamps and remove the cables, negative cable

first. On batteries with posts on top, the use of a

puller specially made for this purpose is recom-

mended. These are inexoensive and available in most alternator or turn the adjusting bolt to adjust belt ten-

sion. Once the desired value is reached, secure the

bolt or locknut and recheck tension.

d”t” lJdlL> X”lt;>. 31°C LtXlllllldl lJdllt2)’ MLJIC, dlt’ X- cured with a small bolt. ST& I REMOVAL &INSTALLATION

Clean the cable clamps and the battery terminal I

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shinv. It is esneciallv imnnr-

tant to c

knife is useful nere), since a smart

material or oxidation there will pre Clean the cable clamps and the battery terminal

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shiny. It is especially impor-

tant to clean the inside of the clamp thoroughly (an old

knife is useful here), since a small deposit of foreign

material or oxidation there will prevent a sound electri-

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batteries. It is also a good

idea to apply some dielectric grease to the terminal, as

this will aid in the prevention of corrosion,

After the clamps and terminals are clean, reinstall

the cables, negative cable last; DO NOT hammer the

clamps onto battery posts. Tighten the clamps se-

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and gauge.

CHARGING

the cables, negative cable last; DO NOT hammer the

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and aauae.

CHARGING

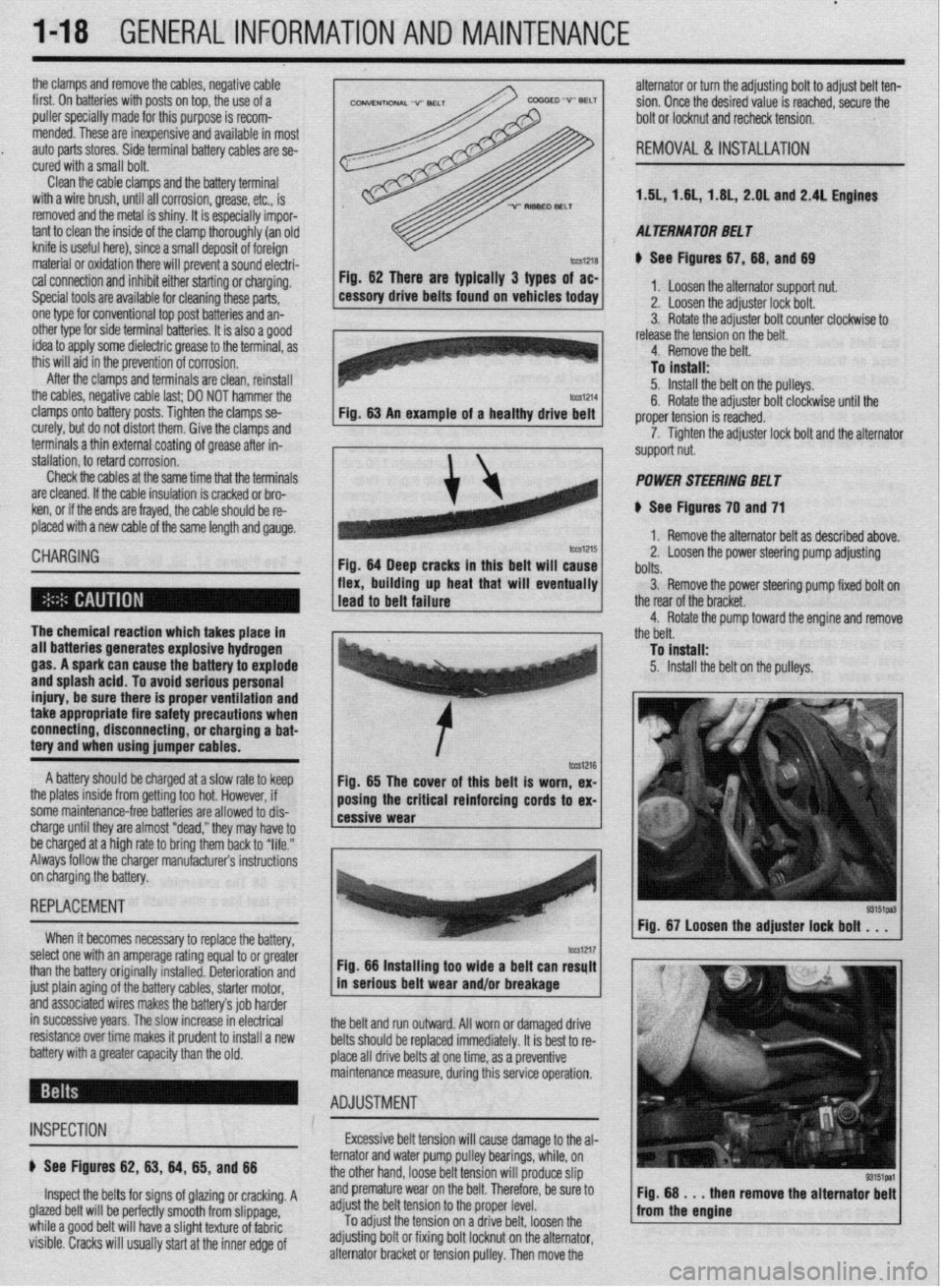

Fig. 62 mere are typically 3 types of ac-

cessory drive belts found on vehicles today 1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

I .I , . . . * . .

I Tn i”et*ll* Fig. 62 There are typically 3 types of ac-

Fig. 64 Deep cracks in this belt will cause

flex, building up heat that will eventually 11, 1.8L, 2.OL and 2.4L Engines

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batterin, I+ if QI@* 3 nnnd

idea to apply some dielectric grr

this will aid in the prevention of ,,vIIuaIUII.

After the clamps and terminals are clean, reinstall 1.5L, 1.6

AL TERNA TOR BE1 T

e See Figures 67,68, and 69

1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

release the tension on the belt.

4. Remove the belt.

To install:

5. Install the belt on the pulleys.

6. Rotate the adjuster bolt clockwise until the

proper tension is reached.

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

8 See Figures 70 and 71

1. Remove the alternator belt as described above.

2. Loosen the power steering pump adjusting

bolts.

3. Remove the power steering oumo fixed bolt on

R Rntatn the cxiillrtm hnit A&+,& until the r -r- .- .- ._.. ._ .______

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

1 ..“‘.I ““..Y...Y up II”“. ..IU. ..m.*

1 lead to belt failure V.

I

I

The chemical reaction which takes place in - 1 the rear of the bracket.

4. Rotate the pump toward the engine and remove

the belt.

all batteries generates explosive hydrogen

gas. A spark can cause the battery to explode

and splash acid. To avoid serious personal

injury, be sure there is proper ventilation and

take appropriate fire safety precautions when

connecting, disconnecting, or charging a bat-

tery and when using jumper cables. To fnstall:

5. Install the belt on the pulleys.

A battery should be charged at a slow rate to keep

the plates inside from getting too hot. However, if

some maintenance-free batteries are allowed to dis-

charge until they are almost “dead,” they may have to

be charged at a high rate to bring them back to “life.”

Always follow the charger manufacturers instructions

on charging the battery. 85 The cover of this belt ex-

Fig. is worn,

REPLACEMENT

When it becomes necessary to reolace thn haeoN

‘” yyL’“‘J’ I or oreMer

select one with an amperage rating equal tc .

a ----

than the battery originally installed. Deterioration and

just plain aging of the battery cables, starter motor,

and associated wires makes the battery’s job harder

in successive years. The slow increase in electrical

resistance over time makes it prudent to install a new

battery with a greater capacity than the old. 1 Fig. 67 Loosen the adjuster lock bolt . . .

I ‘-

I -. -_ tm1217 Fig. 66 Installing too wide a belt can resylt

in serious belt wear and/or breakage

the belt and run outward. All worn or damaged drive

belts should be replaced immediately. It is best to re-

place all drive belts at one time, as a preventive

uring this service operation. maintenance measure, d

- ADJUSTMENT : *

INSPECTION Excessive belt tension will cause damage to the al-

e See Figures 62, 83, 64, 65, and 88

Inspect the belts for signs of glazing or cracking. A

glazed belt will be perfectly smooth from slippage,

while a good belt will have a slight texture of fabric

visible. Cracks will usually start at the inner edge of pulley bearings, while, on

It tension will

Droduce slin ternator and water pump

the other hand, loose be

r ------ r

and premature wear on the belt. Therefore, be sure to

adjust the belt tension to the proper level.

To

adjust the tension ’ ’ ’ ” ’ ‘* adjusting bolt or fixing b

alternator bracket or tens on a onve Den. loosen me I Fig. 68 . . . then

from the engine remove the alternator

bolt locknut on the alternator,

iion pulley. Then move the

Page 20 of 408

GENERALINFORMATIONAND MAINTENANCE l-21

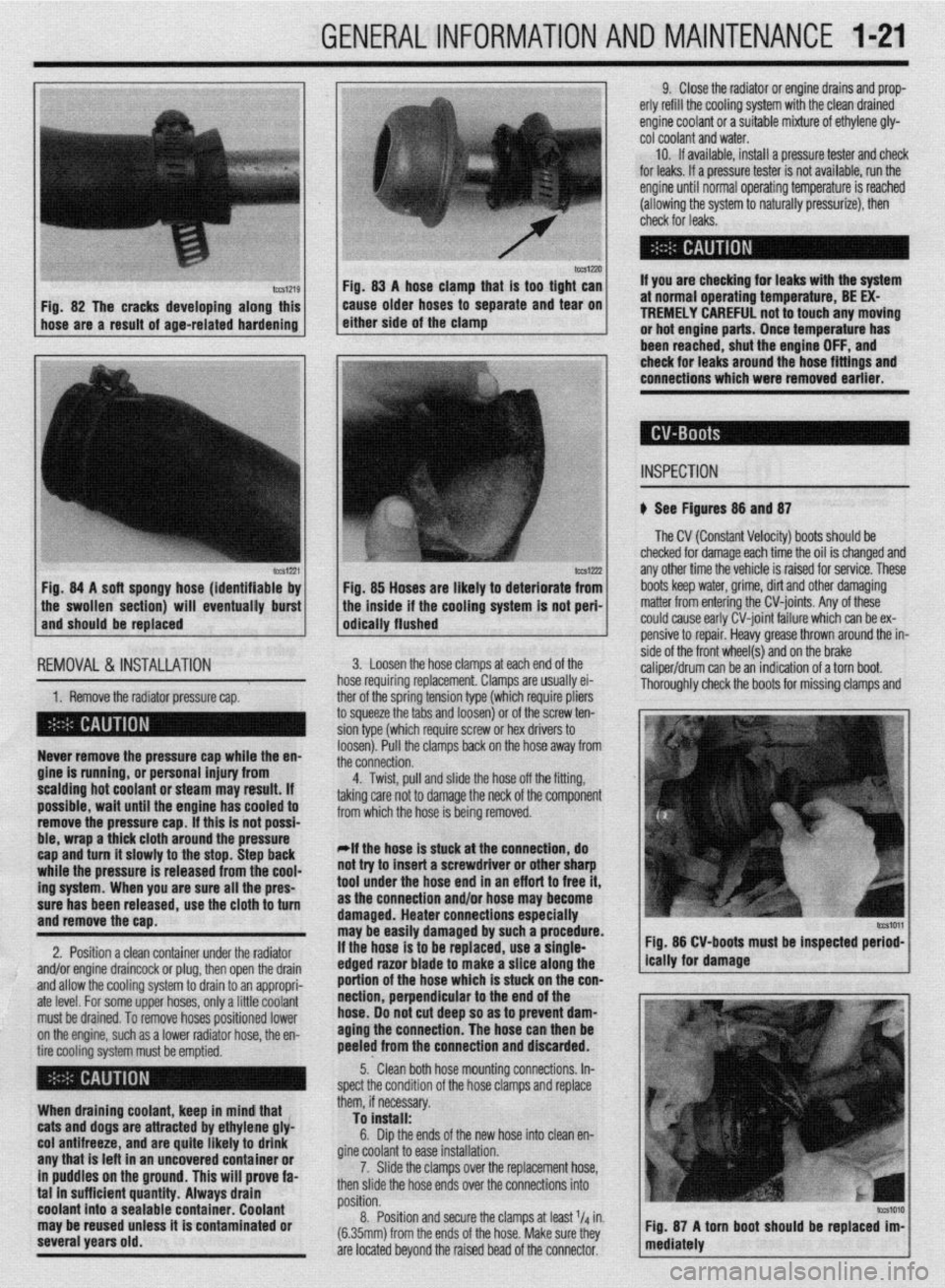

IWSIZXJ FM. 83 A hose clamn that is taa tiaht can

Fig. 82 The cracks developing along this

hose are a result of age-related hardening caise older hoses td separate and ‘iear on

either side of the clamp

lCCS1221 Fig. 84 A soft spongy hose (identifiable by

1 the swollen section) will eventually burst

and should be replaced

IEMOVAL &,INSTALLATION '

1. Remove the radiator pressure cap. her of the sorina tension tvoe (which reouire oliers

3 squeeze the 6bs and loosenj or of the’screw ten-

ion type (which require screw or hex drivers to

oosen). Pull the clamps back on the hose away from

he connection. Never remove the pressure cap while the en-

gine is running, or personal injury from

scalding hot coolant or steam may result. If

possible, wait until the engine has cooled to

remove the pressure cap. If this is not possi-

ble, wrap a thick cloth around the pressure

cap and turn it slowly to the stop. Step back

while the pressure is released from the cool-

ing system. When you are sure all the pres-

sure has been released, use the cloth to turn

and remove the cao.

2. Position a clean container under the radiator

and/or engine draincock or plug, then open the drain

and allow the cooling system to drain to an appropri-

ate level. For some upper hoses, only a little coolant

must be drained. To remove hoses positioned lower

on the engine, such as a lower radiator hose, the en-

tire cooling system must be emptied.

When draining coolant, keep in mind that

cats and dogs are attracted by ethylene gly-

col antifreeze, and are quite likely to drink

any that is left in an uncovered container or

in puddles on the ground. This will prove fa-

tal in sufficient quantity. Always drain

coolant into a sealable container. Coolant

may be reused unless it is contaminated or

several years old. 9. Close the radiator or engine drains and prop-

erly refill the cooling system with the clean drained

engine coolant or a suitable mixture of ethylene gly-

cot coolant and water.

10. If available, install a pressure tester and check

for leaks. If a pressure tester is not available, run the

engine until normal operating temperature is reached

(allowing the system to naturally pressurize), then

check for leaks.

If you are checking for leaks with the system

at normal operating temperature, BE EX-

TREMELY CAREFUL not to touch any moving

or hot engine parts. Once temperature has

been reached. shut the enaine OFF. and

Fig. 85 Hoses are likely to deteriorate from

the inside if the cooling system is not peri-

odically flushed check for leaks around the-hose fittings and

connections which were removed earlier.

INSPECTION

b See Figures 88 and 87

The CV (Constant Velocity) boots should be

checked for damage each time the oil is changed and

any other time the vehicle is raised for service. These

boots keep water, grime, dirt and other damaging

matter from entering the CV-joints. Any of these

could cause early CV-joint failure which can be ex-

pensive to repair. Heavy grease thrown around the in-

side of the front wheel(s) and on the brake

caliper/drum can be an indication of a torn boot.

Thorouahlv check the boots for missina clamos and 3. Loosen the hose clamps at each end of the

rose requiring replacement. Clamps are usually ei-

4. Twist, pull and slide the hose off the fitting,

sking care not to damage the neck of the component

rom which the hose is being removed.

*If the hose is stuck at the connection, do

lot try to insert a screwdriver or other sharp

ool under the hose end in an eff art to free it,

IS the connection and/or hose may become

lamaged. Heater connections especially

nay be easily damaged by such a procedure.

f the hose is to be replaced, use a single-

!dged razor blade to make a slice along the

lortion of the hose which is stuck on the con-

section, perpendicular to the end of the

lose. 00 not cut deep so as to prevent dam-

aging the connection. The hose can then be

keeled from the connection and discarded. Fig. 86 CV-boots must be inspected period-

5.. Clean both hose mounting connections. In-

,pect the condition of the hose clamps and replace

hem, if necessary.

To install:

6. Dip the ends of the new hose into clean en-

fine coolant to ease installation.

7. Slide the clamps over the replacement hose,

hen slide the hose ends over the connections into

rosition.

8. Position and secure the clamps at least l/d in.

6.35mm) from the ends of the hose. Make sure they

Ire located beyond the raised bead of the connector.

Page 22 of 408

t

GENERALINFORMATIONAND MAINTENANCE l-23

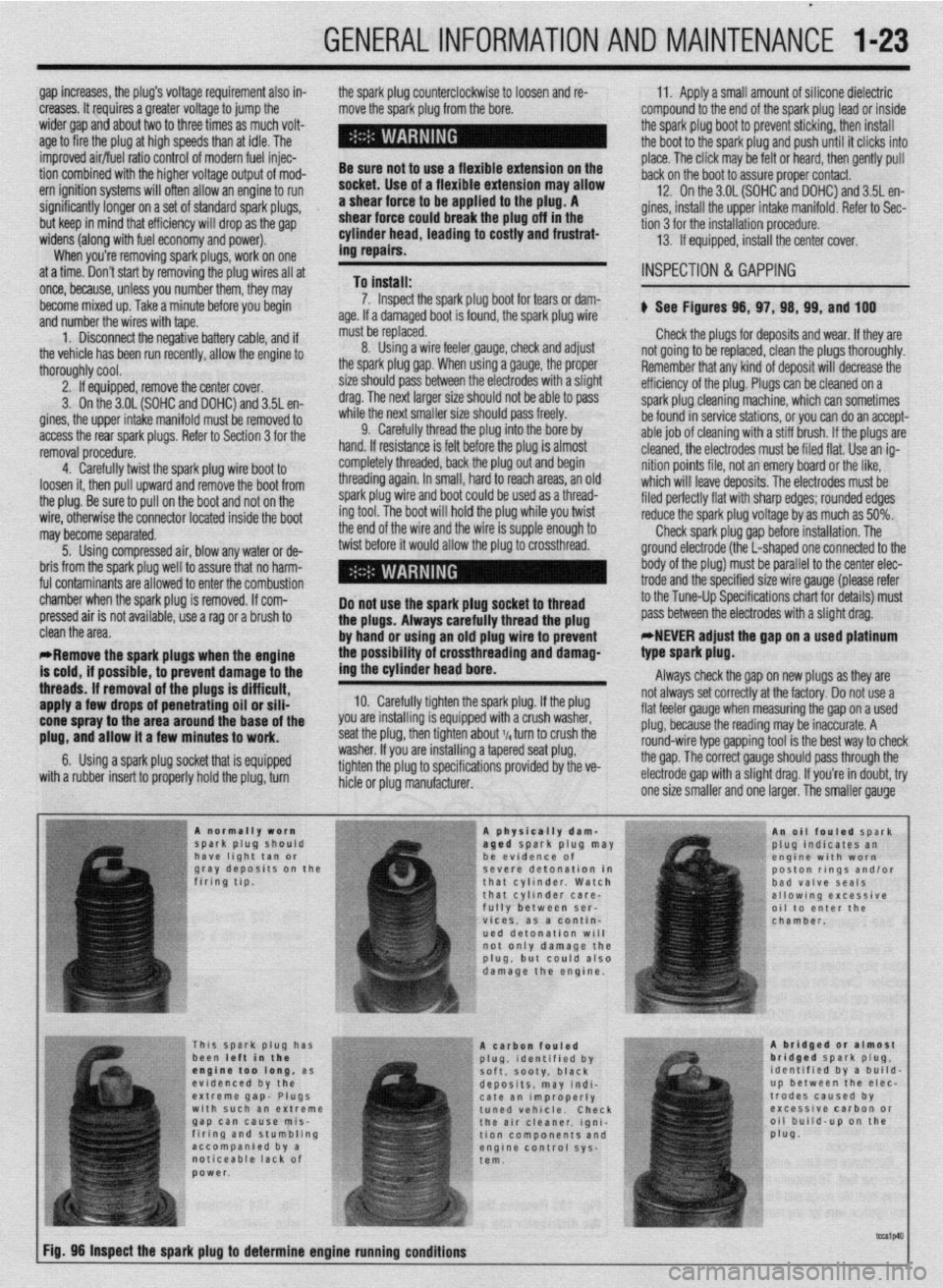

gap increases, the plug’s voltage requirement also in-

creases. It requires a greater voltage to jump the the spark plug counterclockwise to loosen and re-

move the spark plug from the bore.

wider gap and about &o to three times as much volt-

age to fire the plug at high speeds than at idle. The

improved air/fuel ratio control of modern fuel injec-

tion combined with the higher voltage output of mod- Be sure not to use a flexible extension on the place. The click may be felt or heard, then gently pull

ern ignition systems will often allow an engine to run socket. Use of a flexible extension may allow back on the boot to assure proper contact.

.___. . _

significantly longer on a set of standard spark plugs, a shear force to be agptf’ ea to me plug.

A 12. On the 3.OL fSOHC and DOHC) and 3.5L en-

LL_ _I___ -u I_ IL-

but keep in mind that efficiency will drop as the gap shear force could break tne pug on III me

tion 3 for the installation procedure.

widens (along with fuel economy and power). cylinder head, leading to costly and frustrat-

13. If equipped, install the center cover.

When you’re removing spark plugs, work on one ing repairs.

at a time. Don’t start by removing the plug wires all at

once, because, unless you number them, they may To install:

INSPECTION & GAPPING

11. Apply a small amount of silicone dielectric

compound to the end of the spark plug lead or inside

the spark plug boot to prevent sticking, then install

the boot to the spark plug and push until it clicks into

gines, install the upper intake manifold. Refer to Sec-

,,Y” ..1111 uy”’ 1 the neaative bat&v cable and if become mixed up. Take a minute before you begin

and number the wrrpc with +sne

1. Disconnect. ~~.~

--..-., -..-.-, -..-

thevehicle has been run recently, allow the engine to

thoroughly cool.

2. If equipped, remove the center cover.

3. On the 3.OL (SOHC and DOHC) and 3.5L en-

gines, the upper intake manifold must be removed to

access the rear spark plugs. Refer to Section 3 for the

removal procedure.

4. Carefully twist the spark plug wire boot to

loosen it, then pull upward and remove the boot from

the plug. Be sure to pull on the boot and not on the

wire, otherwise the connector located inside the boot

may become separated.

5. Using compressed air, blow any water or de-

bris from the spark plug well to assure that no harm-

ful contaminants are allowed to enter the combustion

chamber when the spark plug is removed. If com-

pressed air is not available, use a raa or a brush to must be replaced.

Check the plugs for deposits and wear, If they are 7. Inspect the spark plug boot for tears or dam-

age. If.a damaged boot is found, the spark plug wire

8. Using a wire feelergauge, check and adjust

the spark plug gap. When using a gauge, the proper

size should pass between the electrodes with a slight

drag. The next larger size should not be able to pass

while the next smaller size should pass freely.

9. Carefully thread the plug into the bore by

hand. If resistance is felt before the plug is almost

completely threaded, back the plug out and begin

threading again. In small, hard to reach areas, an old

spark plug wire and boot could be used as a thread-

ing tool. The boot will hold the plug while you twist

the end of the wire and the wire is supple enough to

twist before it would allow the plug to crossthread.

Do not use the spark plug sock?

l -- K-rrA tha nhme Alwmm rarntdlv thw GL I” IlllGa”

the possibility of crossthreading and damag- lad the plug

. ..Y f..“YY. rn”Y,‘““mY*“.‘, .I**” by hand or using an old plug wire to prevent

ing the cylinder head bore.

10. Carefully tighten the spark plug. If the plug

you are installing is equipped with a crush washer,

seat the plug, then tighten about I/, turn to crush the

washer. If you are installing a tapered seat plug,

tighten the plug to specifications provided by the ve-

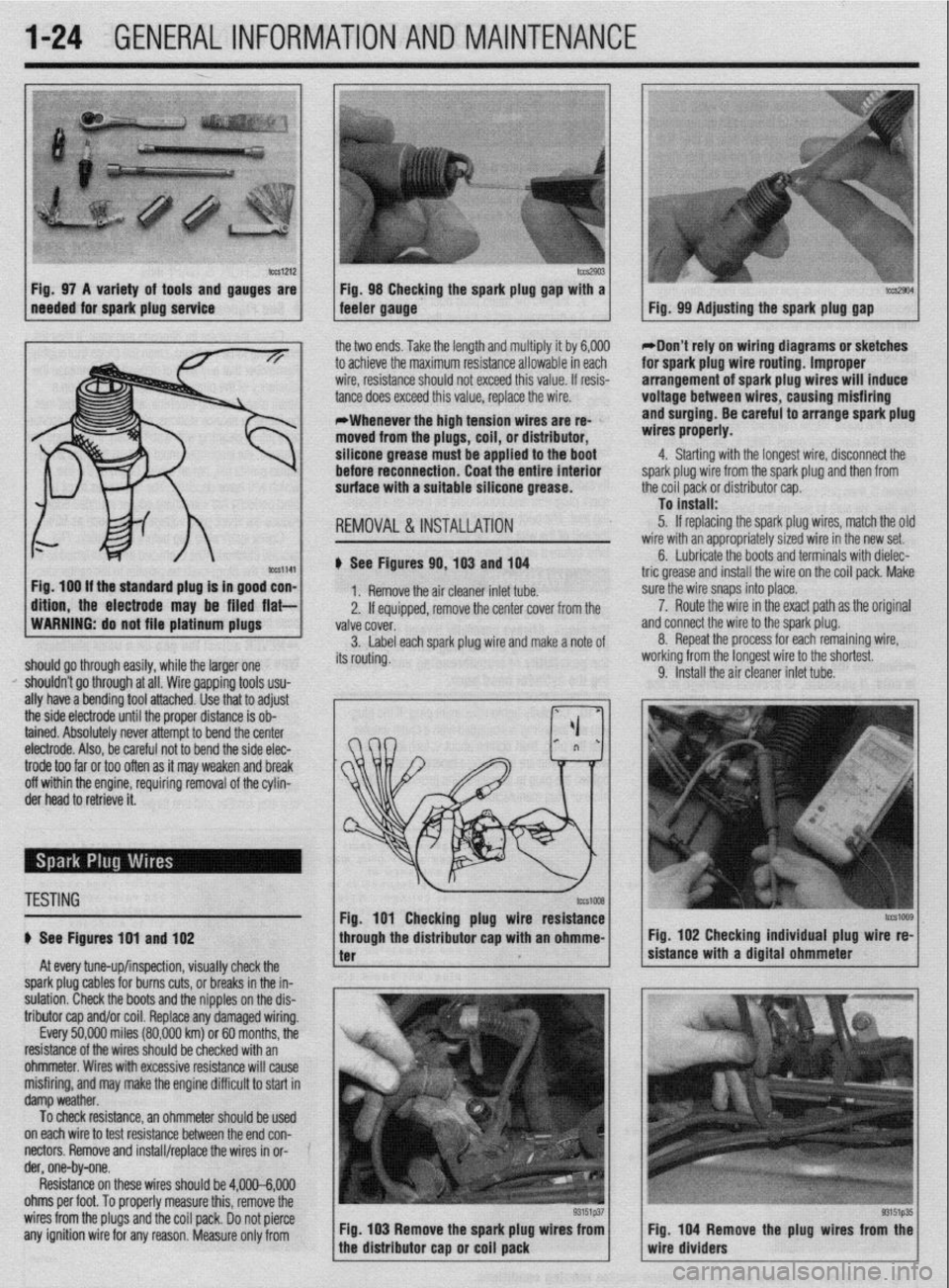

hicle or plug manufacturer. b See Figures 98, 97, 98, 99, and 100

not going to be replaced, clean the plugs thoroughly.

Remember that any kind of deposit will decrease the

efficiency of the plug. Plugs can be cleaned on a

spark plug cleaning machine, which can sometimes

be found in service stations, or you can do an accept-

able job of cleaning with a stiff brush. If the plugs are’

cleaned, the electrodes must be filed flat. Use an ig-

nition points file, not an emery board or the like,

which will leave deposits. The electrodes must be

filed perfectly flat with sharp edges; rounded edges

reduce the spark plug voltage by as much as 50%.

Check spark plug gap before installation. The

ground electrode (the L-shaped one connected to the

body of the plug) must be parallel to the center elec-

trode and the specified size wire gauge (please refer

to the Tune-Up Specifications chart for details) must

pass between the electrodes with a slight drag:

*,NEVER adjust the gap on a used platinum

. clean the area.

*Remove the spark plugs when the engine

is cold, if possible, to prevent damage to the

threads. If removal of the plugs is difficult,

apply a few drops of penetrating oil or sili-

cone spray to the area around the base of the

plug, and allow it a few minutes to work.

6. Using a spark plug socket that is equipped

with a rubber insert to properly hold the plug, turn type spark plug.

Always check the gap on new plugs as they are

not always set correctly at the factory. Do not use a

flat feeler gauge when measuring the gap on a used

plug, because the reading may be inaccurate. A

round-wire type gapping tool is the best way to check

the gap. The correct gauge should pass through the

electrode gap with a slight drag. If you’re in doubt, try

one size smaller and one laraer. The smaller aauqe

Page 23 of 408

l-24 GENERALINFORMATIONAND MAINTENANCE

b%slZl2 Fig. 97 A variety of tools and gauges are

needed for spark plug service tm2903 Fig. 98 Checking the spark plug @au with a tccs2904 feeler gauge. - Fig. 99 Adjusting the spark plug gap

ig. 100 If the standard plug Is in good con-

ftlon, the electrode may be filed flat- the two ends. Take the length and multiply it by 6,000

to achieve the maximum resistance allowable in each

wire, resistance should not exceed this value. If resis-

tance does exceed this value, replace the wire.

*Whenever the high tension wires are re- ’

moved from the plugs, coil, or distributor,

silicone grease must be applied to the boot

before reconnection. Coat the entire Interior

surface with a suitable silicone grease.

REMOVAL &INSTALLATION

# See Figures 90,103 and 104

1. Remove the air cleaner inlet tube.

2. If eouiooed, remove the center cover from the

WARNING: do not file platinum plugs

valve covei.

3. Label each spark plug wire and make a note of

should go through easily, while the larger one its routing.

I’ shouldn’t go through at all. Wire gapping tools usu-

ally have a bending tool attached. Use that to adjust

the side electrode until the proper distance is ob-

tained. Absolutely never attempt to bend the center

electrode. Also, be careful not to bend the side elec- *Don’t rely on wiring diagrams or sketches

for spark plug wire routing. Improper

arrangement of spark plug wires will induce

voltage between wires, causing misfiring

and surging. Be careful to arrange spark plug

wires properly.

4. Starting with the longest wire, disconnect the

spark plug wire from the spark plug and then from

the coil pack or distributor cap.

To install:

5. If replacing the spark plug wires, match the olc

wire with an appropriately sized wire in the new set.

6. Lubricate the boots and terminals with dielec-

tric grease and install the wire on the coil pack. Make

sure the wire snaps into place.

a 7. Route the wire in the exact path as the original

nd connect the wire to the spark plug.

8. Repeat the process for each remaining wire,

iorking from the longest wire to the shortest.

9. Install the air cleaner inlet tube.

trode too far or too often as it may weaken and break

off within the engine, requiring removal of the cylin-

der head to retrieve it.

TESTING

# See Figures 191 and 102

At every tune-up/inspection, visually check the

spark plug cables for burns cuts, or breaks in the in-

sulation. Check the boots and the nipples on the dis-

tributor cap and/or coil. Replace any damaged wiring.

Every 50,000 miles (80,000 km) or 60 months, the

resistance of the wires should be checked with an

ohmmeter. Wires with excessive resistance will cause

misfiring, and may make the engine difficult to start in

damp weather.

To check resistance, an ohmmeter should be used ’

on each wire to test resistance between the end con-

nectors. Remove and install/replace the wires in or- ’

der, one-by-one.

Resistance on these wires should be 4,000-6,000

ohms per foot. To properly measure this, remove the

wires from the plugs and the coil pack. Do not pierce

any ignition wire for any reason. Measure only from Fig. 103 Remove the spark plug wires from

tcG1009 Fig. 102 Checking individual plug wire re-

sistance with a digital ohmmeter

Fig. 104 Remove the plug wires from the

wire dividers

Page 27 of 408

l-28 GENERALINFORMATIONAND MAINTENANCE

may result in skin or eye irritation or frostbite. Al- formed to help maintain the efficiency of the vehicle’s

though low in toxicity (due to chemical stability), in- A/C system. For preventive maintenance, perform the

The idle speed is factory set and usually no ad- halation of concentrated refrigerant fumes is danger- following:

justments are ever necessary. If an adjustment be- ous and can result in death; cases of fatal cardiac

l The easiest and most important preventive

comes necessary, first check that the spark plugs, in- arrhythmia have been reported in people accidentally maintenance for your A/C system is to be sure that it

jectors, idle air control servo and compression subjected to high levels of refrigerant. Some early is used on a regular basis. Running the system for

pressure are all normal. symptoms include loss of concentration and drowsi- five minutes each month (no matter what the season)

Data from various sensors and switches are used ness. + will help ensure that the seals and all internal compo-

by the ECU to determine the proper fuel/air mixture

for optimal engine performance. cGeneraiiy, the limit for exposure is lower nents remain lubricated.

for R-134a than it is for R-12. Exceptional *Some newer vehicles automatically oper-

care must be practiced when handling R- ate the A/C system compressor whenever the

134a. windshield defroster is activated. When run-

Also, refrigerants can decompose at high tempera- ning, the compressor lubricates the A/C sys

tures (near gas heaters or open flame), which may re- tern components; therefore, the A/C system

SYSTEM SERVICE& REPAIR suit in hydrofluoric acid, hydrochloric acid and phos- would not need to be operated each month.

gene (a fatal nerve gas). * In order to prevent heater core freeze-up during

R-12 refrigerant can damage the environment be- A/C operation, it is necessary to maintain proper an-

cause it is a Chlorofluorocarbon (CFC), which has tifreeze protection. Use a hand-held coolant tester

been proven to add to ozone layer depletion, leading (hydrometer) to periodically check the condition of

to increasing levels of UV radiation. UV radiation has the antifreeze in your engine’s cooling system.

been linked with an increase in skin cancer, suppres-

sion of the human immune system, an increase in *Antifreeze should not be used longer than

cataracts, damage to crops, damage to aquatic organ- the manufacturer specifies.

isms, an increase in ground-level ozone, and in- . For efficient operation of an air conditioned ve-

creased global warming. hicle’s cooling system, the radiator cap should have a

R-134a refrigerant is a greenhouse gas which, if holding pressure which meets manufacturers specifi-

allowed to vent into the atmosphere, will contribute to cations. A cap which fails to hold these pressures

global warming (the Greenhouse Effect). should be replaced.

It is usually more economically feasible to have a

l Any obstruction of or damage to the condenser

certified MVAC automotive technician perform A/C configuration will restrict air flow which is essential

system service on your vehicle. Some possible rea- to its efficient operation. It is, therefore, a good rule

sons for this are as follows: to keep this unit clean and in proper physical shape.

l While it is illegal to service an A/C system

without the proper equipment, the home mechanic ti See Figure 122

*it is recommended that the A/C svstem be

serviced by an EPA Section 609 cehified au-

tomotivetechnicfan utilizing a refrigerant re-

covery/recycling machfne.

The do-it-yourselfer should not service his/her

own vehicle’s A/C system for many reasons, includ-

ing legal concerns, personal injury, environmental

damage and cost. The following are some of the rea-

sons why you may decide not to service your own ve-

hicle’s A/C system.

According to the U.S. Clean Air Act, it is a federal

crime to service or repair (involving the refrigerant) a

Motor Vehicle Air Conditioning (MVAC) system for

money without being EPA certified. It is also illegal to

vent R-12 and R-134a refrigerants into the atmos-

phere. Selling or distributing A/C system refrigerant

(in a container which contains less than 20 pounds oi

refrigerant) to any person who is not EPA 609 certi-

fied is also not allowed by law.

State and/or local laws may be more strict than the

federal regulations, so be sure to check with your

state and/or local authorities for further information.

For further federal information on the legality of ser-

vicing your AK system, call the EPA Stratospheric

Ozone Hotline.

*Federal law dictates that a fine of up to

$25,000 may be levied on people convicted

of venting refrigerant into the atmosphere.

Additionally, the EPA may pay up to $10,000

for information or services leading to a crimf

nai conviction of the violation of these laws.

When servicing an A/C system you run the risk of

handling or coming in contact with refrigerant, which

Fig. 122 A label with information concern-

ing the A/C system is typically located in the

engine compartment

f would haveto purchase an expensive refrigerant re-

covery/recycling machine to service his/her own ve-

hicle.

l Since only a certified person may purchase re-

frigerant-according to the Clean Air Act, there are

specific restrictions on selling or distributing A/C

system refrigerant-it is legally impossible (unless

certified) for the home mechanic to service his/her

own vehicle. Procuring refrigerant in an illegal fash-

ion exposes one to the risk of paying a $25,000 fine

to the EPA.

R-12 Refrigerant Conversion

If your vehicle still uses R-12 refrigerant, one

way to save A/C system costs down the road is to invesh-

gate the possibility of having your system converted

to R-134a. The older R-12 systems can be easily

converted to R-134a refrigerant by a certified auto-

motive technician by installing a few new compo-

nents and changing the system oil.

The cost of R-12 is steadily rising and will con-

tinue to increase, because it is no longer imported or

manufactured in the United States. Therefore, it is of-

ten possible to have an R-12 system converted to R-

134a and recharged for less than it would cost to just

charge the system with R-12.

If you are interested in having your system con-

verted, contact local automotive service stations for

more details and information.

u See Figures 123 and 124

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per- Fig. 123 A coolant tester can be used to de-

1 termine the freezing and boiling levels of

the coolant in your vehicle

Fig. 124 To ensure efficient cooling system

operation, inspect the radiator cap gasket

and seal