width MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 98 of 408

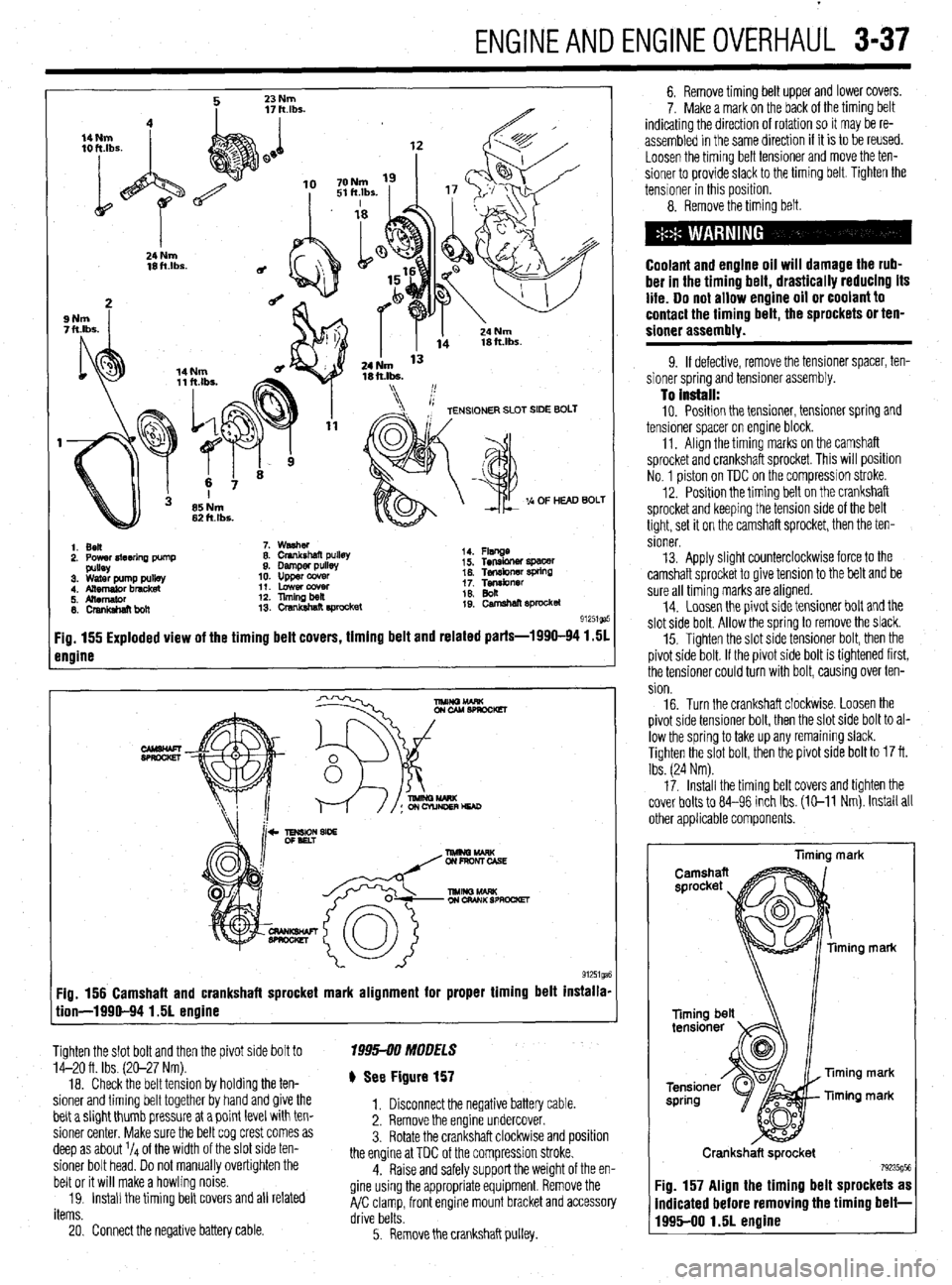

ENGINEANDENGINEOVERHAUL 3-37

1. Ben

2. Power4teerlna Dump 7. washer

8. Crankshaft pullet

9. Damper pulls

10. upper ccwer

11. Lowercowr

12. llmingbeil

13. crsnkshat? E#ocket 14. Flsnge

i 5. Tensbner spacer

16. Tef~kner WkW

1; Tgibnrr

19: camehan sprocket

91251ga

Fig. 155 Exploded view of the timing belt covers, timing belt and related parts-1990-94 1.51

engine

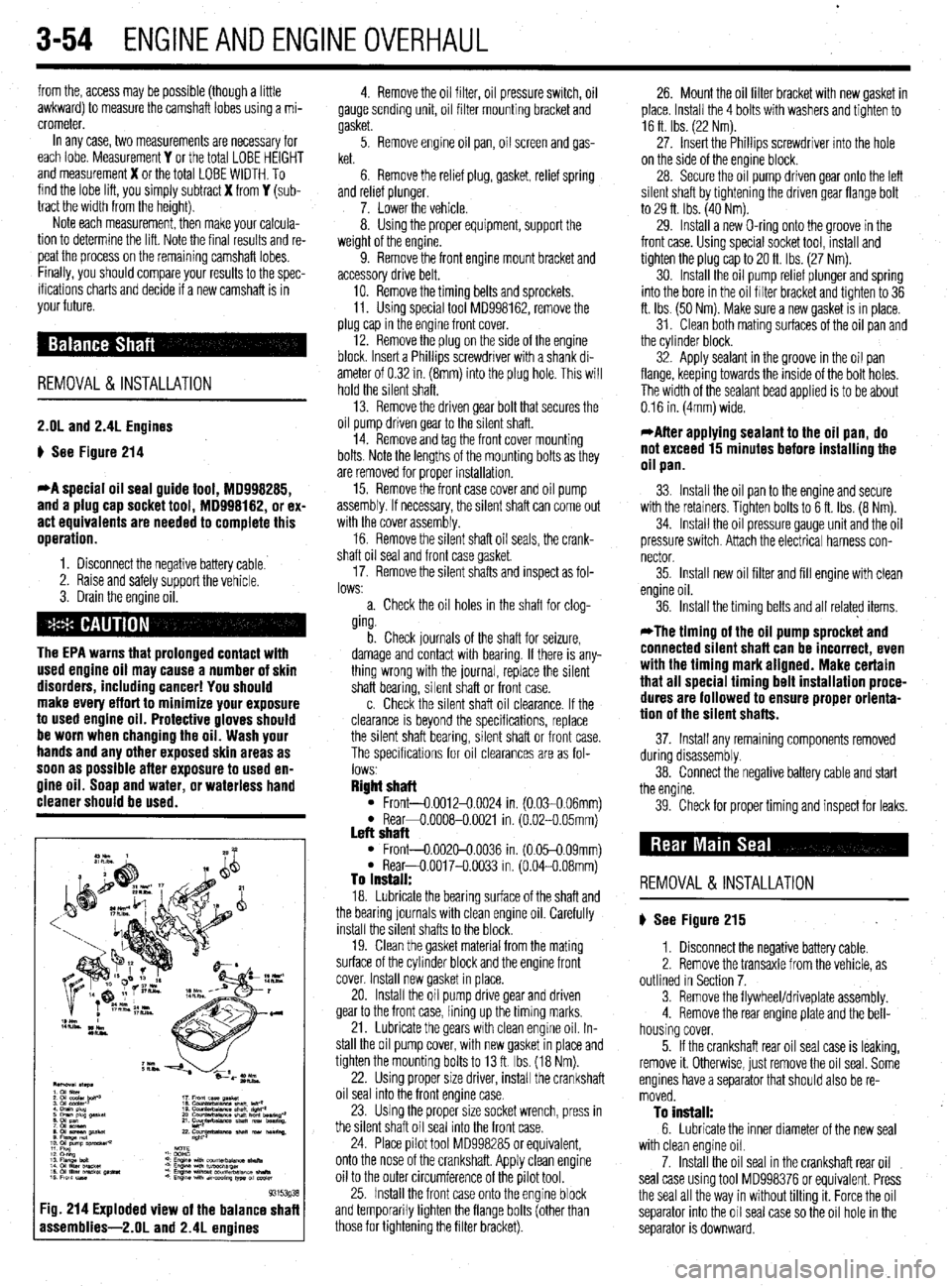

Fig. 156 Camshaft and crankshaft sprocket mark alignment for proper timing belt installa-

tion-1990-94 1.51 engine

Tighten the slot bolt and then the pivot side bolt to

14-20 ft. Ibs. (20-27 Nm).

18. Check the belt tension by holding the ten-

sioner and timing belt together by hand and give the

belt a slight thumb pressure at a point level with ten-

sioner center. Make sure the belt cog crest comes as

deep as about l/4 of the width of the slot side ten-

sioner bolt head. Do not manually overtighten the

belt or it will make a howling noise.

19. Install the timing belt covers and all related

items. 1995-00 MOOFLS

) See Figure 157

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. Rotate the crankshaft clockwlse and position

the engine at TDC of the compression stroke.

4. Raise and safely support the weight of the en-

gine using the appropriate equipment. Remove the

A/C clamp, front engine mount bracket and accessory

drive belts.

20. Connect the negative battery cable.

5. Remove the crankshaft pulley. 6. Remove timing belt upper and lower covers.

7. Make a mark on the back of the timing belt

indicating the direction of rotation so it may be re-

assembled in the same direction if it is to be reused.

Loosen the timing belt tensioner and move the ten-

sioner to provide slack to the timing belt. Tighten the

tensioner in this position.

8. Remove the timing belt.

Coolant and engine oil will damage the rub-

ber in the timing belt, drastically reducing its

life. Do not allow engine oil or coolant to

contact the timing belt, the sprockets or ten-

sioner assembly.

9. If defective, remove the tensioner spacer, ten-

sioner spring and tensioner assembly.

To install: 10. Position the tensioner, tensioner spring and

tensioner spacer on engine block.

11. Align the timing marks on the camshaft

sprocket and crankshaft sprocket. This will position

No. 1 piston on TDC on the compression stroke.

12. Position the timing belt on the crankshaft

sprocket and keeping the tension side of the belt

tight, set it on the camshaft sprocket, then the ten-

sioner.

13. Apply slight counterclockwise force to the

camshaft sprocket to give tension to the belt and be

sure all timing marks are aligned.

14. Loosen the pivot side tensioner bolt and the

slot side bolt. Allow the spring to remove the slack.

15. Tighten the slot side tensioner bolt, then the

pivot side bolt. If the pivot side bolt is tightened first,

the tensioner could turn with bolt, causing over ten-

sion.

16. Turn the crankshaft clockwise. Loosen the

pivot side tensioner bolt, then the slot side bolt to al-

low the spring to take up any remaining slack.

Tighten the slot bolt, then the pivot side bolt to 17 ft.

Ibs. (24 Nm).

17. Install the timing belt covers and tighten the

cover bolts to 84-96 inch Ibs. (E-11 Nm). Install all

other applicable components.

liming mark

ming mark

Timing mark

Timing mark

Crankshaft sprocket

79235g5t Fig. 157 Align the timing belt sprockets as

indicated before removing the timing belt-

1995-00 1.51 engine

Page 115 of 408

3-54 ENGINEANDENGINEOVERHALJL

from the, access may be possible (though a little

awkward) to measure the camshaft lobes using a mi-

crometer

In any case, two measurements are necessary for

each lobe. Measurement Y or the total LOBE HEIGHT

and measurement X or the total LOBE WIDTH. To

find the lobe lift, you simply subtract X from Y (sub-

tract the width from the height).

Note each measurement, then make your calcula-

tion to determine the lift. Note the final results and re-

peat the process on the remaining camshaft lobes.

Finally, you should compare your results to the spec-

ifications charts and decide if a new camshaft is in

your future.

REMOVAL &INSTALLATION

2.OL and 2.4L Engines

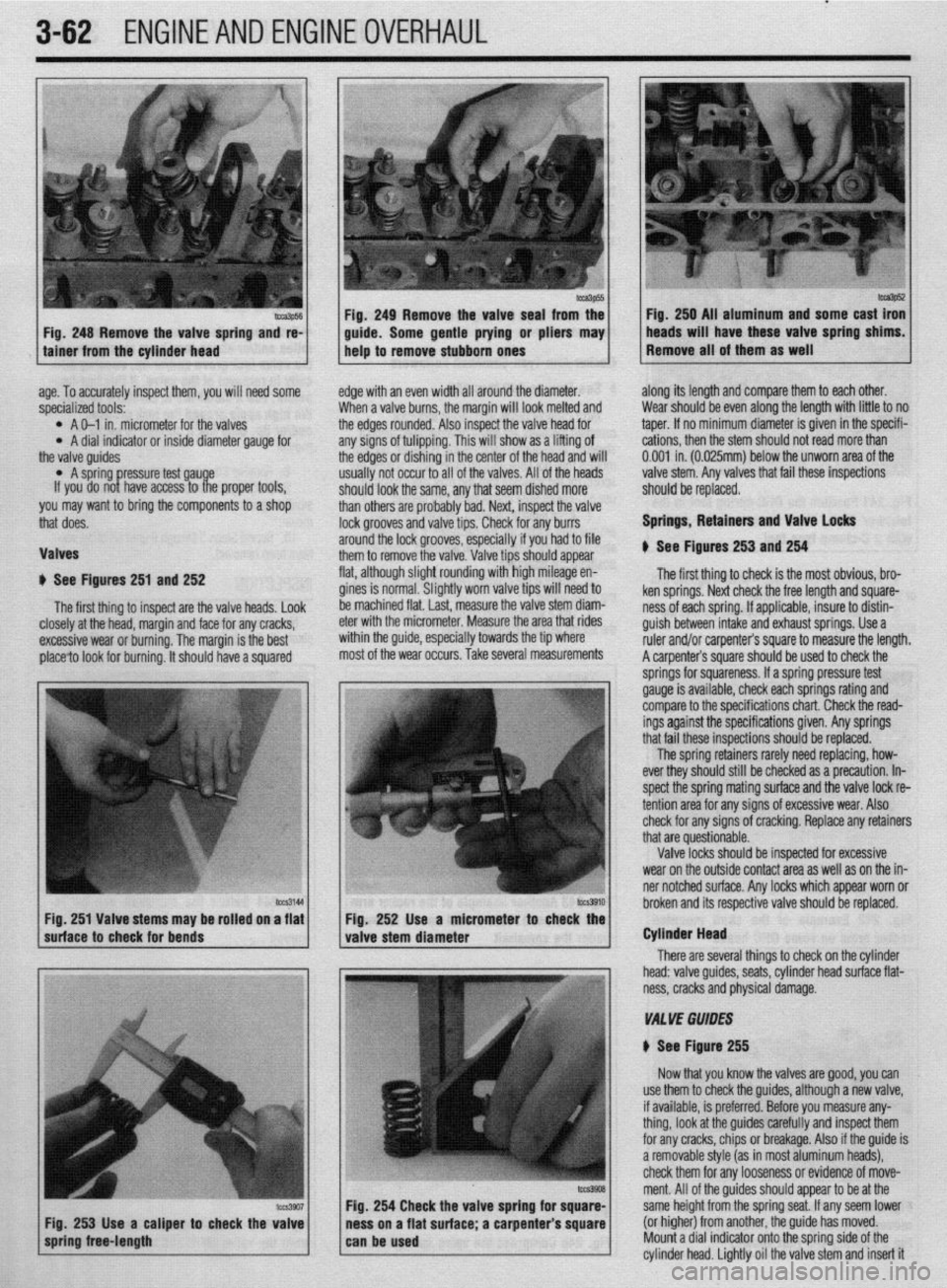

p See Figure 214

*A special oil seal guide tool, 18998285,

and a plug cap socket tool, MD998182, or ex-

act equivalents are needed to complete this

operation.

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

93153g3

:ig. 214 Exploded view of the balance shaf

assemblies-2.01 and 2.4L enoines

4. Remove the oil filter, oil pressure switch, oil

gauge sending unit, oil filter mounting bracket and

gasket.

5. Remove engine oil pan, oil screen and gas-

ket.

6. Remove the relief plug, gasket, relief spring

and relref plunger.

7. Lower the vehicle.

8. Using the proper equipment, support the

weight of the engine.

9. Remove the front engine mount bracket and

accessory drive belt,

10. Remove the timing belts and sprockets.

11. Using special tool MD998162, remove the

plug cap in the engine front cover.

12. Remove the plug on the side of the engine

block. Insert a Phillips screwdriver with a shank di-

ameter of 0.32 in. (8mm) into the plug hole. This will

hold the silent shaft.

13. Remove the driven gear bolt that secures the

oil pump driven gear to the silent shaft.

14. Remove and tag the front cover mounting

bolts. Note the lengths of the mounting bolts as they

are removed for proper installation.

15. Remove the front case cover and oil pump

assembly. If necessary, the silent shaft can come out

with the cover assembly.

16. Remove the silent shaft oil seals, the crank-

shaft oil seal and front case gasket

17. Remove the silent shafts and inspect as fol-

lows:

a. Check the oil holes in the shaft for clog-

ging.

b. Check journals of the shaft for seizure,

damage and contact with bearing. If there is any-

thing wrong with the journal, replace the silent

shaft bearing, silent shaft or front case.

c. Check the silent shaft oil clearance. If the

clearance is beyond the specifications, replace

the silent shaft bearing, silent shaft or front case.

The specifications for oil clearances are as fol-

lows

Right shaft l Front-0.0012-0.0024 in. (0.030.06mml l Rear+0.0008-0.0021 in. (6.02-O 05mm) Left shaft l Front-0.002&0.0036 in. (0.05-0.09mm) l Rear-O.0017-O.0033 in. (0.04-0.08mm) To install: 18. Lubricate the bearing surface of the shaft and

the bearing journals with clean engine oil. Carefully

install the silent shafts to the block.

19. Clean the gasket material from the mating

surface of the cylinder block and the engine front

cover. Install new gasket in place.

20. Install the oil pump drive gear and driven

gear to the front case, lining up the timing marks.

21. Lubricate the gears with clean engine oil. In-

stall the oil pump cover, with new gasket in place and

tighten the mounting bolts to 13 ft. Ibs. (18 Nm).

22. Using proper size driver, install the crankshaft

oil seal into the front engine case.

23. Using the proper size socket wrench, press in

the silent shaft oil seal into the front case.

24. Place pilot tool MD998285 or equivalent,

onto the nose of the crankshaft. Apply clean engine

oil to the outer circumference of the pilot tool.

25. Install the front case onto the engine block

and temporarily tighten the flange bolts (other than

those for tightening the filter bracket). 26. Mount the oil filter bracket with new gasket in

place. Install the 4 bolts with washers and tighten to

16 ft Ibs. (22 Nm).

27. Insert the Phillips screwdriver into the hole

on the side of the engine block.

28. Secure the oil pump driven gear onto the left

silent shaft by tightening the driven gear flange bolt

to 29 ft. Ibs. (40 Nm).

29. Install a new O-ring onto the groove in the

front case. Using special socket tool, install and

tighten the plug cap to 20 ft. Ibs (27 Nm).

30. Install the oil pump relief plunger and spring

into the bore in the oil filter bracket and tighten to 36

ft. Ibs. (50 Nm). Make sure a new gasket is in place.

31. Clean both mating surfaces of the oil pan and

the cylinder block.

32. Apply sealant in the groove in the oil pan

flange, keeping towards the inside of the bolt holes.

The width of the sealant bead applied is to be about

0.16 in. (4mm) wide.

*After applying sealant to the oil pan, do

not exceed 15 minutes before installing the

oil pan.

33. Install the oil pan to the engine and secure

with the retainers. Tighten bolts to 6 ft. Ibs. (8 Nm).

34. Install the oil pressure gauge unit and the oil

pressure switch. Attach the electrical harness con-

nector

35. Install new oil filter and fill engine with clean

engine oil.

36. Install the timing belts and all related items,

*The timing of the oil pump sprocket and

connected silent shaft can be incorrect, even

with the timing mark aligned. Make certain

that all special timing belt installation proce-

dures are followed to ensure proper orienta-

tion of the silent shafts.

37. Install any remaining components removed

during disassembly.

38. Connect the negative battery cable and start

the engine.

39. Check for proper timing and inspect for leaks.

REMOVAL &INSTALLATION

p See Figure 215

1. Disconnect the negative battery cable.

2. Remove the transaxle from the vehicle, as

outlined in Section 7.

3. Remove the flywheel/driveplate assembly.

4. Remove the rear engine plate and the bell-

housing cover.

5. If the crankshaft rear oil seal case is leaking,

remove it. Otherwise, just remove the oil seal. Some

engines have a separator that should also be re-

moved.

To install: 6. Lubricate the inner diameter of the new seal

with clean engine oil.

7. Install the oil seal in the crankshaft rear oil

seal case using tool MD998376 or equivalent. Press

the seal all the way in without tilting it. Force the oil

separator into the oil seal case so the oil hole in the

separator is downward.

Page 123 of 408

.

3-62 ENGINEANDENGINEOVERHAUL

lge. To accurately inspect them, you will need some

,pecialized tools:

l A O-l in. micrometer for the valves l A dial indicator or inside diameter gauge for

he valve guides

l A spring ressure test gau e

If you do no P Yl have access to t e proper tools,

‘ou may want to bring the components to a shop

hat does.

lalves

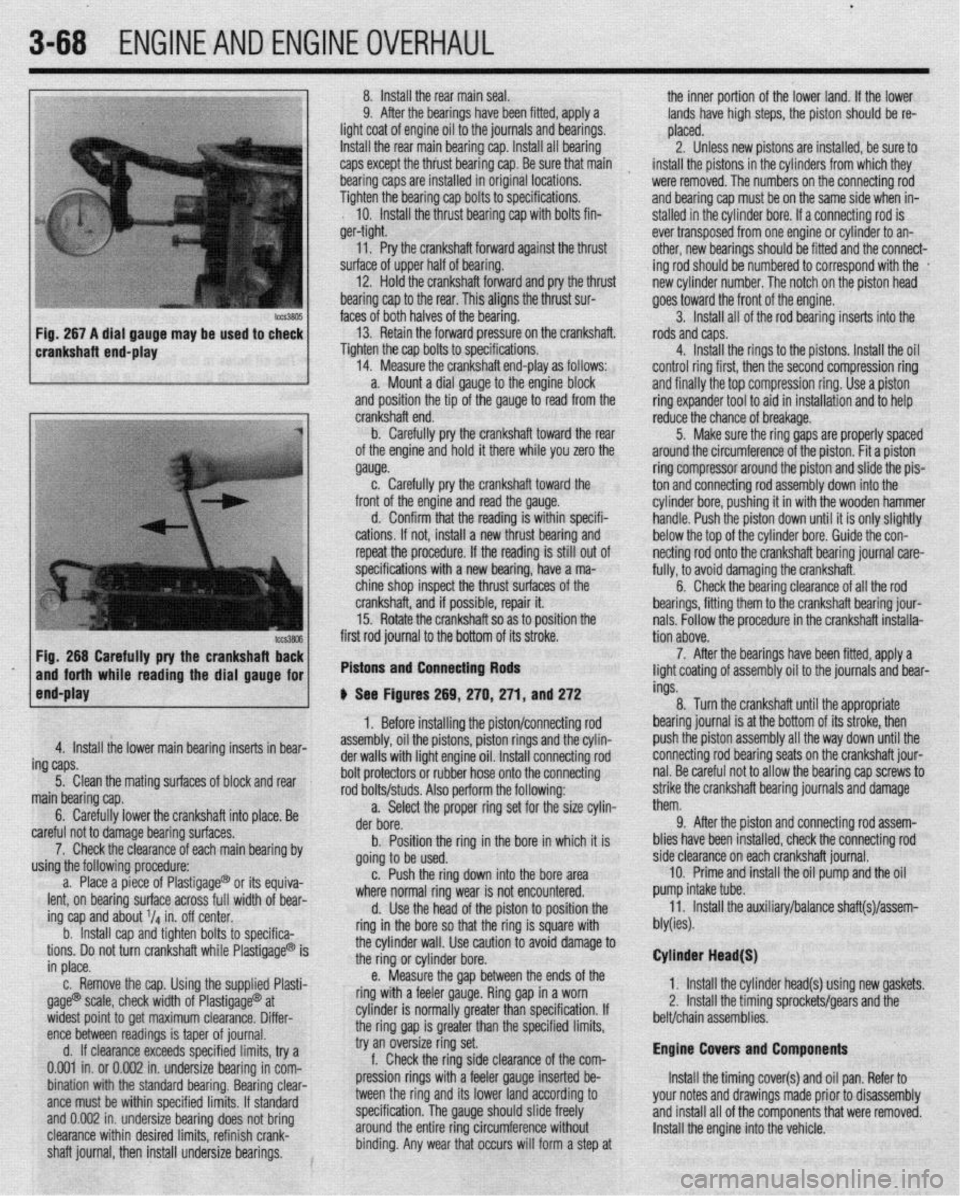

1 See Figures 251 and 252

The first thing to inspect are the valve heads. Look

E :losely at the head, margin and face for any cracks,

rxcessive wear or burning. The margin is the best

)lace?o look for burning. It should have a squared E

c

edge with an even width all around the diameter.

When a valve burns, the margin will look melted and

the edges rounded. Also inspect the valve head for

any signs of tulipping. This will show as a lifting of

the edges or dishing in the center of the head and will

usually not occur to all of the valves. All of the heads

should look the same, any that seem dished more

than others are probably bad. Next, inspect the valve

lock grooves and valve tips. Check for any burrs

around the lock grooves, especially if you had to file

them to remove the valve. Valve tips should appear

flat, although slight rounding with high mileage en-

gines is normal. Slightly worn valve tips will need to

be machined flat. last, measure the valve stem diam-

eter with the micrometer. Measure the area that rides

within the guide, especially towards the tip where

most of the wear occurs. Take several measurements along its length and compare them to each other.

Wear should be even along the length with little to no

taper. If no minimum diameter is given in the specifi-

cations, then the stem should not read more than

0.001 in. (0.025mm) below the unworn area of the

valve stem. Any valves that fail these inspections

should be replaced.

Springs, Retainers and Valve Locks

$ See Figures 253 and 254

The first thing to check is the most obvious, bro-

ken springs. Next check the free length and square-

ness of each spring. If applicable, insure to distin-

guish between intake and exhaust springs. Use a

ruler and/or carpenter’s square to measure the length.

A carpenter’s square should be used to check the

lCZS3144

I I hrnknn itc Fig. 251 Valve stems may be rolled on a flat Fio. 252 Use a micrometer

suhace to check for bends

valve stem diameter r to check the

I

There are seve Cylinder Head

ral things to check on the cylinder

head: valve guides, seats, cylinder head surface flat-

ness, cracks and physical damage.

VA1 YE GUIDES

N See Figure 255

Now that you know the valves are good, you can

254 Check the valve spring fo

s on a flat surface; a carpenter use them to check the guides, although a new valve,

if available, is preferred. Before you measure any-

thing, look at the guides carefully and inspect them

for any cracks, chips or breakage. Also if the guide is

a removable style (as in most aluminum heads),

check them for any looseness or evidence of move-

ment. All of the guides should appear to be at the

same height from the spring seat. If any seem lower

(or higher) from another, the guide has moved.

Mount a dial indicator onto the sorina side of the

cylinder head. Lightly oil the valve stem and insert it

Page 129 of 408

.

3-68 ENGINEANDENGINEOVERHAUL

crankshaft end-play 8. Install the rear main seal.

the inner portion of the lower land. If the lower

9. After the bearings have been fitted, apply a

lands have high steps, the piston should be re-

light coat of engine oil to the journals and bearings.

placed.

Install the rear main bearing cap. Install all bearing

2. Unless new pistons are installed, be sure to

caps except the thiust bearing cap. Be sure that main

I

install the pistons in the cylinders from which they

bearing caps are installed in original locations.

were removed. The numbers on the connecting rod

Tighten the bearing cap bolts to specifications.

and bearing cap must be on the same side when in-

10. Install the thrust bearing cap with bolts fin-

stalled in the cylinder bore. If a connecting rod is

ger-tight.

ever transposed from one engine or cylinder to an-

11. Pry the crankshaft forward against the thrust

other, new bearings should be fitted and the connect-

surface of upper half of bearing.

ing rod should be numbered to correspond with the *

12. Hold the crankshaft forward and pry the thrust

new cylinder number. The notch on the piston head

bearing cap to the rear. This aligns the thrust sur-

goes toward the front of the engine.

faces of both halves of the bearing.

3. Install all of the rod bearing inserts into the

13. Retain the forward pressure on the crankshaft.

rods and caps.

Tighten the cap bolts to specifications.

4. Install the rings to the pistons. Install the oil

14. Measure the crankshaft end-play as follows:

control ring first, then the second compression ring

a. Mount a dial gauge to the engine block

and finally the top compression ring. Use a piston

and position the tip of the gauge to read from the

ring expander tool to aid in installation and to help

Fig. 266 Carefully pry the crankshafl Ez

and forth while reading the dial gauge for

end-play first rod journal to the bottom of its stroke.

Pistons and Connecting Rods

4. Install the lower main bearing inserts in bear-

ing caps.

5. Clean the mating surfaces of block and rear

main bearing cap.

6. Carefully lower the crankshaft into place. Be

careful not to damage bearing surfaces.

7. Check the clearance of each main bearing by

using the following procedure:

a. Place a piece of Plastigage@ or its equiva-

lent, on bearing surface across full width of bear-

ing cap and about V4 in. off center.

b. Install cap and tighten bolts to specifica-

tions. Do not turn crankshaft while Plastigage@ is

in place.

c. Remove the cap. Using the supplied Plasti-

gage@ scale, check width of Plastigage@ at

widest point to get maximum clearance. Differ-

ence between readings is taper of journal.

d. If clearance exceeds specified limits, try a

0.001 in. or 0.002 in. undersize bearing in com-

bination with the standard bearing. Bearing clear-

ante must be within specified limits. If standard

and 0.002 in. undersize bearing does not bring

clearance within desired limits, refinish crank-

shaft journal, then install undersize bearings. crankshaft end.

b. Carefully pry the crankshaft toward the rear

of the engine and hold it there while you zero the

gauge.

c. Carefully pry the crankshaft toward the

front of the engine and read the gauge.

d. Confirm that the reading is within specifi-

cations. If not, install a new thrust bearing and

repeat the procedure. If the reading is still out of

specifications with a new bearing, have a ma-

chine shop inspect the thrust surfaces of the

crankshaft, and if possible, repair it.

15. Rotate the crankshaft so as to position the

# See Figures 269, 270,271, and 272

1. Before installing the piston/connecting rod

assembly, oil the pistons, piston rings and the cylin-

der walls with light engine oil. Install connecting rod

bolt protectors or rubber hose onto the connecting

rod bolts/studs. Also perform the following:

a. Select the proper ring set for the size cylin-

der bore.

b. Position the ring in the bore in which it is

going to be used.

c. Push the ring down into the bore area

where normal ring wear is not encountered.

d. Use the head of the piston to position the

ring in the bore so that the ring is square with

the cylinder wall. Use caution to avoid damage to

the ring or cylinder bore.

e. Measure the gap between the ends of the

ring with a feeler gauge. Ring gap in a worn

cylinder is normally greater than specification. If

the ring gap is greater than the specified limits,

try an oversize ring set.

f. Check the ring side clearance of the com-

pression rings with a feeler gauge inserted be-

tween the ring and its lower land according to

specification. The gauge should slide freely

around the entire ring circumference without

binding. Any wear that occurs will form a step at reduce the chance of breakage.

5. Make sure the ring gaps are properly spaced

around the circumference of the piston. Fit a piston

ring compressor around the piston and slide the pis-

ton and connecting rod assembly down into the

cylinder bore, pushing it in with the wooden hammer

handle. Push the piston down until it is only slightly

below the top of the cylinder bore. Guide the con-

netting rod onto the crankshaft bearing journal care-

fully, to avoid damaging the crankshaft.

6. Check the bearing clearance of all the rod

bearings, fitting them to the crankshaft bearing jour-

nals. Follow the procedure in the crankshaft installa-

tion above.

7. After the bearings have been fitted, apply a

light coating of assembly oil to the journals and bear-

ings.

8. Turn the crankshaft until the appropriate

bearing journal is at the bottom of its stroke, then

push the piston assembly all the way down until the

connecting rod bearing seats on the crankshaft jour-

nal. Be careful not to allow the bearing cap screws to

strike the crankshaft bearing journals and damage

them.

9. After the piston and connecting rod assem-

blies have been installed, check the connecting rod

side clearance on each crankshaft journal.

10. Prime and install the oil pump and the oil

pump intake tube.

11. Install the auxiliary/balance shaft(s)/assem-

bly(ies).

Cylinder Head(S)

1. Install the cylinder head(s) using new gaskets.

2, Install the timing sprockets/gears and the

belt/chain assemblies.

Engine Covers and Components

Install the timing cover(s) and oil pan. Refer to

your notes and drawings made prior to disassembly

and install all of the components that were removed.

Install the engine into the vehicle.

Page 131 of 408

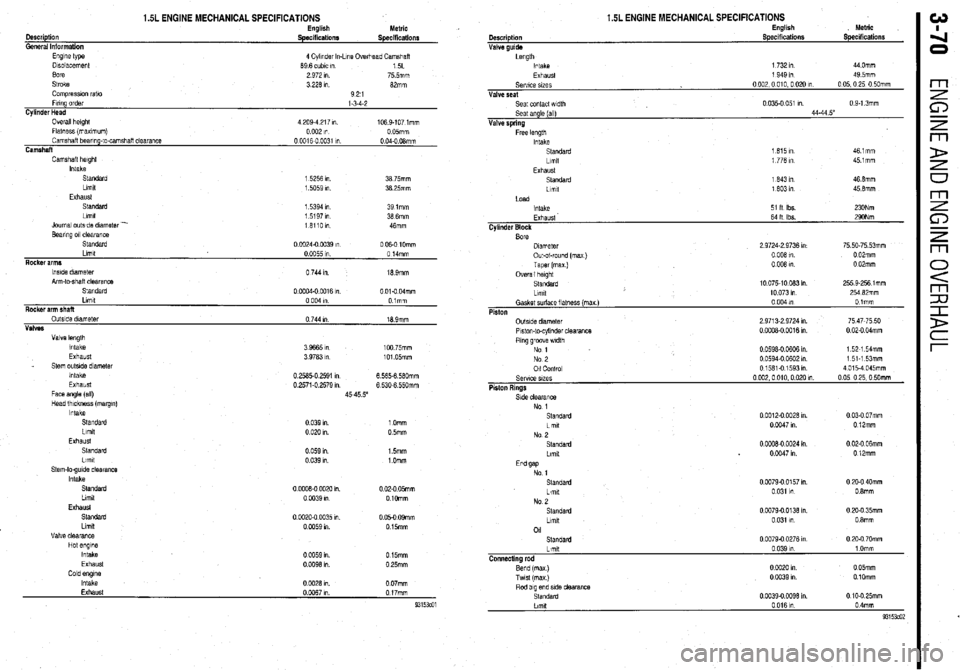

1.5L ENGINE MECHANICAL SPECIFICATIONS English

Metric

Description

Specificationr

Specifications

General Information

Engine type

4 Cylinder In-Line Ovethead Camshaft

Displacement 69 6 cubic I” 15L

sore 2 972 I” 75 5mm

Stroke 3 226 I” 82mm

Compression rat10 921

Firing order

l-3-4-2

Cylinder Head

Overall height 4 209.4 217 I” 1059-107 lmm

Flatness (maximum) 0 002 I” 0 05mm

Camshaft bearing-to-camshaft clearance 0 0016-O 0031 I” 0 04-O OBmm

Camshaft

Camshaft height

Intake

Standard 1 5256 I”. 39 75mm

Limit

1.5059 In 38.25mm

Exhaust

Standard 1 5394 I” 391mm

Llmlt 1 5197 In 38 6mm

Journal outside diameter -

161101”

46mm

Bearing 011 clearance

Standard

0 1X324.0 a)39 I” 0 06-O 10mm

Rocker arms Limit

0 0055 I” 0 14mm

lwde diameter

Arm-to-shalt clearance

Standard 0 744 I”. 18 Smm

0 OCQ4-0 0016 I”. 0 Old 04mm

Llmlt 0 004 I” Olmm

Rocker arm shaft

OutsIde diameter 0 744 I” 16 9mm

Valves

Valve length

Intake 3 9665 I” 100 75mm

Exhaust 3 9763 I” 101.05mm

_ Stem outslde diameter

Intake 0 2585.0 2591 I” 6.565-6 5tlOmm

Exhaust 0 2571-o 2579 I” 6 530-6 55Omm

Face angle (ail)

45-45 5”

Head thickness (margm)

Intake

Standard 0 039 I”. 1 Omm

Llmlt

0 02u In. 05mm

Exhaust

0 059 I”

0 039 I”. 1.5mm

1 .Omm

0 02-O 05mm

0 1Omm

0 05-O OSmm

0 15mm

0 15mm

0 25mm

0 07mm Cescriptlon

Valve guide 1.5L ENGINE MECHANICAL SPECIFICATIONS English

Specifications Metric

Specifications

Length

Intake 1 732 I” 44 Omm

Exhaust

Selwe wes

Valve seat

Seat contact width

Seat angle (all)

Valve spring

Free length

Intake

Standard

Llmlt

Exhaust

Standard

Llmlt 1 949 I” 49 5mm

0002,0010.002cIn 0 05,O 25,O 50mm

0 035-o 051 I” 0 S-1 3mm

44.44 5”

1 615 I” 461mm

1 776 I” 451mm

1 643 I” 46 8mm

1 603 I” 45 6mm

Load

Intake

Exhaust 64 It Ibs. 290Nm

Cylinder Block

Bore

Dnmeter

Out-of-round (ma)

Taper (max.) 2 9724-Z 9736 I” 75 50.75 53mm

0 006 I” 0 02mm

0 006 I” 0 02mm

Overall height

Standard

Llrnbt 10075-10083In 255 9.256 1 mm

10 073 I” 254 62mm

No 1

Standard 0 0012-o 0028 I”. 0 03-O 07mm

Llmlt 0 0047 I” 0 12mm

No 2

Standard 0 OCOE-0 0024 I” 0 02-O 06mm

Llmlt 0 0047 I” 0 l2mm

End gap

No 1

Standard

Limit

No 2

Standard

Ltmlt

01

Standard 0 0079-o 0157 I”.

0 I” 031

0 0079.0.0136 I”

0.031 I”

0 0079.0 0276 I” 0 20-O 40mm

0 8mm

0 20-O 35mm

0.8mm

0 20-O 70mm

Limit

Connecting rod

Bend (mex)

Twst (max) 0 039 I” 1 Omm

0 CO20 I” 0 05mm

0 0039 In 0 10mm

Page 139 of 408

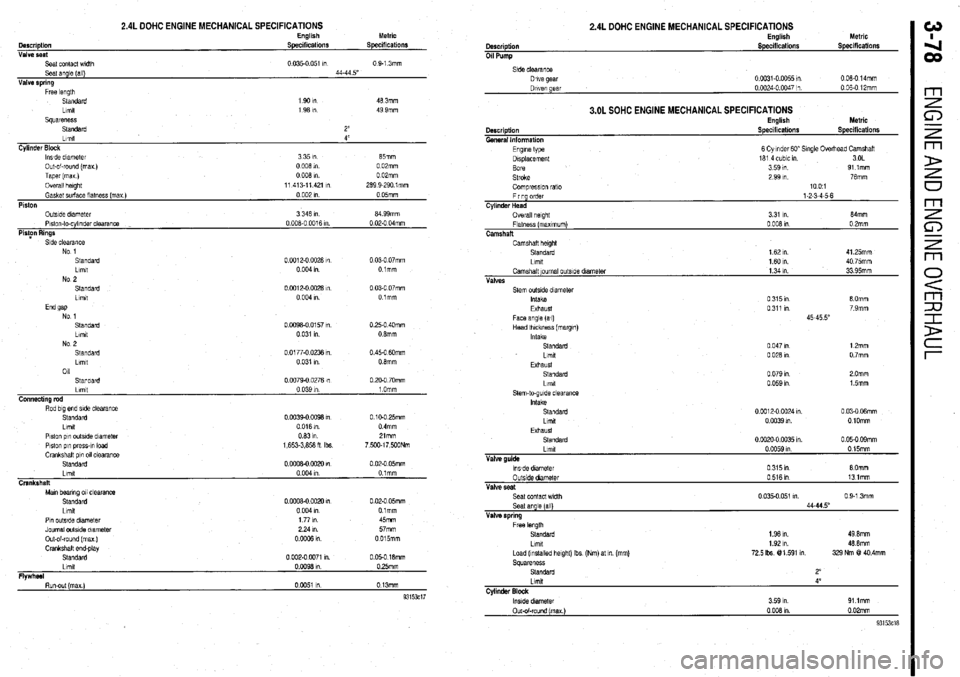

2.4L DOHC ENGINE MECHANICAL SPECIFICATIONS English Metric

Description Specifications Specdications

Valve seat

Seat contact wldlh 0.035-o 051 I”

0 9-l 3mm

Seat angle (all) 44-44 5”

Valve spring

Free length

Standard 1901n 46 3mm

Llmlt

1 96 I” 49 9mm

squareness

Standard 2”

Llmlt 4”

Cylinder Block

lwde diameter 3351n 65mm

Out-of-round (max)

0 006 in 0 02mm

Taper (mu)

0 006 I” 0 02mm

Overall height

11 413-11421 I” 269 9-290 lmm

Gasket surface llatnass (max )

0 002 In 0 05mm

Piston

OutsIde diameter

3 346 In 64 99mm

Plslon-lo-cylinder clearance

0 006.0 0016 m 0 02.0 04mm

PioFn Rings

Side clearance

No 1

Standard

0 0012-O 0026 I”

0 03-O 07mm

Limit

0 004 I”. Olmm

No 2

Standard

0 Cot 2-o 0028 I”

0 03-O 07mm

Llmlt

0 004 I” Olmm

End 9ap

No 1

Standard O.W96-0 0157 I”

0.25-O 40mm

Llmtt

0 031 I”. 0 6mm

NO 9

.__

Standard

Lrmt

011 0 0177-O 0236 I”

0 031 I” 0.45-O 6Omm

0 6mm

Standard

Llmll

Connecting rod

Rod big end side clearance

Standard

Llmlt

Plston pin outsIde dlametar

Piston p,” press-,” load

Crankshatl pin 011 clearance

Standard

Llmlt

Crankshaft

Man bearing 011 clearance

Standard

Llmlt 0

0979.0 0276 I”

0 039 I”

0 0039-o co96 I”

0 016 m.

0631n

1,653.3,656 H Ibs

0

0006-0 0020 I”

0004m

0

0006-0 0020 1”

0 004 I” 0 PO-O 70mm

1 Omm

0 10-O 25mm

0 4mm

Zlmm

7,5Wl7,500Nm

0 02-O 05mm

0 tmm

0 02-O 05mm

Olmm

Pin outstde dlameler

Journal outside diameter

Out-of-round (max )

Crankshalt and-play

Standard

Llmll

Flwhd 177m 45mm

224111 57mm

ooGQ6m 0015mm

0 002-o 0071 I”. 0 05-O 16mm

OW96Ul 0 25mm

I -. Run-out (max)

0 0051 I” 0 13mm

93153ci7

2.4L DOHC ENGINE MECHANICAL SPECIFICATIONS

0 06-O 14mm

3.OL SOHC ENGINE MECHANICAL SPECIFICATIONS

Description

General Information

Engme type

Displacement

Bore

Stroke English

Specifications Metric

Specifications

6 Cylmder GO” Single Overhead Camshatl

161 4 cubic I” 3OL

3 59 I”. 91 lmm

2 99 In. 76mm

Compreswn rat0

Firing order

Cylinder Head

Overall helghl

Flatness (maxImum)

Camshaft 1001

1-2-3-4-5-6

3 31 I” 64mrn

0 006 I” 0 2mm

Camshaft helgM

Standard

1 62 ,n 41 25mm

Llmlt

1601n 40 75mm

Camshaft ~oumal outslde diameter

1 34 I” 33 95mm

Valves

Seat contact width 0 9-1 3mm

Seat angle [all)

Valve spring

Free length

Standard

1.96 I”. 49 0mm

Llmlt

Load (Installed height) Ibs (Nm) at m (mm)

72.5 Ibs @l 591 I”.

Squareness

Standard 46 6mm

329 Nm @! 40.4mm

Lmxt 4’

Cylinder Block m

Page 141 of 408

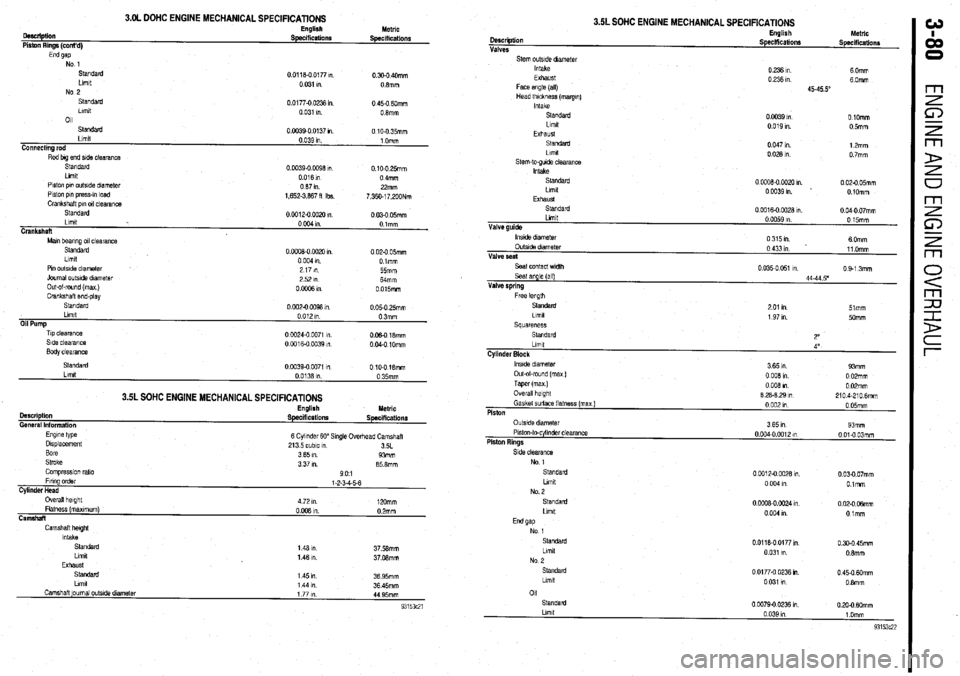

3.OL DOHC ENGINE MECHANICAL SPECIFICATIONS

oescliptiin

Piston Rings (cont’d) English Metric SpeclfiCatiOllS Specifications

End gap No 1

standard

Llmlt

No 2

Standard

Llmlt

011 0 0118-O 0177 ,“.

0.300 40mm

0 031 I” 08mm

0.01770 0236 I” 0 450 6Omm

0 031 I”. 08mm

Standard

Llmlt

Connecting rod

Rod big end side clearance 0.0039-0 0137 I” 0 10-O 35mm

0.039 1” 1 Omm

Slandard

Llmlt

Piston pm outside dnmeter

Piston pi” press-,” load

Crankshaft pm 011 clearance 0.0039-O 0098 m. 0.100 25mm

0016m 0 4mm

087111 22mm

1,652.3,887 fl Ibs.

7,350.17,200Nm

Standard

00012-oOOx)m

0 030 05mm

Llmlt

0 004 I” Olmm

Crankshaft

Mm bearing 011 clearanca

Standard

Llmlt 0 ooO8-0 0020 I” 0 020 05mm

0 004 9”. Dimm

Pm outslde diameter

Journal outs& dlametar

Out-ol-round (max )

Crankshaft end-play

standard

Llmlt

Oil Pump

Tip clearance

Side clearance

Body clearance 2171n

55mm

2521n

Mmm

OoOffiRl 0 015mm

0 002-O 0098 I” 0 05-O 25mm

0 012 I” 03mm

0 CO24.0 0071 m

006018mm

0 0016-O 0039 in. 0 040 1Omm

3.5L SOHC ENGINE MECHANICAL SPECIFICATIONS

Description

General Information

Engme type

Displacement

Bore

Stroke

Comprasslon ratio English Metric

Specifications Specifications

6 Cylinder 60” Single Ovedvzad Camshaft

213 5 cubic I”

3SL

3 65 I”. 93mm

3 37 m. 85 8mm

901

Llmlt

Camshaft ]oumal outs& dtameter 1 44 I”. 36 45mm

1771n

44 95mm

3.5L SOHC ENGINE MECHANICAL SPECIFICATIONS

Llmlt Description

Valve guide Valves

Stem outstde dmmetar

Intake

Exhaust

Face angle (all)

Head thickness (margm)

Intake

Standard

Llmlt

Exhaust

Sl.SldZld

Llmd

stem-to-gude clearance

Intake

standard

Llmlt

EXhaUsl

standarc

0 0059 I” English

0 15mm hletrlc

Speciffcationr

Specificationr

0 236 I”. 6 Omm

0 236 I”. 60mm

4545.5”

0 0039 I” OlOmm

0 019 I”. 05mlll

0 047 I” 12mm

00281n 0 7mm

0

0008-O 0020 I” 0 020 05mm

OW391n 0 lOmm

0

0016-O 0028 I”. 0 040 07mm

lnstde dram&t

OutsIde diameter

Valve seat

Seat contact width

Seal angle (all)

Valve spring

Free knoth 0315m

6 Omm

0 433 I” 11 Omm

0 035-O 051 I” 0 9-l 3mm

44-44 5’

Standard

2 01 I” 51mm

Llmlt

1 97 I”. 5omm

Squareness

Standard

2”

Llmlt

4”

Cylinder Block

lnslde diameter

3 65 I”. 93mm

Out-ol-round (max )

0 008 in 0 02mm

Taper (max ) 0 008 I” 0 02mm

Overall height

8 28-8 29 I” 2104.2106mm

Gasket surface flatness (max)

0 002 I” 0 05mm

Piston

Side clearance

No 1

standard

Llmlt

No. 2

Standard

Llmlt 0 0012-O CO28 1”.

0 03-O 07mm

0 004 In O.lmm

0 CCQ8-0 0024 I” 0 02-O 06mm

0 004 I” Otmm

01

Standard

0 0079-O 0236 I” 0 20-O MXnm

Page 151 of 408

.

4-8 DRIVEABILITYAND EMISSIONS CONTROLS

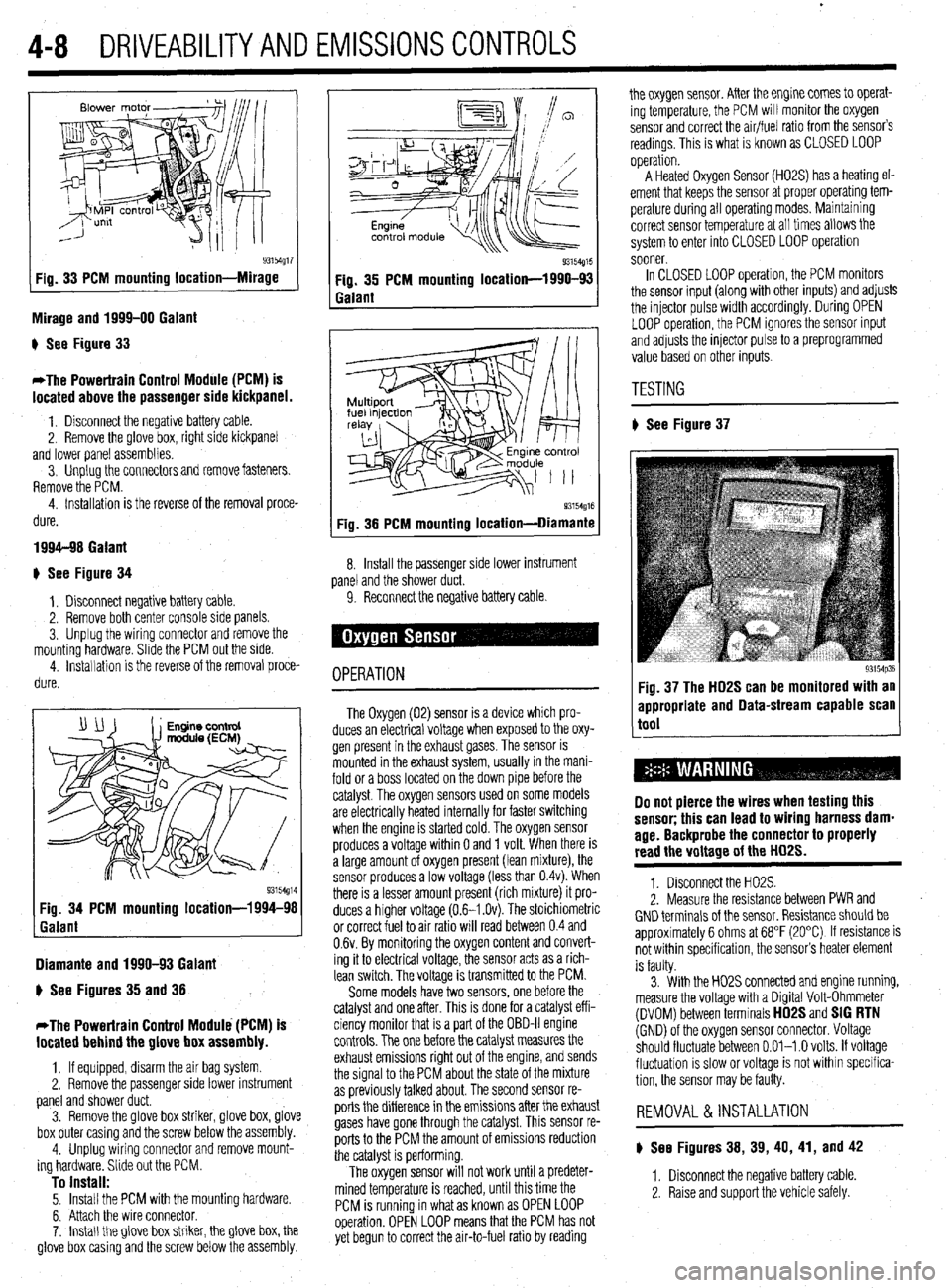

93154g17 Fig. 33 PCM mounting location-Mirage

Mirage and 1999-00 Galant

) See Figure 33

*The Powertrain Control Module (PCM) is

located above the passenger side kickpanel.

1. Disconnect the negative battery cable.

2. Remove the @love box, right side kickpanel

and lower panel assemblies.

3. Unplug the connectors and remove fasteners.

Remove the PCM.

4. Installation is the reverse of the removal proce-

dure.

1994-98 Galant

+ See Figure 34

1, Disconnect negative battery cable.

2. Remove both center console side panels.

3. Unplug the wiring connector and remove the

mounting hardware. Slide the PCM out the side.

4. installation is the reverse of the removal proce-

dure.

Diamante and 1990-93 Galant

) See Figures 35 and 38

*The Powertrain Control Module (PCM) is

located behind the glove box assembly.

1, If equipped, disarm the air bag system

2. Remove the passenger side lower instrument

panel and shower duct.

3. Remove the glove box striker, glove box, glove

box outer casing and the screw below the assembly.

4. Unplug wiring connector and remove mount-

ing hardware. Slide out the PCM.

To install: 5. Install the PCM with the mounting hardware.

6. Attach the wire connector.

7. Install the glove box striker, the glove box, the

glove box casing and the screw below the assembly.

Q3154g15 Fig. 35 PCM mounting location-1990-93

Galant

93154g16 Fig. 38 PCM mounting location-Diamante

8. Install the passenger side lower instrument

panel and the shower duct.

9. Reconnect the negative battery cable

OPERATION

The Oxygen (02) sensor is a device which pro-

duces an electrical voltage when exposed to the oxy-

gen present in the exhaust gases. The sensor is

mounted in the exhaust system, usually in the mani-

fold or a boss located on the down pipe before the

catalyst. The oxygen sensors used on some models

are electrically heated internally for faster switching

when the engine is started cold. The oxygen sensor

produces a voltage within 0 and 1 volt. When there is

a large amount of oxygen present (lean mixture), the

sensor produces a low voltage (less than 0.4~). When

there is a lesser amount present (rich mixture) it pro-

duces a higher voltage (0.6-I .Ov). The stoichiometric

or correct fuel to air ratio will read between 0.4 and

0.6~. By monitoring the oxygen content and convert-

ing it to electrical voltage, the sensor acts as a rich-

lean switch. The voltage is transmitted to the PCM.

Some models have two sensors, one before the

catalyst and one after. This is done for a catalyst eff i-

ciency monitor that is a part of the OBD-II engine

controls. The one before the catalyst measures the

exhaust emissions right out of the engine, and sends

the signal to the PCM about the state of the mixture

as previously talked about. The second sensor re-

ports the difference in the emissions after the exhaust

gases have gone through the catalyst. This sensor re-

ports to the PCM the amount of emissions reduction

the catalyst is performing.

The oxygen sensor will not work until a predeter-

mined temperature is reached, until this time the

PCM is running in what as known as OPEN LOOP

operation. OPEN LOOP means that the PCM has not

yet begun to correct the air-to-fuel ratio by reading the oxygen sensor. After the engine comes to operat-

ing temperature, the PCM will monitor the oxygen

sensor and correct the air/fuel ratio from the sensor’s

readings. This is what is known as CLOSED LOOP

operation.

A Heated Oxygen Sensor (H02S) has a heating el-

ement that keeps the sensor at proper operatmg tem-

perature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into CLOSED LOOP operation

sooner.

In CLOSED LOOP operation, the PCM monitors

the sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During OPEN

LOOP operation, the PCM ignores the sensor input

and adjusts the injector pulse to a preprogrammed

value based on other inputs.

TESTING

# See Figure 37

93154p36 Fig. 37 The HD2S can be monitored with an

appropriate and Data-stream capable scan

tool

Do not pierce the wires when testing this

sensor; this can lead to wiring harness dam-

age. Backprobe the connector to properly

read the voltage of the HD2S.

1. Disconnect the H02S.

2. Measure the resistance between PWR and

GND terminals of the sensor. Resistance should be

approximately 6 ohms at 68°F (20°C) If resistance is

not within specification, the sensor’s heater element

is faulty.

3. With the H02S connected and engine running,

measure the voltage with a Digital Volt-Ohmmeter

(DVOM) between terminals

HD2S and SIG RTN (GND) of the oxygen sensor connector. Voltage

should fluctuate between 0.01-l .O volts. If voltage

fluctuation is slow or voltage is not within specifica-

tion, the sensor may be faulty.

REMOVAL &INSTALLATION

) See Figures 38, 39, 40, 41, and 42

1. Disconnect the negative battery cable

2. Raise and support the vehicle safely.

Page 154 of 408

DRIVEABILITYAND EMISSIONS CONTROLi 4-11

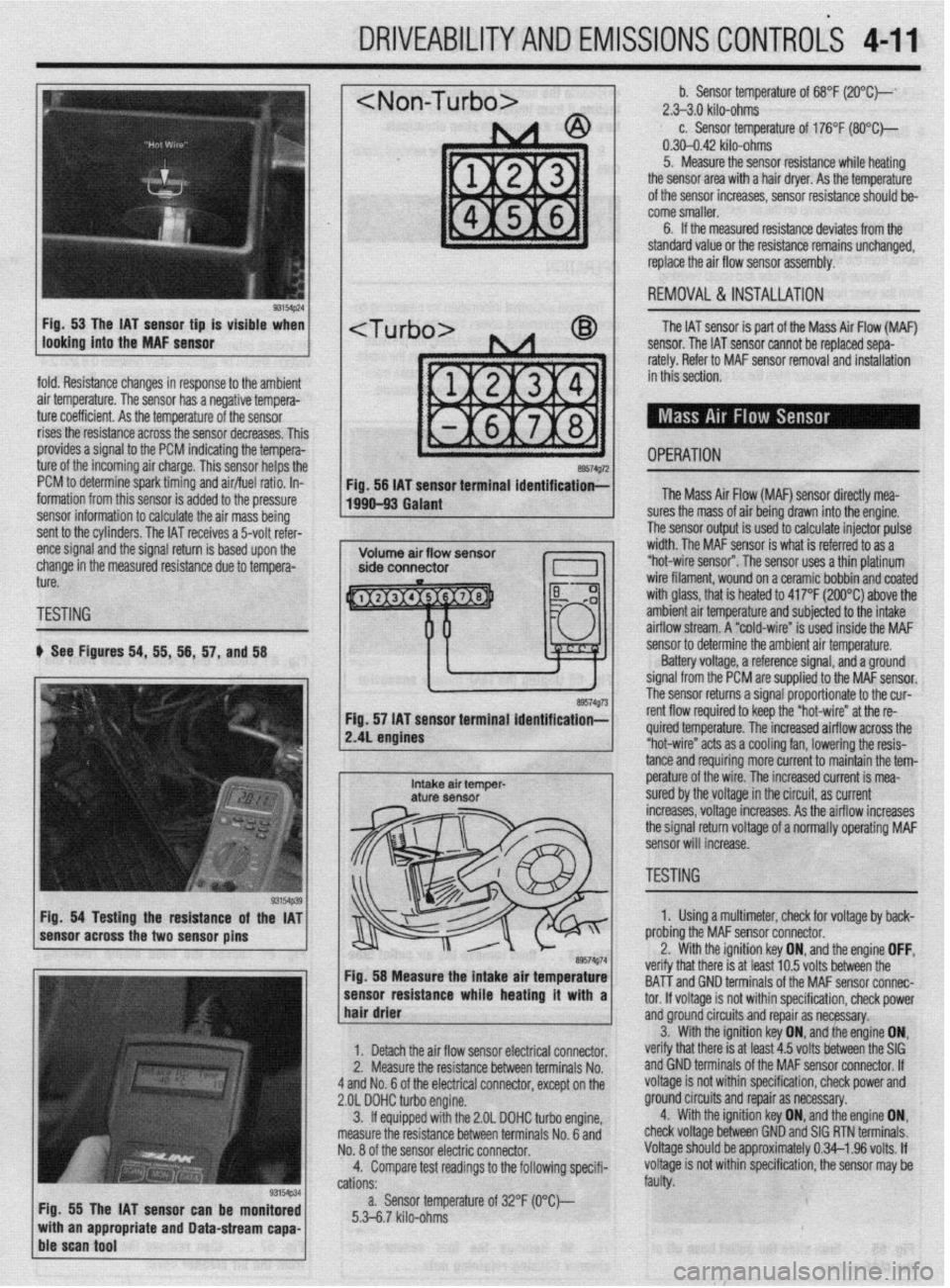

fold. Resistance changes in response to the ambient

air temperature. The sensor has a negative tempera-

ture coefficient. As the temperature of the sensor

rises the resistance across the sensor decreases. Thil

provides a signal to the PCM indicating the tempera-

ture of the incoming air charge. This sensor helps the

PCM to determine spark timing and air/fuel ratio. In-

formation from this sensor is added to the pressure

sensor information to calculate the air mass being

sent to the cylinders. The IAT receives a 5-volt refer-

ence signal and the signal return is based upon the

change in the measured resistance due to tempera-

ture.

TESTING

b See Figures 54, 55, 56, 57, and 58

Fig. 54 Testing the resistance of the IAT

sensor across the two sensor pins

Fig. 55 The IAT sensor can be monitored

with an appropriate and Data-stream capa-

ble scan tool

~1 b. Sensor temperature of 68°F (2O”C)--‘ 2.>3.0 kilo-ohms c. Sensor temperature of 176°F (SO*C)-

0.30-0.42 kilo-ohms

5. Measure the sensor resistance while heating

the sensor area with a hair dryer. As the temperature

of the sensor increases, sensor resistance should be-

come smaller.

6. If the measured resistance deviates from the

standard value or the resistance remains unchanged,

replace the air flow sensor assembly.

1 REMOVAL&INSTALLATION

The IAT sensor is part of the Mass Air Flow (MAF)

sensor. The IAT sensor cannot be replaced sepa-

rately. Refer to MAF sensor removal and installation

in this section.

- OPERATION a9574g72 Fig. 56 IAT sensor terminal identification;-

1990-93 Galant The Mass Air Flow (MAF) sensor directly mea-

lres the mass of air being drawn into the engine.

I ?he sensor output is used to calculate injector pulse

width. The MAF sensor is what is referred to as a

“hot-wire sensor”. The sensor uses a thin platinum

wire filament, wound on a ceramic bobbin and coated

with glass, that is heated to 417°F (200°C) above the

amh+en+ nir +PmnPrfijre and subiected to the intake

..I._ ~ ..-.. .“..‘r-,u.. ai mow stream. A “cold-wire” is used inside the MAF

sensor resuirance wnoe nearmg ir wnn a 1

hair drier ‘hat melt: IS al I~“< ,“.., lvllQ UtiLnbtill ,,,=

tnd GND terminals of the MAF sensor connec-

tor. If voltaae is not within specification, check power

1. Detach the air flow sensor electrical connector.

2. Measure the resistance between terminals No.

4 and No. 6 of the electrical connector, except on the

2.OL DOHC turbo engine.

3. ff equipped with the 2.OL DOHC turbo engine,

measure the resistance between terminals No. 6 and

No. 8 of the sensor electric connector.

4. Compare test readings to the following specifi-

cations:

a. Sensor temperature of 32°F (O“C)--

5.3-6.7 kilo-ohms and groundcircuits and repair as necessary.

verify that there is at least 4.5 volts between the SIG 3. With the ignition key ON, and,the engine ON,

and GND terminals of the MAF sensor connector. If

voltage is not within specification, check power and

ground circuits and repair as necessary.

4. With the ignition key ON, and the engine ON,

check voltage between GND and SIG RTN terminals.

Voltage should be approximately 0.34-l .96 volts. If

voltage is not within specification, the sensor may be

faulty.

/ sensor to determine the ambient air temperature.

Battery voltage, a reference signal, and a ground

signal from the PCM are supplied to the MAF sensor.

rho ~pn**r rp+++rns a signal proportionate to the cur-

re. The increased airflow across the

s a cooling fan, lowering the resis-

mo more current to maintain the tem- tance and requir

e^-‘.._^ ^I LL^

I

Intake air temper- pe~a+ure UI me wire. The increased current is mea- aturf sensor sured by the voltage in the circuit, as current

increases, voltage increases. As the airflow increases

the signal return voltage of a normally operating MAF

sensor will increase.

, ~~1 TESTING - II ire” at the re-

89574g74 Fig. 58 Measure the intake air temperature

-----_ ---1-a---- L..- L--1. . . .*a 1. Using a multimeter, check for voltage by back-

nrr\hinn +hn MAF sensor connector.

the ignition key ON, and the engine OFF, .^-^ :- -’ ‘.txt In E; \mltr hahrman tha veriry t

BAT-T i

Page 372 of 408

10-4 BODYANDTRIM

Fig. 8 Tailgate assembly mounting-Dia-

mante Wagon

6. Remove the tailgate from the vehicle and place

it in a safe place.

7. The installation is the reverse of removal.

Tighten the hinge

nuts to IO ft. Ibs. (14 Nm).

8. Check the alignment of the tailgate.

ALIGNMENT

To adjust the tailgate, loosen the tailgate hinge-to-

body bolts or tailgate latch assembly mounting

screws and adjust as necessary.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Open the trunk lid. Identify the trunk release

cable running from the latch to the body.

3. Disconnect the cable from the latch.

4. Detach any necessary electrical connectors.

5. Outline the position of the hinges on the

trunk lid.

6. Support the trunk lid in the open position.

7. If equipped, insert a small prytool into the

lock cover slit, remove the lock covers, then remove

the trunk lid gas springs.

8. Unfasten the retaining bolts, then remove the

trunk lid hinges.

9. Remove the trunk lid from the vehicle

10. Installation is the reverse of the removal pro-

cedure.

11. If necessary, align the trunk lid.

ALIGNMENT

1. Close the lid and check both the seam width

all around and the closed height. The trunk lid must

be flush with the adjacent panels. Minor height ad-

justments may be made by turning the rubber

bumpers on the trunk lid. Additional adjustments re-

quire loosening and repositioning of the latch and/or

striker.

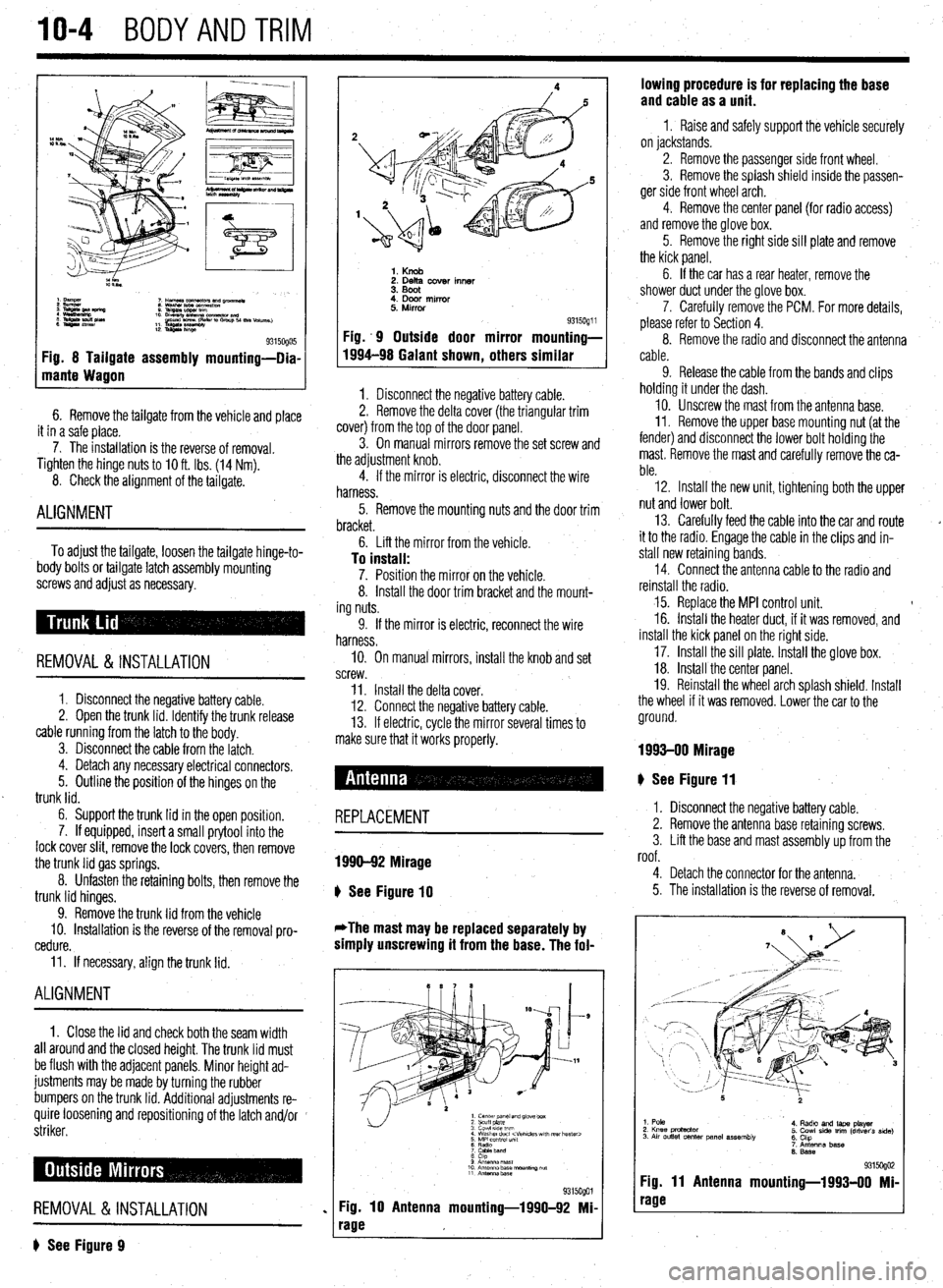

REMOVAL &INSTALLATION

? See Figure 9

1. Knob 2. Delta cover inner

3. Boot

4. Door mirror

5. Mirror

Fig. .9 Outside door mirror

1994-98 Galant shown

, others 9315oQ1 i mounting-

similar

1. Disconnect the negative battery cable.

2. Remove the delta cover (the triangular trim

cover) from the top of the door panel.

3. On manual mirrors remove the set screw and

the adjustment knob.

4. If the mirror is electric, disconnect the wire

harness.

5. Remove the mounting nuts and the door trim

bracket.

6. Lift the mirror from the vehicle.

To install: 7. Position the mirror on the vehicle.

8. Install the door trim bracket and the mount-

ing nuts.

9. If the mirror is electric, reconnect the wire

harness.

IO. On manual mirrors, install the knob and set

screw.

11. Install the delta cover.

12. Connect the negative battery cable.

13. If electric, cycle the mirror several times to

make sure that it works properly.

# See Figure 11

REPLACEMENT

1990-92 Mirage

b

See Figure 10

*The mast may be replaced separately by

simply unscrewing it from the base. The fol-

1. center panel and glove box

2 scuff plate

3 cowl 51ae wm

4 Washer duct

7 CaMeband

8 cap

9 Anrsnna mast

10 Antenna base “ourmng ““f

11 Antennz.base

%i%Qol

Fig. 10 Antenna mounting-1990-92 Mi-

rage lowing procedure is for replacing the base

and cable as a unit.

1 I Raise and safely support the vehicle securely

on jackstands.

2. Remove the passenger side front wheel.

3. Remove the splash shield inside the passen-

ger side front wheel arch.

4. Remove the center panel {for radio access)

and remove the glove box.

5. Remove the right side sill plate and remove

the kick panel.

6. If the car has a rear heater, remove the

shower duct under the glove box.

7. Carefully remove the PCM. For more details,

please refer to Section 4.

8. Remove the radio and disconnect the antenna

cable.

9. Release the cable from the bands and clips

holding it under the dash.

10. Unscrew the mast from the antenna base.

II. Remove the upper base mounting nut (at the

fender) and disconnect the lower bolt holding the

mast. Remove the mast and carefully remove the ca-

ble.

12. Install the new unit, tightening both the upper

nut and lower bolt.

13. Carefully feed the cable into the car and route

it to the radio. Engage the cable in the clips and in-

stall new retaining bands.

14. Connect the antenna cable to the radio and

reinstall the radio.

15. Replace the MPI control unit. t

16. Install the heater duct, if it was removed, and

install the kick panel on the right side.

17. Install the sill plate. Install the glove box.

18. Install the center panel.

19. Reinstall the wheel arch splash shield. Install

the wheel if it was removed. Lower the car to the

ground.

1993-00 Mirage

I. Disconnect the negative battery cable.

2. Remove the antenna base retaining screws.

3. Lift the base and mast assembly up from the

roof.

4. Detach the connector for the antenna.

5. The installation is the reverse of removal.

1. Pole

2. Knee protactor

3. Air outlet center panel assembly 4. Radto and laps player

5. Cowl side trim (driver’s side)

6. Chp

7. Antenna base

6. Base

931 !iogo2 Fig. 11 Antenna mounting-1993-00 Mi-

rage