ECO mode MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 118 of 391

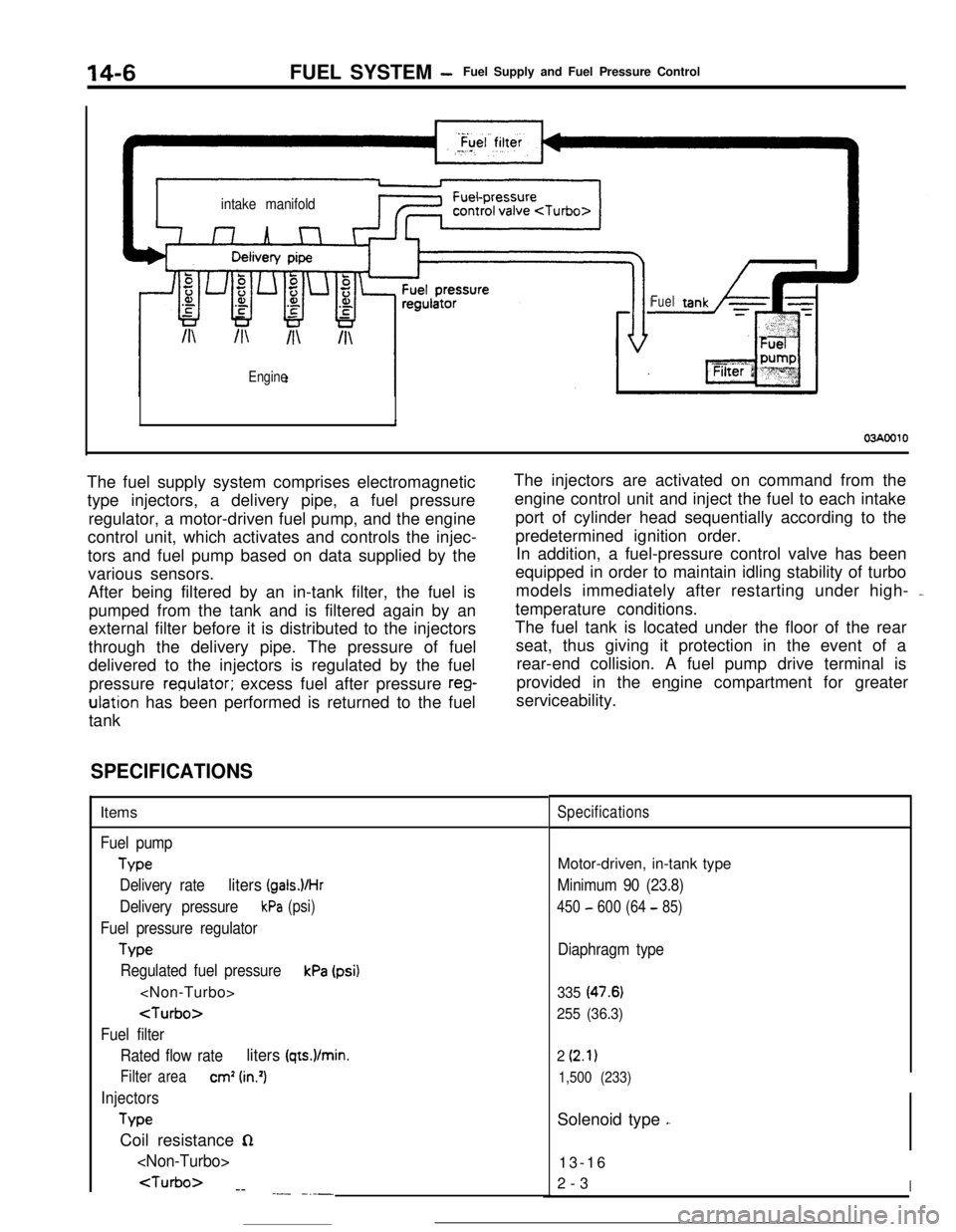

14-6FUEL SYSTEM -Fuel Supply and Fuel Pressure Control

intake manifold/I\

Engine

Fuel

03AOOlOThe fuel supply system comprises electromagnetic

type injectors, a delivery pipe, a fuel pressure

regulator, a motor-driven fuel pump, and the engine

control unit, which activates and controls the injec-

tors and fuel pump based on data supplied by the

various sensors.

After being filtered by an in-tank filter, the fuel is

pumped from the tank and is filtered again by an

external filter before it is distributed to the injectors

through the delivery pipe. The pressure of fuel

delivered to the injectors is regulated by the fuel

pressure

reoulator; excess fuel after pressure reg-ulation has been performed is returned to the fuel

tankThe injectors are activated on command from the

engine control unit and inject the fuel to each intake

port of cylinder head sequentially according to the

predetermined ignition order.

In addition, a fuel-pressure control valve has been

equipped in order to maintain idling stability of turbo

models immediately after restarting under high- -

temperature conditions.

The fuel tank is located under the floor of the rear

seat, thus giving it protection in the event of a

rear-end collision. A fuel pump drive terminal is

provided in the engine compartment for greater

serviceability.

-

SPECIFICATIONSItems

Fuel pump

Type

Delivery rate

liters (gals.VHr

Delivery pressurekPa (psi)

Fuel pressure regulator

Tvw

Regulated fuel pressurekPa (psi)

Fuel filter

Rated flow rate

liters (qts.)/min.

Filter areacm’ (in.‘)

Injectors

TypeCoil resistance

n

--

.- -_-_

SpecificationsMotor-driven, in-tank type

Minimum 90 (23.8)

450 - 600 (64 - 85)

Diaphragm type

335 (47.6)

255 (36.3)

2

(2.1)

1,500 (233)Solenoid type

,.13-16

2-3

I

Page 121 of 391

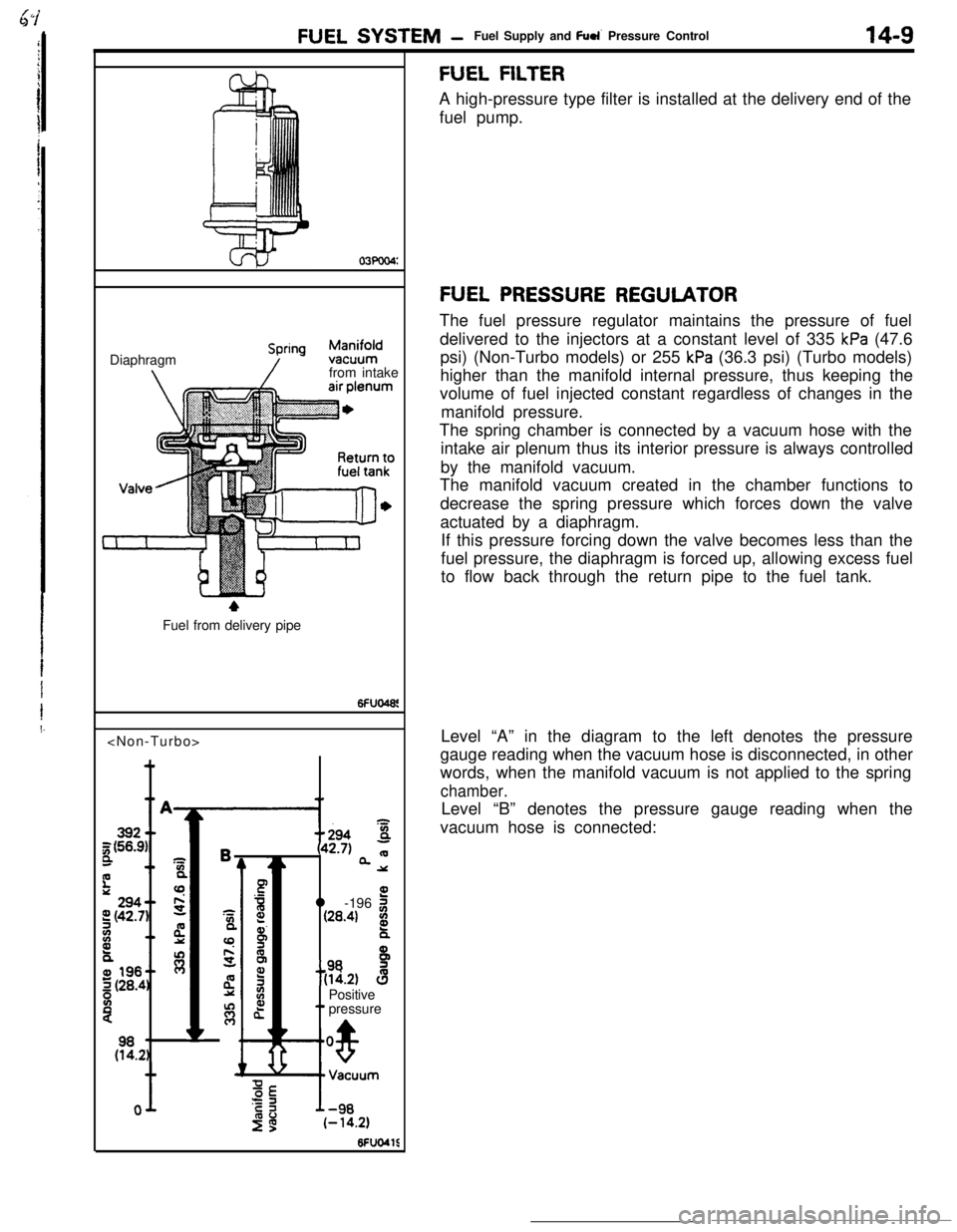

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-9

03Poo4:Diaphragm

from intake

4Fuel from delivery pipe

4m

B(42.7)QQ

2

sl -196 2

(26.4) g

t

$!a d

9

0)Positive5 z‘. pressure

(E.2)

w

FUEL FILTERA high-pressure type filter is installed at the delivery end of the

fuel pump.

FUEL PRESSURE REGULATORThe fuel pressure regulator maintains the pressure of fuel

delivered to the injectors at a constant level of 335

kPa (47.6

psi) (Non-Turbo models) or 255

kPa (36.3 psi) (Turbo models)

higher than the manifold internal pressure, thus keeping the

volume of fuel injected constant regardless of changes in the

manifold pressure.

The spring chamber is connected by a vacuum hose with the

intake air plenum thus its interior pressure is always controlled

by the manifold vacuum.

The manifold vacuum created in the chamber functions to

decrease the spring pressure which forces down the valve

actuated by a diaphragm.

If this pressure forcing down the valve becomes less than the

fuel pressure, the diaphragm is forced up, allowing excess fuel

to flow back through the return pipe to the fuel tank.

Level “A” in the diagram to the left denotes the pressure

gauge reading when the vacuum hose is disconnected, in other

words, when the manifold vacuum is not applied to the spring

chamber.Level “B” denotes the pressure gauge reading when the

vacuum hose is connected:

Page 126 of 391

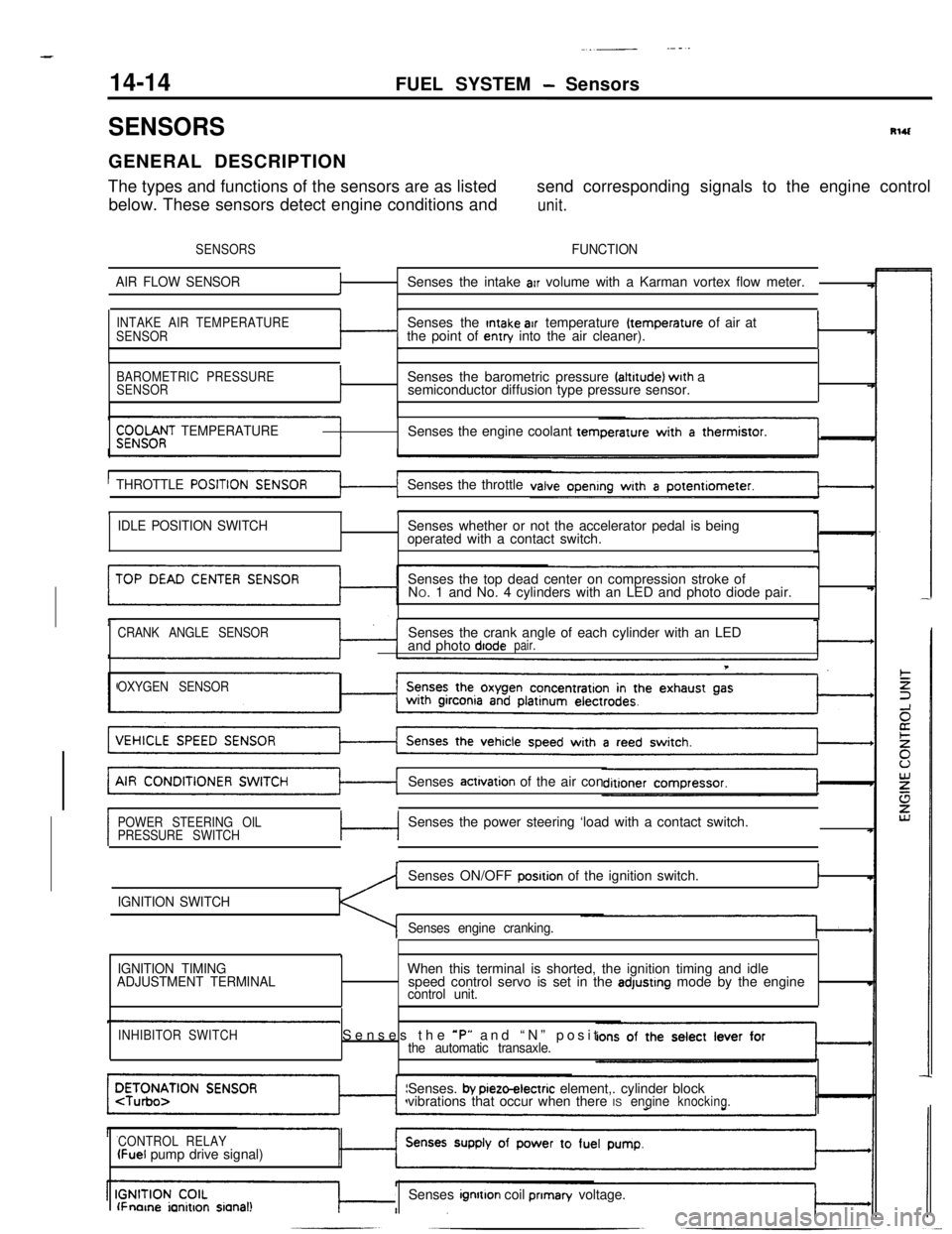

14-14

.._~- ---.FUEL SYSTEM

- Sensors

SENSORSRlUGENERAL DESCRIPTION

The types and functions of the sensors are as listedsend corresponding signals to the engine control

below. These sensors detect engine conditions and

unit.

SENSORSFUNCTION

AIR FLOW SENSOR

fSenses the intake arr volume with a Karman vortex flow meter.

INTAKE AIR TEMPERATURE

SENSORSenses the Intake air temperature (temperature of air at

the point of entry into the air cleaner).I

BAROMETRIC PRESSURE

SENSORISenses the barometric pressure faltrtude) wrth a

semiconductor diffusion type pressure sensor.

$;;OOf;T TEMPERATURESenses the engine coolant tern

THROTTLE

POSITISenses the throttle

tI

IDLE POSITION SWITCHSenses whether or not the accelerator pedal is being

operated with a contact switch.

Senses the top dead center on compression stroke of

NO. 1 and No. 4 cylinders with an LED and photo diode pair.

CRANK ANGLE SENSORSenses the crank angle of each cylinder with an LED

and photo diodepair.

T

OXYGEN SENSORSenses

actrvation of the air con

POWER STEERING OIL

PRESSURE SWITCHc-lSenses the power steering ‘load with a contact switch.

IGNITION SWITCHSenses ON/OFF

posrtion of the ignition switch.I

Senses engine cranking.

,

IGNITION TIMING

ADJUSTMENT TERMINALWhen this terminal is shorted, the ignition timing and idle

speed control servo is set in the adjustrng mode by the enginecontrol unit.

INHIBITOR SWITCHSenses the *P” and “N” positthe automatic transaxle.Senses.

by pieto-electric element,. cylinder block

vibrations that occur when there ISengineknocking.

CONTROL RELAY

(Fuel pump drive signal)

lFnorne ianitron sianal!Senses ignrtton coil prIman/ voltage.

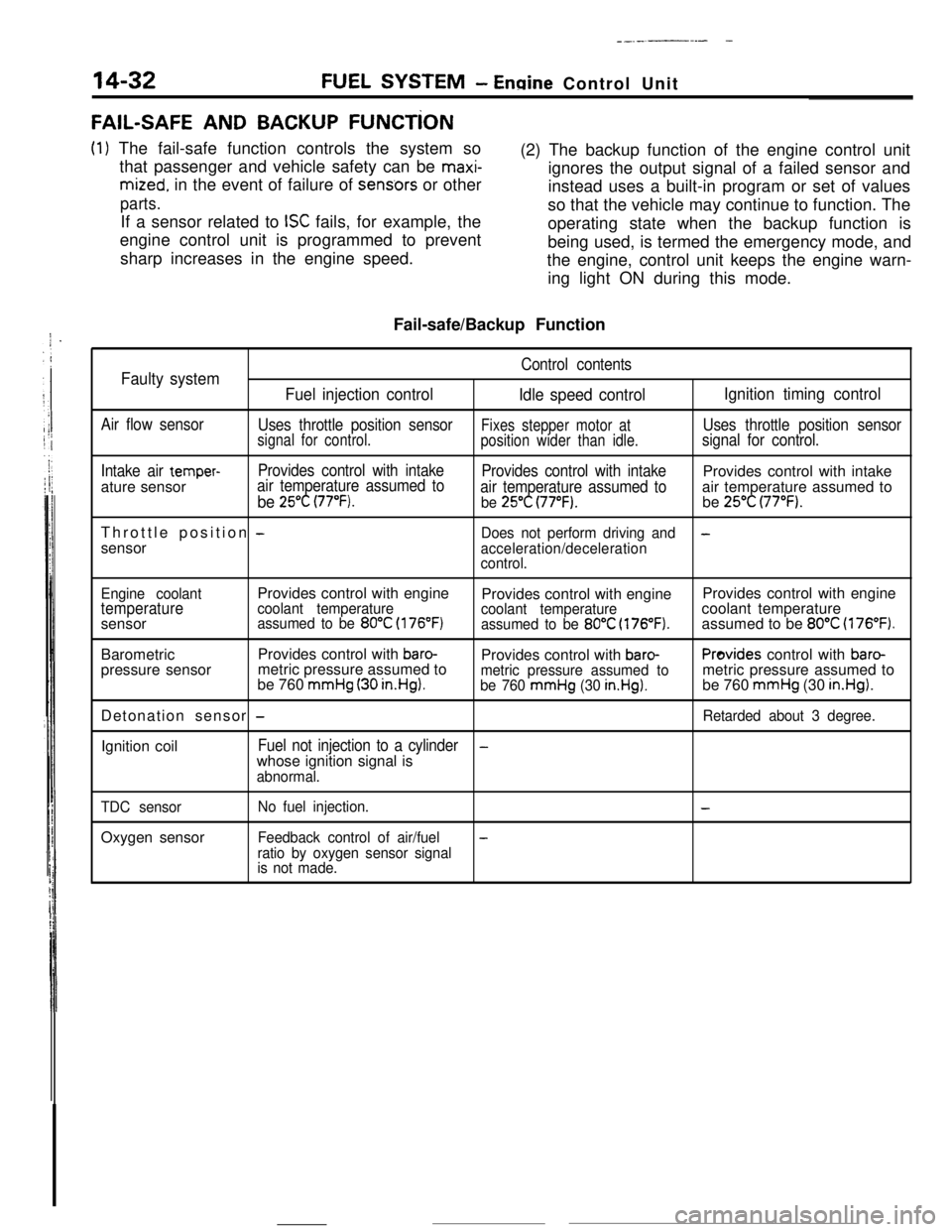

Page 144 of 391

__.-~-..- -

FUEL SYSTEM- Ermine Control Unit

FAIL-SAFE AND BACKUP FUNCTiON

(1) The fail-safe function controls the system so

that passenger and vehicle safety can be

maxi-

mized. in the event of failure of sens.ors or other

parts.If a sensor related to

ISC fails, for example, the

engine control unit is programmed to prevent

sharp increases in the engine speed.(2) The backup function of the engine control unit

ignores the output signal of a failed sensor and

instead uses a built-in program or set of values

so that the vehicle may continue to function. The

operating state when the backup function is

being used, is termed the emergency mode, and

the engine, control unit keeps the engine warn-

ing light ON during this mode.

Fail-safe/Backup Function

Control contentsFaulty system

Fuel injection control

Idle speed controlIgnition timing control

Air flow sensor

Uses throttle position sensorFixes stepper motor atUses throttle position sensorsignal for control.

position wider than idle.signal for control.

Intake air

temper-Provides control with intake

Provides control with intakeProvides control with intake

ature sensorair temperature assumed to

be 25°C (77°F).air temperature assumed toair temperature assumed tobe 25°C (77°F).be 25°C (77°F).Throttle position

-Does not perform driving and-sensor

acceleration/deceleration

control.

Engine coolantProvides control with engine

Provides control with engineProvides control with engine

temperaturecoolant temperature

coolant temperaturecoolant temperature

sensorassumed to be 80°C (176°F)assumed to be 80°C (176°F).assumed to be 80°C (176°F).BarometricProvides control with

baro-Provides control with baro-Provides control with baro-pressure sensormetric pressure assumed to

be 760

mmHg (30 in.HgI.metric pressure assumed tometric pressure assumed tobe 760 mmHg (30 in.Hg).be 760 mmHg (30 in.Hg).Detonation sensor

-Retarded about 3 degree.Ignition coil

Fuel not injection to a cylinder-whose ignition signal is

abnormal.

TDC sensorOxygen sensor

No fuel injection.-

Feedback control of air/fuel-

ratio by oxygen sensor signal

is not made.

Page 146 of 391

-

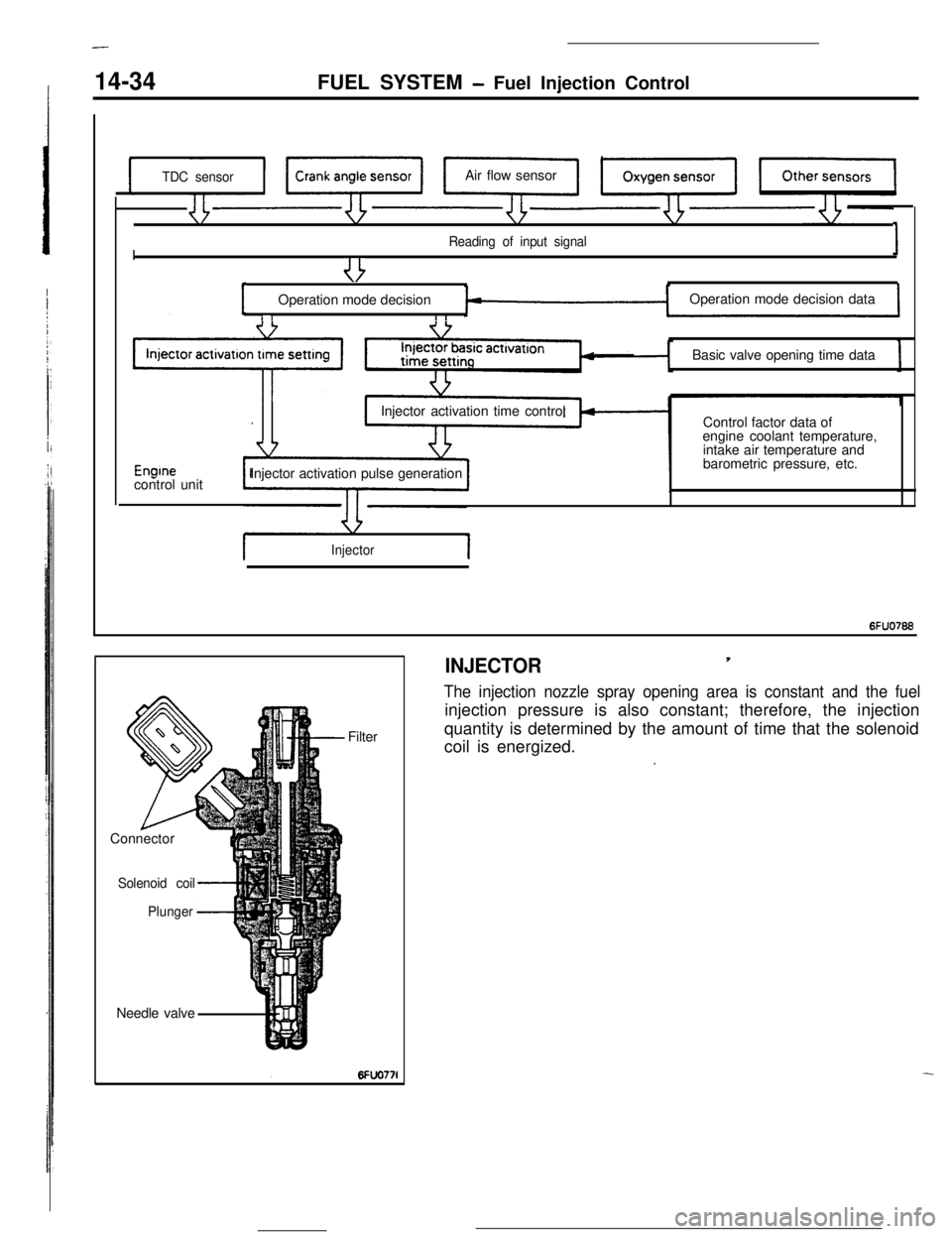

14-34FUEL SYSTEM - Fuel Injection Control

TDC sensorAir flow sensor

I

Reading of input signal1

I ,,

uOperation mode decisionOperation mode decision data

I rBasic valve opening time data

Enginecontrol unitInjector activation time control

Injector activation pulse generationControl factor data of

engine coolant temperature,

intake air temperature and

barometric pressure, etc.

Injector1

6FUO766Needle valveFilter

Connector

Solenoid coil

Plunger

-4

INJECTOR,

The injection nozzle spray opening area is constant and the fuelinjection pressure is also constant; therefore, the injection

quantity is determined by the amount of time that the solenoid

coil is energized.

.

Page 148 of 391

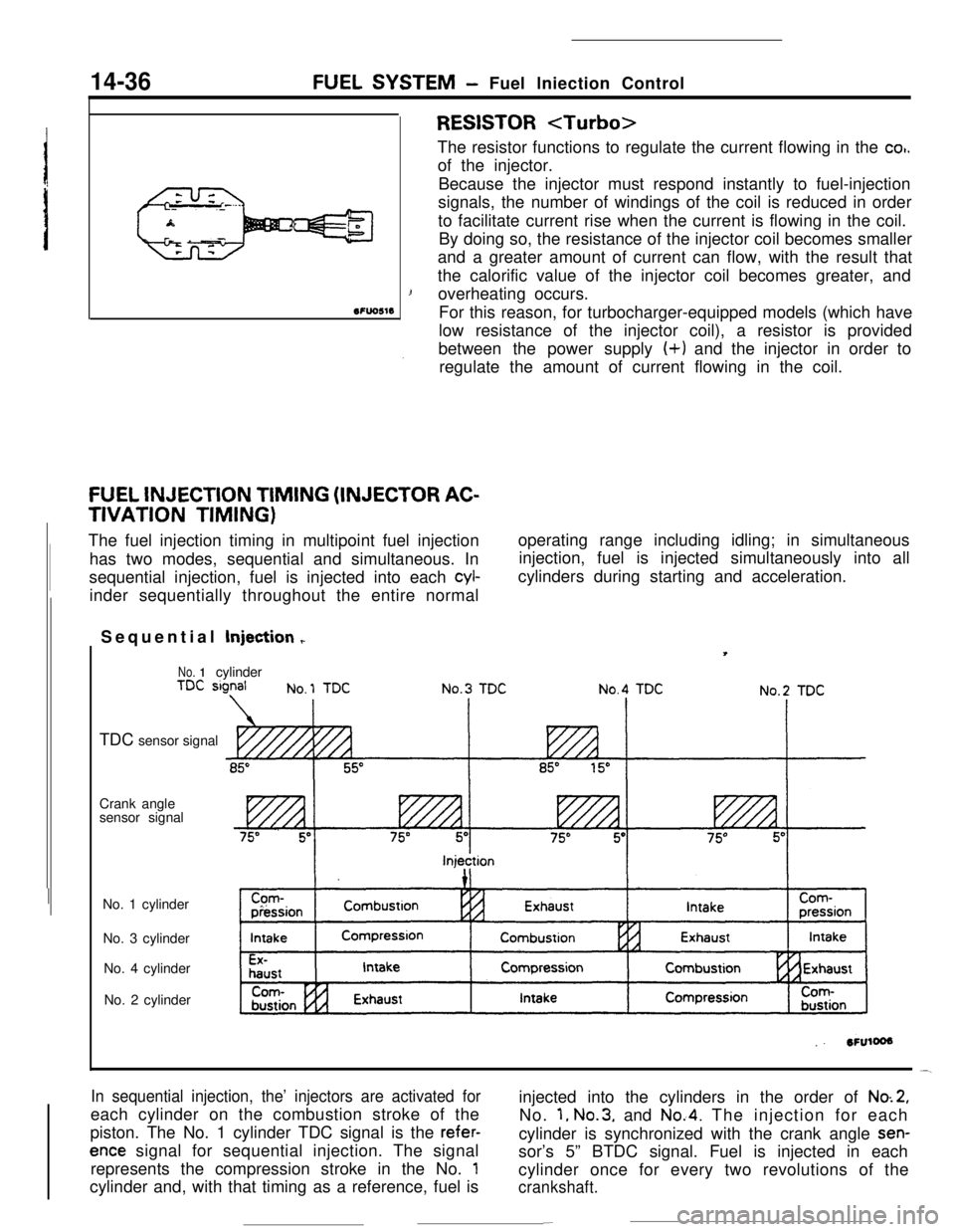

14-36FUEL SYSTEM- Fuel lniection Control

SFUOSlS

RESISTOR

co,.of the injector.

Because the injector must respond instantly to fuel-injection

signals, the number of windings of the coil is reduced in order

to facilitate current rise when the current is flowing in the coil.

By doing so, the resistance of the injector coil becomes smaller

and a greater amount of current can flow, with the result that

the calorific value of the injector coil becomes greater, and

1overheating occurs.

For this reason, for turbocharger-equipped models (which have

low resistance of the injector coil), a resistor is provided

between the power supply (+) and the injector in order to

regulate the amount of current flowing in the coil.

FUEL INJECTION TIMING (INJECTOR AC-

TIVATION TIMING)

The fuel injection timing in multipoint fuel injection

has two modes, sequential and simultaneous. In

sequential injection, fuel is injected into each

cyl-inder sequentially throughout the entire normaloperating range including idling; in simultaneous

injection, fuel is injected simultaneously into all

cylinders during starting and acceleration.

Sequential Injection

r

No. 1cylinder

TDC sensor signal

Crank angle

sensor signal

No. 1 cylinder

No. 3 cylinder

No. 4 cylinder

No. 2 cylinder

In sequential injection, the’ injectors are activated foreach cylinder on the combustion stroke of the

piston. The No. 1 cylinder TDC signal is the

refer-

ence signal for sequential injection. The signal

represents the compression stroke in the No.

1cylinder and, with that timing as a reference, fuel isinjected into the cylinders in the order of

No.2,No.

1, No.3, and No.4. The injection for each

cylinder is synchronized with the crank angle

sen-sor’s 5” BTDC signal. Fuel is injected in each

cylinder once for every two revolutions of the

crankshaft.

-

Page 167 of 391

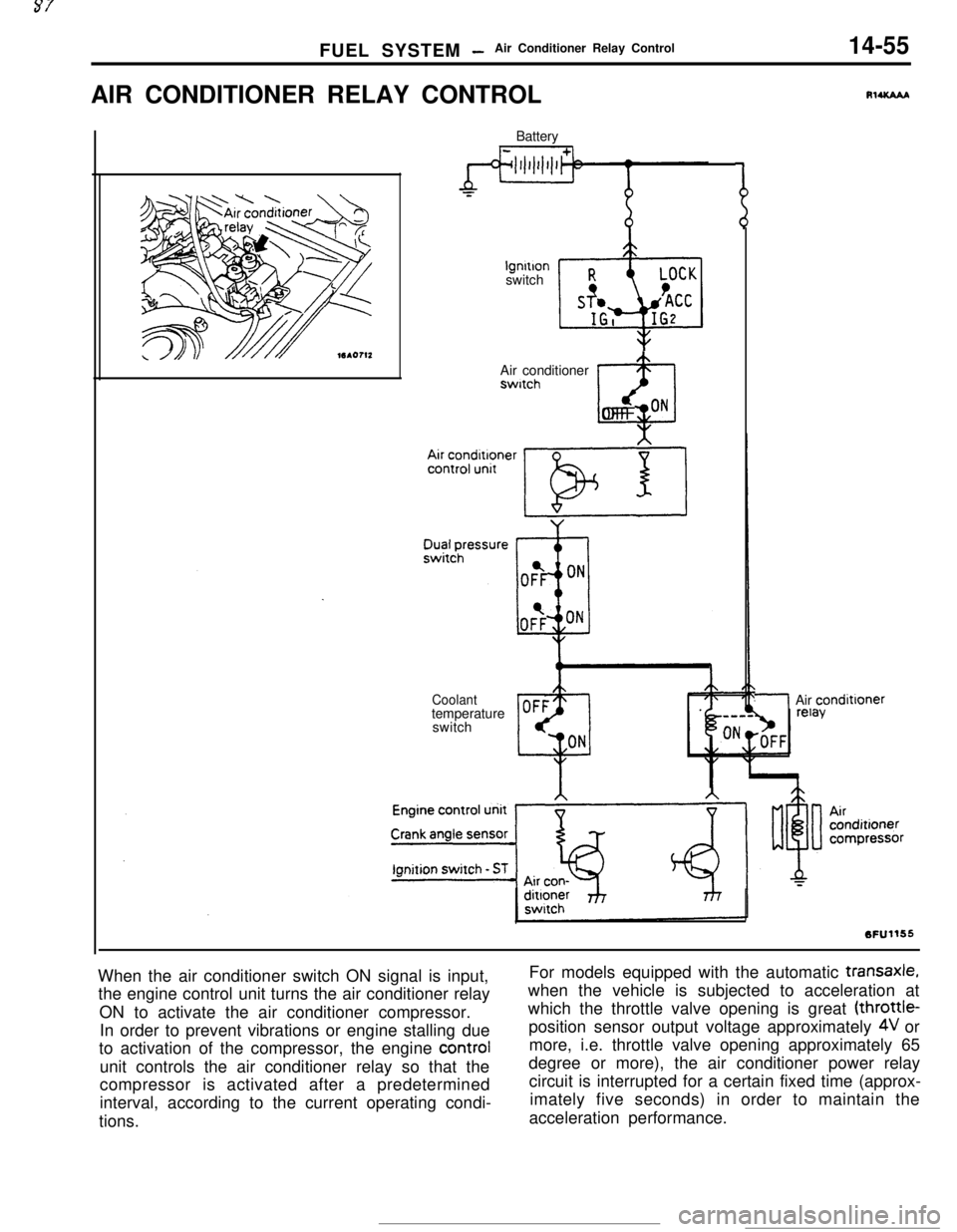

FUEL SYSTEM -Air Conditioner Relay Control14-55AIR CONDITIONER RELAY CONTROL

Batterylgnltlon

switch

Air conditionerswitch

@OFF ON

Coolanttemperature

switch

RlUCAAA

/Air condittoner

When the air conditioner switch ON signal is input,

the engine control unit turns the air conditioner relay

ON to activate the air conditioner compressor.

In order to prevent vibrations or engine stalling due

to activation of the compressor, the engine control

unit controls the air conditioner relay so that the

compressor is activated after a predetermined

interval, according to the current operating condi-

tions.For models equipped with the automatic

transaxle,when the vehicle is subjected to acceleration at

which the throttle valve opening is great (throttle-

position sensor output voltage approximately

4V or

more, i.e. throttle valve opening approximately 65

degree or more), the air conditioner power relay

circuit is interrupted for a certain fixed time (approx-

imately five seconds) in order to maintain the

acceleration performance.

Page 176 of 391

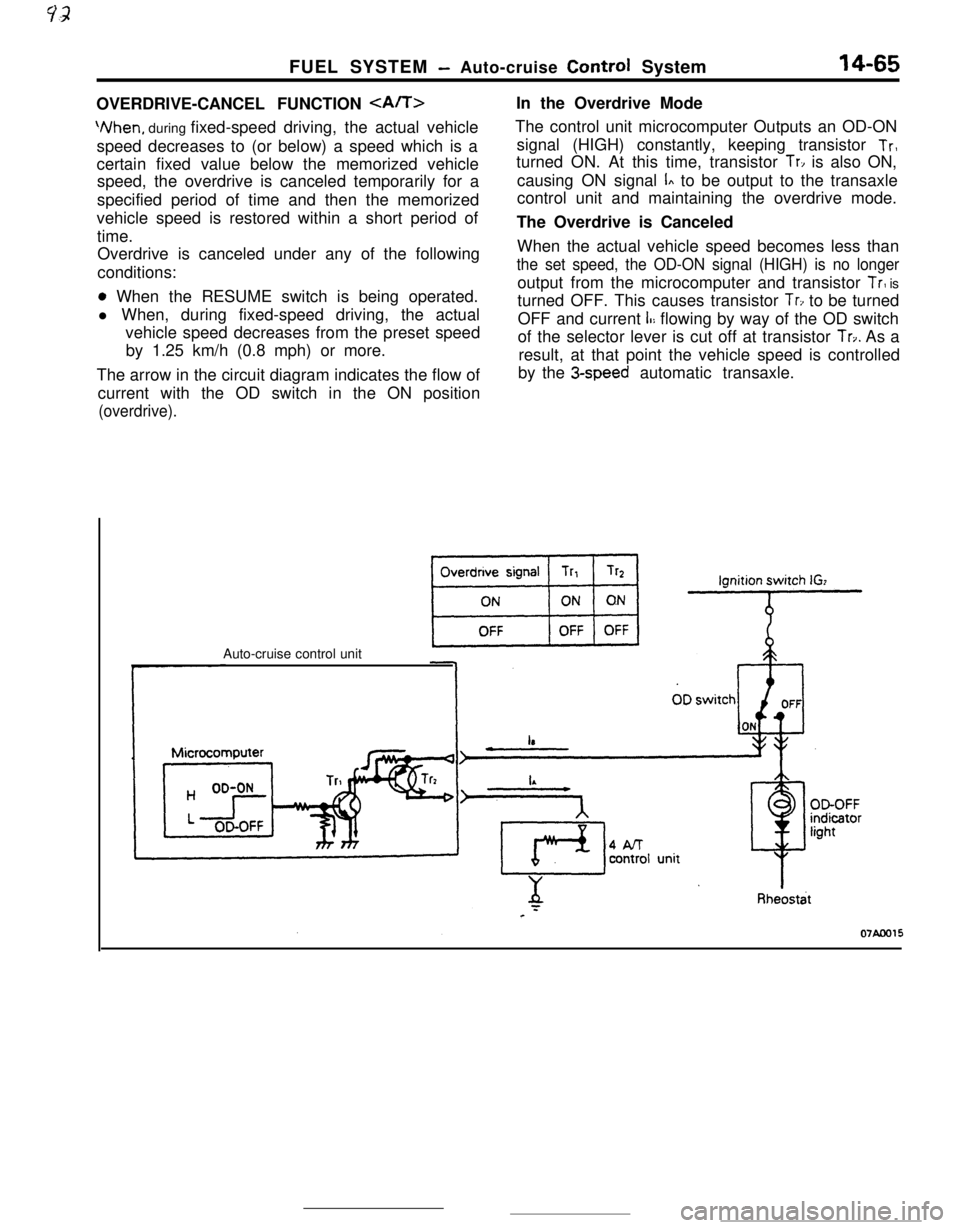

![MITSUBISHI ECLIPSE 1990 Service Manual 14-64FUEL SYSTEM - Auto-cruise Control System

FixedAccelera-FixedSpeed -c tion-LC speed

High

Vehic’e iapprox. 40 km/hspeedG!5 mph) or hagher]Low

’When the RESUME

(ACCEL) Switch is Kept Turned

Whi MITSUBISHI ECLIPSE 1990 Service Manual 14-64FUEL SYSTEM - Auto-cruise Control System

FixedAccelera-FixedSpeed -c tion-LC speed

High

Vehic’e iapprox. 40 km/hspeedG!5 mph) or hagher]Low

’When the RESUME

(ACCEL) Switch is Kept Turned

Whi](/img/19/57103/w960_57103-175.png)

14-64FUEL SYSTEM - Auto-cruise Control System

FixedAccelera-FixedSpeed -c tion-LC speed

High

Vehic’e iapprox. 40 km/hspeedG!5 mph) or hagher]Low

’When the RESUME

(ACCEL) Switch is Kept Turned

While the RESUME switch is ON, the actuator’s DC

mote,caused to rotate to the PULL side; the vehicle speed when the

switch is switched OFF as acceleration continues is entered in

the memory, and is thereafter controlled as the fixed speed.

CANCELLATION

When, during fixed-speed driving, the signals described below

are input, conductivity to the electromagnetic clutch is inter-

rupted, thus

cancelling the auto-cruise control system.

l Stop light switch ON (brake pedal depressed)

l Clutch switch ON (clutch pedal depressed)

lInhibitor switch ON (selector lever at

“P” or “N” position)

LOW-SPEED LIMIT

There is automatic cancellation at or below the low-speed limit

vehicle speed [approximately 40 km/h (25 mph)].

HIGH-SPEED LIMIT

The vehicle cannot be driven at a fixed speed which is at or

higher than the high-speed limit [approximately 145 km/h

(90

mph)l.Note that the vehicle speed memorized when the SET switch

a5pressed while the vehicle is traveling at the high-speed limit or

higher

vvill be the high-speed limit vehicle speed.

FAIL-SAFE FUNCTION

When the following situations are encountered during fixed-

speed driving, the signals to interrupt, conductivity to the

electromagnetic clutch are input, thus canceling the auto-cruise

control system.

0

0

0When vehicle speed decreases to the low-speed limit

[approx. 40 km/h (25 mph)].

If the vehicle speed decreases to a speed which is

approximately 20 km/h (12 mph) or more below ‘the

memorized vehicle speed.

When the vehicle speed drops by 20 km/h

(12 mph) or more

after having reached the set speed -10 km/h (-6 mph) in

the RESUME mode.

If there is damaged or disconnected wiring of the input line

(stop light switch load side) of the stop light switch.

if there is no input of the vehicle speed signal for a certain

fixed time (1 second or longer).

If the SET and RESUME control switches are switched ON

at the same time.

If the cancel switches (stop light switch, clutch switch or

inhibitor switch) and command switches (SET switch

orRESUME switch) are switched ON at the same time.

if the actuator clutch driver (transistor) of the control unk

remains ON (short-circuit).

Page 177 of 391

Page 186 of 391

14-74

_ ,.-..FUEL SYSTEM

- Auto-cruise Control System

When Canceled by the Stop Light Switch (broad

solid-line arrows)

The stop light switch is a four-pole type that

integrates the switch for the stop light (NO) with

that for the auto-cruise control (NC).

When the brake pedal is depressed, the contacts forthe auto-cruise control (NC) open, cutting off the

circuit to energize the electromagnetic clutch coil.

At the same time, the contacts for the stop light

(NO) close to allow a cancel signal to be input from

the

12-V power supply of the control unit to the

cancel circuit and to the microcomputer. As a result,the transistor which energizes the actuator electro-

magnetic clutch coil turns OFF and the electro-

magnetic clutch coil grounding circuit is cut off, thus

canceling the auto-cruise control mode.

When Canceled by the Clutch Switch (thin

solid-line arrows)

When the clutch pedal is depressed, the clutch

switch is turned ON and the battery voltage is

applied to the cancel circuit of the control unit. then,a cancel signal is input to the microcomputer.

causing the transistor that energizes the actuator

electromagnetic clutch coil to turn OFF. This results

in the electromagnetic clutch coil grounding circuit

bma$ndge cut off, which cancels the auto-cruise control

When Canceled by the Selector Lever (position“N”) (dotted-line arrows)

When the transaxle control selector lever is placed

in the “N” (neutral) position, the inhibitor switch is

turned ON and, as a result, current flows from the

control unit to the inhibitor switch, starter, and

ground. Then, a cancel signal is input from the

cancel circuit to the control unit, causing the

transistor which energizes the actuator electro-

magnetic clutch coil to be turned OFF. As a result,

the electromagnetic clutch coil grounding circuit is

cut off and the auto-cruise control mode is canceled.Although a small current (voltage 5 V) flows through

the starter, it is not activated.

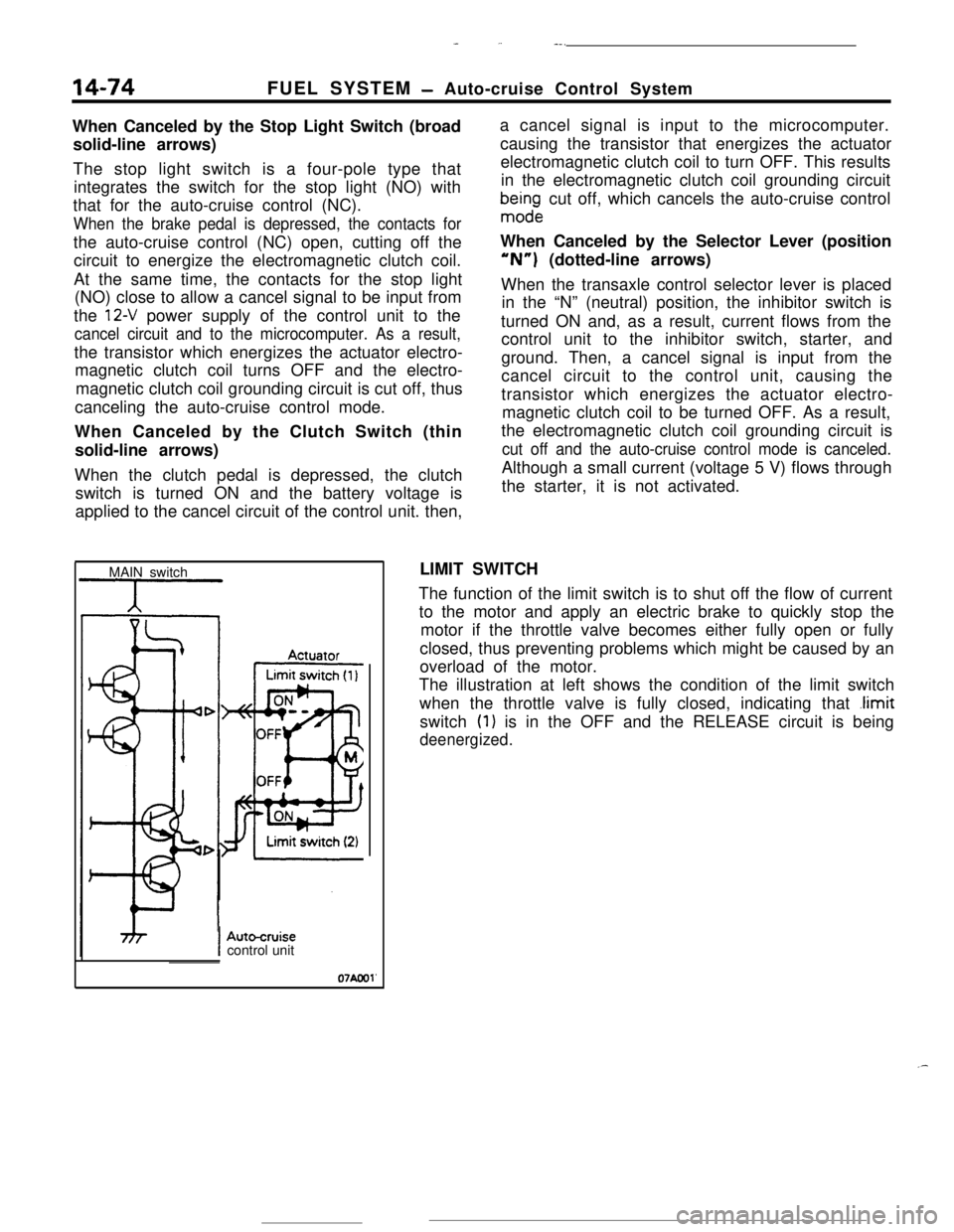

MAIN switchLIMIT SWITCH

The function of the limit switch is to shut off the flow of current

to the motor and apply an electric brake to quickly stop the

motor if the throttle valve becomes either fully open or fully

closed, thus preventing problems which might be caused by an

overload of the motor.

The illustration at left shows the condition of the limit switch

when the throttle valve is fully closed, indicating that

.limitswitch

(1) is in the OFF and the RELEASE circuit is being

deenergized.

IAutocruisecontrol unit

07Aool'

.-