ignition MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 9 of 391

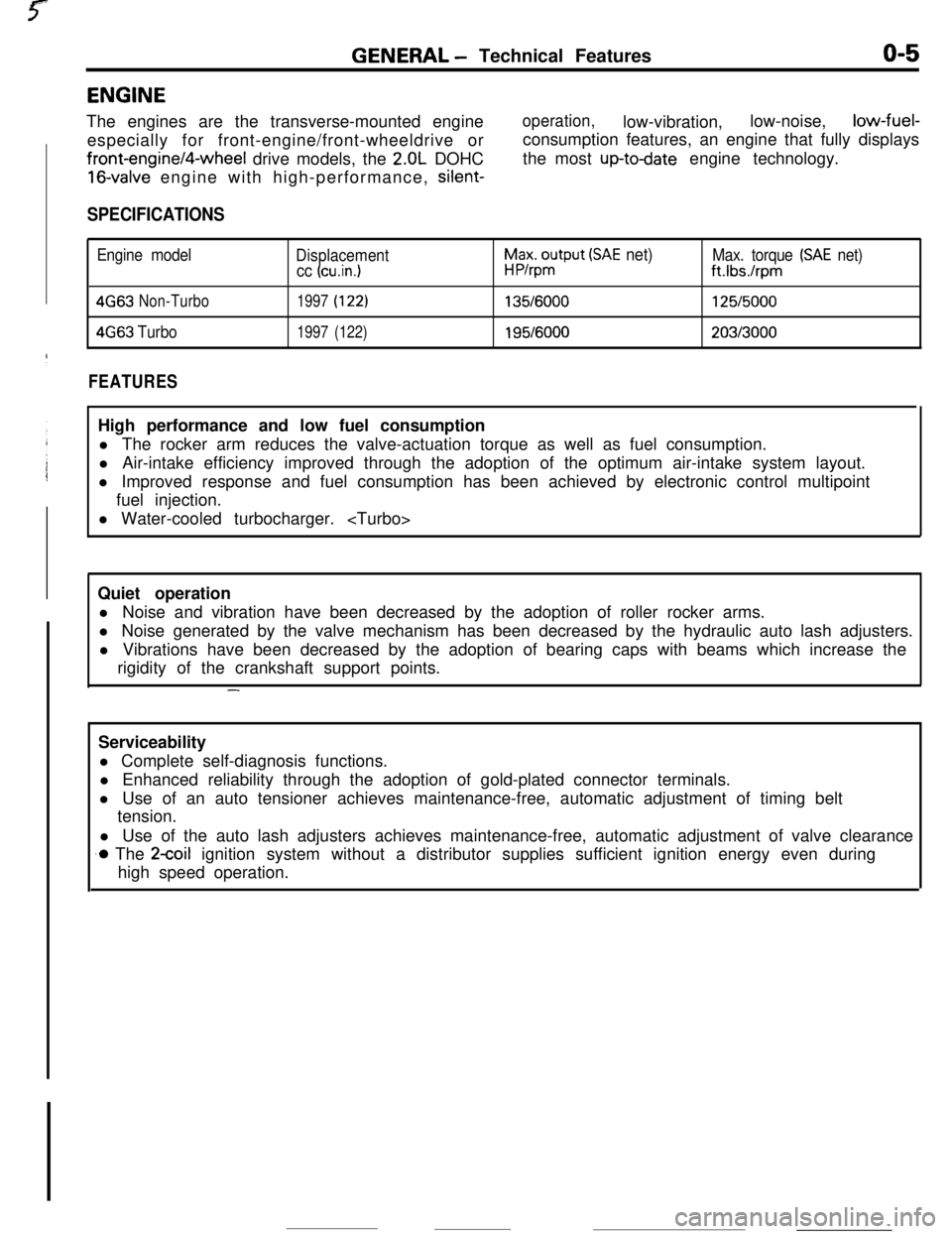

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 10 of 391

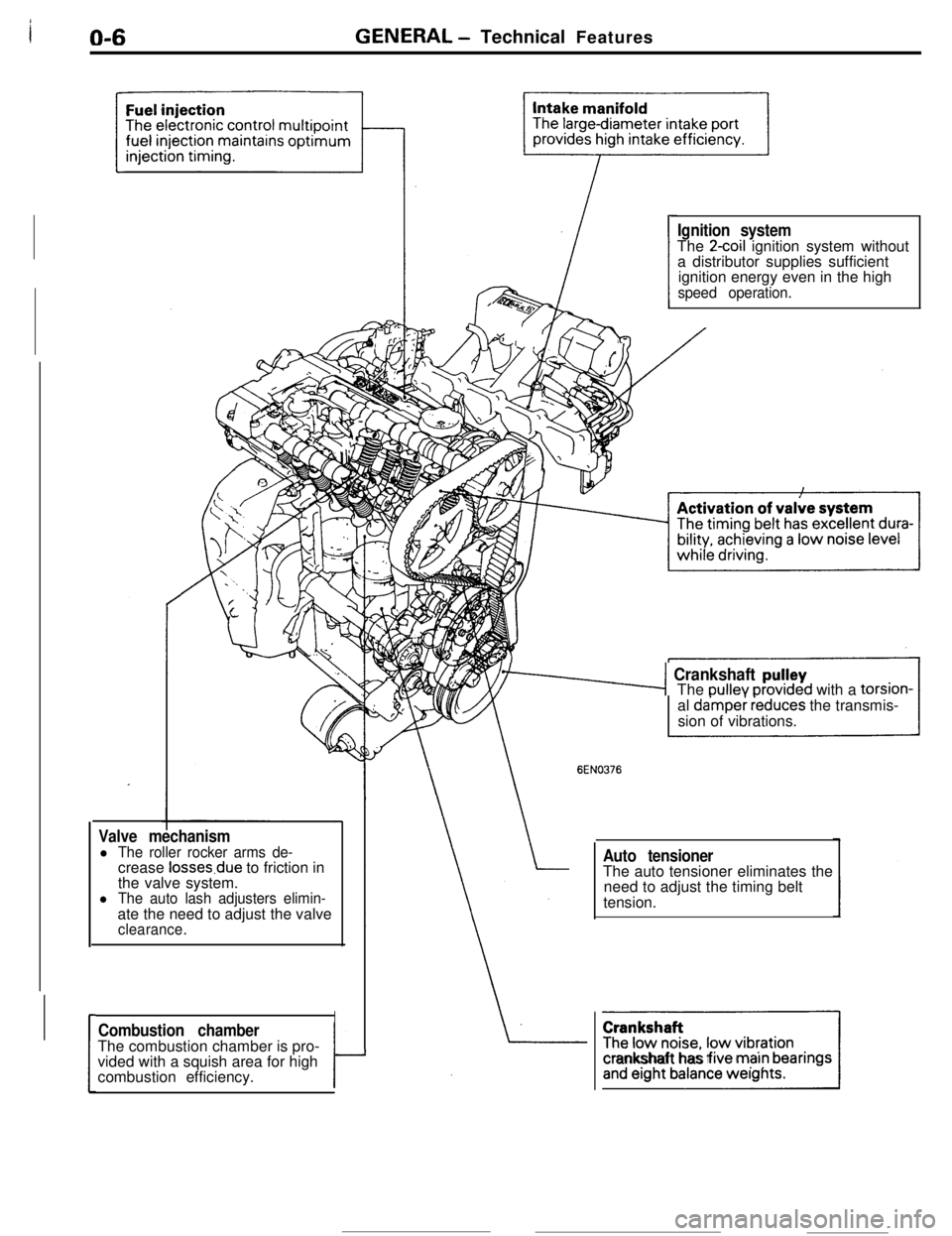

O-6GENERAL - Technical Features

Valve mechanisml The roller rocker arms de-crease losses.due to friction in

the valve system.

l The auto lash adjusters elimin-ate the need to adjust the valve

clearance.

ICombustion chamberThe combustion chamber is pro-

vided with a squish area for high

combustion efficiency.

tJ

Ignition systemThe 2coil ignition system without

a distributor supplies sufficient

ignition energy even in the high

speed operation.

76-4 Crankshaft pu!leyThe oullev orovrded with a torsion-

al

da’mper ieduces the transmis-

sion of vibrations.

EN0376

Auto tensionerThe auto tensioner eliminates the

need to adjust the timing belt

tension.

]Icrankshaft has five marn bearings

Page 11 of 391

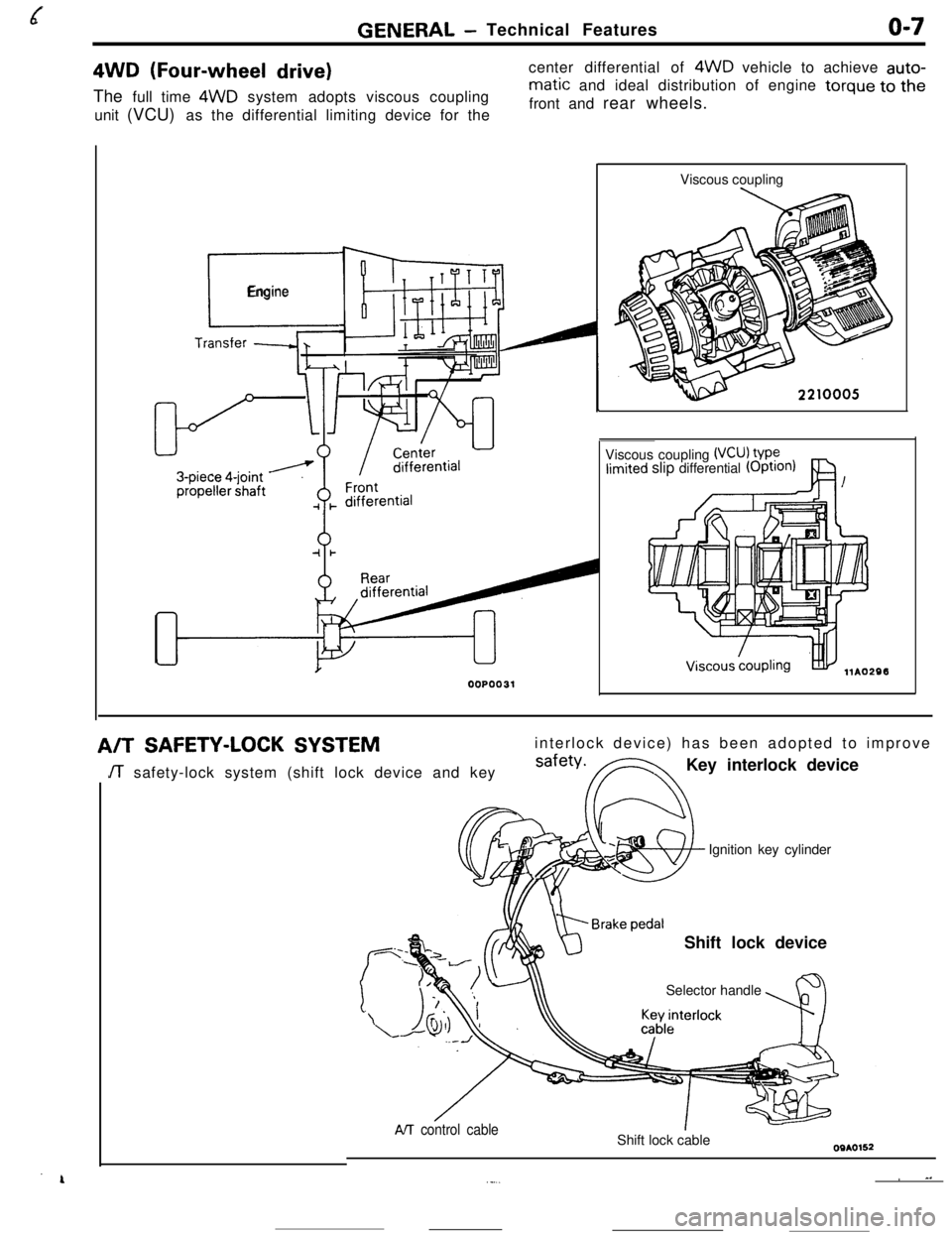

GENERAL -Technical Featureso-74WD

(Four-wheel drive)The full time 4WD system adopts viscous coupling

unit (VCU) as the differential limiting device for thecenter differential of 4WD vehicle to achieve auto-

matic and ideal distribution of engine torque to the

front and rear wheels.

r_

Engine

00P0031Viscous coupling

Viscous coupling

(VCU) VP?limited slip differential (OptIOn)

A/TSAFETY-LOCK SYSTEMinterlock device) has been adopted to improve

JT safety-lock system (shift lock device and keysafety*FNKey interlock device

Ignition key cylinder

Shift lock device

Selector handle

AIT control cableShift lock cable

~ ^.._...

Page 55 of 391

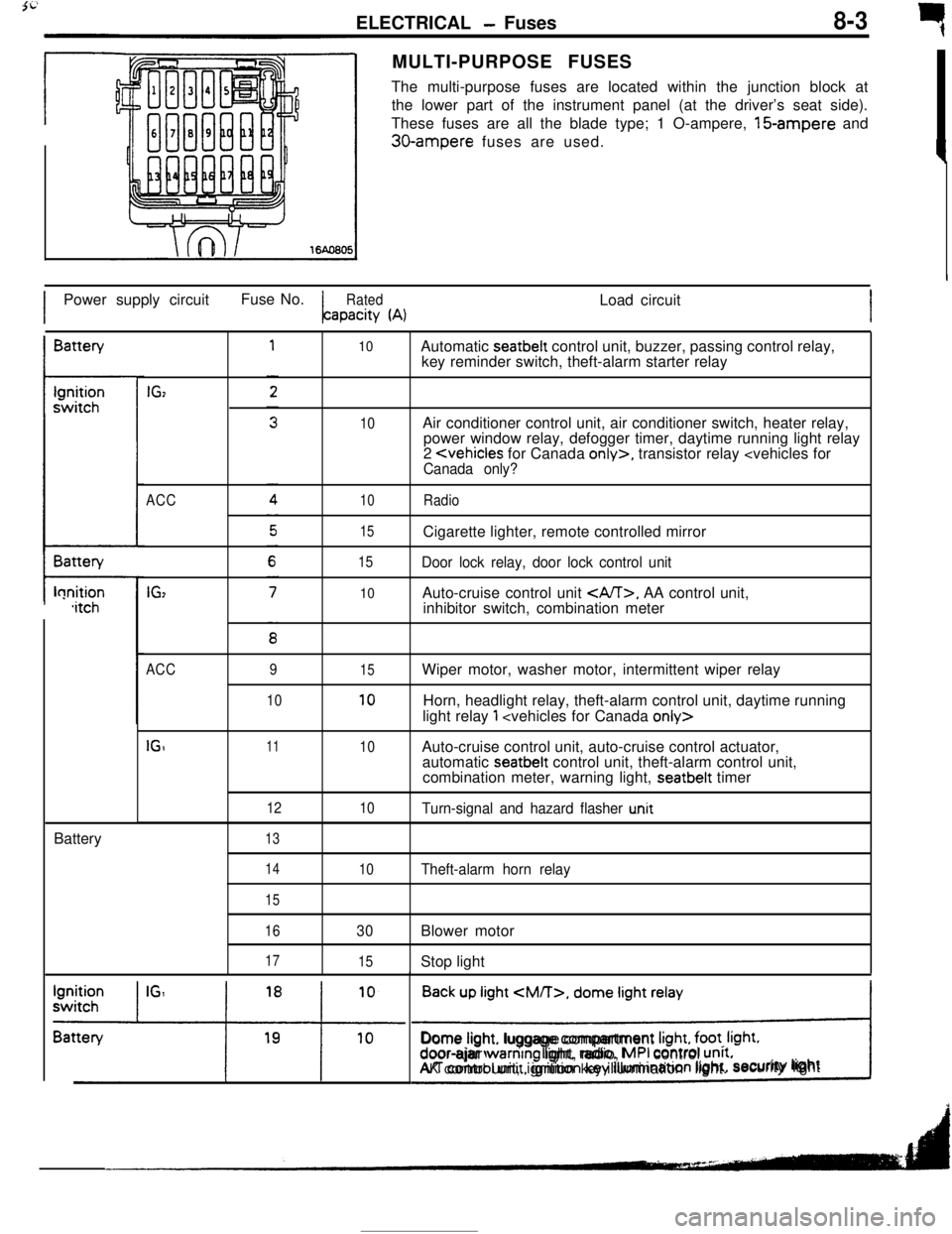

ELECTRICAL - Fuses8-3q

rMULTI-PURPOSE FUSES

The multi-purpose fuses are located within the junction block at

the lower part of the instrument panel (at the driver’s seat side).

These fuses are all the blade type; 1 O-ampere, 15-ampere and

30-ampere fuses are used.

IPower supply circuitFuse No.

RatedLoad circuitapacity

(A)IBattery

t-lonition,itchBattery

IGz

ACC

IG,

10

10

10

15

15

10Automatic seatbelt control unit, buzzer, passing control relay,

key reminder switch, theft-alarm starter relay

Air conditioner control unit, air conditioner switch, heater relay,

power window relay, defogger timer, daytime running light relay

2

Door lock relay, door lock control unitAuto-cruise control unit

, AA control unit,

inhibitor switch, combination meter

ACC

IGI9

1011

12

1315

10

10

10Wiper motor, washer motor, intermittent wiper relay

Horn, headlight relay, theft-alarm control unit, daytime running

light relay

1

automatic seatbelt control unit, theft-alarm control unit,

combination meter, warning light, seatbelt timer

Turn-signal and hazard flasher u.nit

14

15

16

17

10Theft-alarm horn relay

30Blower motor

15Stop light

Back up light

CM/T>, dome light relay

!Dome light. luggage compartment

Irght, foot. Irght.door-ajar warntng light, radio, MPI control unrt.AK control unit, ignition key illumination light.security lightI

Page 67 of 391

. . .&L : __,ELECTRICAL

- Inspection Terminal

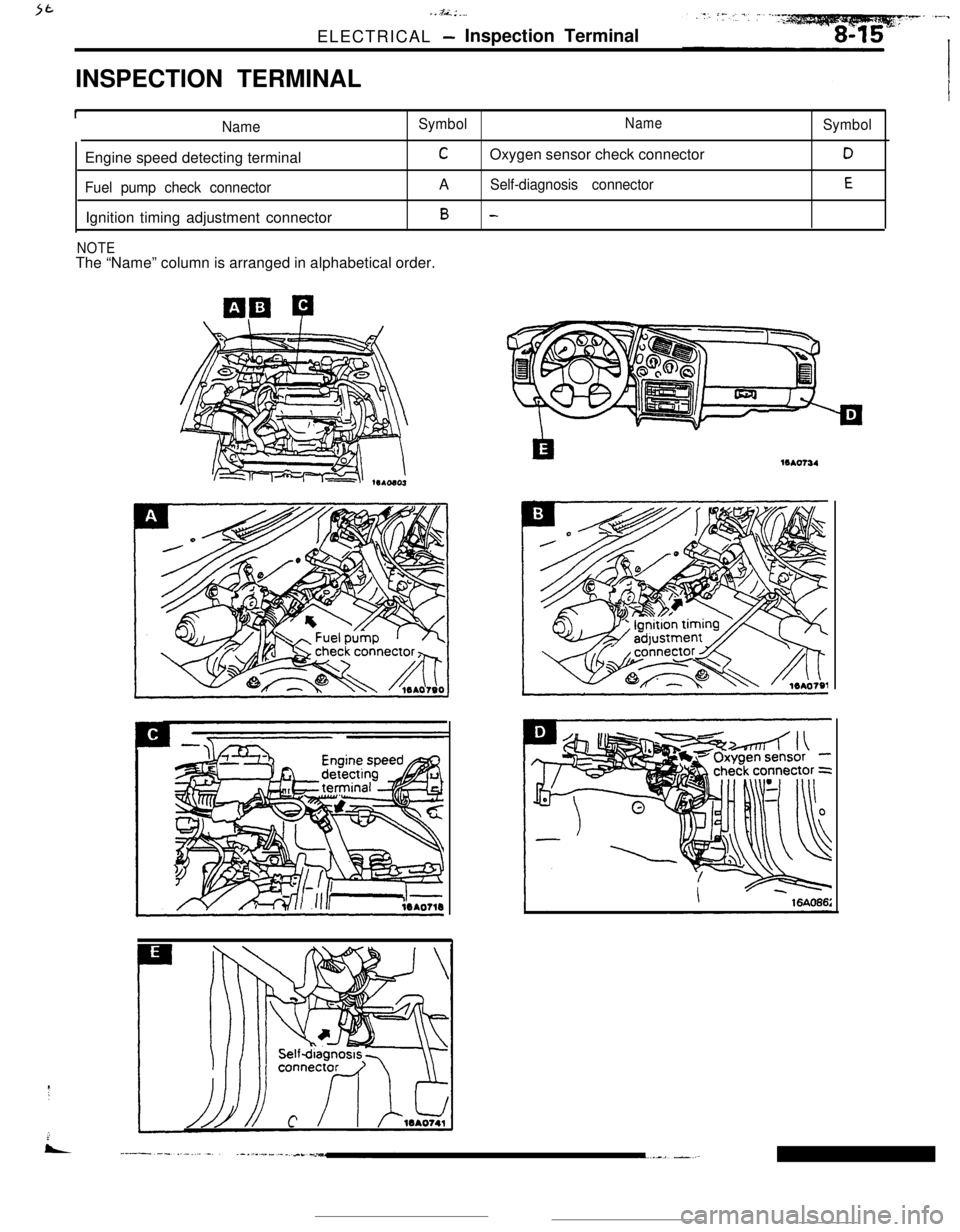

INSPECTION TERMINAL

INameSymbolNameEngine speed detecting terminal

COxygen sensor check connector

Fuel pump check connectorASelf-diagnosis connectorIgnition timing adjustment connector

B -

NOTEThe “Name” column is arranged in alphabetical order.

Symbol

D

E16Ao734

Page 74 of 391

8-22ELECTRICAL - Lighting--Ignition ON

switch OFF

prDoor ON

switch OFF

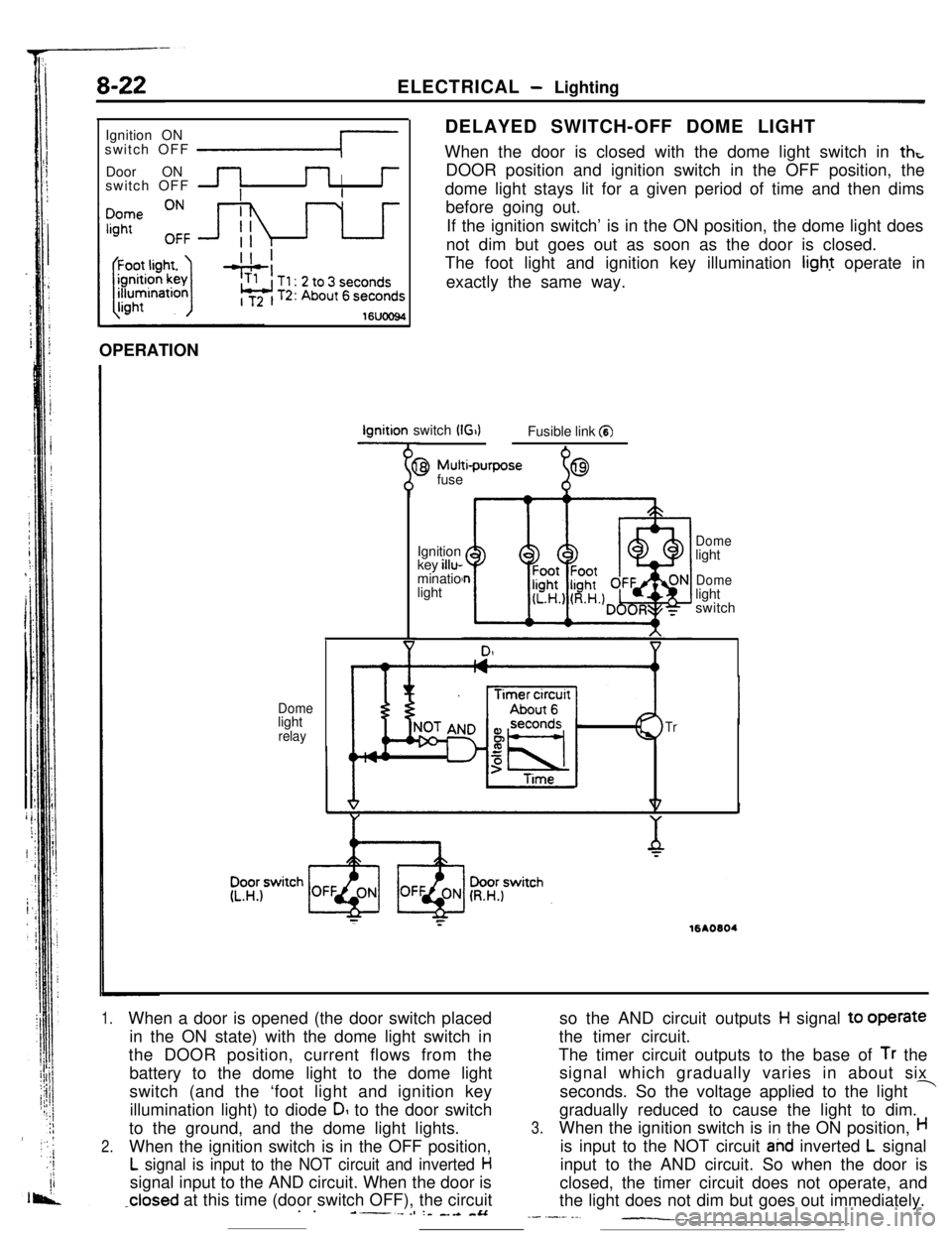

IDELAYED SWITCH-OFF DOME LIGHT

When the door is closed with the dome light switch in

thtDOOR position and ignition switch in the OFF position, the

dome light stays lit for a given period of time and then dims

before going out.

If the ignition switch’ is in the ON position, the dome light does

not dim but goes out as soon as the door is closed.

The foot light and ignition key illumination light operate in

exactly the same way.

16UOO94OPERATIONIgnition switch

(G)Fusible link a

Domelight

relay

9 Mutti-purpose

fuse

%69Ignition

key illu-

minatio

light

Domelight

Domelight

switch

Tr

;:16AO604

1.When a door is opened (the door switch placed

in the ON state) with the dome light switch in

the DOOR position, current flows from the

battery to the dome light to the dome light

switch (and the ‘foot light and ignition key

illumination light) to diode

DI to the door switch

to the ground, and the dome light lights.

2.When the ignition switch is in the OFF position,

L signal is input to the NOT circuit and inverted Hsignal input to the AND circuit. When the door is

-closed at this time (door switch OFF), the circuit

. .----es :- _.a -&Aso the AND circuit outputs

H signal to operate

the timer circuit.

The timer circuit outputs to the base of

Tr the

signal which gradually varies in about six

seconds. So the voltage applied to the light

-gradually reduced to cause the light to dim.

3.When the ignition switch is in the ON position,His input to the NOT circuit

ahd inverted L signal

input to the AND circuit. So when the door is

closed, the timer circuit does not operate, and

the light does not dim but goes out immediately.

_- .-._. ._-__._

Page 77 of 391

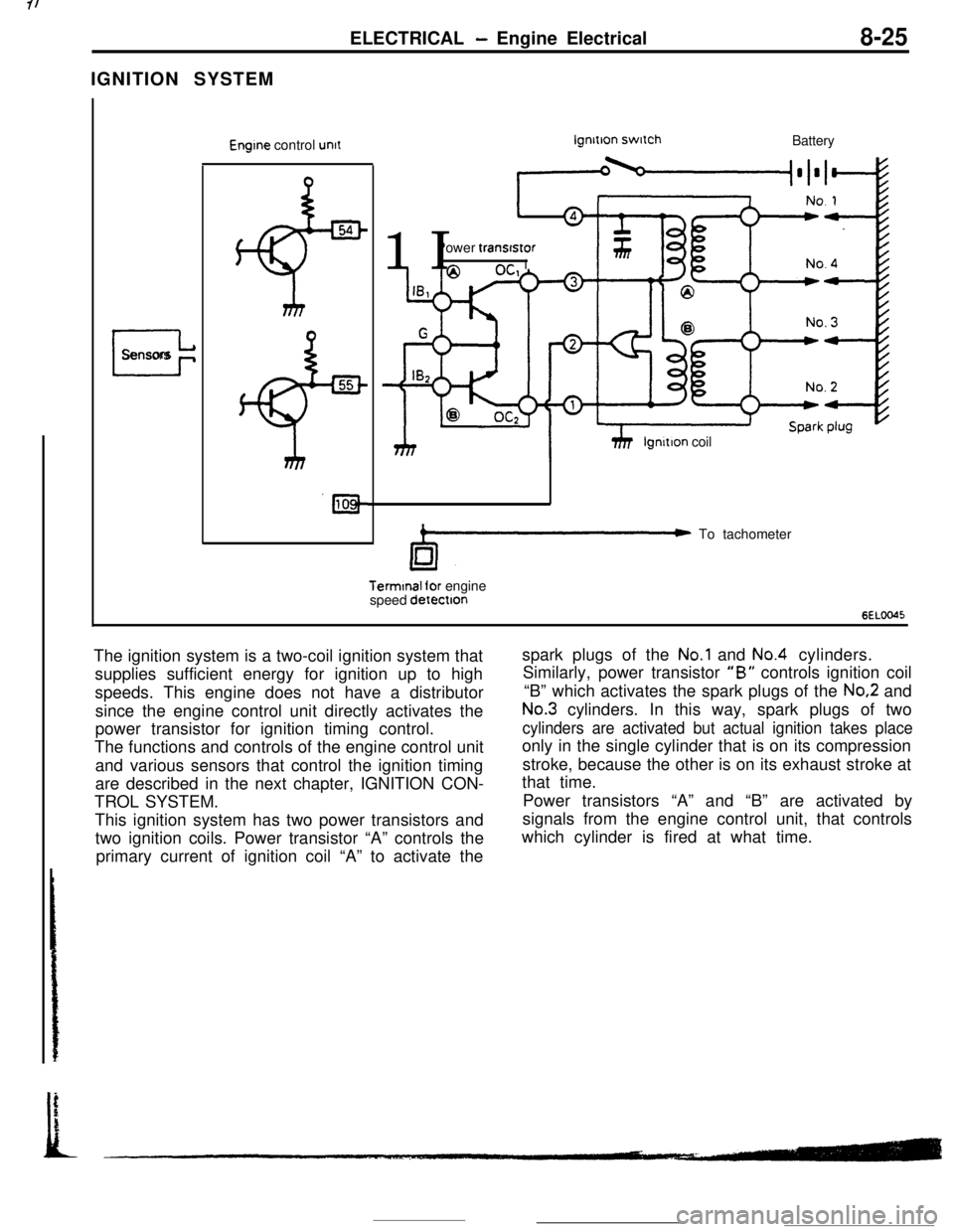

IGNITION SYSTEMELECTRICAL - Engine Electrical8-25

I

Sensors

Engine control unitlgnltlon switch

Battery

11 IPower transfstor

hhP 1

Ilgnltion coil

C To tachometerTerminal for engine

speed detectton

6ELOO45The ignition system is a two-coil ignition system that

supplies sufficient energy for ignition up to high

speeds. This engine does not have a distributor

since the engine control unit directly activates the

power transistor for ignition timing control.

The functions and controls of the engine control unit

and various sensors that control the ignition timing

are described in the next chapter, IGNITION CON-

TROL SYSTEM.

This ignition system has two power transistors and

two ignition coils. Power transistor “A” controls the

primary current of ignition coil “A” to activate thespark plugs of the

No.1 and No.4 cylinders.

Similarly, power transistor

“B” controls ignition coil

“B” which activates the spark plugs of the

No.2 and

No.3 cylinders. In this way, spark plugs of two

cylinders are activated but actual ignition takes placeonly in the single cylinder that is on its compression

stroke, because the other is on its exhaust stroke at

that time.

Power transistors “A” and “B” are activated by

signals from the engine control unit, that controls

which cylinder is fired at what time.

Page 78 of 391

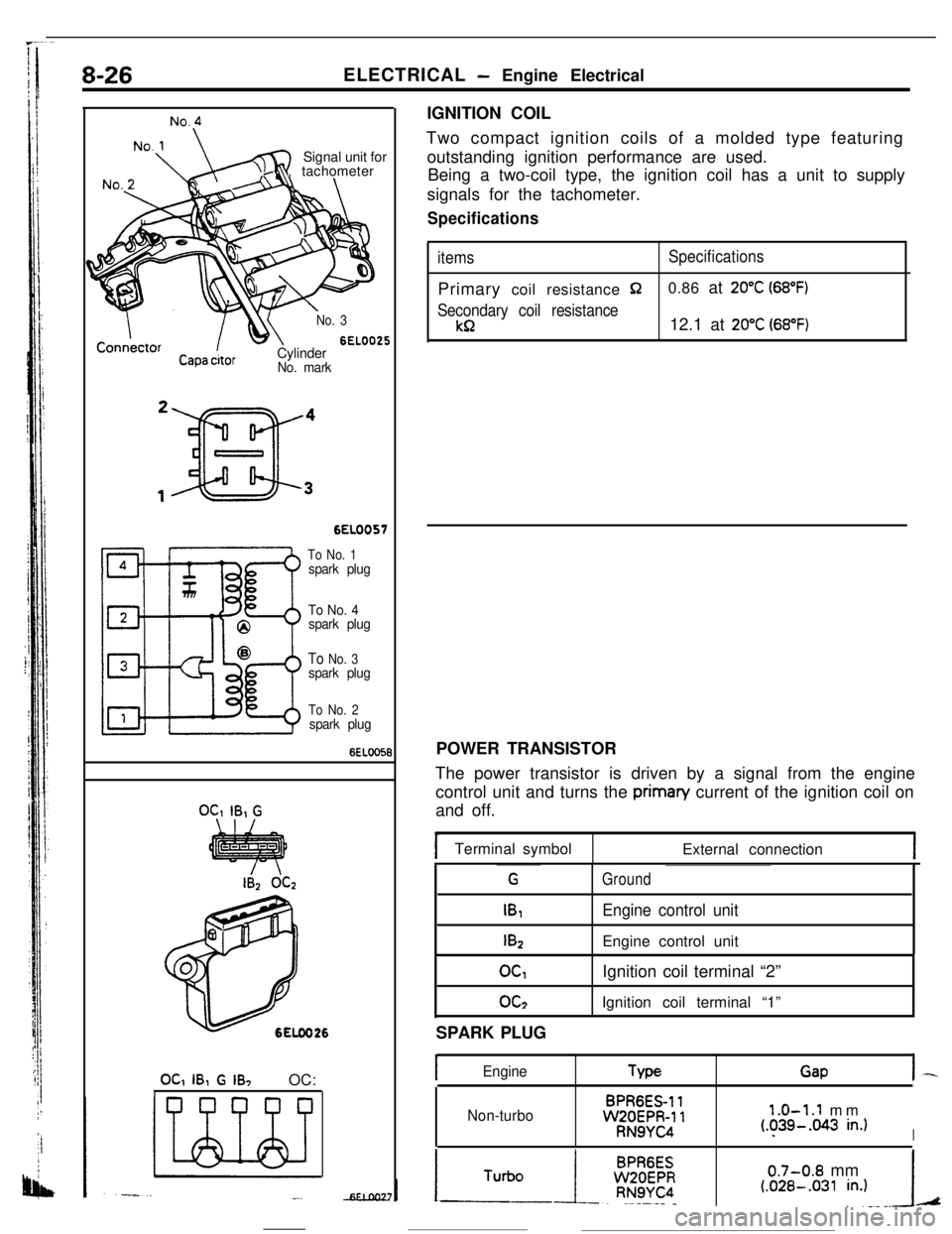

8-26ELECTRICAL - Engine Electrical

No.:

4Signal unit for

, tachometer

71

x

No. 3

6EL0025

Capa &orCylinderNo. mark

6EL0057

To No. 1spark plug

To No. 4

spark plug

To No. 3spark plug

To No. 2spark plug

6EL005t

OC,IB, G

OC, IB, G IB, OC:IGNITION COIL

Two compact ignition coils of a molded type featuring

outstanding ignition performance are used.

Being a two-coil type, the ignition coil has a unit to supply

signals for the tachometer.

Specifications

itemsSpecificationsPrimary coil resistance

$20.86 at 20°C (68°F)

Secondary coil resistance

kR12.1 at 20°C (68°F)POWER TRANSISTOR

The power transistor is driven by a signal from the engine

control unit and turns the priman/ current of the ignition coil on

and off.

Terminal symbol

External connection

G

IB,

I&

Ground

Engine control unitEngine control unit

OGoc2Ignition coil terminal “2”

Ignition coil terminal “1”

SPARK PLUG

IEngineTypeGapI-

Non-turboBPR6ES-11WZOEPR-11RN9YC4

1.0-1.1 mm(.?39-.043 in.)I

0.7-0.8 mm(.OZB-.031 in.)A

Page 79 of 391

-----. _-- ___ELECTRICAL

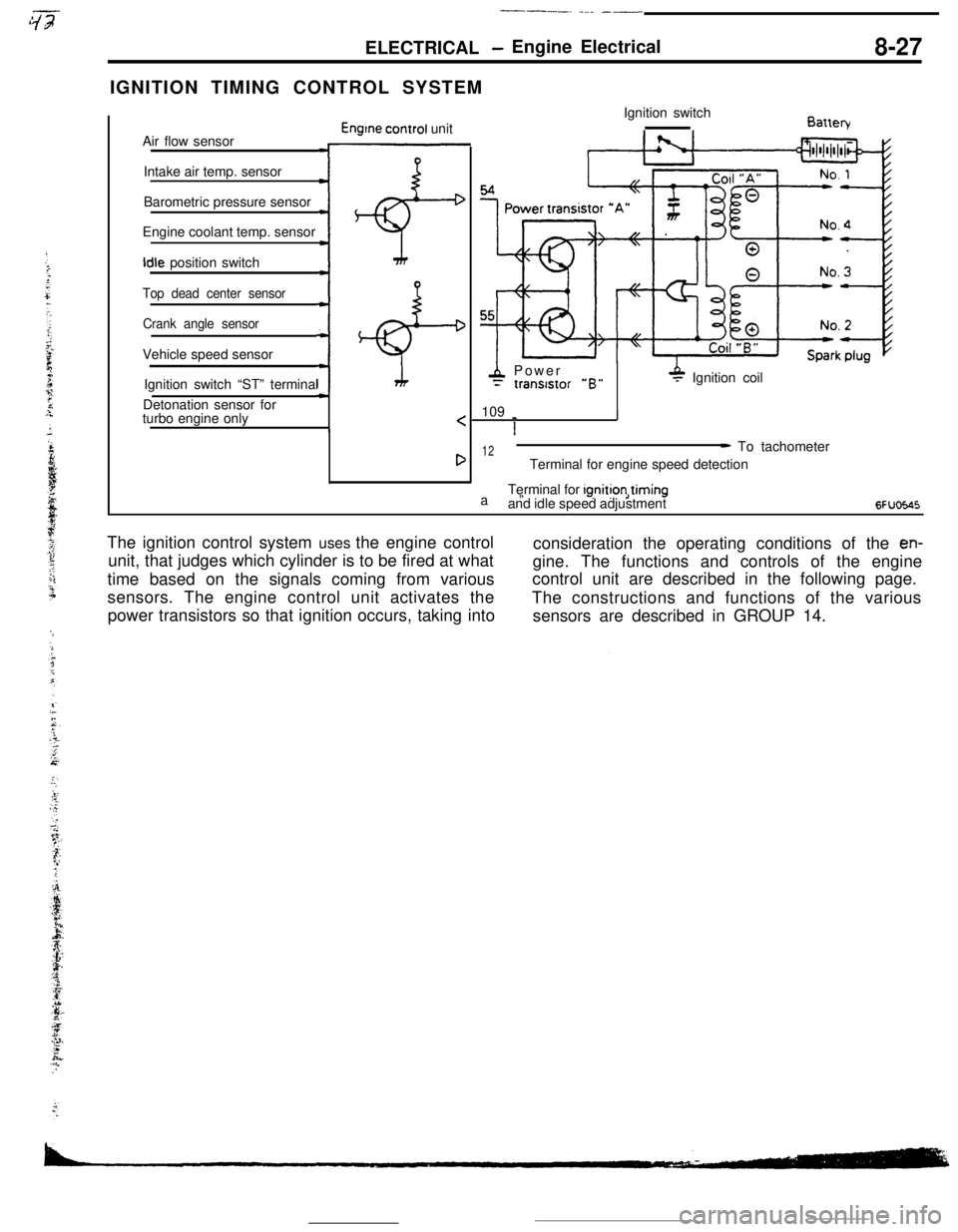

- Engine Electrical8-27IGNITION TIMING CONTROL SYSTEM

Air flow sensor

Engtne control unit

Intake air temp. sensor

Barometric pressure sensor

Engine coolant temp. sensorIdle position switch

:+

Top dead center sensor

Crank angle sensorVehicle speed sensor

;+Ignition switch “ST” terminal

Detonation sensor for

turbo engine only

4 Power= tranststor “B”P Ignition coil

109

_

I

1

12a”- To tachometer

Terminal for engine speed detection

Terminal for ignition,timing

and idle speed adjustment

6FUoE.45The ignition control system uses the engine control

consideration the operating conditions of the

en-unit, that judges which cylinder is to be fired at what

gine. The functions and controls of the engine

time based on the signals coming from variouscontrol unit are described in the following page.

sensors. The engine control unit activates the

The constructions and functions of the various

power transistors so that ignition occurs, taking into

sensors are described in GROUP 14.

Page 80 of 391

8-28ELECTRICAL- Engine Electrical

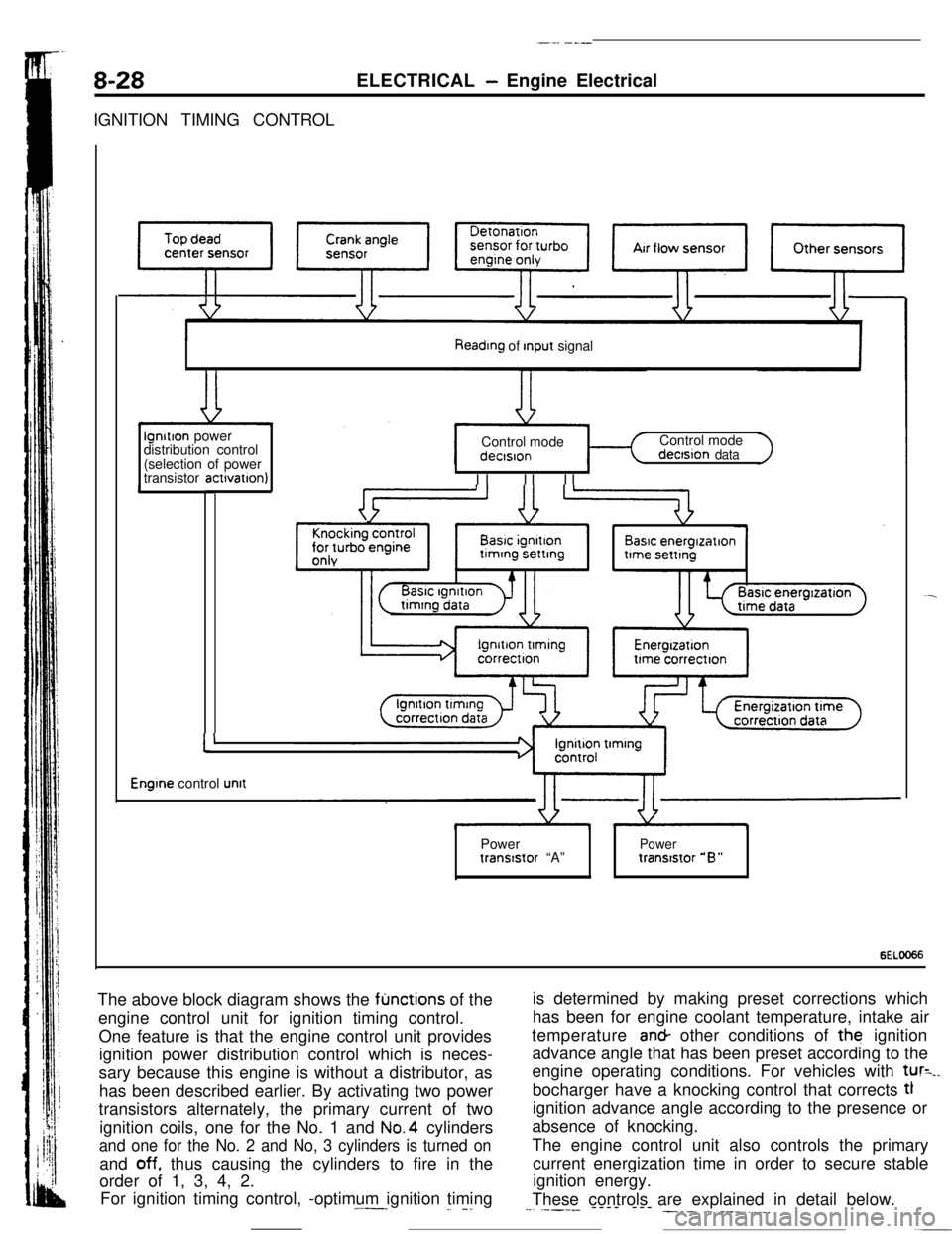

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__