fuel type MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 120 of 391

14-8

rFUEL SYSTEM

-Fuel Supply and Fuel Pressure Control

FUEL PUMP

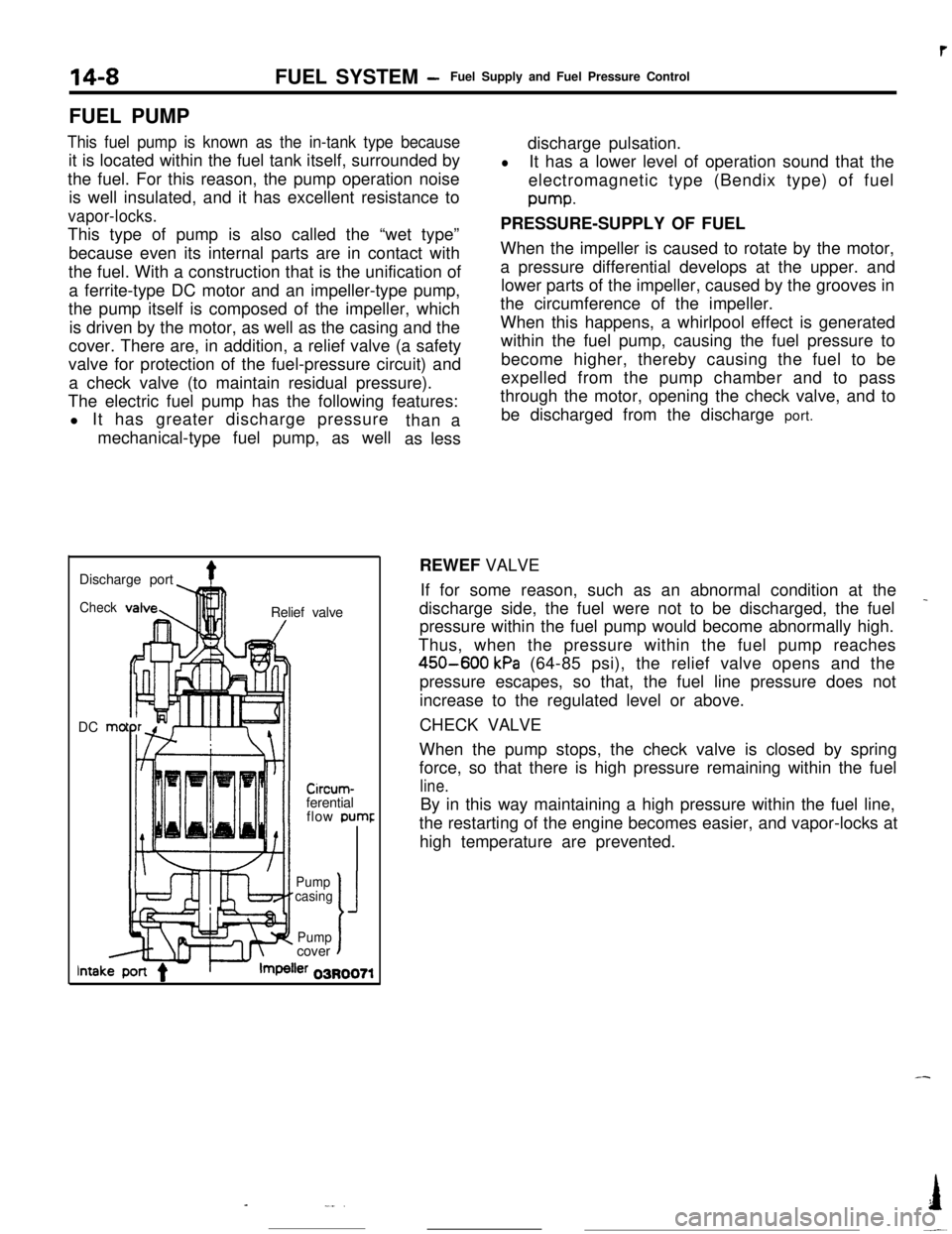

This fuel pump is known as the in-tank type becauseit is located within the fuel tank itself, surrounded by

the fuel. For this reason, the pump operation noise

is well insulated, and it has excellent resistance to

vapor-locks.This type of pump is also called the “wet type”

because even its internal parts are in contact with

the fuel. With a construction that is the unification of

a ferrite-type DC motor and an impeller-type pump,

the pump itself is composed of the impeller, which

is driven by the motor, as well as the casing and the

cover. There are, in addition, a relief valve (a safety

valve for protection of the fuel-pressure circuit) and

a check valve (to maintain residual pressure).

The electric fuel pump has the following features:

l It has greater discharge pressure

mechanical-type fuel pump, as wellthan a

as lessdischarge pulsation.

lIt has a lower level of operation sound that the

electromagnetic type (Bendix type) of fuelpump.

PRESSURE-SUPPLY OF FUEL

When the impeller is caused to rotate by the motor,

a pressure differential develops at the upper. and

lower parts of the impeller, caused by the grooves in

the circumference of the impeller.

When this happens, a whirlpool effect is generated

within the fuel pump, causing the fuel pressure to

become higher, thereby causing the fuel to be

expelled from the pump chamber and to pass

through the motor, opening the check valve, and to

be discharged from the discharge port.

Discharge port

4Check!nRelief valve

DC mo

-lllll1 I/

Circum-ferential

flow pumr

II’ f-Pump

casing

J

Pumpcovert

lntakler 03R0071REWEF VALVE

If for some reason, such as an abnormal condition at the

_discharge side, the fuel were not to be discharged, the fuel

pressure within the fuel pump would become abnormally high.

Thus, when the pressure within the fuel pump reaches

450-600 kPa (64-85 psi), the relief valve opens and the

pressure escapes, so that, the fuel line pressure does not

increase to the regulated level or above.

CHECK VALVE

When the pump stops, the check valve is closed by spring

force, so that there is high pressure remaining within the fuel

line.By in this way maintaining a high pressure within the fuel line,

the restarting of the engine becomes easier, and vapor-locks at

high temperature are prevented.

-

-_..I

-~

Page 121 of 391

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-9

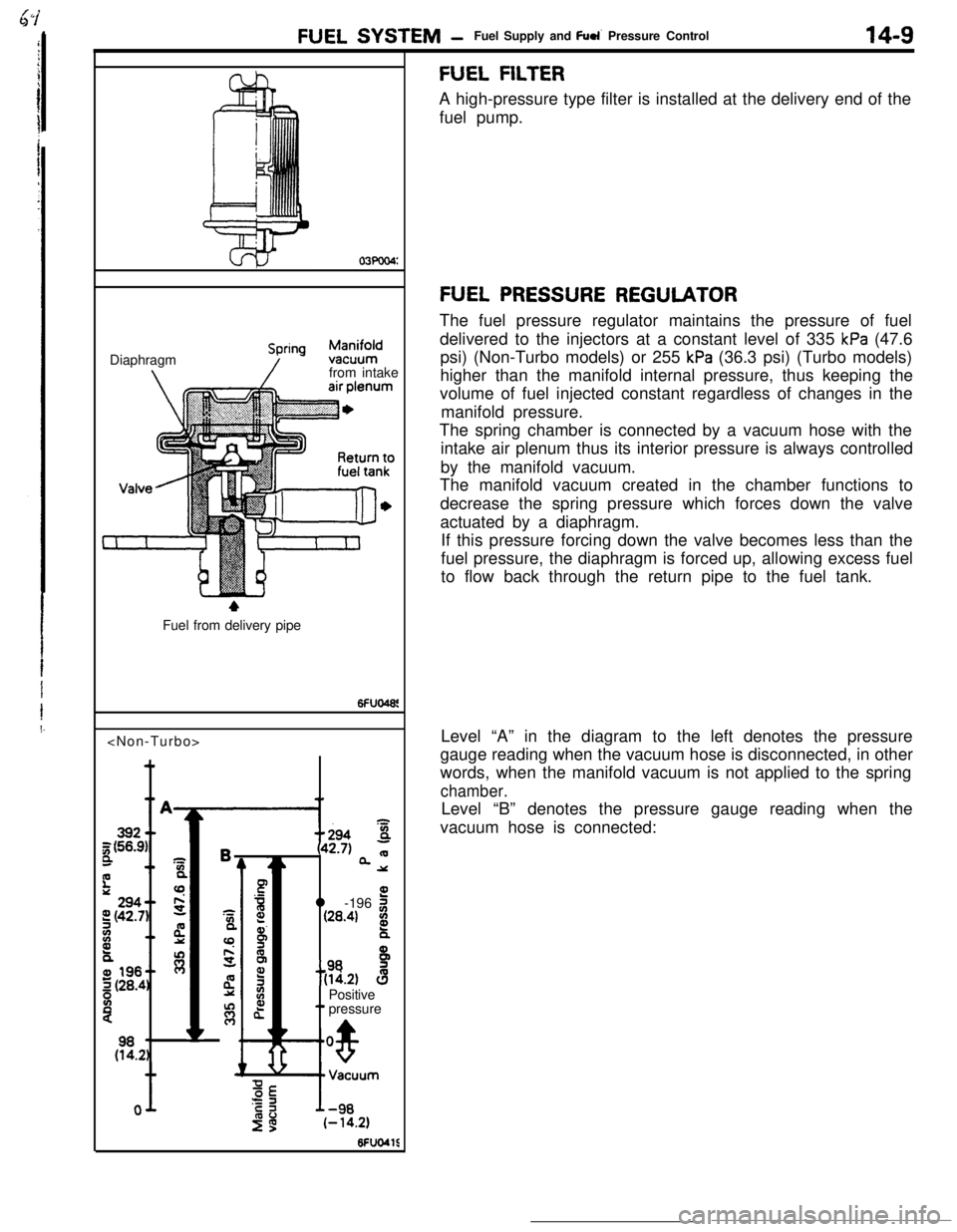

03Poo4:Diaphragm

from intake

4Fuel from delivery pipe

4m

B(42.7)QQ

2

sl -196 2

(26.4) g

t

$!a d

9

0)Positive5 z‘. pressure

(E.2)

w

FUEL FILTERA high-pressure type filter is installed at the delivery end of the

fuel pump.

FUEL PRESSURE REGULATORThe fuel pressure regulator maintains the pressure of fuel

delivered to the injectors at a constant level of 335

kPa (47.6

psi) (Non-Turbo models) or 255

kPa (36.3 psi) (Turbo models)

higher than the manifold internal pressure, thus keeping the

volume of fuel injected constant regardless of changes in the

manifold pressure.

The spring chamber is connected by a vacuum hose with the

intake air plenum thus its interior pressure is always controlled

by the manifold vacuum.

The manifold vacuum created in the chamber functions to

decrease the spring pressure which forces down the valve

actuated by a diaphragm.

If this pressure forcing down the valve becomes less than the

fuel pressure, the diaphragm is forced up, allowing excess fuel

to flow back through the return pipe to the fuel tank.

Level “A” in the diagram to the left denotes the pressure

gauge reading when the vacuum hose is disconnected, in other

words, when the manifold vacuum is not applied to the spring

chamber.Level “B” denotes the pressure gauge reading when the

vacuum hose is connected:

Page 125 of 391

FUEL SYSTEM- Intake Air Control

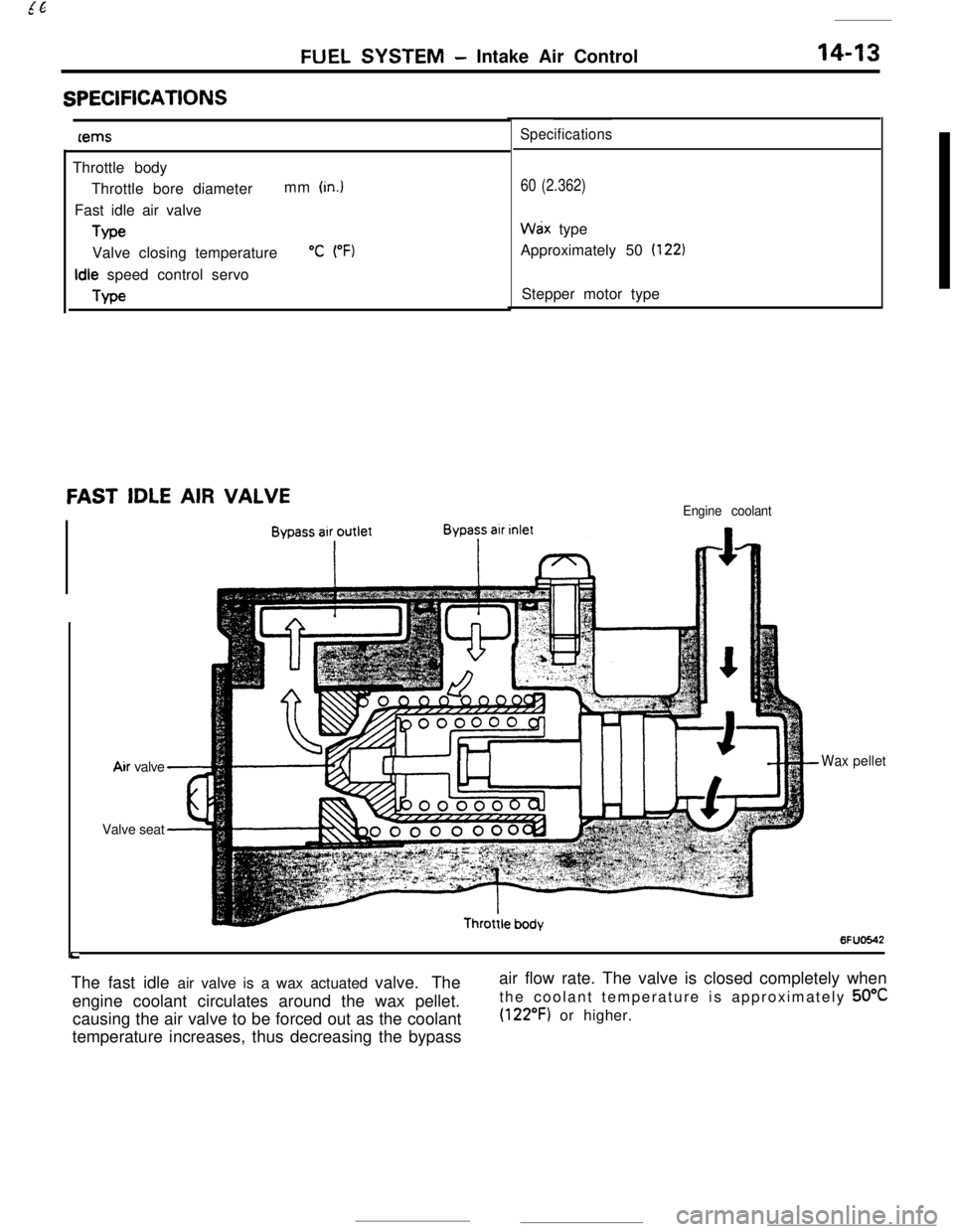

SPECIFICATIONS

ternsThrottle body

Throttle bore diametermm

(in.1Fast idle air valve

TwValve closing temperature

“C (“F)

Idle speed control servo

TypeSpecifications

60 (2.362)

WAX type

Approximately 50

(122)Stepper motor type

FAST IDLE AIR VALVEEngine coolant

LAir valve

Waxpellet

Valve seat

6FUO642The fast idle air valve is a wax actuated valve. The

engine coolant circulates around the wax pellet.

causing the air valve to be forced out as the coolant

temperature increases, thus decreasing the bypassair flow rate. The valve is closed completely when

the coolant temperature is approximately 50°C

(122°F) or higher.

Page 126 of 391

14-14

.._~- ---.FUEL SYSTEM

- Sensors

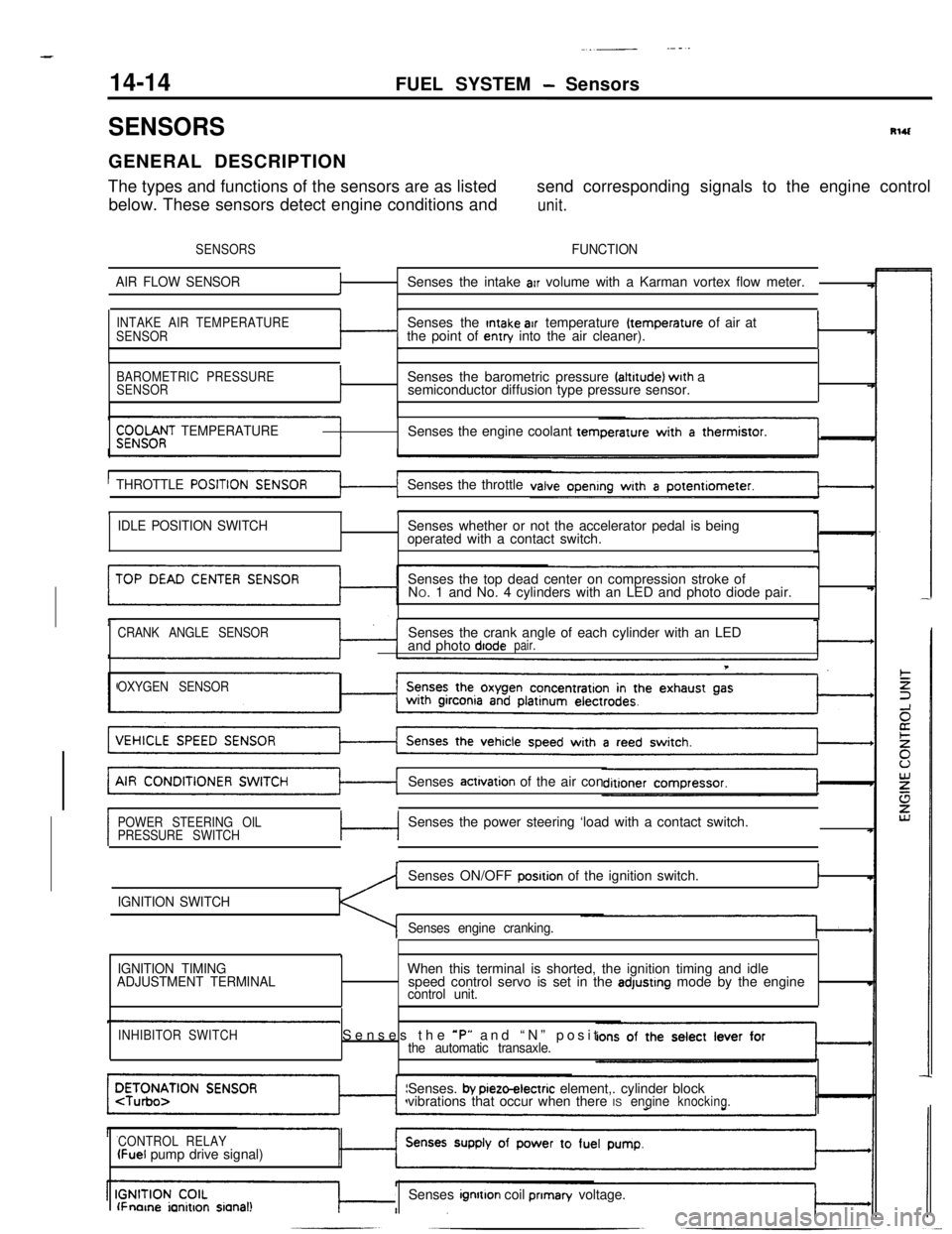

SENSORSRlUGENERAL DESCRIPTION

The types and functions of the sensors are as listedsend corresponding signals to the engine control

below. These sensors detect engine conditions and

unit.

SENSORSFUNCTION

AIR FLOW SENSOR

fSenses the intake arr volume with a Karman vortex flow meter.

INTAKE AIR TEMPERATURE

SENSORSenses the Intake air temperature (temperature of air at

the point of entry into the air cleaner).I

BAROMETRIC PRESSURE

SENSORISenses the barometric pressure faltrtude) wrth a

semiconductor diffusion type pressure sensor.

$;;OOf;T TEMPERATURESenses the engine coolant tern

THROTTLE

POSITISenses the throttle

tI

IDLE POSITION SWITCHSenses whether or not the accelerator pedal is being

operated with a contact switch.

Senses the top dead center on compression stroke of

NO. 1 and No. 4 cylinders with an LED and photo diode pair.

CRANK ANGLE SENSORSenses the crank angle of each cylinder with an LED

and photo diodepair.

T

OXYGEN SENSORSenses

actrvation of the air con

POWER STEERING OIL

PRESSURE SWITCHc-lSenses the power steering ‘load with a contact switch.

IGNITION SWITCHSenses ON/OFF

posrtion of the ignition switch.I

Senses engine cranking.

,

IGNITION TIMING

ADJUSTMENT TERMINALWhen this terminal is shorted, the ignition timing and idle

speed control servo is set in the adjustrng mode by the enginecontrol unit.

INHIBITOR SWITCHSenses the *P” and “N” positthe automatic transaxle.Senses.

by pieto-electric element,. cylinder block

vibrations that occur when there ISengineknocking.

CONTROL RELAY

(Fuel pump drive signal)

lFnorne ianitron sianal!Senses ignrtton coil prIman/ voltage.

Page 131 of 391

FUEL SYSTEM - Sensors

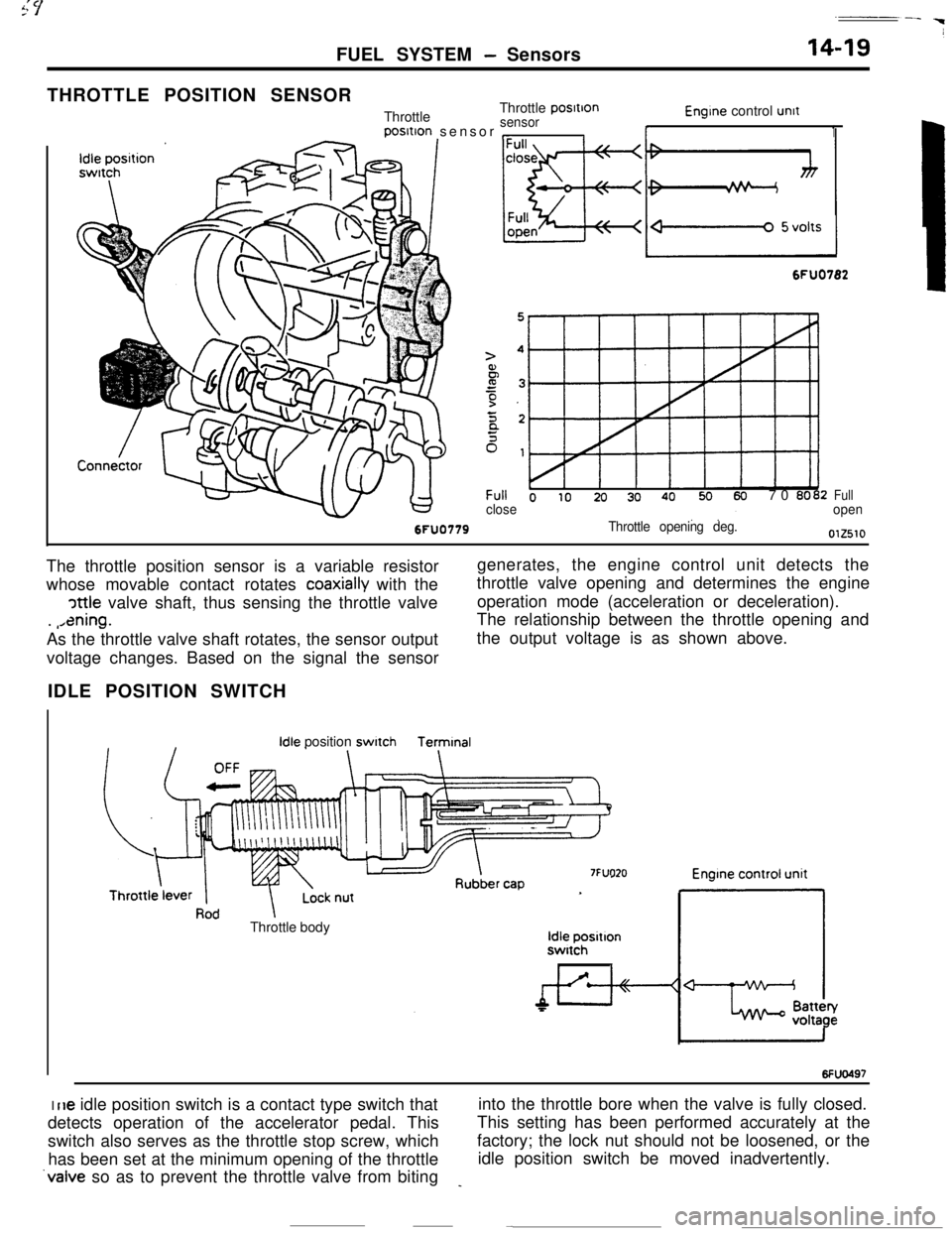

THROTTLE POSITION SENSOR

ThrottleThrottle

posItIon

sensorposltion sensor

,_Il-

Engine control unit

1

6FU0782

Throttle opening deg.

Full o IO 20 30 4070 0002closeFullopenThe throttle position sensor is a variable resistor

whose movable contact rotates

coaxially with the

cattle valve shaft, thus sensing the throttle valve

.

,,ening.As the throttle valve shaft rotates, the sensor outputgenerates, the engine control unit detects the

throttle valve opening and determines the engine

operation mode (acceleration or deceleration).

The relationship between the throttle opening and

the output voltage is as shown above.

voltage changes. Based on the signal the sensor

IDLE POSITION SWITCH

Idle positionswitchTermtnal

7FUO20Throttle body

Idle positlonswitch

I6Fw497I

rle idle position switch is a contact type switch thatinto the throttle bore when the valve is fully closed.

detects operation of the accelerator pedal. ThisThis setting has been performed accurately at the

switch also serves as the throttle stop screw, whichfactory; the lock nut should not be loosened, or the

has been set at the minimum opening of the throttleidle position switch be moved inadvertently.

‘valve so as to prevent the throttle valve from biting_

Page 134 of 391

14-22FUEL SYSTEM - Sensors

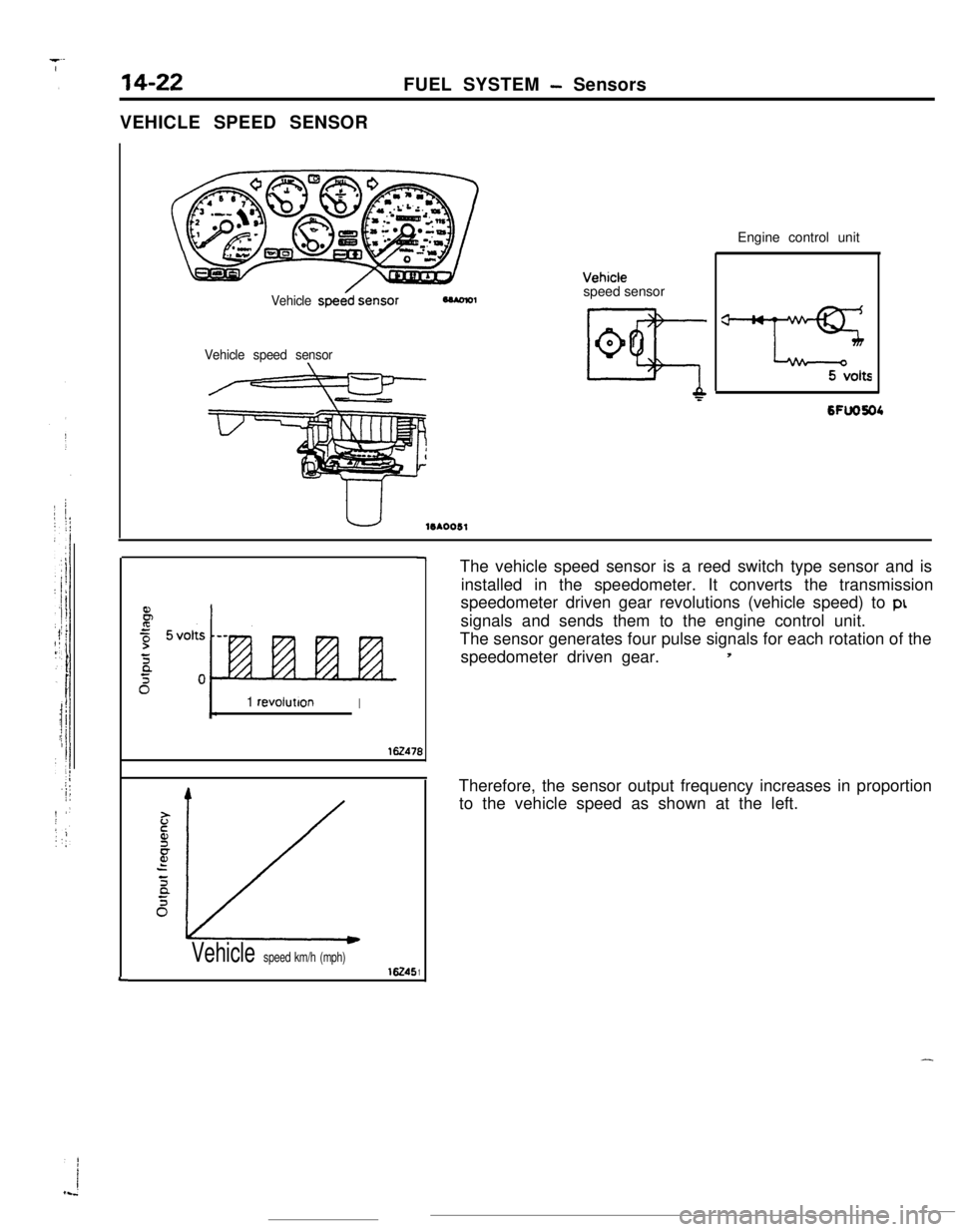

VEHICLE SPEED SENSOR

L

Vehicle speessensor

Vehicle speed sensor

10*0051speed sensorEngine control unit

6FlJO604

1 revoluttonI

‘r’471

16245

7

B

1Vehicle speed km/h (mph)The vehicle speed sensor is a reed switch type sensor and is

installed in the speedometer. It converts the transmission

speedometer driven gear revolutions (vehicle speed) to

ptsignals and sends them to the engine control unit.

The sensor generates four pulse signals for each rotation of the

speedometer driven gear.

5Therefore, the sensor output frequency increases in proportion

to the vehicle speed as shown at the left.

-

Page 157 of 391

3-d__- .

FUEL SYSTEM

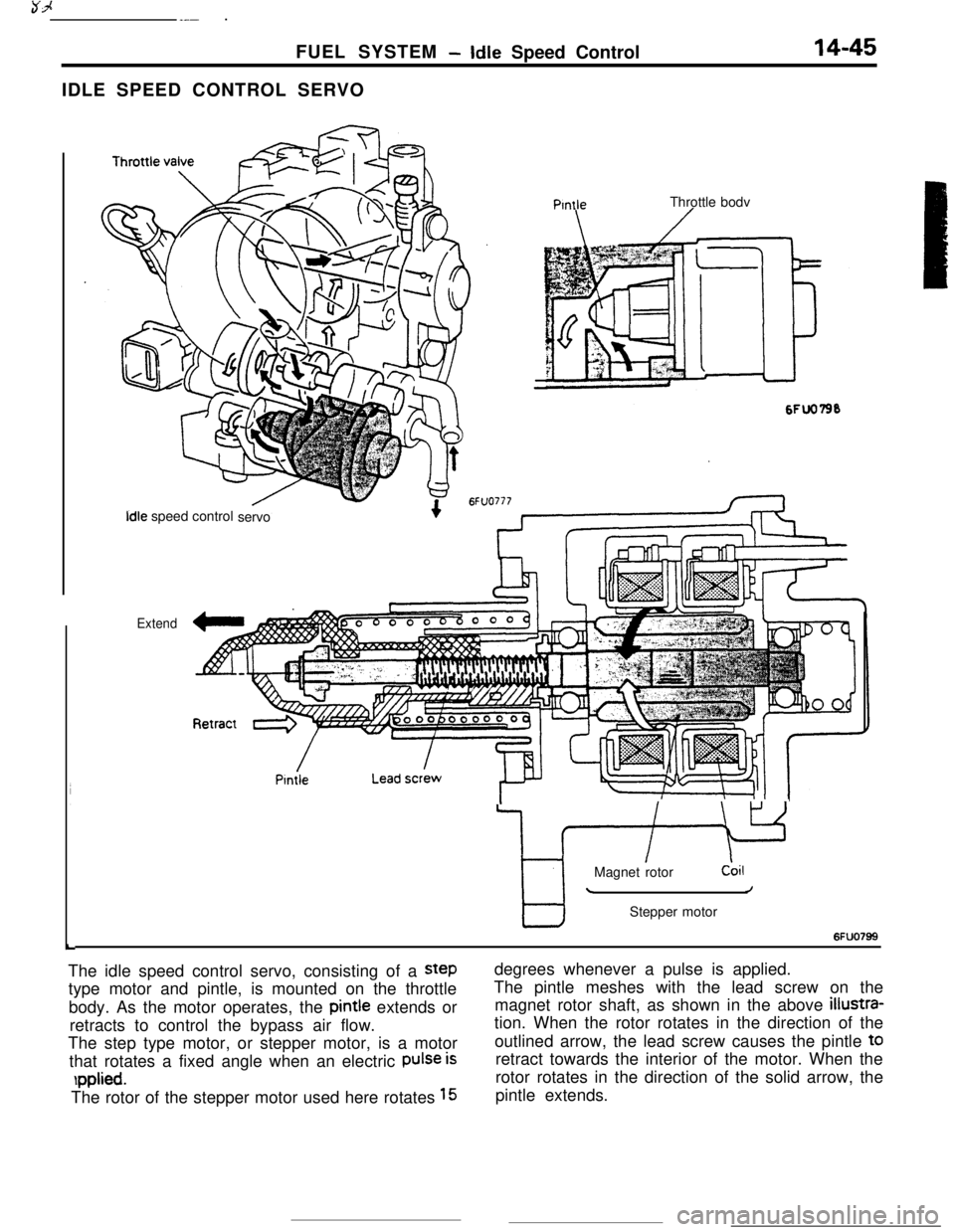

-Idle Speed Control14-45IDLE SPEED CONTROL SERVO

L

PtntleThrottle bodv

Idle speed control

servo

Extend

7 -IMagnet rotordoil

/Stepper motor

6FUO799The idle speed control servo, consisting of a

steptype motor and pintle, is mounted on the throttle

body. As the motor operates, the pintie extends or

retracts to control the bypass air flow.

The step type motor, or stepper motor, is a motor

that rotates a fixed angle when an electric

Pulse is

rpplied.The rotor of the stepper motor used here rotates

15degrees whenever a pulse is applied.

The pintle meshes with the lead screw on the

magnet rotor shaft, as shown in the above

illustra-tion. When the rotor rotates in the direction of the

outlined arrow, the lead screw causes the pintle t0

retract towards the interior of the motor. When the

rotor rotates in the direction of the solid arrow, the

pintle extends.

Page 169 of 391

FUEL SYSTEMAir Flow Sensor (AFSI Filter Reset Control

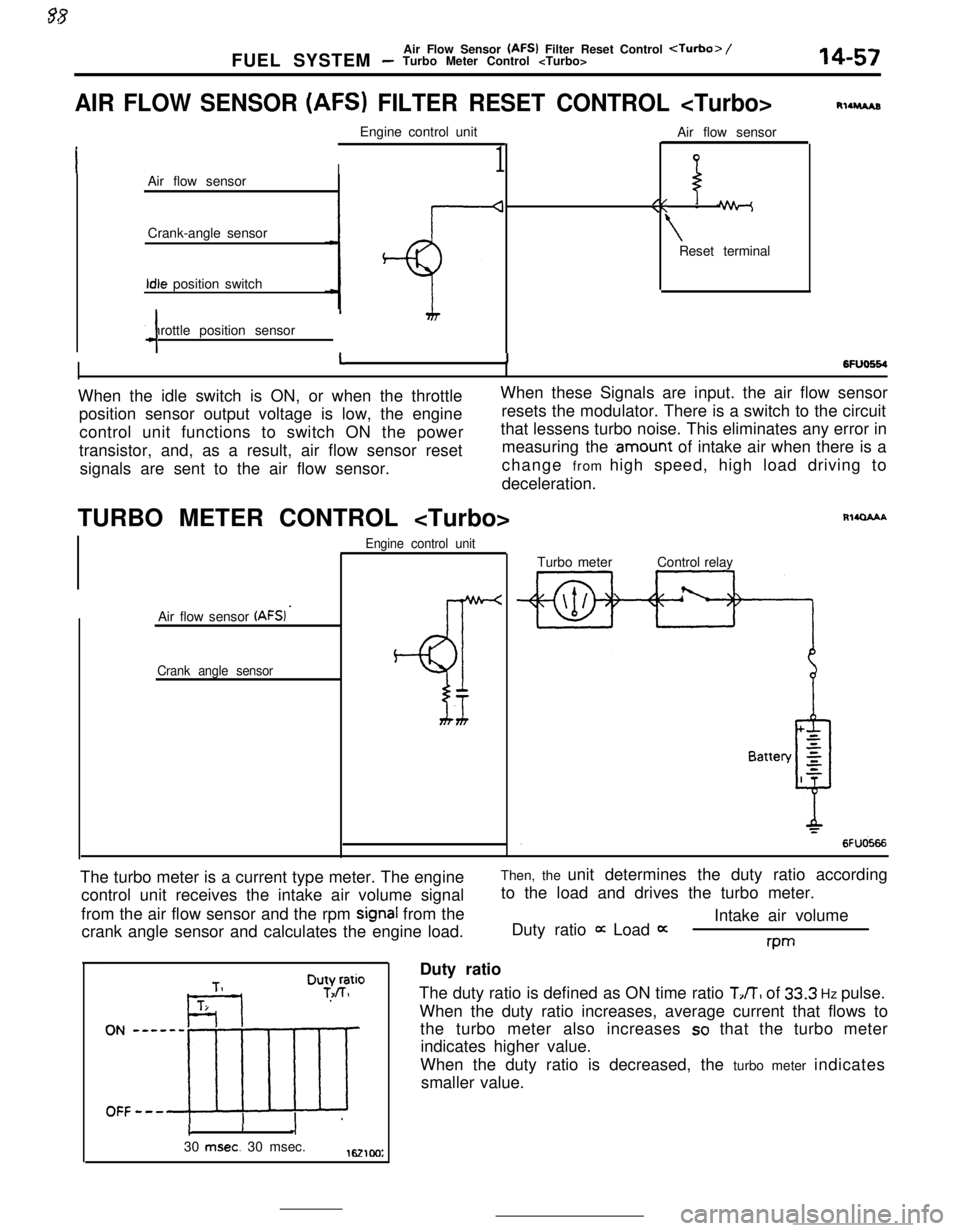

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL

I1Air flow sensor

Crank-angle sensorIdle position switch

Throttle position sensor

4Air flow sensor

//\\ -

\Reset terminal

RllruAs

6FlJo664I11When the idle switch is ON, or when the throttleWhen these Signals are input. the air flow sensor

position sensor output voltage is low, the engineresets the modulator. There is a switch to the circuit

control unit functions to switch ON the powerthat lessens turbo noise. This eliminates any error in

transistor, and, as a result, air flow sensor resetmeasuring the

.amount of intake air when there is a

signals are sent to the air flow sensor.change from high speed, high load driving to

deceleration.

TURBO METER CONTROL

Air flow sensor

(AFSI ’

Crank angle sensorEngine control unit

BT

Rl4QAAATurbo meterControl relay

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal

from the air flow sensor and the rpm

signal from the

crank angle sensor and calculates the engine load.Then, the unit determines the duty ratio according

to the load and drives the turbo meter.

Intake air volume

Duty ratio

it Load 0:rwDuty ratio

The duty ratio is defined as ON time ratio

TJT, of 33.3 Hz pulse.

When the duty ratio increases, average current that flows to

the turbo meter also increases

so that the turbo meter

indicates higher value.

When the duty ratio is decreased, the turbo meter indicates

smaller value.

cI30

msec. 30 msec.1621cm:

Page 170 of 391

._ ..-

14-58

.-FUEL SYSTEM

- Accelerator Components

-7

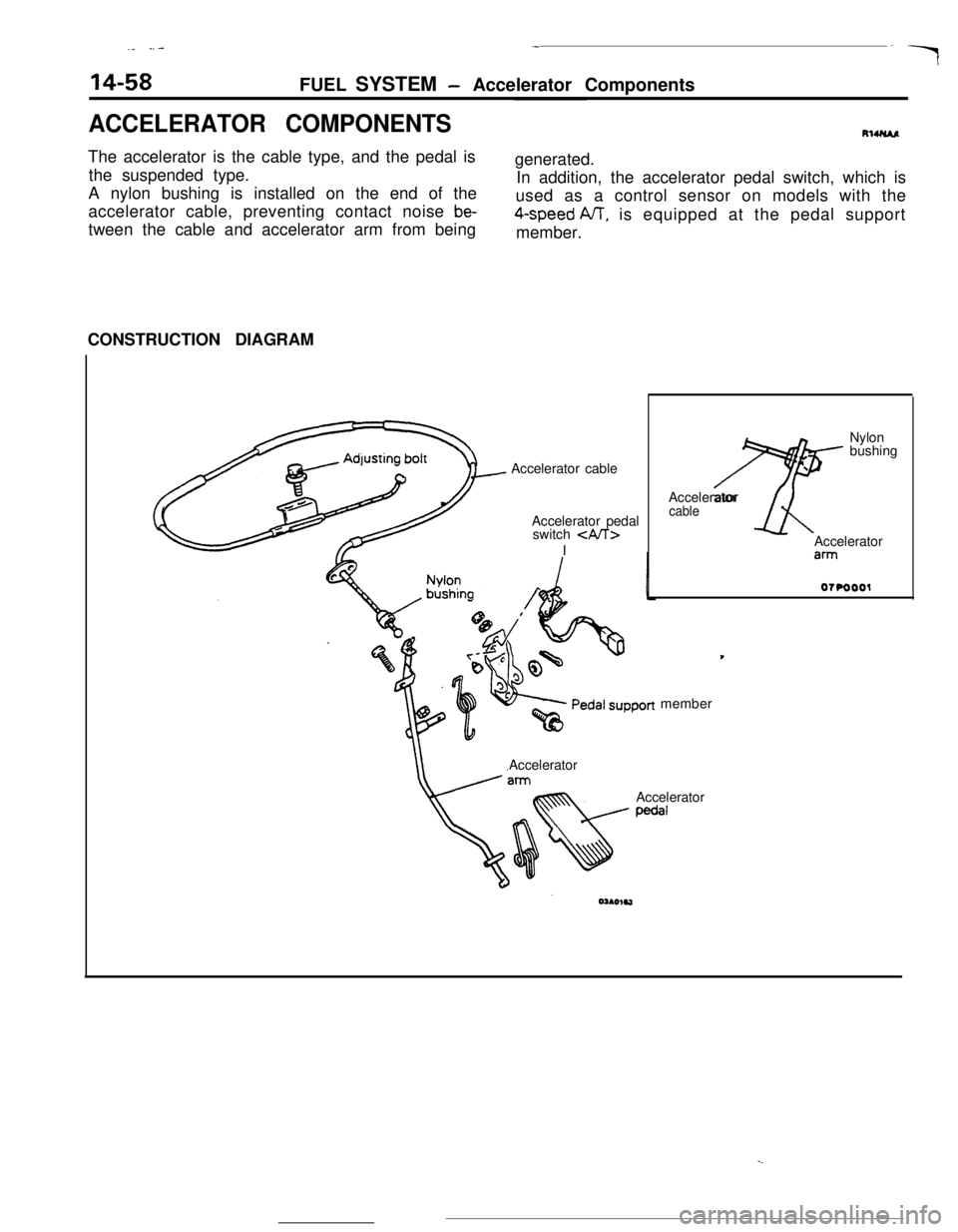

ACCELERATOR COMPONENTSRlUUAAThe accelerator is the cable type, and the pedal is

the suspended type.

A nylon bushing is installed on the end of the

accelerator cable, preventing contact noise

be-tween the cable and accelerator arm from beinggenerated.

In addition, the accelerator pedal switch, which is

used as a control sensor on models with the4-speed NT, is equipped at the pedal support

member.

CONSTRUCTION DIAGRAM

Accelerator cable

Accelerator pedal

switch

\Accelerator

cableAccelerator

ahmember

Accelerator

Accelerator

pedal

Page 171 of 391

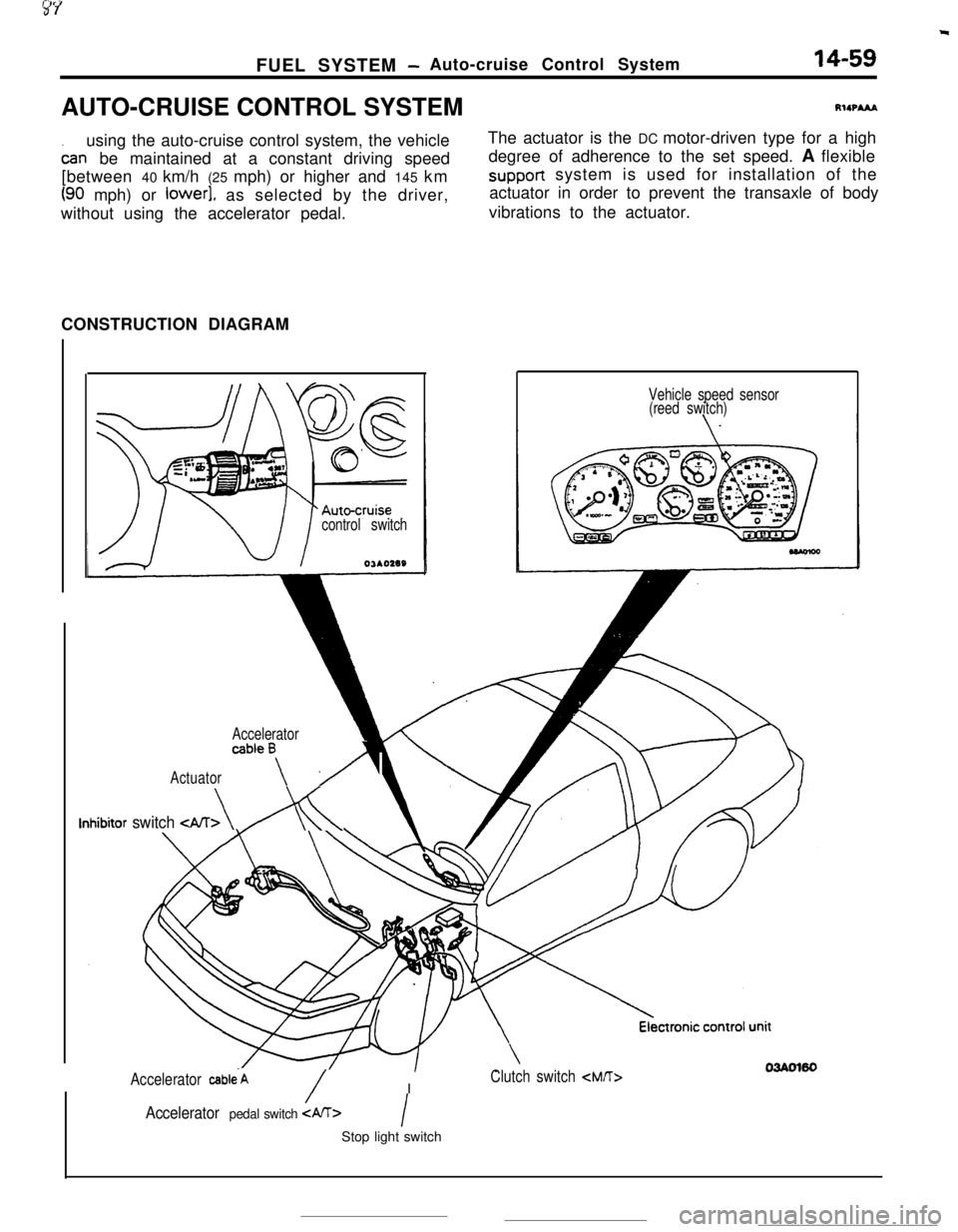

FUEL SYSTEM -Auto-cruise Control System14-59AUTO-CRUISE CONTROL SYSTEMRIIPA&A

using the auto-cruise control system, the vehicle

oar-rbe maintained at a constant driving speed

[between 40 km/h (25 mph) or higher and 145 km

(90 mph) or lower], as selected by the driver,

without using the accelerator pedal.The actuator is the DC motor-driven type for a high

degree of adherence to the set speed. A flexiblesupport system is used for installation of the

actuator in order to prevent the transaxle of body

vibrations to the actuator.

CONSTRUCTION DIAGRAM

control switchOJAO2SS

Accelerator

Actuator

ab’ea\ A

Inhibitor switch

(reed switch)

Accelerator cab1e.A/IClutch switch

/Accelerator pedal switch IStop light switch