oil change MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 192 of 391

PROPELLER SHAFT -General Information / Liibro Joint16-3

SPEClFlCATlONSterns

‘repeller shaft

Type

Length

x O.D.mm (in.)

Front

Center

RearUniversal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Ldbro joint]

No. 4 (rear)Cross type universal joint bearing

Cross type universal joint journal O.D.mm (in.)Constant velocity joint type

Constant velocity joint size O.D.mm (in.)

NOTE

Specifications

4 joint propeller shaft707

x 50.8 (27.8 x 2.00)647.5 x 50.8 (25.5 x

2.00)530.5 x 50.8 (20.9 x

2.00)

Cross type

Cross type

CV type

Cross type

Needle roller bearing (oilless type)

14.689 i.5783)

LGbro joint (oilless type)94

(3.7)The propeller shaft length is the length between the centers of the joints.

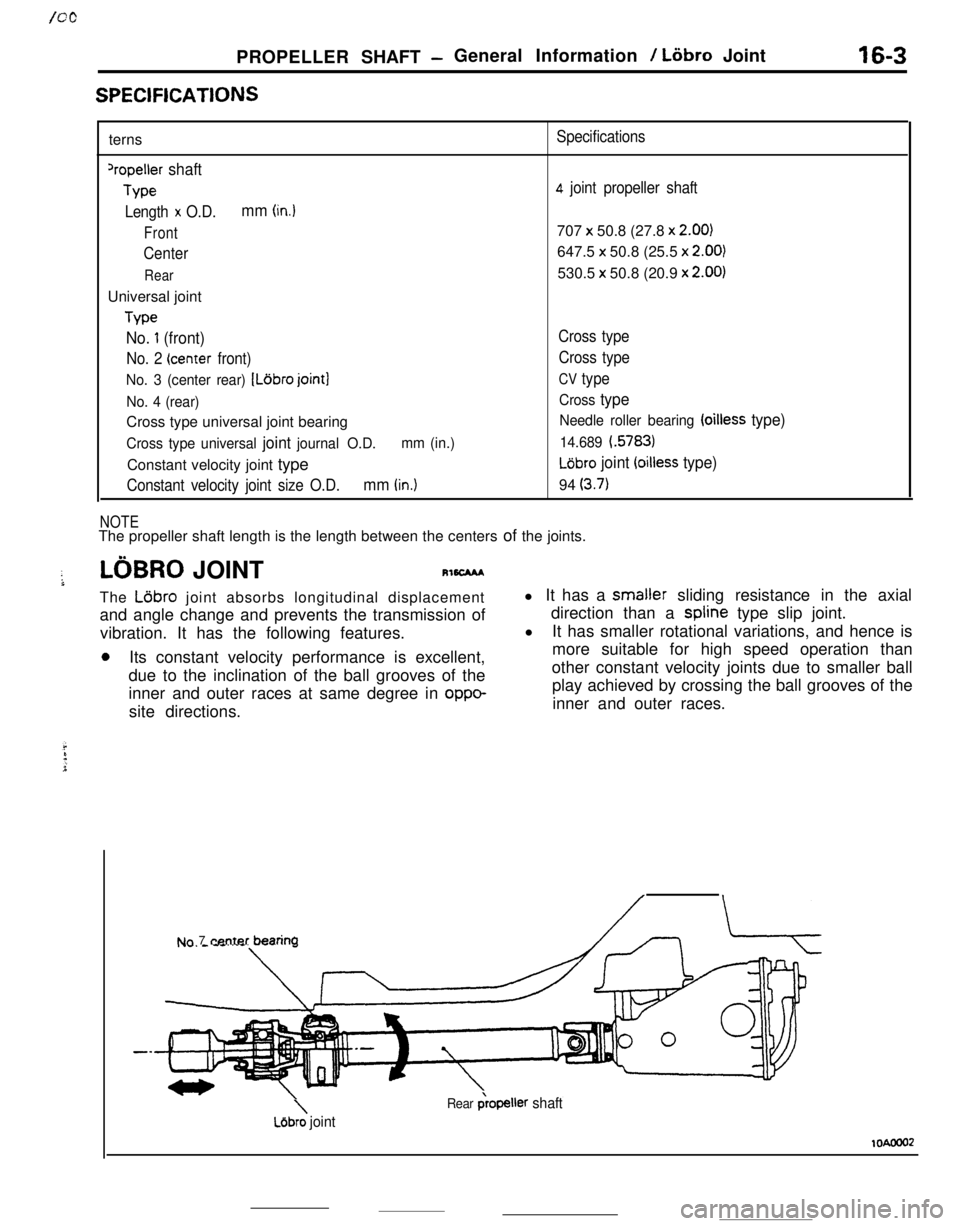

LOBRO JOINTRl6CMAThe

L6bro joint absorbs longitudinal displacement

and angle change and prevents the transmission of

vibration. It has the following features.

0Its constant velocity performance is excellent,

due to the inclination of the ball grooves of the

inner and outer races at same degree in

oppo-site directions.l It has a smaller sliding resistance in the axial

direction than a spline type slip joint.

l

It has smaller rotational variations, and hence is

more suitable for high speed operation than

other constant velocity joints due to smaller ball

play achieved by crossing the ball grooves of the

inner and outer races.

Nn 7 center bearina

\Lejbro joint

Rear &opeller shaft

lOAooo2

Page 219 of 391

POWER STEERING - Oil Pump13A0067

Insi

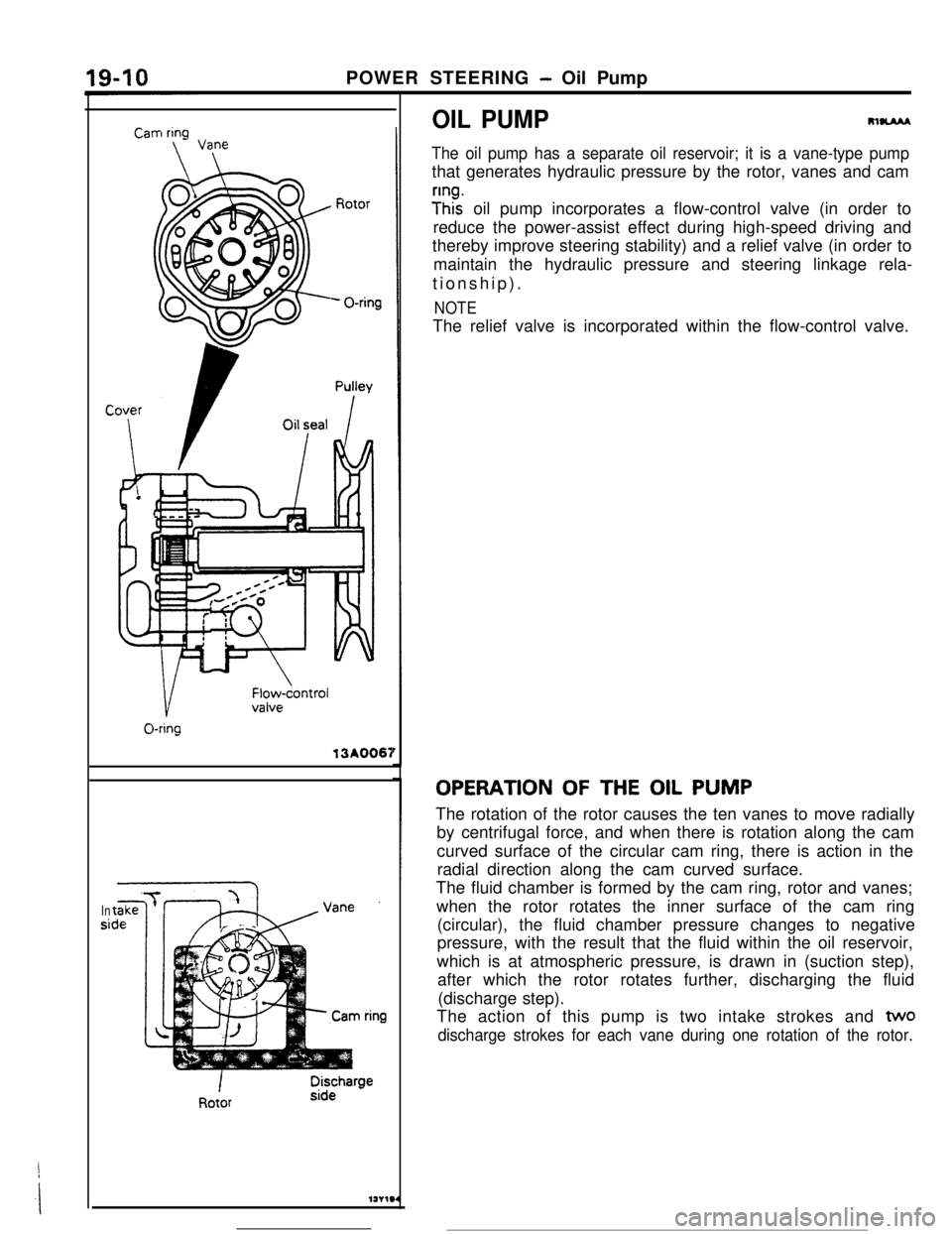

OIL PUMPRlUAM

The oil pump has a separate oil reservoir; it is a vane-type pumpthat generates hydraulic pressure by the rotor, vanes and cam

y”ht oil pump incorporates a flow-control valve (in order to

reduce the power-assist effect during high-speed driving and

thereby improve steering stability) and a relief valve (in order to

maintain the hydraulic pressure and steering linkage rela-

tionship).

NOTEThe relief valve is incorporated within the flow-control valve.

OPERATION OF THE OIL PUMP

The rotation of the rotor causes the ten vanes to move radially

by centrifugal force, and when there is rotation along the cam

curved surface of the circular cam ring, there is action in the

radial direction along the cam curved surface.

The fluid chamber is formed by the cam ring, rotor and vanes;

when the rotor rotates the inner surface of the cam ring

(circular), the fluid chamber pressure changes to negative

pressure, with the result that the fluid within the oil reservoir,

which is at atmospheric pressure, is drawn in (suction step),

after which the rotor rotates further, discharging the fluid

(discharge step).

The action of this pump is two intake strokes and

two

discharge strokes for each vane during one rotation of the rotor.

Page 221 of 391

POWER STEERING - Oil Pump

OIL PUMP13A0067

Insi

m-

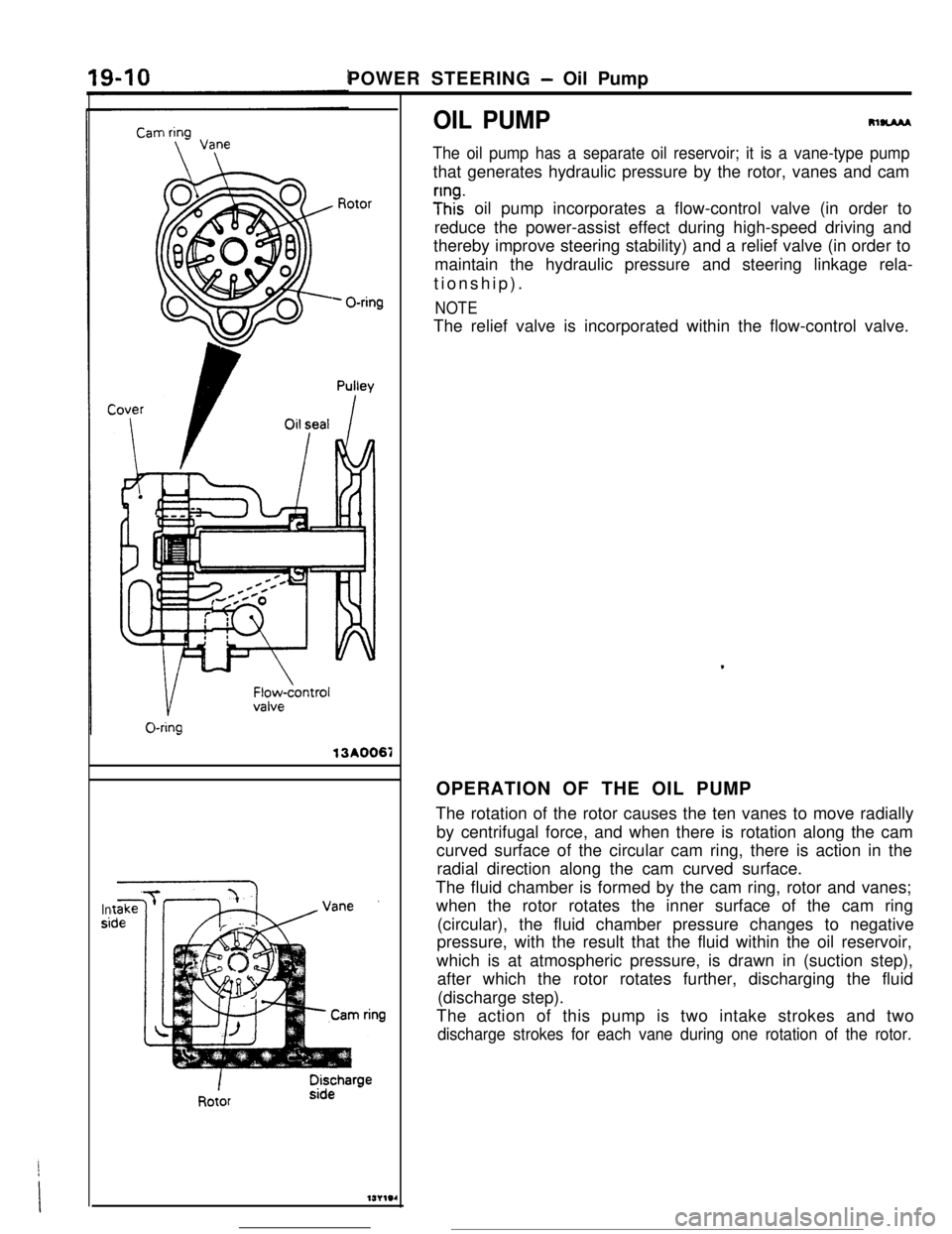

The oil pump has a separate oil reservoir; it is a vane-type pumpthat generates hydraulic pressure by the rotor, vanes and cam

;Inhz oil pump incorporates a flow-control valve (in order to

reduce the power-assist effect during high-speed driving and

thereby improve steering stability) and a relief valve (in order to

maintain the hydraulic pressure and steering linkage rela-

tionship).

NOTEThe relief valve is incorporated within the flow-control valve.

.OPERATION OF THE OIL PUMP

The rotation of the rotor causes the ten vanes to move radially

by centrifugal force, and when there is rotation along the cam

curved surface of the circular cam ring, there is action in the

radial direction along the cam curved surface.

The fluid chamber is formed by the cam ring, rotor and vanes;

when the rotor rotates the inner surface of the cam ring

(circular), the fluid chamber pressure changes to negative

pressure, with the result that the fluid within the oil reservoir,

which is at atmospheric pressure, is drawn in (suction step),

after which the rotor rotates further, discharging the fluid

(discharge step).

The action of this pump is two intake strokes and two

discharge strokes for each vane during one rotation of the rotor.

Page 237 of 391

MANUAL TRANSAXLE <4WD> - Viscous Coupling .(VClJ)21-13In contrast, the inner plates have no such spacer rings, and

each can slide to some extent over the hub spline shaft

between the outer plates.

The space between the housing and outer and inner plates is

filled with mixture of silicone oil and air.

Plate A

Moving atvelocity V*

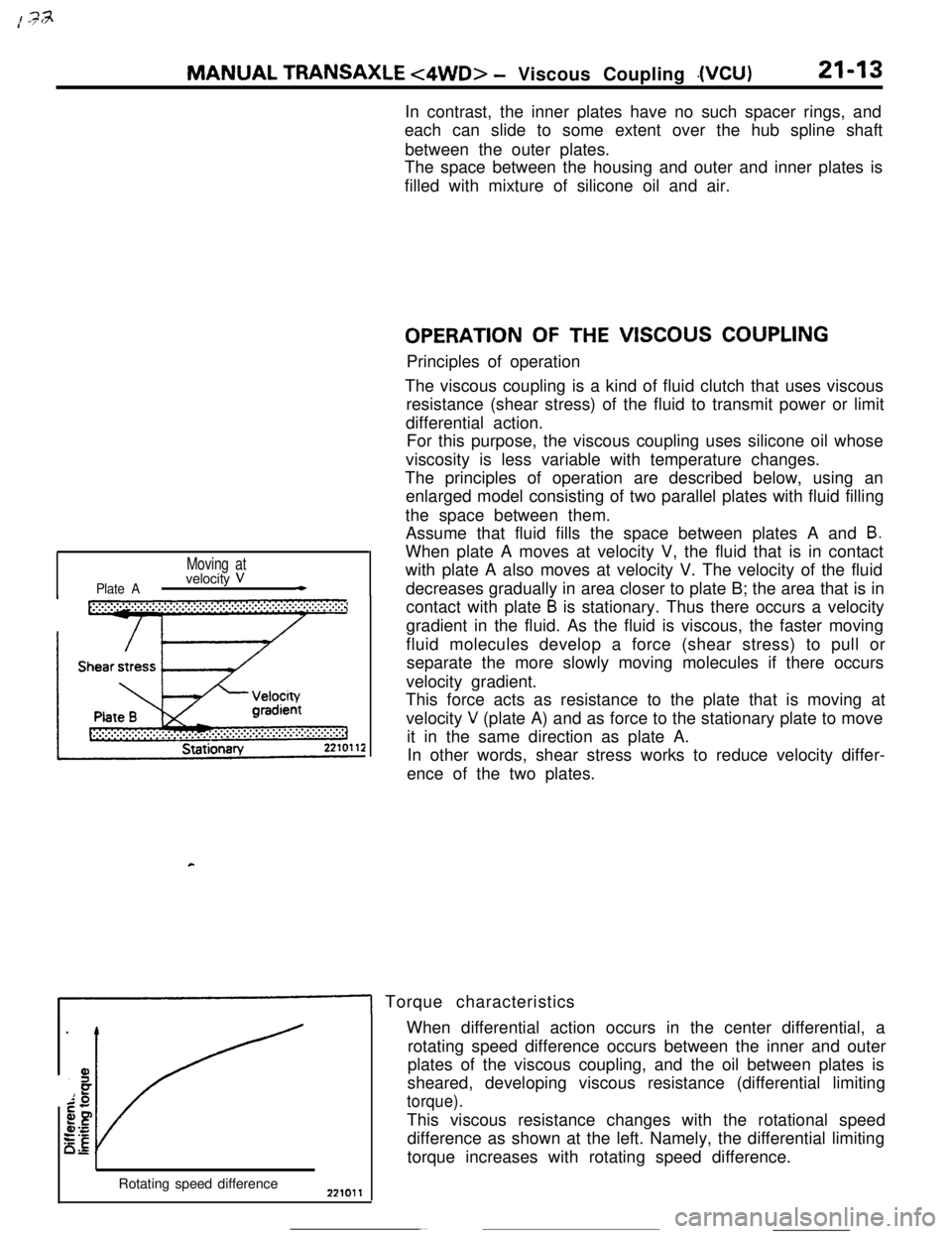

OPERATION OF THE VISCOUS COUPLINGPrinciples of operation

The viscous coupling is a kind of fluid clutch that uses viscous

resistance (shear stress) of the fluid to transmit power or limit

differential action.

For this purpose, the viscous coupling uses silicone oil whose

viscosity is less variable with temperature changes.

The principles of operation are described below, using an

enlarged model consisting of two parallel plates with fluid filling

the space between them.

Assume that fluid fills the space between plates A and

B.When plate A moves at velocity V, the fluid that is in contact

with plate A also moves at velocity V. The velocity of the fluid

decreases gradually in area closer to plate B; the area that is in

contact with plate

B is stationary. Thus there occurs a velocity

gradient in the fluid. As the fluid is viscous, the faster moving

fluid molecules develop a force (shear stress) to pull or

separate the more slowly moving molecules if there occurs

velocity gradient.

This force acts as resistance to the plate that is moving at

velocity

V (plate A) and as force to the stationary plate to move

it in the same direction as plate A.

In other words, shear stress works to reduce velocity differ-

ence of the two plates.

1 Torque characteristics

Rotating speed differenceWhen differential action occurs in the center differential, a

rotating speed difference occurs between the inner and outer

plates of the viscous coupling, and the oil between plates is

sheared, developing viscous resistance (differential limiting

torque).This viscous resistance changes with the rotational speed

difference as shown at the left. Namely, the differential limiting

torque increases with rotating speed difference.

Page 269 of 391

‘4) Once the operation is step (2) is completed, the

hydraulic control device functions by hydraulic

pressure force to change the state of the

clutches and brakes to accomplish the gear

shifting. To minimize the shock that would

otherwise be produced during gear shifting,

hydraulic pressure is controlled during the gear

shifting period by the “duty control” of the

pressure control solenoid valve. The duty control

is explained later.

‘HYDRAULIC PRESSURE CONTROL DURING

SHFIING(1) The hydraulic pressure that functions during

gear shifting to engage the clutches and apply

the brakes is regulated by the pressure control

valve, The hydraulic pressure that works on the

pressure control valve is further regulated by the

pressure control solenoid valve which functions

under the control of the transaxle control unit.

The transaxle control unit controls the solenoid

valve through the duty control, thus providing

appropriate regulation of the hydraulic pressure.

(2)

(3)

(4)The transaxle control unit decides the timing of

the gear shifting period (during which ‘it per-

forms hydraulic pressure control for gear shift-

ing) according to the change in the kickdown

drum rotating speed that it detects. The unit

identifies the time just before the kickdown

brake is applied and uses that as the timing for

initiating control of the hydraulic pressure which

is to be applied to the kickdown brake.

When the transaxle is cold, the fluid viscosity is

high, causing slower oil pressure response. in

such conditions, the transaxle control unit pro-

vides a correction for the oil pressure by

changing the control duty of the pressure control

solenoid valve.

This control is performed when the fluid temper-

atures as indicated by the oil temperature

sensor is lower than

60°C (140°F).After the engine has been started and the

vehicle is inmotion, the transaxle

continues torefine its performance

est possiblegear shifting.control unit

for smooth-

tHFigure B

- Duty(%)

17500661750067

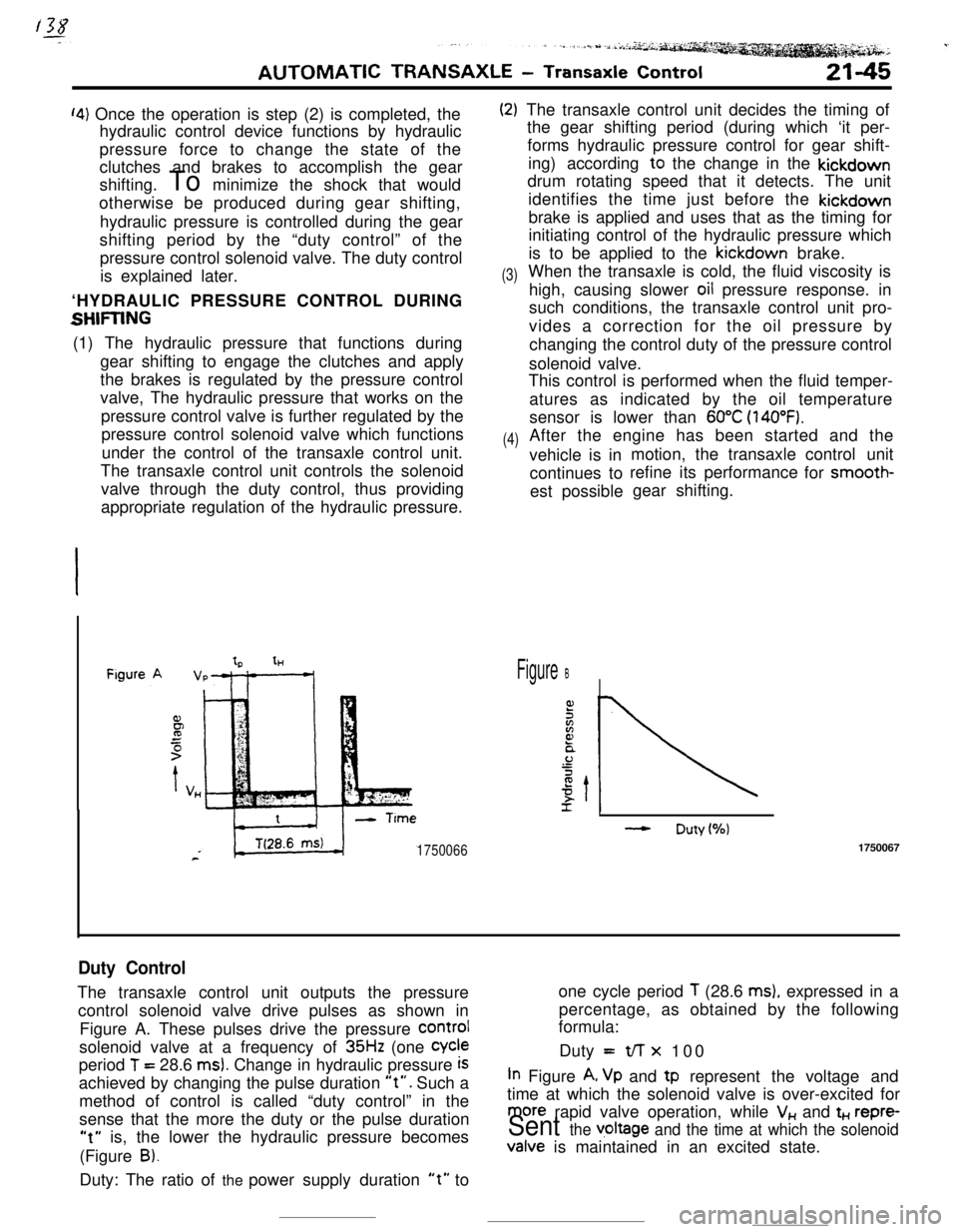

Duty ControlThe transaxle control unit outputs the pressureone cycle period

T (28.6 ms), expressed in a

control solenoid valve drive pulses as shown inpercentage, as obtained by the following

formula:

Figure A. These pulses drive the pressure

COrmIsolenoid valve at a frequency of

35Hz (one Cycleperiod

T = 28.6 ms). Change in hydraulic pressure iSDuty =t/-r x 100

achieved by changing the pulse duration

“t”. Such aIn Figure A, Vp and tp represent the voltage and

method of control is called “duty control” in thetime at which the solenoid valve is over-excited for

sense that the more the duty or the pulse duration

more rapid valve operation, while V,, and t+., repre-

“t” is, the lower the hydraulic pressure becomesSent the v,oltage and the time at which the solenoid(Figure

B).Valve is maintained in an excited state.

Duty: The ratio of the power supply duration

“t” to

Page 272 of 391

21-48AUTOMATIC TRANSAXLE - Transaxle Control

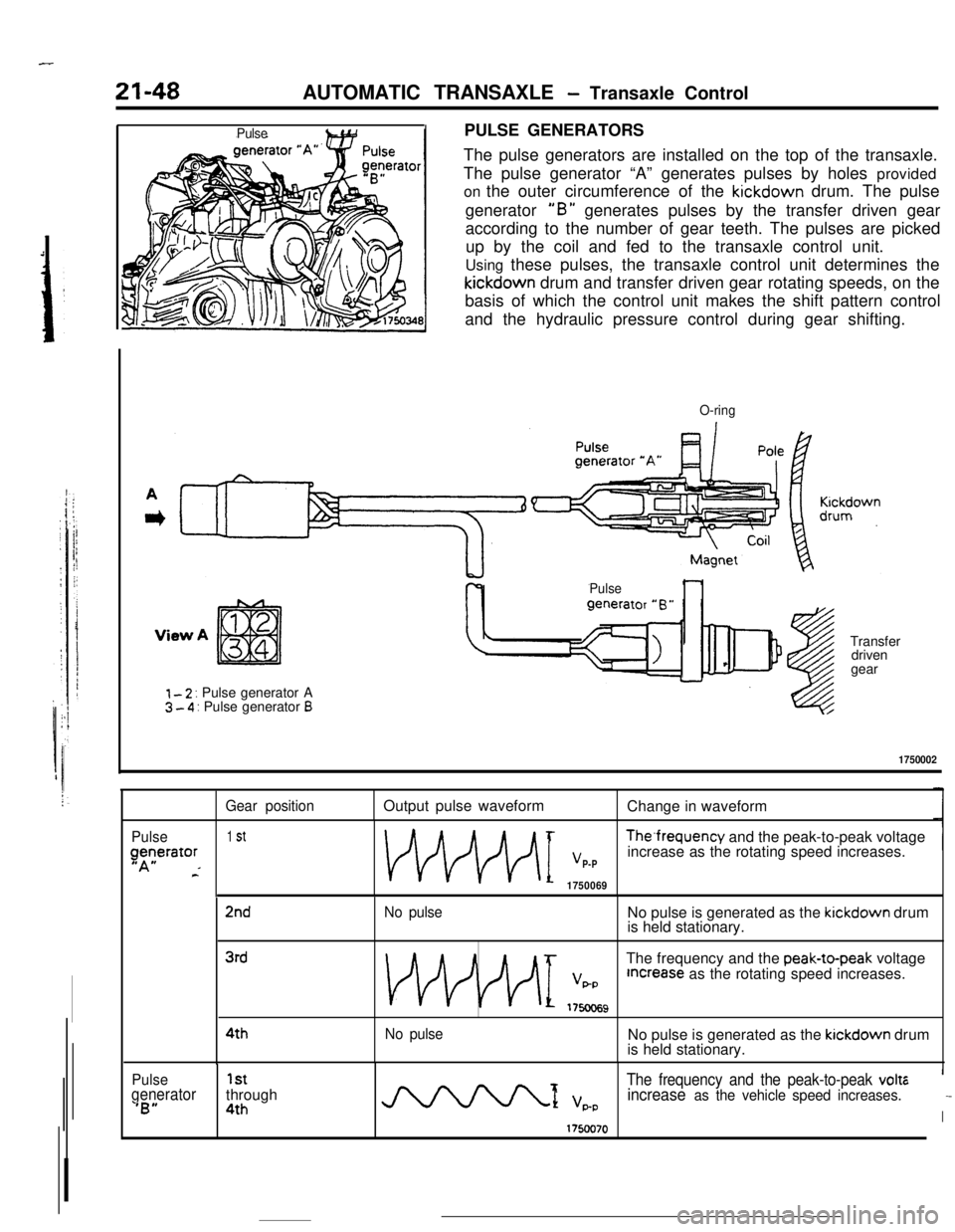

PulsePULSE GENERATORS

The pulse generators are installed on the top of the transaxle.

The pulse generator “A” generates pulses by holes provided

on the outer circumference of the kickdown drum. The pulse

generator

“B” generates pulses by the transfer driven gear

according to the number of gear teeth. The pulses are picked

up by the coil and fed to the transaxle control unit.

Using these pulses, the transaxle control unit determines thekickdown drum and transfer driven gear rotating speeds, on the

basis of which the control unit makes the shift pattern control

and the hydraulic pressure control during gear shifting.

O-ring

Pulse

View ATransfer

driven

gear

I - 2 : Pulse generator A3 - 4 : Pulse generator B

1750002

Gear positionOutput pulse waveform

Change in waveform

Pulse1 St

Tcerator-FThe‘frequency and the peak-to-peak voltageVP-Pincrease as the rotating speed increases.

1750069

2ndNo pulseNo pulse is generated as the kickdown drum

is held stationary.

3rdThe frequency and the peak-to-peak voltage

VF+PIncrease as the rotating speed increases.

175oc69

4thNo pulseNo pulse is generated as the kickdown drum

is held stationary.

Pulse1st

generator‘B”through4th-1 VP-P

The frequency and the peak-to-peak volt6’

increase as the vehicle speed increases.

I

-

Page 291 of 391

/gi--__ .--.-9

Reducingvalve

To kickdown

servo via 1 - 2

shift valveLine pressureAUTOMATIC TRANSAXLE

- Transaxle Control21-69

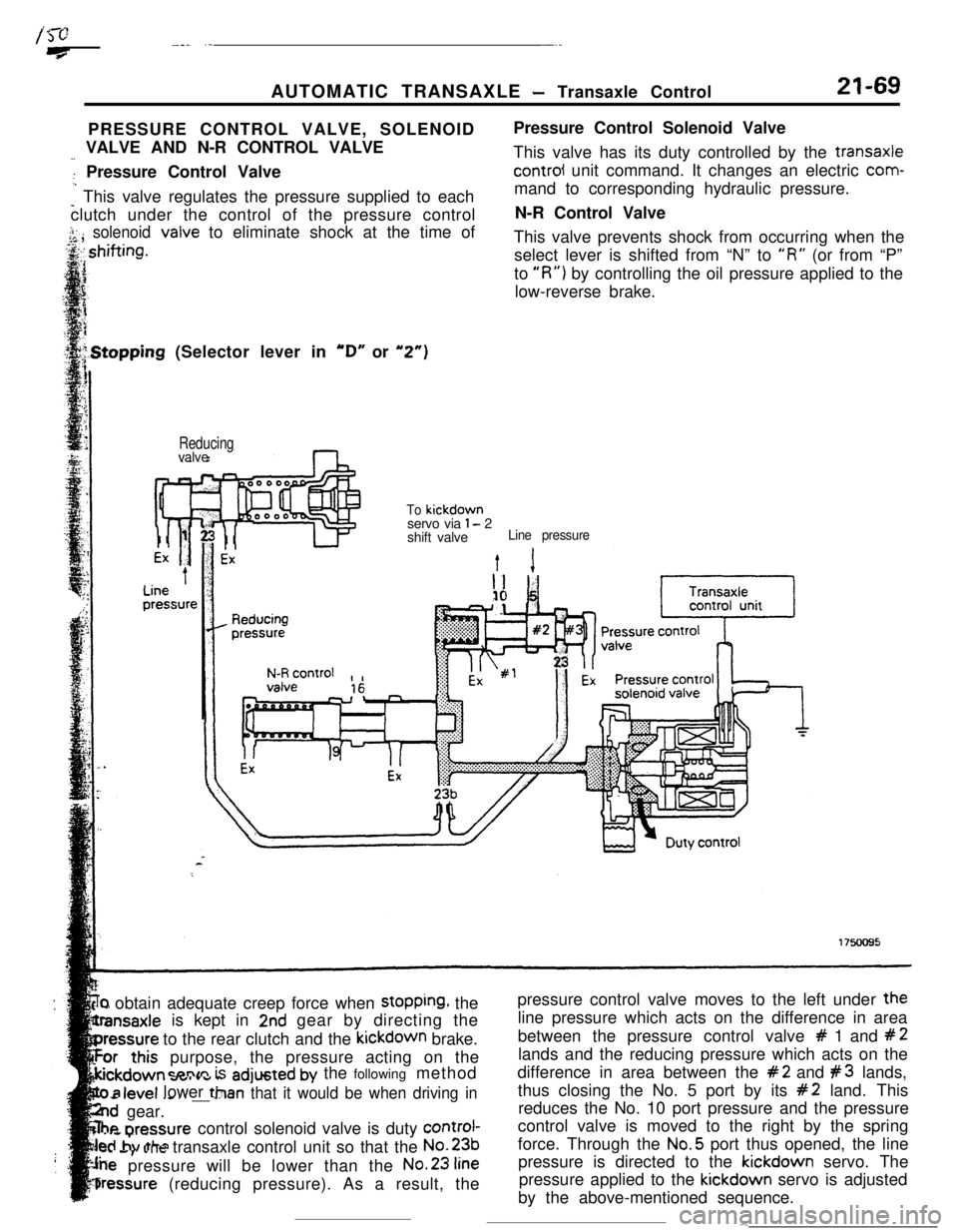

PRESSURE CONTROL VALVE, SOLENOID

-_ VALVE AND N-R CONTROL VALVE

: Pressure Control Valve

: This valve regulates the pressure supplied to each

clutch under the control of the pressure control

j.. solenoid<,A ,valve to eliminate shock at the time ofPressure Control Solenoid Valve

This valve has its duty controlled by the transaxlecontrol unit command. It changes an electric com-

mand to corresponding hydraulic pressure.

N-R Control Valve

This valve prevents shock from occurring when the

select lever is shifted from “N” to

“R” (or from “P”

to

“R”) by controlling the oil pressure applied to the

low-reverse brake..Stopping (Selector lever in

“D” or “2”)

‘r) obtain adequate creep force when stopping, the

is kept in

2nd gear by directing the

to the rear clutch and the kickdown brake.

purpose, the pressure acting on the

=nnm is adjusted by the following method

- .--v.._ _ _ __ --Tan that it would be when driving in

..d gear.

he nrennurecontrol solenoid valve is duty control-

..s,. ..Jtransaxle control unit so that the No.231..a

pressure will be lower than the No.23

fine

bressure (reducing pressure). As a result, the

level lower ttlpressure control valve moves to the left under the

line pressure which acts on the difference in area

between the pressure control valve

# 1 and #2lands and the reducing pressure which acts on the

difference in area between the

#2 and #3 lands,

thus closing the No. 5 port by its

#2 land. This

reduces the No. 10 port pressure and the pressure

control valve is moved to the right by the spring

force. Through the No.5 port thus opened, the line

pressure is directed to the kickdown servo. The

pressure applied to the kickdown servo is adjusted

by the above-mentioned sequence.

-