steering wheel MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 8 of 391

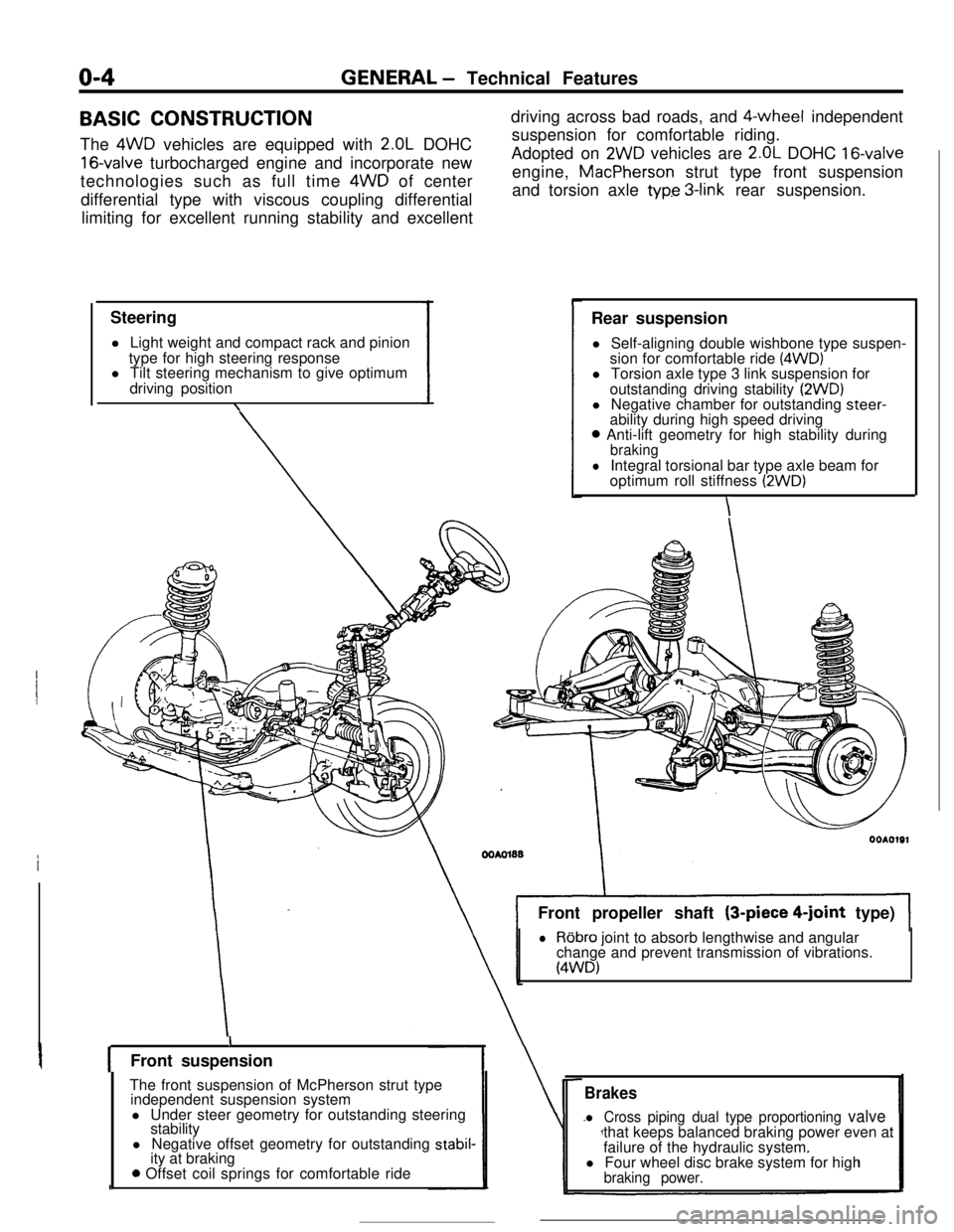

o-4GENERAL - Technical Features

BASIC CONSTRUCTION

The 4WD vehicles are equipped with

2.OL DOHC

16-valve turbocharged engine and incorporate new

technologies such as full time 4WD of center

differential type with viscous coupling differential

limiting for excellent running stability and excellent

Steering

l Light weight and compact rack and pinion

type for high steering response

l Tilt steering mechanism to give optimum

driving position

\driving across bad roads, and $-wheel independent

suspension for comfortable riding.

Adopted on

2WD vehicles are 2.OL DOHC 16-valveengine, MacPherson strut type front suspension

and torsion axle

typ.e 3-link rear suspension.

Rear suspension

l Self-aligning double wishbone type suspen-

sion for comfortable ride

(4WD)l Torsion axle type 3 link suspension for

outstanding driving stability

(2WD)l Negative chamber for outstanding steer-

ability during high speed driving

0 Anti-lift geometry for high stability duringbraking

lIntegral torsional bar type axle beam for

optimum roll stiffness (2WD)

\Front propeller shaft (3-piece

4-joint type)

lRobro joint to absorb lengthwise and angular

change and prevent transmission of vibrations.

(4WD)

IFront suspension

The front suspension of McPherson strut type

independent suspension system

l Under steer geometry for outstanding steering

stability

l Negative offset geometry for outstanding

stabil-ity at braking

0 Offset coil springs for comfortable ride

Brakes

l Cross piping dual type proportioning valvethat keeps balanced braking power even at

failure of the hydraulic system.

l Four wheel disc brake system for high

braking power.

Page 136 of 391

--

,

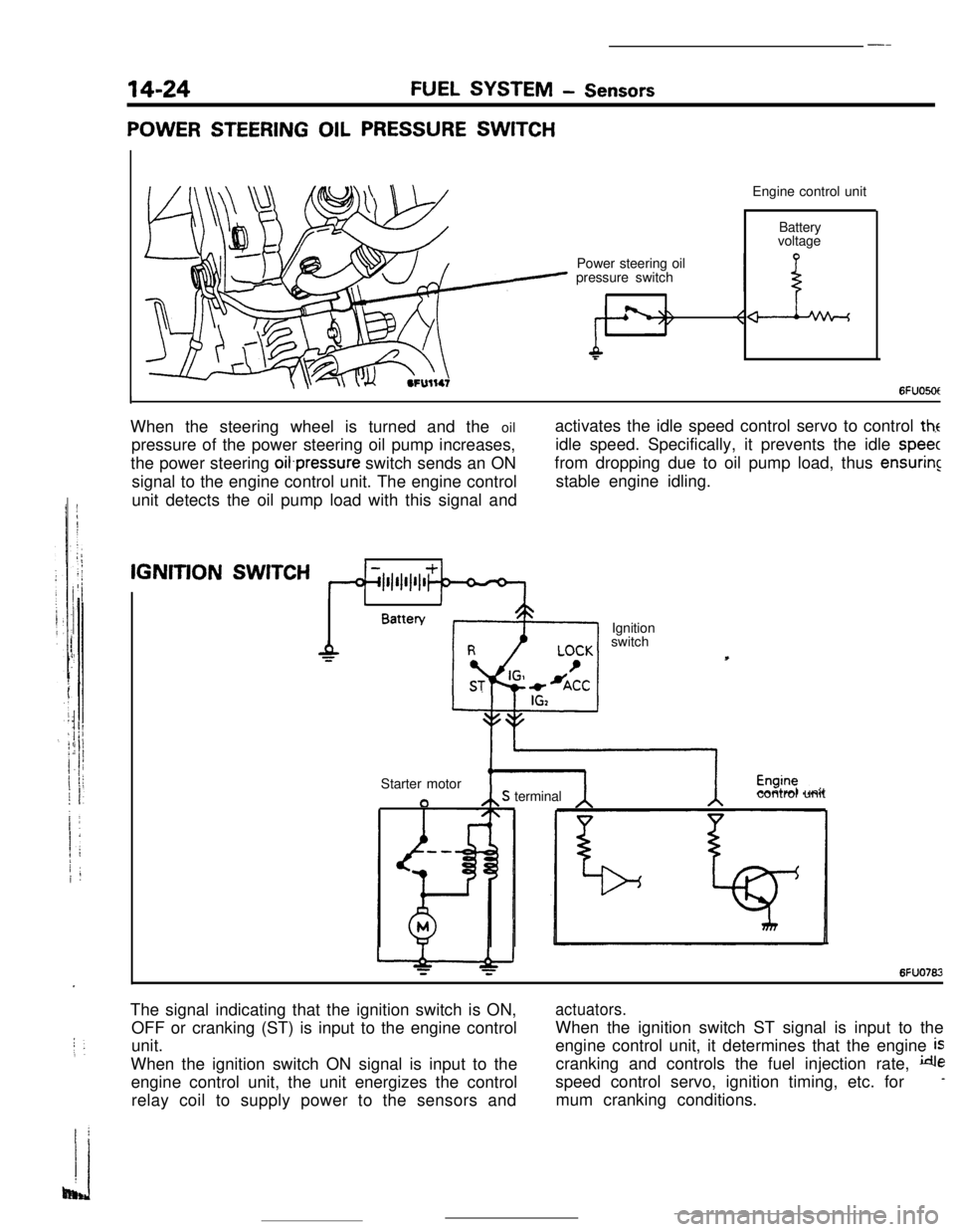

14-24FUEL SYSTEM - Sensors

POWER STEERING OIL PRESSURE SWITCHEngine control unit

Power steering oil

pressure switchBattery

voltage

6FUO5OtIWhen the steering wheel is turned and the oil

pressure of the power steering oil pump increases,

the power steering oifpressure switch sends an ON

signal to the engine control unit. The engine control

unit detects the oil pump load with this signal andactivates the idle speed control servo to control

theidle speed. Specifically, it prevents the idle

speecfrom dropping due to oil pump load, thus

ensuringstable engine idling.IGNITION

SWITCH

1IBattery

Ignition

switch

Starter motor

aS terminalcontrol unit

6FUO762The signal indicating that the ignition switch is ON,

OFF or cranking (ST) is input to the engine control

unit.

When the ignition switch ON signal is input to the

engine control unit, the unit energizes the control

relay coil to supply power to the sensors and

actuators.When the ignition switch ST signal is input to the

engine control unit, it determines that the engine

iscranking and controls the fuel injection rate,

despeed control servo, ignition timing, etc. for

-mum cranking conditions.

Page 162 of 391

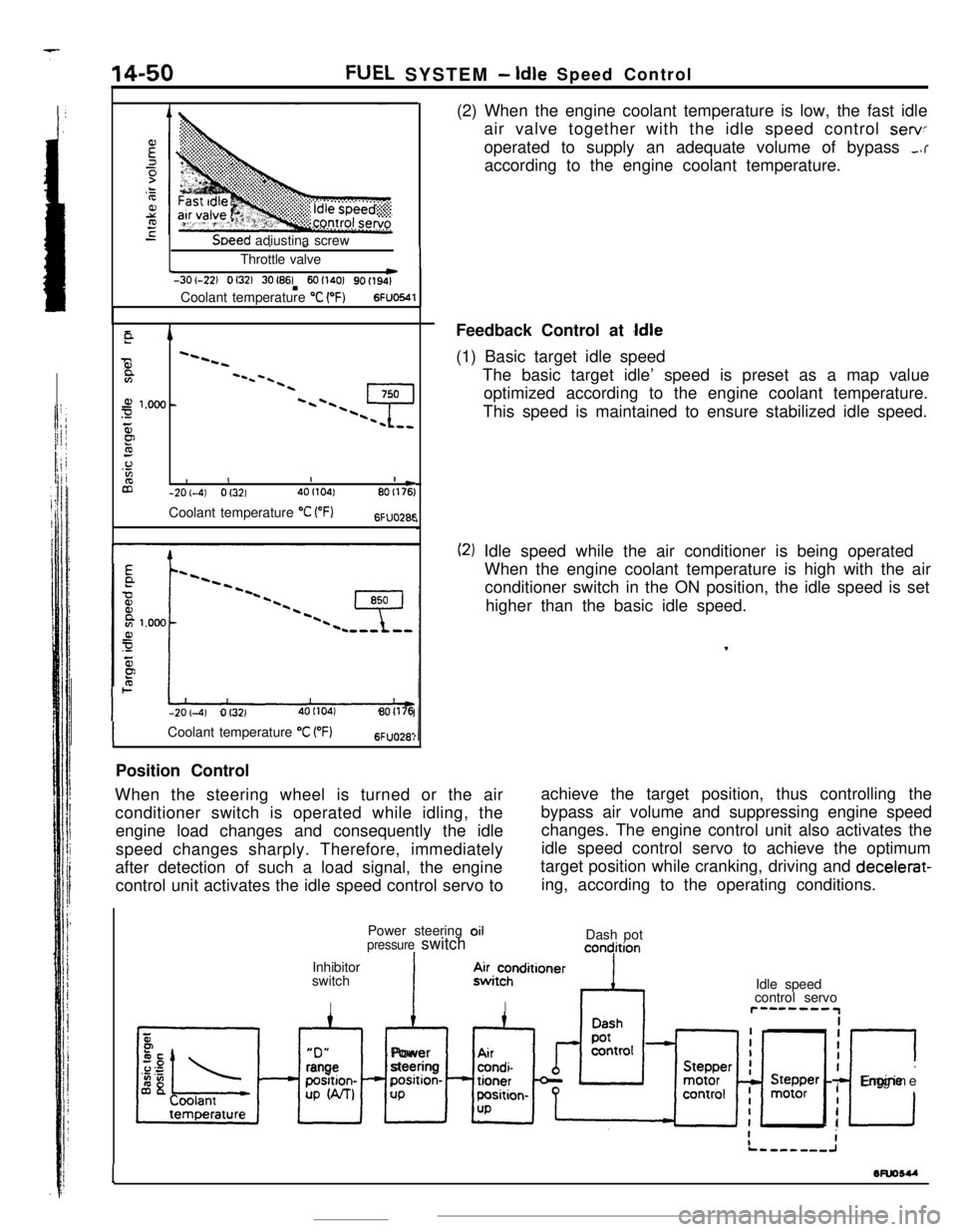

14-50FUEL SYSTEM- Idle Speed Control

SDeed adiustina screwI -Throttle valve

Lw-3O(-22) 0132) 30(86! 601140) 9ofl94)Coolant temperature

“C (OF)6FUO641

E94

72--2--I

Q--.-.-z

3201.000 --4-\-\

5P9.o%IIIaI L-2O(-41 Of3214Of104)801176)Coolant temperature

“C VF)6FU028E

-201-4) Of3214OI104180(176(2) When the engine coolant temperature is low, the fast idle

air valve together with the idle speed control

servoperated to supply an adequate volume of bypass

,.raccording to the engine coolant temperature.

Feedback Control at

Idle(1) Basic target idle speed

The basic target idle’ speed is preset as a map value

optimized according to the engine coolant temperature.

This speed is maintained to ensure stabilized idle speed.

(2) Idle speed while the air conditioner is being operated

When the engine coolant temperature is high with the air

conditioner switch in the ON position, the idle speed is set

higher than the basic idle speed.

,

ICoolant temperature “C VF)6FUO28:Position Control

When the steering wheel is turned or the air

conditioner switch is operated while idling, theachieve the target position, thus controlling the

engine load changes and consequently the idlebypass air volume and suppressing engine speed

changes. The engine control unit also activates the

speed changes sharply. Therefore, immediately

after detection of such a load signal, the engine

control unit activates the idle speed control servo toidle speed control servo to achieve the optimum

target position while cranking, driving and decelerat-

ing, according to the operating conditions.

Power steering oil

pressure switchIInhibitor

switch

IDash pot

concjition“D”

xl

rangeposition-

UP W-U

IAlPower

steeringposition-

UP.4~i~hnditioner

IIdle speed

control servor”--““IiiI

I

c

IEngine

I

I

1wuosu

-

Page 163 of 391

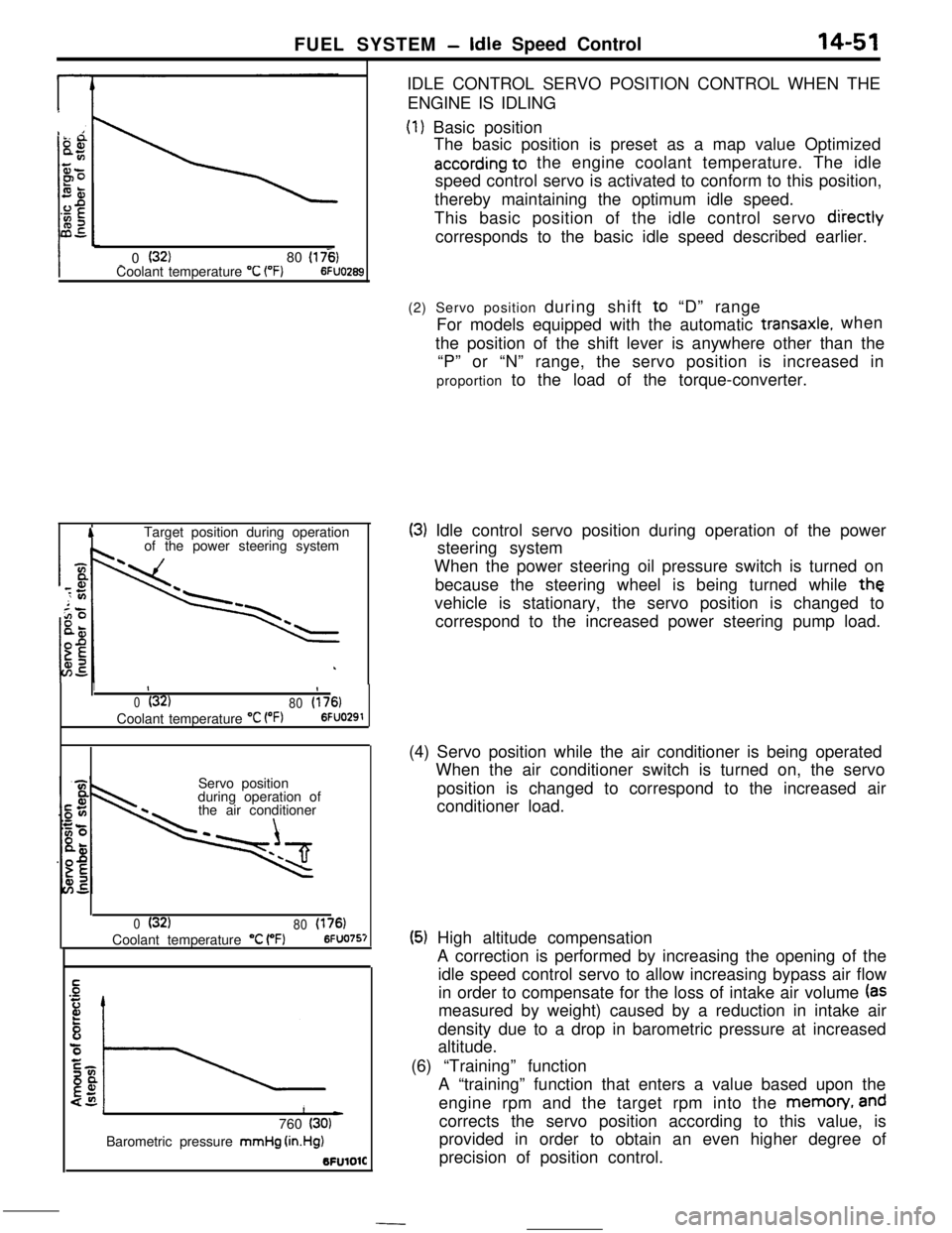

FUEL SYSTEM -Idle Speed Control14-51

_ 0 (32)80 (175)Coolant temperature “C (“F)6FUO2653

ATarget position during operation

of the power steering systemIDLE CONTROL SERVO POSITION CONTROL WHEN THE

ENGINE IS IDLING

(1) Basic position

The basic position is preset as a map value Optimized

according to the engine coolant temperature. The idle

speed control servo is activated to conform to this position,

thereby maintaining the optimum idle speed.

This basic position of the idle control servo

diiectlycorresponds to the basic idle speed described earlier.

1II

0(32)

80(176)Coolant temperature

“C VW6FUO291Servo position

during operation of

the air conditioner

0(32)

80(176)Coolant temperature “C (“F)6FUO757

1L)760 (30)Barometric pressure mmHg

(in.Hg)BFUlOlC(2) Servo position during shift to “D” range

For models equipped with the automatic

transaxle.when

the position of the shift lever is anywhere other than the

“P” or “N” range, the servo position is increased in

proportion to the load of the torque-converter.

(3) Idle control servo position during operation of the power

steering system

When the power steering oil pressure switch is turned on

because the steering wheel is being turned while

thevehicle is stationary, the servo position is changed to

correspond to the increased power steering pump load.

(4) Servo position while the air conditioner is being operated

When the air conditioner switch is turned on, the servo

position is changed to correspond to the increased air

conditioner load.

(5) High altitude compensation

A correction is performed by increasing the opening of the

idle speed control servo to allow increasing bypass air flow

in order to compensate for the loss of intake air volume

(asmeasured by weight) caused by a reduction in intake air

density due to a drop in barometric pressure at increased

altitude.

(6) “Training” function

A “training” function that enters a value based upon the

engine rpm and the target rpm into the memon/,

andcorrects the servo position according to this value, is

provided in order to obtain an even higher degree of

precision of position control.

Page 204 of 391

. -.-REAR SUSPENSION

- Double Wishbone SuspensionDOUBLE WISHBONE SUSPENSION

CONSTRUCTION AND OPERATION17-11

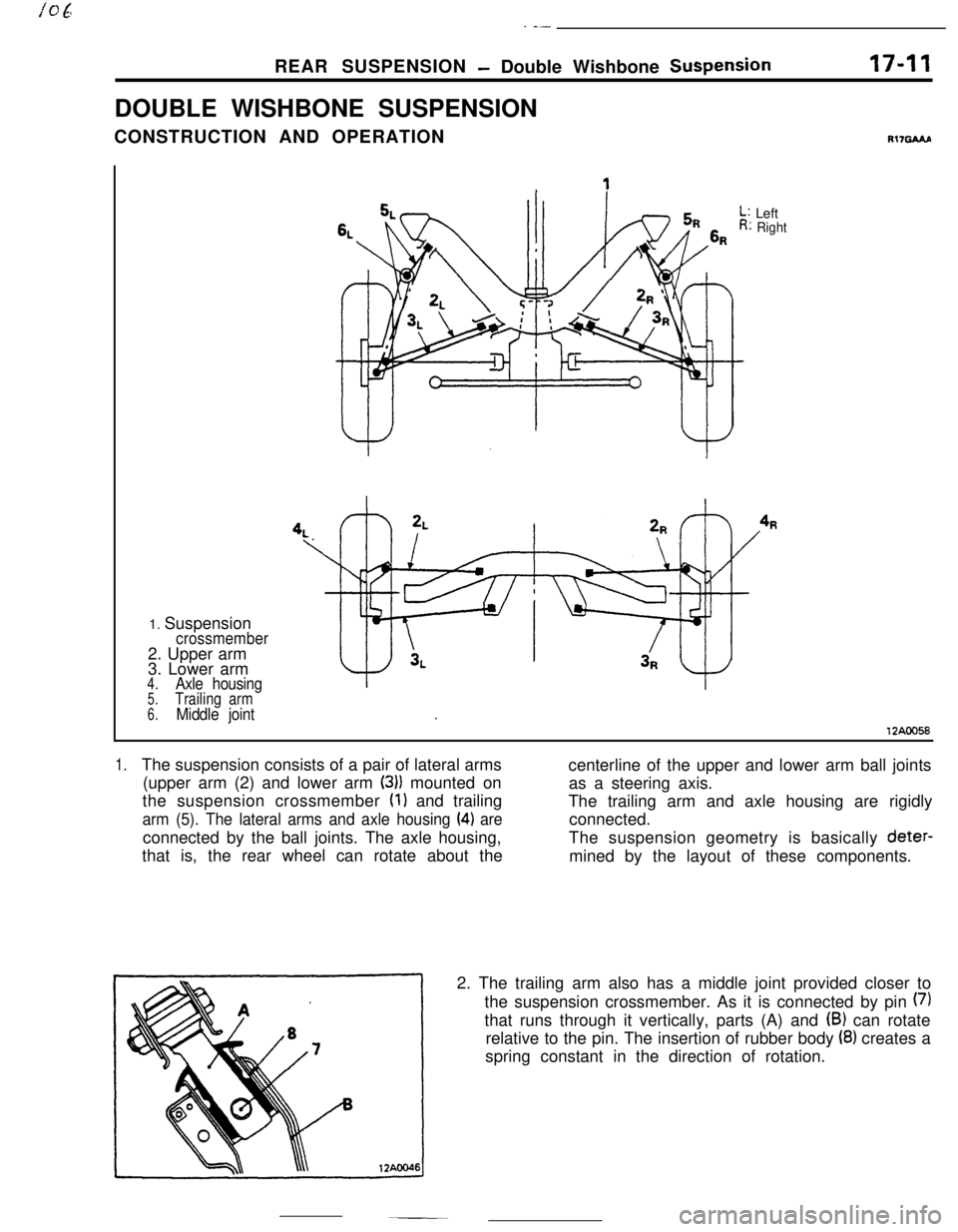

R17GAAP1. Suspension

crossmember2. Upper arm

3. Lower arm

4.Axle housing5.Trailing arm

6.Middle jointLeft

Right

12AOO58

1.The suspension consists of a pair of lateral arms

centerline of the upper and lower arm ball joints

(upper arm (2) and lower arm

(3)) mounted on

as a steering axis.

the suspension crossmember

(1) and trailing

The trailing arm and axle housing are rigidly

arm (5). The lateral arms and axle housing (4) areconnected.

connected by the ball joints. The axle housing,The suspension geometry is basically deter-

that is, the rear wheel can rotate about the

mined by the layout of these components.

2. The trailing arm also has a middle joint provided closer to

the suspension crossmember. As it is connected by pin

(7)that runs through it vertically, parts (A) and

(B) can rotate

relative to the pin. The insertion of rubber body

(8) creates a

spring constant in the direction of rotation.

Page 205 of 391

17-12REAR SUSPENSION - Double Wishbone Suspension

12AWY

lZAOOS!

When cornering. I.to the right

I Toe-inToe angle

ReboundBump-

PositiveCamber(to body)

- Camber to ground: 0

Bump

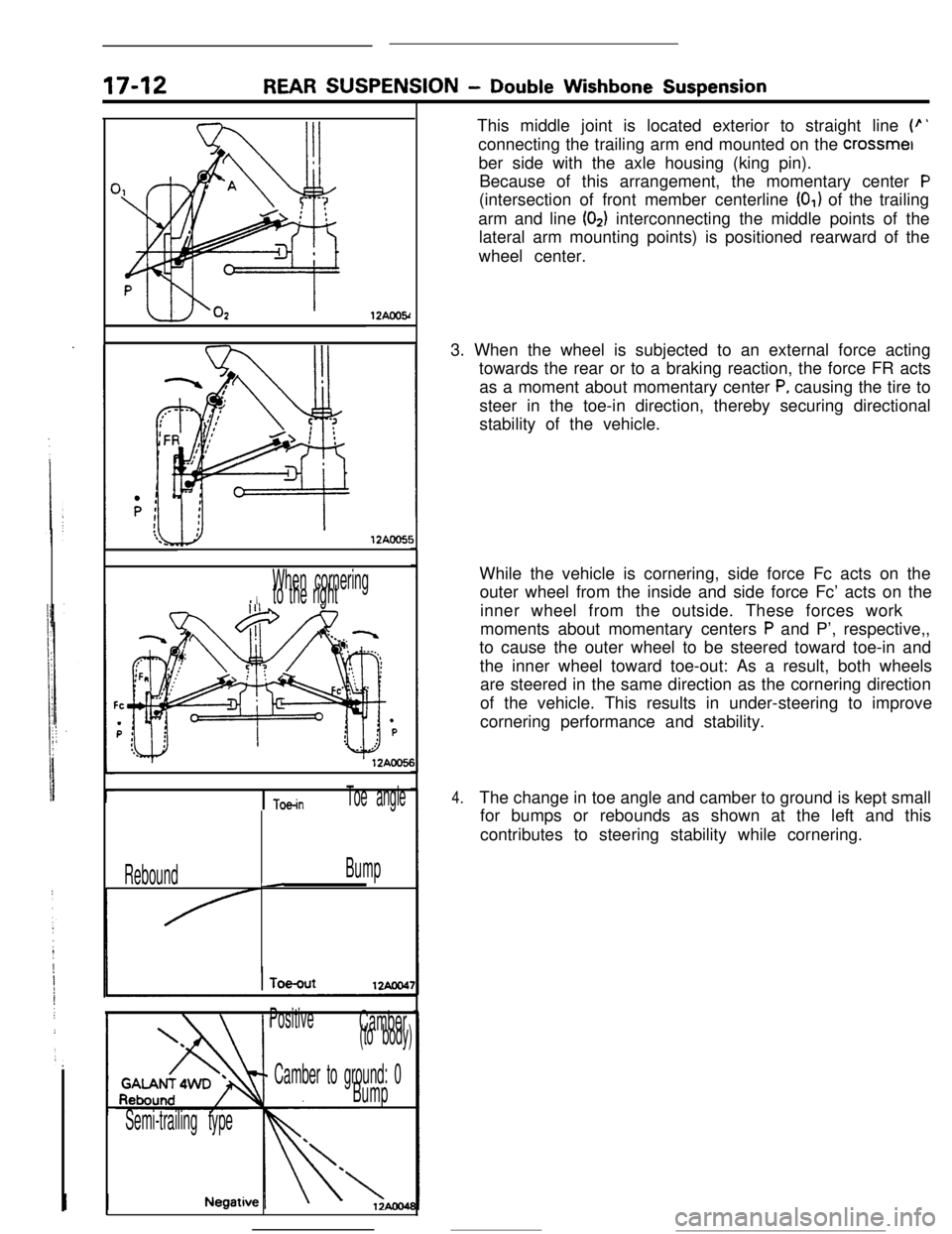

Semi-trailing typeThis middle joint is located exterior to straight line

(p’connecting the trailing arm end mounted on the crossmet

ber side with the axle housing (king pin).

Because of this arrangement, the momentary center

P(intersection of front member centerline

(0,) of the trailing

arm and line

(02) interconnecting the middle points of the

lateral arm mounting points) is positioned rearward of the

wheel center.

3. When the wheel is subjected to an external force acting

towards the rear or to a braking reaction, the force FR acts

as a moment about momentary center

P, causing the tire to

steer in the toe-in direction, thereby securing directional

stability of the vehicle.

While the vehicle is cornering, side force Fc acts on the

outer wheel from the inside and side force Fc’ acts on the

inner wheel from the outside. These forces work

moments about momentary centers

P and P’, respective,,

to cause the outer wheel to be steered toward toe-in and

the inner wheel toward toe-out: As a result, both wheels

are steered in the same direction as the cornering direction

of the vehicle. This results in under-steering to improve

cornering performance and stability.

4.The change in toe angle and camber to ground is kept small

for bumps or rebounds as shown at the left and this

contributes to steering stability while cornering.

Page 206 of 391

-

REAR SUSPENSION -Double Wishbone Suspension17-13

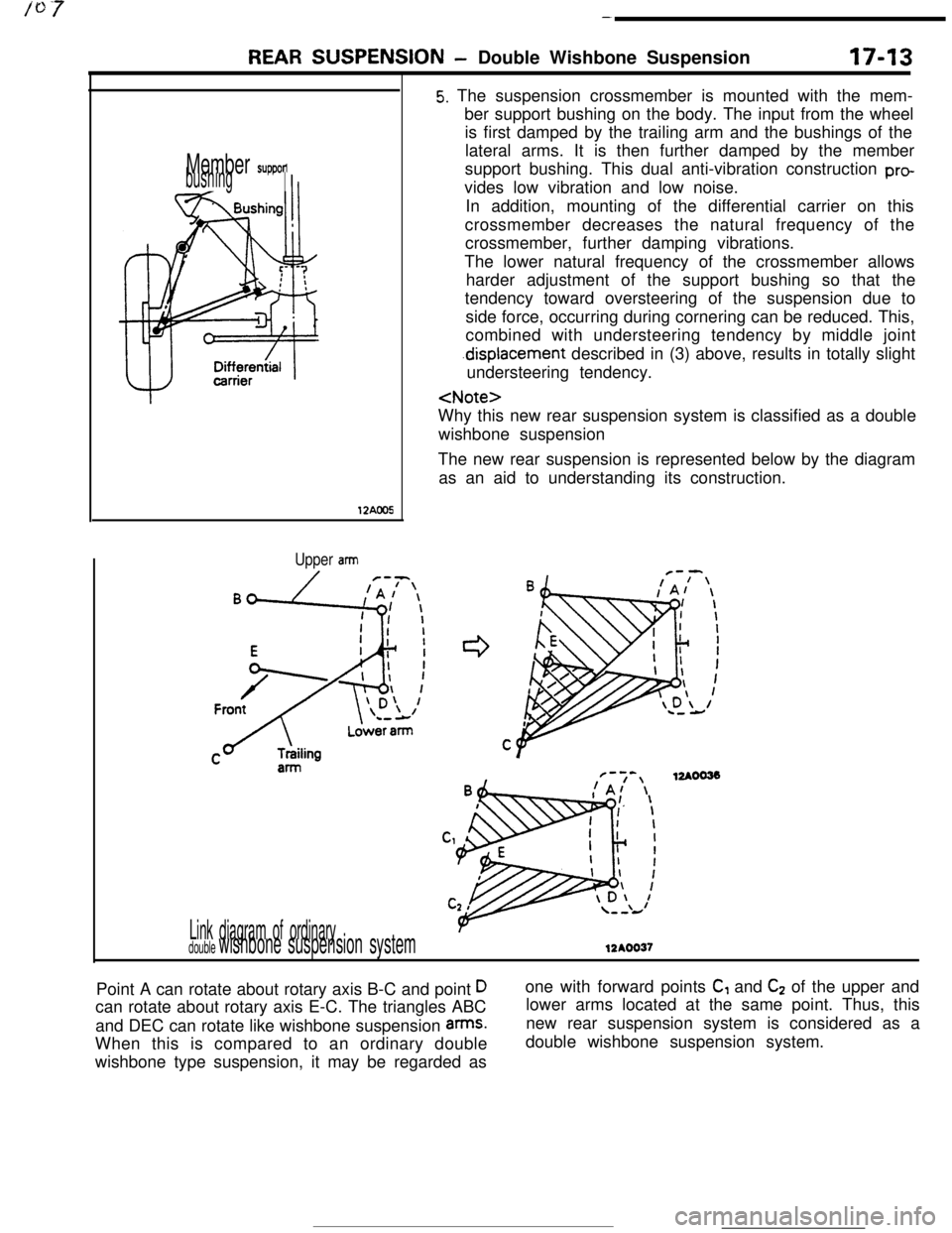

Member supponbushingI

12AOO5

Upper arm

Link diagram of ordinarydouble wishbone suspension system

5. The suspension crossmember is mounted with the mem-

ber support bushing on the body. The input from the wheel

is first damped by the trailing arm and the bushings of the

lateral arms. It is then further damped by the member

support bushing. This dual anti-vibration construction

provides low vibration and low noise.

In addition, mounting of the differential carrier on this

crossmember decreases the natural frequency of the

crossmember, further damping vibrations.

The lower natural frequency of the crossmember allows

harder adjustment of the support bushing so that the

tendency toward oversteering of the suspension due to

side force, occurring during cornering can be reduced. This,

combined with understeering tendency by middle joint

.displacement described in (3) above, results in totally slight

understeering tendency.

wishbone suspension

The new rear suspension is represented below by the diagram

as an aid to understanding its construction.

F-7-,12AOO33!A/ \

12AOO37Point A can rotate about rotary axis B-C and point

Dcan rotate about rotary axis E-C. The triangles ABC

and DEC can rotate like wishbone suspension

arms.When this is compared to an ordinary double

wishbone type suspension, it may be regarded asone with forward points

C, and C2 of the upper and

lower arms located at the same point. Thus, this

new rear suspension system is considered as a

double wishbone suspension system.

Page 212 of 391

POWER STEERING- General Information19-3

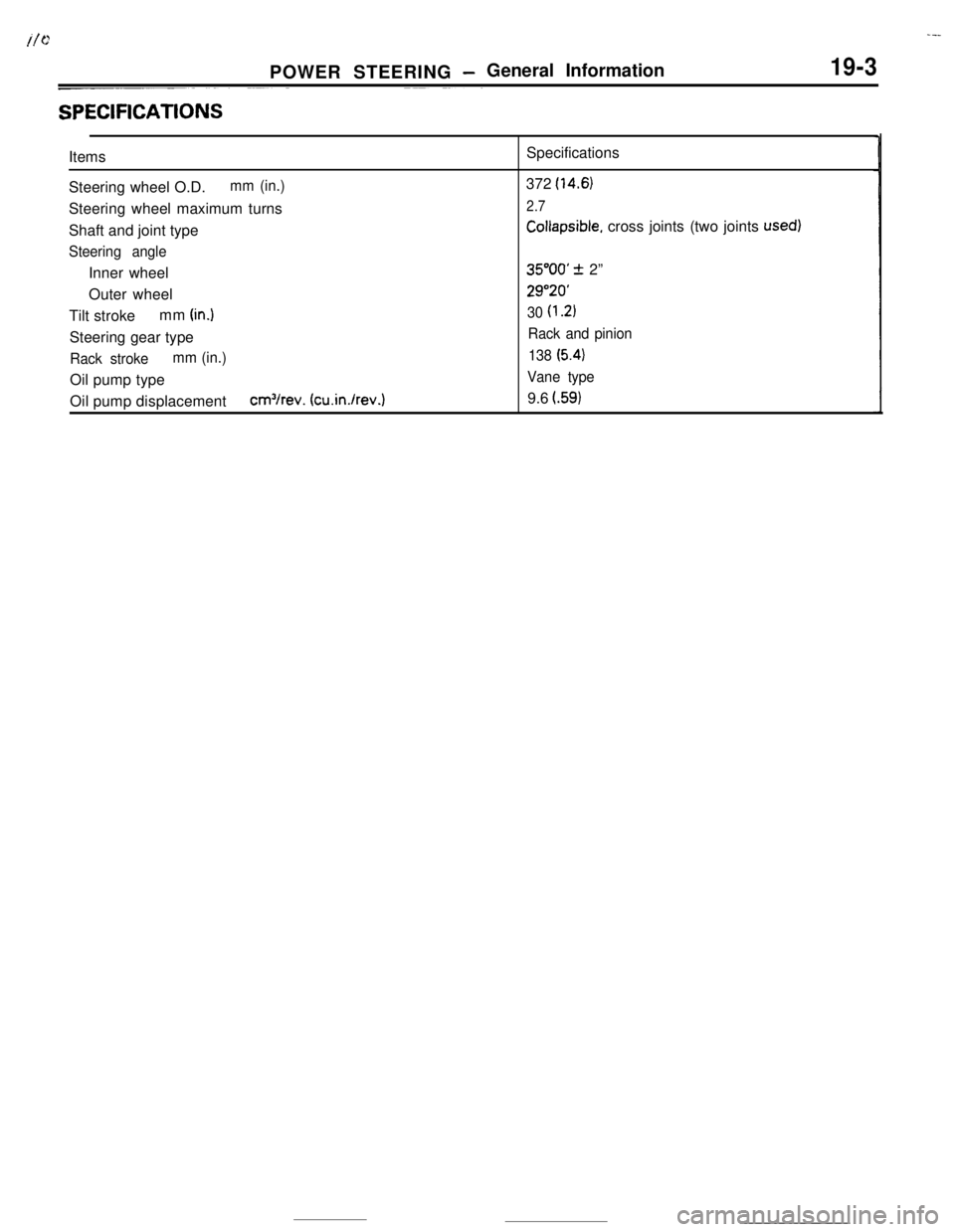

SPEClFlCATlONSItems

Steering wheel O.D.

mm (in.)Steering wheel maximum turns

Shaft and joint type

Steering angleInner wheel

Outer wheel

Tilt strokemm

(in.1Steering gear type

Rack strokemm (in.)Oil pump type

Oil pump displacement

cm3/rev. (cu.in./rev.)Specifications

372

(14.6)

2.7

Collapsible, cross joints (two joints used)

35”OO’ + 2”

29”20’

30

(1.2)

Rack and pinion

138

(5.41

Vane type9.6

l.59)

Page 215 of 391

19-6POWER STEERING- Pinion and Valve Assembly Construction

PINION AND VALVE ASSEMBLY

CONSTRUCTION

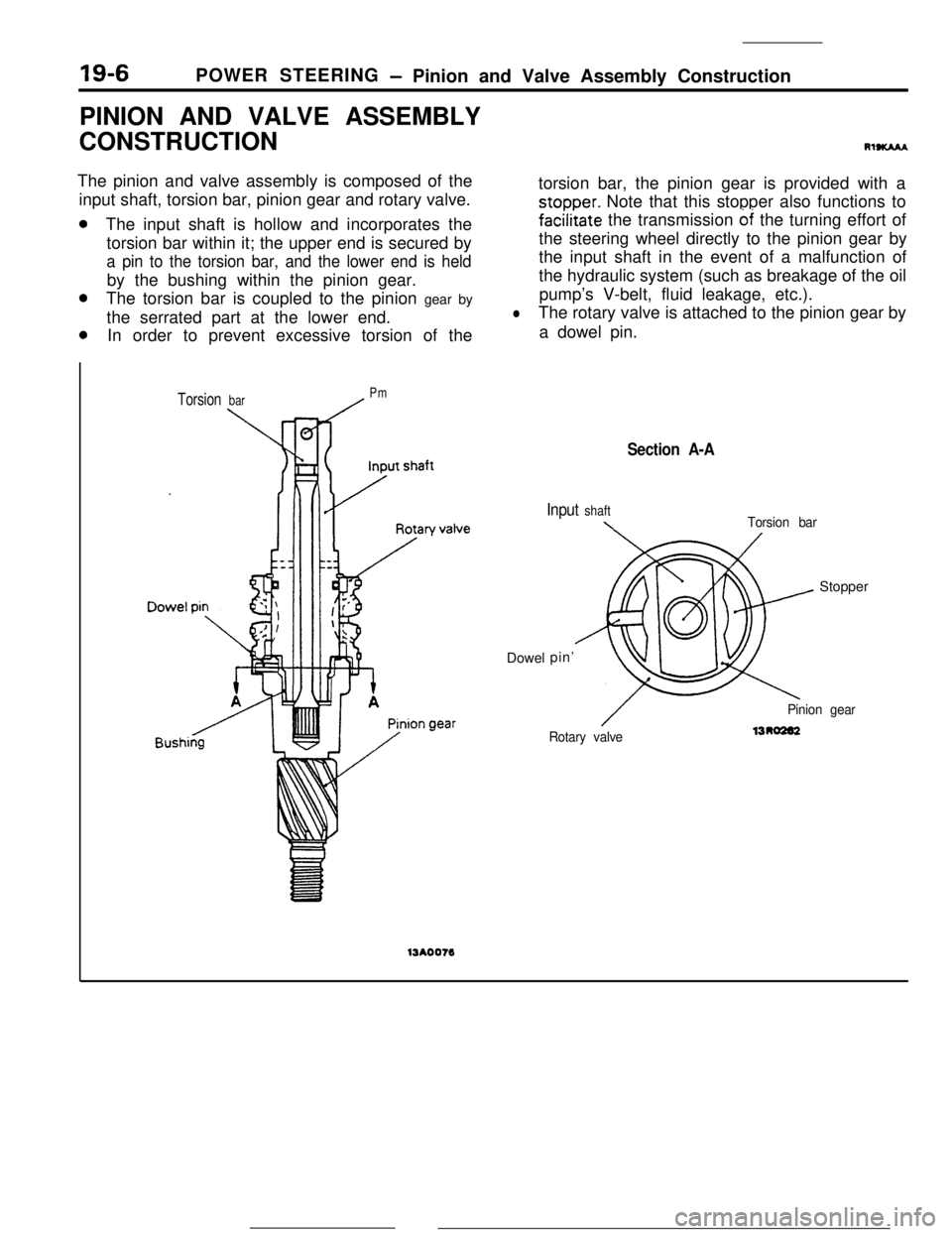

RISKAMThe pinion and valve assembly is composed of the

input shaft, torsion bar, pinion gear and rotary valve.torsion bar, the pinion gear is provided with a

stopper. Note that this stopper also functions to

The input shaft is hollow and incorporates the

fa&tate the transmission 6i the turning effort of

torsion bar within it; the upper end is secured bythe steering wheel directly to the pinion gear by

a pin to the torsion bar, and the lower end is heldthe input shaft in the event of a malfunction of

by the bushing within the pinion gear.the hydraulic system (such as breakage of the oil

The torsion bar is coupled to the pinion gear bypump’s V-belt, fluid leakage, etc.).

the serrated part at the lower end.

lThe rotary valve is attached to the pinion gear by

In order to prevent excessive torsion of thea dowel pin.

Torsion barPm13AOO76Dowel

Section A-A

Input shaft\Torsion barpin’Stopper

/Rotary valvePinion gear1310202

Page 216 of 391

:POWER STEERING

- Pinion and Valve Assembly Construction19-7 ’fOPERATION OF THE PINION AND VALVE

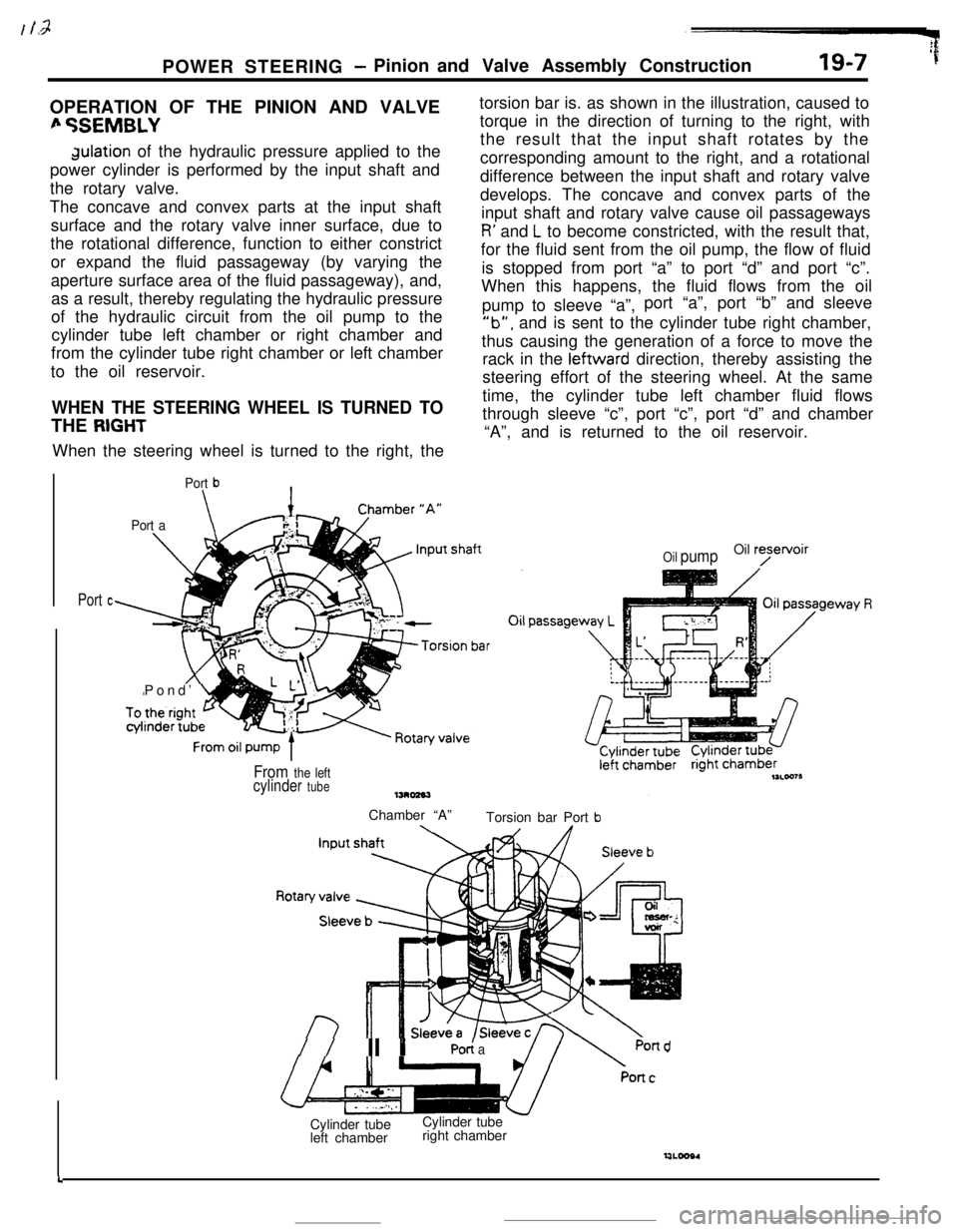

fi %EMBLYdulation of the hydraulic pressure applied to the

power cylinder is performed by the input shaft and

the rotary valve.

The concave and convex parts at the input shaft

surface and the rotary valve inner surface, due to

the rotational difference, function to either constrict

or expand the fluid passageway (by varying the

aperture surface area of the fluid passageway), and,

as a result, thereby regulating the hydraulic pressure

of the hydraulic circuit from the oil pump to the

cylinder tube left chamber or right chamber and

from the cylinder tube right chamber or left chamber

to the oil reservoir.

WHEN THE STEERING WHEEL IS TURNED TOTHE

RIGHTWhen the steering wheel is turned to the right, the

Port b\

Port a\Pond’

Ltorsion bar is. as shown in the illustration, caused to

torque in the direction of turning to the right, with

the result that the input shaft rotates by the

corresponding amount to the right, and a rotational

difference between the input shaft and rotary valve

develops. The concave and convex parts of the

input shaft and rotary valve cause oil passageways

R’ and L to become constricted, with the result that,

for the fluid sent from the oil pump, the flow of fluid

is stopped from port “a” to port “d” and port “c”.

When this happens, the fluid flows from the oil

pump to sleeve “a”,port “a”, port “b” and sleeve

‘lb”, and is sent to the cylinder tube right chamber,

thus causing the generation of a force to move the

rack in the leftward direction, thereby assisting the

steering effort of the steering wheel. At the same

time, the cylinder tube left chamber fluid flows

through sleeve “c”, port “c”, port “d” and chamber

“A”, and is returned to the oil reservoir.

Port c

Oil pumpOil ryetvoir

From the leftcylinder tubeChamber “A”

Torsion bar Port

b

//II YPO< aPond

4Cylinder tube

left chamberCylinder tube

right chamber