belt MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 348 of 391

BODY - Seat Belts

._-- -

23-31

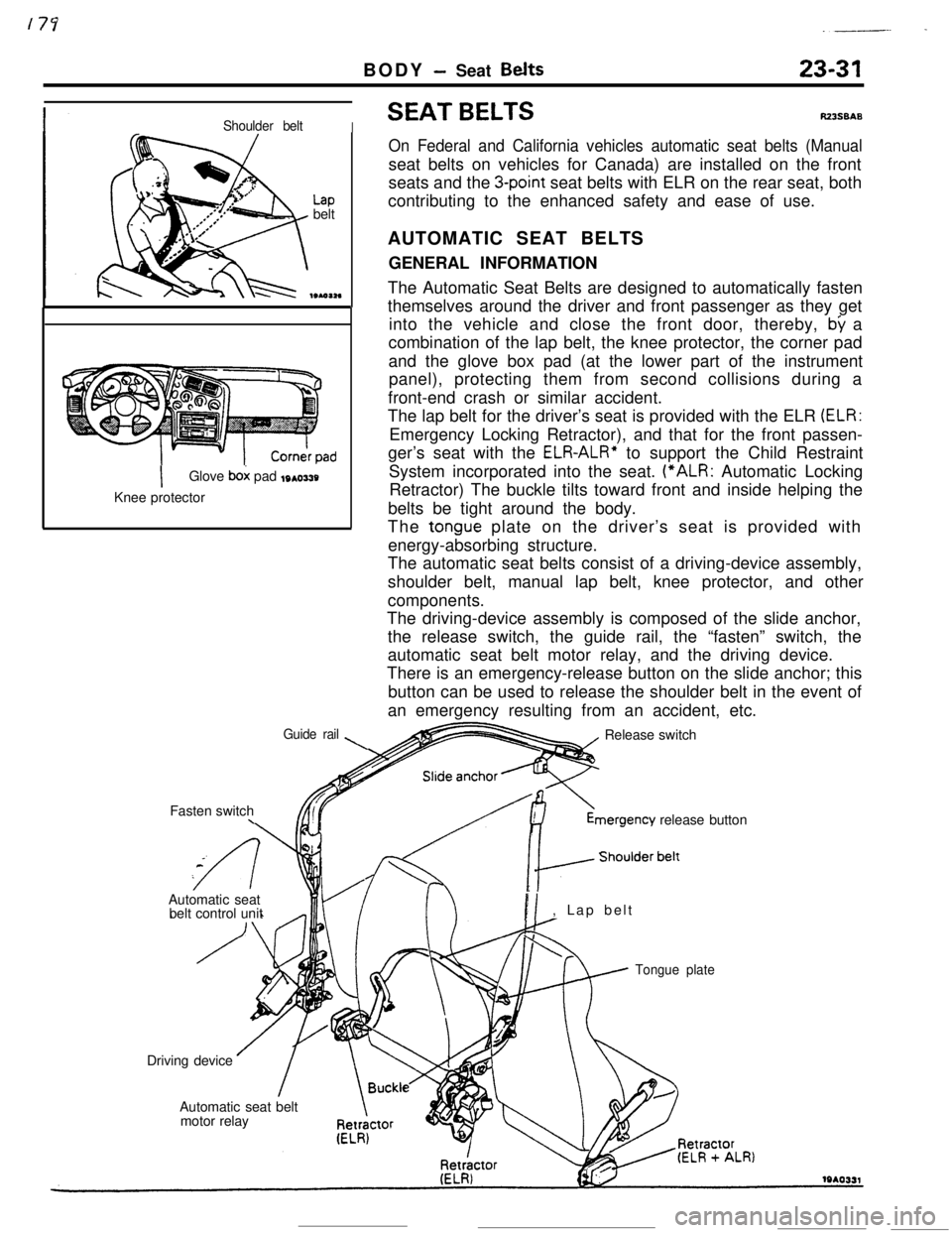

Shoulder beltI

Lapbelt

IGlove box pad toasty

Knee protector

Guide rail\Fasten switch

\

SEAT BELTSRZ3SBAS

On Federal and California vehicles automatic seat belts (Manualseat belts on vehicles for Canada) are installed on the front

seats and the

3-point seat belts with ELR on the rear seat, both

contributing to the enhanced safety and ease of use.

AUTOMATIC SEAT BELTS

GENERAL INFORMATION

The Automatic Seat Belts are designed to automatically fasten

themselves around the driver and front passenger as they get

into the vehicle and close the front door, thereby,

by a

combination of the lap belt, the knee protector, the corner pad

and the glove box pad (at the lower part of the instrument

panel), protecting them from second collisions during a

front-end crash or similar accident.

The lap belt for the driver’s seat is provided with the ELR

(ELR:Emergency Locking Retractor), and that for the front passen-

ger’s seat with the

ELR-ALR” to support the Child Restraint

System incorporated into the seat. (“ALR: Automatic Locking

Retractor) The buckle tilts toward front and inside helping the

belts be tight around the body.

The

tongue plate on the driver’s seat is provided with

energy-absorbing structure.

The automatic seat belts consist of a driving-device assembly,

shoulder belt, manual lap belt, knee protector, and other

components.

The driving-device assembly is composed of the slide anchor,

the release switch, the guide rail, the “fasten” switch, the

automatic seat belt motor relay, and the driving device.

There is an emergency-release button on the slide anchor; this

button can be used to release the shoulder belt in the event of

an emergency resulting from an accident, etc.

Release switchmergency

release button

Automatic seat

belt control unit

PI, Lap belt

Tongue plateDriving device

Automatic seat belt

motor relay

Page 349 of 391

23-32BODY - Seat Belts

OPERATION OF AUTOMATIC SEAT BELTS

The operation of the Automatic Seat Belts is as follows.

(1) The belts fasten itself around the occupant when the front

door is closed with the ignition switch in the “ON” position.

(2) The belts release itself from the occupant when the front

door is opened with the ignition switch in the

*“ON” or

“LOCK” or “ACC” position.

(3) The belts cease to fasten itself around the occupant if the

ignition switch is turned to “LOCK” or “ACC” or when the

front door is opened during the belt motion.

(4) The belts for the driver’s and front passenger’s seats

operate independently of each other.

Lever springStopper, Rod A

Sub paw1

Gear B

Rod B19po37:

Sub’pawlIWO374

IStopperGear AI

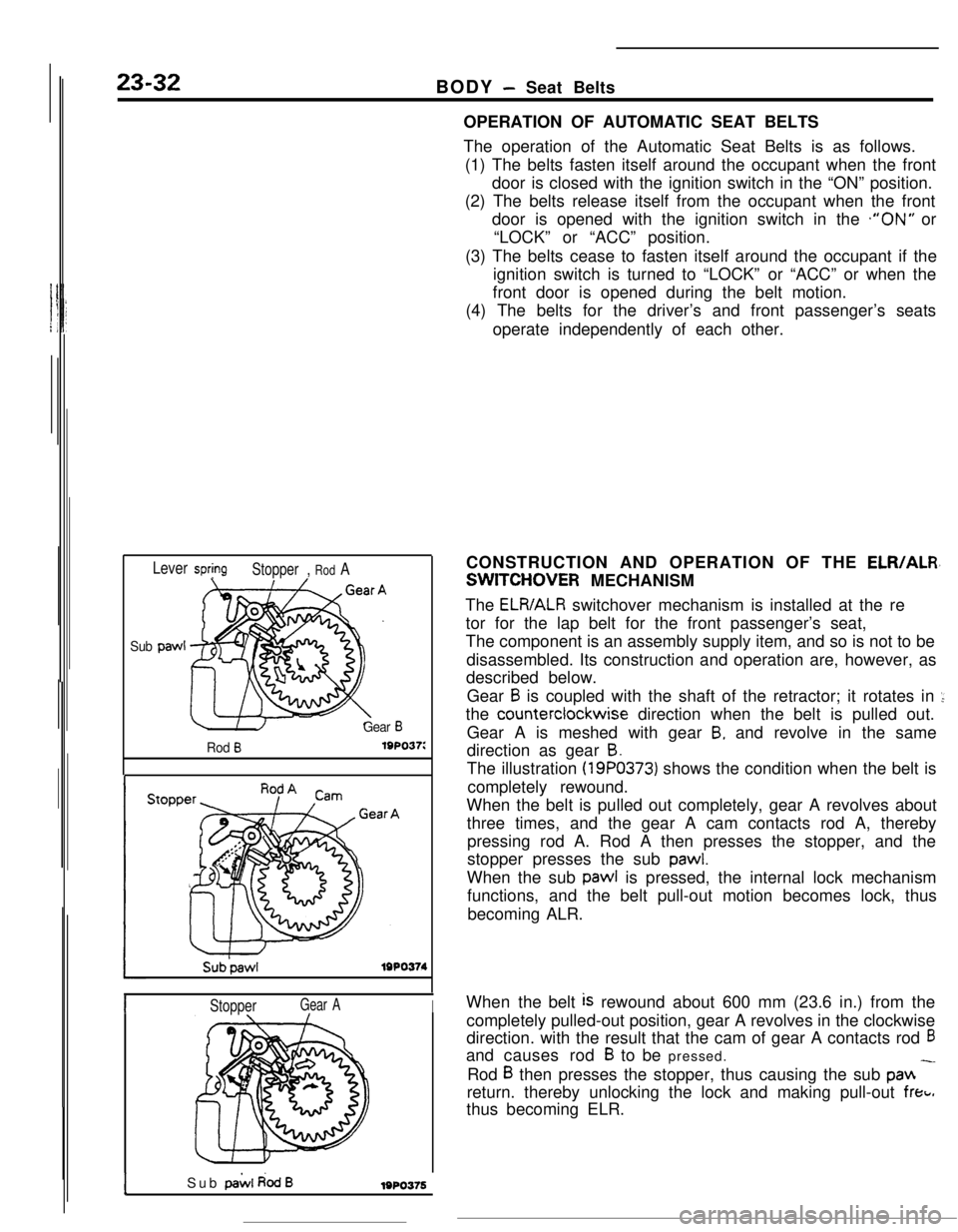

ISub pai.4 dodB1980376CONSTRUCTION AND OPERATION OF THE

ELR/ALR,

SWITCHOVER MECHANISM

The

ELR/ALR switchover mechanism is installed at the re

tor for the lap belt for the front passenger’s seat,

The component is an assembly supply item, and so is not to be

disassembled. Its construction and operation are, however, as

described below.

Gear

B is coupled with the shaft of the retractor; it rotates in ::the counterclockwise direction when the belt is pulled out.

Gear A is meshed with gear

B, and revolve in the same

direction as gear

B.The illustration

(19PO373) shows the condition when the belt is

completely rewound.

When the belt is pulled out completely, gear A revolves about

three times, and the gear A cam contacts rod A, thereby

pressing rod A. Rod A then presses the stopper, and the

stopper presses the sub

pawl.When the sub pawl is pressed, the internal lock mechanism

functions, and the belt pull-out motion becomes lock, thus

becoming ALR.

When the belt

is rewound about 600 mm (23.6 in.) from the

completely pulled-out position, gear A revolves in the clockwise

direction. with the result that the cam of gear A contacts rod

6and causes rod

B to be pressed.

Rod

B then presses the stopper, thus causing the sub pan -return. thereby unlocking the lock and making pull-out

freti.thus becoming ELR.

Page 350 of 391

BODY - Seat Belts23-33

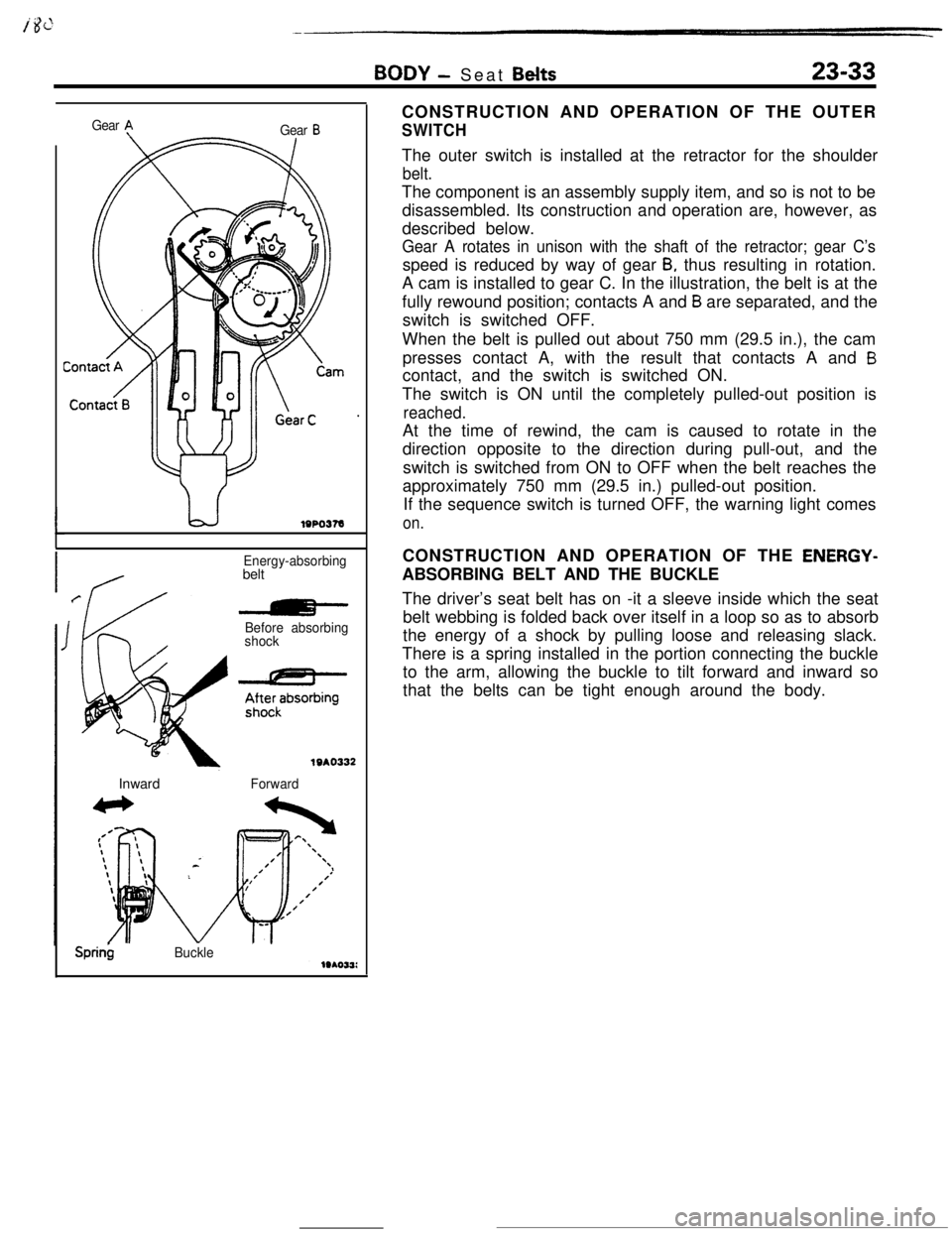

Gear eGear B

Energy-absorbingbelt

Before absorbing

shock

19AO332Inward

Forward

Sprin$BuckleCONSTRUCTION AND OPERATION OF THE OUTER

SWITCHThe outer switch is installed at the retractor for the shoulder

belt.The component is an assembly supply item, and so is not to be

disassembled. Its construction and operation are, however, as

described below.

Gear A rotates in unison with the shaft of the retractor; gear C’sspeed is reduced by way of gear

B, thus resulting in rotation.

A cam is installed to gear C. In the illustration, the belt is at the

fully rewound position; contacts A and

B are separated, and the

switch is switched OFF.

When the belt is pulled out about 750 mm (29.5 in.), the cam

presses contact A, with the result that contacts A and

Bcontact, and the switch is switched ON.

The switch is ON until the completely pulled-out position is

reached.At the time of rewind, the cam is caused to rotate in the

direction opposite to the direction during pull-out, and the

switch is switched from ON to OFF when the belt reaches the

approximately 750 mm (29.5 in.) pulled-out position.

If the sequence switch is turned OFF, the warning light comes

on.CONSTRUCTION AND OPERATION OF THE

ENERGY-ABSORBING BELT AND THE BUCKLE

The driver’s seat belt has on -it a sleeve inside which the seat

belt webbing is folded back over itself in a loop so as to absorb

the energy of a shock by pulling loose and releasing slack.

There is a spring installed in the portion connecting the buckle

to the arm, allowing the buckle to tilt forward and inward so

that the belts can be tight enough around the body.

Page 351 of 391

23-34BODY - Seat Belts

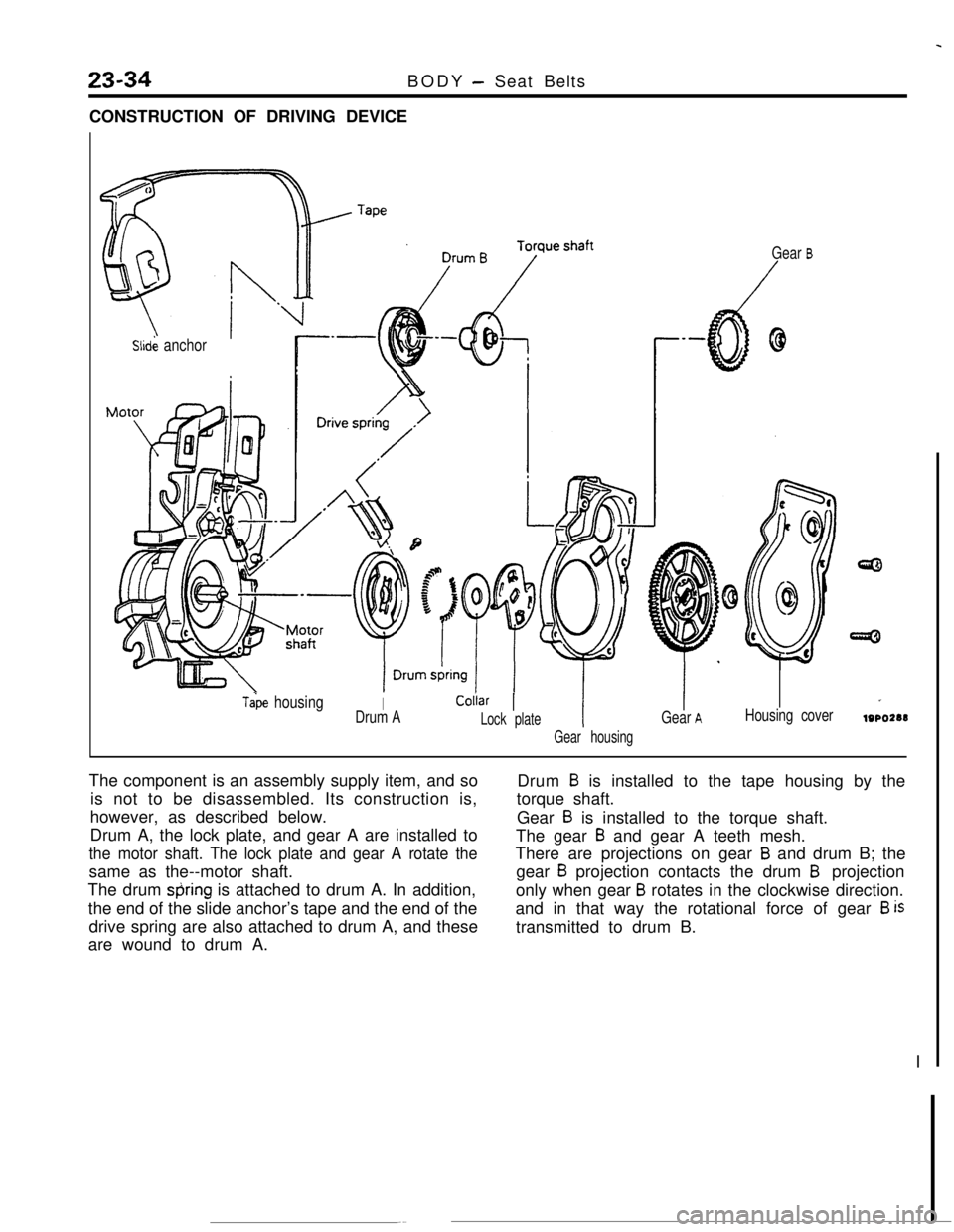

CONSTRUCTION OF DRIVING DEVICE

Slid& anchor

Tabe housingIColiar 1

Drum ALock plate

Gear housing

Gear B

Gear AHousing cover

I

lOPO288The component is an assembly supply item, and so

is not to be disassembled. Its construction is,

however, as described below.

Drum A, the lock plate, and gear A are installed to

the motor shaft. The lock plate and gear A rotate thesame as the--motor shaft.

The drum

&ring is attached to drum A. In addition,

the end of the slide anchor’s tape and the end of the

drive spring are also attached to drum A, and these

are wound to drum A.Drum

B is installed to the tape housing by the

torque shaft.

Gear

B is installed to the torque shaft.

The gear

B and gear A teeth mesh.

There are projections on gear

B and drum B; the

gear

B projection contacts the drum B projection

only when gear

B rotates in the clockwise direction.

and in that way the rotational force of gear

B istransmitted to drum B.

I

Page 352 of 391

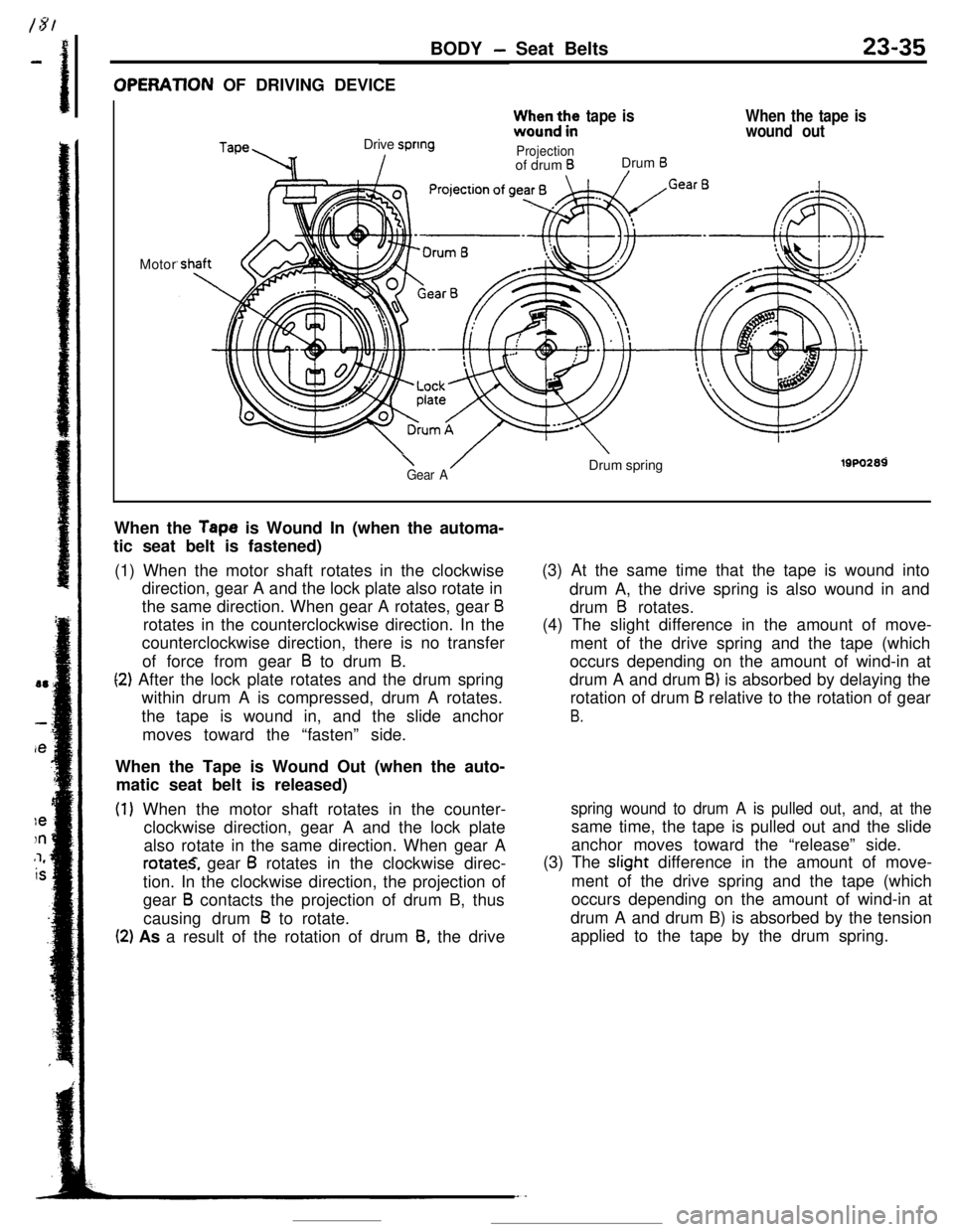

BODY - Seat Belts23-35OPERATlON OF DRIVING DEVICE

TapeDrive spring

Izz;b3;:,e

tape is

Projectionof drum BDrum B/

When the tape is

wound outMotor

\ /Gear ADrum springi9w2a9When the

Tape is Wound In (when the automa-

tic seat belt is fastened)

(1) When the motor shaft rotates in the clockwise

direction, gear A and the lock plate also rotate in

the same direction. When gear A rotates, gear

Brotates in the counterclockwise direction. In the

counterclockwise direction, there is no transfer

of force from gear

B to drum B.

(2) After the lock plate rotates and the drum spring

within drum A is compressed, drum A rotates.

the tape is wound in, and the slide anchor

moves toward the “fasten” side.

When the Tape is Wound Out (when the auto-

matic seat belt is released)

(1) When the motor shaft rotates in the counter-

clockwise direction, gear A and the lock plate

also rotate in the same direction. When gear A

rotate.S, gear B rotates in the clockwise direc-

tion. In the clockwise direction, the projection of

gear

B contacts the projection of drum B, thus

causing drum

B to rotate.

(2) As a result of the rotation of drum 8, the drive(3) At the same time that the tape is wound into

drum A, the drive spring is also wound in and

drum

B rotates.

(4) The slight difference in the amount of move-

ment of the drive spring and the tape (which

occurs depending on the amount of wind-in at

drum A and drum

B) is absorbed by delaying the

rotation of drum

B relative to the rotation of gear

B.

spring wound to drum A is pulled out, and, at thesame time, the tape is pulled out and the slide

anchor moves toward the “release” side.

(3) The slight difference in the amount of move-

ment of the drive spring and the tape (which

occurs depending on the amount of wind-in at

drum A and drum B) is absorbed by the tension

applied to the tape by the drum spring.

Page 353 of 391

23-36BODY -Seat Belts

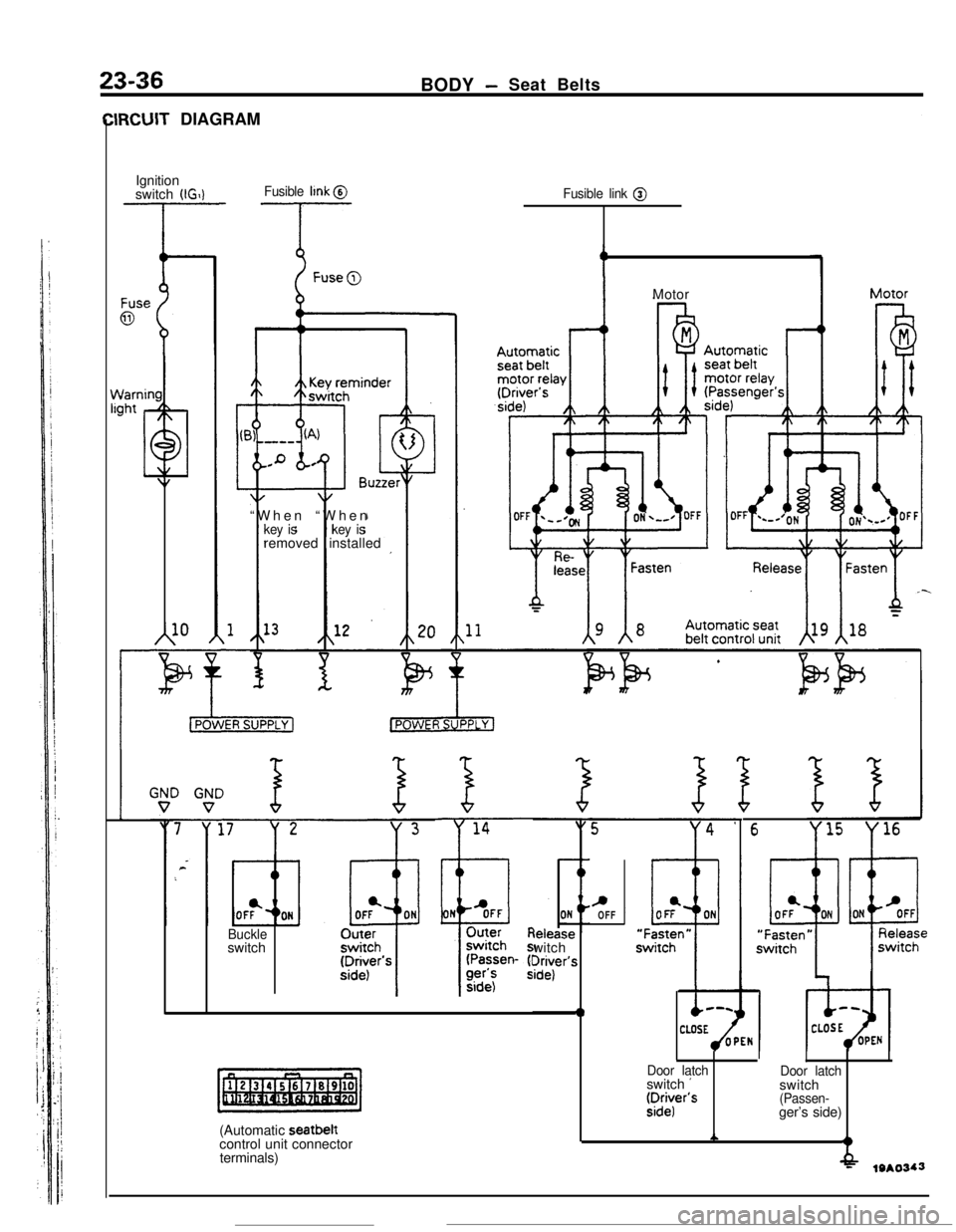

IRCUIT DIAGRAM

Ignition

switch

(IGIlFusible llnk @

-T- --T-

A10“When “When

key iskey isremoved installed

Fusible link @

Buckleswitch

(Automatic seatbelt

control unit connector

terminals)leiease

witch

?r$r’s

0Motor

c,OFF

6

Door latchswitch ’fDr:r’s

Door latchswitch

(Passen-ger’s side)

A?

-f&19*0343

Page 354 of 391

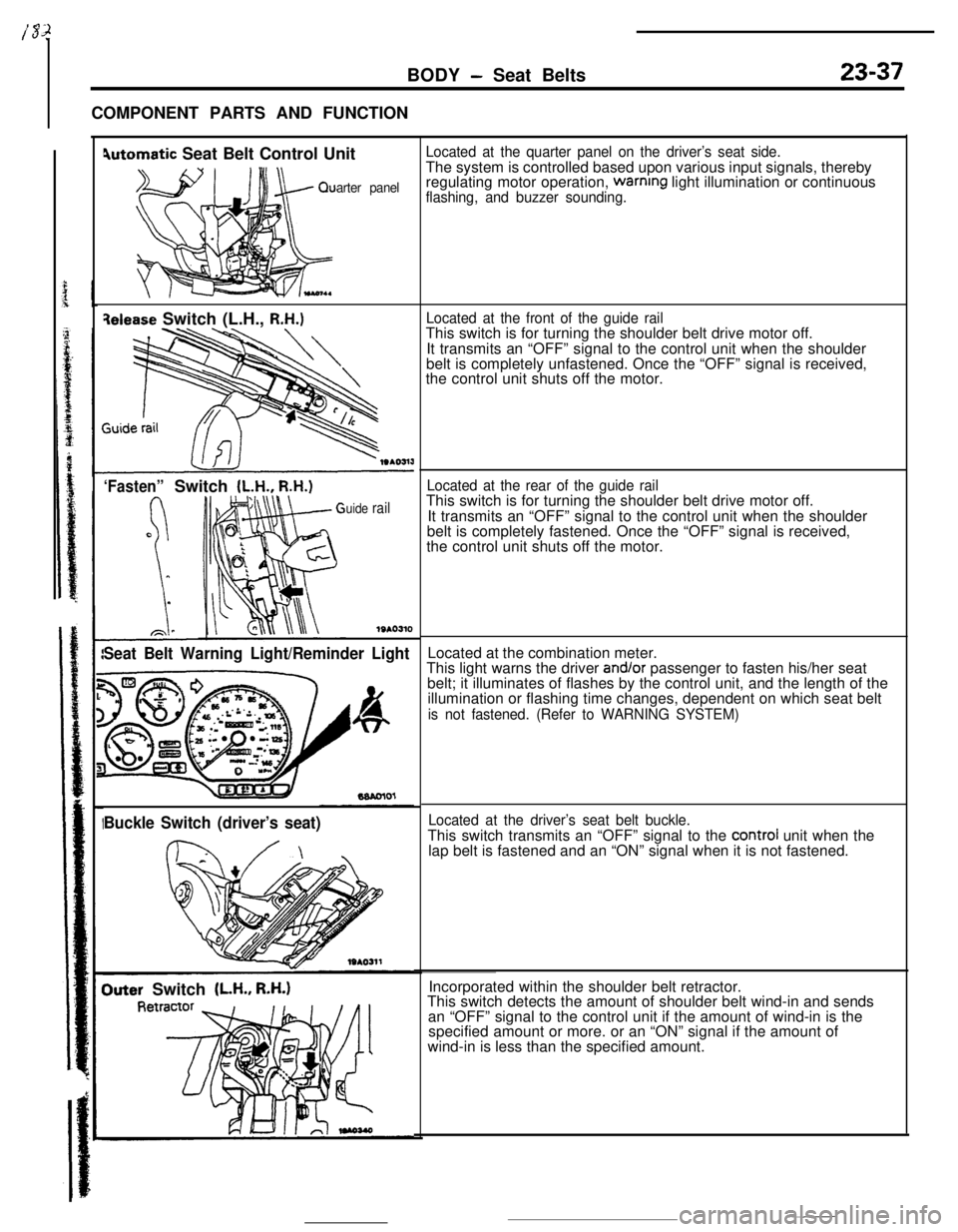

BODY - Seat Belts23-37COMPONENT PARTS AND FUNCTION

4utomatic Seat Belt Control Unit

arter panel

qelease Switch (L.H., R.H.)

‘Fasten”Switch (L.H., R.H.)

uide rail

1SAO310

Seat Belt Warning Light/Reminder Light

Buckle Switch (driver’s seat)

Outer Switch (LH., R.H.)

Located at the quarter panel on the driver’s seat side.The system is controlled based upon various input signals, thereby

regulating motor operation,

warnrng light illumination or continuousflashing, and buzzer sounding.

Located at the front of the guide railThis switch is for turning the shoulder belt drive motor off.

It transmits an “OFF” signal to the control unit when the shoulder

belt is completely unfastened. Once the “OFF” signal is received,

the control unit shuts off the motor.

Located at the rear of the guide railThis switch is for turning the shoulder belt drive motor off.

It transmits an “OFF” signal to the control unit when the shoulder

belt is completely fastened. Once the “OFF” signal is received,

the control unit shuts off the motor.

Located at the combination meter.

This light warns the driver

and/or passenger to fasten his/her seat

belt; it illuminates of flashes by the control unit, and the length of the

illumination or flashing time changes, dependent on which seat belt

is not fastened. (Refer to WARNING SYSTEM)

Located at the driver’s seat belt buckle.This switch transmits an “OFF” signal to the

control unit when the

lap belt is fastened and an “ON” signal when it is not fastened.

Incorporated within the shoulder belt retractor.

This switch detects the amount of shoulder belt wind-in and sends

an “OFF” signal to the control unit if the amount of wind-in is the

specified amount or more. or an “ON” signal if the amount of

wind-in is less than the specified amount.

Page 355 of 391

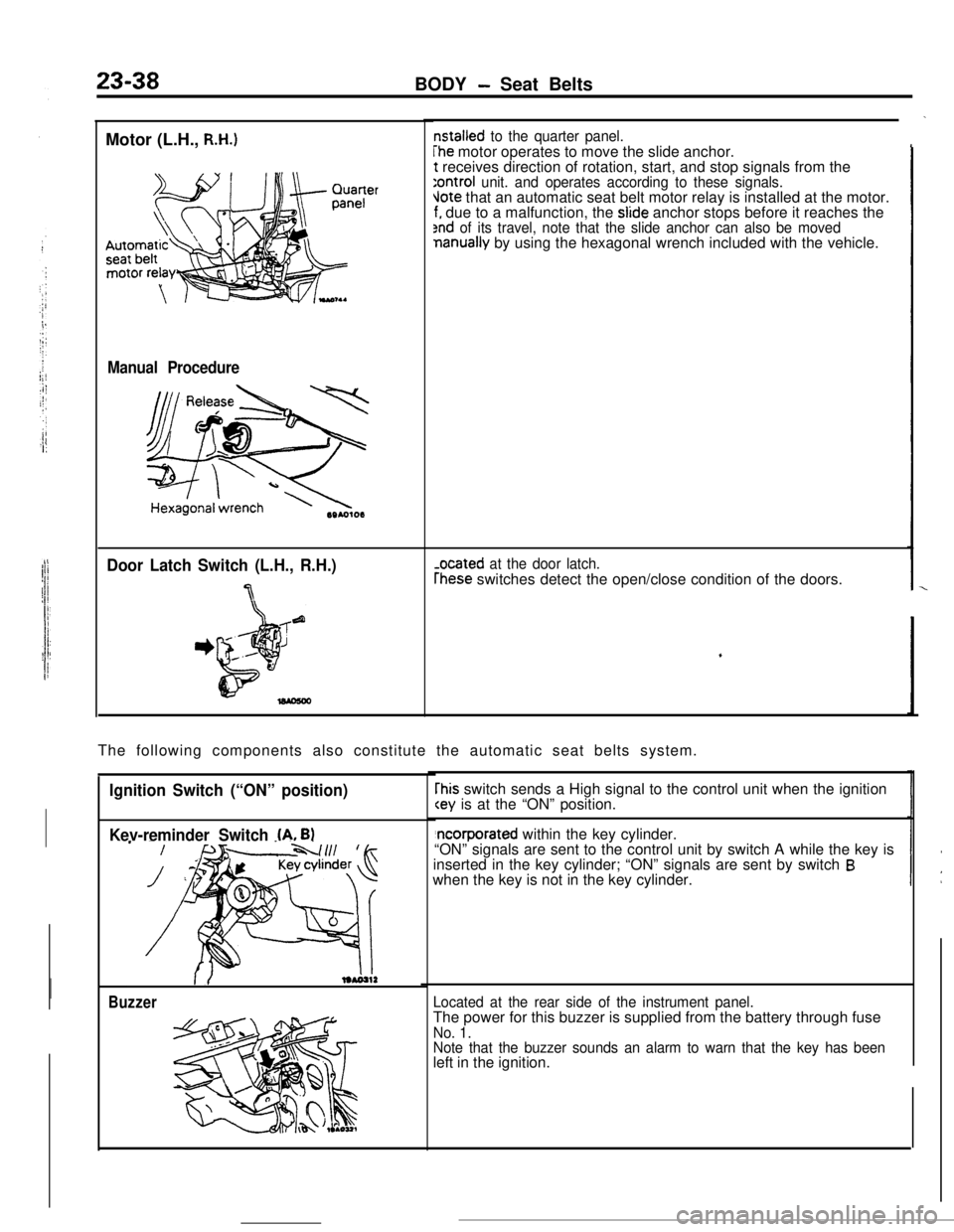

23-38BODY - Seat Belts

Motor (L.H.,

R.H.)

Manual Procedure

Door Latch Switch (L.H., R.H.)

7

nstalled to the quarter panel.

The motor operates to move the slide anchor.t receives direction of rotation, start, and stop signals from the

:ontroi unit. and operates according to these signals.Jote that an automatic seat belt motor relay is installed at the motor.f. due to a malfunction, the slide anchor stops before it reaches the2nd of its travel, note that the slide anchor can also be movednanually by using the hexagonal wrench included with the vehicle.

-ocated at the door latch.

rhese switches detect the open/close condition of the doors.

The following components also constitute the automatic seat belts system.

Ignition Switch (“ON” position)

Kev-reminder Switch

(A. B)

Buzzer

rhis switch sends a High signal to the control unit when the ignition

“ON” signals are sent to the control unit by switch A while the key is

inserted in the key cylinder; “ON” signals are sent by switch

Bwhen the key is not in the key cylinder.

Located at the rear side of the instrument panel.The power for this buzzer is supplied from the battery through fuse

No. 1.

Note that the buzzer sounds an alarm to warn that the key has beenleft in the ignition.

Page 356 of 391

BODY - Seat Belts23-39

OPERATlON

Belt Fastening Motion

(1) If the belt is not in the fastening position (the

L.H. or R.H. door latch switch at Door Closed

position; the L.H. or R.H. “fasten” switch at

“ON” position) when the door is closed with the

ignition switch in the “ON” position, the belt

automatically moves to the fastening position.

For the period between the initiation and com-

pletion of the belt’s motion in the fastening

direction, the seat belt warning light either stays

lit or blinks.

Belt Releasing Motion

(1) When the belt is not in the release position, the

L.H. or R.H. release switch is in the “ON”

position, and the left or right door is opened, the

belt will automatically move to the release

position if the ignition switch is at either the

“ON”,“LOCK” or “ACC” position.

For the belt at the driver’s seat side moveover,

the belt will automatically move to the release

position if the

key is taken out while the belt is

fastened.

The buzzer sounds for approximately 0.7 secondsince the start of thebelt’s motion.When the belt is completely fastened, the

“fasten” switch is switched OFF and the motor

stops.(2) With a lapse of approximately 60 seconds after

the belt has stopped its fastening motion due to

foreign object wedged in the mechanism, the

protective timer of the control unit is activated

causing the motor output to the shut off.

When the belt completes its releasing motion,

the L.H. or R.H. release switch is turned OFF,

and the motor stops.

(2)If the belt is still in the process of releasing with

a lapse of approximately 60 seconds after the

start of motion, the protective timer in control

unit is activated causing the motor output to be

shut off.

At the same time, the buzzer sounds for

approximately 0.7 second.

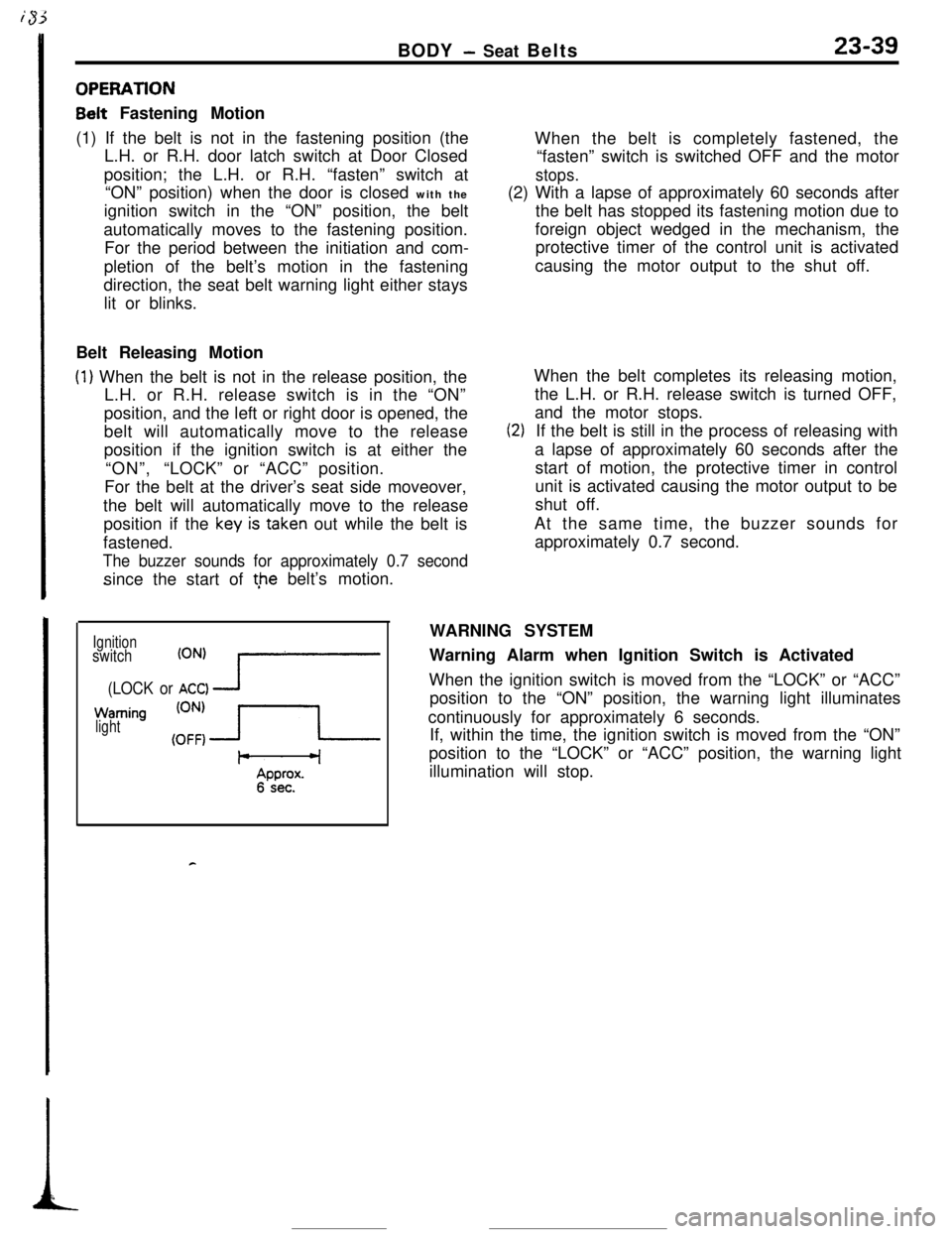

Ignitionswitch

(ONI I------(LOCK or ACC) -J

Warning

light

I-6 sec. ’

cWARNING SYSTEM

Warning Alarm when Ignition Switch is Activated

When the ignition switch is moved from the “LOCK” or “ACC”

position to the “ON” position, the warning light illuminates

continuously for approximately 6 seconds.

If, within the time, the ignition switch is moved from the “ON”

position to the “LOCK” or “ACC” position, the warning light

illumination will stop.

Page 357 of 391

23-40BODY - Seat Belts

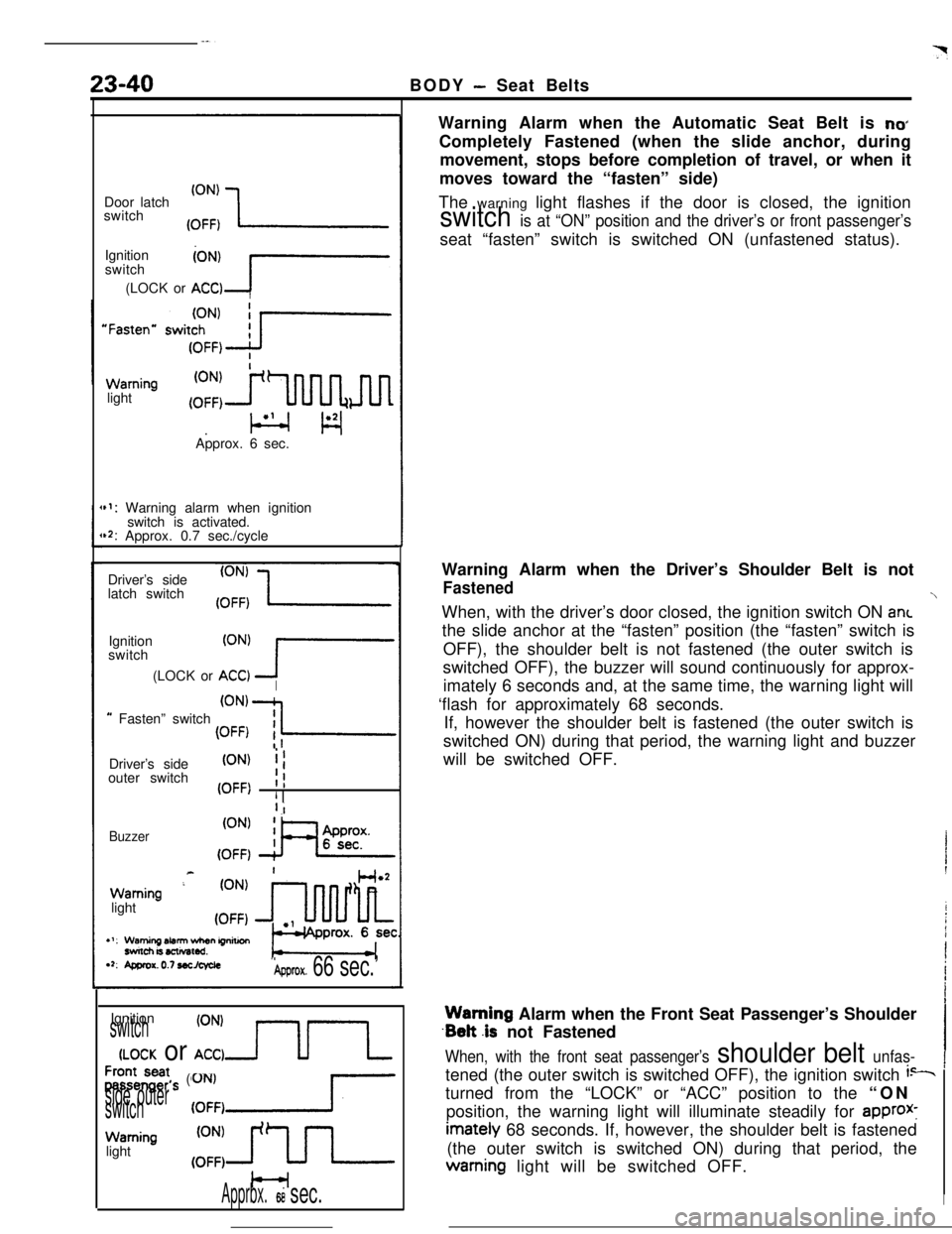

Door latch

switch

Ignition

switch

(LOCK or

ZjTI

Warninglight

.

F-w4Approx. 6 sec.

~1: Warning alarm when ignition

switch is activated.

r2: Approx. 0.7 sec./cycle

Driver’s side

latch switch

Ignition

switch

(LOCK or

Er:rI

ti Fasten” switch

Driver’s side

(ON) i;outer switch

(OFF)I!

’ III

Buzzer(ON’

(OFF)c

Warning ’light

kprox. 66 sec.’Ignition

switch

(LOCK or zm

zs;;;$s (ON)

side outer

switch(OFFIr

Warninglight

Apprbx.ti sec.Warning Alarm when the Automatic Seat Belt is

no*Completely Fastened (when the slide anchor, during

movement, stops before completion of travel, or when it

moves toward the “fasten” side)

The warning light flashes if the door is closed, the ignition

switch is at “ON” position and the driver’s or front passenger’sseat “fasten” switch is switched ON (unfastened status).

Warning Alarm when the Driver’s Shoulder Belt is not

FastenedWhen, with the driver’s door closed, the ignition switch ON ant

the slide anchor at the “fasten” position (the “fasten” switch is

OFF), the shoulder belt is not fastened (the outer switch is

switched OFF), the buzzer will sound continuously for approx-

imately 6 seconds and, at the same time, the warning light will

‘flash for approximately 68 seconds.

If, however the shoulder belt is fastened (the outer switch is

switched ON) during that period, the warning light and buzzer

will be switched OFF.Warning Alarm when the Front Seat Passenger’s Shoulder

.Belt .is not Fastened

When, with the front seat passenger’s shoulder belt unfas-tened (the outer switch is switched OFF), the ignition switch

i--turned from the “LOCK” or “ACC” position to the “ON

position, the warning light will illuminate steadily for

approx-imately 68 seconds. If, however, the shoulder belt is fastened

(the outer switch is switched ON) during that period, thewarning light will be switched OFF.

I