oil type MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 126 of 391

14-14

.._~- ---.FUEL SYSTEM

- Sensors

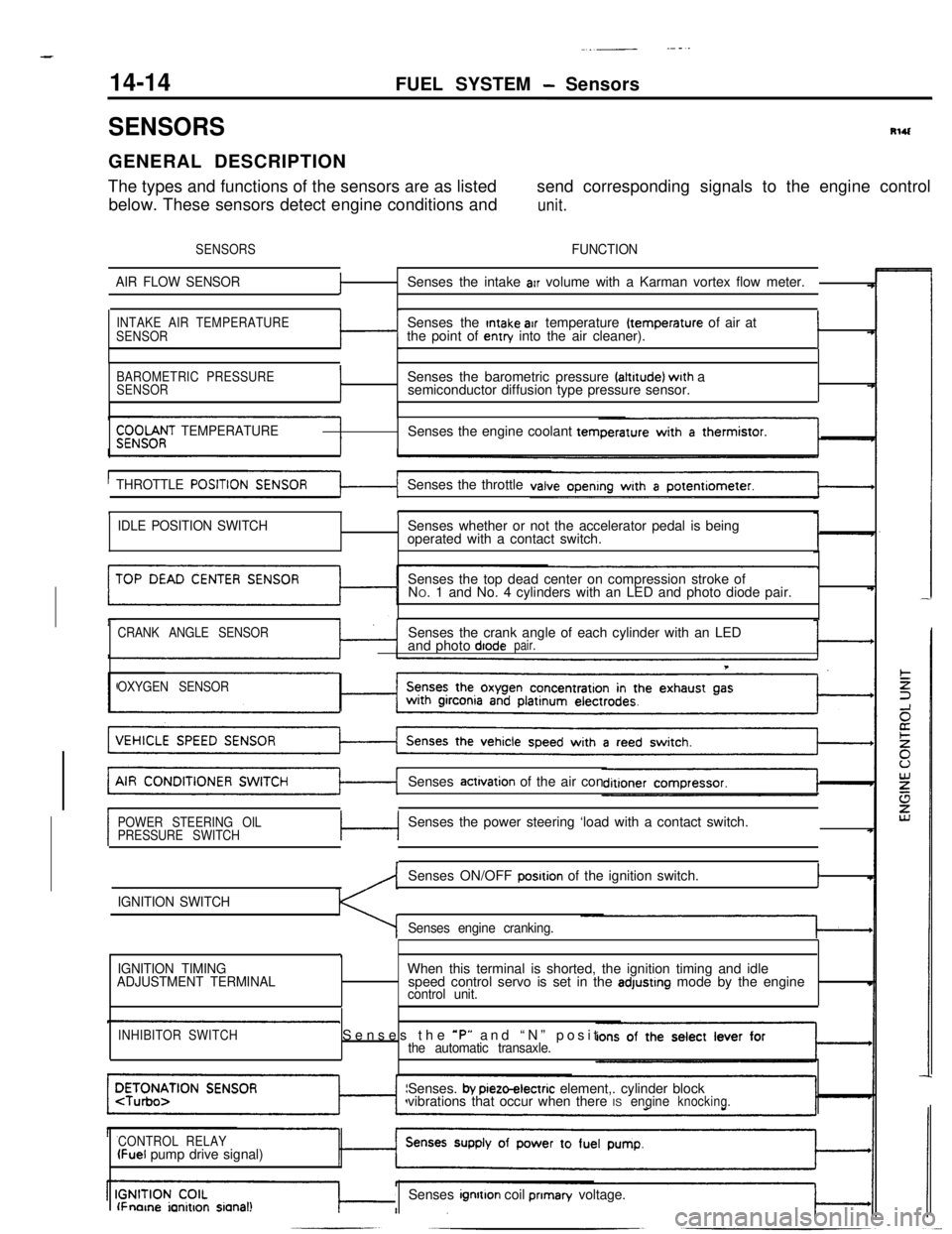

SENSORSRlUGENERAL DESCRIPTION

The types and functions of the sensors are as listedsend corresponding signals to the engine control

below. These sensors detect engine conditions and

unit.

SENSORSFUNCTION

AIR FLOW SENSOR

fSenses the intake arr volume with a Karman vortex flow meter.

INTAKE AIR TEMPERATURE

SENSORSenses the Intake air temperature (temperature of air at

the point of entry into the air cleaner).I

BAROMETRIC PRESSURE

SENSORISenses the barometric pressure faltrtude) wrth a

semiconductor diffusion type pressure sensor.

$;;OOf;T TEMPERATURESenses the engine coolant tern

THROTTLE

POSITISenses the throttle

tI

IDLE POSITION SWITCHSenses whether or not the accelerator pedal is being

operated with a contact switch.

Senses the top dead center on compression stroke of

NO. 1 and No. 4 cylinders with an LED and photo diode pair.

CRANK ANGLE SENSORSenses the crank angle of each cylinder with an LED

and photo diodepair.

T

OXYGEN SENSORSenses

actrvation of the air con

POWER STEERING OIL

PRESSURE SWITCHc-lSenses the power steering ‘load with a contact switch.

IGNITION SWITCHSenses ON/OFF

posrtion of the ignition switch.I

Senses engine cranking.

,

IGNITION TIMING

ADJUSTMENT TERMINALWhen this terminal is shorted, the ignition timing and idle

speed control servo is set in the adjustrng mode by the enginecontrol unit.

INHIBITOR SWITCHSenses the *P” and “N” positthe automatic transaxle.Senses.

by pieto-electric element,. cylinder block

vibrations that occur when there ISengineknocking.

CONTROL RELAY

(Fuel pump drive signal)

lFnorne ianitron sianal!Senses ignrtton coil prIman/ voltage.

Page 157 of 391

3-d__- .

FUEL SYSTEM

-Idle Speed Control14-45IDLE SPEED CONTROL SERVO

L

PtntleThrottle bodv

Idle speed control

servo

Extend

7 -IMagnet rotordoil

/Stepper motor

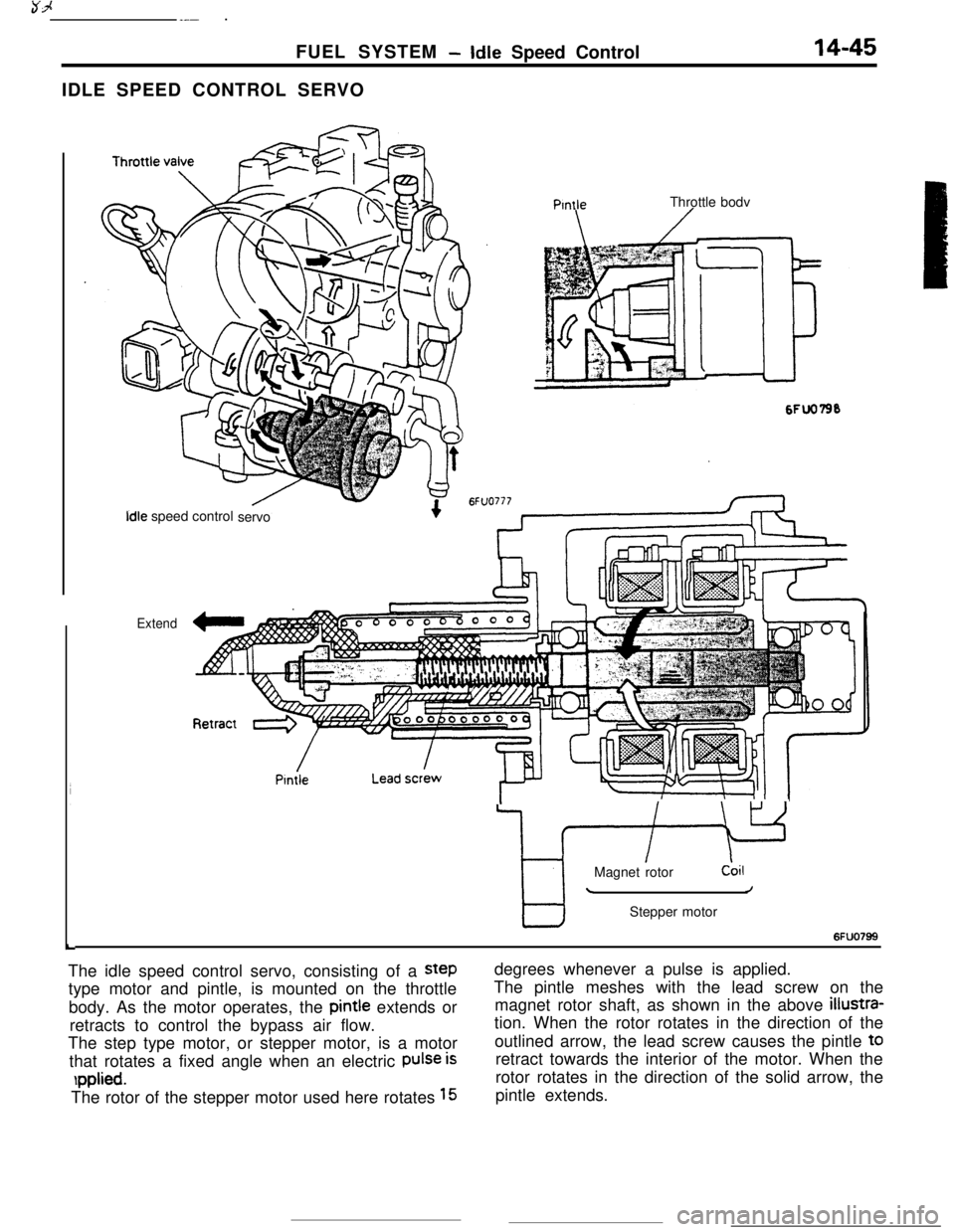

6FUO799The idle speed control servo, consisting of a

steptype motor and pintle, is mounted on the throttle

body. As the motor operates, the pintie extends or

retracts to control the bypass air flow.

The step type motor, or stepper motor, is a motor

that rotates a fixed angle when an electric

Pulse is

rpplied.The rotor of the stepper motor used here rotates

15degrees whenever a pulse is applied.

The pintle meshes with the lead screw on the

magnet rotor shaft, as shown in the above

illustra-tion. When the rotor rotates in the direction of the

outlined arrow, the lead screw causes the pintle t0

retract towards the interior of the motor. When the

rotor rotates in the direction of the solid arrow, the

pintle extends.

Page 186 of 391

14-74

_ ,.-..FUEL SYSTEM

- Auto-cruise Control System

When Canceled by the Stop Light Switch (broad

solid-line arrows)

The stop light switch is a four-pole type that

integrates the switch for the stop light (NO) with

that for the auto-cruise control (NC).

When the brake pedal is depressed, the contacts forthe auto-cruise control (NC) open, cutting off the

circuit to energize the electromagnetic clutch coil.

At the same time, the contacts for the stop light

(NO) close to allow a cancel signal to be input from

the

12-V power supply of the control unit to the

cancel circuit and to the microcomputer. As a result,the transistor which energizes the actuator electro-

magnetic clutch coil turns OFF and the electro-

magnetic clutch coil grounding circuit is cut off, thus

canceling the auto-cruise control mode.

When Canceled by the Clutch Switch (thin

solid-line arrows)

When the clutch pedal is depressed, the clutch

switch is turned ON and the battery voltage is

applied to the cancel circuit of the control unit. then,a cancel signal is input to the microcomputer.

causing the transistor that energizes the actuator

electromagnetic clutch coil to turn OFF. This results

in the electromagnetic clutch coil grounding circuit

bma$ndge cut off, which cancels the auto-cruise control

When Canceled by the Selector Lever (position“N”) (dotted-line arrows)

When the transaxle control selector lever is placed

in the “N” (neutral) position, the inhibitor switch is

turned ON and, as a result, current flows from the

control unit to the inhibitor switch, starter, and

ground. Then, a cancel signal is input from the

cancel circuit to the control unit, causing the

transistor which energizes the actuator electro-

magnetic clutch coil to be turned OFF. As a result,

the electromagnetic clutch coil grounding circuit is

cut off and the auto-cruise control mode is canceled.Although a small current (voltage 5 V) flows through

the starter, it is not activated.

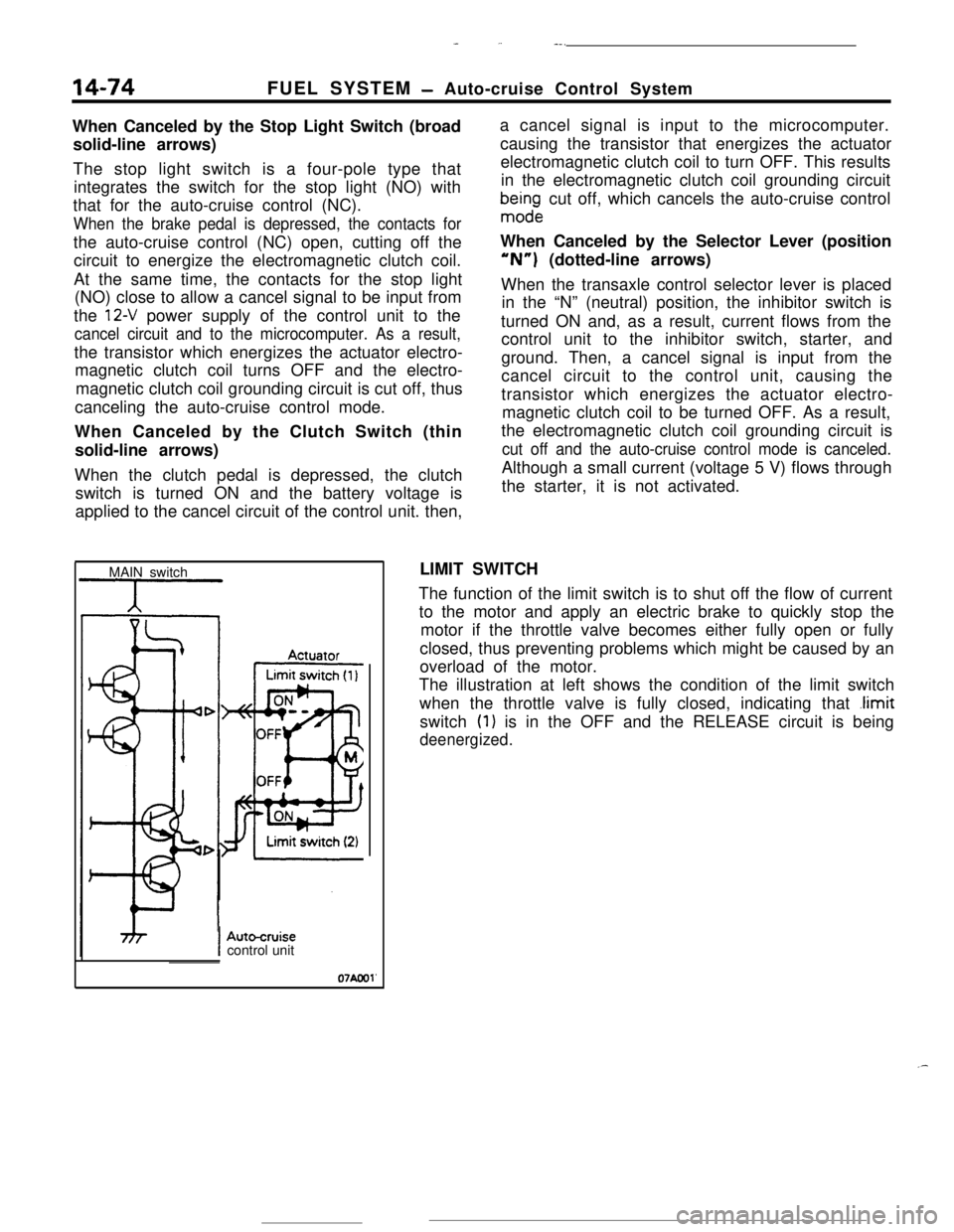

MAIN switchLIMIT SWITCH

The function of the limit switch is to shut off the flow of current

to the motor and apply an electric brake to quickly stop the

motor if the throttle valve becomes either fully open or fully

closed, thus preventing problems which might be caused by an

overload of the motor.

The illustration at left shows the condition of the limit switch

when the throttle valve is fully closed, indicating that

.limitswitch

(1) is in the OFF and the RELEASE circuit is being

deenergized.

IAutocruisecontrol unit

07Aool'

.-

Page 192 of 391

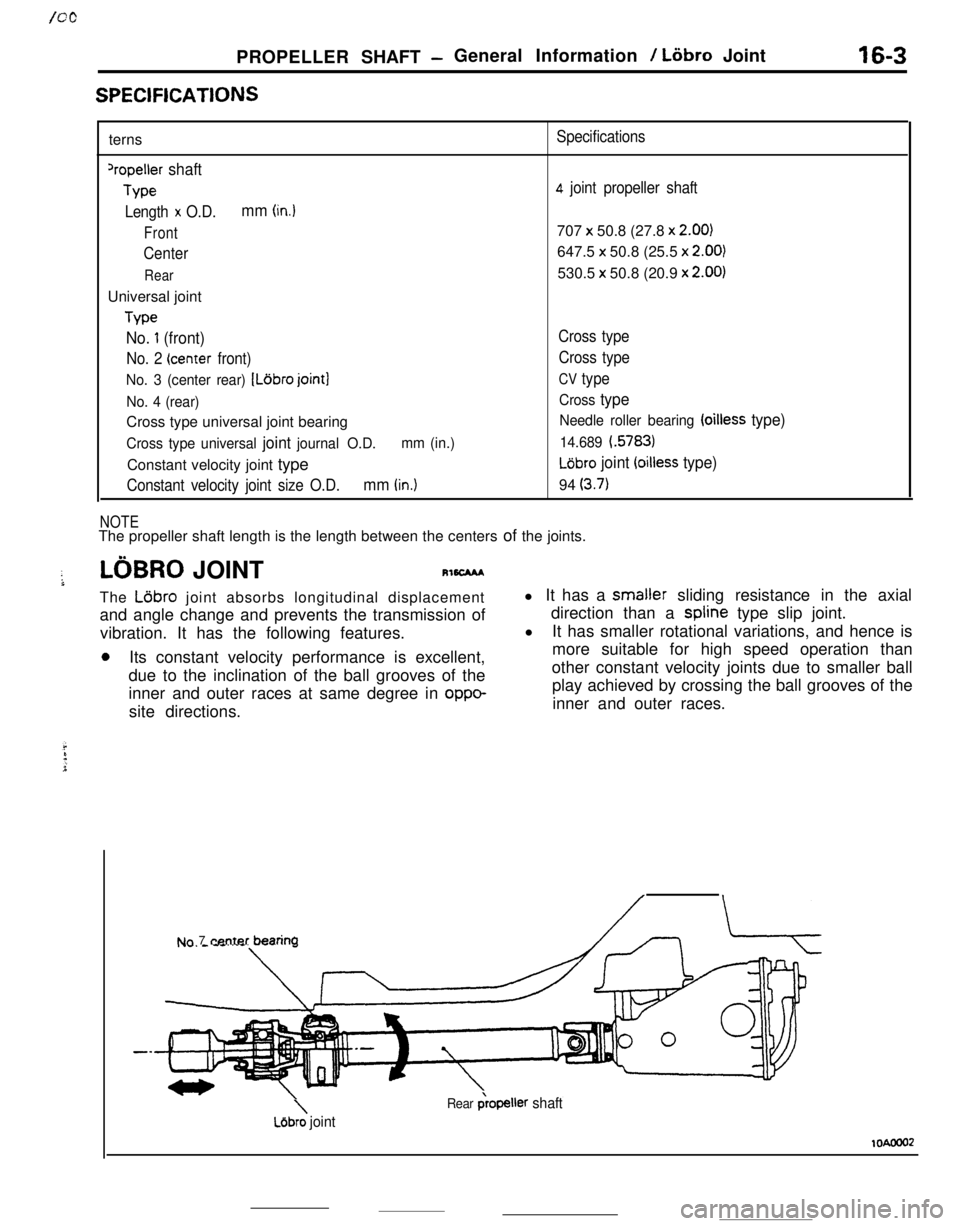

PROPELLER SHAFT -General Information / Liibro Joint16-3

SPEClFlCATlONSterns

‘repeller shaft

Type

Length

x O.D.mm (in.)

Front

Center

RearUniversal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Ldbro joint]

No. 4 (rear)Cross type universal joint bearing

Cross type universal joint journal O.D.mm (in.)Constant velocity joint type

Constant velocity joint size O.D.mm (in.)

NOTE

Specifications

4 joint propeller shaft707

x 50.8 (27.8 x 2.00)647.5 x 50.8 (25.5 x

2.00)530.5 x 50.8 (20.9 x

2.00)

Cross type

Cross type

CV type

Cross type

Needle roller bearing (oilless type)

14.689 i.5783)

LGbro joint (oilless type)94

(3.7)The propeller shaft length is the length between the centers of the joints.

LOBRO JOINTRl6CMAThe

L6bro joint absorbs longitudinal displacement

and angle change and prevents the transmission of

vibration. It has the following features.

0Its constant velocity performance is excellent,

due to the inclination of the ball grooves of the

inner and outer races at same degree in

oppo-site directions.l It has a smaller sliding resistance in the axial

direction than a spline type slip joint.

l

It has smaller rotational variations, and hence is

more suitable for high speed operation than

other constant velocity joints due to smaller ball

play achieved by crossing the ball grooves of the

inner and outer races.

Nn 7 center bearina

\Lejbro joint

Rear &opeller shaft

lOAooo2

Page 202 of 391

_ -. ..__ .-

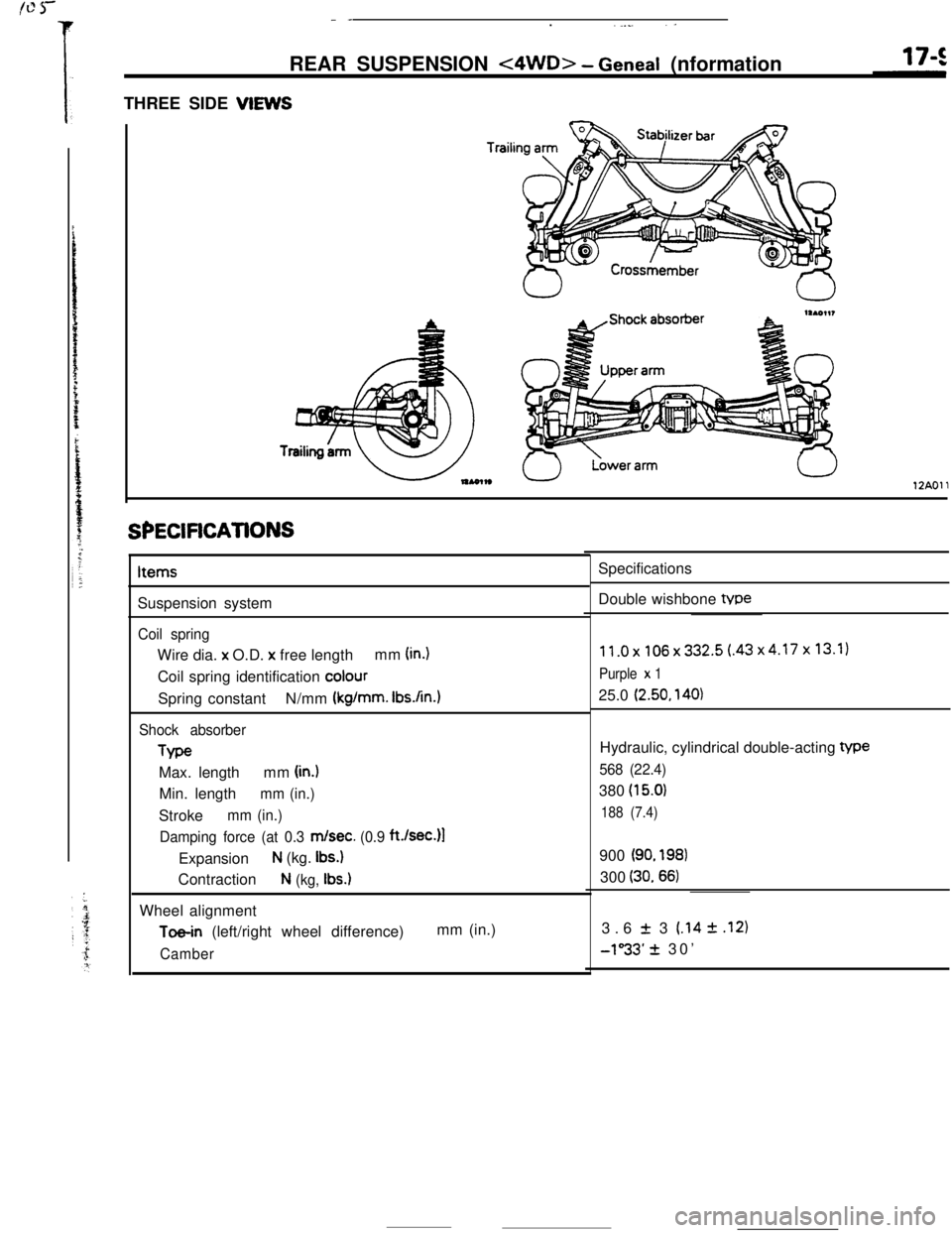

REAR SUSPENSION

<4WD> - Geneal (nformation

THREE SIDE VIEWS

Trailil

12AOll

SPECiFiCATiONSItems

Suspension system

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification

colourSpring constantN/mm

(kg/mm. Ibs.An.1

Shock absorberType

Max. lengthmm

(in.)Min. length

mm (in.)Stroke

mm (in.)

Damping force (at 0.3

m/set. (0.9 ft./sec.)l

Expansion

N (kg. Ibs.)Contraction

N (kg, Ibs.)Wheel alignment

Toe-in (left/right wheel difference)mm (in.)

CamberSpecifications

Double wishbone tvpe

11.0x106x332.5(.43x4.17x13.1)

Purple x 125.0

(2.50, 140)Hydraulic, cylindrical double-acting

We

568 (22.4)380

(15.0)

188 (7.4)900

(90. 198)300

(30.66)3.6

f 3 (.14 2 .I21

-1”33’ + 30’

Page 207 of 391

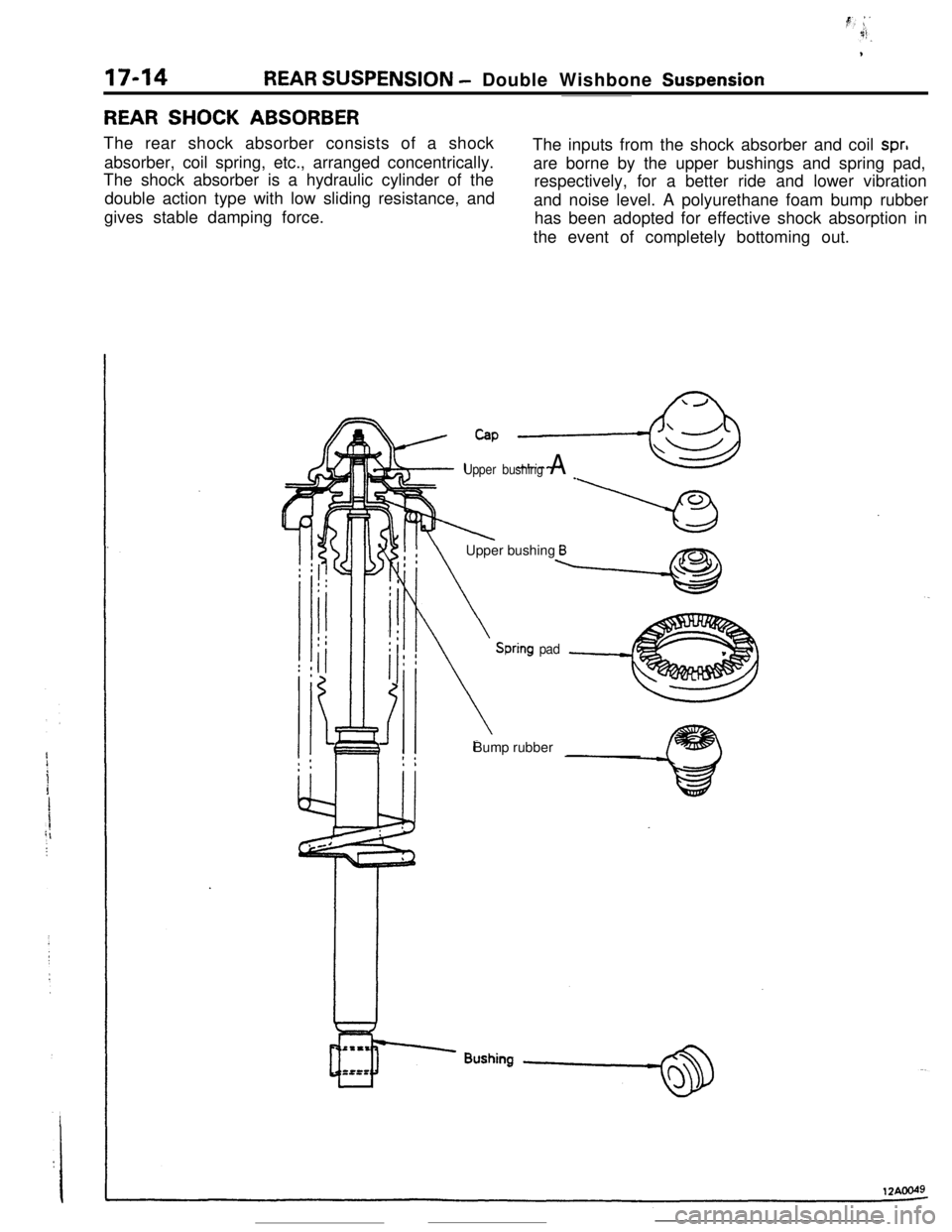

17-14REAR SUSPENSION - Double Wishbone Suwension

REAR SHOCK ABSORBERThe rear shock absorber consists of a shock

absorber, coil spring, etc., arranged concentrically.

The shock absorber is a hydraulic cylinder of the

double action type with low sliding resistance, and

gives stable damping force.The inputs from the shock absorber and coil

spr,are borne by the upper bushings and spring pad,

respectively, for a better ride and lower vibration

and noise level. A polyurethane foam bump rubber

has been adopted for effective shock absorption in

the event of completely bottoming out.

Cap ,-&

Upper bushing A _

IlXk!! \Upper bushing Bx?nb

Spring padBump rubber

Page 211 of 391

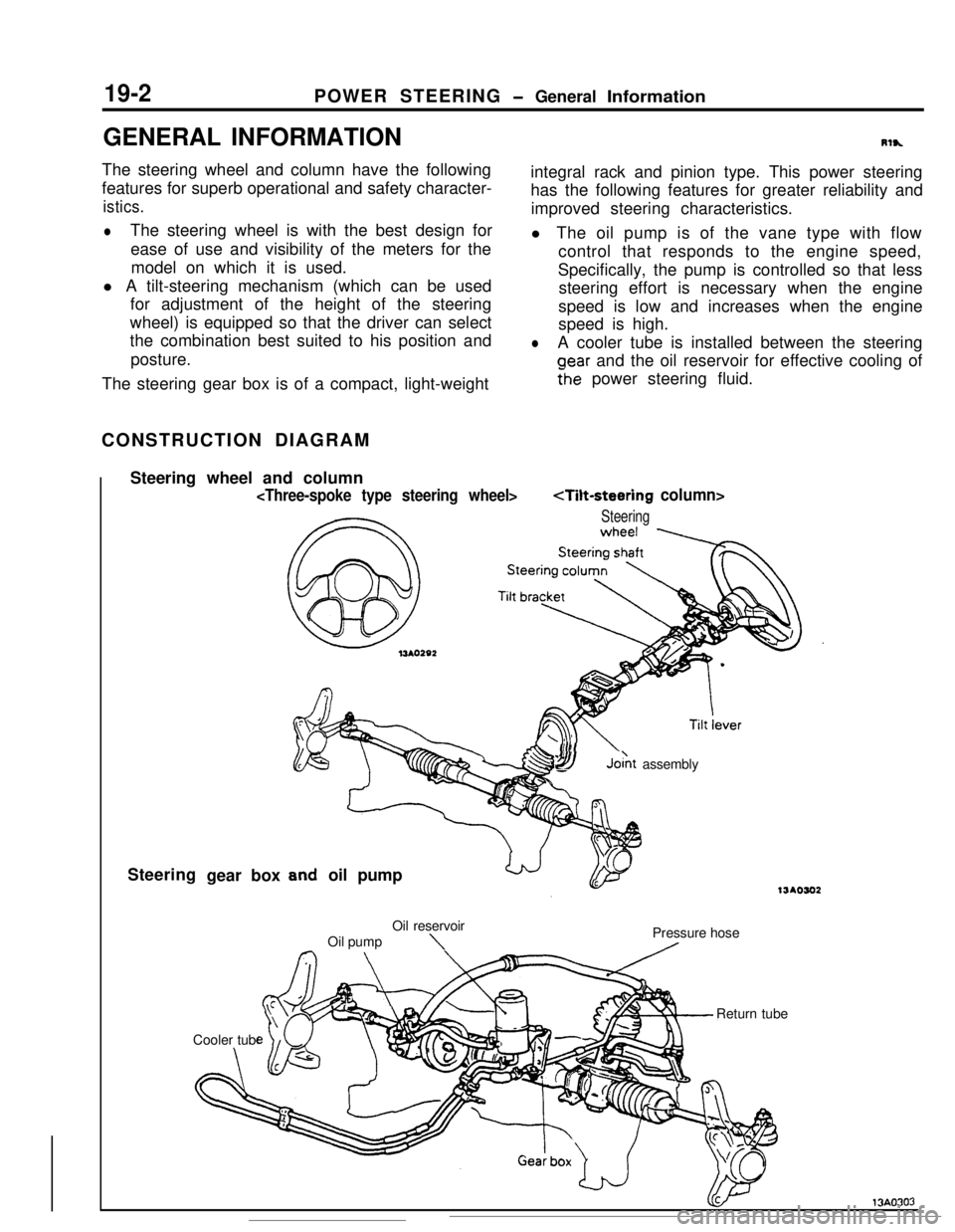

19-2 POWER STEERING

Rlh

integral rack and pinion type. This power steering

oear and the oil reservoir for effective cooling of

Fhe power steering fluid.The steering gear box is of a compact, light-weight

Steering

SYJo& assembly

oil pump

\Pressure hose

A

Page 212 of 391

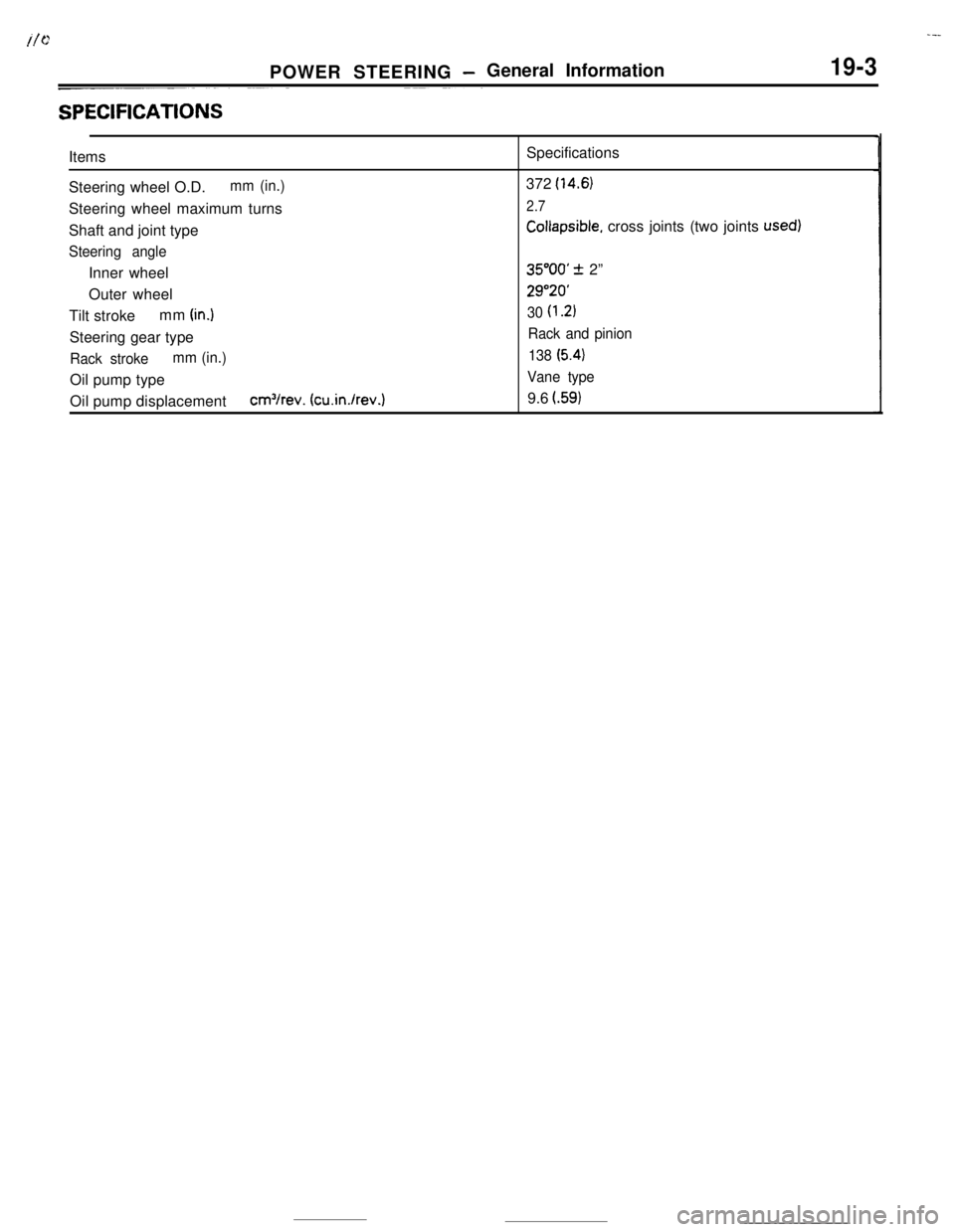

POWER STEERING- General Information19-3

SPEClFlCATlONSItems

Steering wheel O.D.

mm (in.)Steering wheel maximum turns

Shaft and joint type

Steering angleInner wheel

Outer wheel

Tilt strokemm

(in.1Steering gear type

Rack strokemm (in.)Oil pump type

Oil pump displacement

cm3/rev. (cu.in./rev.)Specifications

372

(14.6)

2.7

Collapsible, cross joints (two joints used)

35”OO’ + 2”

29”20’

30

(1.2)

Rack and pinion

138

(5.41

Vane type9.6

l.59)

Page 214 of 391

.-. --POWER STEERING

- Power Steering Gear Box Construction19-5

-POWER STEERING GEAR BOX CONSTRUCTIONRlsJLIIUB,

ne steering gear box is of the rack and pinion type

with a built-in hydraulic control unit which uses a

compact and highly reliable rotary valve.The steering gear box, in the same way as the

manual steering gear box, is installed to the body by

way of the mounting rubber in order to reduce the

transmission of vibrations.

Section A-A

Beari

1-$ysy input shaft

To oilreservoir

LFrom oil

I’Rotary valve

Yoke spring

13A0257

Section B-B

From oil pumpTo oil reservoir

To cylinder tubeleft chamber

To cylinder tube

13A0077right chamber

Page 219 of 391

POWER STEERING - Oil Pump13A0067

Insi

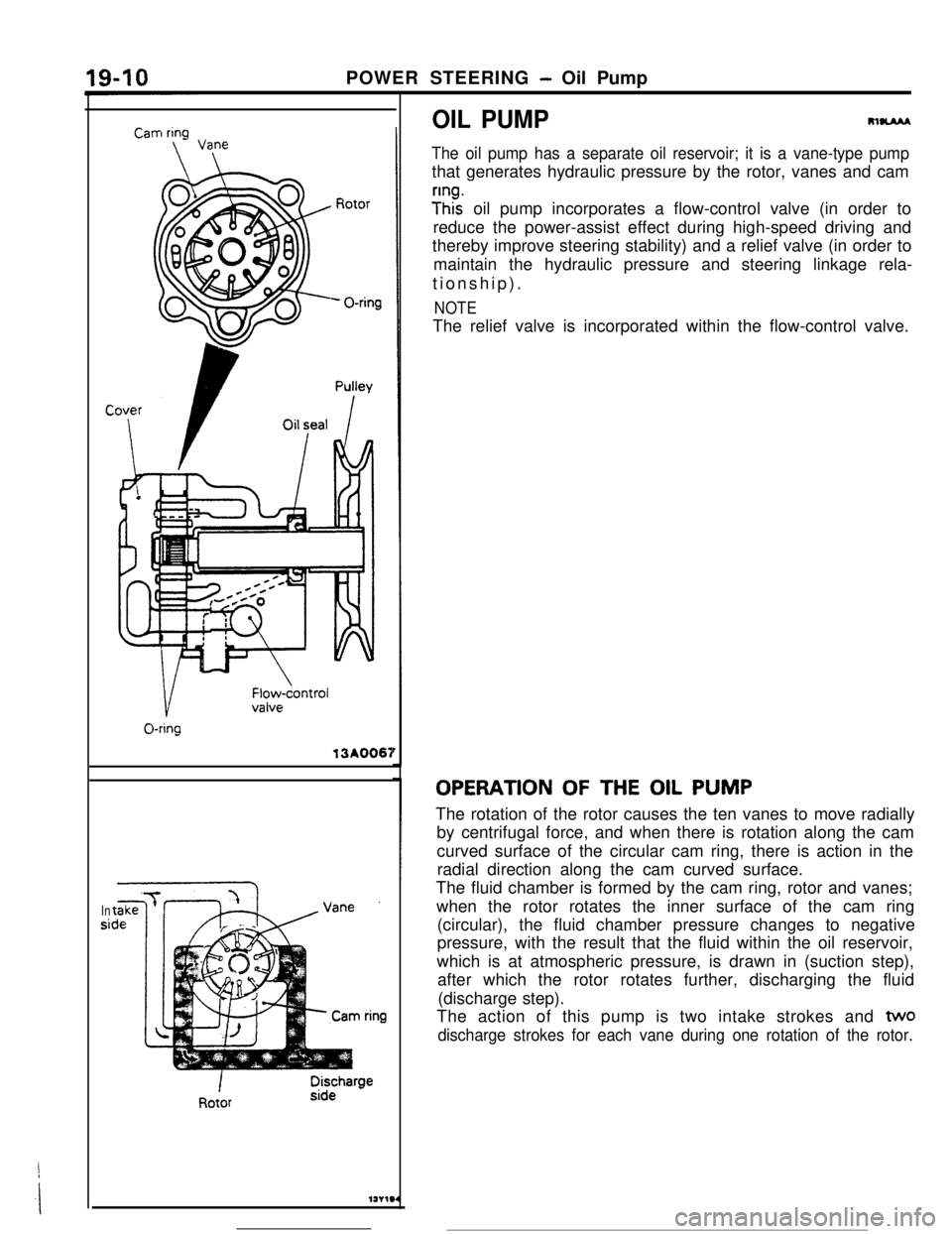

OIL PUMPRlUAM

The oil pump has a separate oil reservoir; it is a vane-type pumpthat generates hydraulic pressure by the rotor, vanes and cam

y”ht oil pump incorporates a flow-control valve (in order to

reduce the power-assist effect during high-speed driving and

thereby improve steering stability) and a relief valve (in order to

maintain the hydraulic pressure and steering linkage rela-

tionship).

NOTEThe relief valve is incorporated within the flow-control valve.

OPERATION OF THE OIL PUMP

The rotation of the rotor causes the ten vanes to move radially

by centrifugal force, and when there is rotation along the cam

curved surface of the circular cam ring, there is action in the

radial direction along the cam curved surface.

The fluid chamber is formed by the cam ring, rotor and vanes;

when the rotor rotates the inner surface of the cam ring

(circular), the fluid chamber pressure changes to negative

pressure, with the result that the fluid within the oil reservoir,

which is at atmospheric pressure, is drawn in (suction step),

after which the rotor rotates further, discharging the fluid

(discharge step).

The action of this pump is two intake strokes and

two

discharge strokes for each vane during one rotation of the rotor.