oil MITSUBISHI ECLIPSE 1990 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 163 of 391

FUEL SYSTEM -Idle Speed Control14-51

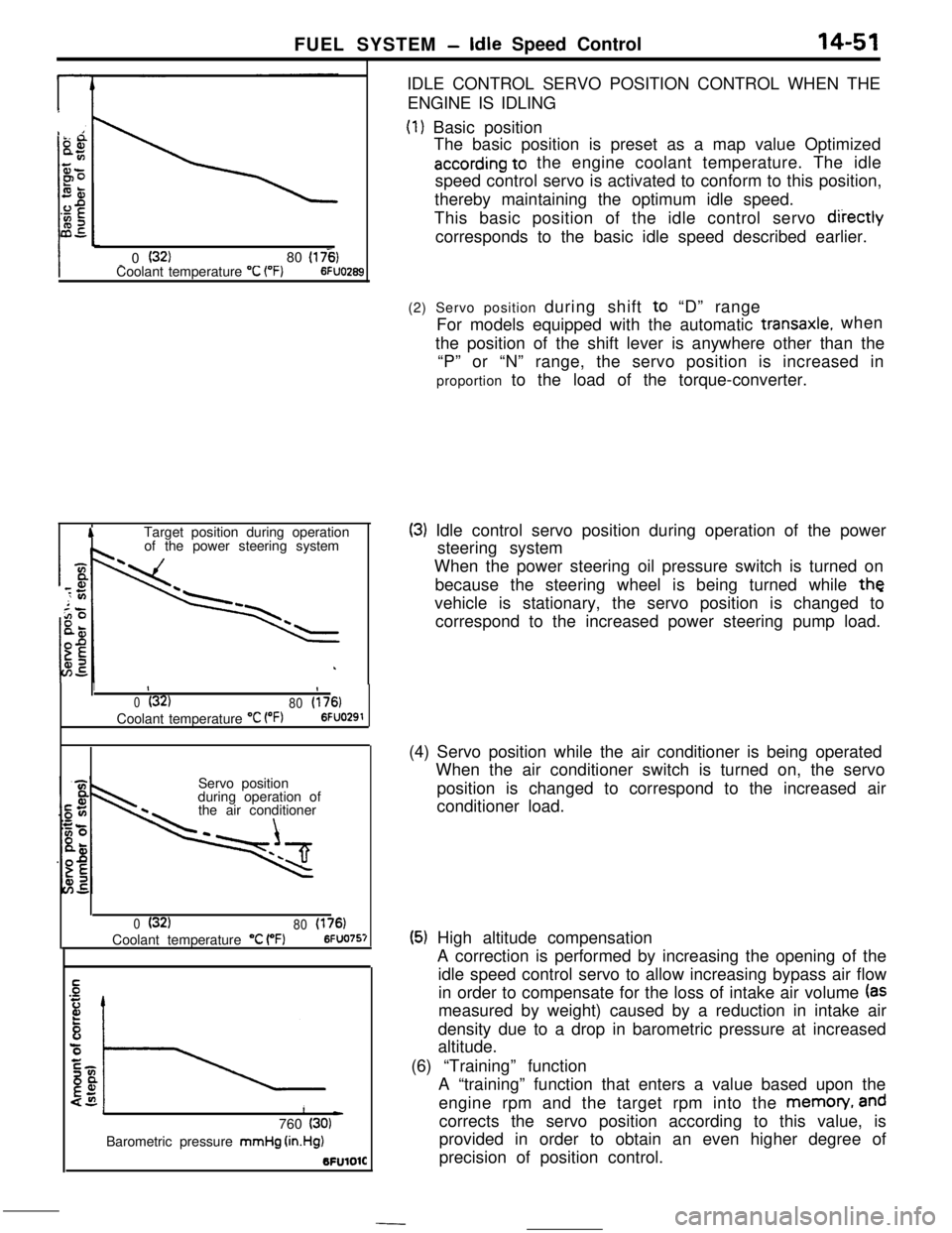

_ 0 (32)80 (175)Coolant temperature “C (“F)6FUO2653

ATarget position during operation

of the power steering systemIDLE CONTROL SERVO POSITION CONTROL WHEN THE

ENGINE IS IDLING

(1) Basic position

The basic position is preset as a map value Optimized

according to the engine coolant temperature. The idle

speed control servo is activated to conform to this position,

thereby maintaining the optimum idle speed.

This basic position of the idle control servo

diiectlycorresponds to the basic idle speed described earlier.

1II

0(32)

80(176)Coolant temperature

“C VW6FUO291Servo position

during operation of

the air conditioner

0(32)

80(176)Coolant temperature “C (“F)6FUO757

1L)760 (30)Barometric pressure mmHg

(in.Hg)BFUlOlC(2) Servo position during shift to “D” range

For models equipped with the automatic

transaxle.when

the position of the shift lever is anywhere other than the

“P” or “N” range, the servo position is increased in

proportion to the load of the torque-converter.

(3) Idle control servo position during operation of the power

steering system

When the power steering oil pressure switch is turned on

because the steering wheel is being turned while

thevehicle is stationary, the servo position is changed to

correspond to the increased power steering pump load.

(4) Servo position while the air conditioner is being operated

When the air conditioner switch is turned on, the servo

position is changed to correspond to the increased air

conditioner load.

(5) High altitude compensation

A correction is performed by increasing the opening of the

idle speed control servo to allow increasing bypass air flow

in order to compensate for the loss of intake air volume

(asmeasured by weight) caused by a reduction in intake air

density due to a drop in barometric pressure at increased

altitude.

(6) “Training” function

A “training” function that enters a value based upon the

engine rpm and the target rpm into the memon/,

andcorrects the servo position according to this value, is

provided in order to obtain an even higher degree of

precision of position control.

Page 166 of 391

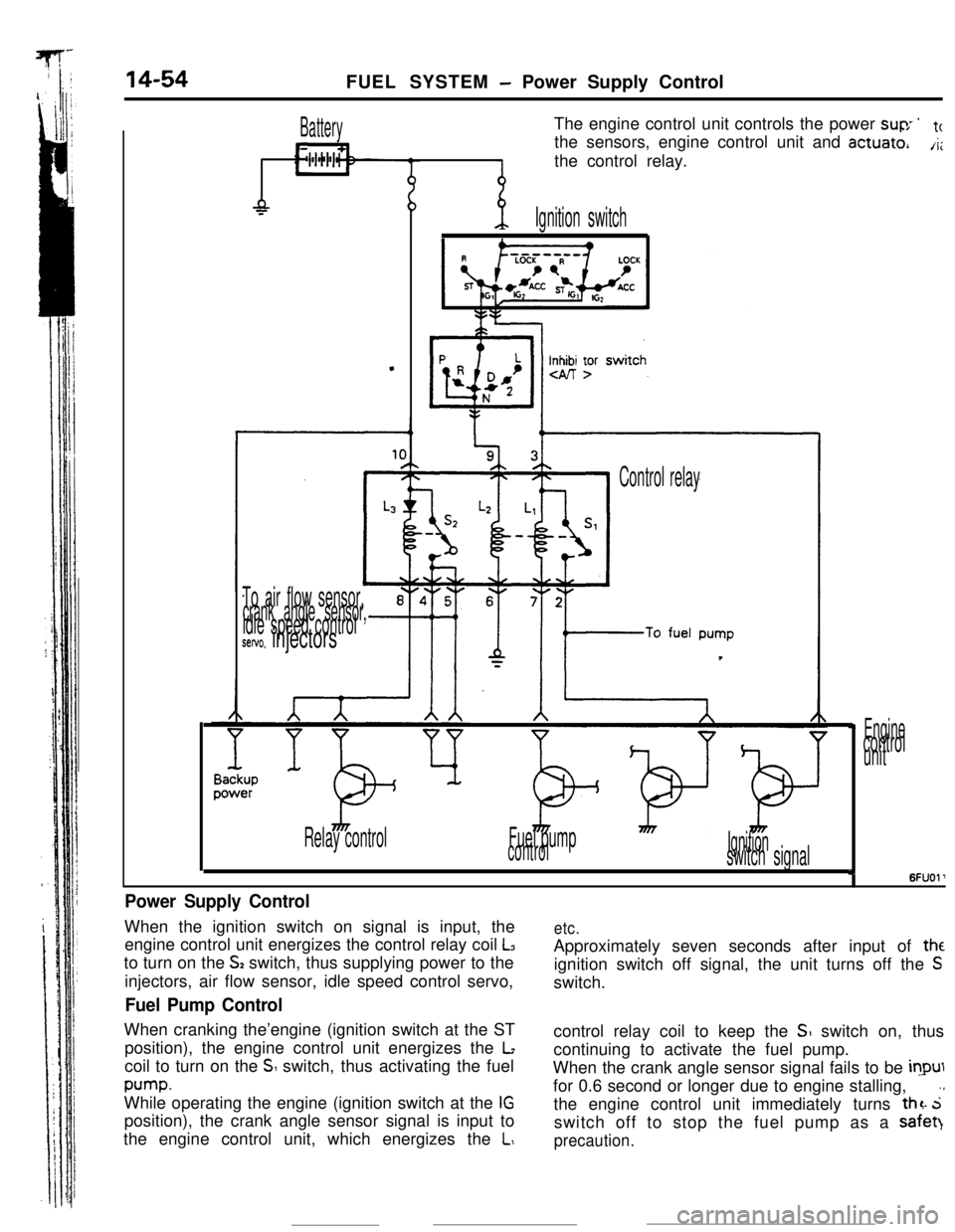

FUEL SYSTEM- Power Supply Control

Battery

L11The engine control unit controls the power

suv ’tcthe sensors, engine control unit and

actuate,A;the control relay.

-P

.

-p.Ignition switch

Inn yr

To air flow sensor,crank angle sensor,idle speed controlsetvo. injectors

Control relay

Relay controlFuel pump

controlIgnitionswitch signal

Enginecontrol

unit

I6FUOl’

Power Supply ControlWhen the ignition switch on signal is input, the

engine control unit energizes the control relay coil

L3to turn on the

S2 switch, thus supplying power to the

injectors, air flow sensor, idle speed control servo,

Fuel Pump ControlWhen cranking the’engine (ignition switch at the ST

position), the engine control unit energizes the

Lcoil to turn on the

S switch, thus activating the fuel

pump.While operating the engine (ignition switch at the

IGposition), the crank angle sensor signal is input to

the engine control unit, which energizes the

L,

etc.Approximately seven seconds after input of

theignition switch off signal, the unit turns off the

Sswitch.

control relay coil to keep the

SI switch on, thus

continuing to activate the fuel pump.

When the crank angle sensor signal fails to be

inputfor 0.6 second or longer due to engine stalling,

.,the engine control unit immediately turns

thz. 5switch off to stop the fuel pump as a safet)

precaution.

Page 173 of 391

F

FUEL SYSTEM -Auto-cruise Control System'l4-61

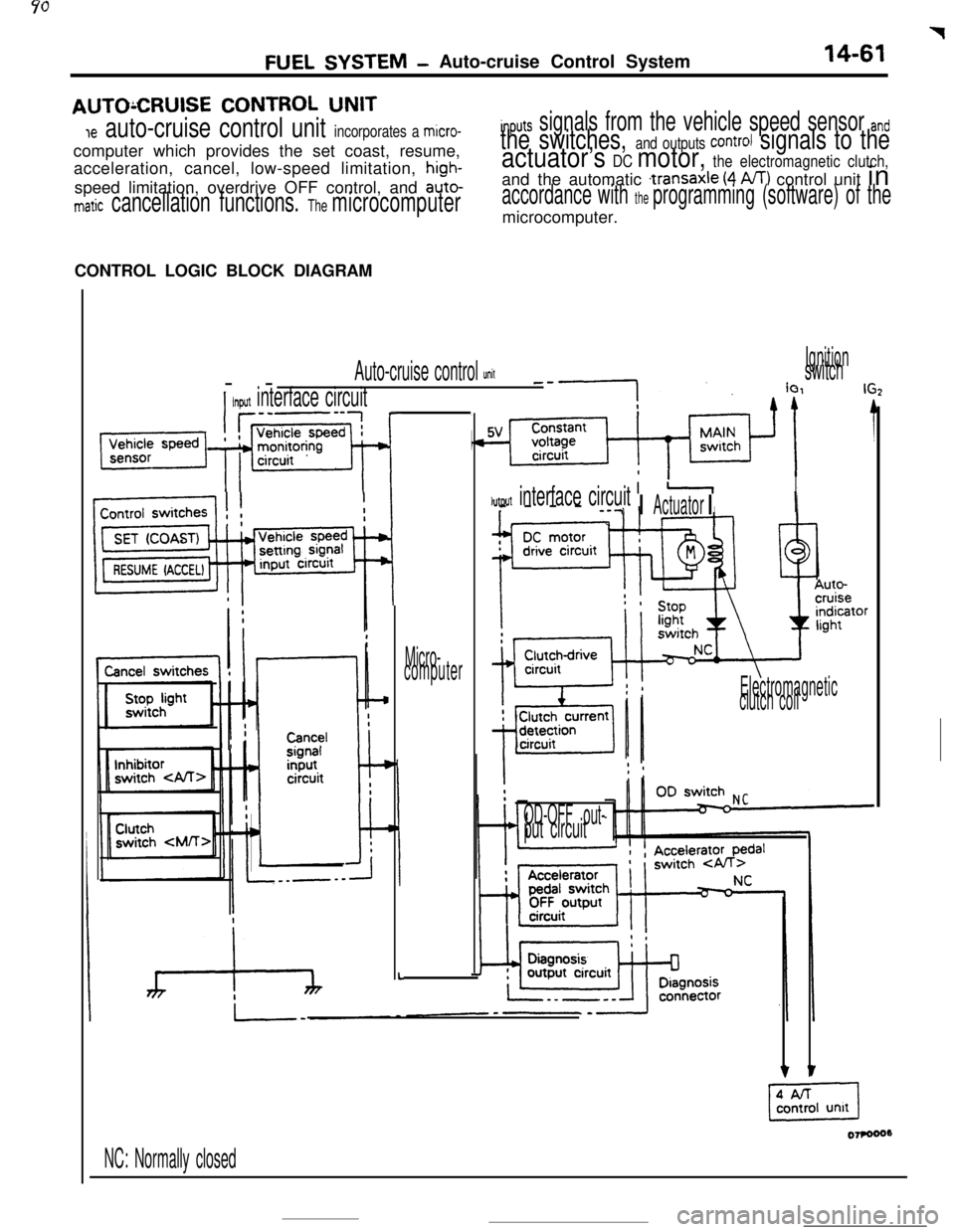

AUTOCRUISE CONTROL UNIT

Je auto-cruise control unit incorporates a micro-computer which provides the set coast, resume,

acceleration, cancel, low-speed limitation,

high-speed limitation, overdrive OFF control, and

auto-

matic cancellation functions. The microcomputer

inputs signals from the vehicle speed sensor and

the switches, and outputs Control signals to the

actuator’s DC motor, the electromagnetic clutch,and the automatic

.transaxle (4 A/T) control unit in

accordance with the programming (software) of themicrocomputer.

CONTROL LOGIC BLOCK DIAGRAM

--

Auto-cruise control UnitIgnitionswitcha.-.

I

Input interface circuit

piz7q.f~~

I

L

Micro-

computer

jutput interface circuitIr--lI----

--7I IActuatorI

Electromagnetic

clutch coil

OD-OFF out-

put circuit

NC: Normally closed

Page 181 of 391

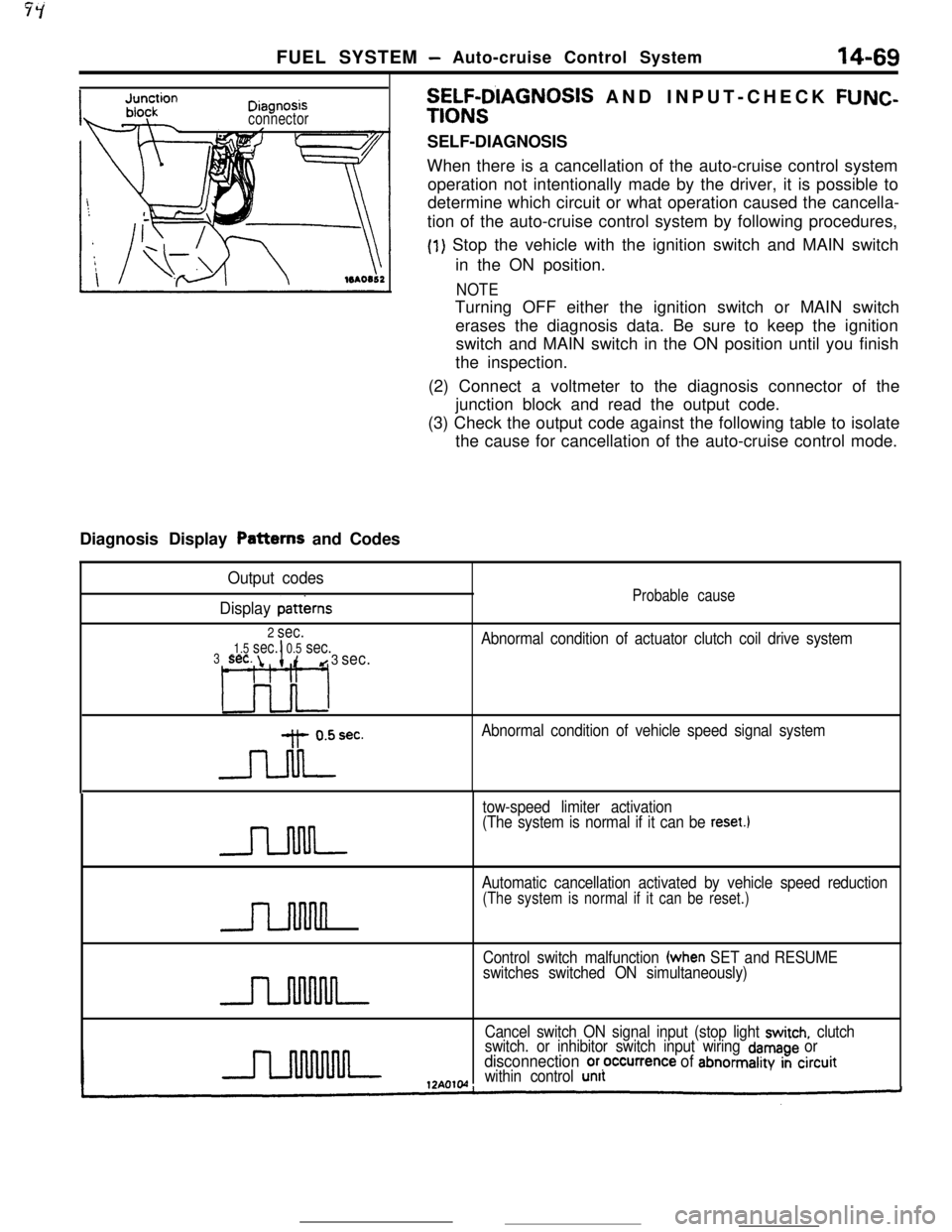

FUEL SYSTEM- Auto-cruise Control System14-69

ni2nnncisv,“y’I”“.-

connectorDiagnosis Display Patterns and Codes

SELF-D’IAGNOSIS AND INPUT-CHECK FUNC-

TIONSSELF-DIAGNOSIS

When there is a cancellation of the auto-cruise control system

operation not intentionally made by the driver, it is possible to

determine which circuit or what operation caused the cancella-

tion of the auto-cruise control system by following procedures,

(1) Stop the vehicle with the ignition switch and MAIN switch

in the ON position.

NOTETurning OFF either the ignition switch or MAIN switch

erases the diagnosis data. Be sure to keep the ignition

switch and MAIN switch in the ON position until you finish

the inspection.

(2) Connect a voltmeter to the diagnosis connector of the

junction block and read the output code.

(3) Check the output code against the following table to isolate

the cause for cancellation of the auto-cruise control mode.

Output codes

Display

patterns

2 sec.

1.5 sec.I0.5 sec.3sec. id 3 sec.

L3o-l

-Jdrec.

Probable cause

Abnormal condition of actuator clutch coil drive system

Abnormal condition of vehicle speed signal system

tow-speed limiter activation

(The system is normal if it can be

reset.1

n

Automatic cancellation activated by vehicle speed reduction

(The system is normal if it can be reset.)

Control switch malfunction (when SET and RESUME

switches switched ON simultaneously)

Cancel switch ON signal input (stop light

switch, clutch

switch. or inhibitor switch input wiring damage ordisconnection or,occurrence of abnormality in circuitwithin control unit

Page 183 of 391

Y 5-FUEL SYSTEM

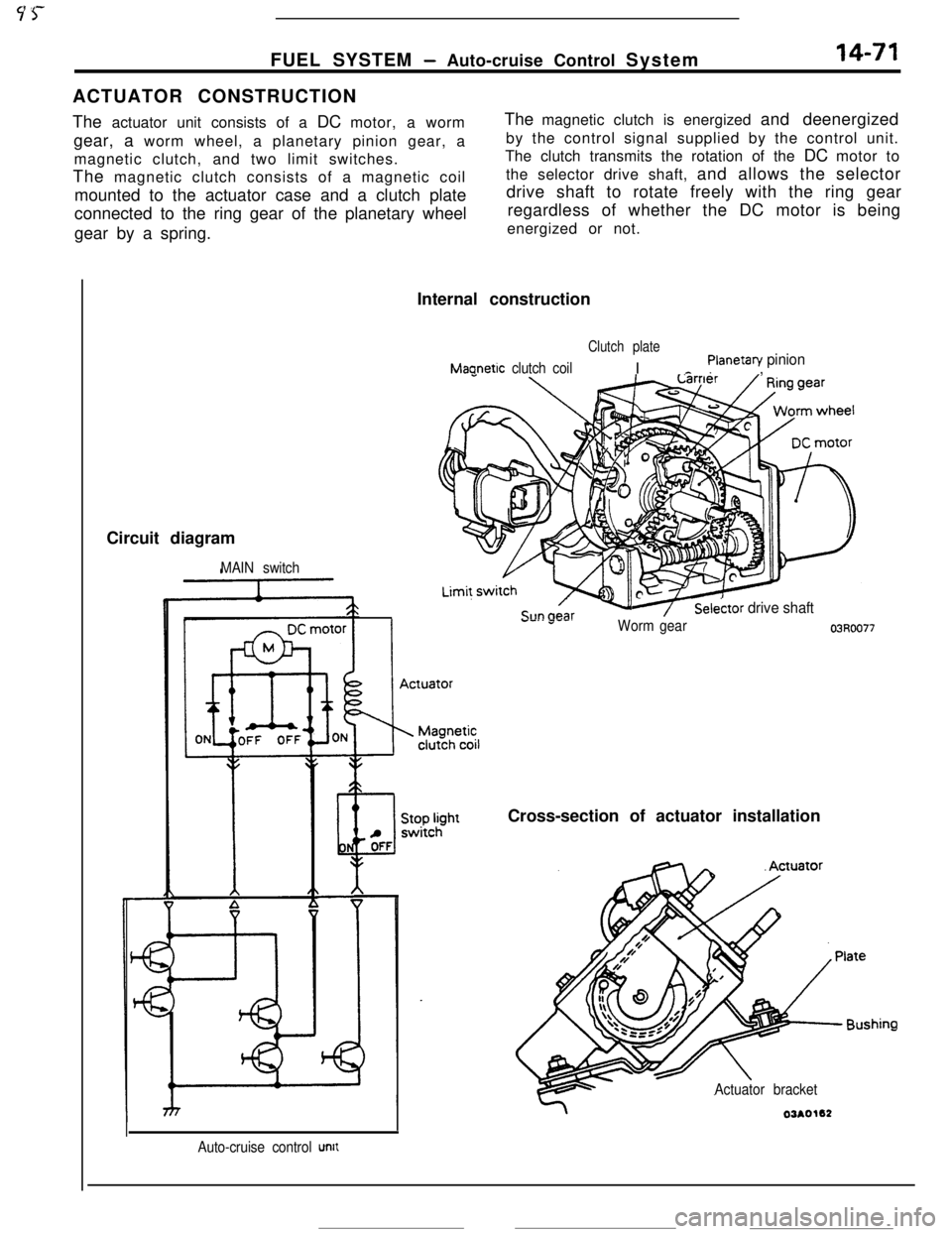

- Auto-cruise Control System14-71ACTUATOR CONSTRUCTION

The actuator unit consists of a DC motor, a worm

gear, a worm wheel, a planetary pinion gear, a

magnetic clutch, and two limit switches.

The magnetic clutch consists of a magnetic coil

mounted to the actuator case and a clutch plate

connected to the ring gear of the planetary wheel

gear by a spring.The magnetic clutch is energized and deenergized

by the control signal supplied by the control unit.

The clutch transmits the rotation of the DC motor to

the selector drive shaft, and allows the selector

drive shaft to rotate freely with the ring gear

regardless of whether the DC motor is being

energized or not.

Internal construction

Clutch plate

Maanetic clutch coilI ^. ,Planetan/ pinionCircuit diagram

MAIN switch

%tn m.=ir

Auto-cruise control unit

7S&&or drive shaft

Worm gear03R0077

Cross-section of actuator installation

Actuator bracket

Page 184 of 391

14-72

._FUEL SYSTEM

- Auto-cruise Control System

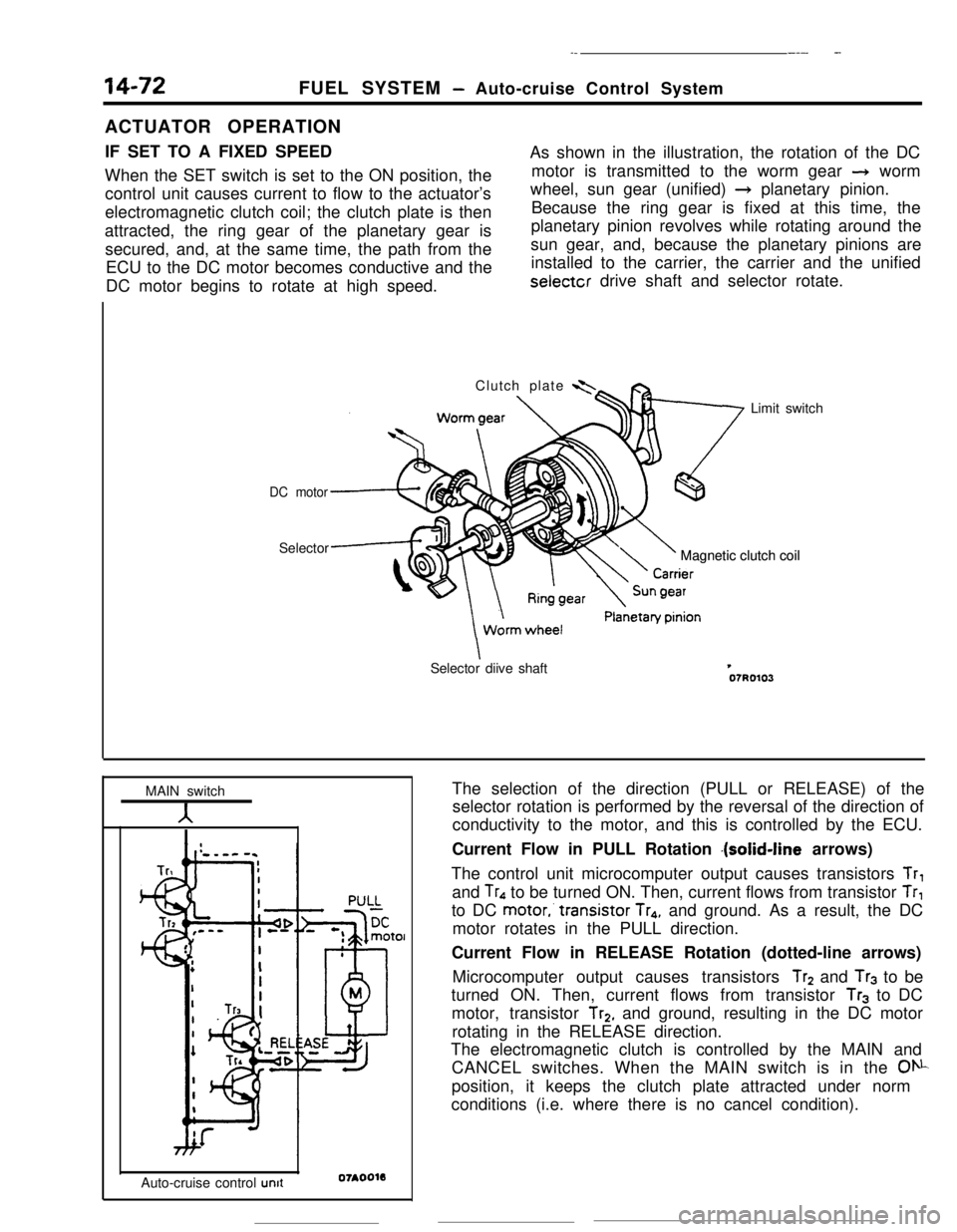

___ -ACTUATOR OPERATION

IF SET TO A FIXED SPEED

When the SET switch is set to the ON position, the

control unit causes current to flow to the actuator’s

electromagnetic clutch coil; the clutch plate is then

attracted, the ring gear of the planetary gear is

secured, and, at the same time, the path from the

ECU to the DC motor becomes conductive and the

DC motor begins to rotate at high speed.As shown in the illustration, the rotation of the DC

motor is transmitted to the worm gear

--, worm

wheel, sun gear (unified)

+ planetary pinion.

Because the ring gear is fixed at this time, the

planetary pinion revolves while rotating around the

sun gear, and, because the planetary pinions are

installed to the carrier, the carrier and the unifiedselectcr drive shaft and selector rotate.

Clutch plate

<

7 Limit switch

DC motorSelector

Magnetic clutch coil Magnetic clutch coil

Selector diive shaft

MAIN switchTrl

4sTn

aAuto-cruise control

unit07AOO11The selection of the direction (PULL or RELEASE) of the

selector rotation is performed by the reversal of the direction of

conductivity to the motor, and this is controlled by the ECU.

Current Flow in PULL Rotation

.(soiid-line arrows)

The control unit microcomputer output causes transistors

Tr,and Tr, to be turned ON. Then, current flows from transistor

Tr,to DC motor,‘transistor

Tr,, and ground. As a result, the DC

motor rotates in the PULL direction.

Current Flow in RELEASE Rotation (dotted-line arrows)

Microcomputer output causes transistors

Tr2 and Tr3 to be

turned ON. Then, current flows from transistor

Tr3 to DC

motor, transistor

Tr2, and ground, resulting in the DC motor

rotating in the RELEASE direction.

The electromagnetic clutch is controlled by the MAIN and

CANCEL switches. When the MAIN switch is in the

01\L.position, it keeps the clutch plate attracted under norm

conditions (i.e. where there is no cancel condition).

Page 186 of 391

14-74

_ ,.-..FUEL SYSTEM

- Auto-cruise Control System

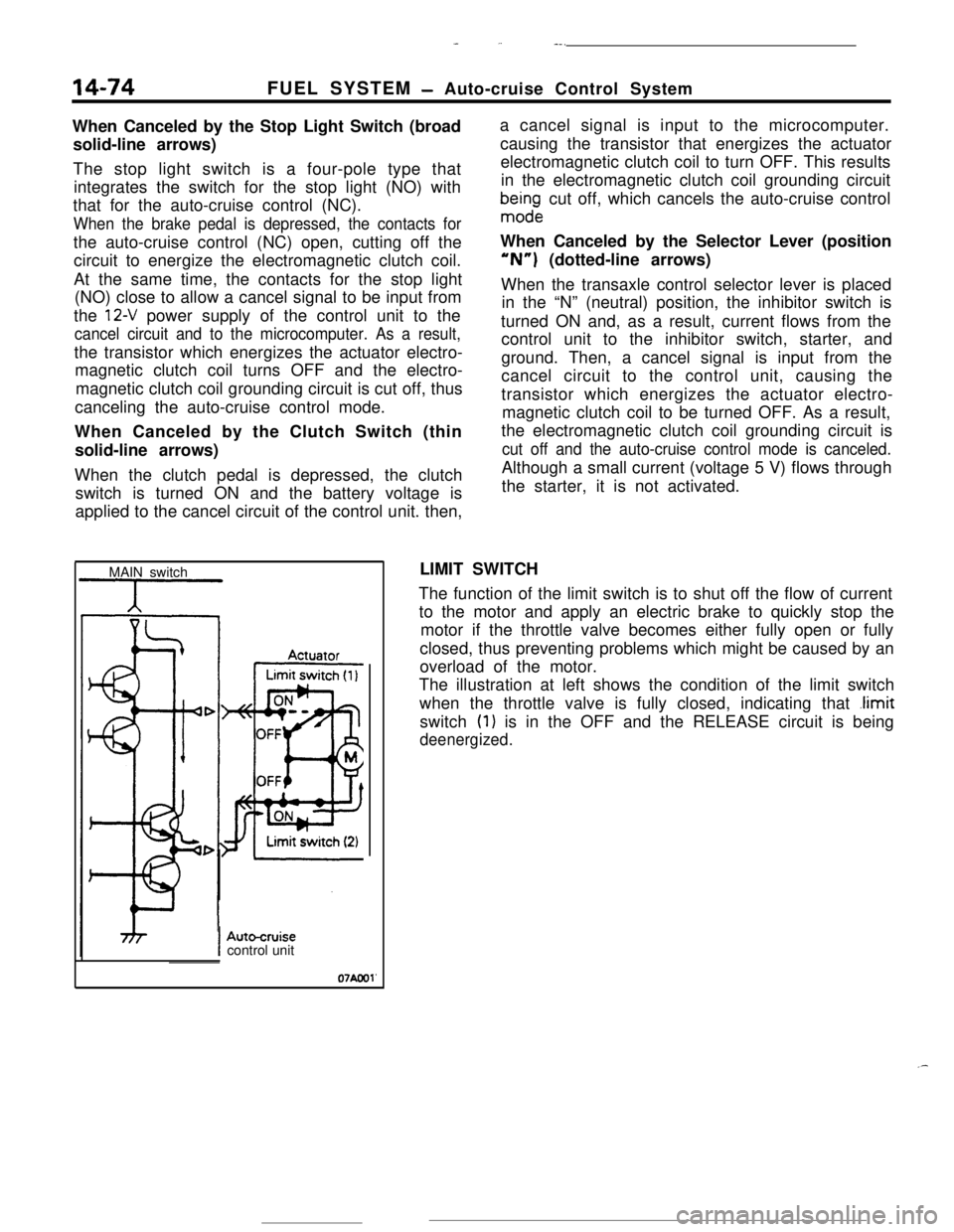

When Canceled by the Stop Light Switch (broad

solid-line arrows)

The stop light switch is a four-pole type that

integrates the switch for the stop light (NO) with

that for the auto-cruise control (NC).

When the brake pedal is depressed, the contacts forthe auto-cruise control (NC) open, cutting off the

circuit to energize the electromagnetic clutch coil.

At the same time, the contacts for the stop light

(NO) close to allow a cancel signal to be input from

the

12-V power supply of the control unit to the

cancel circuit and to the microcomputer. As a result,the transistor which energizes the actuator electro-

magnetic clutch coil turns OFF and the electro-

magnetic clutch coil grounding circuit is cut off, thus

canceling the auto-cruise control mode.

When Canceled by the Clutch Switch (thin

solid-line arrows)

When the clutch pedal is depressed, the clutch

switch is turned ON and the battery voltage is

applied to the cancel circuit of the control unit. then,a cancel signal is input to the microcomputer.

causing the transistor that energizes the actuator

electromagnetic clutch coil to turn OFF. This results

in the electromagnetic clutch coil grounding circuit

bma$ndge cut off, which cancels the auto-cruise control

When Canceled by the Selector Lever (position“N”) (dotted-line arrows)

When the transaxle control selector lever is placed

in the “N” (neutral) position, the inhibitor switch is

turned ON and, as a result, current flows from the

control unit to the inhibitor switch, starter, and

ground. Then, a cancel signal is input from the

cancel circuit to the control unit, causing the

transistor which energizes the actuator electro-

magnetic clutch coil to be turned OFF. As a result,

the electromagnetic clutch coil grounding circuit is

cut off and the auto-cruise control mode is canceled.Although a small current (voltage 5 V) flows through

the starter, it is not activated.

MAIN switchLIMIT SWITCH

The function of the limit switch is to shut off the flow of current

to the motor and apply an electric brake to quickly stop the

motor if the throttle valve becomes either fully open or fully

closed, thus preventing problems which might be caused by an

overload of the motor.

The illustration at left shows the condition of the limit switch

when the throttle valve is fully closed, indicating that

.limitswitch

(1) is in the OFF and the RELEASE circuit is being

deenergized.

IAutocruisecontrol unit

07Aool'

.-

Page 192 of 391

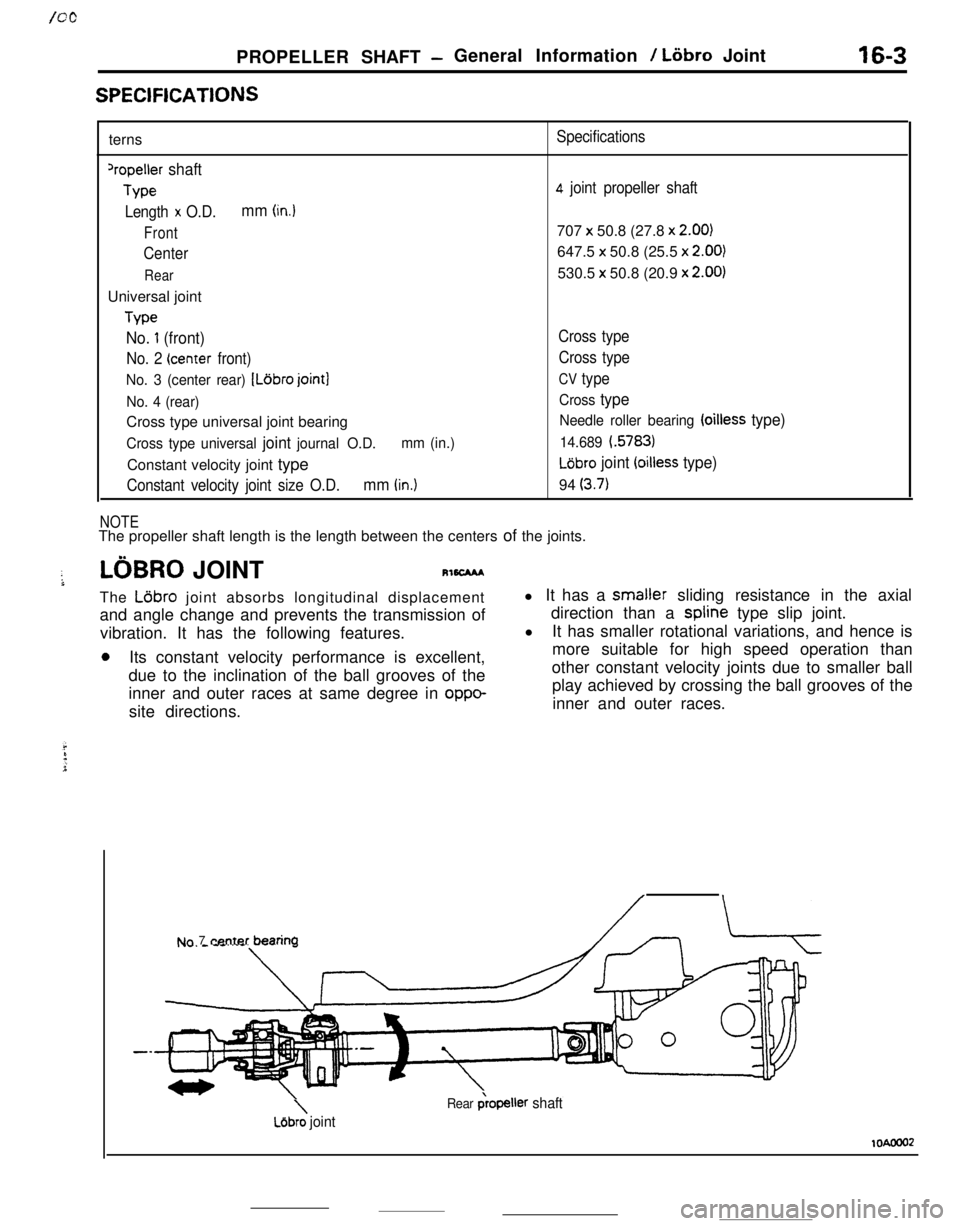

PROPELLER SHAFT -General Information / Liibro Joint16-3

SPEClFlCATlONSterns

‘repeller shaft

Type

Length

x O.D.mm (in.)

Front

Center

RearUniversal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Ldbro joint]

No. 4 (rear)Cross type universal joint bearing

Cross type universal joint journal O.D.mm (in.)Constant velocity joint type

Constant velocity joint size O.D.mm (in.)

NOTE

Specifications

4 joint propeller shaft707

x 50.8 (27.8 x 2.00)647.5 x 50.8 (25.5 x

2.00)530.5 x 50.8 (20.9 x

2.00)

Cross type

Cross type

CV type

Cross type

Needle roller bearing (oilless type)

14.689 i.5783)

LGbro joint (oilless type)94

(3.7)The propeller shaft length is the length between the centers of the joints.

LOBRO JOINTRl6CMAThe

L6bro joint absorbs longitudinal displacement

and angle change and prevents the transmission of

vibration. It has the following features.

0Its constant velocity performance is excellent,

due to the inclination of the ball grooves of the

inner and outer races at same degree in

oppo-site directions.l It has a smaller sliding resistance in the axial

direction than a spline type slip joint.

l

It has smaller rotational variations, and hence is

more suitable for high speed operation than

other constant velocity joints due to smaller ball

play achieved by crossing the ball grooves of the

inner and outer races.

Nn 7 center bearina

\Lejbro joint

Rear &opeller shaft

lOAooo2

Page 199 of 391

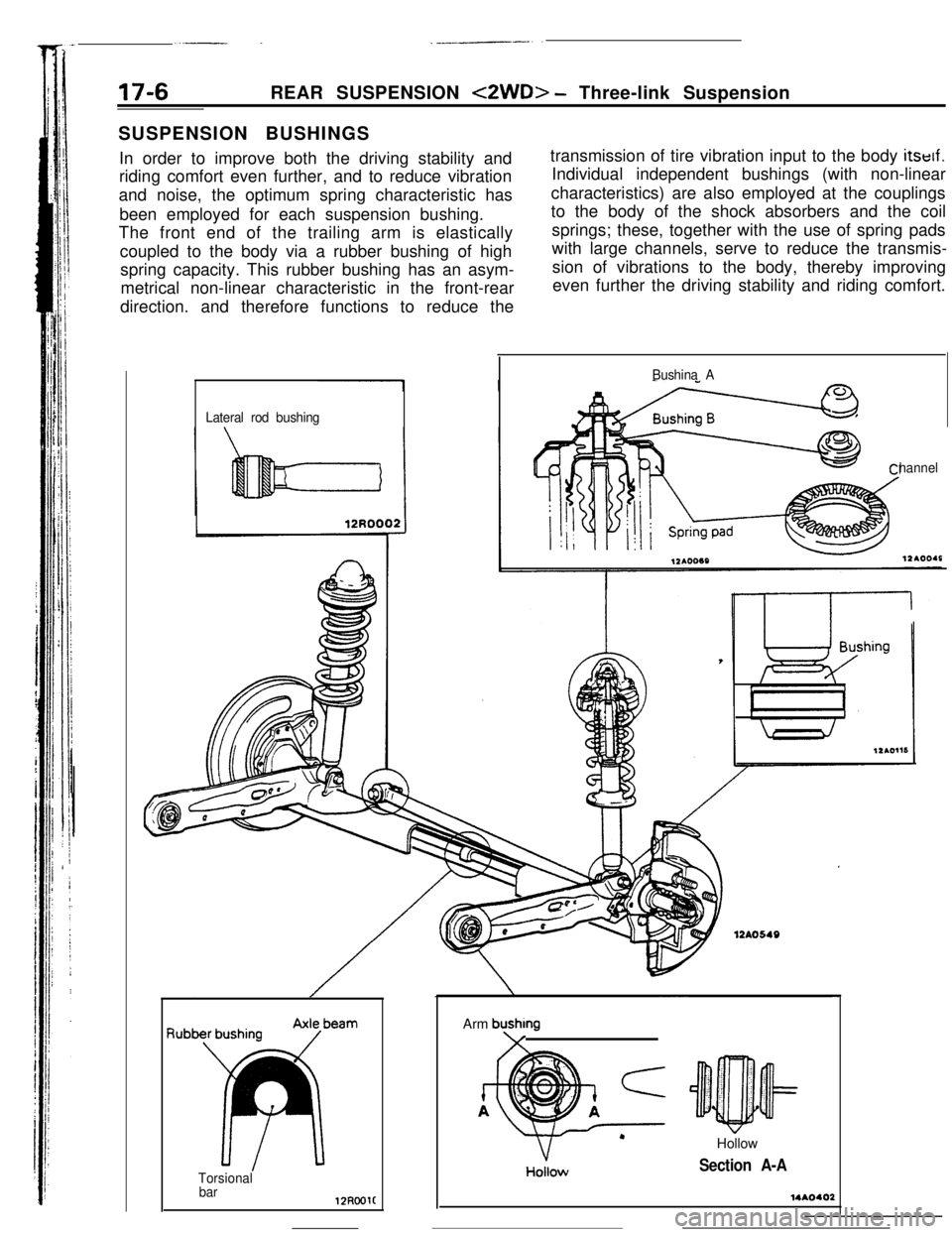

17-6REAR SUSPENSION <2WD> - Three-link Suspension

SUSPENSION BUSHINGS

In order to improve both the driving stability and

riding comfort even further, and to reduce vibration

and noise, the optimum spring characteristic has

been employed for each suspension bushing.

The front end of the trailing arm is elastically

coupled to the body via a rubber bushing of high

spring capacity. This rubber bushing has an asym-

metrical non-linear characteristic in the front-rear

direction. and therefore functions to reduce thetransmission of tire vibration input to the body itself.

Individual independent bushings (with non-linear

characteristics) are also employed at the couplings

to the body of the shock absorbers and the coil

springs; these, together with the use of spring pads

with large channels, serve to reduce the transmis-

sion of vibrations to the body, thereby improving

even further the driving stability and riding comfort.

Lateral rod bushingBushina A

hannel

f3ub

Torsional

barArm

bushmg\/HollowHoilow

Section A-A

Page 202 of 391

_ -. ..__ .-

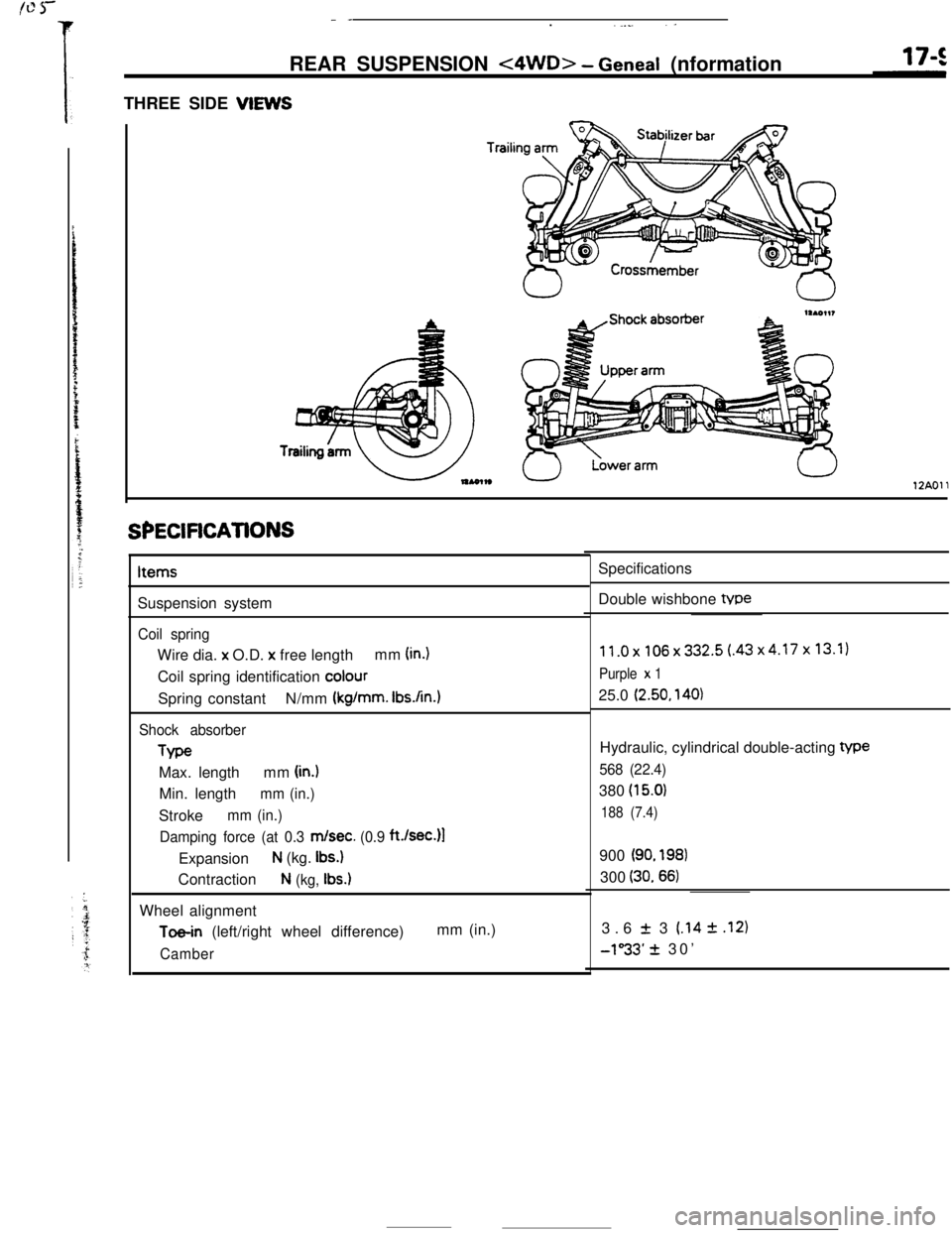

REAR SUSPENSION

<4WD> - Geneal (nformation

THREE SIDE VIEWS

Trailil

12AOll

SPECiFiCATiONSItems

Suspension system

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification

colourSpring constantN/mm

(kg/mm. Ibs.An.1

Shock absorberType

Max. lengthmm

(in.)Min. length

mm (in.)Stroke

mm (in.)

Damping force (at 0.3

m/set. (0.9 ft./sec.)l

Expansion

N (kg. Ibs.)Contraction

N (kg, Ibs.)Wheel alignment

Toe-in (left/right wheel difference)mm (in.)

CamberSpecifications

Double wishbone tvpe

11.0x106x332.5(.43x4.17x13.1)

Purple x 125.0

(2.50, 140)Hydraulic, cylindrical double-acting

We

568 (22.4)380

(15.0)

188 (7.4)900

(90. 198)300

(30.66)3.6

f 3 (.14 2 .I21

-1”33’ + 30’