ECU MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 55 of 391

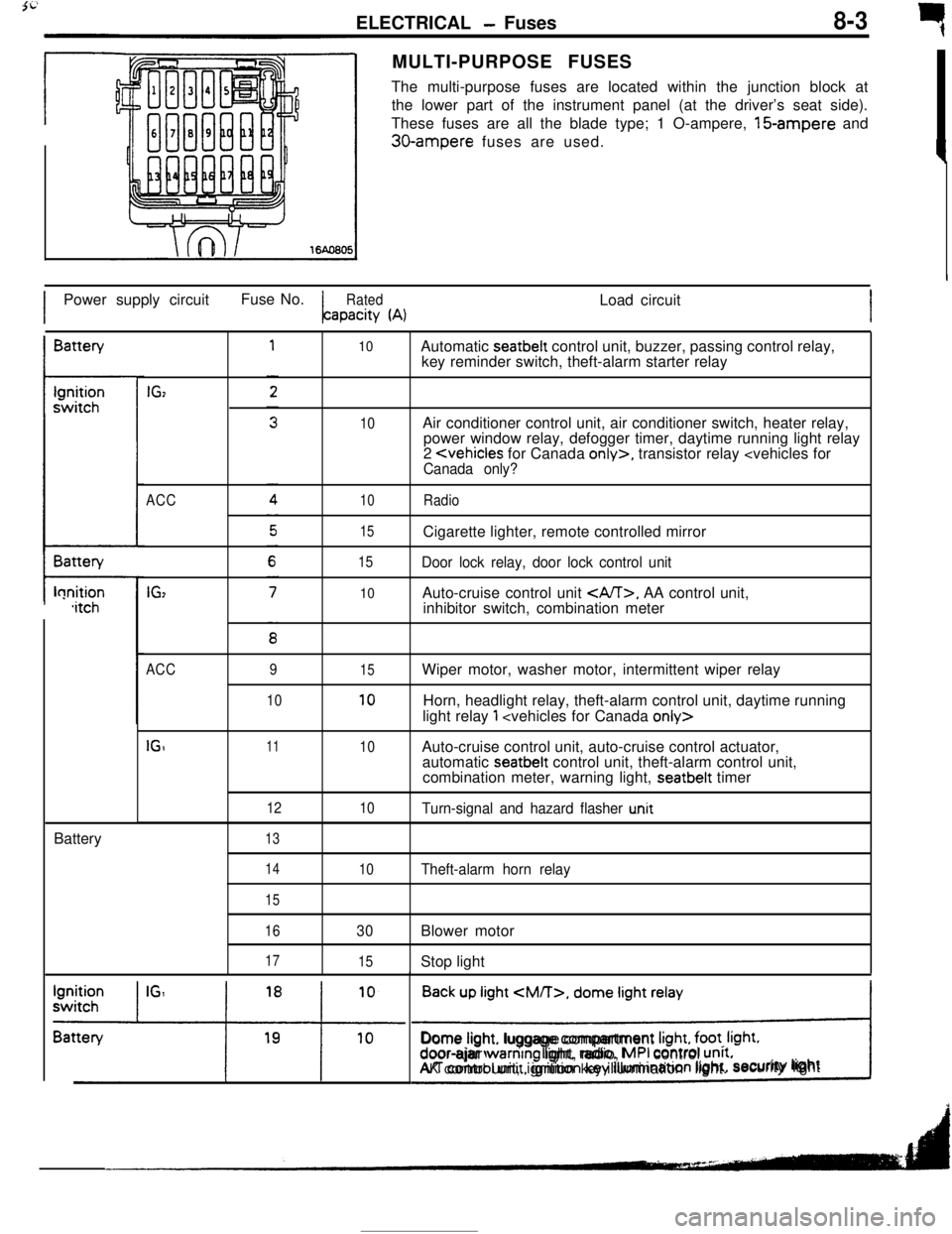

ELECTRICAL - Fuses8-3q

rMULTI-PURPOSE FUSES

The multi-purpose fuses are located within the junction block at

the lower part of the instrument panel (at the driver’s seat side).

These fuses are all the blade type; 1 O-ampere, 15-ampere and

30-ampere fuses are used.

IPower supply circuitFuse No.

RatedLoad circuitapacity

(A)IBattery

t-lonition,itchBattery

IGz

ACC

IG,

10

10

10

15

15

10Automatic seatbelt control unit, buzzer, passing control relay,

key reminder switch, theft-alarm starter relay

Air conditioner control unit, air conditioner switch, heater relay,

power window relay, defogger timer, daytime running light relay

2

Door lock relay, door lock control unitAuto-cruise control unit

, AA control unit,

inhibitor switch, combination meter

ACC

IGI9

1011

12

1315

10

10

10Wiper motor, washer motor, intermittent wiper relay

Horn, headlight relay, theft-alarm control unit, daytime running

light relay

1

automatic seatbelt control unit, theft-alarm control unit,

combination meter, warning light, seatbelt timer

Turn-signal and hazard flasher u.nit

14

15

16

17

10Theft-alarm horn relay

30Blower motor

15Stop light

Back up light

CM/T>, dome light relay

!Dome light. luggage compartment

Irght, foot. Irght.door-ajar warntng light, radio, MPI control unrt.AK control unit, ignition key illumination light.security lightI

Page 80 of 391

8-28ELECTRICAL- Engine Electrical

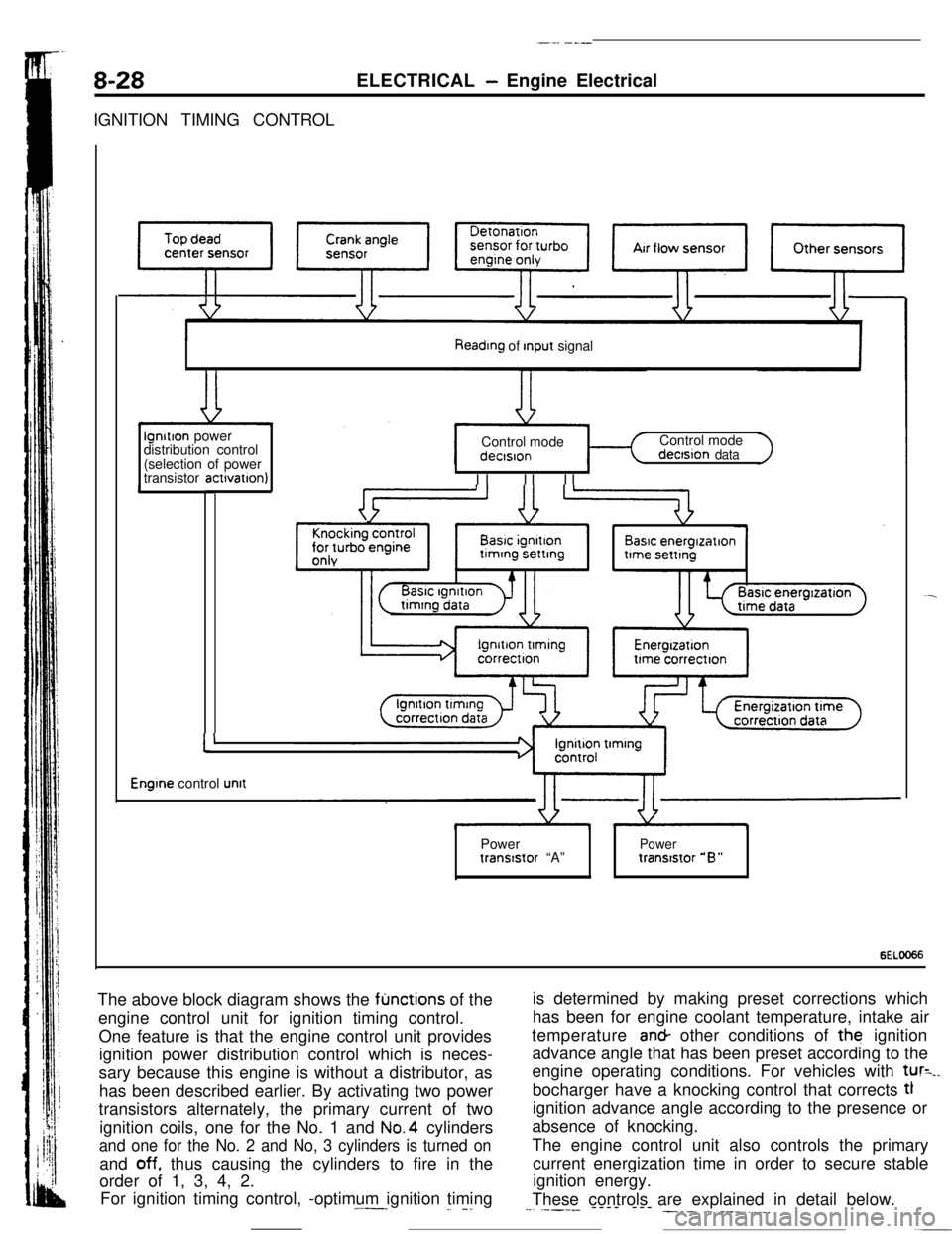

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__

Page 82 of 391

8-30ELECTRICAL - Engine Electrical

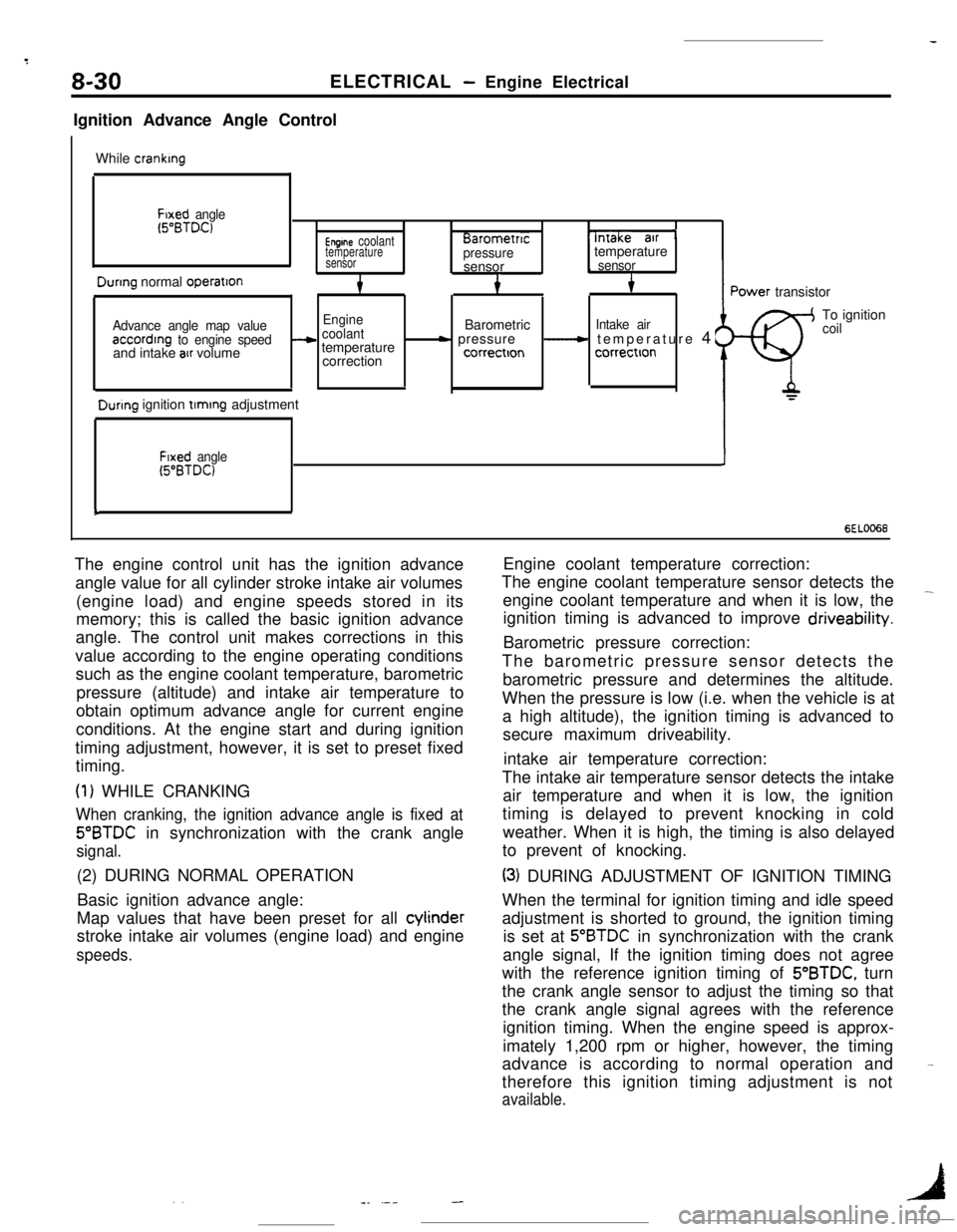

Ignition Advance Angle Control

While

cranking

Fixed angle(5”BTD.C)Engme coolantBarometnc‘-Intake air 1temperaturepressuretemperaturesensorsensor, sensor

Dunng normal operatlon4i+

Advance angle map valueEngine

coolantBarometricIntake airaccording to engine speed4and intake air volumetemperature- pressure__c temperature 4

correctioncorrectloncorrectton

Durtng ignition tlmmg adjustment

Fixed angle(5”BTDC)

c

=ower transistor

-$To ignition

coil

s

6EL0066The engine control unit has the ignition advance

angle value for all cylinder stroke intake air volumes

(engine load) and engine speeds stored in its

memory; this is called the basic ignition advance

angle. The control unit makes corrections in this

value according to the engine operating conditions

such as the engine coolant temperature, barometric

pressure (altitude) and intake air temperature to

obtain optimum advance angle for current engine

conditions. At the engine start and during ignition

timing adjustment, however, it is set to preset fixed

timing.

(1) WHILE CRANKING

When cranking, the ignition advance angle is fixed at

5”BTDC in synchronization with the crank angle

signal.(2) DURING NORMAL OPERATION

Basic ignition advance angle:

Map values that have been preset for all cylinder

stroke intake air volumes (engine load) and engine

speeds.Engine coolant temperature correction:

The engine coolant temperature sensor detects the

engine coolant temperature and when it is low, the

-ignition timing is advanced to improve driveability.

Barometric pressure correction:

The barometric pressure sensor detects the

barometric pressure and determines the altitude.

When the pressure is low (i.e. when the vehicle is at

a high altitude), the ignition timing is advanced to

secure maximum driveability.

intake air temperature correction:

The intake air temperature sensor detects the intake

air temperature and when it is low, the ignition

timing is delayed to prevent knocking in cold

weather. When it is high, the timing is also delayed

to prevent of knocking.

(3) DURING ADJUSTMENT OF IGNITION TIMING

When the terminal for ignition timing and idle speed

adjustment is shorted to ground, the ignition timing

is set at

5”BTDC in synchronization with the crank

angle signal, If the ignition timing does not agree

with the reference ignition timing of 5’BTDC, turn

the crank angle sensor to adjust the timing so that

the crank angle signal agrees with the reference

ignition timing. When the engine speed is approx-

imately 1,200 rpm or higher, however, the timing

advance is according to normal operation and

therefore this ignition timing adjustment is not

available.

-

. .1-_ .---

Page 83 of 391

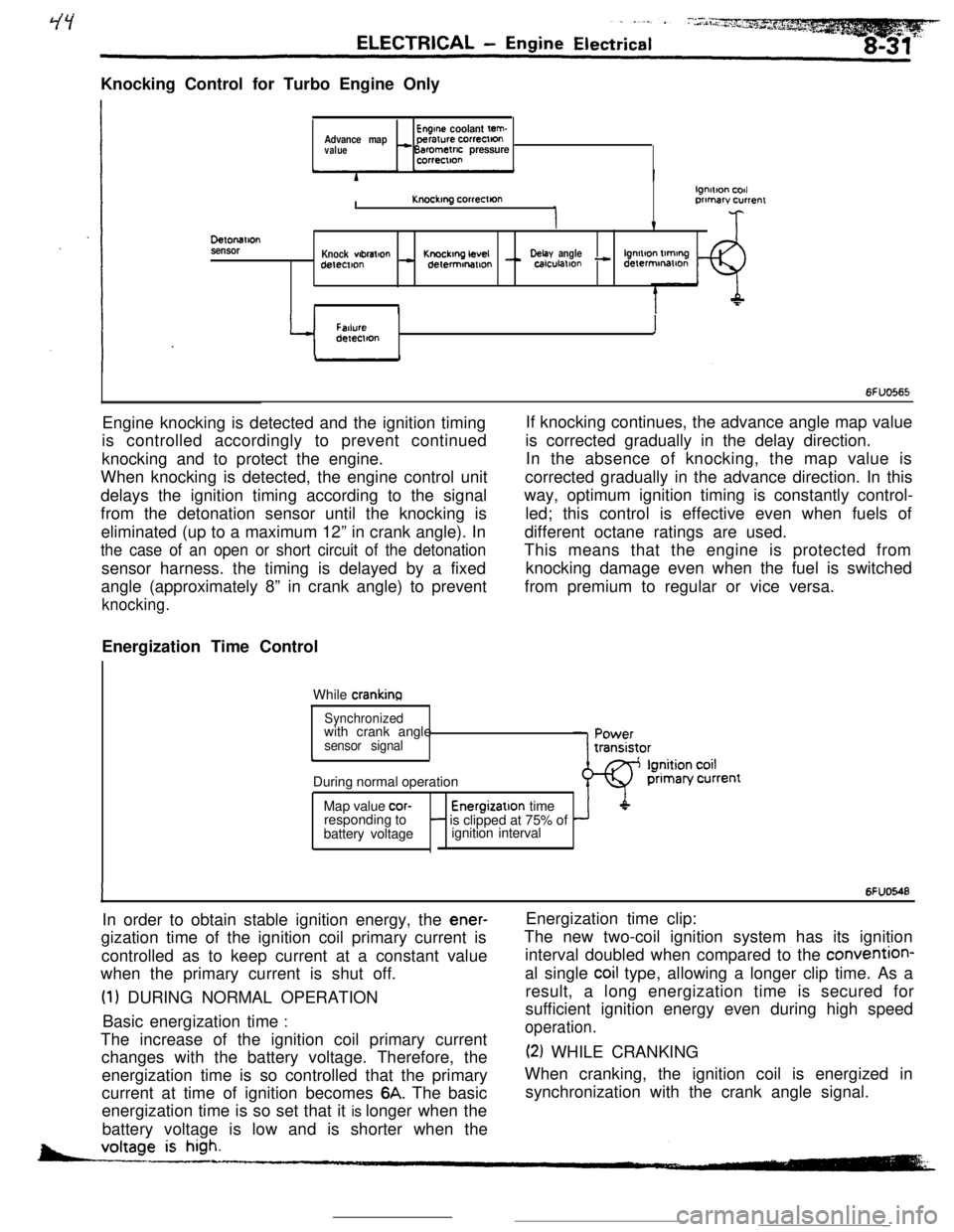

Knocking Control for Turbo Engine OnlyEngine coolant tern.Advance mapperarure correctton

value- Barometric pressurecorrectton

DelonaIlon

sensorI

lgnmon codKnockmg correcllonprimary currenr

v

Knock wbral+onKnockmg LevelDelay anglelgnmon tlmtngdetemon- delermonmon - calculallon - derermmatlon

II

Y

FatlureIdeIeclton

6FUO565Engine knocking is detected and the ignition timing

is controlled accordingly to prevent continued

knocking and to protect the engine.

When knocking is detected, the engine control unit

delays the ignition timing according to the signal

from the detonation sensor until the knocking is

eliminated (up to a maximum 12” in crank angle). In

the case of an open or short circuit of the detonationsensor harness. the timing is delayed by a fixed

angle (approximately 8” in crank angle) to prevent

knocking.Energization Time Control

While

crankinaIf knocking continues, the advance angle map value

is corrected gradually in the delay direction.

In the absence of knocking, the map value is

corrected gradually in the advance direction. In this

way, optimum ignition timing is constantly control-

led; this control is effective even when fuels of

different octane ratings are used.

This means that the engine is protected from

knocking damage even when the fuel is switched

from premium to regular or vice versa.

Synchronizedwith crank angle

sensor signalcDuring normal operation

Map value

cor-Energizatlon time

responding to- is clipped at 75% of

battery voltageignition interval

IIn order to obtain stable ignition energy, the

ener-gization time of the ignition coil primary current is

controlled as to keep current at a constant value

when the primary current is shut off.

(1) DURING NORMAL OPERATION

Basic energization time

:The increase of the ignition coil primary current

changes with the battery voltage. Therefore, the

energization time is so controlled that the primary

current at time of ignition becomes

6A. The basic

energization time is so set that it is longer when the

battery voltage is low and is shorter when the

6FUO548Energization time clip:

The new two-coil ignition system has its ignition

interval doubled when compared to the convention-

al single

coil type, allowing a longer clip time. As a

result, a long energization time is secured for

sufficient ignition energy even during high speed

operation.

(2) WHILE CRANKING

When cranking, the ignition coil is energized in

synchronization with the crank angle signal.

-

Page 84 of 391

8-32ELECTRICAL - Theft-alarm System

THEFT-ALARM SYSTEM

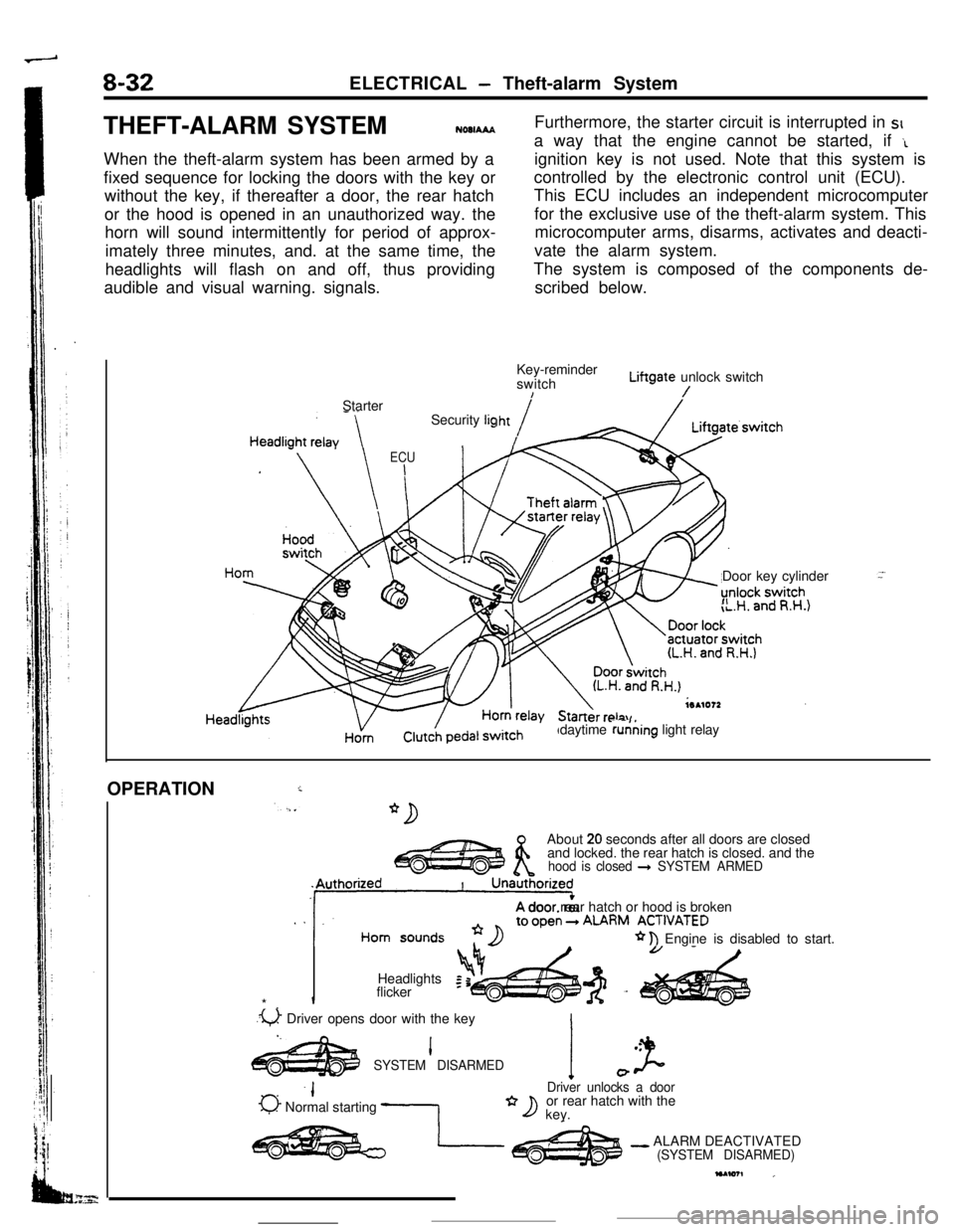

NOOIAAAWhen the theft-alarm system has been armed by a

fixed sequence for locking the doors with the key or

without the key, if thereafter a door, the rear hatch

or the hood is opened in an unauthorized way. the

horn will sound intermittently for period of approx-

imately three minutes, and. at the same time, the

headlights will flash on and off, thus providing

audible and visual warning. signals.Furthermore, the starter circuit is interrupted in SIa way that the engine cannot be started, if

‘Lignition key is not used. Note that this system is

controlled by the electronic control unit (ECU).

This ECU includes an independent microcomputer

for the exclusive use of the theft-alarm system. This

microcomputer arms, disarms, activates and deacti-

vate the alarm system.

The system is composed of the components de-

scribed below.

Key-reminder

switchLiftgate unlock switch

!/Starter

Door key cylinder

”daytime running light relay Security

lig

ECU

I

HornOPERATION

iAbout

20 seconds after all doors are closed

and locked. the rear hatch is closed. and the

hood is closed + SYSTEM ARMED

. .‘11A door rear hatch or hood is brokenALARM ACT,“ATED

* n Engine is disabled to start.

Headlights

Iflicker

*.

.u Driver opens door with the key

I.l .

SYSTEM DISARMEDI J-0

-IDriver unlocks a door

0 Normal starting -1or rear hatch with the*D key.

- ALARM DEACTIVATED(SYSTEM DISARMED)

Page 85 of 391

ELECTRICAL - Theft-alarm System8-33ARMING THE SYSTEM

After the following procedures have been completed, the SECURITY light illuminates for about 20 seconds,

and when illumination stops, the system is armed.

(1) Pull out the ignition key from the key cylinder.

(2) Open a door. (The other door is closed.)

(3) Lock the door with the key or the

keyless-locking method.

(The central door locking system will then function to lock all doors.)

NOTE(1) The system is set regardless of whether the hood and liftgate are open or

closed, and is armed as

soon as the light goes out.

(2) Even after the system has been armed, if the key is used to open the liftgate, the system will not be

activated; when the liftgate is then

closed, moreover, the system will be armed.

DISARMING THE SYSTEM

(1) The system will be disarmed if the key is used to unlock a door.

(2) If the system is armed while the driver is still in the vehicle, the system can be disarmed by inserting the

ignition key and turning it to the ACC or ON position.

(3) If the door lock is unlocked while closing the door or the door is ajar.

(4) If the door is unfastened while the SECURITY light illuminates.

ACTIVATING THE ALARM

(1) if an attempt is made to open a door, the liftgate or the hood, without using the key, while the system is

armed, the horn will sound intermittently and the headlights will flash on and off for approximately

three,

minutes.Furthermore, the starter circuit is interrupted at this time also, making starting of the engine impossible.

(2) if a further attempt at *forcible entry is made after the first three-minute alarm has finished, the

three-minute alarm will be activated again.

DEACTIVATING THE ALARM

(1) To deactivate the alarm, insert the key into the door’s key cylinder and turn the key.

(2) The alarm is deactivated and the system is disarmed when the iiftgate is unlocked with the key.

CHECKING THE SYSTEM OPERATION

The activation/operation of the system can be checked by following the steps below.

(1) Turn the ignition key to the ON position and then use the power-window switch to fully open the window

at the driver’s seat side.

(2) Turn the ignition key to the LOCK position and then remove the key from the ignition.

(3) Open only the driver’s door, and close all the other doors, as well as the hood and the rear hatch.

(4) Lock the driver’s door by the key or the

keyless-locking method.

(5) All doors will then be

locked, and the SECURITY light (within the combination meter) will illuminate; check

to be sure that illumination stops in about 20 seconds.

(6) After about two seconds have passed after the SECURITY light illumination stopped, reach through the

window of the driver’s door, pull up the lock lever to unlock the door, and then open the door.

(7) Check to be sure that, when the door is opened, the horn starts sounding and the headlights flash on and

Off.

(8) To stop the alarm, insert the key into the door’s key cylinder and turn the key.

!?iEeck the alarm for the opening of the liftgate or hood open the liftgate (or the hood) by using the

remote liftgate release lever (or the hood release lever),

located at the driver’s seat side either before the

alarm is activated by the opening of a door, or after the finish of the first three-minute alarm.

Page 153 of 391

FUEL SYSTEM -Fuel Injection Control

14-41

During normal operation (including idling), the en-

gine control unit controls the injector activation time

tcThieve the stoichiometric air/fuel ratio, which

e.;res maximum efficiency of the catalytic conver-

ter, on the basis of the oxygen sensor signal.

When the air/fuel mixture is richer than the

stoichiometric ratio, there is less oxygen in the

exhaust gas and thus the oxygen sensor output

voltage is higher; hence a “mixture rich” signal is

input to the engine control unit. Then, the engine

control unit decreases the amount of fuel injected. If

the air/fuel ratio decreases to the point that and the

mixture becomes leaner than the stoichiometric

ratio, the oxygen concentration in the exhaust gas

increases and the oxygen sensor output voltage

becomes lower. Then, a “mixture lean” signal isinput to the engine control unit.

Upon input of this signal, the engine control unit

increases the feedback correction factor, thus caus-

ing more fuel to be injected.

By means of the above-mentioned controls (collec-

tively called “feedback control”), the air-fuel mixture

is maintained at the stoichiometric ratio.

Under the following specific conditions, this feed-

back control is not performed, in order to improve

driveability.

(11

(2)

::I

(5)While cranking the engine

During engine warm-up when engine coolant

temperature is less than

45°C (113°F)During acceleration/deceleration

During high load operation

When oxygen sensor is not functioning

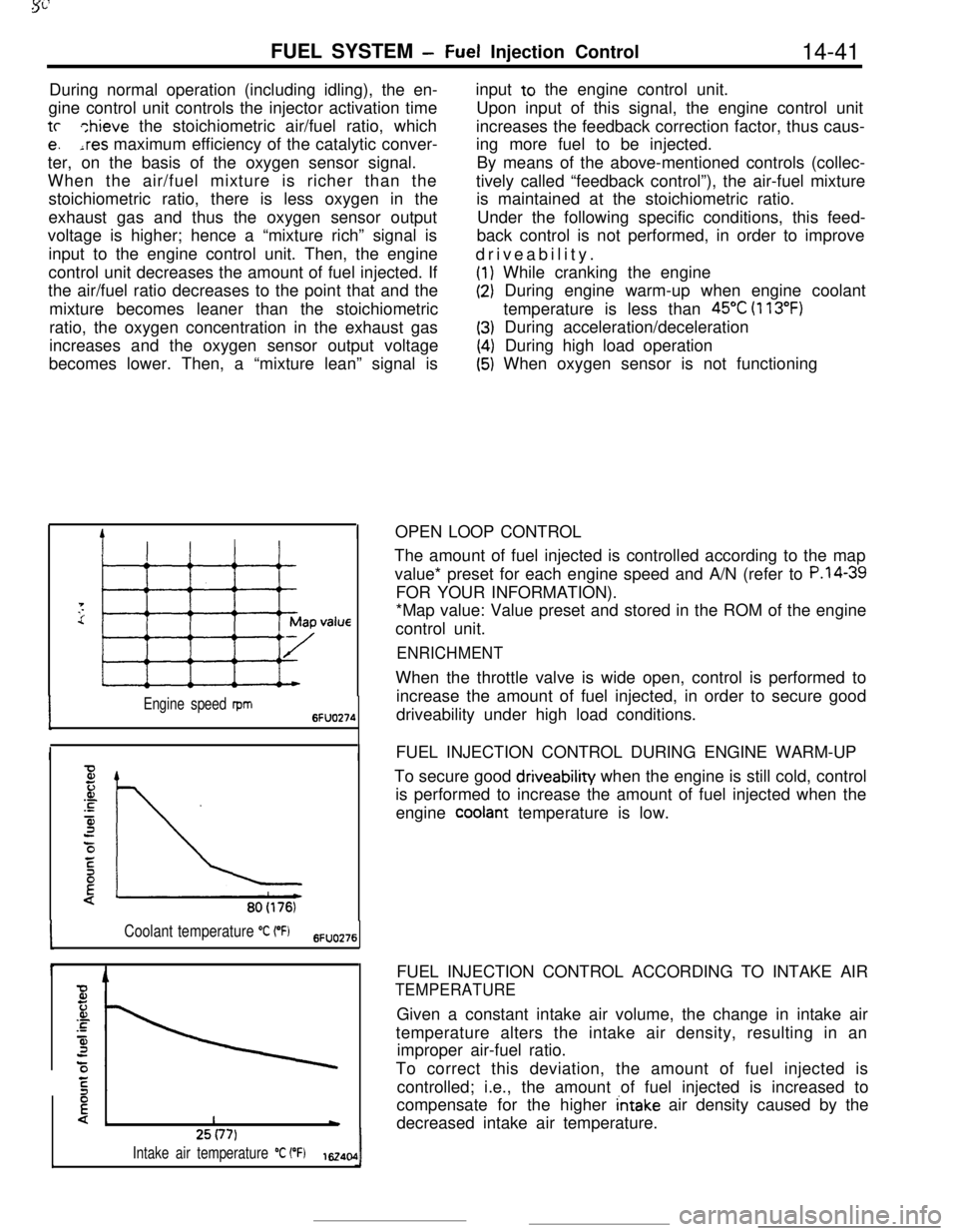

IOPEN LOOP CONTROL

Engine speed rpm6FUO274

II

80(176)

Coolant temperature “C (“Fj6FlJO276

I425(77)

Intake air temperature “C (“F)1~40,0IThe amount of fuel injected is controlled according to the map

value* preset for each engine speed and A/N (refer to

P.l4-39FOR YOUR INFORMATION).

*Map value: Value preset and stored in the ROM of the engine

control unit.

ENRICHMENTWhen the throttle valve is wide open, control is performed to

increase the amount of fuel injected, in order to secure good

driveability under high load conditions.

FUEL INJECTION CONTROL DURING ENGINE WARM-UP

To secure good driveability when the engine is still cold, control

is performed to increase the amount of fuel injected when the

engine

cooiant temperature is low.

FUEL INJECTION CONTROL ACCORDING TO INTAKE AIR

TEMPERATUREGiven a constant intake air volume, the change in intake air

temperature alters the intake air density, resulting in an

improper air-fuel ratio.

To correct this deviation, the amount of fuel injected is

controlled; i.e., the amount of fuel injected is increased to

compensate for the higher

intake air density caused by the

decreased intake air temperature.

Page 154 of 391

14-42

FUEL SYSTEM- Fuel Injection Control

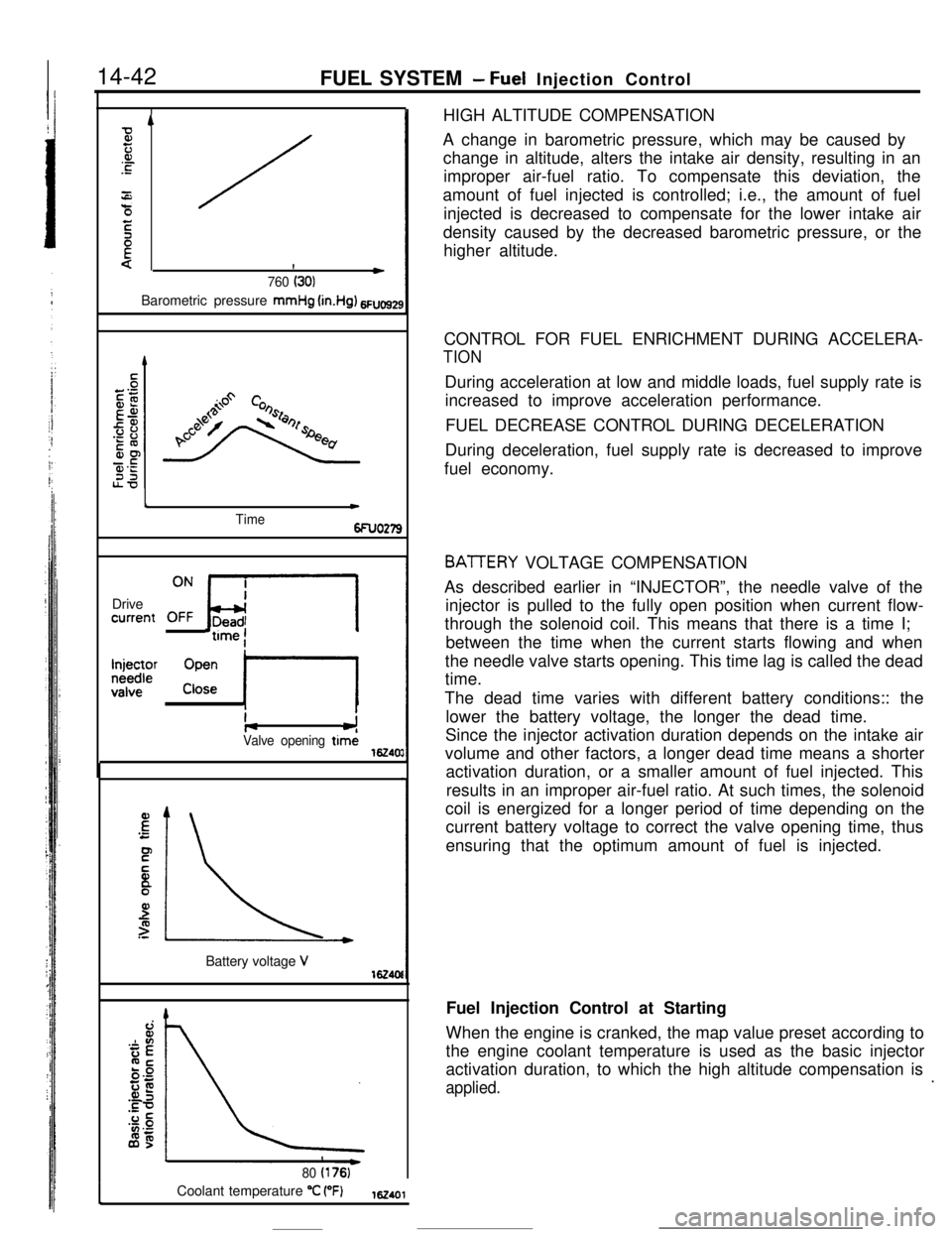

4

Fz.or.c

4:0/

E

{!*760 (301Barometric pressure

mmHg (in.Hg) 6Fuo9z

c

Timet

6FUO279Drivecurrent

0: bri

F2JJ’ ipe; II

I+-JValve opening timi16240:

E‘C

F

.-

is

3

3:\Battery voltage

V162406

80 (176)Coolant temperature

“C (“F)162401HIGH ALTITUDE COMPENSATION

A change in barometric pressure, which may be caused by

change in altitude, alters the intake air density, resulting in an

improper air-fuel ratio. To compensate this deviation, the

amount of fuel injected is controlled; i.e., the amount of fuel

injected is decreased to compensate for the lower intake air

density caused by the decreased barometric pressure, or the

higher altitude.

CONTROL FOR FUEL ENRICHMENT DURING ACCELERA-

TIONDuring acceleration at low and middle loads, fuel supply rate is

increased to improve acceleration performance.

FUEL DECREASE CONTROL DURING DECELERATION

During deceleration, fuel supply rate is decreased to improve

fuel economy.

BATTERY VOLTAGE COMPENSATION

As described earlier in “INJECTOR”, the needle valve of the

injector is pulled to the fully open position when current flow-

through the solenoid coil. This means that there is a time I;

between the time when the current starts flowing and when

the needle valve starts opening. This time lag is called the dead

time.

The dead time varies with different battery conditions:: the

lower the battery voltage, the longer the dead time.

Since the injector activation duration depends on the intake air

volume and other factors, a longer dead time means a shorter

activation duration, or a smaller amount of fuel injected. This

results in an improper air-fuel ratio. At such times, the solenoid

coil is energized for a longer period of time depending on the

current battery voltage to correct the valve opening time, thus

ensuring that the optimum amount of fuel is injected.

Fuel Injection Control at Starting

When the engine is cranked, the map value preset according to

the engine coolant temperature is used as the basic injector

activation duration, to which the high altitude compensation is

applied..

Page 184 of 391

14-72

._FUEL SYSTEM

- Auto-cruise Control System

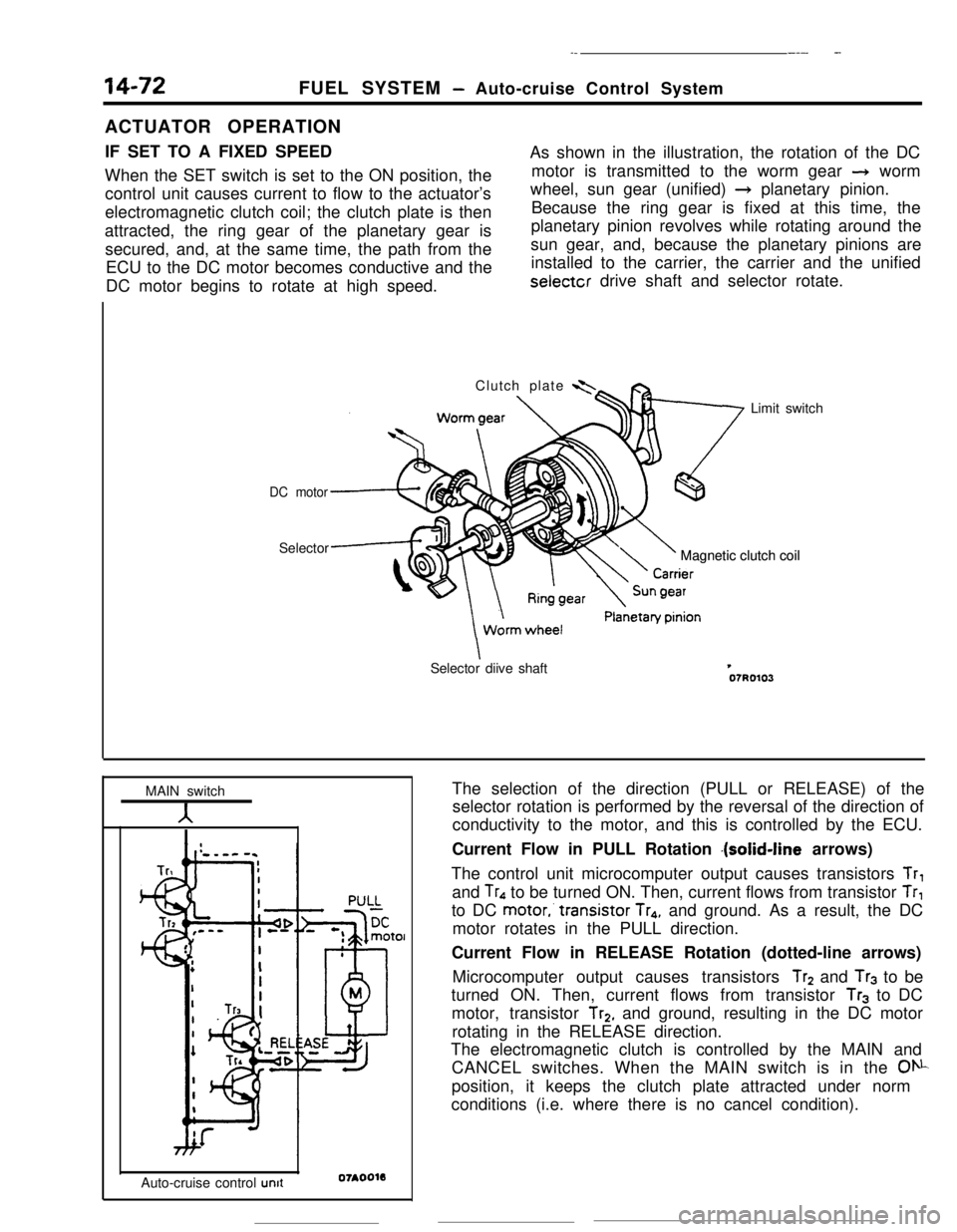

___ -ACTUATOR OPERATION

IF SET TO A FIXED SPEED

When the SET switch is set to the ON position, the

control unit causes current to flow to the actuator’s

electromagnetic clutch coil; the clutch plate is then

attracted, the ring gear of the planetary gear is

secured, and, at the same time, the path from the

ECU to the DC motor becomes conductive and the

DC motor begins to rotate at high speed.As shown in the illustration, the rotation of the DC

motor is transmitted to the worm gear

--, worm

wheel, sun gear (unified)

+ planetary pinion.

Because the ring gear is fixed at this time, the

planetary pinion revolves while rotating around the

sun gear, and, because the planetary pinions are

installed to the carrier, the carrier and the unifiedselectcr drive shaft and selector rotate.

Clutch plate

<

7 Limit switch

DC motorSelector

Magnetic clutch coil Magnetic clutch coil

Selector diive shaft

MAIN switchTrl

4sTn

aAuto-cruise control

unit07AOO11The selection of the direction (PULL or RELEASE) of the

selector rotation is performed by the reversal of the direction of

conductivity to the motor, and this is controlled by the ECU.

Current Flow in PULL Rotation

.(soiid-line arrows)

The control unit microcomputer output causes transistors

Tr,and Tr, to be turned ON. Then, current flows from transistor

Tr,to DC motor,‘transistor

Tr,, and ground. As a result, the DC

motor rotates in the PULL direction.

Current Flow in RELEASE Rotation (dotted-line arrows)

Microcomputer output causes transistors

Tr2 and Tr3 to be

turned ON. Then, current flows from transistor

Tr3 to DC

motor, transistor

Tr2, and ground, resulting in the DC motor

rotating in the RELEASE direction.

The electromagnetic clutch is controlled by the MAIN and

CANCEL switches. When the MAIN switch is in the

01\L.position, it keeps the clutch plate attracted under norm

conditions (i.e. where there is no cancel condition).

Page 188 of 391

- -----.--..

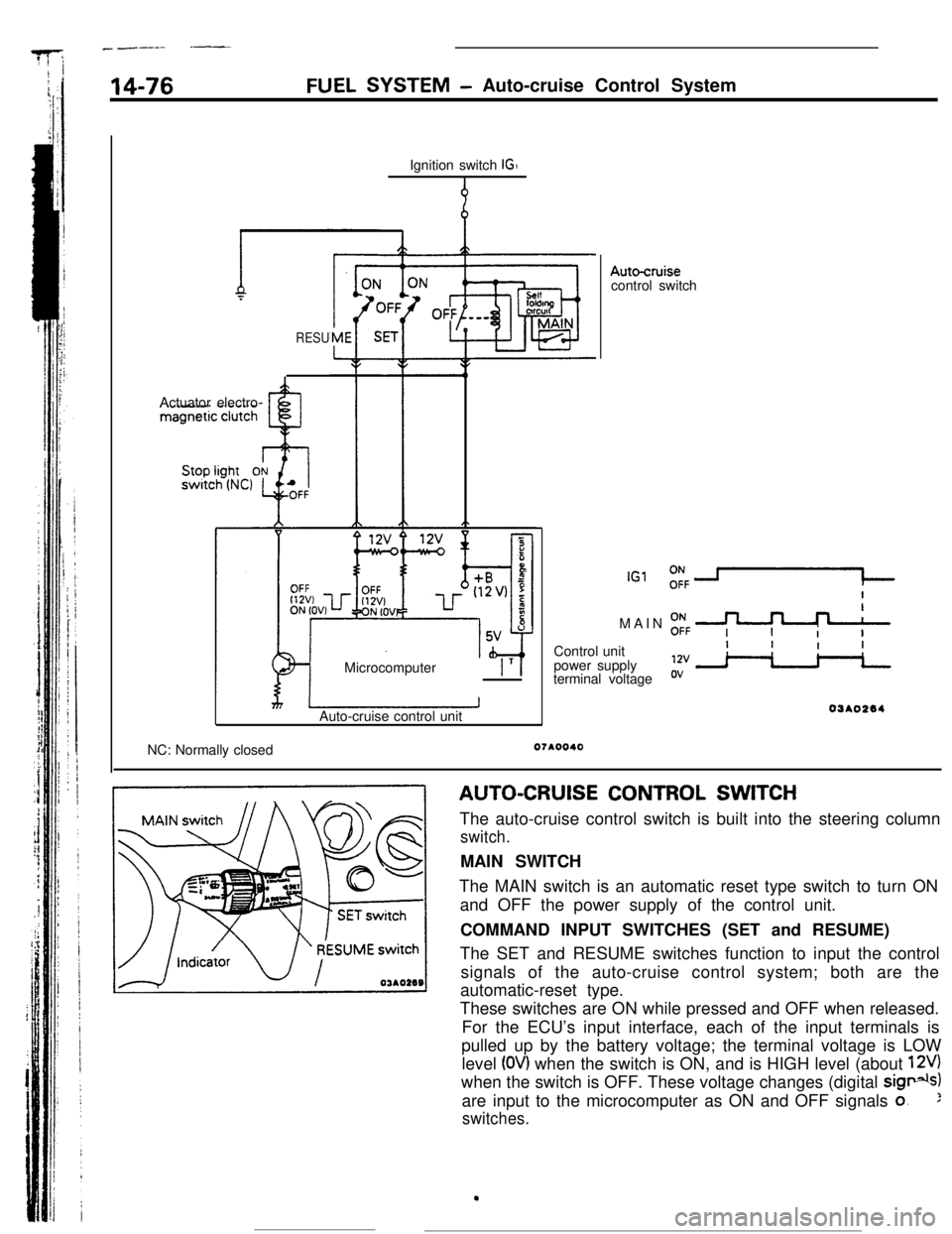

14-76FUEL SYSTEM -Auto-cruise Control System

Ignition switch

IGI

9

RESUActuator electro-

Microcomputer

1 T 1

rn’Auto-cruise control unit

Autocruisecontrol switch

IGlMAIN

;FF -+++&Control unit

power supply

terminal voltage

03AO264NC: Normally closed

07*0040

AUTO-CRUISE CONTROL SWITCH

The auto-cruise control switch is built into the steering column

switch.MAIN SWITCH

The MAIN switch is an automatic reset type switch to turn ON

and OFF the power supply of the control unit.

COMMAND INPUT SWITCHES (SET and RESUME)

The SET and RESUME switches function to input the control

signals of the auto-cruise control system; both are the

automatic-reset type.

These switches are ON while pressed and OFF when released.

For the ECU’s input interface, each of the input terminals is

pulled up by the battery voltage; the terminal voltage is LOW

level

(OV) when the switch is ON, and is HIGH level (about 12V)when the switch is OFF. These voltage changes (digital

sig*)are input to the microcomputer as ON and OFF signals

o.:

switches.

.