turn signal MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 55 of 391

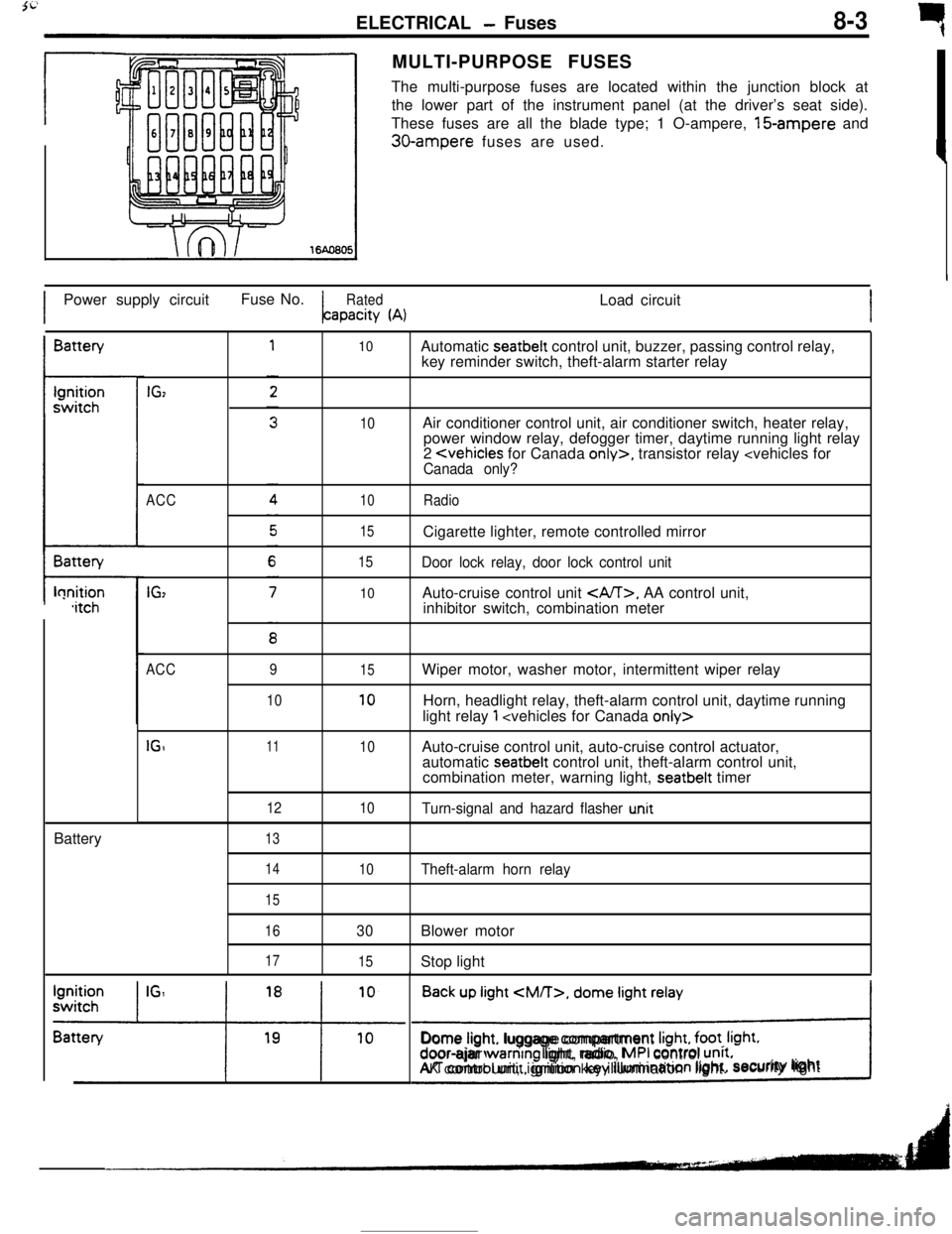

ELECTRICAL - Fuses8-3q

rMULTI-PURPOSE FUSES

The multi-purpose fuses are located within the junction block at

the lower part of the instrument panel (at the driver’s seat side).

These fuses are all the blade type; 1 O-ampere, 15-ampere and

30-ampere fuses are used.

IPower supply circuitFuse No.

RatedLoad circuitapacity

(A)IBattery

t-lonition,itchBattery

IGz

ACC

IG,

10

10

10

15

15

10Automatic seatbelt control unit, buzzer, passing control relay,

key reminder switch, theft-alarm starter relay

Air conditioner control unit, air conditioner switch, heater relay,

power window relay, defogger timer, daytime running light relay

2

Door lock relay, door lock control unitAuto-cruise control unit

, AA control unit,

inhibitor switch, combination meter

ACC

IGI9

1011

12

1315

10

10

10Wiper motor, washer motor, intermittent wiper relay

Horn, headlight relay, theft-alarm control unit, daytime running

light relay

1

automatic seatbelt control unit, theft-alarm control unit,

combination meter, warning light, seatbelt timer

Turn-signal and hazard flasher u.nit

14

15

16

17

10Theft-alarm horn relay

30Blower motor

15Stop light

Back up light

CM/T>, dome light relay

!Dome light. luggage compartment

Irght, foot. Irght.door-ajar warntng light, radio, MPI control unrt.AK control unit, ignition key illumination light.security lightI

Page 65 of 391

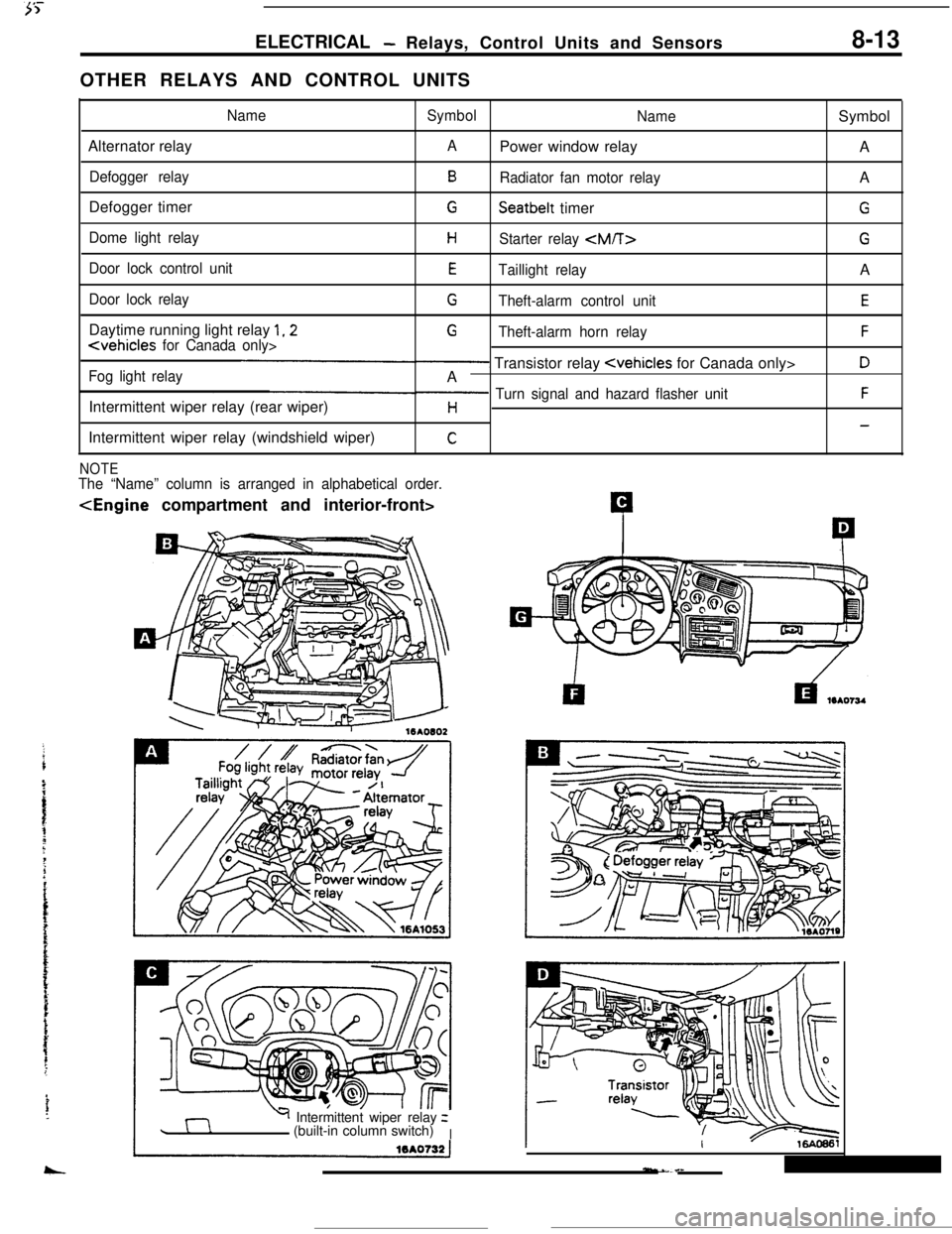

ELECTRICAL- Relays, Control Units and Sensors8-13OTHER RELAYS AND CONTROL UNITS

NameSymbol

NameSymbol

Alternator relay

APower window relay

A

Defogger relayBRadiator fan motor relayA

Defogger timer

GSeatbelt timerG

Dome light relayHStarter relay

Door lock control unitETaillight relayA

Door lock relayGTheft-alarm control unitEDaytime running light relay

1,2G

Fog light relay- Transistor relay

Intermittent wiper relay (rear wiper)

p Turn signal and hazard flasher unitFH-Intermittent wiper relay (windshield wiper)

C

NOTEThe “Name” column is arranged in alphabetical order.

Y Intermittent wiper relayz

(built-in column switch)

I

Page 69 of 391

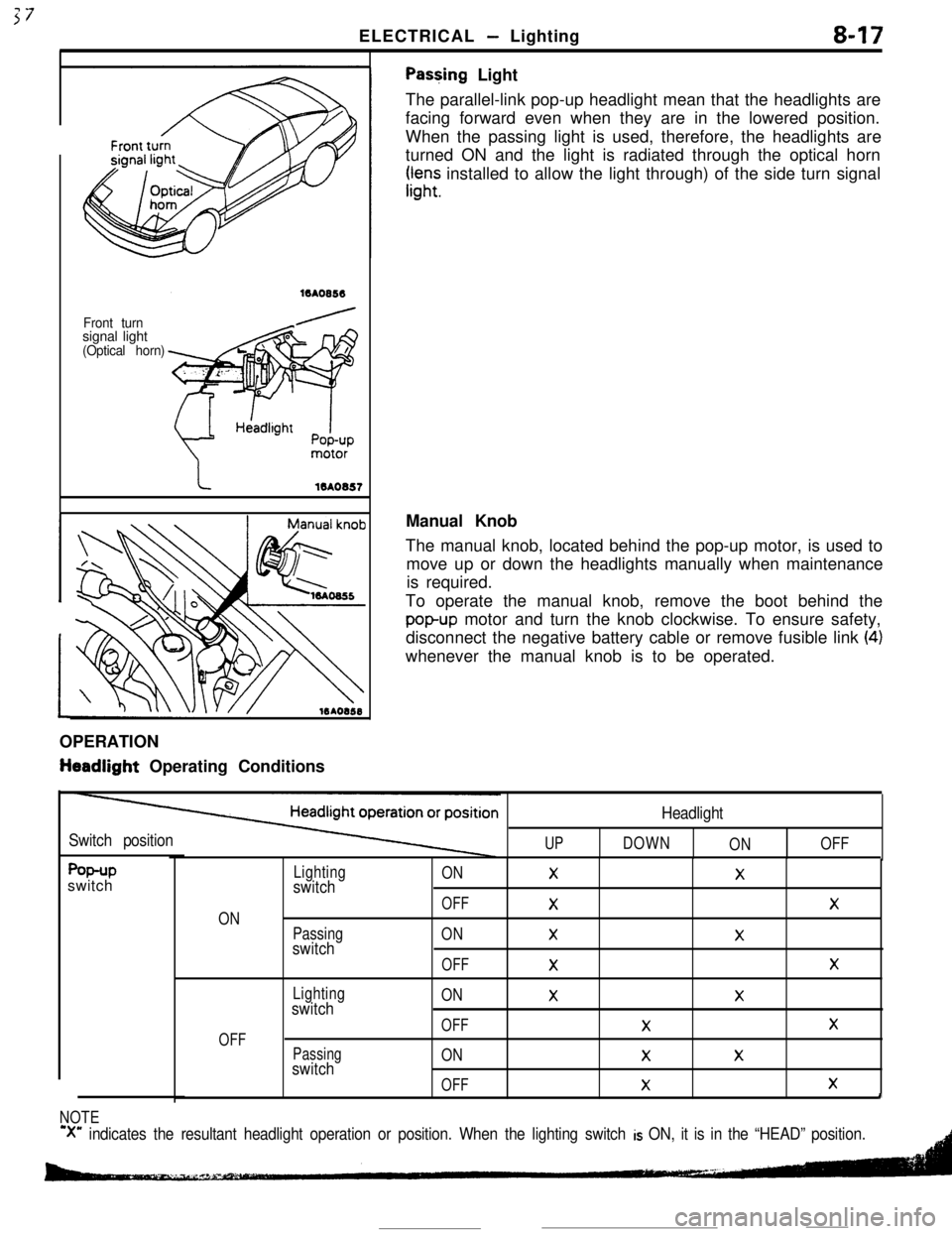

ELECTRICAL - Lighting8-17

Front turnsignal light

(Optical horn)

Pas+ing Light

The parallel-link pop-up headlight mean that the headlights are

facing forward even when they are in the lowered position.

When the passing light is used, therefore, the headlights are

turned ON and the light is radiated through the optical horn

rr,“;; installed to allow the light through) of the side turn signal

OPERATION

tieadlight Operating ConditionsManual Knob

The manual knob, located behind the pop-up motor, is used to

move up or down the headlights manually when maintenance

is required.

To operate the manual knob, remove the boot behind the

popup motor and turn the knob clockwise. To ensure safety,

disconnect the negative battery cable or remove fusible link

(4)whenever the manual knob is to be operated.

Switch positionUP

Headlight

DOWN

ONOFF

f%+Pswitch

ON

OFF

Lightingswitch

Passingswitch

Lightingswitch

Passingswitch

ONXX

OFF

XX

ONXX

OFF

XX

ONXX

OFFXX

ONXX

OFF

XXI

NOTE

‘X” indicates the resultant headlight operation or position. When the lighting switch is ON, it is in the “HEAD” position.

Page 78 of 391

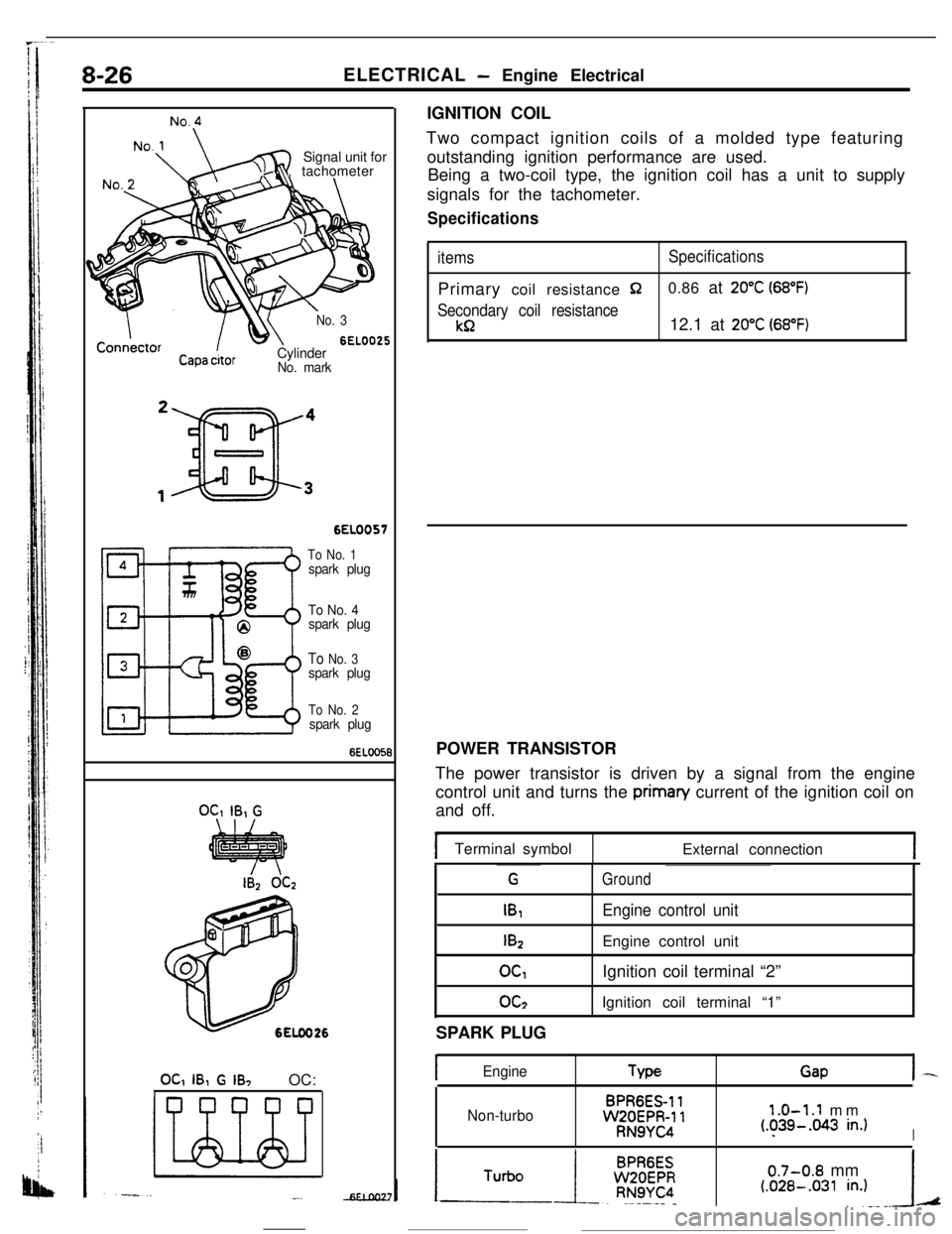

8-26ELECTRICAL - Engine Electrical

No.:

4Signal unit for

, tachometer

71

x

No. 3

6EL0025

Capa &orCylinderNo. mark

6EL0057

To No. 1spark plug

To No. 4

spark plug

To No. 3spark plug

To No. 2spark plug

6EL005t

OC,IB, G

OC, IB, G IB, OC:IGNITION COIL

Two compact ignition coils of a molded type featuring

outstanding ignition performance are used.

Being a two-coil type, the ignition coil has a unit to supply

signals for the tachometer.

Specifications

itemsSpecificationsPrimary coil resistance

$20.86 at 20°C (68°F)

Secondary coil resistance

kR12.1 at 20°C (68°F)POWER TRANSISTOR

The power transistor is driven by a signal from the engine

control unit and turns the priman/ current of the ignition coil on

and off.

Terminal symbol

External connection

G

IB,

I&

Ground

Engine control unitEngine control unit

OGoc2Ignition coil terminal “2”

Ignition coil terminal “1”

SPARK PLUG

IEngineTypeGapI-

Non-turboBPR6ES-11WZOEPR-11RN9YC4

1.0-1.1 mm(.?39-.043 in.)I

0.7-0.8 mm(.OZB-.031 in.)A

Page 80 of 391

8-28ELECTRICAL- Engine Electrical

IGNITION TIMING CONTROL

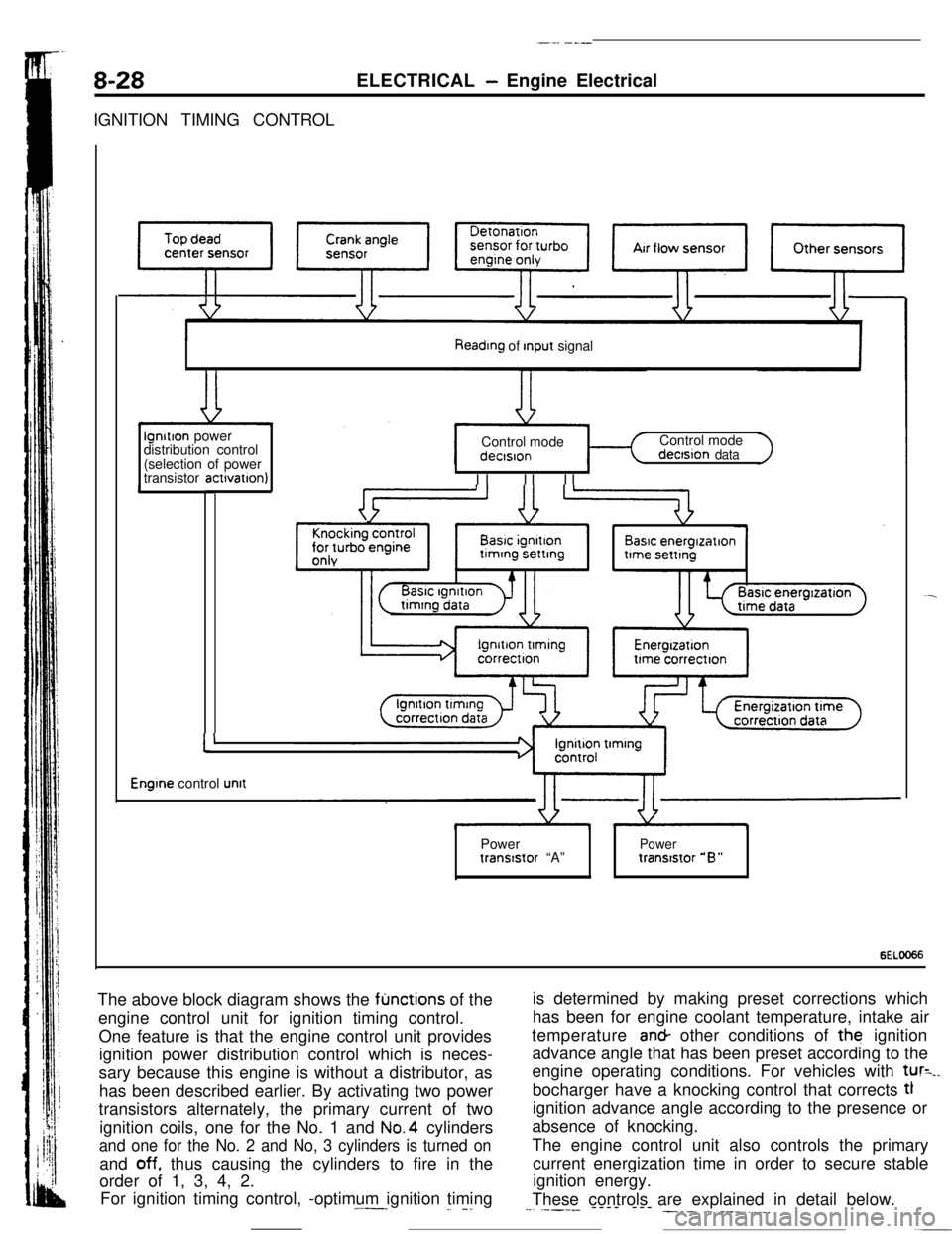

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__

Page 81 of 391

. ,-s- ,-T,“~:~y.“‘~...:tg==ELECTRICAL

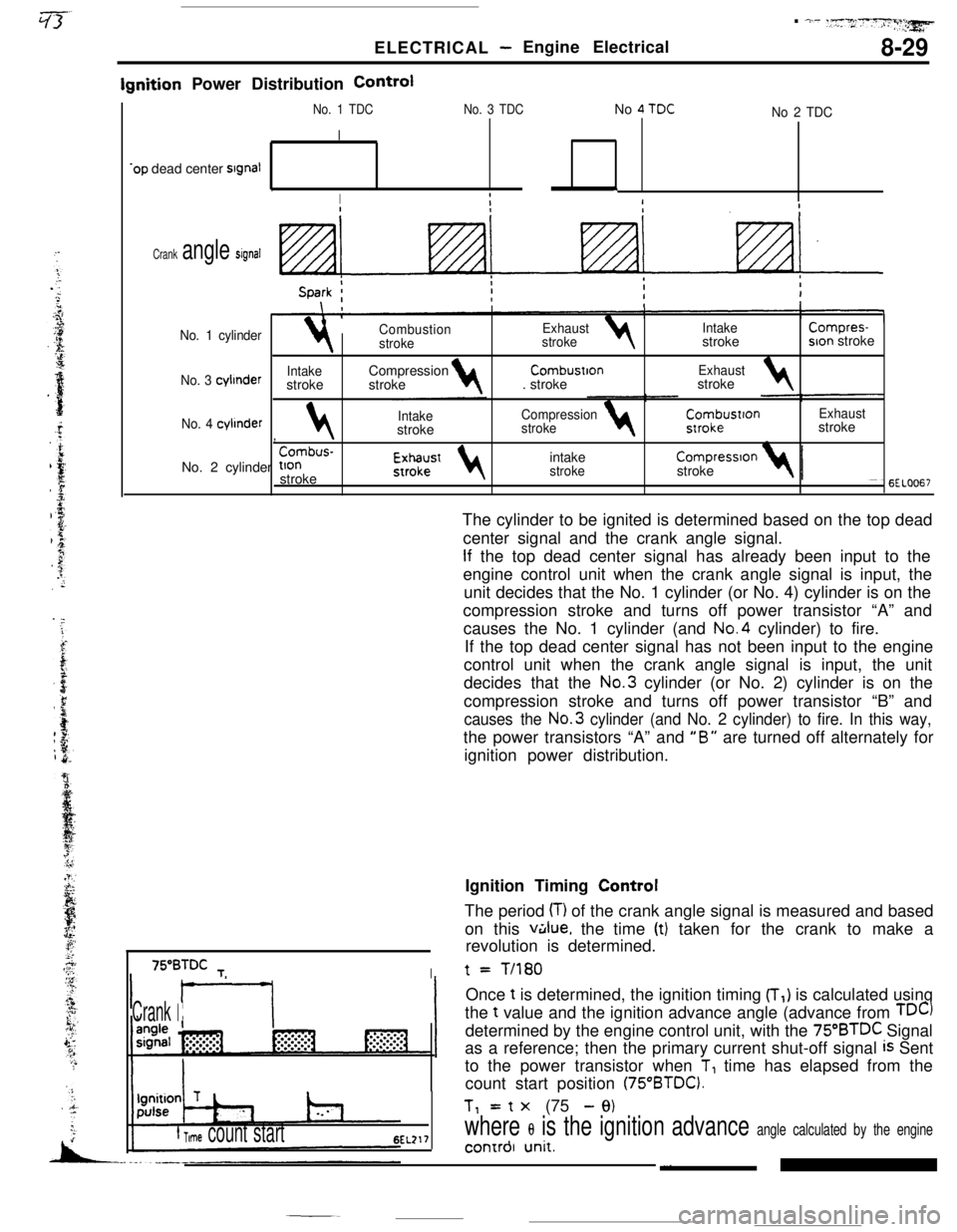

-Engine Electrical8-29Ignition Power Distribution Control

No. 1 TDC

I

No. 3 TDCNo 4TDCNo 2 TDC

‘op dead center signal,\

I1IIII

Crank angle signal

No. 1 cylinderCombustionExhaustIntakeCompres-

strokestrokestrokeslon stroke

IntakeCompression

t\

CombustionExhaust

No. 3 cyltnderstrokestroke. strokestroke

No. 4 cylinder, t\

IntakeCompressionstrokestroker$,mkbeustlonExhauststroke

Combus-No. 2 cylinder tlon

strokeintake

strokeCompresslon

stroke6EL0067

75”BTDC TI

Crank 1

f Time count start6EL217The cylinder to be ignited is determined based on the top dead

center signal and the crank angle signal.

If the top dead center signal has already been input to the

engine control unit when the crank angle signal is input, the

unit decides that the No. 1 cylinder (or No. 4) cylinder is on the

compression stroke and turns off power transistor “A” and

causes the No. 1 cylinder (and No.4 cylinder) to fire.

If the top dead center signal has not been input to the engine

control unit when the crank angle signal is input, the unit

decides that the No.3 cylinder (or No. 2) cylinder is on the

compression stroke and turns off power transistor “B” and

causes the No.3 cylinder (and No. 2 cylinder) to fire. In this way,the power transistors “A” and

“B” are turned off alternately for

ignition power distribution.t

= T/180Once

t is determined, the ignition timing (T,) is calculated using

the t value and the ignition advance angle (advance from

TDC)determined by the engine control unit, with the

75”BTDC Signal

as a reference; then the primary current shut-off signal

is Sent

to the power transistor when

T, time has elapsed from the

count start position

(75“BTDC).Tl= t

x (75 - 9)

where 8 is the ignition advance angle calculated by the engine_, ~4 -‘*Lonrrol unlr.Ignition Timing Control

The period

(T) of the crank angle signal is measured and based

on this

v&lue, the time (t) taken for the crank to make a

revolution is determined.

Page 82 of 391

8-30ELECTRICAL - Engine Electrical

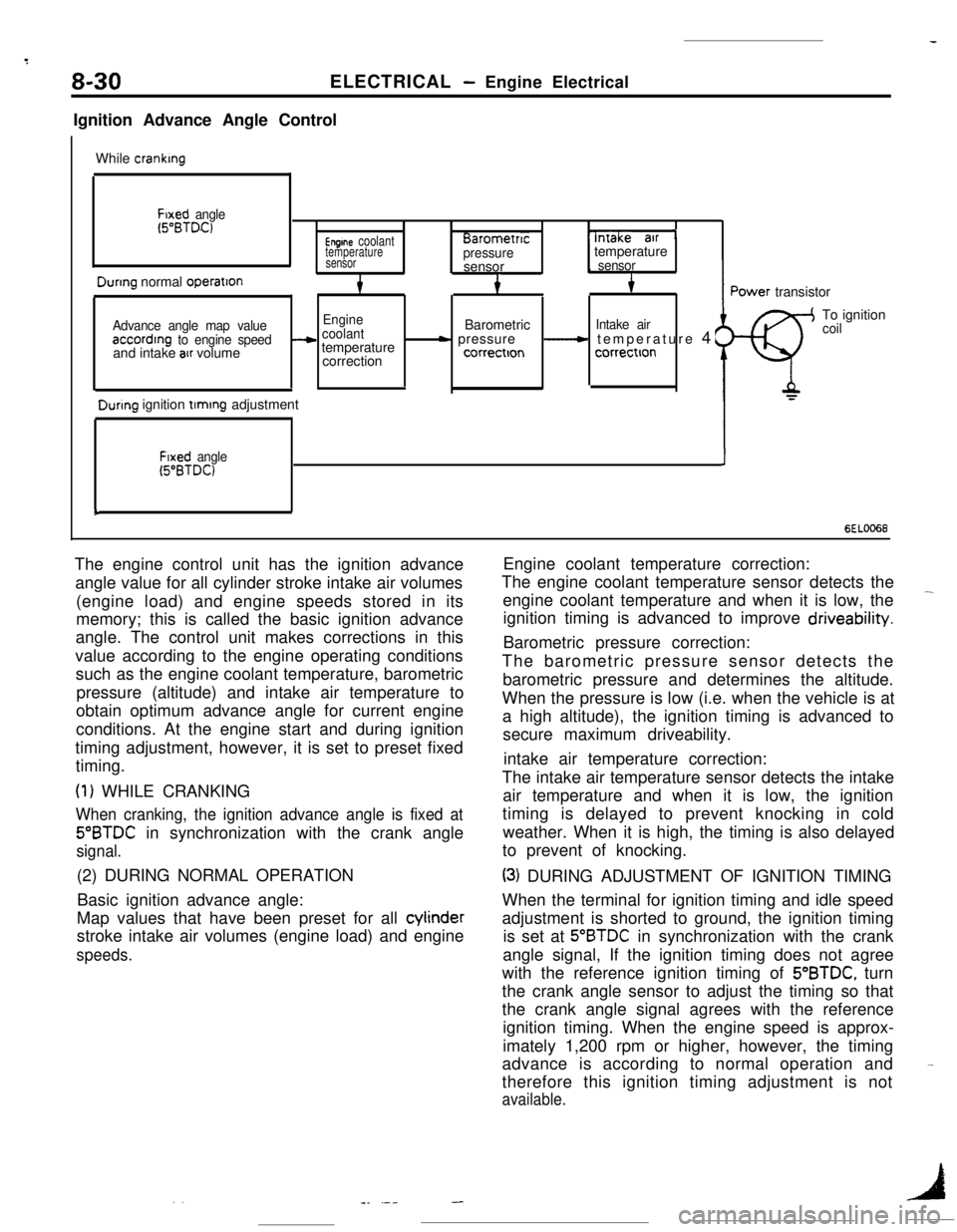

Ignition Advance Angle Control

While

cranking

Fixed angle(5”BTD.C)Engme coolantBarometnc‘-Intake air 1temperaturepressuretemperaturesensorsensor, sensor

Dunng normal operatlon4i+

Advance angle map valueEngine

coolantBarometricIntake airaccording to engine speed4and intake air volumetemperature- pressure__c temperature 4

correctioncorrectloncorrectton

Durtng ignition tlmmg adjustment

Fixed angle(5”BTDC)

c

=ower transistor

-$To ignition

coil

s

6EL0066The engine control unit has the ignition advance

angle value for all cylinder stroke intake air volumes

(engine load) and engine speeds stored in its

memory; this is called the basic ignition advance

angle. The control unit makes corrections in this

value according to the engine operating conditions

such as the engine coolant temperature, barometric

pressure (altitude) and intake air temperature to

obtain optimum advance angle for current engine

conditions. At the engine start and during ignition

timing adjustment, however, it is set to preset fixed

timing.

(1) WHILE CRANKING

When cranking, the ignition advance angle is fixed at

5”BTDC in synchronization with the crank angle

signal.(2) DURING NORMAL OPERATION

Basic ignition advance angle:

Map values that have been preset for all cylinder

stroke intake air volumes (engine load) and engine

speeds.Engine coolant temperature correction:

The engine coolant temperature sensor detects the

engine coolant temperature and when it is low, the

-ignition timing is advanced to improve driveability.

Barometric pressure correction:

The barometric pressure sensor detects the

barometric pressure and determines the altitude.

When the pressure is low (i.e. when the vehicle is at

a high altitude), the ignition timing is advanced to

secure maximum driveability.

intake air temperature correction:

The intake air temperature sensor detects the intake

air temperature and when it is low, the ignition

timing is delayed to prevent knocking in cold

weather. When it is high, the timing is also delayed

to prevent of knocking.

(3) DURING ADJUSTMENT OF IGNITION TIMING

When the terminal for ignition timing and idle speed

adjustment is shorted to ground, the ignition timing

is set at

5”BTDC in synchronization with the crank

angle signal, If the ignition timing does not agree

with the reference ignition timing of 5’BTDC, turn

the crank angle sensor to adjust the timing so that

the crank angle signal agrees with the reference

ignition timing. When the engine speed is approx-

imately 1,200 rpm or higher, however, the timing

advance is according to normal operation and

therefore this ignition timing adjustment is not

available.

-

. .1-_ .---

Page 115 of 391

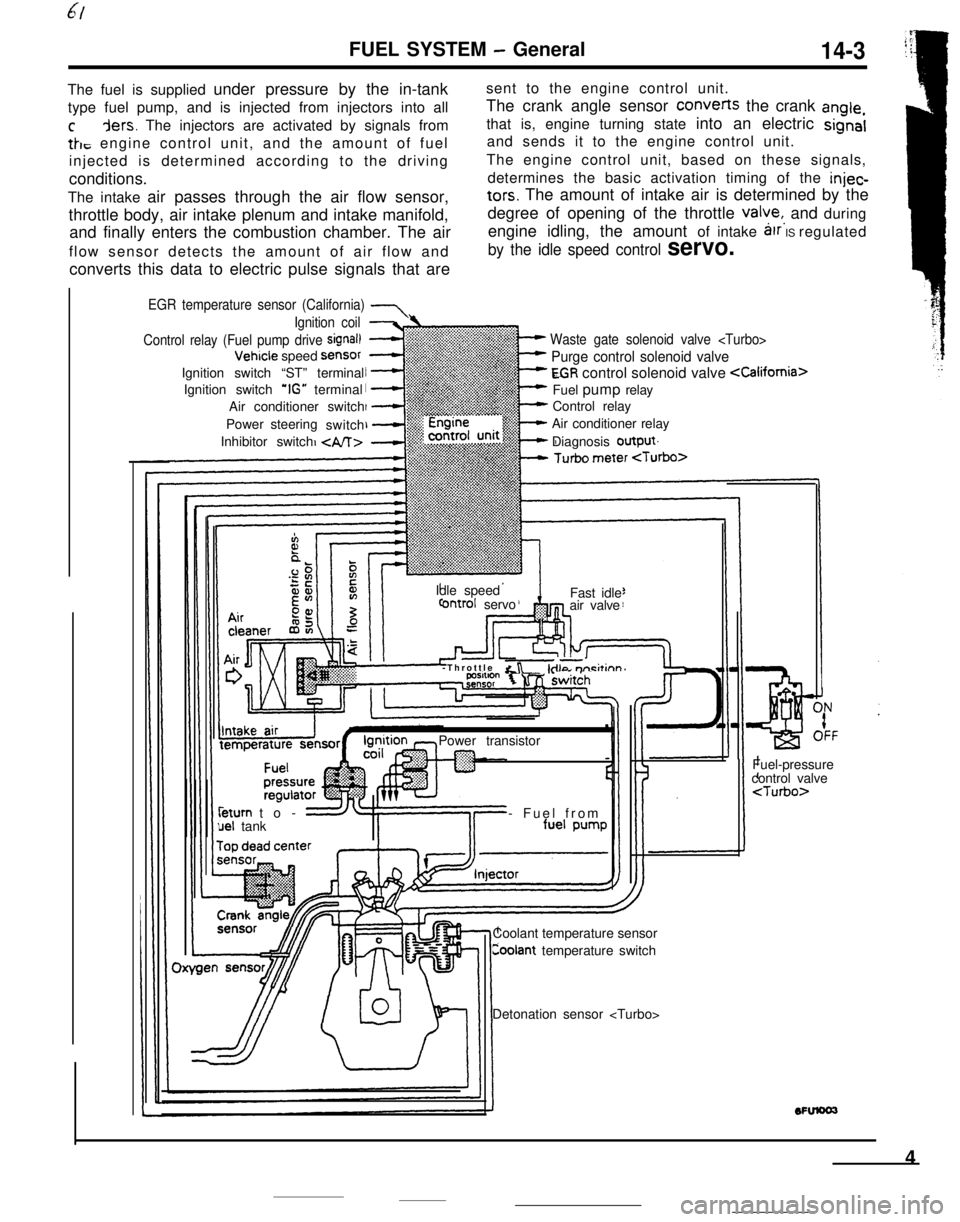

FUEL SYSTEM - General14-3The fuel is supplied under pressure by the in-tanksent to the engine control unit.

type fuel pump, and is injected from injectors into allThe crank angle sensor converts the crank

angle,

cders. The injectors are activated by signals fromthat is, engine turning state into an electric signal

tk, engine control unit, and the amount of fueland sends it to the engine control unit.

injected is determined according to the drivingThe engine control unit, based on these signals,

conditions.determines the basic activation timing of the

injec-The intake air passes through the air flow sensor,

tars. The amount of intake air is determined by the

throttle body, air intake plenum and intake manifold,degree of opening of the throttle

valye,, and during

and finally enters the combustion chamber. The airengine idling, the amount of intake

arr IS regulated

flow sensor detects the amount of air flow and

by the idle speed control servo.converts this data to electric pulse signals that are

EGR temperature sensor (California) 7

Waste gate solenoid valve

Purge control solenoid valve

EGR control solenoid valve

Control relay

Air conditioner relay

Diagnosis output

Ignition coil

Control relay (Fuel pump drive

signal)Vehicle speed

SensorIgnition switch “ST” terminal

Ignition switch

‘IG” terminal

Air conditioner switch

Power steering

switch

Inhibitor switch

Idle speed

ontrol servoFast idle

air valve

-Throttle

&r -kilo m-i&inn’Power transistorleturn to-

uel tank- Fuel from

Coolant temperature sensor

Coolant temperature switchFuel-pressure

control valve

4

Page 135 of 391

‘7JFUEL SYSTEM

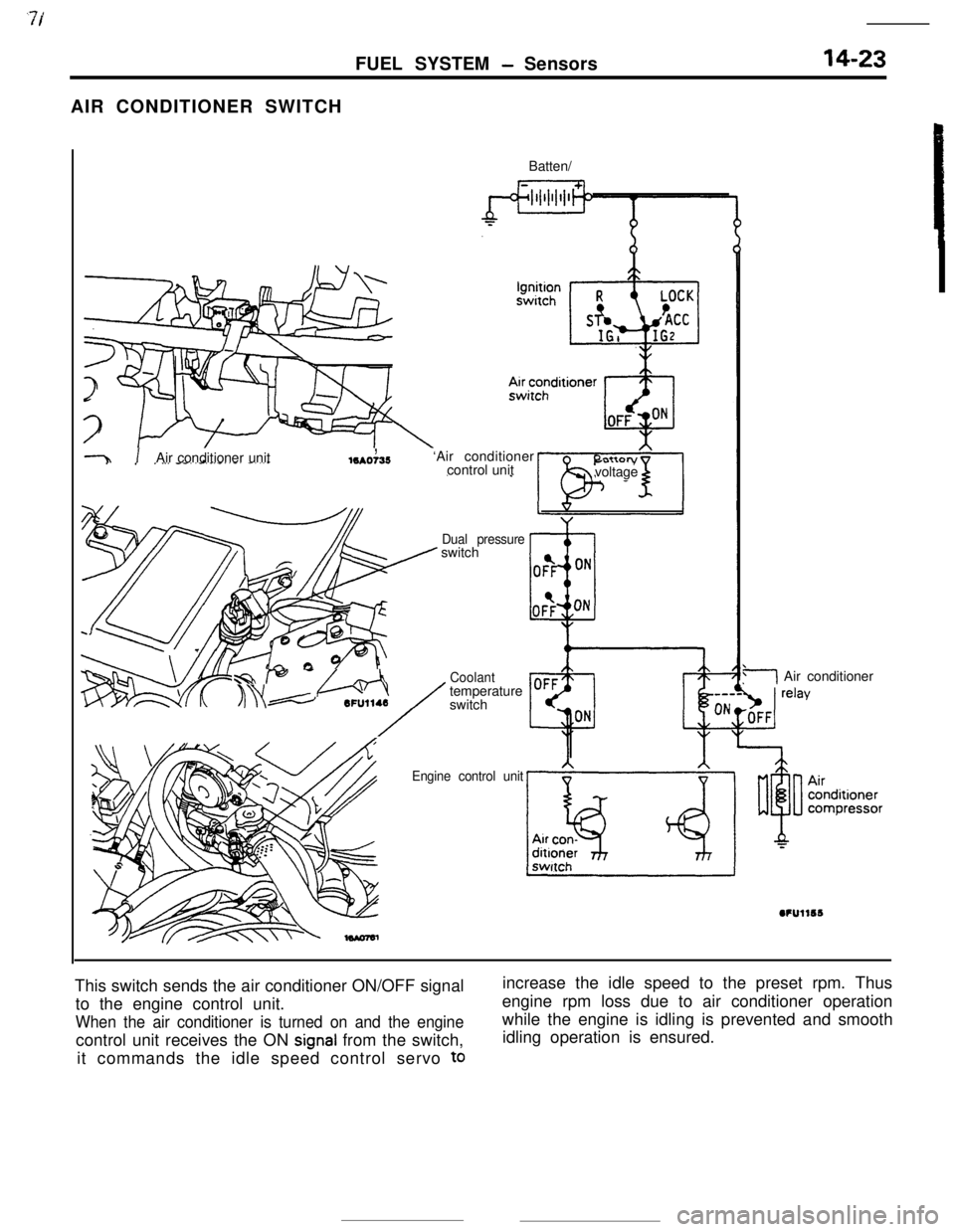

- Sensors14-23AIR CONDITIONER SWITCH

Batten/

-31 .,Air conditioner unitlSAO735‘Air conditioner

control unitI”.._. ,voltage

Dual pressureswitch

-f@ -//Q.j

/

Coolanttemperature6FU1148

switch

Engine control unit

3Air conditioner

This switch sends the air conditioner ON/OFF signal

to the engine control unit.

When the air conditioner is turned on and the enginecontrol unit receives the ON

signal from the switch,

it commands the idle speed control servo

toincrease the idle speed to the preset rpm. Thus

engine rpm loss due to air conditioner operation

while the engine is idling is prevented and smooth

idling operation is ensured.

Page 136 of 391

--

,

14-24FUEL SYSTEM - Sensors

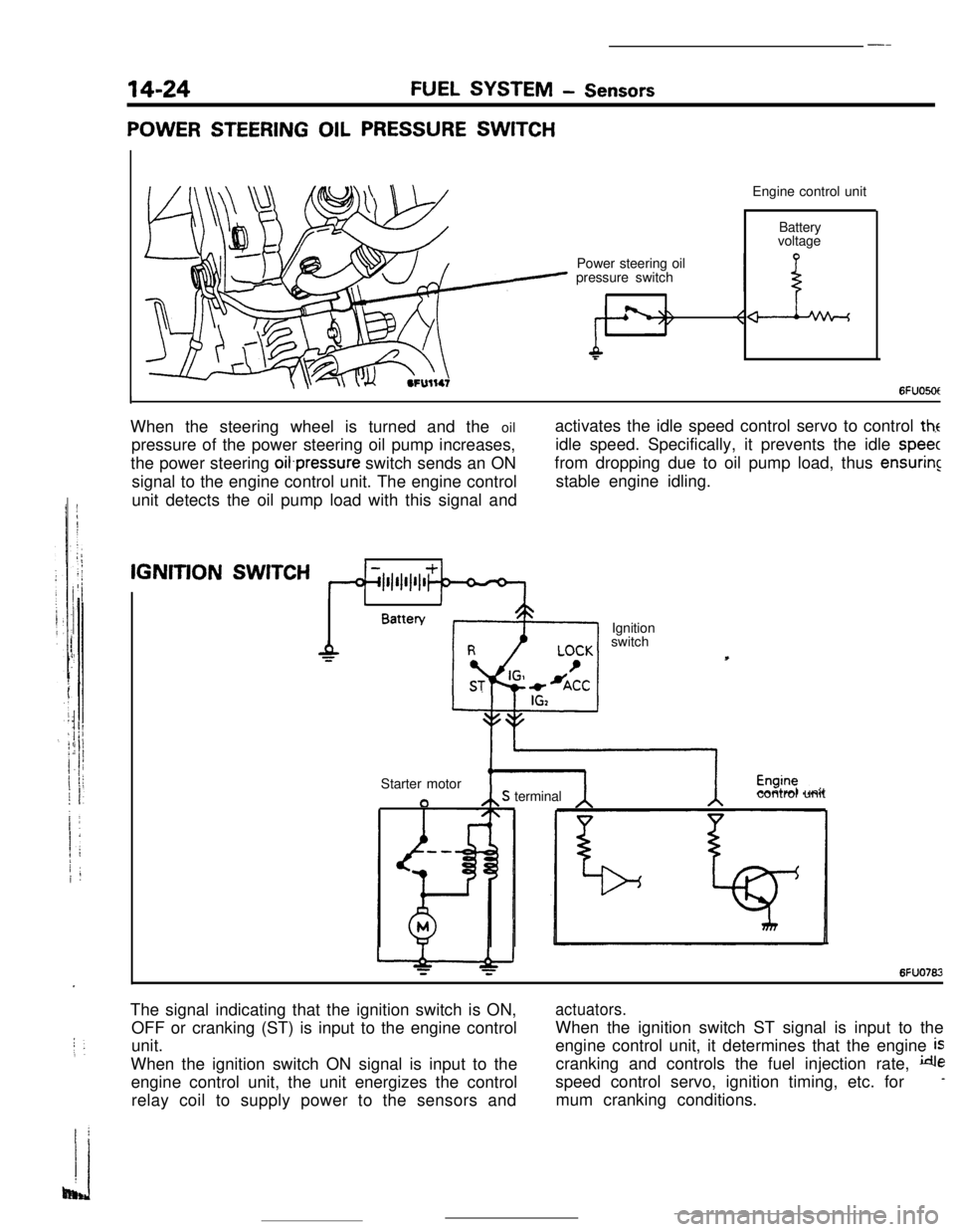

POWER STEERING OIL PRESSURE SWITCHEngine control unit

Power steering oil

pressure switchBattery

voltage

6FUO5OtIWhen the steering wheel is turned and the oil

pressure of the power steering oil pump increases,

the power steering oifpressure switch sends an ON

signal to the engine control unit. The engine control

unit detects the oil pump load with this signal andactivates the idle speed control servo to control

theidle speed. Specifically, it prevents the idle

speecfrom dropping due to oil pump load, thus

ensuringstable engine idling.IGNITION

SWITCH

1IBattery

Ignition

switch

Starter motor

aS terminalcontrol unit

6FUO762The signal indicating that the ignition switch is ON,

OFF or cranking (ST) is input to the engine control

unit.

When the ignition switch ON signal is input to the

engine control unit, the unit energizes the control

relay coil to supply power to the sensors and

actuators.When the ignition switch ST signal is input to the

engine control unit, it determines that the engine

iscranking and controls the fuel injection rate,

despeed control servo, ignition timing, etc. for

-mum cranking conditions.