engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1 of 1216

BACKUPGROUP INDEX &ma

;r Service Manual

LASER

TALON

1991

Volume-l

Engine, Chassis

& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

‘* publication.It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your originalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional information

Thank you. G~mm~emymanual@hotma~l.com

1,

wA

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design 0’: tomake additions to or improvements in its products without lmqoslngd ., . any obligations upon itself to install them on its products previouslymanufactured.

0 1990 Mitsubishi Motors CorporationPrinted in U.S.A.Introduction and

Master

Troubleshooting. . . . . .,. . . . . . . . . r...m,

Lubrication and Maintenance . . . . . . . . ‘-0‘8

; “. i,

.Front Suspension. . . . . . . . . . . . . . ..*............d...Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘.....................

/

ServiceBrakes-Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................‘t.

Cooling. . . . . . . . . . . . . . . . . ..i....................................

,., .‘,-,

Engine..i....~....r...............~....~.*,.~.~.~,‘~~...;..~~..Intake and Exhaust

. . . . . . ..L....................Fuel System

. . . . . . . . . . . ..ti.......r................~...Propeller Shaft

.......................................IRear

Suspensiori.............................y.f...

ManualSteering- Power.....................................Manual

I

transaxle-Automatic .............:;i...,;.....;Wheels

and Tires.................................

Body.............................................................Heater & Air Conditioning

..............Emission

Contr6l Systems..............

INOTE: For Electrical, refer toVolume-2 “Electrical”.

Page 2 of 1216

2INTRODUCTION AND MASTER TROUBLESHOOTING - How to Use This Manual

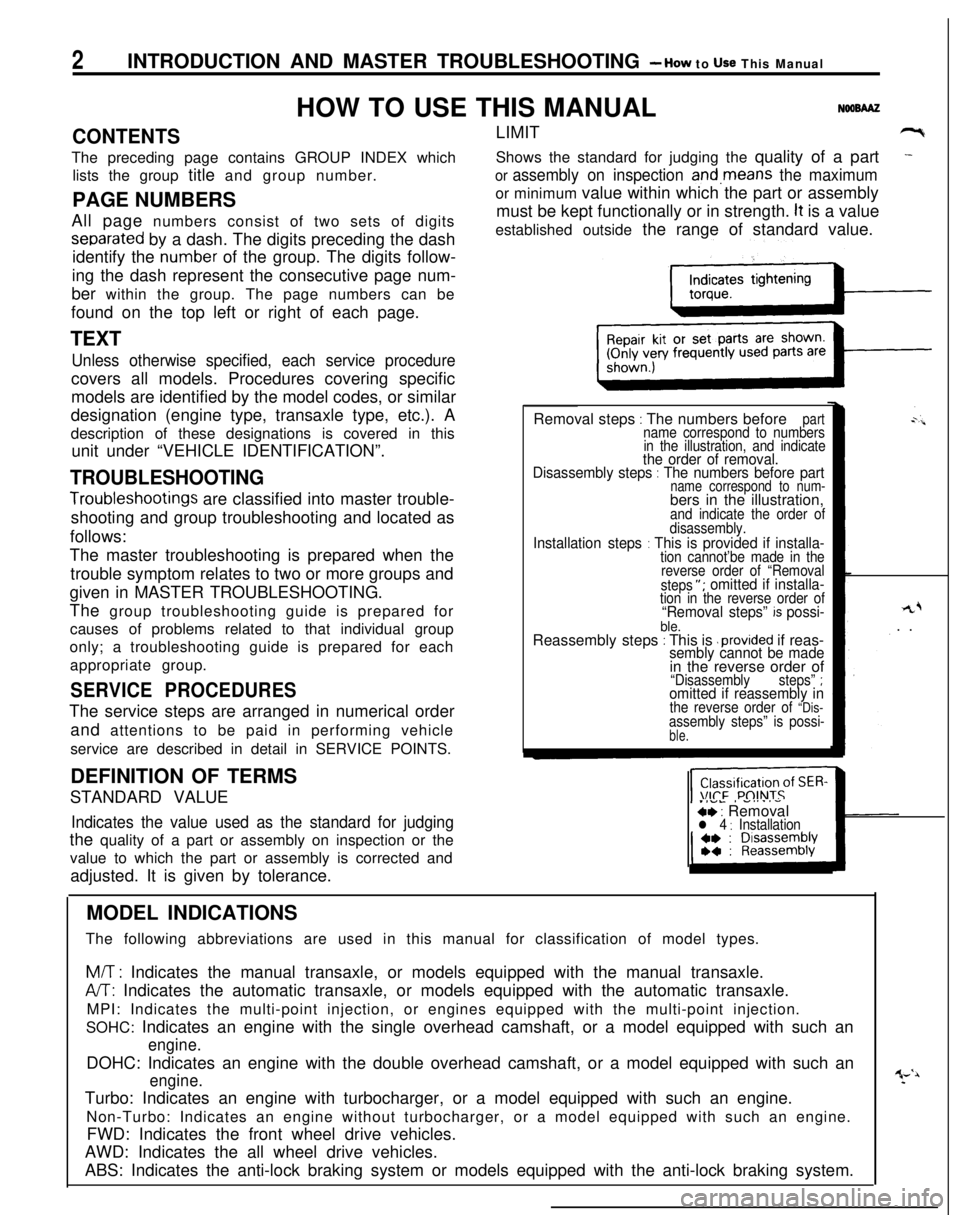

HOW TO USE THIS MANUALNOaM

CONTENTSThe preceding page contains GROUP INDEX which

lists the group title and group number.

PAGE NUMBERS

All page numbers consist of two sets of digits

separated by a dash. The digits preceding the dash

identify the

number of the group. The digits follow-

ing the dash represent the consecutive page num-

ber within the group. The page numbers can be

found on the top left or right of each page.

TEXT

Unless otherwise specified, each service procedurecovers all models. Procedures covering specific

models are identified by the model codes, or similar

designation (engine type, transaxle type, etc.). A

description of these designations is covered in this

unit under “VEHICLE IDENTIFICATION”.

TROUBLESHOOTING

Troubleshootings are classified into master trouble-

shooting and group troubleshooting and located as

follows:

The master troubleshooting is prepared when the

trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for

causes of problems related to that individual group

only; a troubleshooting guide is prepared for each

appropriate group.LIMIT

-9Shows the standard for judging the quality of a part

-

or assembly on inspection and,means the maximumor minimum value within which the part or assembly

must be kept functionally or in strength.

It is a value

established outside the range of standard value.

Removal steps

: The numbers beforepartname correspond to numbers

in the illustration, and indicate

the order of removal.

Disassembly steps : The numbers before partname correspond to num-bers in the illustration,

and indicate the order of

disassembly.

Installation steps : This is provided if installa-tion cannot’be made in the

reverse order of “Removal

steps

“; omitted if installa-tion in the reverse order of“Removal steps” k possi-ble.Reassembly steps : This is .provided if reas-sembly cannot be made

rL+. .

in the reverse order of

“Disassemblysteps” ;omitted if reassembly inthe reverse order of “Dis-assembly steps” is possi-ble.

SERVICE PROCEDURESThe service steps are arranged in numerical order

and attentions to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

.IVL, -....-ce : Removall 4 : InstallationDEFINITION OF TERMS

STANDARD VALUEIndicates the value used as the standard for judgingthe quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T : Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T: Indicates the automatic transaxle, or models equipped with the automatic transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-point injection.

SOHC: Indicates an engine with the single overhead camshaft, or a model equipped with such an

engine.DOHC: Indicates an engine with the double overhead camshaft, or a model equipped with such an

engine.Turbo: Indicates an engine with turbocharger, or a model equipped with such an engine.

Non-Turbo: Indicates an engine without turbocharger, or a model equipped with such an engine.

FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles.

ABS: Indicates the anti-lock braking system or models equipped with the anti-lock braking system.

Page 6 of 1216

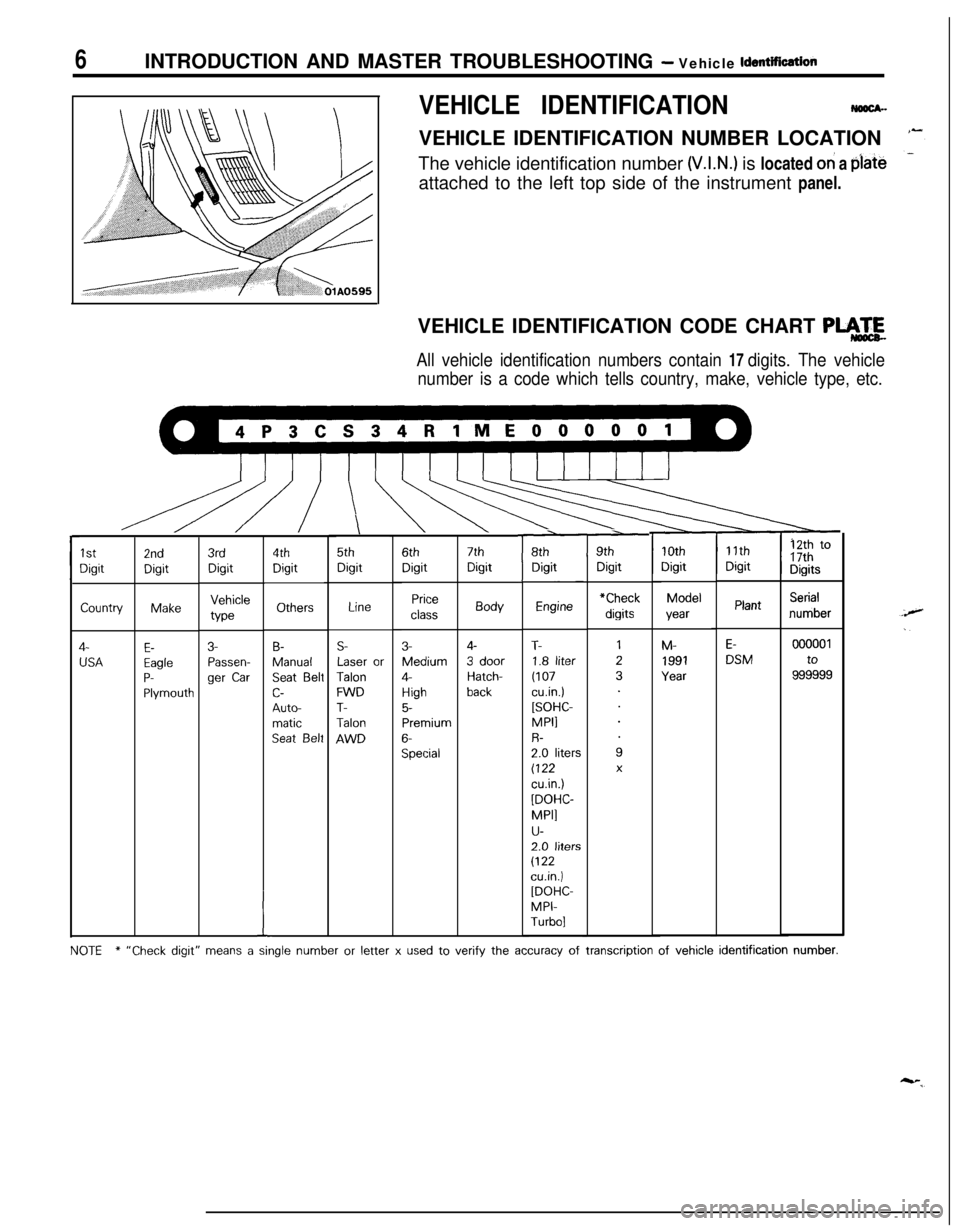

6INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identificetion

VEHICLE IDENTIFICATIONNmx-VEHICLE IDENTIFICATION NUMBER LOCATION

The vehicle identification number

(V.I.N.) is located oh a plate

attached to the left top side of the instrument panel.

VEHICLE IDENTIFICATION CODE CHART

PLA.4

All vehicle identification numbers contain 17 digits. The vehicle

number is a code which tells country, make, vehicle type, etc.

\5thDigit

r8thDigitr9thDigit

11thDigit12th to17thDigits

10thDigitModelyearM-

1991Year

7thDigitBody

4-

3 doorHatch-back

Engine

T-1.8 liter

(107cu.in.)[SOHC-MPI1R-2.0 liters(122

cu.in.)

[DOHC-

MPI]

u-2.0 liters

(122cuin.)[DOHC-MPI-Turbo]6thDigit

Price

class

3-Medium

4-

High5-Premium

6-Special

4thDigit

Others

B-Manual

Seat Beltc-

Auto-matic

Seat Belt

3rdDigitVehicleWe

3-Passen-ger

Car

2ndDigitMake

E-EagleP-Plymouth

1stDigitCountry

4-

USA

Serialnumber*CheckPlantLine

E-DSMS-Laser or

TalonFWDT-Talon

AWD

000001to

999999

I

NOTE* “Check digit” means a single number or letter x used to verify the accuracy of transcription of vehicle identification number.

Page 7 of 1216

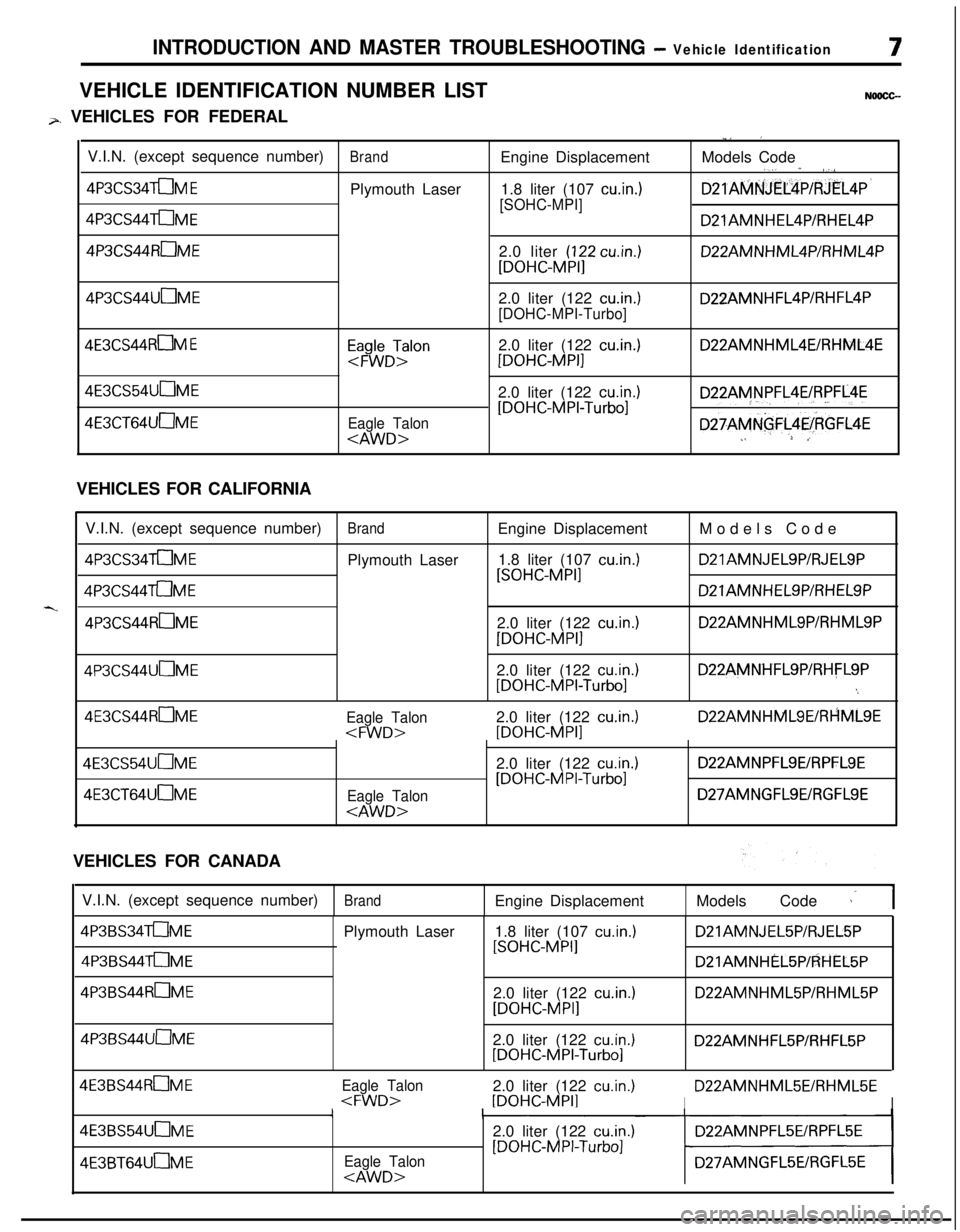

INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle IdentificationVEHICLE IDENTIFICATION NUMBER LIST

NOOCC--

p, VEHICLES FOR FEDERAL

,.. IV.I.N. (except sequence number)

BrandEngine DisplacementModels Code,,; * /./

4P3CS34aM EPlymouth Laser1.8 liter (107 cuin.)D21AMNJElXP/RJEL4P’

4P3CS44aME[SOHC-MPI]

D21AMNHEL4P/RHEL4P4P3CS44ROME2.0 liter

(122 cuin.)

[DOHC-MPI]D22AMNHML4P/RHML4P4P3CS44UuME2.0 liter (122

cu.in.)

[DOHC-MPI-Turbo]D22AMNHFL4P/RHFL4P

4E3CS44ROM EEap$DTrlon2.0 liter (122 cu.in.)

[DOHC-MPI]D22AMNHML4EIRHML4E4E3CS54UnME4E3CT64UOME

Eagle Talon

cu.in.)

[DOHC-MPI-Turbo]D22AMNPFL4EIRPFL4E

D27AMNGFL4E/kGFL4E.1L *,VEHICLES FOR CALIFORNIA

V.I.N. (except sequence number)

BrandEngine DisplacementModels Code

4P3CS34aMEPlymouth Laser1.8 liter (107 cu.in.)D21AMNJELSP/RJELSP

4P3CS44aME

[SOHC-MPI]D21AMNHELSP/RHELSP

4P3CS44RmME2.0 liter (122 cuin.)

[DOHC-MPI]

D22AMNHMLSP/RHMLSP4P3CS44UOME2.0 liter (122

cu.in.1[DOHC-MPI-Turbo]

D22AMNHFLSP/RHFLSP

‘.4E3CS44RuME

Eagle Talon2.0 liter (122 cu.in.1

D22AMNHMLSE/RHMLSE4E3CS54UOME4E3CT64UOME

Eagle Talon

cu.in.1[DOHC-MPI-Turbo]

D22AMNPFLSElRPFLSE

D27AMNGFLSE/RGFLSEVEHICLES FOR CANADA

V.I.N. (except sequence number)

BrandEngine DisplacementModels Code 1’1

4P3BS34aME

4P3BS44aMEPlymouth Laser1.8 liter (107

cu.in.1[SOHC-MPI]D21AMNJEL5P/RJEL5PD21AMNHiL5P/RHEL5P4P3BS44ROME

2.0 liter (122

cuin.)

[DOHC-MPI]D22AMNHML5P/RHML5P4P3BS44UuME

2.0 liter (122

cu.in.)[DOHC-MPI-Turbo]D22AMNHFL5P/RHFL5P4E3BS44ROME

Eagle Talon2.0 liter (122 cu.in.)D22AMNHML5EiRHML5E

Eagle Talon

cu.in.1

[DOHC-MPI-Turbo]

Page 8 of 1216

8INTRODUCTION AND MASTER TROUBLESHOOTING - Vehicle Identification

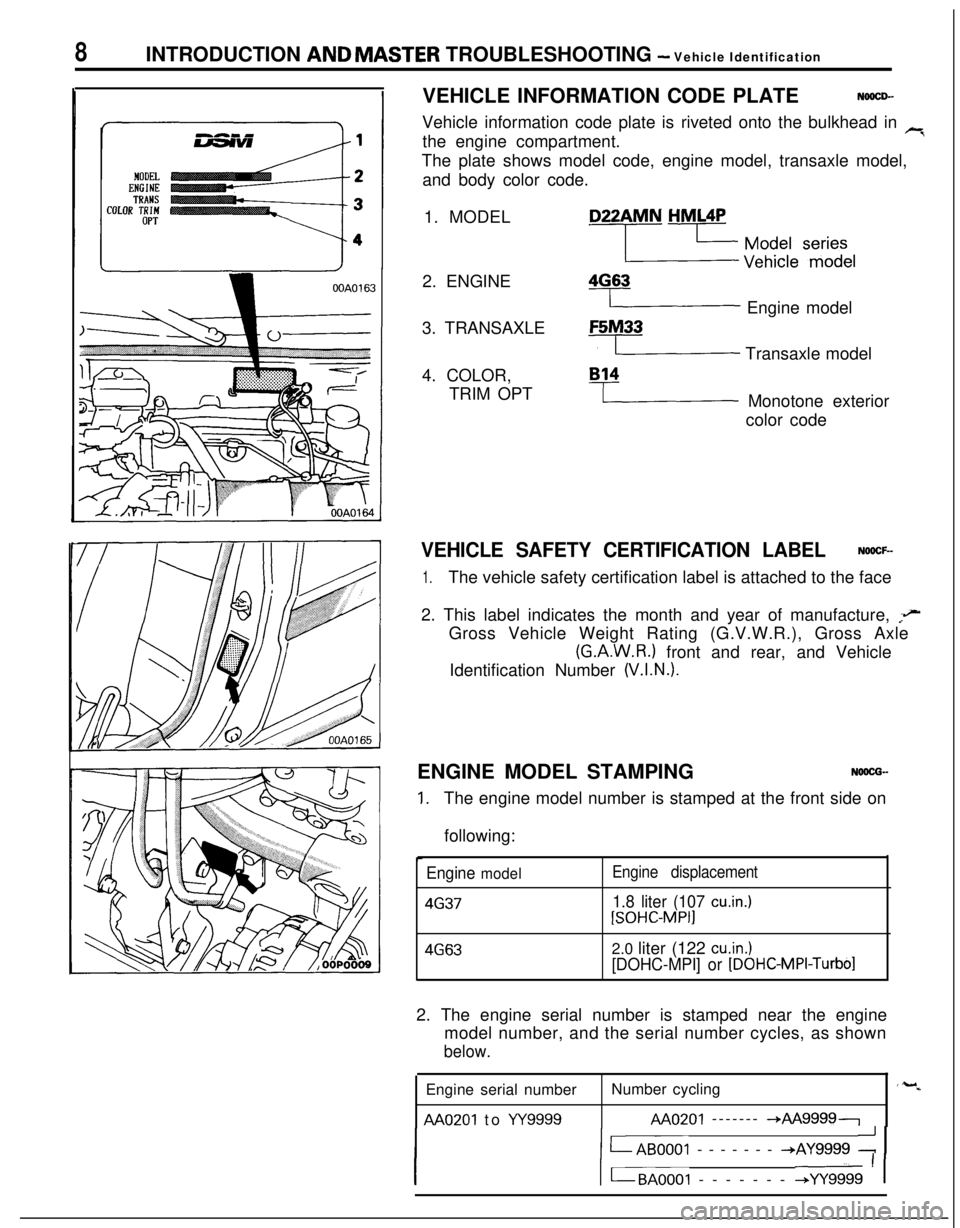

VEHICLE INFORMATION CODE PLATE

NOOCD-Vehicle information code plate is riveted onto the bulkhead in

rithe engine compartment.

The plate shows model code, engine model, transaxle model,

and body color code.

1. MODEL

2. ENGINE

3. TRANSAXLE

4. COLOR,

TRIM OPTD22AMN

HML4P

2 y$y:/e ‘f$$l

4G63

I Engine modelF5M33

y Transaxle model

B14

I Monotone exterior

color code

VEHICLE SAFETY CERTIFICATION LABELNOOCF-

1.The vehicle safety certification label is attached to the face

2. This label indicates the month and year of manufacture,

;eGross Vehicle Weight Rating (G.V.W.R.), Gross Axle

(G.A.W.R.) front and rear, and Vehicle

Identification Number

(V.I.N.).ENGINE MODEL STAMPING

NOOCG-

1.The engine model number is stamped at the front side on

following:

Engine model4637Engine displacement

1.8 liter (107 cu.in.)

[SOHC-MPI]

4G632.0 liter (122 cuin.)

[DOHC-MPI] or

[DOHC-MPI-Turbo]2. The engine serial number is stamped near the engine

model number, and the serial number cycles, as shown

below.Engine serial numberNumber cycling

AA0201 to w9999AA0201 ------- -*AA99997

I1 LAB0001 ------- +AY9999 : 1

I1 t-BAOOOI ------- +YY9999 ’ 1

‘-w

Page 9 of 1216

INTRODUCTlON AND MASTER TROUBLESHOOTING - Vehicle Identification9

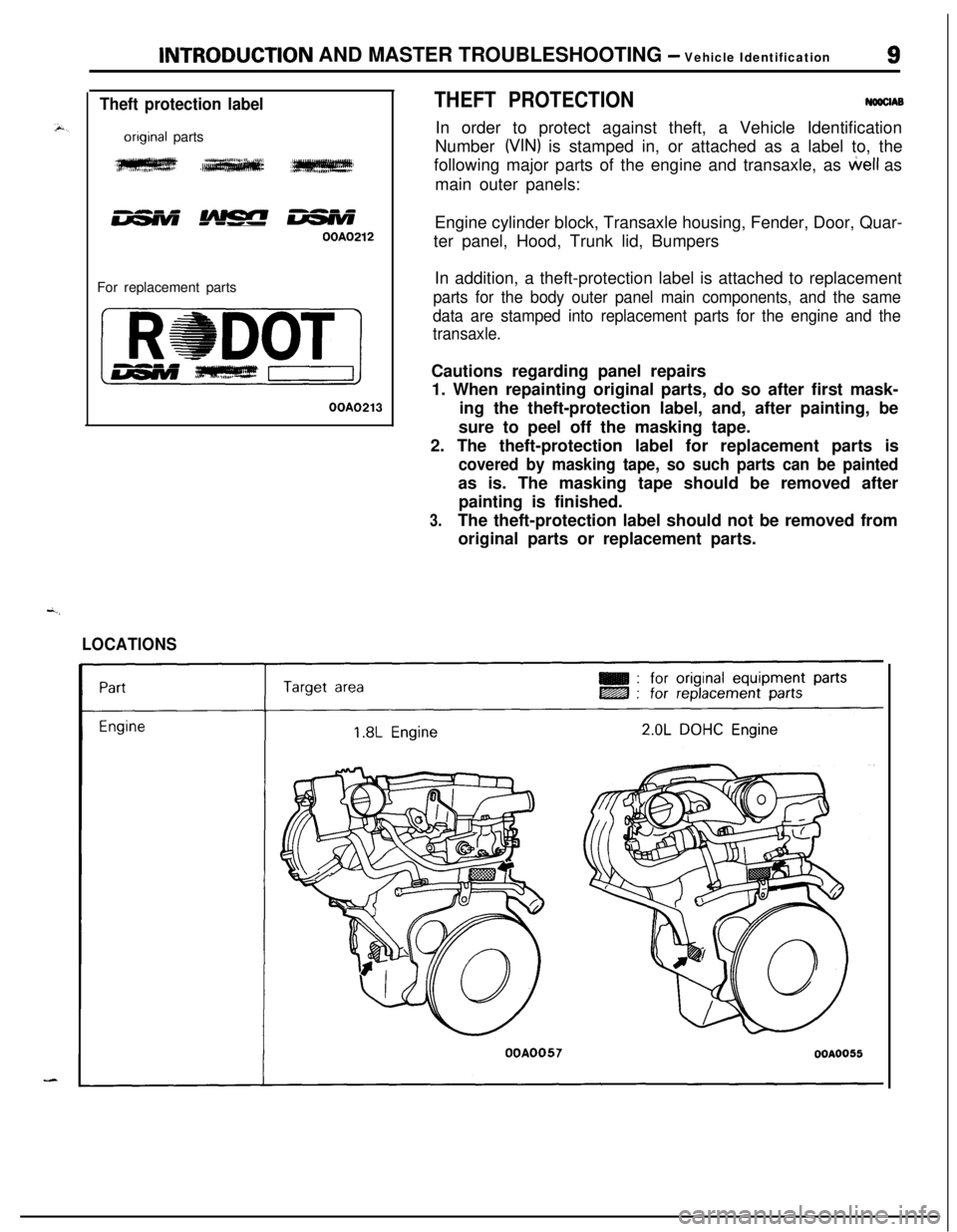

Theft protection label

onginal parts

w ,IeIW

B ,w w

OOA0212For replacement parts

OOA0213

LOCATIONS

THEFT PROTECTIONNowlABIn order to protect against theft, a Vehicle Identification

Number

WIN) is stamped in, or attached as a label to, the

following major parts of the engine and transaxle, as

tiell as

main outer panels:

Engine cylinder block, Transaxle housing, Fender, Door, Quar-

ter panel, Hood, Trunk lid, Bumpers

In addition, a theft-protection label is attached to replacement

parts for the body outer panel main components, and the same

data are stamped into replacement parts for the engine and the

transaxle.Cautions regarding panel repairs

1. When repainting original parts, do so after first mask-

ing the theft-protection label, and, after painting, be

sure to peel off the masking tape.

2. The theft-protection label for replacement parts is

covered by masking tape, so such parts can be paintedas is. The masking tape should be removed after

painting is finished.

3.The theft-protection label should not be removed from

original parts or replacement parts.

OOA0057OOA0055

Page 14 of 1216

I4INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Service

mm (In.1smo59

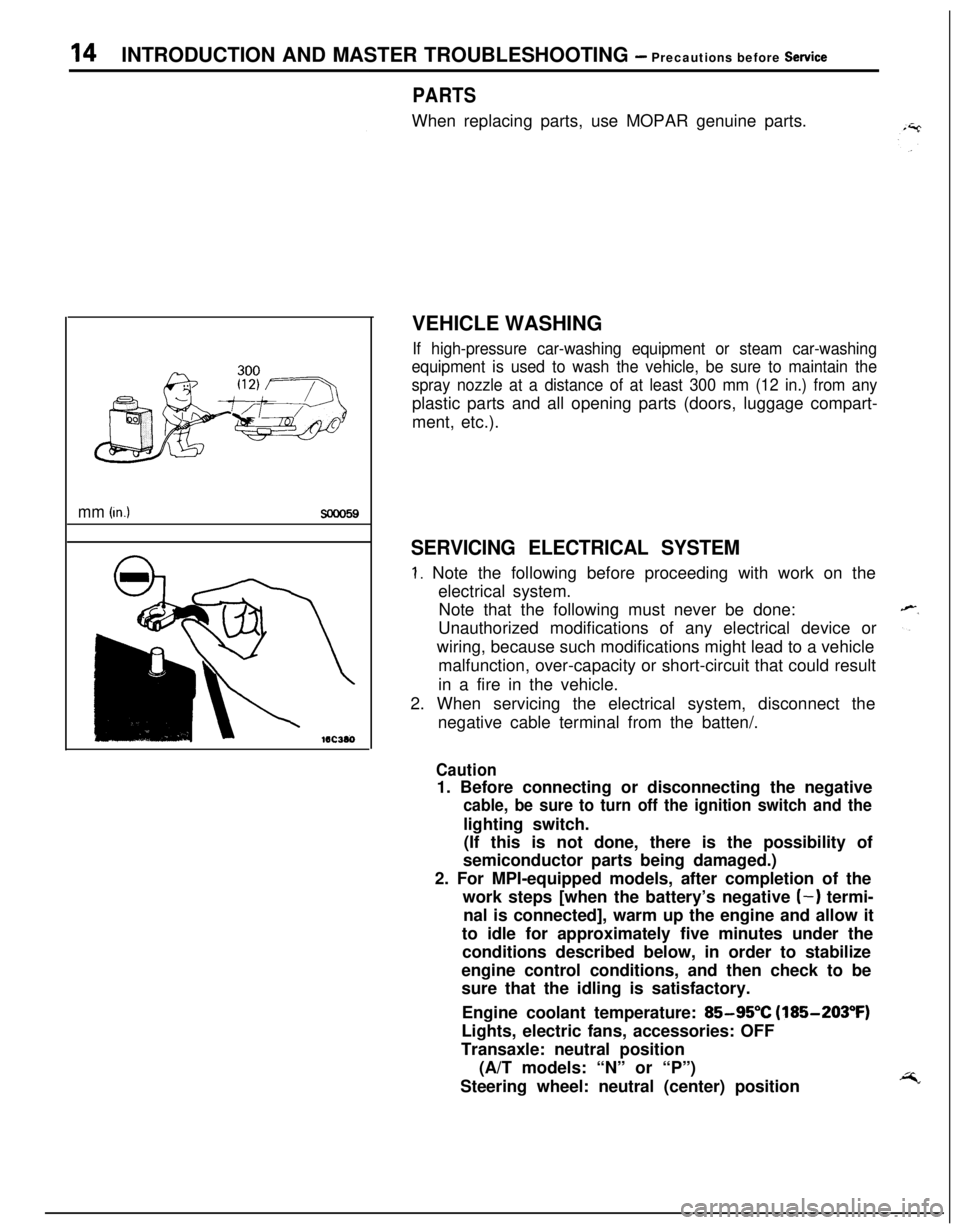

PARTSWhen replacing parts, use MOPAR genuine parts.

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (12 in.) from anyplastic parts and all opening parts (doors, luggage compart-

ment, etc.).

SERVICING ELECTRICAL SYSTEM

1. Note the following before proceeding with work on the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result

in a fire in the vehicle.

2. When servicing the electrical system, disconnect the

negative cable terminal from the batten/.

Caution1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and thelighting switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. For MPI-equipped models, after completion of the

work steps [when the battery’s negative

(-) termi-

nal is connected], warm up the engine and allow it

to idle for approximately five minutes under the

conditions described below, in order to stabilize

engine control conditions, and then check to be

sure that the idling is satisfactory.

Engine coolant temperature:

85-95°C (185-203°F)

Lights, electric fans, accessories: OFF

Transaxle: neutral position

(A/T models: “N” or “P”)

Steering wheel: neutral (center) position

Page 15 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Set&e15

F16171

Correct

Cl6385

Cl6367

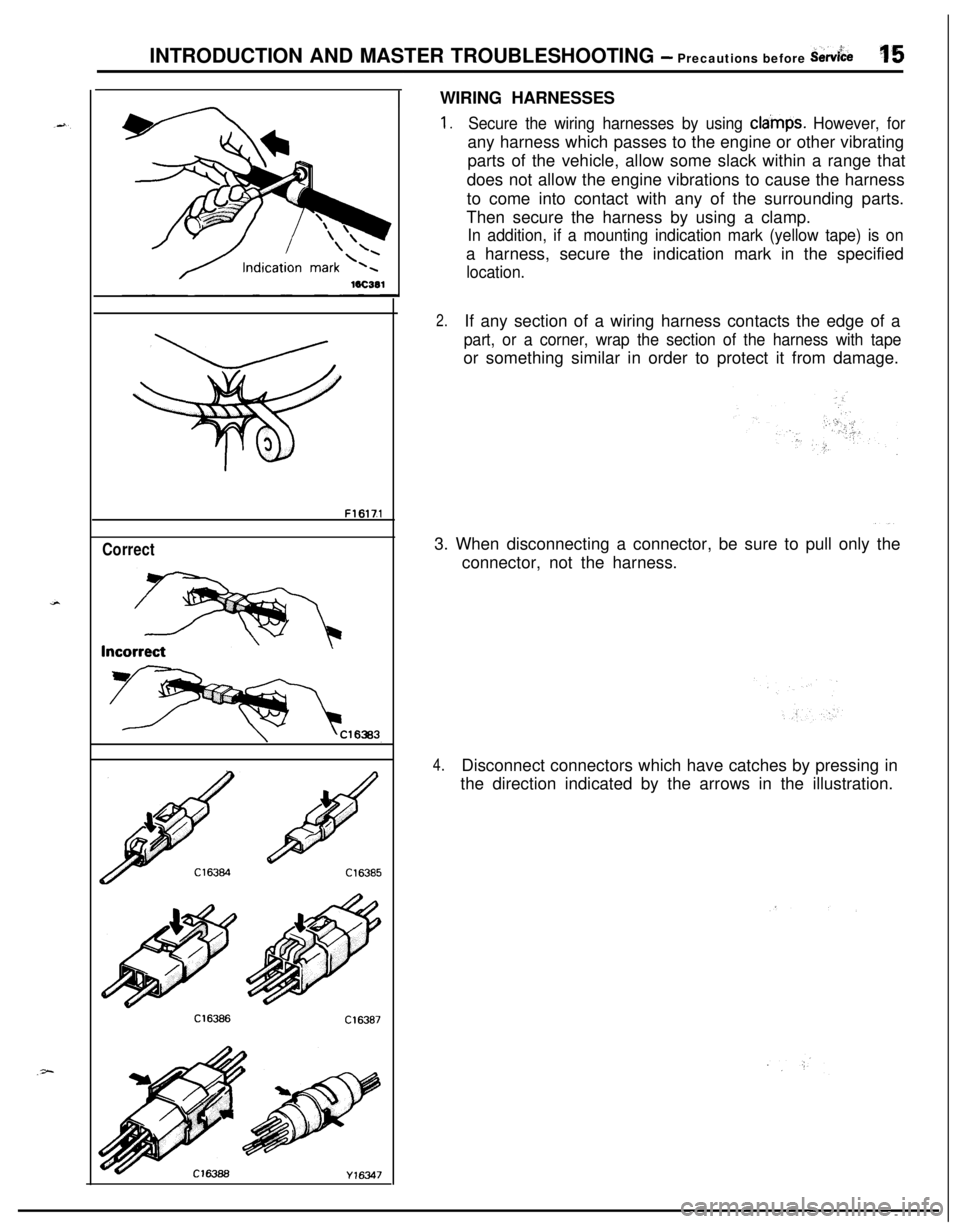

Y16347WIRING HARNESSES

1.Secure the wiring harnesses by using cla’mps. However, forany harness which passes to the engine or other vibrating

parts of the vehicle, allow some slack within a range that

does not allow the engine vibrations to cause the harness

to come into contact with any of the surrounding parts.

Then secure the harness by using a clamp.

In addition, if a mounting indication mark (yellow tape) is ona harness, secure the indication mark in the specified

location.

2.If any section of a wiring harness contacts the edge of a

part, or a corner, wrap the section of the harness with tapeor something similar in order to protect it from damage.

3. When disconnecting a connector, be sure to pull only the

connector, not the harness.

4.Disconnect connectors which have catches by pressing in

the direction indicated by the arrows in the illustration.

Page 17 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Sew&e‘37

Nominal

sizeSAE

gi:ePermissible current

In engine

Othercompart-areasment

0.3mm2AWG22-5A

0.5

mm2AWG207A13A

0.85

mm’AWG189A17A

1.25

mm2AWG1612A22A

2.0mm2AWG1416A30A

3.0mm’AWG1221A40A

5.0mm2AWG1031A54A

r ‘.

oorsas

2. If additional optional equipment is to be installed, in ttievehicle, follow the procedure listed in the

ap@@priateinstruction manual; however, be sure to pay “careful

attention to the following points:

“9:(1) In order to avoid overloading the

wiring;’ take the

electrical current load of the optional

,equipment into

consideration, and determine the appropriate .wire size:(2) Where possible, route the wiring through the existing

harnesses.(3) If an ammeter or similar instrument is to be

connectedto a live-wire circuit, use tape to protect the wire, use a

clamp to secure the wire, and make sure that there is

no contact with any other parts.

(4) Be sure to provide a fuse for the load circuit of the

optional equipment.

TUBES AND OTHER RUBBER PARTS

Be careful to avoid spilling any gasoline, oil, etc., or rubber

parts, they might be adversely affected.

LUBRICANTSIn accordance with the instructions in this Service Manual,

apply the specified lubricants in the specified locations during

assembly and installation.

!’IV/ :>,I

BRAKE FLUID

Be careful to avoid spilling any brake fluid on painted surfaces,because the paint coat might be discolored or damaged.

Page 18 of 1216

18INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions b&ire Service

DOING SERVICE WORK IN GROUPS OF VO’bRMORE TECHNICIANS

.-I-7.IIf the service work is to be done by two or more technicians

working together, extra caution must be taken.

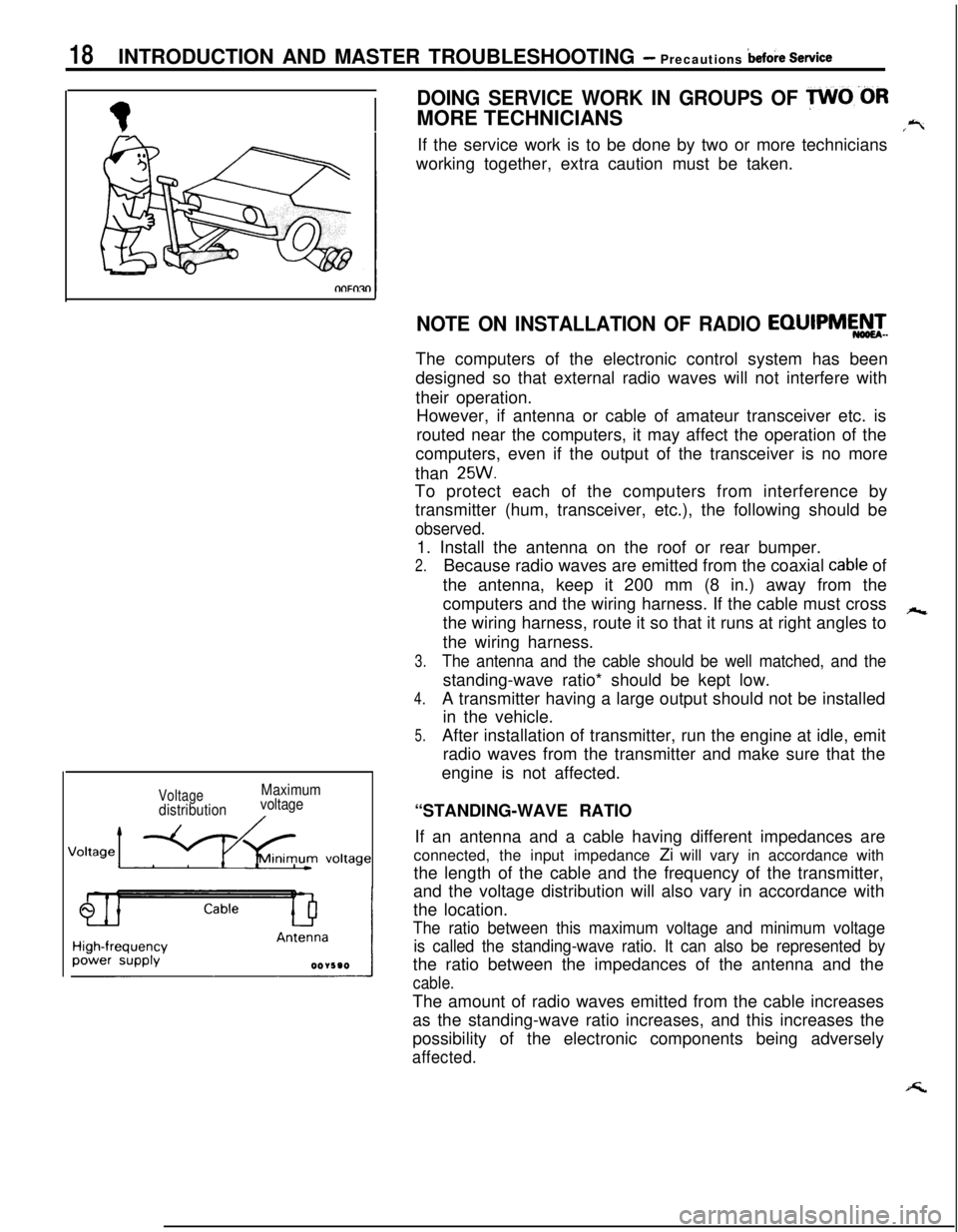

VoltagedistributionMaximum

voltage

NOTE ON INSTALLATION OF RADIO EQIJIPMEATeThe computers of the electronic control system has been

designed so that external radio waves will not interfere with

their operation.

However, if antenna or cable of amateur transceiver etc. is

routed near the computers, it may affect the operation of the

computers, even if the output of the transceiver is no more

than

25W.To protect each of the computers from interference by

transmitter (hum, transceiver, etc.), the following should be

observed.1. Install the antenna on the roof or rear bumper.

2.Because radio waves are emitted from the coaxial cable of

the antenna, keep it 200 mm (8 in.) away from the

computers and the wiring harness. If the cable must cross

hthe wiring harness, route it so that it runs at right angles to

the wiring harness.

3.The antenna and the cable should be well matched, and thestanding-wave ratio* should be kept low.

4.A transmitter having a large output should not be installed

in the vehicle.

5.After installation of transmitter, run the engine at idle, emit

radio waves from the transmitter and make sure that the

engine is not affected.

“STANDING-WAVE RATIO

If an antenna and a cable having different impedances are

connected, the input impedance Zi will vary in accordance with

the length of the cable and the frequency of the transmitter,

and the voltage distribution will also vary in accordance with

the location.

The ratio between this maximum voltage and minimum voltage

is called the standing-wave ratio. It can also be represented bythe ratio between the impedances of the antenna and the

cable.The amount of radio waves emitted from the cable increases

as the standing-wave ratio increases, and this increases the

possibility of the electronic components being adversely

affected.