wheel torque MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 24 of 1216

24 INTRODUCTION AND MASTER TROUBLESHOOTING - fSo%k%:~~it’ndrU~ionsREAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow the

same procedures as for the front wheel measurements.

,’

~.Braking force of AWD models with VCU

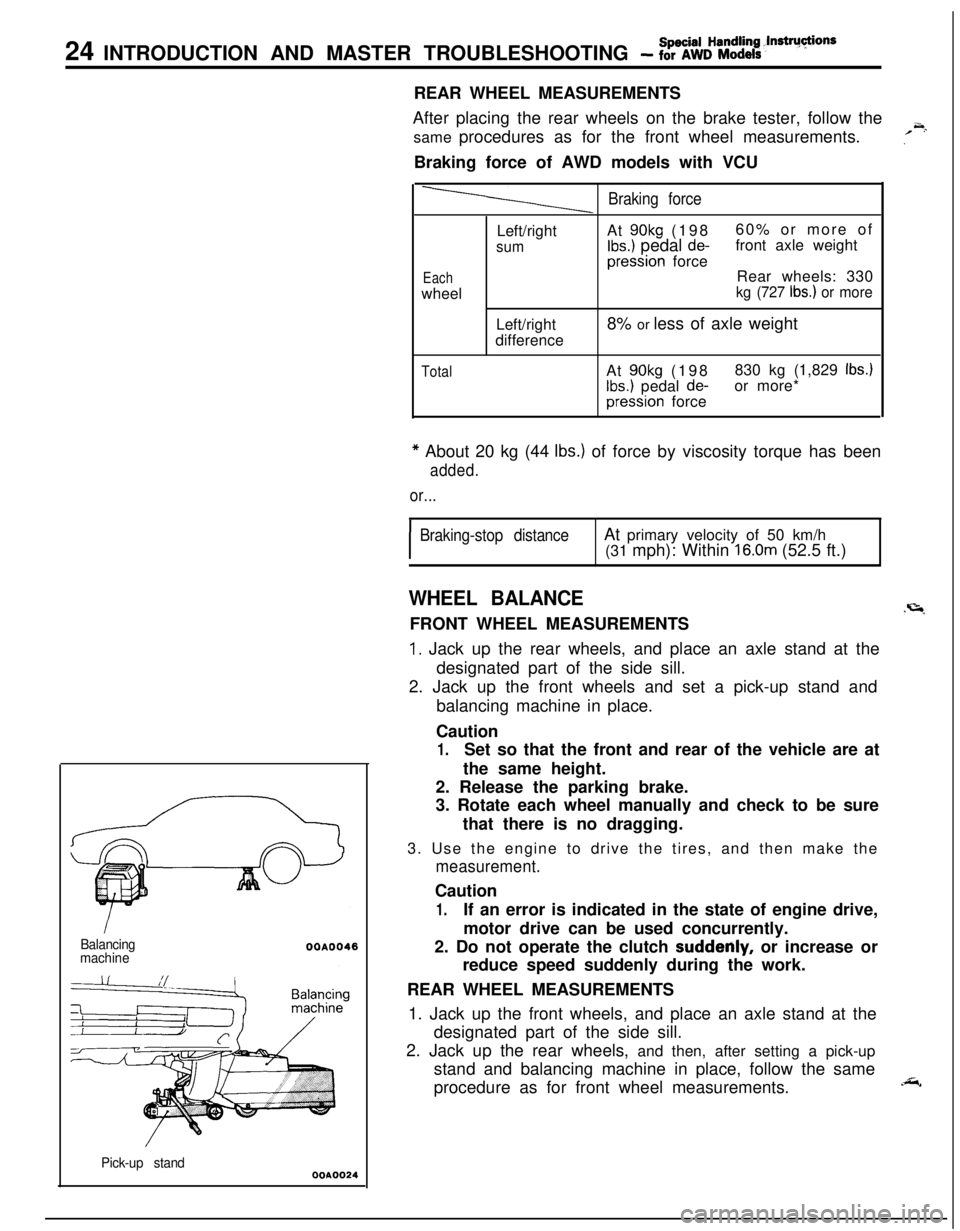

Balancing

machine

Pick-up stand

WA0024

Braking force

EachwheelLeft/right

sumLeft/right

differenceAt

90kg (19860% or more ofIbs.) pedal de-front axle weightpression force

Rear wheels: 330

kg (727 Ibs.) or more8% or less of axle weight

TotalAt 90kg (198830 kg (1,829 Ibs.)

Ibs.) pedal de-or more*pression force

* About 20 kg (44 Ibs.) of force by viscosity torque has been

added.

or...

I

Braking-stop distanceAt primary velocity of 50 km/h

(31 mph): Within 16.0m (52.5 ft.)

WHEEL BALANCE.r=lFRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the front wheels and set a pick-up stand and

balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are at

the same height.

2. Release the parking brake.

3. Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tires, and then make the

measurement.Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2. Do not operate the clutch

suddenly, or increase or

reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the rear wheels, and then, after setting a pick-up

stand and balancing machine in place, follow the same

procedure as for front wheel measurements.

.&,

Page 46 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Service

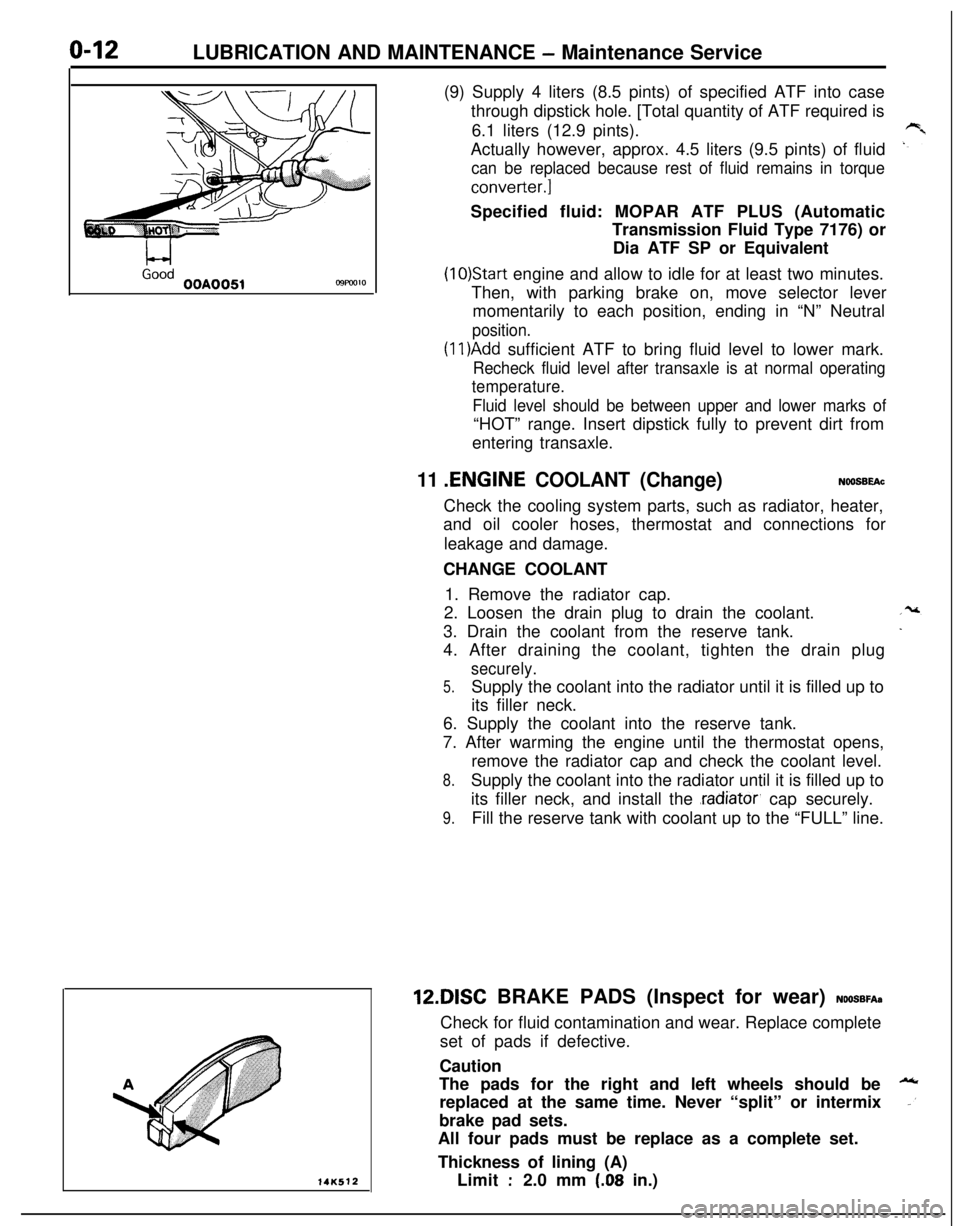

L-4GoodOOA0051C9FW1014K512(9) Supply 4 liters (8.5 pints) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is

6.1 liters (12.9 pints).

Actually however, approx. 4.5 liters (9.5 pints) of fluid

can be replaced because rest of fluid remains in torque

converter.]Specified fluid: MOPAR ATF PLUS (Automatic

Transmission Fluid Type 7176) or

Dia ATF SP or Equivalent

(10)Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever

momentarily to each position, ending in “N” Neutral

position.

(1 l)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature.

Fluid level should be between upper and lower marks of“HOT” range. Insert dipstick fully to prevent dirt from

entering transaxle.

11 .ENGINE COOLANT (Change)NOOSBEAcCheck the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug

securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens,

remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the

.radiator, cap securely.

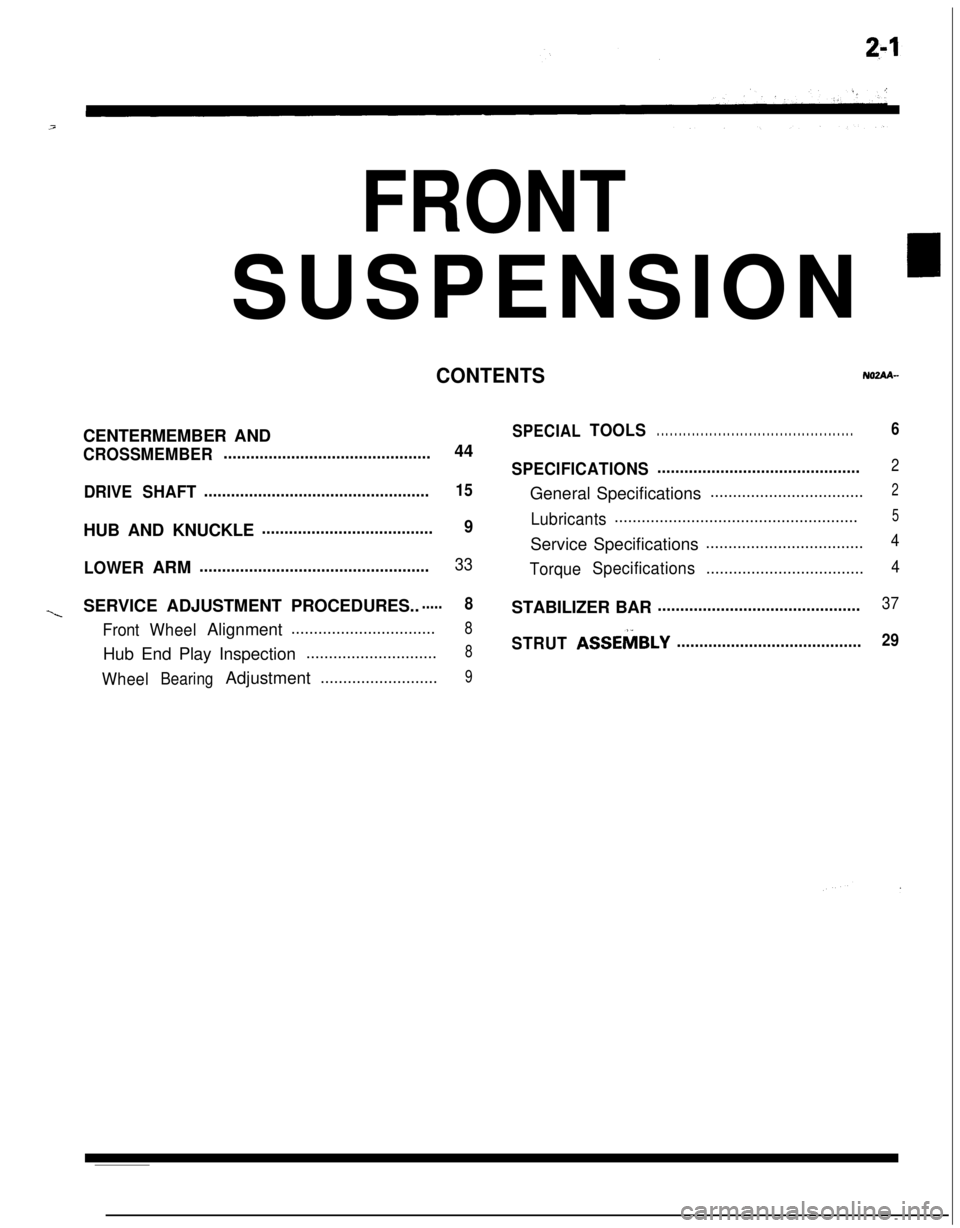

9.Fill the reserve tank with coolant up to the “FULL” line.12DISC BRAKE PADS (Inspect for wear)

NOOSBFA~Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

replaced at the same time. Never “split” or intermix

brake pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit

:2.0 mm (.08 in.)

Page 49 of 1216

FRONTSUSPENSION

’

CONTENTSNOZAA-CENTERMEMBER AND

CROSSMEMBER..............................................44

DRIVESHAFT..................................................15HUB AND KNUCKLE

......................................9

LOWERARM

...................................................33

~SERVICE ADJUSTMENT PROCEDURES.......8

FrontWheelAlignment................................8Hub End Play Inspection

.............................8

WheelBearingAdjustment..........................9

SPECIALTOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SPECIFICATIONS.............................................2General Specifications

..................................2

Lubricants......................................................5Service Specifications

...................................4

TorqueSpecifications...................................4STABILIZER BAR

.............................................37

STRUTASSEMBLY.........................................29

Page 52 of 1216

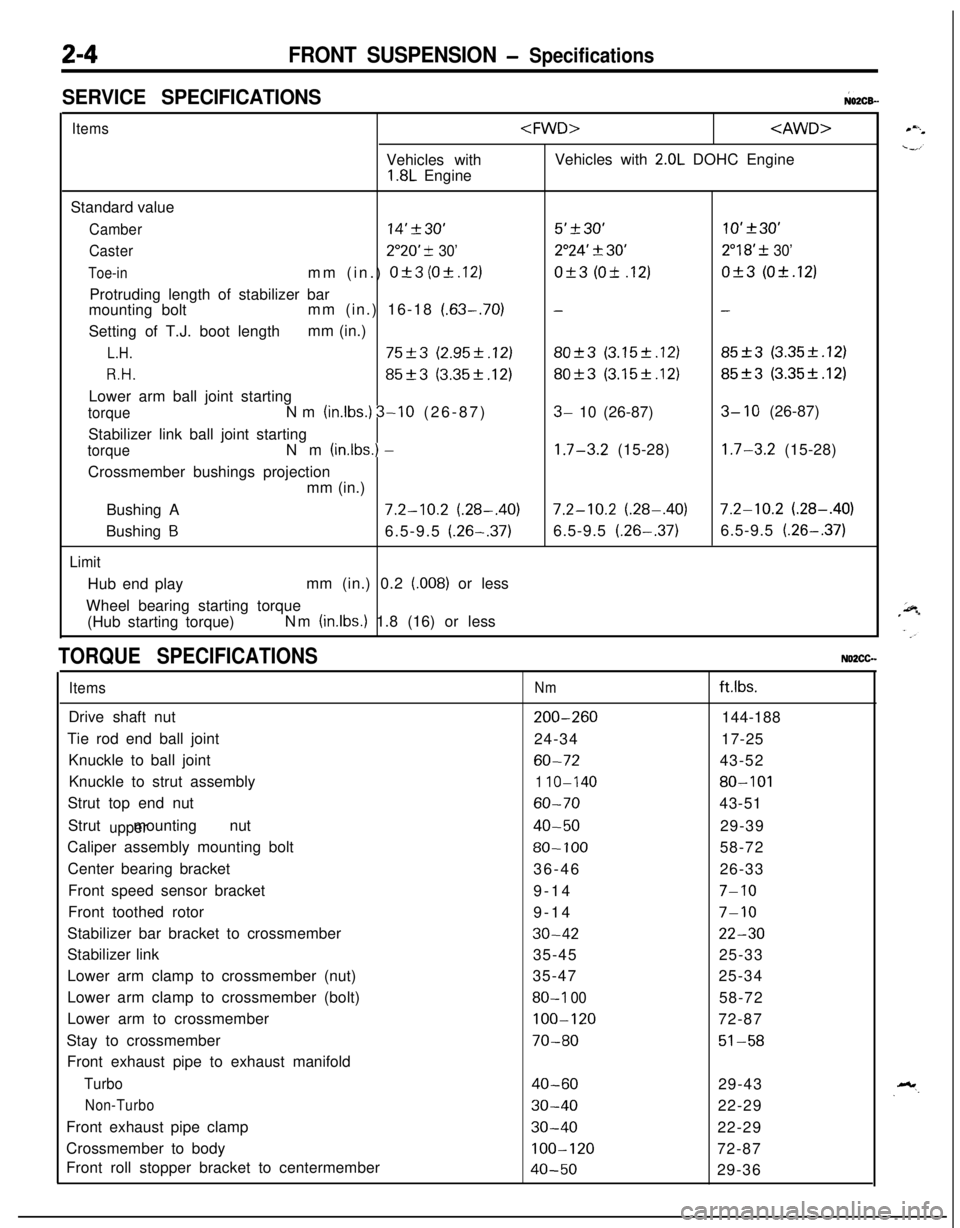

2-4FRONT SUSPENSION - Specifications

SERVICE SPECIFICATIONS;02CB-

ItemsVehicles with

1.8L Engine

2.0L DOHC Engine

Standard value

Camber14’230’5’+30’10’+30’

Caster2”20’ -t 30’2”24’ 3130’2”18’ f 30’

Toe-inmm (in.) Of3 (Ok.12)Of3 (Ok .12)Of3 (Ok.12)

Protruding length of stabilizer bar

mounting boltmm (in.) 16-18

(.63-.70)--Setting of T.J. boot lengthmm (in.)

L.H.75+3 (2.95f.12)80-+3 (3.15f.12)85_+3 (3.35k.12)

R.H.85f3 (3.35k.12)80+3 (3.15k.12)85f3 (3.35f.12)Lower arm ball joint starting

torqueNm (in.lbs.) 3-10 (26-87)3- 10 (26-87)3- 10 (26-87)

Stabilizer link ball joint starting

torqueNm (inlbs.) -1.7-3.2 (15-28)1.7-3.2 (15-28)

Crossmember bushings projection

mm (in.)

Bushing A

7.2-10.2 (.28-.40)7.2-10.2 (.28-.40)7.2-10.2 (.28-.40)

Bushing

B6.5-9.5 (.26-.37)6.5-9.5 (.26-.37)6.5-9.5 (.26-.37)

LimitHub end playmm (in.) 0.2

(.008) or less

Wheel bearing starting torque

(Hub starting torque)Nm

(in.lbs.) 1.8 (16) or less

TORQUE SPECIFICATIONSNO2CG.

ItemsDrive shaft nut

Tie rod end ball joint

Knuckle to ball joint

Knuckle to strut assembly

Strut top end nut

Strut mounting nut

upperCaliper assembly mounting bolt

Center bearing bracket

Front speed sensor bracket

Front toothed rotor

Stabilizer bar bracket to crossmember

Stabilizer link

Lower arm clamp to crossmember (nut)

Lower arm clamp to crossmember (bolt)

Lower arm to crossmember

Stay to crossmember

Front exhaust pipe to exhaust manifold

Turbo

Non-TurboFront exhaust pipe clamp

Crossmember to body

Front roll stopper bracket to centermember

Nmftlbs.

200-260144-188

24-3417-25

60-7243-52

1 IO-14080-101

60-7043-51

40-5029-39

80-10058-72

36-4626-33

9-14

7-109-14

7-10

30-4222-3035-4525-33

35-4725-34

80-I 0058-72

100-12072-87

70-8051-58

40-6029-43

30-4022-29

30-4022-29

100-12072-87

40-5029-36

Page 60 of 1216

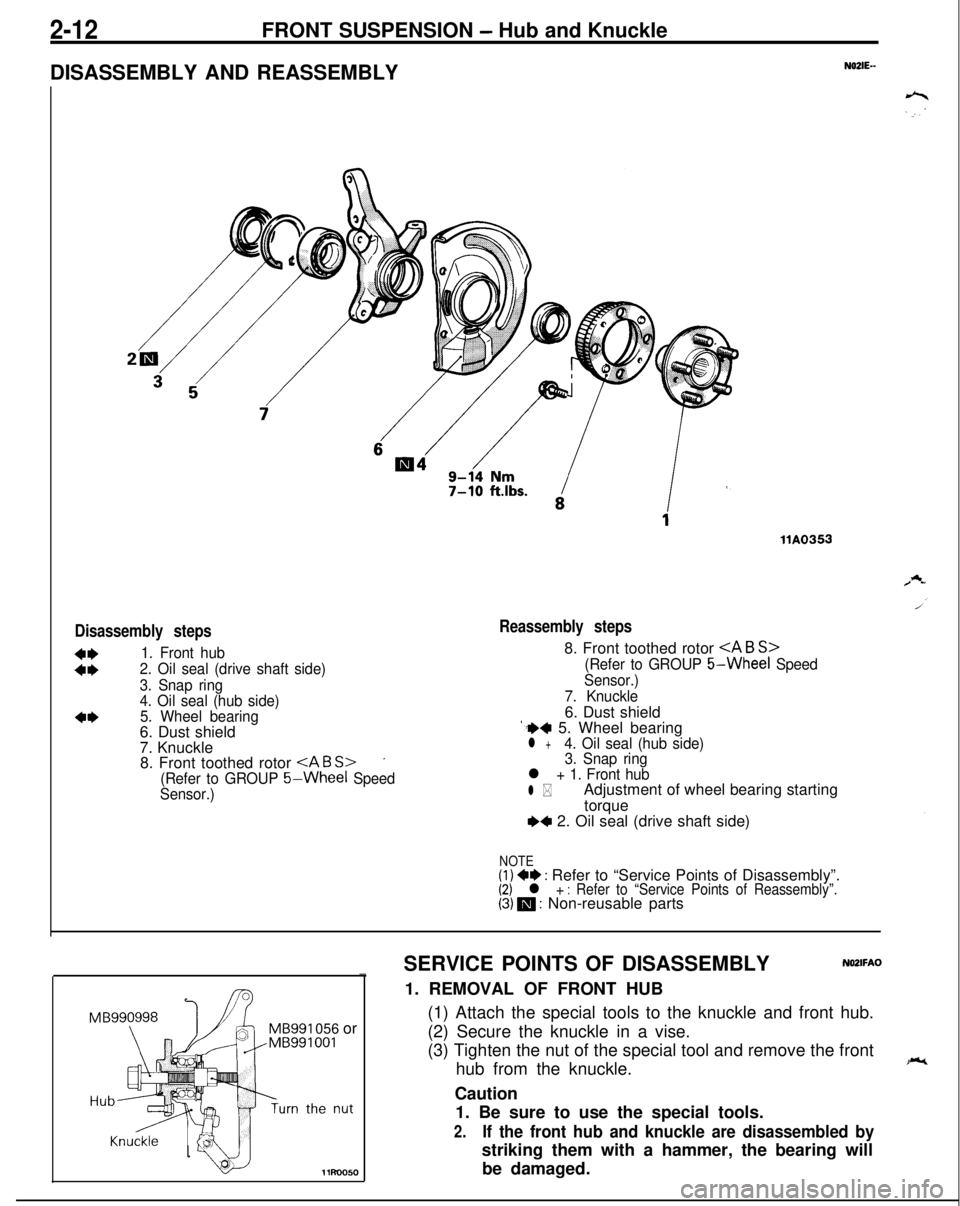

2-12FRONT SUSPENSION - Hub and Knuckle

DISASSEMBLY AND REASSEMBLY

N02lE--

Disassembly steps

:t

1. Front hub

2. Oil seal (drive shaft side)

3. Snap ring

4. Oil seal (hub side)

5. Wheel bearing6. Dust shield

7. Knuckle

8. Front toothed rotor

’

(Refer to GROUP 5-Wheel Speed

Sensor.)

llA0353

Reassembly steps8. Front toothed rotor

(Refer to GROUP 5-Wheel Speed

Sensor.)

7. Knuckle6. Dust shield

‘.++ 5. Wheel bearingl +4. Oil seal (hub side)

3. Snap ring

l + 1. Front hub

l *Adjustment of wheel bearing starting

torque

~~ 2. Oil seal (drive shaft side)

NOTE(1) +e : Refer to “Service Points of Disassembly”.(2) l + : Refer to “Service Points of Reassembly”.(3) m : Non-reusable parts

MB991 056 or

11uo050SERVICE POINTS OF DISASSEMBLY

NO2lFAO-1. REMOVAL OF FRONT HUB

(1) Attach the special tools to the knuckle and front hub.

(2) Secure the knuckle in a vise.

(3) Tighten the nut of the special tool and remove the front

hub from the knuckle.

Caution

1. Be sure to use the special tools.

2.If the front hub and knuckle are disassembled bystriking them with a hammer, the bearing will

be damaged.

Page 62 of 1216

2-14FRONT SUSPENSION - Hub and Knuckle

llR0032

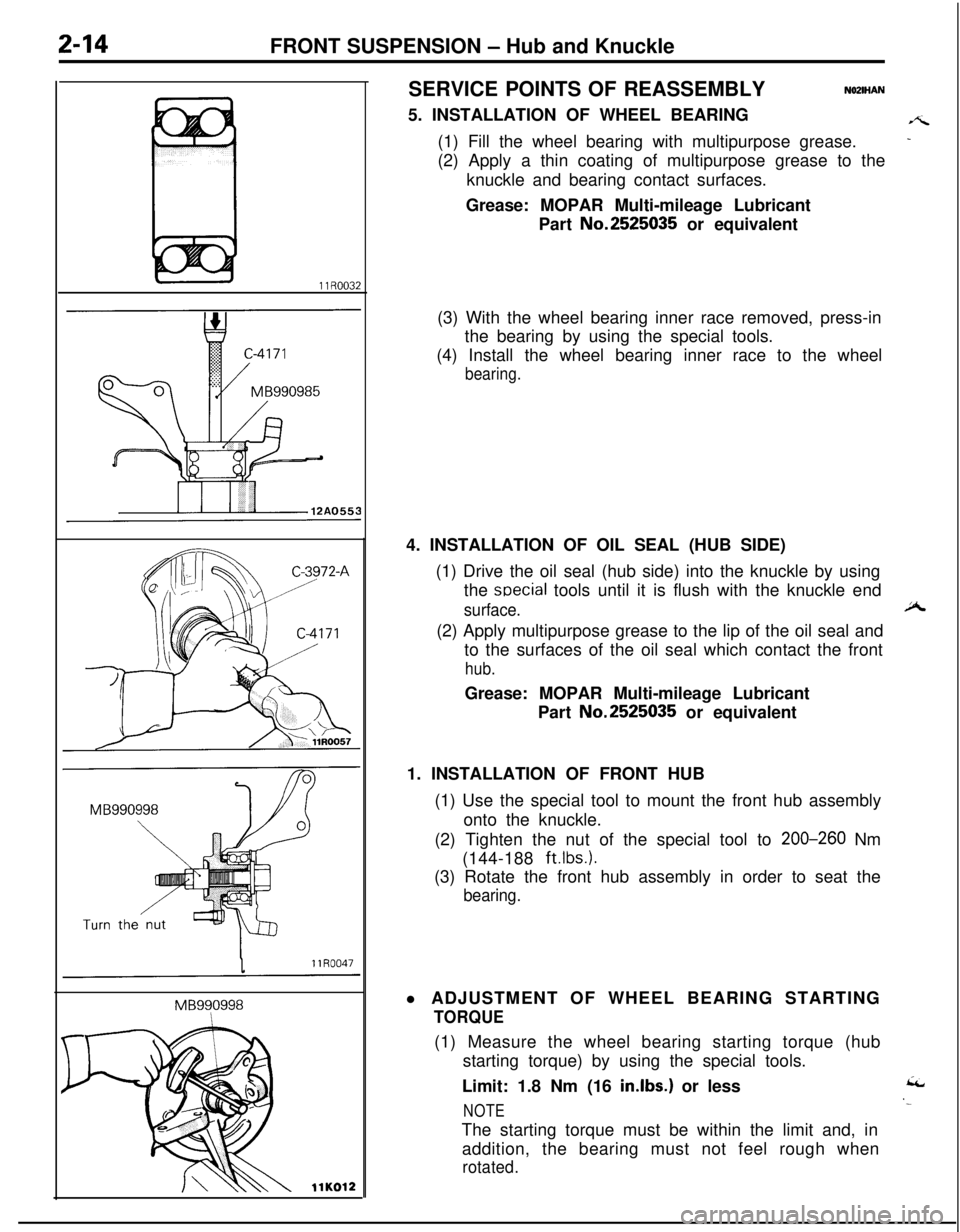

llK012SERVICE POINTS OF REASSEMBLY

NOZIHAN5. INSTALLATION OF WHEEL BEARING

A(1) Fill the wheel bearing with multipurpose grease.

-(2) Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(3) With the wheel bearing inner race removed, press-in

the bearing by using the special tools.

(4) Install the wheel bearing inner race to the wheel

bearing.4. INSTALLATION OF OIL SEAL (HUB SIDE)

(1) Drive the oil seal (hub side) into the knuckle by using

the

soecial tools until it is flush with the knuckle end

surface.A(2) Apply multipurpose grease to the lip of the oil seal and

to the surfaces of the oil seal which contact the front

hub.Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

1. INSTALLATION OF FRONT HUB

(1) Use the special tool to mount the front hub assembly

onto the knuckle.

(2) Tighten the nut of the special tool to 200-260 Nm

(144-188

ft.lbs.).(3) Rotate the front hub assembly in order to seat the

bearing.l ADJUSTMENT OF WHEEL BEARING STARTING

TORQUE(1) Measure the wheel bearing starting torque (hub

starting torque) by using the special tools.

Limit: 1.8 Nm (16

in.lbs.) or lessic

‘-NOTEThe starting torque must be within the limit and, in

addition, the bearing must not feel rough when

rotated.

Page 103 of 1216

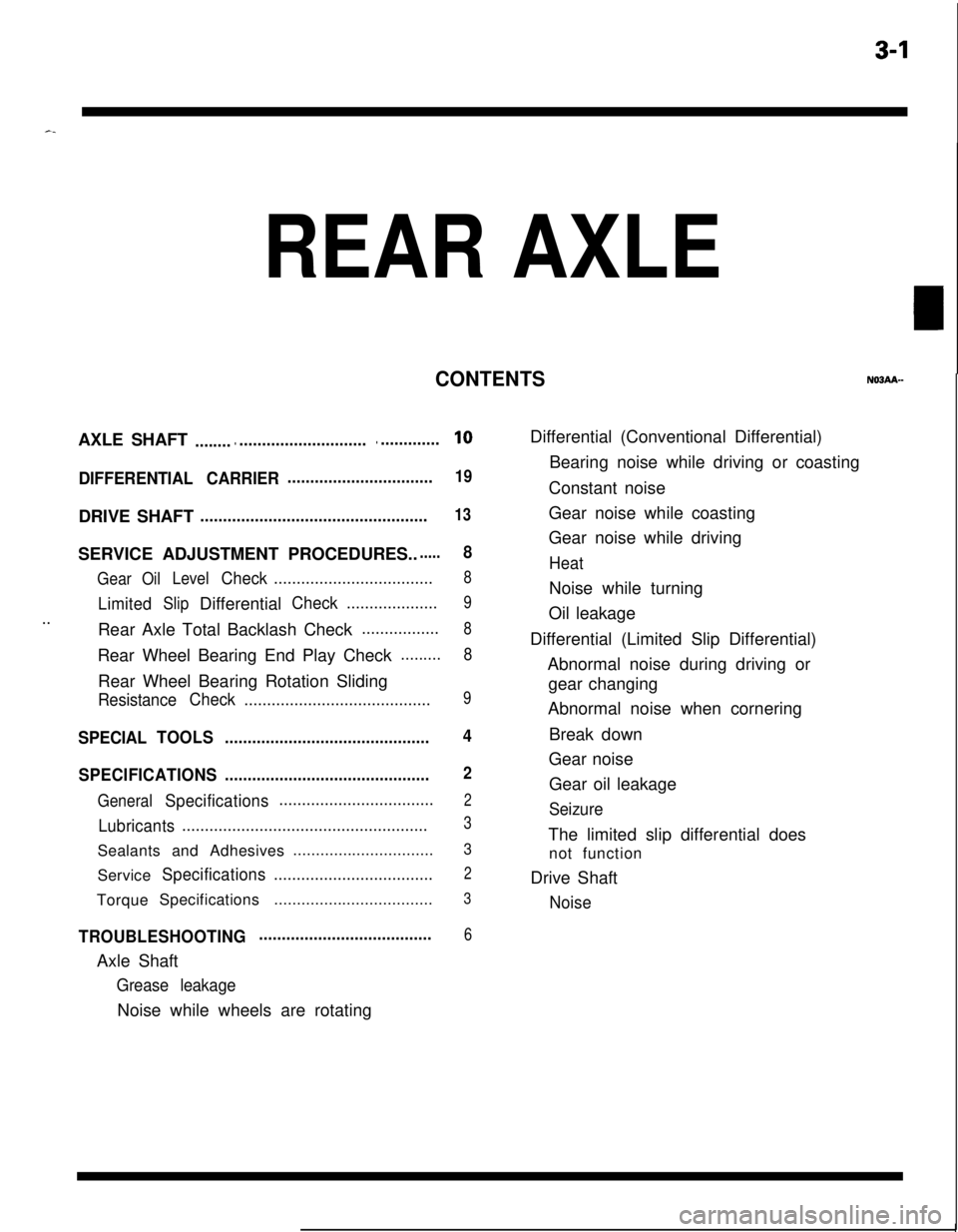

3-1

REAR AXLE

CONTENTSAXLE SHAFT

...................................................10

DIFFERENTIAL CARRIER................................19DRIVE SHAFT

..................................................13SERVICE ADJUSTMENT PROCEDURES..

.....8

GearOilLevelCheck...................................8

LimitedSlipDifferentialCheck....................9

..Rear Axle Total Backlash Check.................8Rear Wheel Bearing End Play Check

.........

8Rear Wheel Bearing Rotation Sliding

ResistanceCheck.........................................9

SPECIALTOOLS.............................................4

SPECIFICATIONS.............................................

2

GeneralSpecifications..................................2

Lubricants......................................................3Sealants and Adhesives...............................

3Service

Specifications...................................2TorqueSpecifications...................................

3

TROUBLESHOOTING......................................6Axle Shaft

Grease leakageNoise while wheels are rotatingDifferential (Conventional Differential)

Bearing noise while driving or coasting

Constant noise

Gear noise while coasting

Gear noise while driving

HeatNoise while turning

Oil leakage

Differential (Limited Slip Differential)

Abnormal noise during driving or

gear changing

Abnormal noise when cornering

Break down

Gear noise

Gear oil leakage

SeizureThe limited slip differential does

not function

Drive Shaft

Noise

Page 104 of 1216

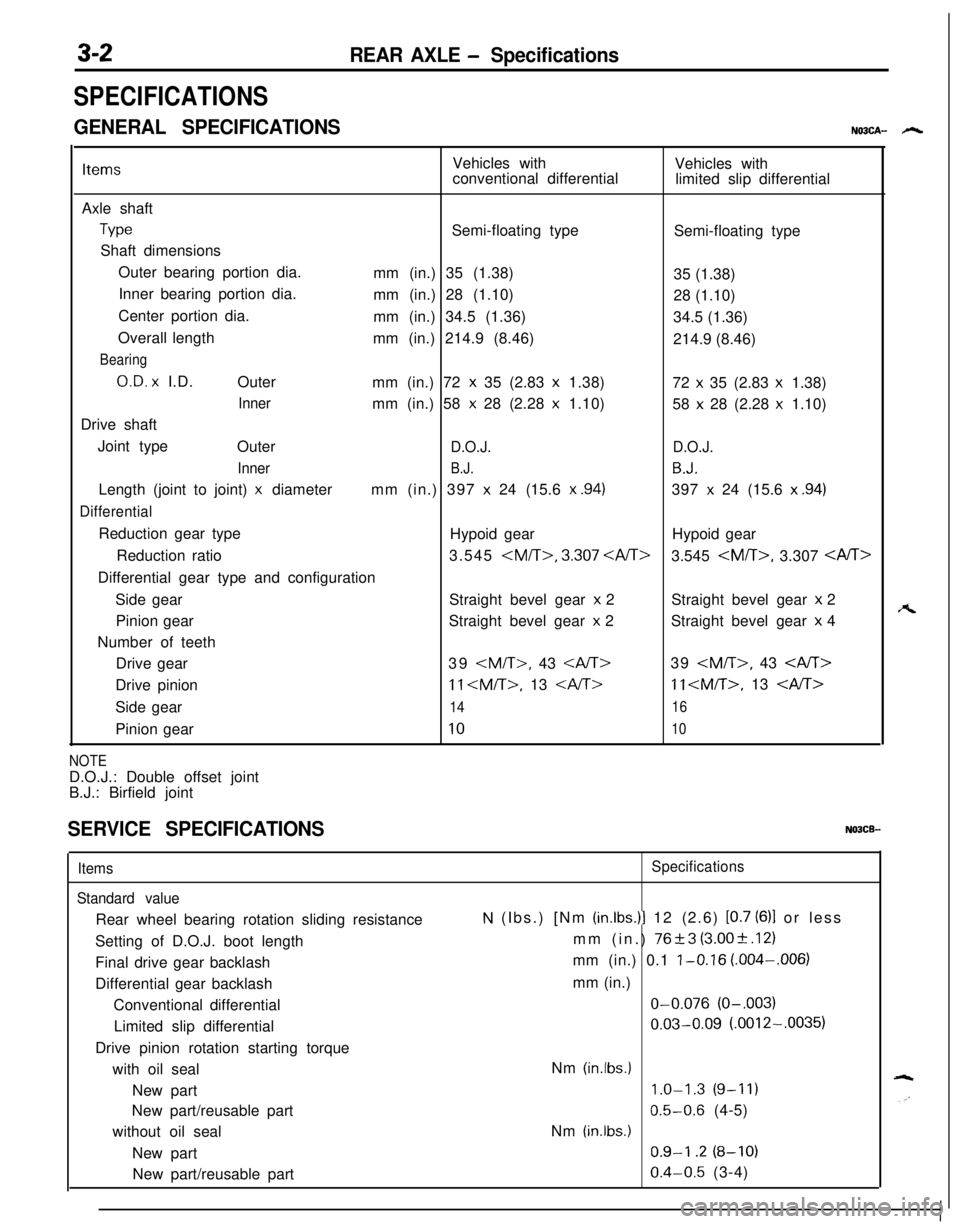

3-2REAR AXLE - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSNO3CA- h

ItemsVehicles with

Vehicles with

conventional differential

limited slip differential

Axle shaft

TypeSemi-floating type

Semi-floating type

Shaft dimensions

Outer bearing portion dia.

mm (in.) 35 (1.38)

35 (1.38)

Inner bearing portion dia.

mm (in.) 28 (1.10)

28 (1.10)

Center portion dia.

mm (in.) 34.5 (1.36)

34.5 (1.36)

Overall length

mm (in.) 214.9 (8.46)

214.9 (8.46)

Bearing

O.D. x I.D.

Outer

mm (in.) 72 x 35 (2.83 x 1.38)

72 x 35 (2.83 x 1.38)

Innermm (in.) 58 x 28 (2.28 x 1.10)

58 x 28 (2.28 x 1.10)

Drive shaft

Joint type

Outer

D.O.J.D.O.J.

Inner

B.J.B.J.Length (joint to joint)

x diametermm (in.) 397 x 24 (15.6 x .94)397 x 24 (15.6 x .94)

DifferentialReduction gear type

Hypoid gearHypoid gear

Reduction ratio3.545

3.545

Side gearStraight bevel gear

x 2Straight bevel gear x 2

Pinion gearStraight bevel gear

x 2Straight bevel gear x 4

Number of teeth

Drive gear39

11

Side gear

1416Pinion gear

1010

NOTED.O.J.: Double offset joint

B.J.: Birfield joint

SERVICE SPECIFICATIONSNOBCB-

Items

Standard valueRear wheel bearing rotation sliding resistance

Setting of D.O.J. boot length

Final drive gear backlash

Differential gear backlash

Conventional differential

Limited slip differential

Drive pinion rotation starting torque

with oil seal

New part

New part/reusable part

without oil seal

New part

New part/reusable partSpecifications

N (Ibs.) [Nm (in.lbs.)l 12 (2.6) [0.7 (6)l or less

mm (in.)

76+3 (3.00+.12)

mm (in.) 0.1

l-0.16 (.004-,006)

mm (in.)O-0.076

(O-.003)

0.03-0.09 (.0012-.0035)

Nm

(in.lbs.)

1.0-1.3 (9-11)

0.5-0.6 (4-5)

Nm

(in.lbs.)

0.9-I .2 (8-10)

0.4-0.5 (3-4)

A

Page 105 of 1216

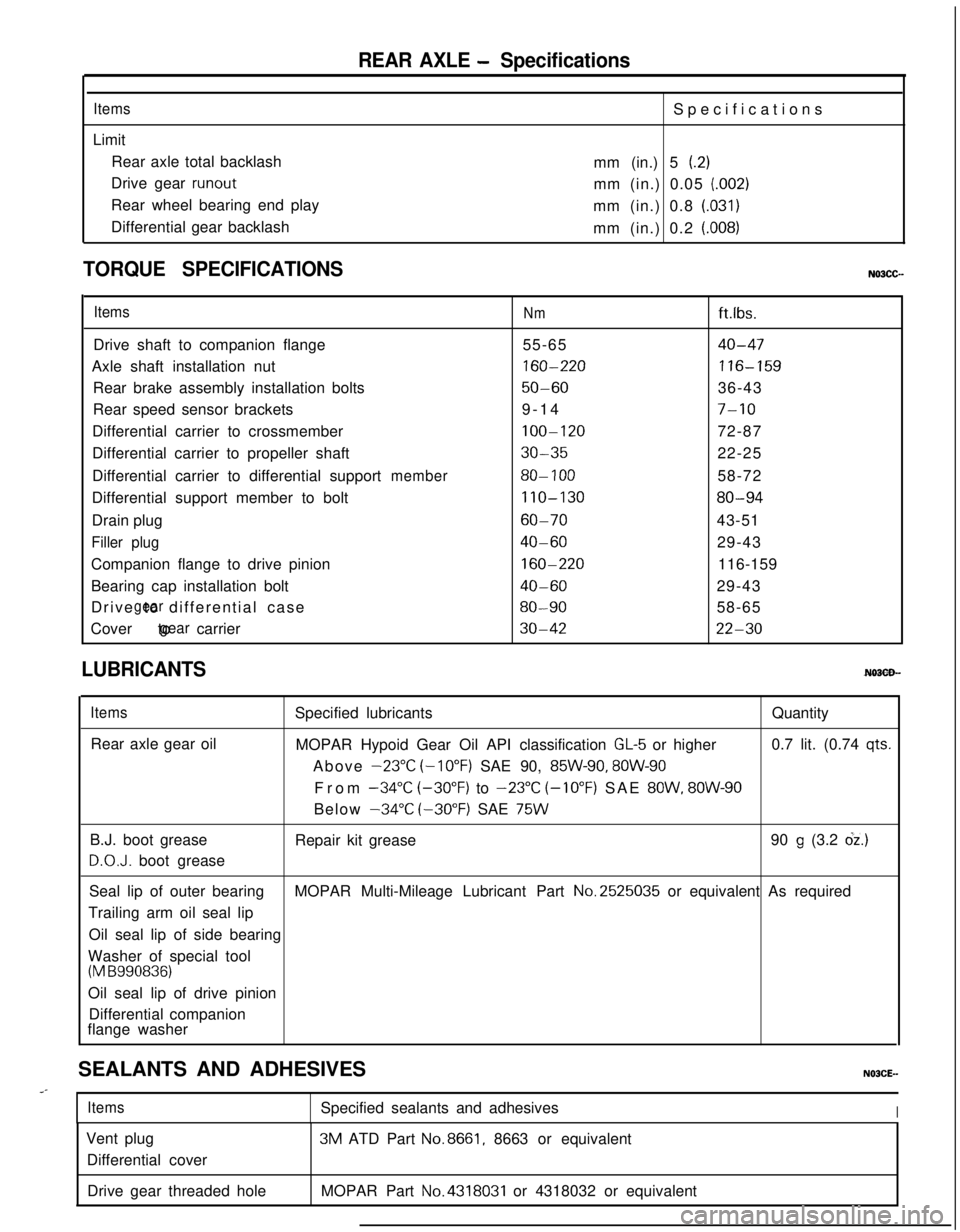

REAR AXLE - Specifications

ItemsLimit

Rear axle total backlash

Drive gear

runoutRear wheel bearing end play

Differential gear backlashSpecifications

mm (in.) 5

(.2)mm (in.) 0.05

(.002)mm (in.) 0.8

(.031)mm (in.) 0.2

(.008)

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Drive shaft to companion flange55-65

40-47Axle shaft installation nut

160-220116-159Rear brake assembly installation bolts

50-6036-43

Rear speed sensor brackets9-14

7-10Differential carrier to crossmember

100-12072-87

Differential carrier to propeller shaft

30-3522-25

Differential carrier to differential support

member80- 10058-72

Differential support member to bolt

110-13080-94Drain plug

60-7043-51

Filler plug40-6029-43

Companion flange to drive pinion

160-220116-159

Bearing cap installation bolt

40-6029-43

Drive to differential case

gear80-9058-65

Cover to carrier

gear30-4222-30

LUBRICANTS

ItemsRear axle gear oilSpecified lubricantsQuantity

MOPAR Hypoid Gear Oil API classification

GL-5 or higher0.7 lit. (0.74 qts.Above

-23°C (-10°F) SAE 90, 85W-90, 8OW-90From

-34°C (-30°F) to -23°C (-10°F) SAE 8OW, 8OW-90Below

-34°C (-30°F) SAE 75WB.J. boot grease

D.O.J. boot greaseRepair kit grease90

g (3.2 dz.)Seal lip of outer bearingMOPAR Multi-Mileage Lubricant Part No.2525035 or equivalent As required

Trailing arm oil seal lip

Oil seal lip of side bearing

Washer of special tool

(M B990836)Oil seal lip of drive pinion

Differential companion

flange washer

SEALANTS AND ADHESIVES

..-

ItemsSpecified sealants and adhesivesIVent plug

Differential cover3M ATD Part

No.8661, 8663 or equivalent

Drive gear threaded holeMOPAR Part

No.4318031 or 4318032 or equivalent

Page 106 of 1216

REAR AXLE - SDecial Tools

SPECIAL TOOLSN03DA--

ToolNumber

Name

UseMB990767

End yoke holderMeasurement of rotation torque of the limiter

/slip differentialStop axle shaft turning

CT-l 003Axle shaft pullerPress-fitting the drive pinion rear bearing outerace

Sliding hammer set

Removal of the axle shaftMB990560

Bearing removerRemoval of the axle shaft dust cover, oute

bearing and rear rotor

Press-in the outer wheel bearing and rear rotorMB991115

Oil seal installer

Press-fitting of drive shaft oil seal

Side bearing puller

Removal of the side