engine MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 53 of 1216

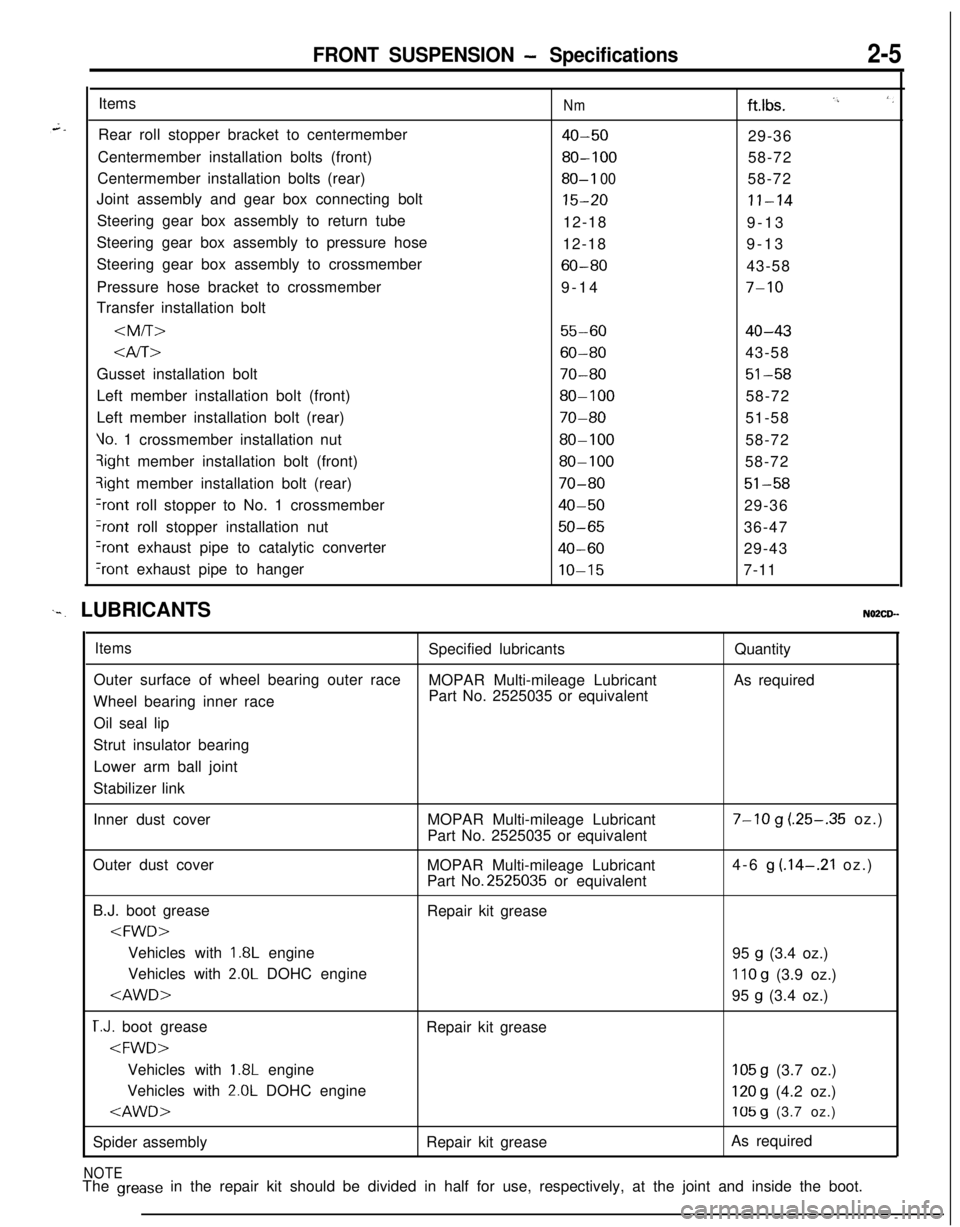

FRONT SUSPENSION - Specifications2-5Items

Rear roll stopper bracket to centermember

Centermember installation bolts (front)

Centermember installation bolts (rear)

Joint assembly and gear box connecting bolt

Steering gear box assembly to return tube

Steering gear box assembly to pressure hose

Steering gear box assembly to crossmember

Pressure hose bracket to crossmember

Transfer installation bolt

Nmftlbs. I’, ‘,

40-5029-36

80-10058-72

80-I 0058-72

15-20II-1412-18

9-13

12-189-13

60-8043-58

9-14

7-10

55-6040-43

Gusset installation bolt

70-8051-58Left member installation bolt (front)

80-10058-72

Left member installation bolt (rear)

70-8051-58

Vo. 1 crossmember installation nut80-10058-72qight member installation bolt (front)

80-10058-72?ight member installation bolt (rear)

70-8051-58

+ont roll stopper to No. 1 crossmember40-5029-36

?ont roll stopper installation nut50-6536-47

Iront exhaust pipe to catalytic converter40-6029-43

‘rant exhaust pipe to hangerIO-157-11

‘-. LUBRICANTSNO2CD--

ItemsSpecified lubricantsQuantity

Outer surface of wheel bearing outer race

MOPAR Multi-mileage LubricantAs required

Wheel bearing inner racePart No. 2525035 or equivalent

Oil seal lip

Strut insulator bearing

Lower arm ball joint

Stabilizer link

Inner dust coverMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7-10 g (.25-.35 oz.)

Outer dust cover

MOPAR Multi-mileage Lubricant

Part

No.2525035 or equivalent4-6

g (.14-.21 oz.)

B.J. boot grease

Repair kit grease

1.8L engine

95 g (3.4 oz.)

Vehicles with

2.0L DOHC engine110 g (3.9 oz.)

T.J. boot grease

Repair kit grease

1.8L engine105 g (3.7 oz.)

Vehicles with

2.0L DOHC engine120 g (4.2 oz.)

Spider assemblyRepair kit greaseAs required

NOTEThe grease in the repair kit should be divided in half for use, respectively, at the joint and inside the boot.

Page 68 of 1216

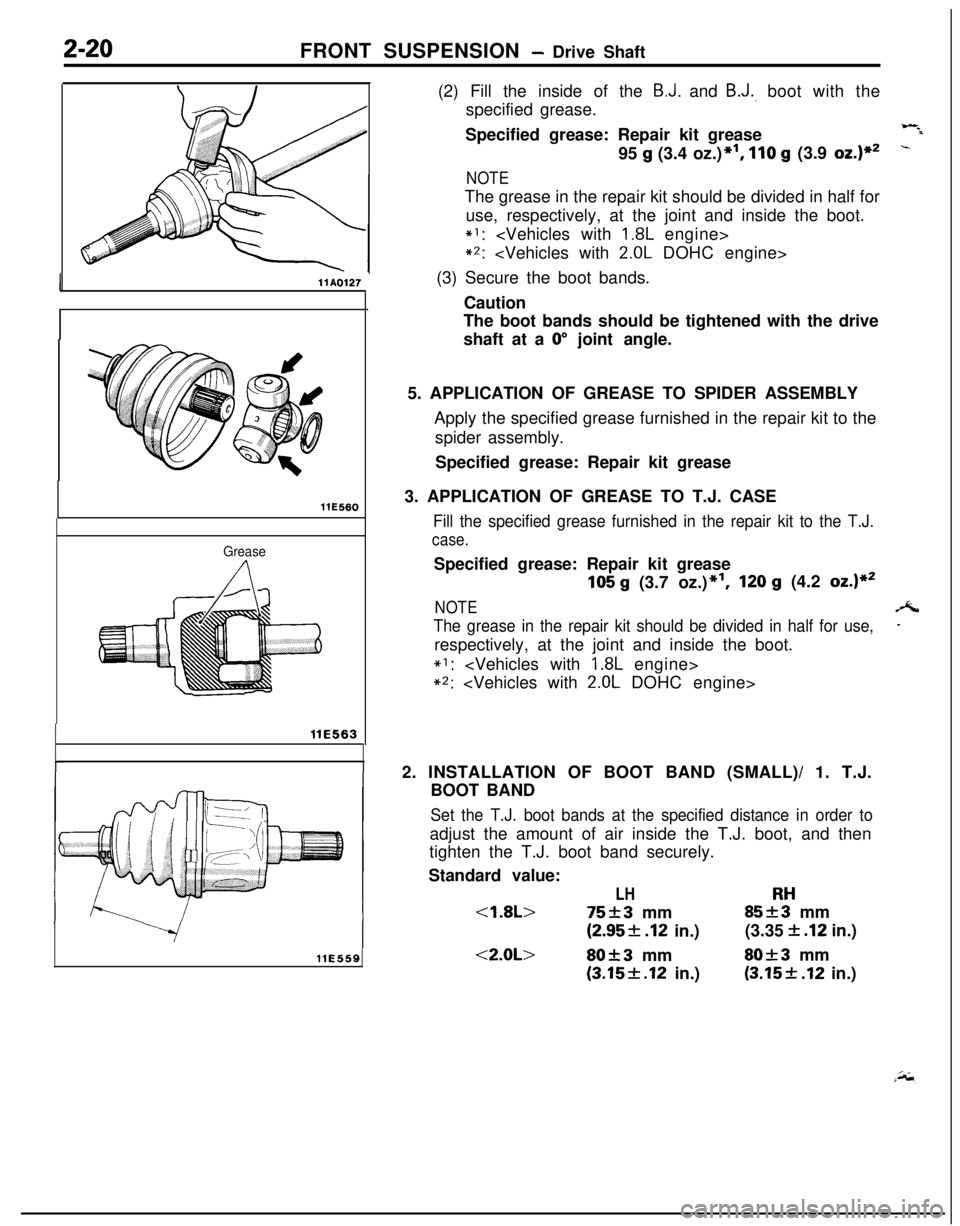

FRONT SUSPENSION - Drive Shaft

IllA0127

llE560

Grease

llE563

llE559(2) Fill the inside of the

B.J. and B.J., boot with the

specified grease.

Specified grease: Repair kit grease

Wil95

g (3.4 oz.)*I, 110 g (3.9 oz.)**-

NOTEThe grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

*I:

*2:

(3) Secure the boot bands.

Caution

The boot bands should be tightened with the drive

shaft at a

0” joint angle.

5. APPLICATION OF GREASE TO SPIDER ASSEMBLY

Apply the specified grease furnished in the repair kit to the

spider assembly.

Specified grease: Repair kit grease

3. APPLICATION OF GREASE TO T.J. CASE

Fill the specified grease furnished in the repair kit to the T.J.

case.Specified grease: Repair kit grease

105 g (3.7 oz.)*‘I,120 g (4.2 oz.)**

NOTEA

The grease in the repair kit should be divided in half for use,-respectively, at the joint and inside the boot.

*I:

*2:

2. INSTALLATION OF BOOT BAND (SMALL)/ 1. T.J.

BOOT BAND

Set the T.J. boot bands at the specified distance in order toadjust the amount of air inside the T.J. boot, and then

tighten the T.J. boot band securely.

Standard value:

LHRH

(2.95f .I2 in.)(3.35 f .I2 in.)

<2.0L>80f3 mmSO+3 mm

(3.15f.12 in.)(3.15+ .I2 in.)

Page 92 of 1216

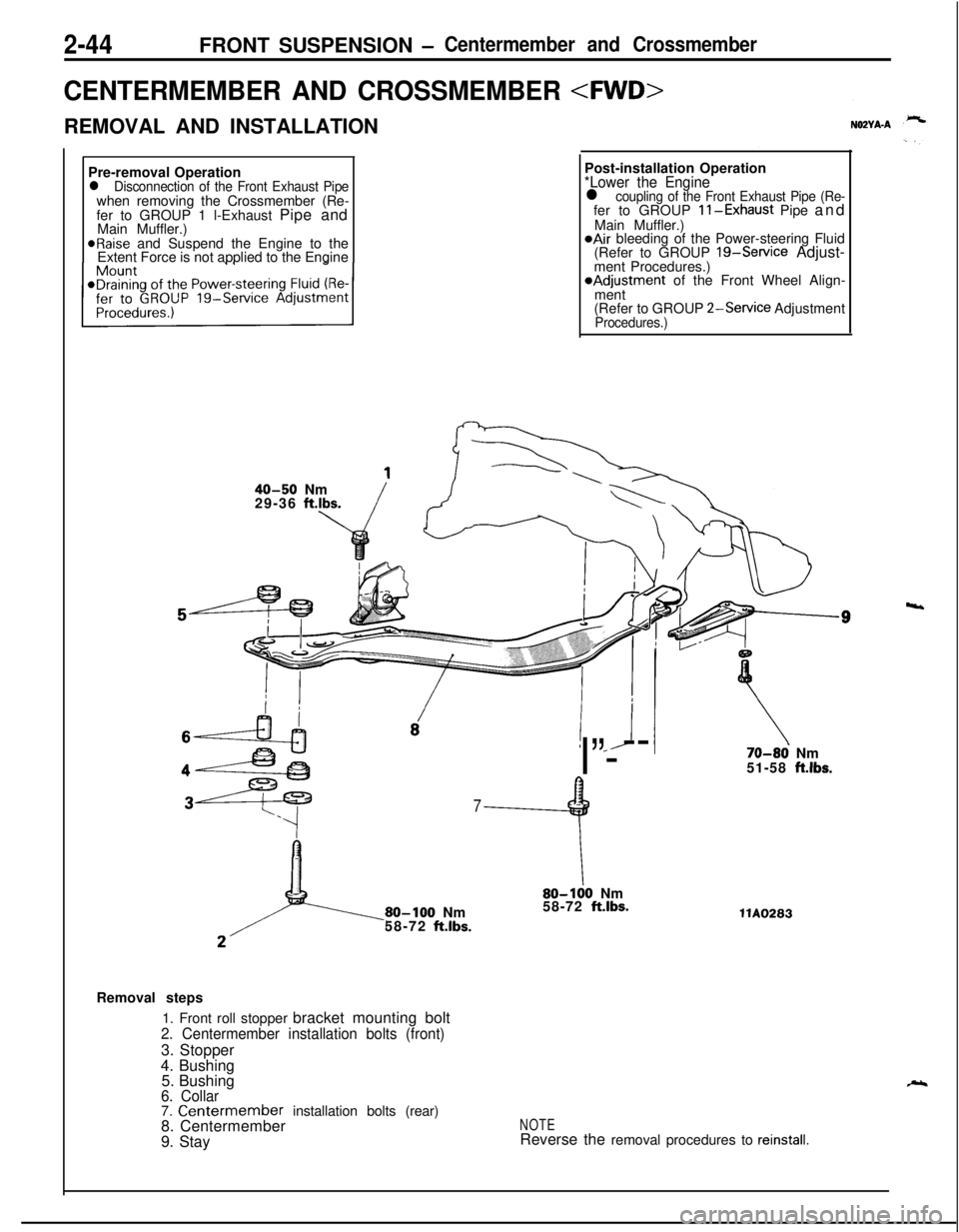

2-44FRONT SUSPENSION -Centermember and Crossmember

CENTERMEMBER AND CROSSMEMBER

REMOVAL AND INSTALLATION

Pre-removal Operation

l Disconnection of the Front Exhaust Pipewhen removing the Crossmember (Re-

fer to GROUP 1 l-Exhaust Pipe and

Main Muffler.)

@Raise and Suspend the Engine to the

Extent Force is not applied to the EnginePost-installation Operation

*Lower the Enginel coupling of the Front Exhaust Pipe (Re-fer to GROUP ll-Exhaust Pipe and

Main Muffler.)

@Air bleeding of the Power-steering Fluid

(Refer to GROUP 19-Service Adjust-

ment Procedures.)*Adjustment of the Front Wheel Align-

ment

(Refer to GROUP

2-Service AdjustmentProcedures.)

40-50 Nm

29-36 ft.lbs.

! *J

I”---

7

9

80-100 Nm

58-72 ft.lbs.

\80-100 Nm

58-72 ft.lbs.

70-86 Nm

51-58 ft.lbs.llA0283

Removal steps

1. Front roll stopper bracket mounting bolt

2. Centermember installation bolts (front)3. Stopper

4. Bushing

5. Bushing

6. Collar7. Centermember installation bolts (rear)

8. Centermember

9. StayNOTEReverse the removal procedures to reinstall.

4

Page 109 of 1216

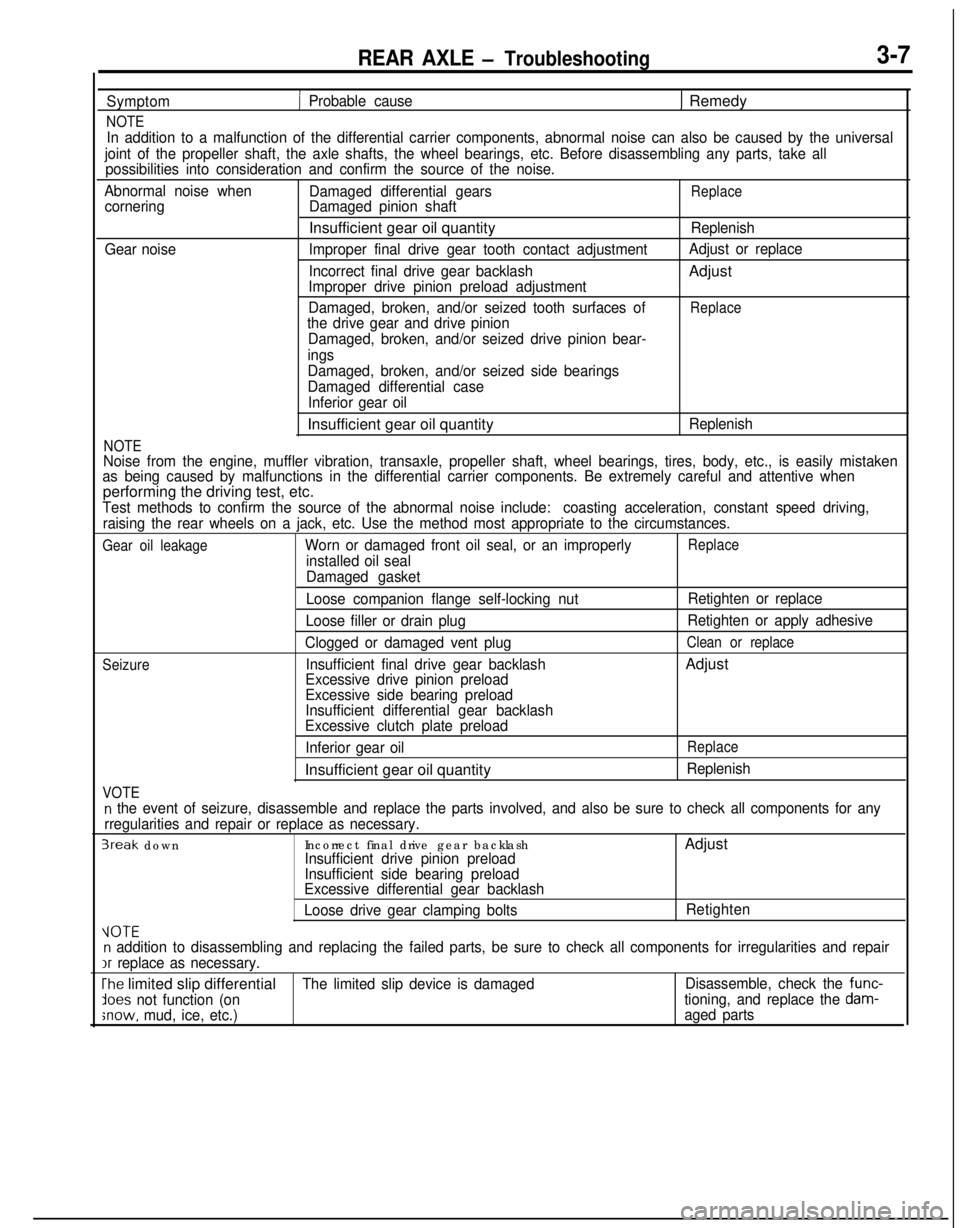

REAR AXLE - Troubleshooting3-7

Symptom

NOTE

1 Probable cause1 Remedy

In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the universal

joint of the propeller shaft, the axle shafts, the wheel bearings, etc. Before disassembling any parts, take all

possibilities into consideration and confirm the source of the noise.

Abnormal noise when

Damaged differential gears

ReplacecorneringDamaged pinion shaftInsufficient gear oil quantity

Replenish

Gear noiseImproper final drive gear tooth contact adjustmentAdjust or replace

Incorrect final drive gear backlashAdjust

Improper drive pinion preload adjustment

Damaged, broken, and/or seized tooth surfaces of

Replacethe drive gear and drive pinion

Damaged, broken, and/or seized drive pinion bear-

ings

NOTE

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oilInsufficient gear oil quantity

Replenish

Noise from the engine, muffler vibration, transaxle, propeller shaft, wheel bearings, tires, body, etc., is easily mistaken

as being caused by malfunctions in the differential carrier components. Be extremely careful and attentive whenperforming the driving test, etc.

Test methods to confirm the source of the abnormal noise include:coasting acceleration, constant speed driving,

raising the rear wheels on a jack, etc. Use the method most appropriate to the circumstances.

Gear oil leakageWorn or damaged front oil seal, or an improperlyReplace

installed oil seal

Damaged gasket

Seizure

VOTE

Loose companion flange self-locking nut

Loose filler or drain plug

Clogged or damaged vent plug

Insufficient final drive gear backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear oilInsufficient gear oil quantityRetighten or replace

Retighten or apply adhesive

Clean or replaceAdjust

Replace

Replenish

n the event of seizure, disassemble and replace the parts involved, and also be sure to check all components for any

rregularities and repair or replace as necessary.

3reak downIncorrect final drive gear backlashAdjustInsufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

Loose drive gear clamping boltsRetighten

VOTEn addition to disassembling and replacing the failed parts, be sure to check all components for irregularities and repairIr

replace as necessary.

The limited slip differentialThe limited slip device is damagedDisassemble, check the func-

lees not function (ontioning, and replace the dam-

;now, mud, ice, etc.)aged parts

Page 149 of 1216

BRAKES - Anti-lock Braking System Troubleshooting5-9

ANTI-LOCK BRAKING SYSTEM

-- TROUBLESHOOTINGNO!JEBAE

PARTICULAR CHARACTERISTICS OF

THE ANTI-LOCK BRAKING SYSTEMModels equipped with the anti-lock braking system

(A.B.S.) may exhibit one or more of the following

characteristics from time to time, but none of these

is abnormal.

(1) A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.Actually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.(2) When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), a

whining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place, but this noise is simply the result

of a self-check being made of the anti-lock

braking system operation.

TROUBLESHOOTING METHODSProblems related to the anti-lock braking system

(A.B.S.) can be classified into two general categor-

ies: problems in the electrical system and those in

the hydraulic system.For problems in the electrical system, the

self-diagnosis function is built into the electronic control

unit (E.C.U.) causing the A.B.S. warning light to

illuminate as a warning to the driver.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check todetermine whether the problem is related to ordin-

ary brake components or to the components relatedto the A.B.S.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART(1) Using the flow chart, check the ABS warning

light light-up sequence and check the condition

of braking operation.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Explana-tion] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTEECU: Electronic control unit

HU: Hydraulic unit

MUT: Multi-use tester

Page 150 of 1216

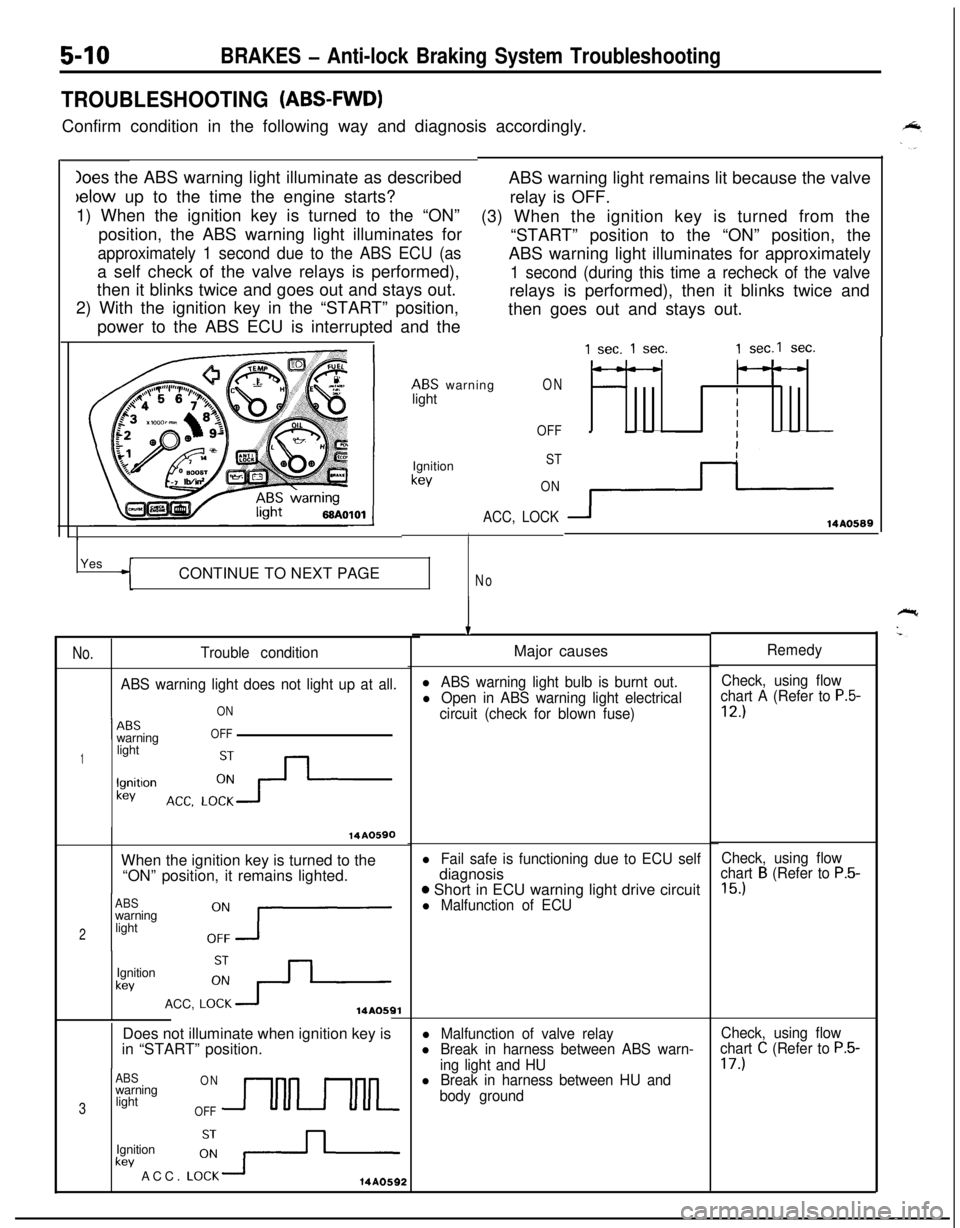

Ioes the ABS warning light illuminate as describedbelow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light illuminates for

approximately 1 second due to the ABS ECU (asa self check of the valve relays is performed),

then it blinks twice and goes out and stays out.

2) With the ignition key in the “START” position,

power to the ABS ECU is interrupted and the

5-10BRAKES - Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS-FWD)Confirm condition in the following way and diagnosis accordingly.

ABS warning light remains lit because the valve

relay is OFF.

(3) When the ignition key is turned from the

“START” position to the “ON” position, the

ABS warning light illuminates for approximately

1 second (during this time a recheck of the valverelays is performed), then it blinks twice and

then goes out and stays out.

ABS warning

lightON

OFF

1Ignition

kev

ST

ON

ACC, LOCK

IYes

CONTINUE TO NEXT PAGE

No

No.Trouble condition

ABS warning light does not light up at all.

ON

1 --ABSwarningOFF

1lightlgnitlon

kev

14A0590When the ignition key is turned to the

“ON” position, it remains lighted.

ABSwarning

2light

Ignition

kevACC,

LO:+14AOSQlDoes not illuminate when ignition key is

in “START” position.

ABSONwarning

3lightOFFUULkev ACC.

LO:-+-Ignition14A0592

1 sec. 1 sec.1 sec.1 sec.

---

IIII

3114AO589

IMajor causes

l ABS warning light bulb is burnt out.Check, using flow

l Open in ABS warning light electricalchart A (Refer to P.5-

circuit (check for blown fuse)12.)

l Fail safe is functioning due to ECU selfdiagnosis

o Short in ECU warning light drive circuitl Malfunction of ECU

l Malfunction of valve relayl Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

body groundRemedy

Check, using flow

chart

B (Refer to P.5-

15.)

Check, using flow

chart C (Refer to P.5-17.)

Page 153 of 1216

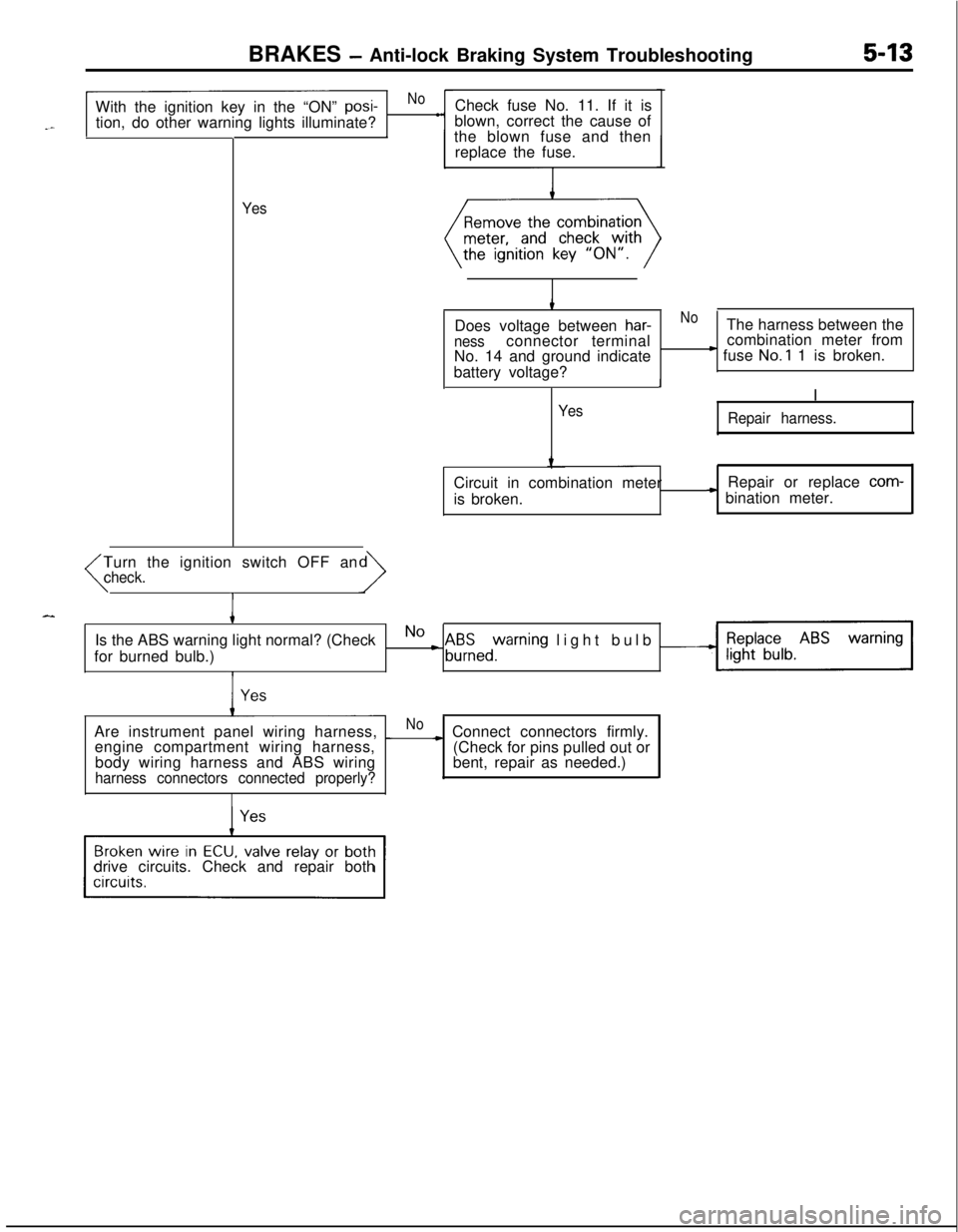

BRAKES - Anti-lock Braking System Troubleshooting5-13With the ignition key in the “ON”

posi-Nol

tion, do other warning lights illuminate?

II

YesCheck fuse No. 11. If it is

blown, correct the cause of

the blown fuse and then

replace the fuse.

Does voltage between

har-NoThe harness between thenessconnector terminalcombination meter from

No. 14 and ground indicate) fuse No.1 1 is broken.

battery voltage?

II

Yes

Repair harness.Circuit in combination meter

is broken.Repair or replace

com-

* bination meter.

Turn the ignition switch OFF an

(check.

IIs the ABS warning light normal? (Check

for burned bulb.)

No L A&zed%rning light bulb -Are instrument panel wiring harness,

_Noengine compartment wiring harness,~ Connect connectors firmly.

(Check for pins pulled out or

bent, repair as needed.) body wiring harness and ABS wiring

harness connectors connected properly?drive circuits. Check and repair both

Page 155 of 1216

![MITSUBISHI ECLIPSE 1991 Owners Guide BRAKES - Anti-lock Braking System Troubleshooting5-15

--

BABS warning light illuminated after the engine is started and remains on.

[Explanation]

This is the symptom when the ABS ECU does not

power up MITSUBISHI ECLIPSE 1991 Owners Guide BRAKES - Anti-lock Braking System Troubleshooting5-15

--

BABS warning light illuminated after the engine is started and remains on.

[Explanation]

This is the symptom when the ABS ECU does not

power up](/img/19/57104/w960_57104-154.png)

BRAKES - Anti-lock Braking System Troubleshooting5-15

--

BABS warning light illuminated after the engine is started and remains on.

[Explanation]

This is the symptom when the ABS ECU does not

power up due to broken ECU power circuit, etc.,

when the fail safe function operates and isolates thesystem or when the warning light drive circuit is

short circuited.

MAINIGNITION

FUSIBLELINK

@IEYCH

z

A:7

J/B

rb

0

10A

I

:c

r

I

1vAI23

f

! 127ABS ECUCheck, using check chart

E-l -E-6.Check warning light drive

circuit.

t

Does the ABS warning lightNoShort in ECU transistor

remainilluminated even

with the ECU connector dis-

connected?

I

1 YesIReplace

I

Does the ABS warning light

remainilluminated even

with the ECU connector dis-

connected?

Yes

IReplace HU or replacevalve relay.I

Page 164 of 1216

![MITSUBISHI ECLIPSE 1991 Owners Guide 5-24BRAKES - Anti-lock Braking System Troubleshooting

E-6 Abnormality of motor drive circuit

[Explanation]The ABS ECU illuminates the warning light for the

motor relay and motor in the following cases MITSUBISHI ECLIPSE 1991 Owners Guide 5-24BRAKES - Anti-lock Braking System Troubleshooting

E-6 Abnormality of motor drive circuit

[Explanation]The ABS ECU illuminates the warning light for the

motor relay and motor in the following cases](/img/19/57104/w960_57104-163.png)

5-24BRAKES - Anti-lock Braking System Troubleshooting

E-6 Abnormality of motor drive circuit

[Explanation]The ABS ECU illuminates the warning light for the

motor relay and motor in the following cases.

l When the motor relay does not function

lWhen there is trouble with the motor itself and it

does not revolve

lWhen the motor ground line is disconnected and

[Hint]If there is motor operation noise when wheel speed

exceeds

Gkm/h (4mph) when starting up after the

engine is started, there is a broken or short circuitedmotor monitor wire.

the motor does not revolve

l When the motor continues to revolve

14A0605Does the motor make a

YesBroken wire or short cir-noise when wheel speedcuit in motor monitor line

exceeds 6 km/h (4 mph)?

1Repair the harness be-

tween HU and ECU.

, NoRemove the motor relay.

Remove the motor relay andcheck resistance values.

No. 85-No. 86:resistancevalue

30-60 52No.30-No.87: no continui-

ty

Battery voltage is applied onterminals No. 86 and No.85

grounded.No.30-No.87: continuity

IYesIs pump motor ground con-

NoConnect ground wire.

netted normally?

IlYes

motor relay and re-

move HU connector.>Does voltage between body

connector terminal 51 and

No c Broken wire in pump

motor power circuit

ground indicate battery vol-

tage?4Repair the harness.

YesIs resistance between body

NoMalfunction of harnessconnector terminal No. 2 andbetween HU and ECUNo.26 30-60 ohms?iII1Repair harness.

Page 165 of 1216

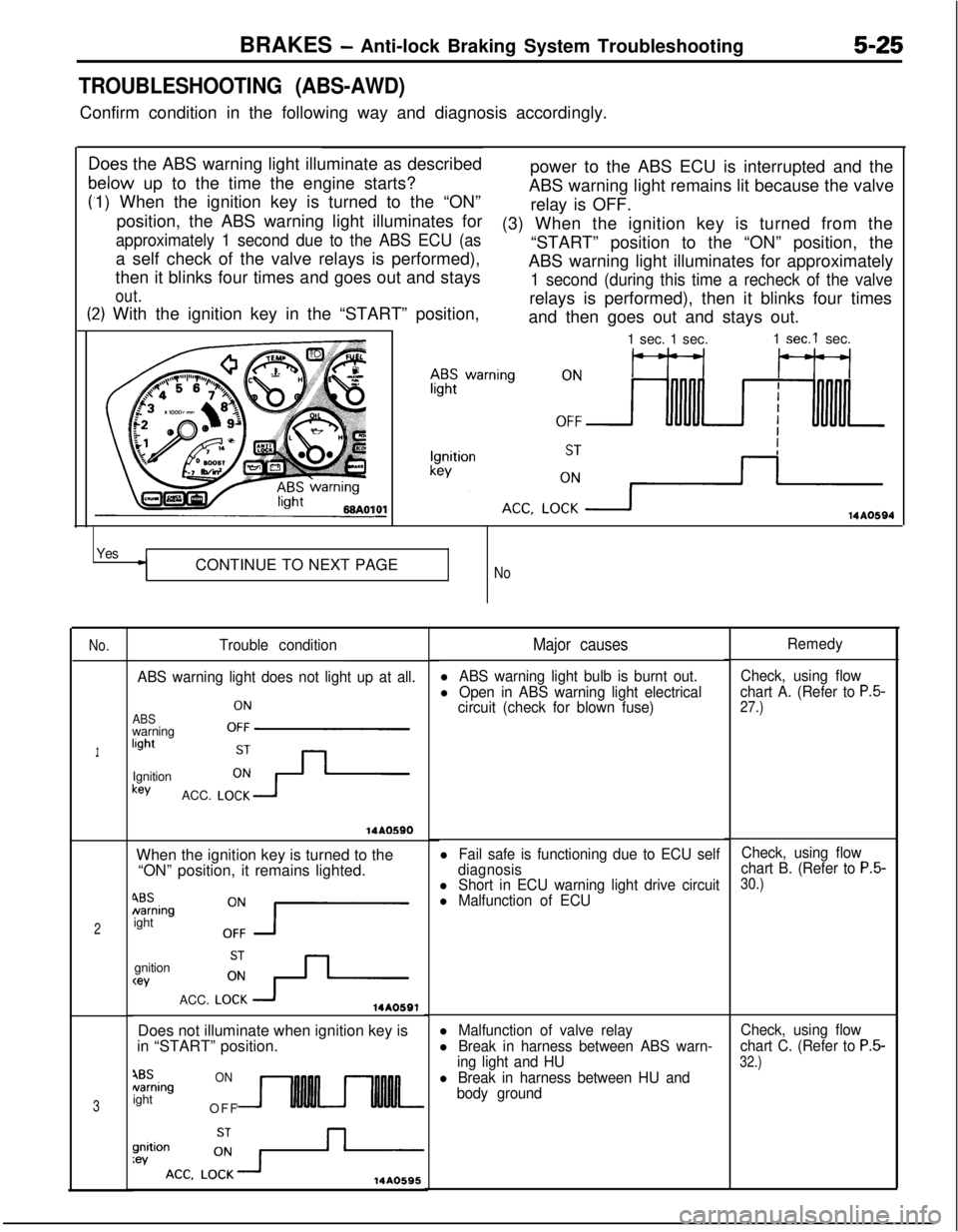

BRAKES - Anti-lock Braking System Troubleshooting5-25

TROUBLESHOOTING (ABS-AWD)Confirm condition in the following way and diagnosis accordingly.

C

F

>oes the ABS warning light illuminate as described

relow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light illuminates for

approximately 1 second due to the ABS ECU (asa self check of the valve relays is performed),

then it blinks four times and goes out and stays

out.power to the ABS ECU is interrupted and the

ABS warning light remains lit because the valve

relay is OFF.

t:2) With the ignition key in the “START” position,(3) When the ignition key is turned from the

“START” position to the “ON” position, the

ABS warning light illuminates for approximately

1 second (during this time a recheck of the valverelays is performed), then it blinks four times

and then goes out and stays out.IO1

-1 sec. 1 sec.1

sec.1 sec.

14AO594

YesCONTINUE TO NEXT PAGE

No

No.

1

2

3

Trouble condition

ABS warning light does not light up at all.

ABSwarninglightOFFIgnitionkey

ACC.

LO;-+

14AOSSOWhen the ignition key is turned to the

“ON” position, it remains lighted.

4BSNamingight

0:7gnition

wACC.

LO:+14A0591Does not illuminate when ignition key is

in “START” position.

4BSNamingightONOFF

14A0595

Major causes

l ABS warning light bulb is burnt out.

l Open in ABS warning light electrical

circuit (check for blown fuse)

l Fail safe is functioning due to ECU self

diagnosis

l Short in ECU warning light drive circuitl Malfunction of ECU

l Malfunction of valve relay

l Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

body groundRemedy

Check, using flow

chart A. (Refer to

P.5-27.)

Check, using flow

chart B. (Refer to P.5-30.)

Check, using flow

chart C. (Refer to

P.5-

32.)