oil filter MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 35 of 1216

LUBRICATION AND’ I

MAINTENANCE

CONTENTSGENERAL INFORMATION

..............................2MAINTENANCE SERVICE

...............................7Air

CleanerElement.....................................7Automatic Transaxle....................................

11Ball Joint and Steering Linkage Seals

........13Brake Hoses

.................................................12

DiscBrakePads...........................................12-lbDrive Belt (For Water Pump and

Alternator).....................................................8

DriveShaftBoots.........................................13

EngineCoolant.............................................12

EngineOil.....................................................9

EngineOilFilter...........................................9Exhaust System

............................................13

FuelHose.....................................................7

FuelSystem.................................................7

ManualTransaxle..........................................10

RearAxle......................................................13

SparkPlugs...................................................8

TimingBelt......................................................8RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE

..................4SCHEDULED MAINTENANCE TABLE

............3

Page 37 of 1216

LUBRICATION AND MAINTENANCE - Scheduled MaintenanCe Table. &3

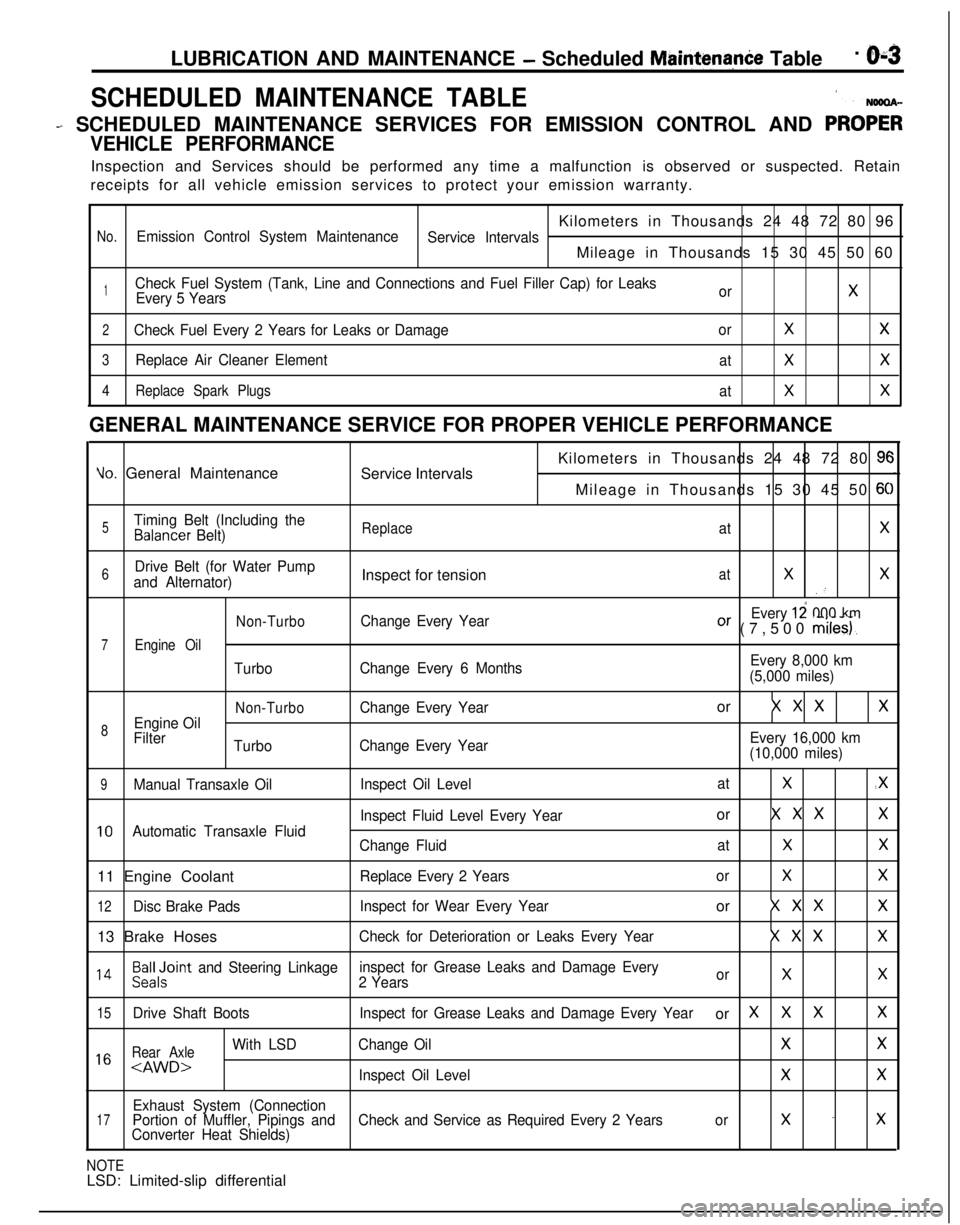

SCHEDULED MAINTENANCE TABLE1

- SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PRO;;

VEHICLE PERFORMANCEInspection and Services should be performed any time a malfunction is observed or suspected. Retain

receipts for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emission Control System Maintenance

Service IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Filler Cap) for Leaks

Every 5 YearsorX

2Check Fuel Every 2 Years for Leaks or DamageorXX

3Replace Air Cleaner Element

atXX

4Replace Spark Plugs

atXXGENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

Yo. General Maintenance

Service IntervalsKilometers in Thousands 24 48 72 80 9cMileage in Thousands 15 30 45 50

6C

5Timing Belt (Including theBalancer Belt)ReplaceatX

6Drive Belt (for Water Pump

and Alternator)Inspect for tensionatXX.’

Non-TurboChange Every YearEvery 12 000 kmOr (7,500 miles).

7Engine Oil

TurboChange Every 6 MonthsEvery 8,000 km

(5,000 miles)

Non-TurboChange Every Yearor X X XX

8Engine Oil

Filter

TurboChange Every YearEvery 16,000 km

(10,000 miles)

9Manual Transaxle OilInspect Oil LevelatX.X

Inspect Fluid Level Every Yearor X X XX

10Automatic Transaxle Fluid

Change FluidatXX11 Engine Coolant

Replace Every 2 YearsorXX

12Disc Brake PadsInspect for Wear Every Yearor X X XX13 Brake Hoses

Check for Deterioration or Leaks Every YearX X XX

l 4Beiloint and Steering Linkageinspect for Grease Leaks and Damage Every

2 YearsorXX

15Drive Shaft BootsInspect for Grease Leaks and Damage Every Yearor XXXX

Rear Axle

With LSDChange OilXX1 6

Exhaust System (Connection17Portion of Muffler, Pipings andCheck and Service as Required Every 2 Yearsorx -xConverter Heat Shields)

NOTELSD: Limited-slip differential

Page 38 of 1216

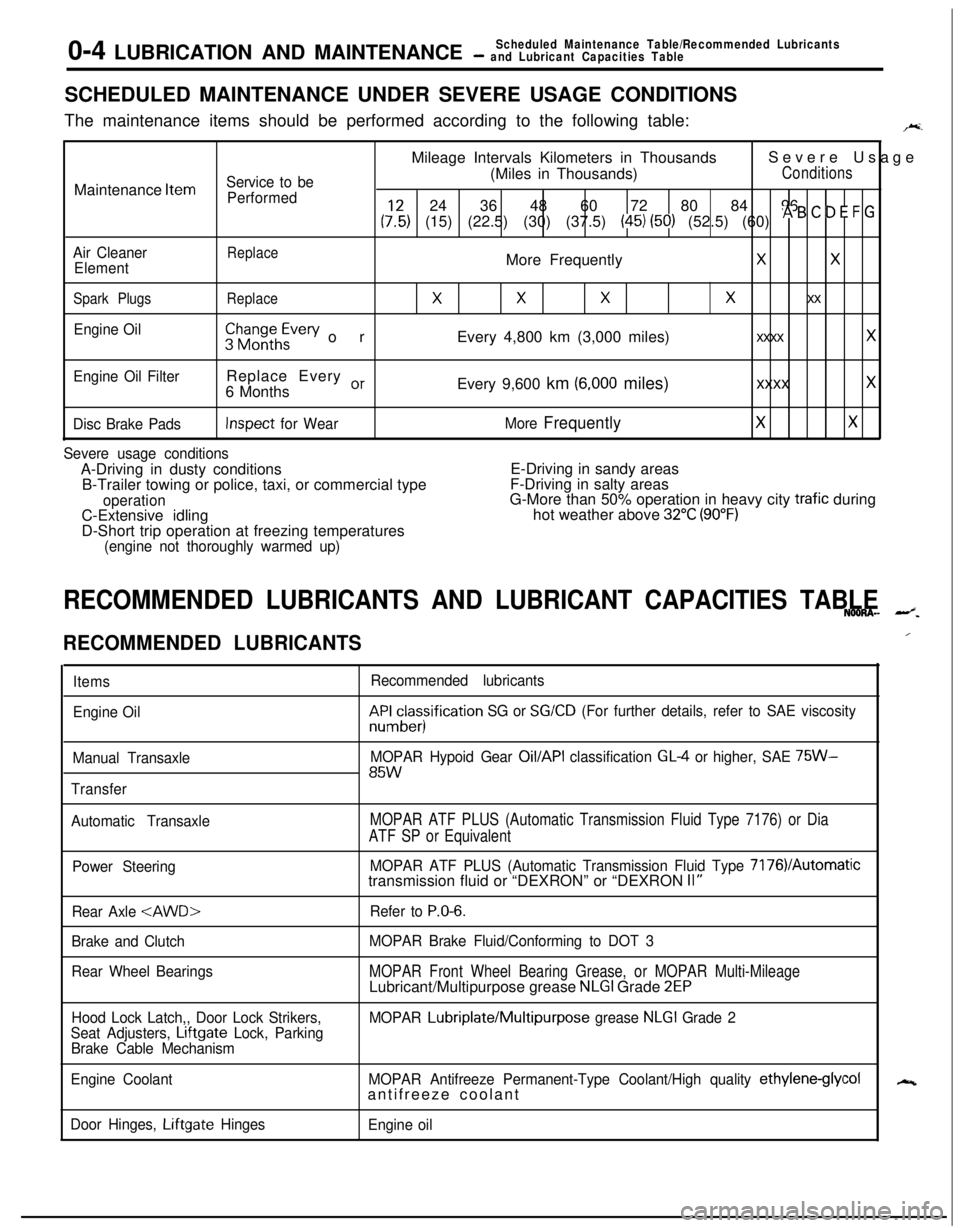

0-4 LUBRICATION AND MAINTENANCEScheduled Maintenance Table/Recommended Lubricants- and Lubricant Capacities TableSCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

F.Mileage Intervals Kilometers in ThousandsSevere Usage

Service to be(Miles in Thousands)ConditionsMaintenance

Item

Performed24 36 48 60 72 80 84 96

(:,:) (15) (22.5) (30) (37.5) (45) (50) (52.5) (60) * B ’ D E F G

Air CleanerReplaceElementMore FrequentlyXX

Spark PlugsReplace

XXXx xx

Engine Oil$$~~~h~vev orEvery 4,800 km (3,000 miles)xxxx x

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 km (6,000 miles)xxxx x

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditionsA-Driving in dusty conditionsE-Driving in sandy areas

B-Trailer towing or police, taxi, or commercial typeF-Driving in salty areas

operationG-More than 50% operation in heavy city trafic during

C-Extensive idlinghot weather above 32°C (90°F)D-Short trip operation at freezing temperatures

(engine not thoroughly warmed up)

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLENOONA- --z.

RECOMMENDED LUBRICANTS

Items

Engine Oil

Manual Transaxle

TransferRecommended lubricantskF&cesisification

SG or SG/CD (For further details, refer to SAE viscosity

MOPAR Hypoid Gear

Oil/API classification GL4 or higher, SAE 75W-85W

Automatic TransaxleMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176) or Dia

ATF SP or Equivalent

Power SteeringMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176VAutomatictransmission fluid or “DEXRON” or “DEXRON II”

Rear Axle

Brake and Clutch

Rear Wheel BearingsRefer to

P.O-6.

MOPAR Brake Fluid/Conforming to DOT 3

MOPAR Front Wheel Bearing Grease, or MOPAR Multi-MileageLubricant/Multipurpose grease NLGI Grade 2EP

Hood Lock Latch,, Door Lock Strikers,

Seat Adjusters, Lrftgate Lock, Parking

Brake Cable MechanismMOPAR Lubriplate/Multipurpose grease NLGI Grade 2

Engine CoolantMOPAR Antifreeze Permanent-Type Coolant/High quality

ethylene-glycolantifreeze coolant

Door Hinges, Liftgate Hinges

Engine oil

/

N

Page 39 of 1216

LUBRICATION AND MAINTENANCE - Recommended Lubrie’ntsand Lubrtcant Capacttles Table

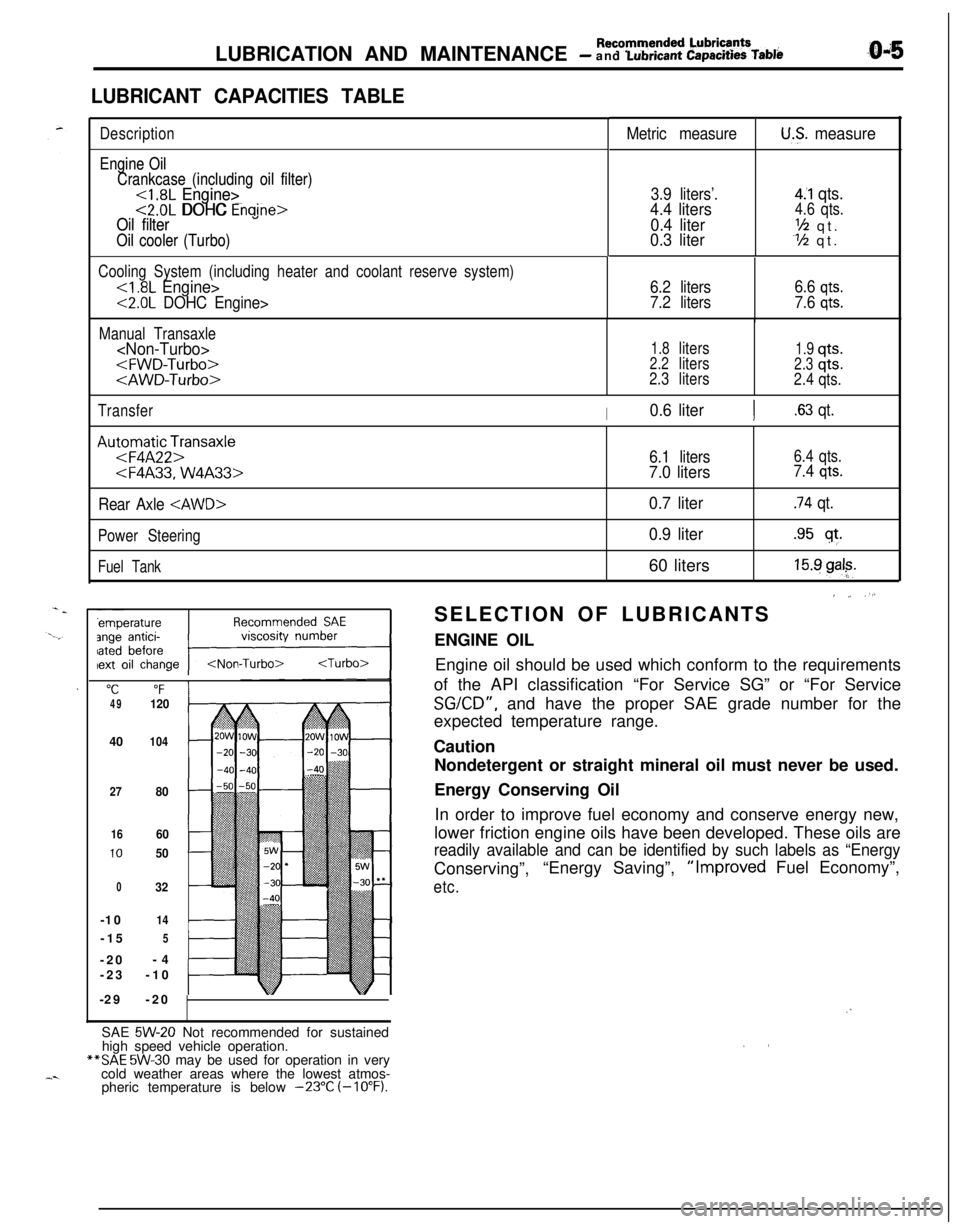

LUBRICANT CAPACITIES TABLE

Description

Engine Oil Engine Oil

Crankcase (including oil filter) Crankcase (including oil filter)

<1.8L Engine><1.8L Engine><2.0L DOHC Engine><2.0L DOHC Enaine>Oil filter Oil filter

Oil cooler (Turbo) Oil cooler (Turbo)

Metric measureU.S. measure

3.9 liters’.4.4 liters

0.4 liter

0.3 liter

4.‘1 qts.4.6 qts.

‘h qt.Y2 qt.

Cooling System (including heater and coolant reserve system)

<2.0L DOHC Engine>6.2 liters

7.2 liters6.6

qts.

7.6 qts.

Manual Transaxle

1.8liters1.9qts.2.2liters2.3qts.

2.3liters

2.4qts.

Transfer

I0.6 literI.63 qt.

Au:oFmqaAtF2pnsaxle

Rear Axle

Power Steering

Fuel Tank

"C“F4912040

104

27

80

1660

1050

032-10

14-15

5-20-4

-23-10

-29-20

6.1 liters6.4 qts.

7.0 liters7.4 qts.

0.7 liter.74 qt.

0.9 liter.95 sf.60 liters

15.9 gal?.

’ ~ “.SELECTION OF LUBRICANTS

ENGINE OIL

Engine oil should be used which conform to the requirements

of the API classification “For Service SG” or “For Service

SGKD”, and have the proper SAE grade number for the

expected temperature range.

Caution

Nondetergent or straight mineral oil must never be used.

Energy Conserving Oil

In order to improve fuel economy and conserve energy new,

lower friction engine oils have been developed. These oils are

readily available and can be identified by such labels as “EnergyConserving”,“Energy Saving”,“Improved Fuel Economy”,

etc.

/”SAE

5W-20 Not recommended for sustained

high speed vehicle operation.**SAE

5W-30 may be used for operation in very

cold weather areas where the lowest atmos-

pheric temperature is below

-23°C (-10°F).

Page 43 of 1216

LUBRICATION AND MAINTENANCE - Maintenance ServiceO-9

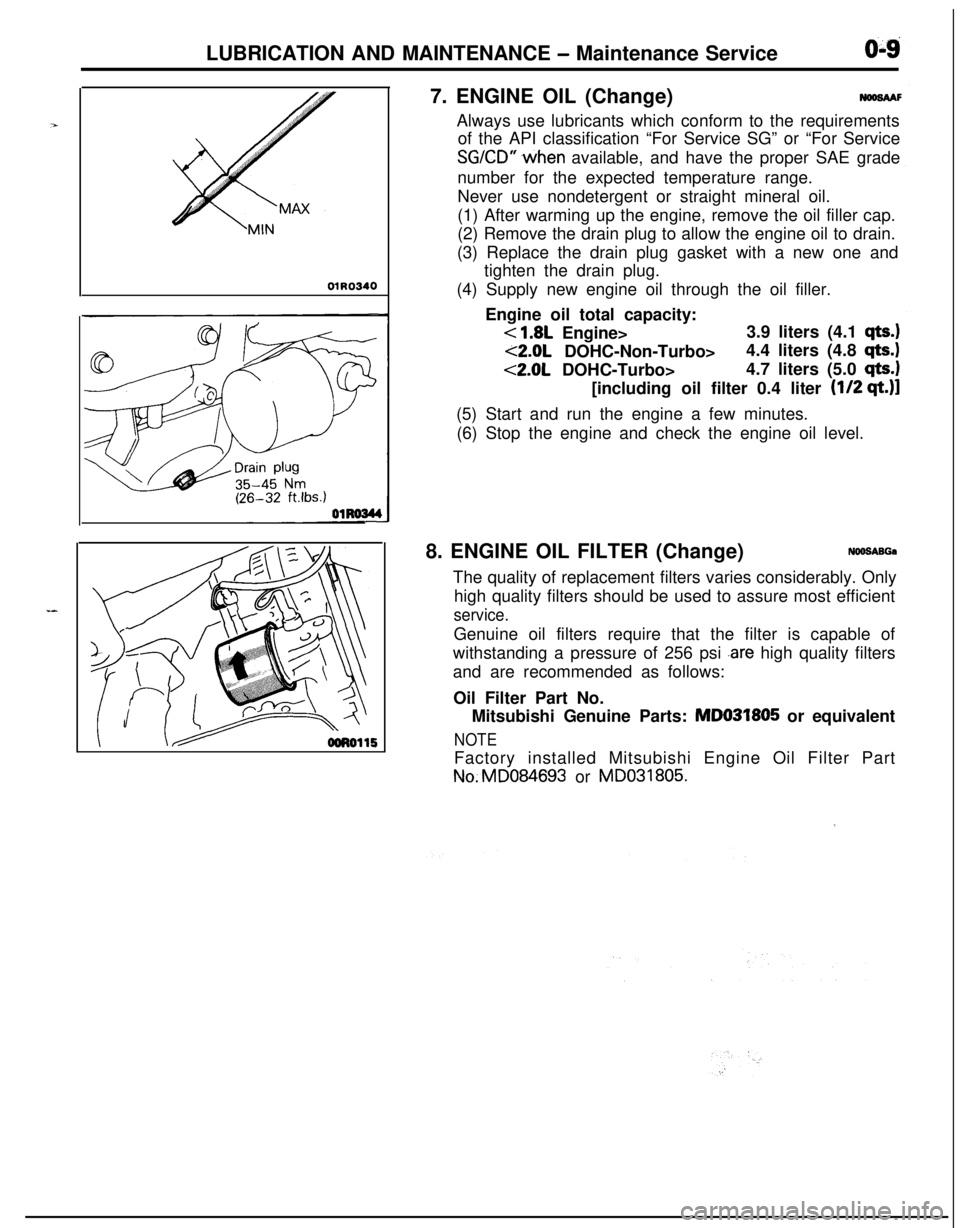

01R03407. ENGINE OIL (Change)

NWSAAFAlways use lubricants which conform to the requirements

of the API classification “For Service SG” or “For Service

SGKD” .when available, and have the proper SAE grade

number for the expected temperature range.

Never use nondetergent or straight mineral oil.

(1) After warming up the engine, remove the oil filler cap.

(2) Remove the drain plug to allow the engine oil to drain.

(3) Replace the drain plug gasket with a new one and

tighten the drain plug.

(4) Supply new engine oil through the oil filler.

Engine oil total capacity:

< 1.8L Engine>3.9 liters (4.1 qts.)

<2.0L DOHC-Non-Turbo>4.4 liters (4.8 qts.)

<2.0L DOHC-Turbo>4.7 liters (5.0 qts.1[including oil filter 0.4 liter

(l/2 qt.)]

(5) Start and run the engine a few minutes.

(6) Stop the engine and check the engine oil level.

8. ENGINE OIL FILTER (Change)

NOO!SABGaThe quality of replacement filters varies considerably. Only

high quality filters should be used to assure most efficient

service.Genuine oil filters require that the filter is capable of

withstanding a pressure of 256 psi

.are high quality filters

and are recommended as follows:

Oil Filter Part No.

Mitsubishi Genuine Parts: MD031805 or equivalent

NOTEFactory installed Mitsubishi Engine Oil Filter PartNo.MD084693 or MD031805.

’

Page 44 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Service

osFol2ENGINE

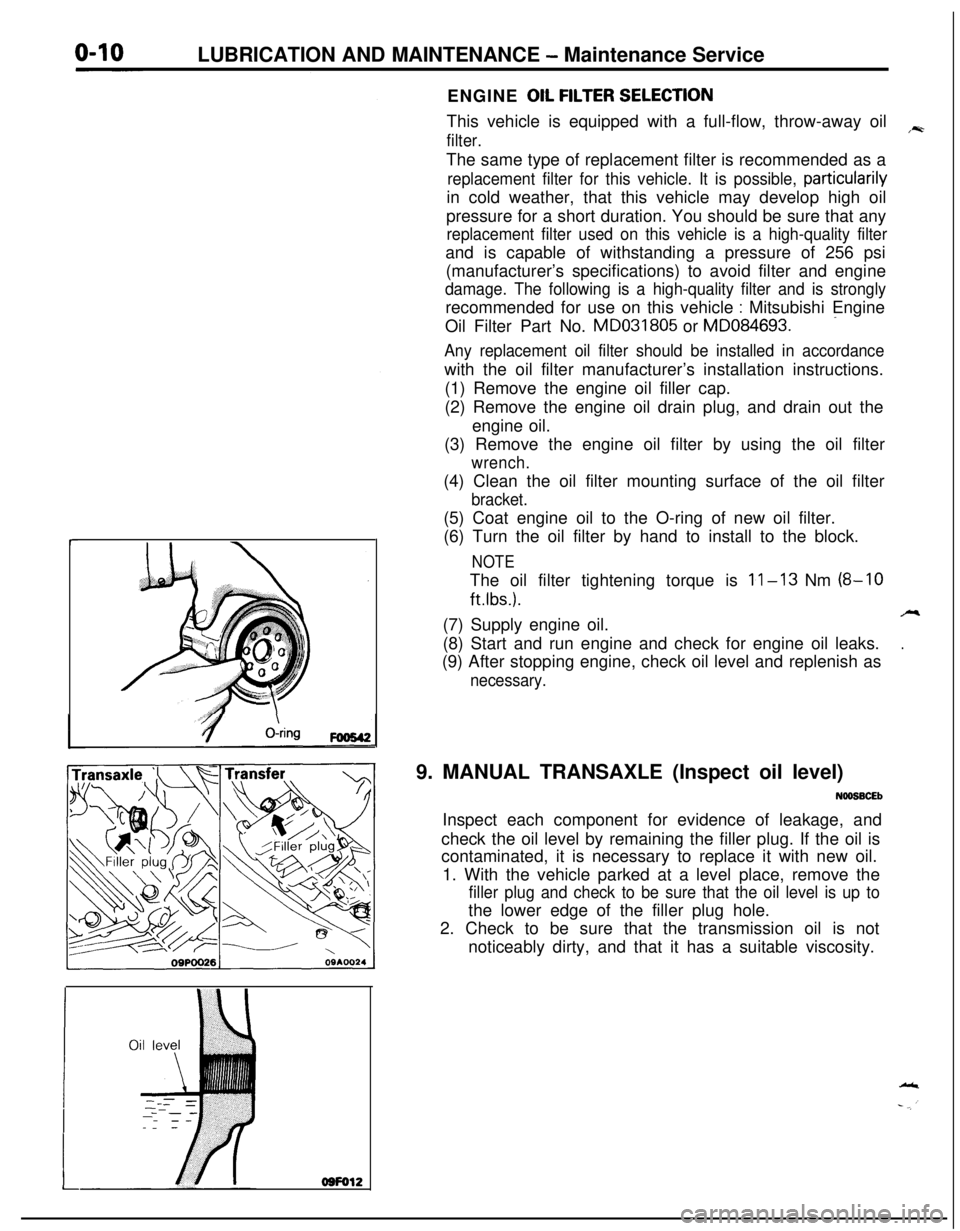

OIL FtLTER SELECTtONThis vehicle is equipped with a full-flow, throw-away oil

,~

filter.The same type of replacement filter is recommended as a

replacement filter for this vehicle. It is possible, particularilyin cold weather, that this vehicle may develop high oil

pressure for a short duration. You should be sure that any

replacement filter used on this vehicle is a high-quality filterand is capable of withstanding a pressure of 256 psi

(manufacturer’s specifications) to avoid filter and engine

damage. The following is a high-quality filter and is stronglyrecommended for use on this vehicle

: Mitsubishi Engine

-Oil Filter Part No. MD031805 or MD084693.

Any replacement oil filter should be installed in accordancewith the oil filter manufacturer’s installation instructions.

(1) Remove the engine oil filler cap.

(2) Remove the engine oil drain plug, and drain out the

engine oil.

(3) Remove the engine oil filter by using the oil filter

wrench.(4) Clean the oil filter mounting surface of the oil filter

bracket.(5) Coat engine oil to the O-ring of new oil filter.

(6) Turn the oil filter by hand to install to the block.

NOTEThe oil filter tightening torque is

11-13 Nm (8-10

ftlbs.).A(7) Supply engine oil.

.(8) Start and run engine and check for engine oil leaks.

(9) After stopping engine, check oil level and replenish as

necessary.9. MANUAL TRANSAXLE (Inspect oil level)

NOOSBCEbInspect each component for evidence of leakage, and

check the oil level by remaining the filler plug. If the oil is

contaminated, it is necessary to replace it with new oil.

1. With the vehicle parked at a level place, remove the

filler plug and check to be sure that the oil level is up tothe lower edge of the filler plug hole.

2. Check to be sure that the transmission oil is not

noticeably dirty, and that it has a suitable viscosity.

Page 45 of 1216

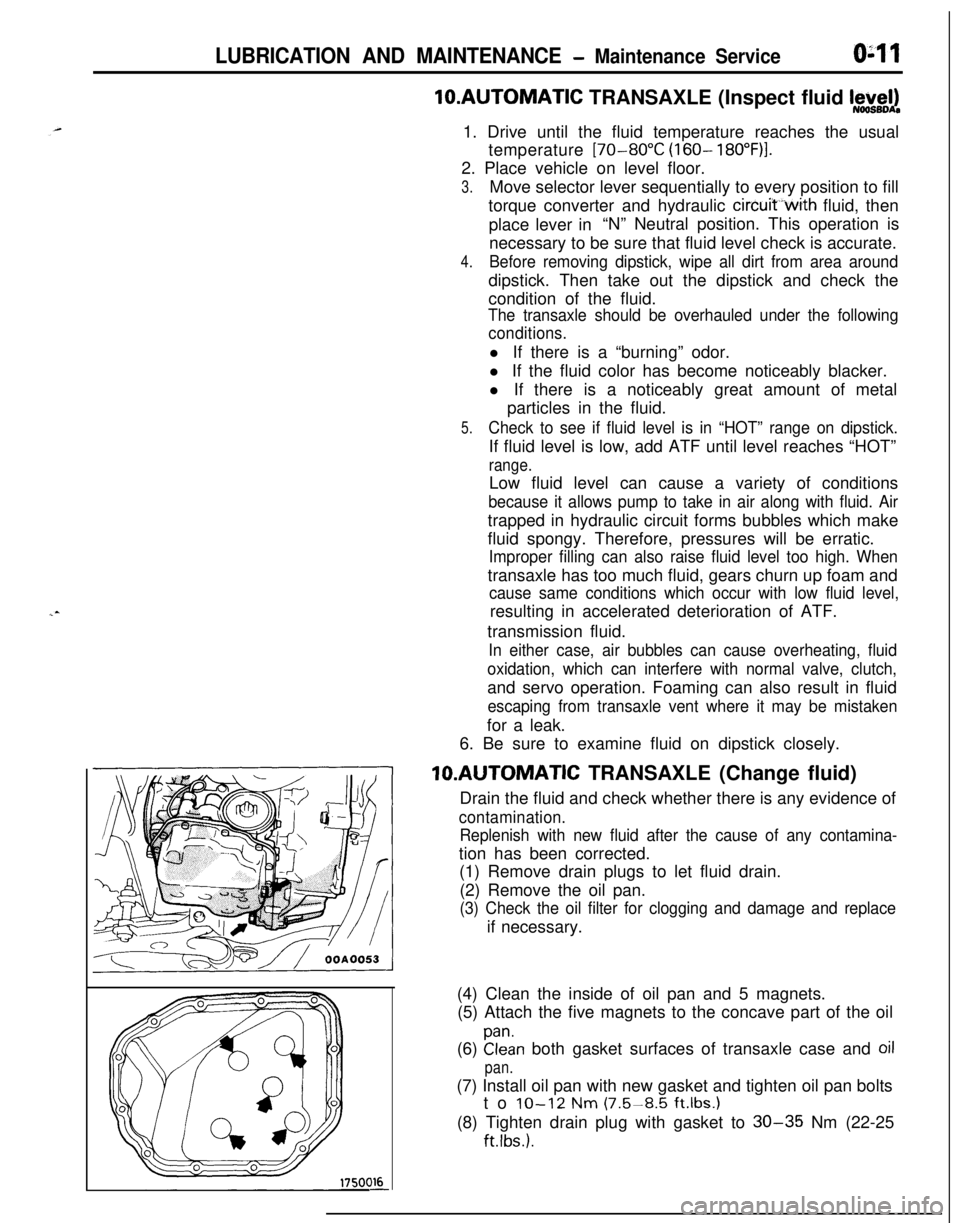

LUBRICATION AND MAINTENANCE - Maintenance ServiceO:lllO.AUTOMATIC TRANSAXLE (Inspect fluid

I~~+v~!1. Drive until the fluid temperature reaches the usual

temperature

[70-80°C (160- 18O”F)l.2. Place vehicle on level floor.

3.Move selector lever sequentially to every position to fill

torque converter and hydraulic

circuitwith fluid, then

place lever in“N” Neutral position. This operation is

necessary to be sure that fluid level check is accurate.

4.Before removing dipstick, wipe all dirt from area arounddipstick. Then take out the dipstick and check the

condition of the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

l If there is a noticeably great amount of metal

particles in the fluid.

5.Check to see if fluid level is in “HOT” range on dipstick.If fluid level is low, add ATF until level reaches “HOT”

range.Low fluid level can cause a variety of conditions

because it allows pump to take in air along with fluid. Airtrapped in hydraulic circuit forms bubbles which make

fluid spongy. Therefore, pressures will be erratic.

Improper filling can also raise fluid level too high. Whentransaxle has too much fluid, gears churn up foam and

cause same conditions which occur with low fluid level,resulting in accelerated deterioration of ATF.

transmission fluid.

In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,and servo operation. Foaming can also result in fluid

escaping from transaxle vent where it may be mistakenfor a leak.

6. Be sure to examine fluid on dipstick closely.lO.AUTOMATIC TRANSAXLE (Change fluid)

Drain the fluid and check whether there is any evidence of

contamination.

Replenish with new fluid after the cause of any contamina-tion has been corrected.

(1) Remove drain plugs to let fluid drain.

(2) Remove the oil pan.

(3) Check the oil filter for clogging and damage and replaceif necessary.

(4) Clean the inside of oil pan and 5 magnets.

(5) Attach the five magnets to the concave part of the oil

(6)

Elan both gasket surfaces of transaxle case and oil

pan.(7) Install oil pan with new gasket and tighten oil pan bolts

to

IO-12 Nm (7.5-8.5 ft.lbs.1(8) Tighten drain plug with gasket to

30-35 Nm (22-25

ftlbs.).

Page 185 of 1216

BRAKES - Service Adiustment Procedures5-45I

\\14A0416

2314A04.54

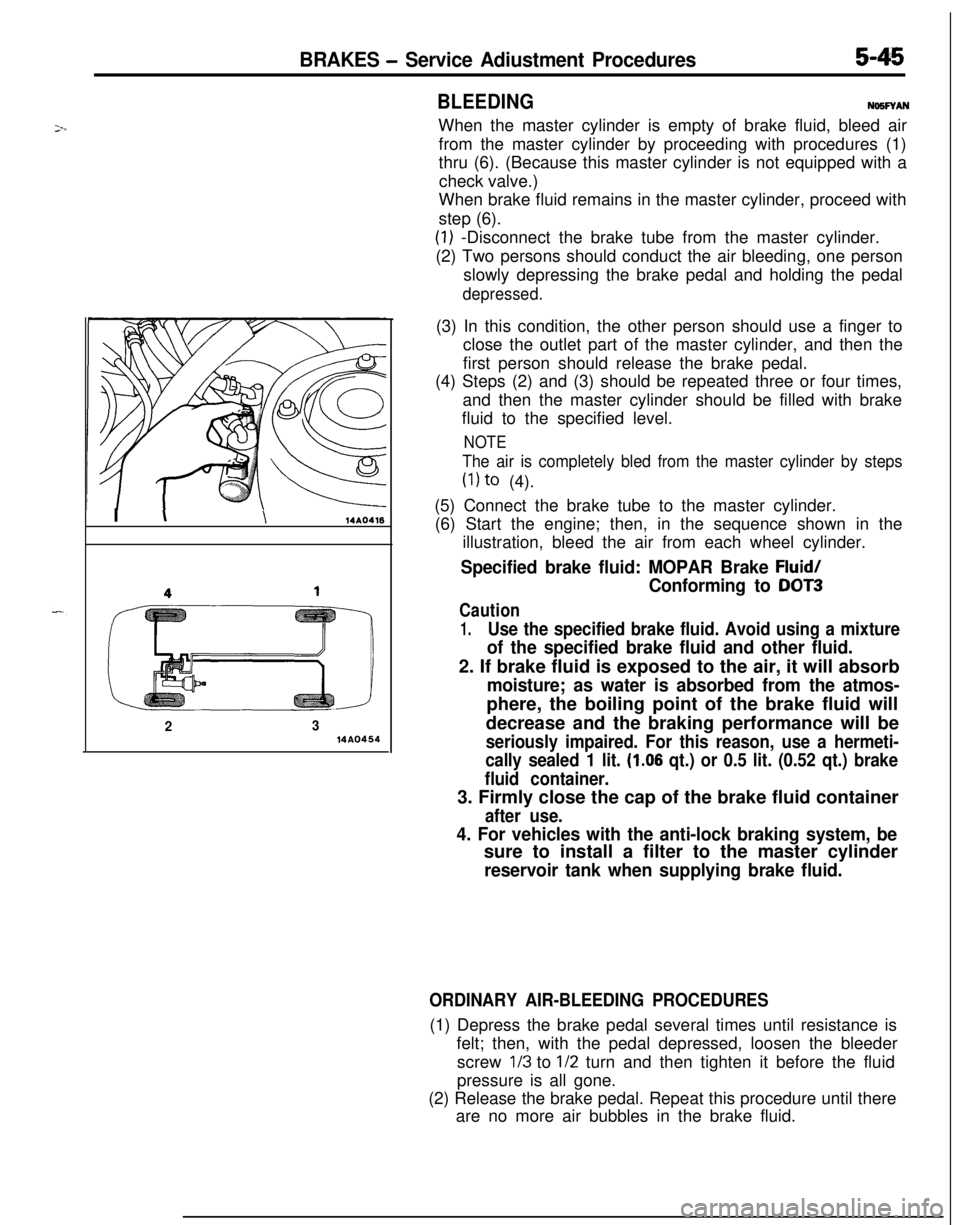

BLEEDINGN65FYAN

When the master cylinder is empty of brake fluid, bleed air

from the master cylinder by proceeding with procedures (1)

thru (6). (Because this master cylinder is not equipped with a

check valve.)

When brake fluid remains in the master cylinder, proceed with

step (6).

(1) -Disconnect the brake tube from the master cylinder.

(2) Two persons should conduct the air bleeding, one person

slowly depressing the brake pedal and holding the pedal

depressed.(3) In this condition, the other person should use a finger to

close the outlet part of the master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times,

and then the master cylinder should be filled with brake

fluid to the specified level.

NOTE

The air is completely bled from the master cylinder by steps

(1) to (4).

(5) Connect the brake tube to the master cylinder.

(6) Start the engine; then, in the sequence shown in the

illustration, bleed the air from each wheel cylinder.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3

Caution

1.Use the specified brake fluid. Avoid using a mixture

of the specified brake fluid and other fluid.2. If brake fluid is exposed to the air, it will absorb

moisture; as water is absorbed from the atmos-phere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed 1 lit.

(1.06 qt.) or 0.5 lit. (0.52 qt.) brake

fluid container.3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, besure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

ORDINARY AIR-BLEEDING PROCEDURES(1) Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

l/3 to l/2 turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

Page 291 of 1216

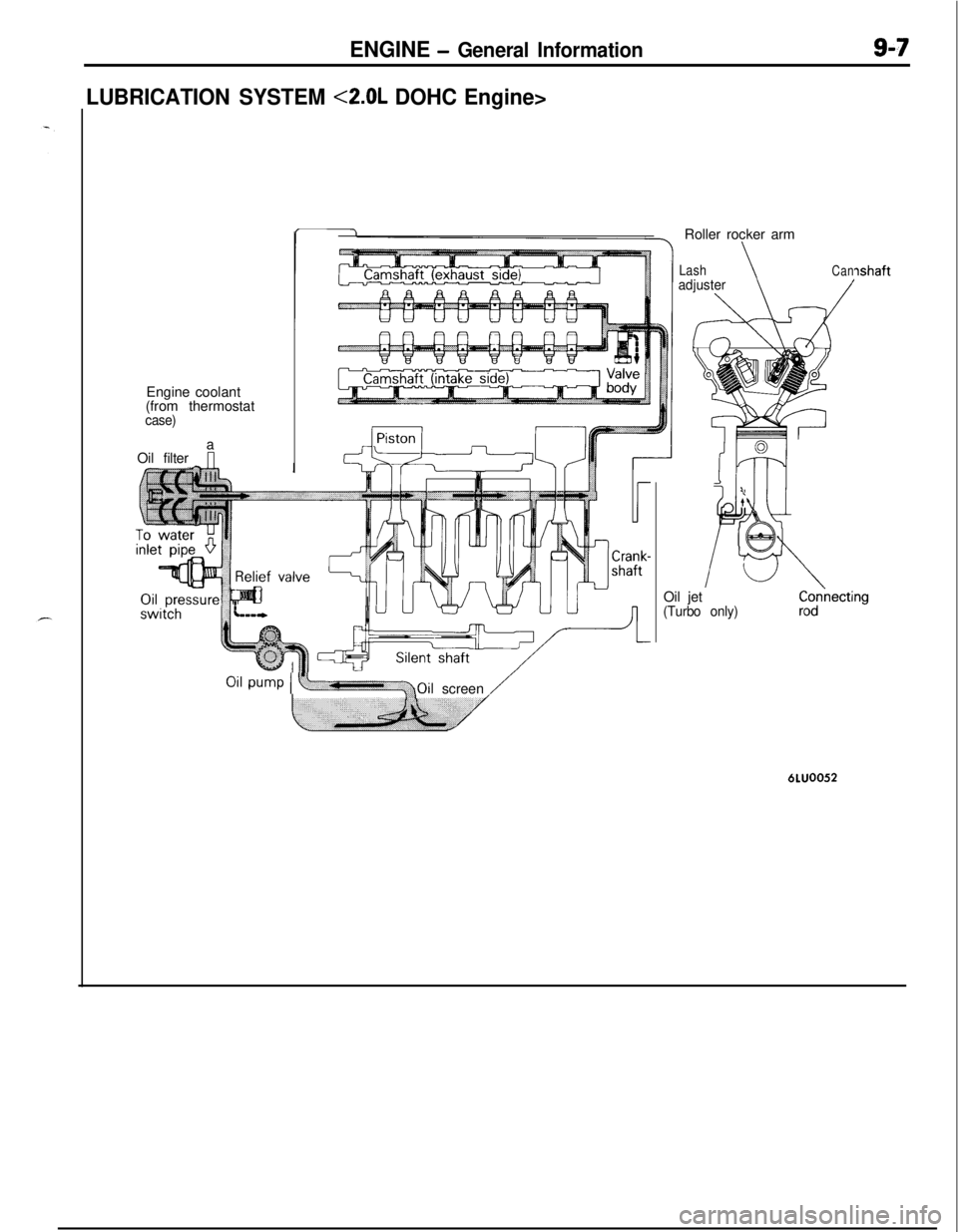

ENGINE - General Information9-7

LUBRICATION SYSTEM <2.0L DOHC Engine>Engine coolant

(from thermostat

case)a

Oil filterRoller rocker arm

LashadjusterCan

/

ILt

K

63

ishaftOil jet

(Turbo only)

Oil pump I y+Oilscreen /6LUOO52

Page 302 of 1216

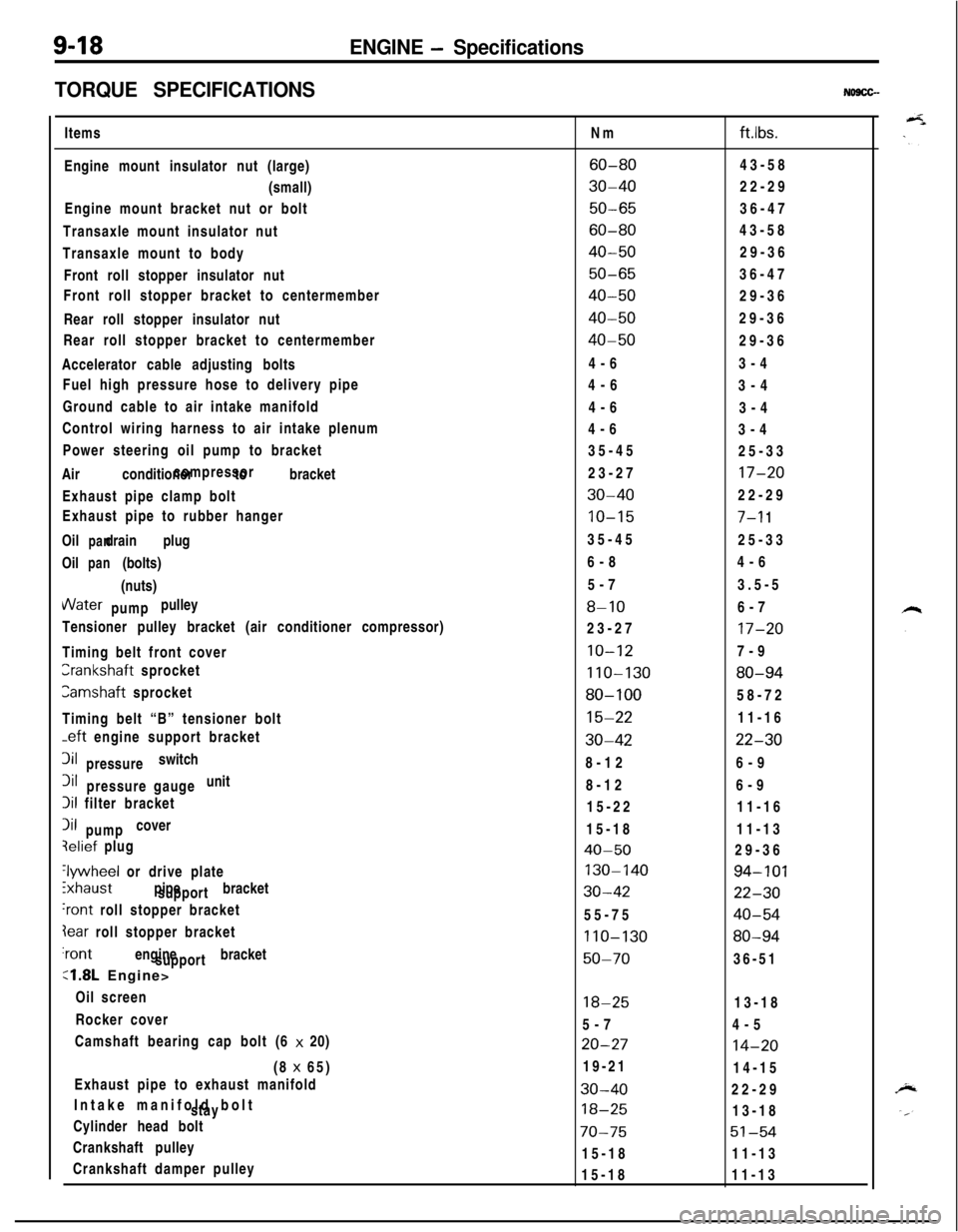

9-18ENGINE - Specifications

TORQUE SPECIFICATIONS

NO9CG-Items

Engine mount insulator nut (large)

(small)

Engine mount bracket nut or bolt

Transaxle mount insulator nut

Transaxle mount to body

Front roll stopper insulator nut

Front roll stopper bracket to centermember

Rear roll stopper insulator nut

Rear roll stopper bracket to centermember

Accelerator cable adjusting bolts

Fuel high pressure hose to delivery pipe

Ground cable to air intake manifold

Control wiring harness to air intake plenum

Power steering oil pump to bracket

Air conditioner to bracketcompressor

Exhaust pipe clamp bolt

Exhaust pipe to rubber hanger

Oil drain plug

panOil (bolts)

pan(nuts)VVater pulley

pump

Tensioner pulley bracket (air conditioner compressor)

Timing belt front coverCrankshaft sprocket

Camshaft sprocket

Timing belt “B” tensioner bolt

-eft engine support bracket3il switch

pressure3il unit

pressure gauge

Iii filter bracket

Iii cover

pumpqelief plug

‘lywheel or drive plate

ixhaust pipe bracket

support

‘rant roll stopper bracket

Iear roll stopper bracket‘rant engine bracket

support

:1.8L Engine>

Oil screen

Rocker cover

Camshaft bearing cap bolt (6 x 20)

(8 x 65)

Exhaust pipe to exhaust manifold

Intake manifold bolt

stay

Cylinder head bolt

Crankshaft pulley

Crankshaft damper pulleyNm

ftlbs.

60-8043-58

30-4022-29

50-6536-47

60-8043-58

40-5029-36

50-6536-47

40-5029-36

40-5029-36

40-5029-36

4-63-4

4-6

3-4

4-6

3-4

4-6

3-4

35-45

25-33

23-27

17-20

30-4022-29

10-157-l 135-45

25-33

6-84-6

5-73.5-5

8-106-7

23-27

17-20

10-127-9

110-13080-94

80-10058-72

15-2211-16

30-4222-308-126-9

8-126-9

15-2211-16

15-1811-13

40-5029-36

130-14094-101

30-4222-3055-75

40-54

110-13080-94

50-7036-51

18-2513-18

5-74-5

20-2714-2019-21

14-15

30-4022-29

18-2513-18

70-7551-5415-1811-13

15-1811-13