low oil pressure MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 325 of 1216

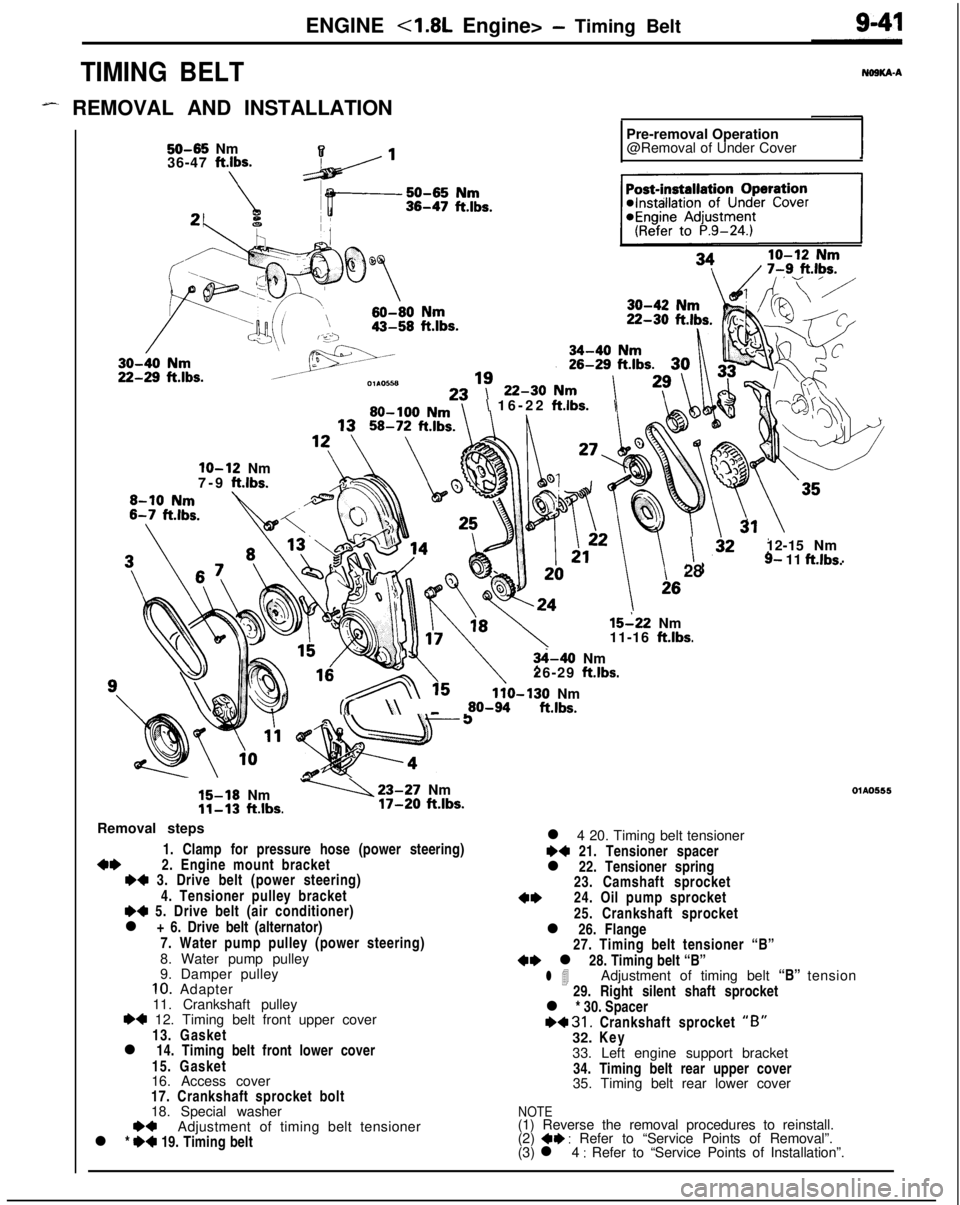

ENGINE <1.8L Engine> - Timing Belt

TIMING BELT

- REMOVAL AND INSTALLATION,

50-65 Nm

36-47 ft.lbs.Pre-removal Operation

@Removal of Under Cover

\ 16-22 ftlbs.\

lo-12 Nm

7-9 ft.lbs.

I28

15-22 Nm

11-16 ft.lbs.

3hO Nm

26-29 ft.lbs.

110-130 Nm(( \\ _ 60-94 ftlbs.

15-16 Nm-23-27 Nm

11-13 ft.lbs.17-20 ft.lbs.12-15 Nm

9- 11 ft.lbs.OlAO555

Removal steps

1. Clamp for pressure hose (power steering)

4*2. Engine mount bracketI)* 3. Drive belt (power steering)

4. Tensioner pulley bracket

H 5. Drive belt (air conditioner)

l + 6. Drive belt (alternator)

7. Water pump pulley (power steering)

8. Water pump pulley

9. Damper pulley

10. Adapter

11. Crankshaft pulley

I)4 12. Timing belt front upper cover

13. Gasket

l 14. Timing belt front lower cover

15. Gasket

16. Access cover

17. Crankshaft sprocket bolt

18. Special washer

Adjustment of timing belt tensioner

l *

:: 19. Timing beltl 4 20. Timing belt tensioner

I)+ 21. Tensioner spacer

l 22. Tensioner spring

23. Camshaft sprocket

4*24. Oil pump sprocket

25. Crankshaft sprocket

l 26. Flange

27. Timing belt tensioner “B”

~~ l 28. Timing belt “B”

l 4Adjustment of timing belt “B” tension

29. Right silent shaft sprocket

l * 30. Spacer

~~ 31. Crankshaft sprocket “B”32. Key

33. Left engine support bracket

34. Timing belt rear upper cover

35. Timing belt rear lower cover

NOTE(1) Reverse the removal procedures to reinstall.

(2)

4* : Refer to “Service Points of Removal”.

(3) l 4 : Refer to “Service Points of Installation”.

Page 331 of 1216

ENGINE <1.8L Engine> - Timing Belt9-47

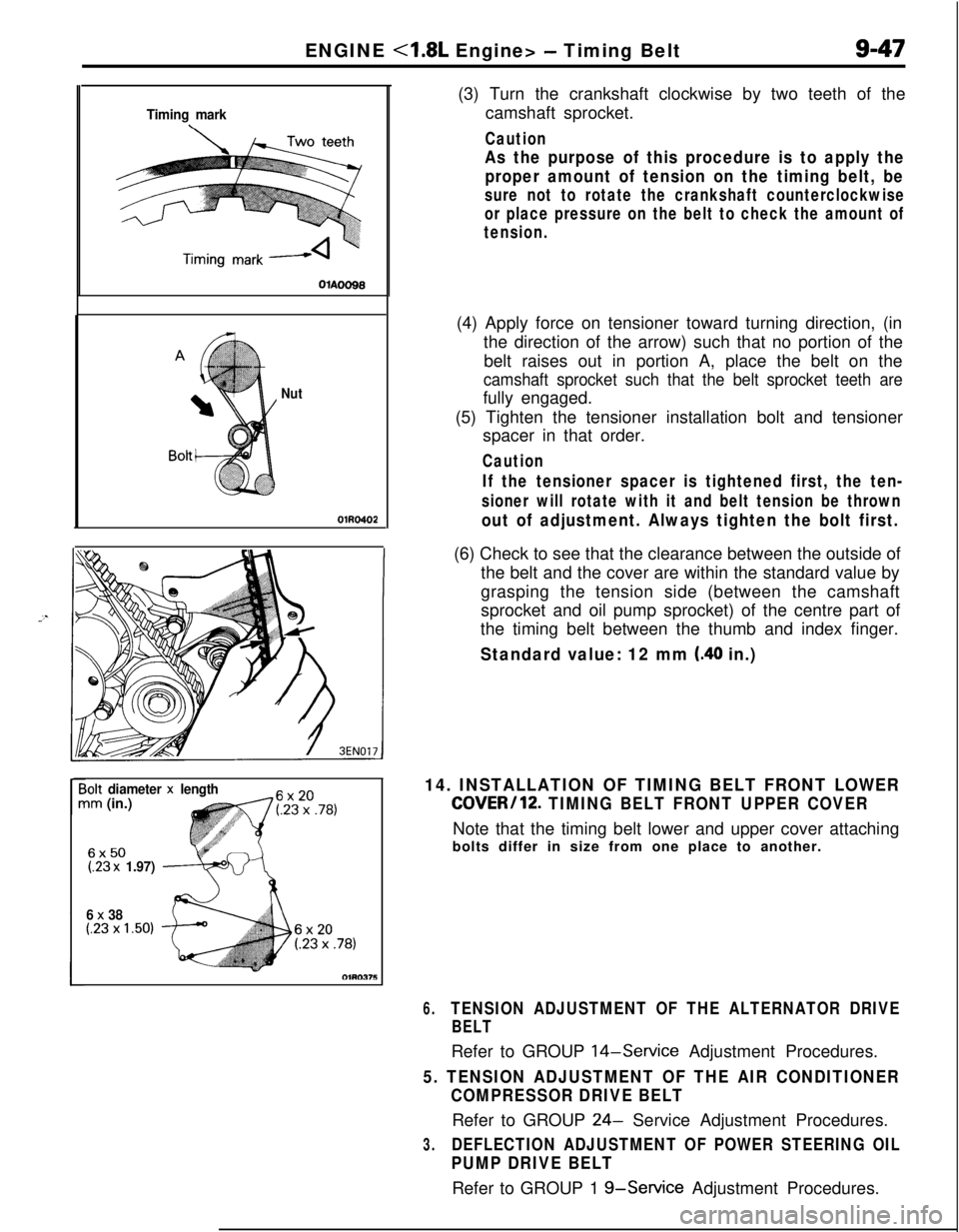

Timing mark

Nut

;olt diameter x lengthim (in.)

6x50(.23 x 1.97)

6

x 38(.23 x 1.50)(3) Turn the crankshaft clockwise by two teeth of the

camshaft sprocket.

Caution

As the purpose of this procedure is to apply the

proper amount of tension on the timing belt, be

sure not to rotate the crankshaft counterclockwise

or place pressure on the belt to check the amount of

tension.(4) Apply force on tensioner toward turning direction, (in

the direction of the arrow) such that no portion of the

belt raises out in portion A, place the belt on the

camshaft sprocket such that the belt sprocket teeth arefully engaged.

(5) Tighten the tensioner installation bolt and tensioner

spacer in that order.

Caution

If the tensioner spacer is tightened first, the ten-

sioner will rotate with it and belt tension be thrown

out of adjustment. Always tighten the bolt first.(6) Check to see that the clearance between the outside of

the belt and the cover are within the standard value by

grasping the tension side (between the camshaft

sprocket and oil pump sprocket) of the centre part of

the timing belt between the thumb and index finger.

Standard value: 12 mm (.40 in.)

14. INSTALLATION OF TIMING BELT FRONT LOWER

COVER/12. TIMING BELT FRONT UPPER COVERNote that the timing belt lower and upper cover attaching

bolts differ in size from one place to another.

6.TENSION ADJUSTMENT OF THE ALTERNATOR DRIVE

BELTRefer to GROUP

14-Service Adjustment Procedures.

5. TENSION ADJUSTMENT OF THE AIR CONDITIONER

COMPRESSOR DRIVE BELTRefer to GROUP

24- Service Adjustment Procedures.

3.DEFLECTION ADJUSTMENT OF POWER STEERING OIL

PUMP DRIVE BELTRefer to GROUP 1

g-Service Adjustment Procedures.

Page 379 of 1216

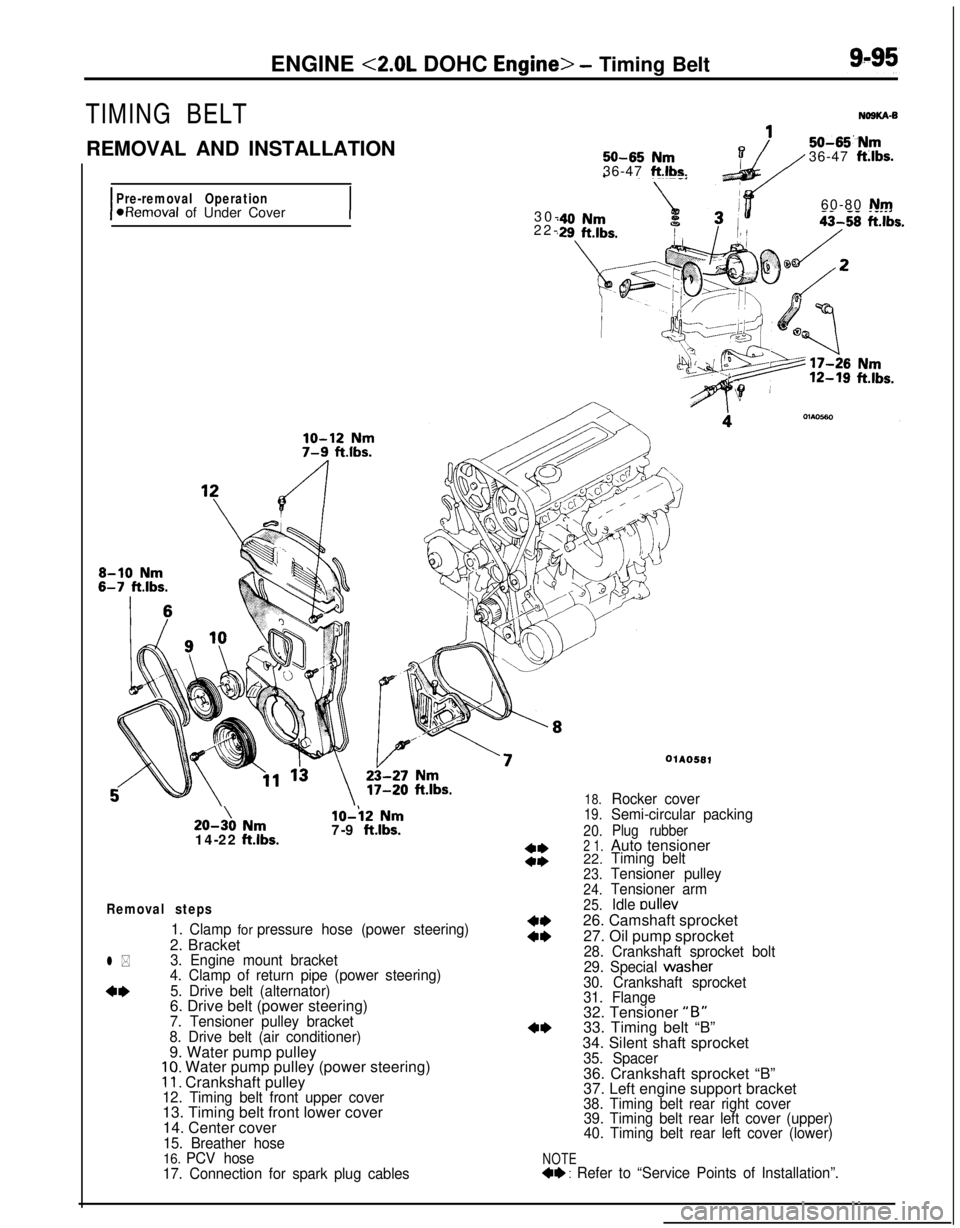

ENGINE <2.0L DOHC Engine> - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

I

Pre-removal Operation*Removal of Under Cover

I

50-65 Nm36-47 ft.lbs.

50-65“Nm36-47 ft:lbs.30-60-80

Nm22-20-3\0

Nm14-22 ftlbs.

lo-i2 Nm7-9 ftlbs.

Removal steps

1. Clamp for pressure hose (power steering)2. Bracket

3. Engine mount bracket

4. Clamp of return pipe (power steering)

5. Drive belt (alternator)6. Drive belt (power steering)

7. Tensioner pulley bracket

8. Drive belt (air conditioner)9. Water pump pulley

10. Water pump pulley (power steering)11. Crankshaft pulley12. Timing belt front upper cover13. Timing belt front lower cover

14. Center cover

15. Breather hose16. PCV hose

17. Connection for spark plug cables

l *

4*

NOTE4+ : Refer to “Service Points of Installation”.

WA0581

18.Rocker cover19.Semi-circular packing

20.Plug rubber2 1.Auto tensioner

22.Timing belt

23.Tensioner pulley

24.Tensioner arm

25.Idle oullev26. Camshaft sprocket

27. Oil pump sprocket

28. Crankshaft sprocket bolt

29. Special wastier

30. Crankshaft sprocket

31. Flange32. Tensioner

“B”33. Timing belt “B”

34. Silent shaft sprocket

35. Spacer36. Crankshaft sprocket “B”

37. Left engine support bracket

38. Timing belt rear right cover

39. Timing belt rear left cover (upper)

40. Timing belt rear left cover (lower)

Page 380 of 1216

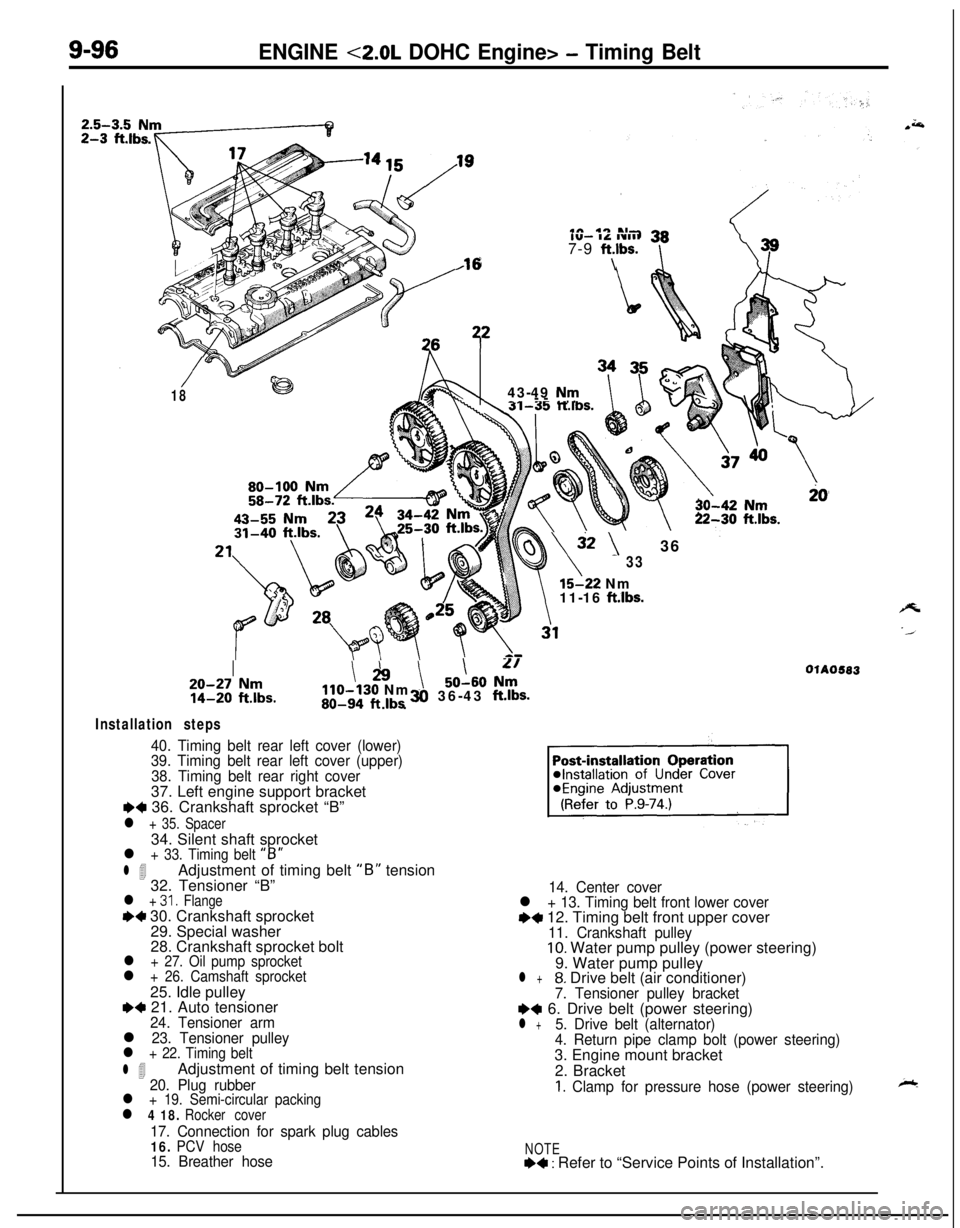

9-96ENGINE <2.0L DOHC Engine> - Timing Belt

116

/18

Iv- IL 1’11117-9 ftlbs.

\43-49

Nm-_---. . .

30-42 Nm$0

22-30 ftlbs.

\

j2 \ 36

33

15-22 Nm

11-16 ftlbs.

I20-27 Nm\h \

14-20 f&.lbs.110-130 Nm cI,60-94 f

\z/OIAOS83-ama .I~..su--Du Nrnt Ibs .,iJ 36-43 ft.lbs.. .

Installation steps

40. Timing belt rear left cover (lower)

39. Timing belt rear left cover (upper)

38. Timing belt rear right cover37. Left engine support bracket

I)+ 36. Crankshaft sprocket “B”

l + 35. Spacer34. Silent shaft sprocket

l + 33. Timing belt “B”

l 4Adjustment of timing belt “B” tension

32. Tensioner “B”

l + 31. Flange++ 30. Crankshaft sprocket

29. Special washer

28. Crankshaft sprocket bolt

l + 27. Oil pump sprocketl + 26. Camshaft sprocket25. Idle pulley

e+ 21. Auto tensioner24. Tensioner arml 23. Tensioner pulleyl + 22. Timing belt

l 4Adjustment of timing belt tension20. Plug rubberl + 19. Semi-circular packingl 4 18. Rocker cover

17. Connection for spark plug cables16. PCV hose15. Breather hose14. Center cover

l + 13. Timing belt front lower covere+ 12. Timing belt front upper cover11. Crankshaft pulley10. Water pump pulley (power steering)

9. Water pump pulley

l +8. Drive belt (air conditioner)7. Tensioner pulley bracketI)+ 6. Drive belt (power steering)l +5. Drive belt (alternator)

4. Return pipe clamp bolt (power steering)3. Engine mount bracket

2. Bracket

1. Clamp for pressure hose (power steering)

NOTE+4 : Refer to “Service Points of Installation”.

Page 385 of 1216

ENGINE <2.0L DOHC Engine> - Timinn Belt

SpacerChahfered

6s

il seal

6EN009Silent shaft

nsprocketI

Timing

markCrankshaft

) ~sprocket “6”Center of

tensioner

pulley

Center of

installation bolt

installation bolt

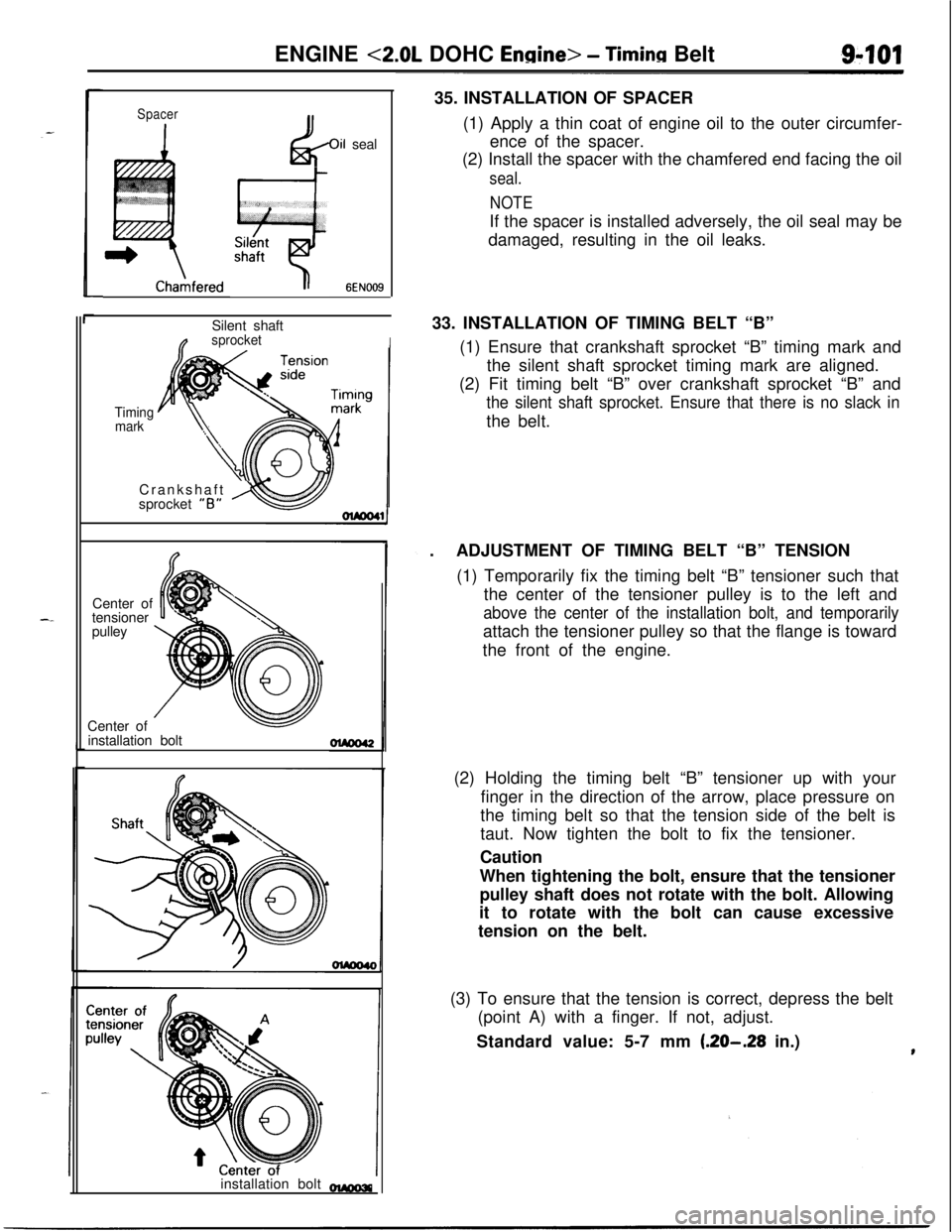

-35. INSTALLATION OF SPACER

(1) Apply a thin coat of engine oil to the outer circumfer-

ence of the spacer.

(2) Install the spacer with the chamfered end facing the oil

seal.

NOTEIf the spacer is installed adversely, the oil seal may be

damaged, resulting in the oil leaks.

33. INSTALLATION OF TIMING BELT “B”

(1) Ensure that crankshaft sprocket “B” timing mark and

the silent shaft sprocket timing mark are aligned.

(2) Fit timing belt “B” over crankshaft sprocket “B” and

the silent shaft sprocket. Ensure that there is no slack inthe belt.

.ADJUSTMENT OF TIMING BELT “B” TENSION

(1) Temporarily fix the timing belt “B” tensioner such that

the center of the tensioner pulley is to the left and

above the center of the installation bolt, and temporarilyattach the tensioner pulley so that the flange is toward

the front of the engine.

(2) Holding the timing belt “B” tensioner up with your

finger in the direction of the arrow, place pressure on

the timing belt so that the tension side of the belt is

taut. Now tighten the bolt to fix the tensioner.

Caution

When tightening the bolt, ensure that the tensioner

pulley shaft does not rotate with the bolt. Allowing

it to rotate with the bolt can cause excessive

tension on the belt.

(3) To ensure that the tension is correct, depress the belt

(point A) with a finger. If not, adjust.

Standard value: 5-7 mm

(.20-.28 in.)

Page 410 of 1216

9-126ENGINE <2.0L DOHC Engine>- Front Case, Oil Pump and Silent Shaft

6EN0213

w Crank pulley side

Oil pan

from lower side

‘- Apply sealant7LUOOO0

6LUOO49 tBracket side

-----Be

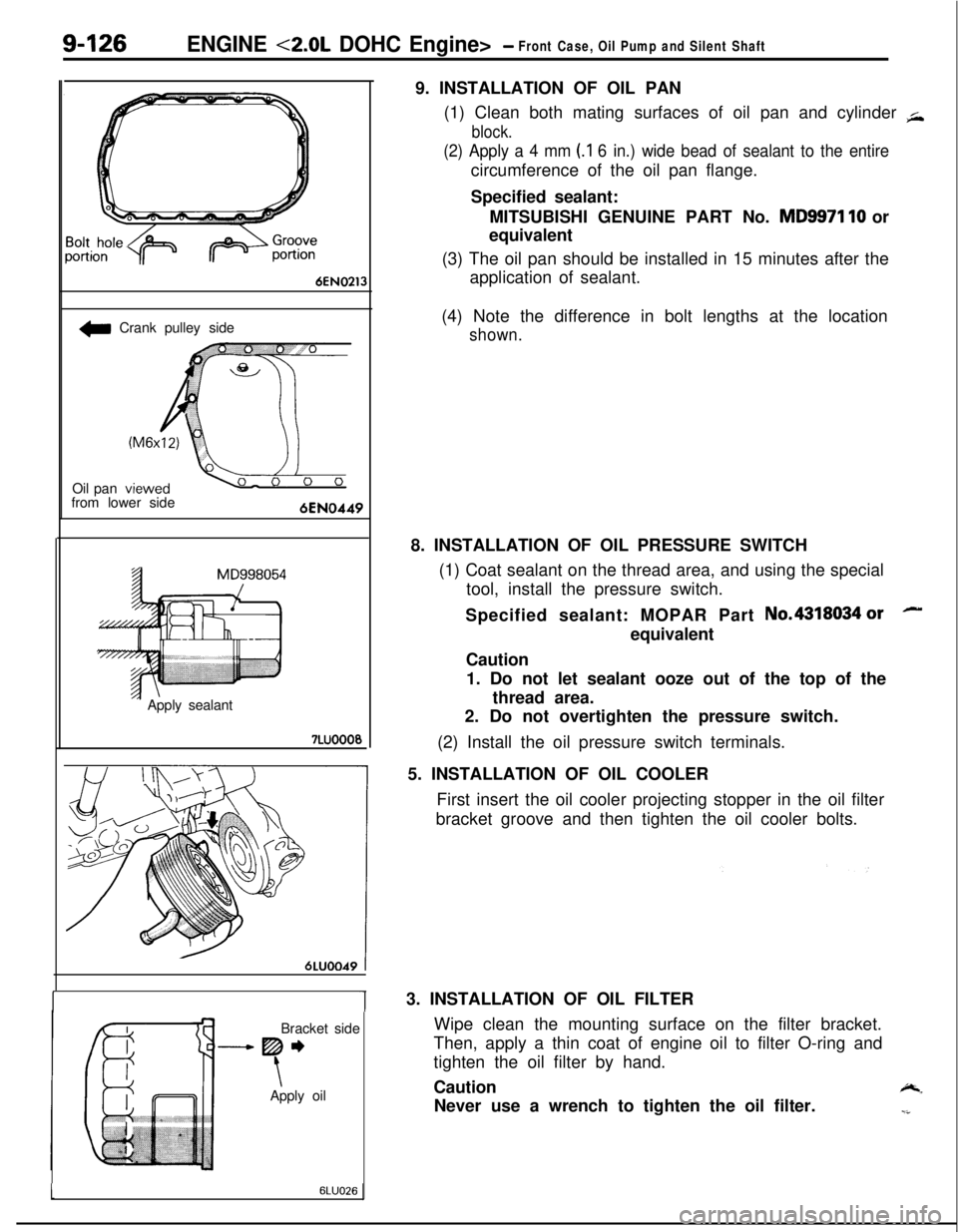

\Apply oil9. INSTALLATION OF OIL PAN

(1) Clean both mating surfaces of oil pan and cylinder

+

block.

(2) Apply a 4 mm (.I 6 in.) wide bead of sealant to the entirecircumference of the oil pan flange.

Specified sealant:

MITSUBISHI GENUINE PART No.

MD9971 10 or

equivalent

(3) The oil pan should be installed in 15 minutes after the

application of sealant.

(4) Note the difference in bolt lengths at the location

shown.8. INSTALLATION OF OIL PRESSURE SWITCH

(1) Coat sealant on the thread area, and using the special

tool, install the pressure switch.

Specified sealant: MOPAR Part No.4318034

orequivalent

Caution

1. Do not let sealant ooze out of the top of the

thread area.

2. Do not overtighten the pressure switch.

(2) Install the oil pressure switch terminals.

5. INSTALLATION OF OIL COOLER

First insert the oil cooler projecting stopper in the oil filter

bracket groove and then tighten the oil cooler bolts.lu3. INSTALLATION OF OIL FILTER

Wipe clean the mounting surface on the filter bracket.

Then, apply a thin coat of engine oil to filter O-ring and

tighten the oil filter by hand.

Caution

-.Never use a wrench to tighten the oil filter.

-i

16LUO26

Page 457 of 1216

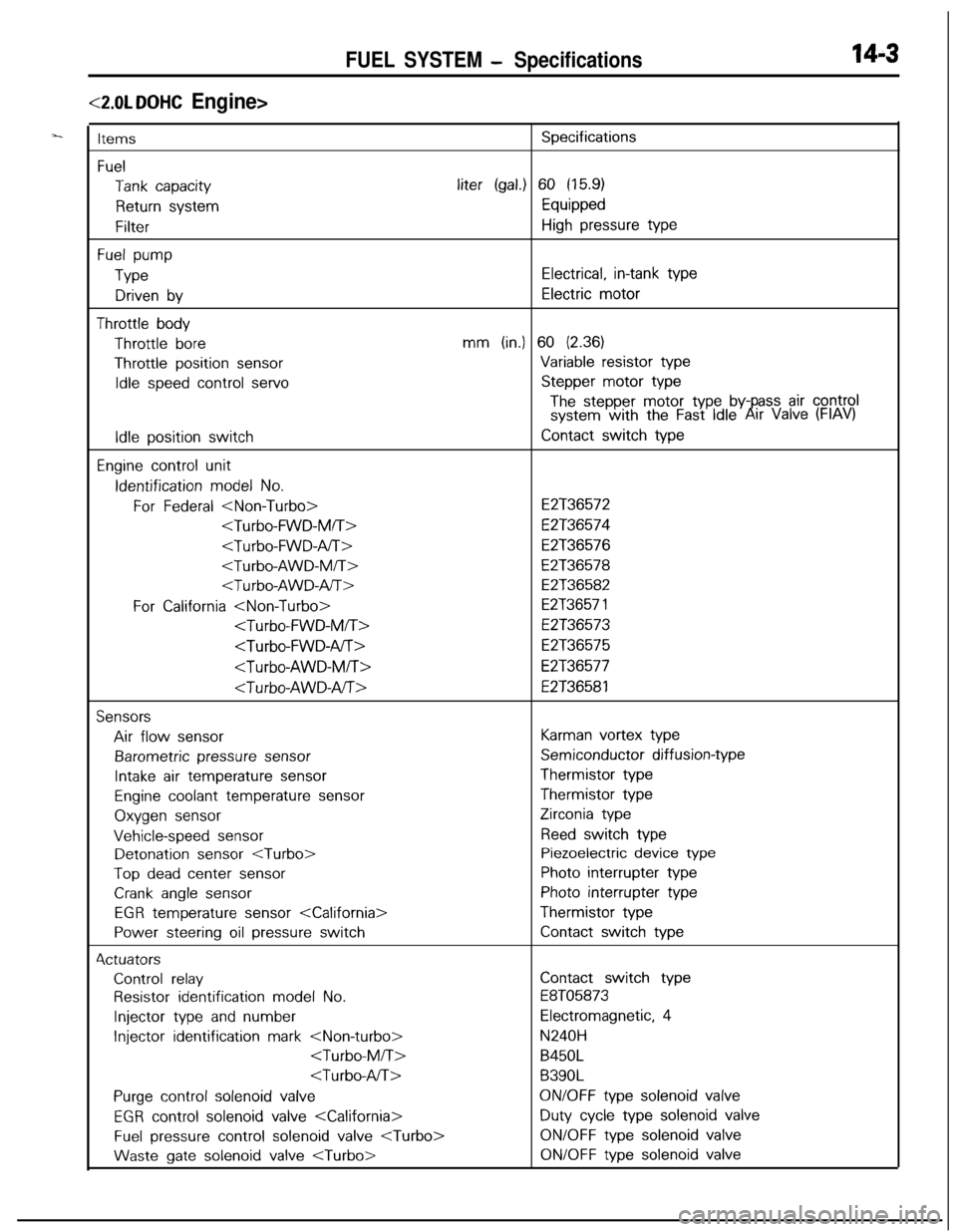

FUEL SYSTEM - Specifications14-3

<2.0L DOHC Engine>

ItemsSpecifications

Fuel

Tank capacityliter (gal.) 60 (15.9)

Return systemEquipped

FilterHigh pressure type

Fuel pump

TypeElectrical, in-tank type

Driven byElectric motor

Throttle bodyThrottle

boremm (in.) 60 (2.36)Throttle position

sensorVariable resistor type

Idle speed control servoStepper motor type

The stepper motor type by- ass air controlsystem with the Fast Idle6!rr Valve (FIAV)

Idle position switchContact switch type

Engine control unitIdentification

model No.

For Federal

E2T36574

E2T36576

E2T36578

E2T36582

For California

E2T36573

E2T36575

E2T36577

E2T36581

SensorsAir flow

sensorKarman vortex type

Barometric pressure sensorSemiconductor diffusion-type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Vehicle-speed sensorReed switch typeDetonation

sensor

Top dead center sensorPhoto interrupter type

Crank angle sensorPhoto interrupter type

EGR temperature sensor

Power steering oil pressure switchContact switch type4ctuators

Control relayContact switch type

Resistor identification model No.E8T05873

Injector type and numberElectromagnetic, 4

Injector identification mark

B450L

B390L

Purge control solenoid valveON/OFF type solenoid valve

EGR control solenoid valve

Fuel pressure control solenoid valve

gate solenoid valve

Page 459 of 1216

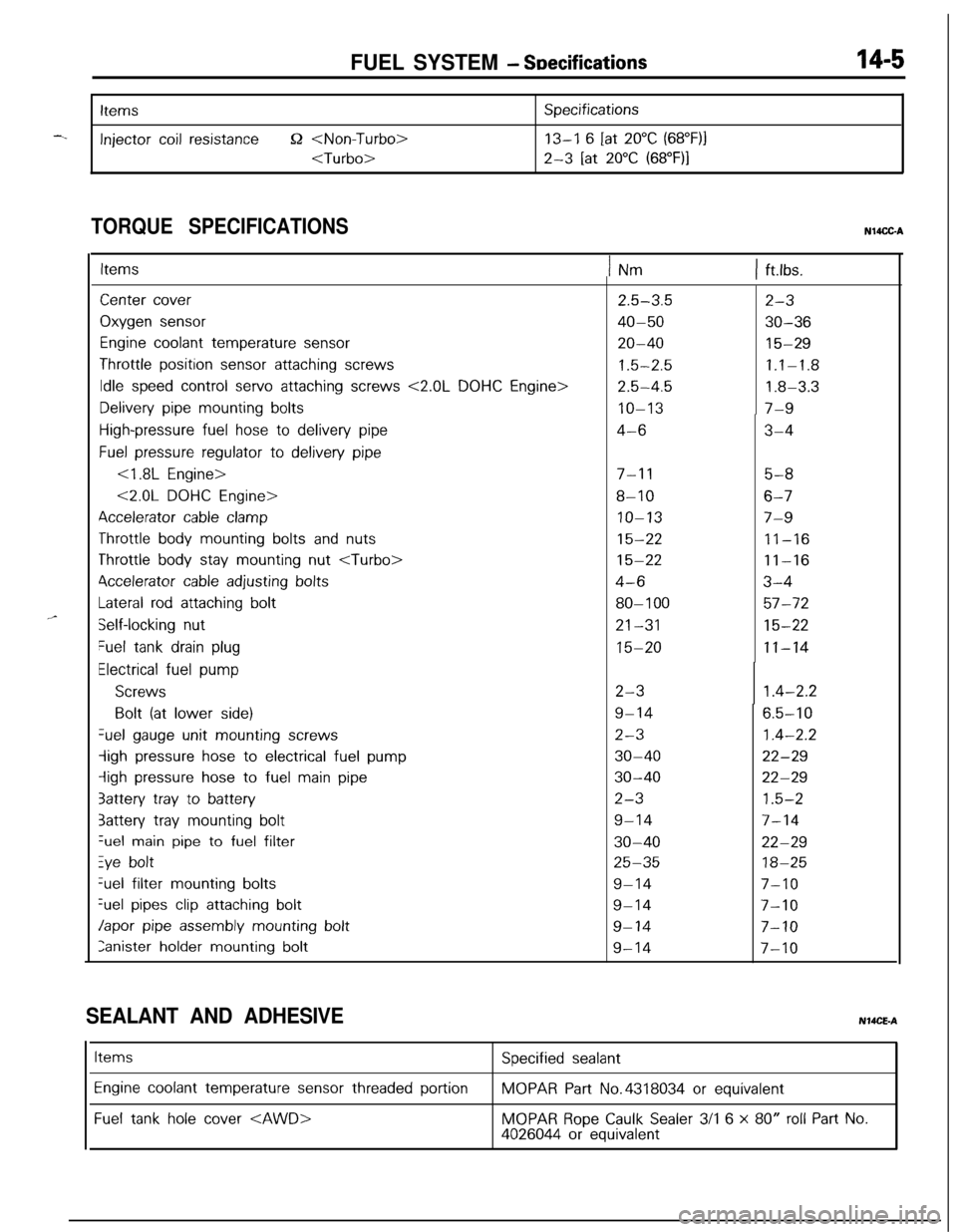

FUEL SYSTEM - SDecifications14-5

-.

Items

Injector coil resistance52

Specifications

13-I 6 [at 20°C (68”F)j

2-3 [at 20°C (68”F)I

TORQUE SPECIFICATIONSN14CC-A

,,-

ItemsINm1 ft.lbs.

Center cover

Oxygen sensor

Engine coolant temperature sensor

Throttle position sensor attaching screws

Idle speed control servo attaching screws <2.0L DOHC Engine>

Delivery pipe mounting bolts

High-pressure fuel hose to delivery pipe

Fuel pressure regulator to delivery pipe

<1.8L Engine>

<2.0L DOHC Engine>

Accelerator cable clamp

Throttle body mounting bolts and nuts

Throttle body stay mounting nut

4ccelerator cable adjusting bolts

Lateral rod attaching bolt

Self-locking nut

Fuel tank drain plug

Electrical fuel pump

Screws

Bolt (at lower side)Gel

gauge unit mounting screws

-ligh pressure hose to electrical fuel pump

iigh pressure hose to fuel main pipe

3attery tray to battery

3attery tray mounting boltGel

main pipe to fuel filter

Zye boltGel filter

mounting bolts

%el pipes clip attaching bolt

Japor pipe assembly mounting bolt

Ianister holder mounting bolt

2.5-3.5

40-50

20-40

1.5-2.5

2.5-4.5

IO-13

4-6

7-l 15-8

8-106-7

IO-137-9

15-2211-16

15-2211-16

4-63-4

80-l 0057-72

21-3115-22

15-2011-14

2-3

9-14

2-3

30-40

30-40

2-3

9-14

30-40

25-35

9-14

9-14

9-14

9-14

2-3

30-36

15-29

1.1-1.8

1.8-3.3

7-9

3-4

1.4-2.2

6.5-10

1.4-2.2

22-29

22-29

1.5-2

7-14

22-29

18-25

7-10

7-10

7-10

7-10

SEALANT AND ADHESIVENMCE-A

Items

Engine coolant temperature sensor threaded portion

Fuel tank hole cover

Specified sealant

MOPAR Part No.4318034 or equivalent

MOPAR Rope Caulk Sealer 3/l 6 x 80” roll Part No.4026044 or equivalent

Page 460 of 1216

14-6FUEL SYSTEM - Special Tools/Troubleshooting

SPECIAL TOOLSNWA-B

Number

M D998742

Name

Hose adapter

Usel Measurement

of fuel pressure (to be usedtogether

with MD9987091

MD998709Adapter hosel Measurement of fuel pressure (to be usedtogether

with MD9987421

TROUBLESHOOTING

When checking and correcting engine troubles, it is

important to start with inspection of the basic

systems.

In case you have such troubles as (1) engine start

failure, (2) rough idling or (3) poor acceleration,

therefore, you should first check the following basic

systems:

(1) Power supply

0 Batteryl

Fusible linkl

Fuse

(2) Body ground

(3) Fuel supplyl

Fuel linel

Fuel filter

l

Fuel pump

N14EBBH

(4) Ignition systeml

Spark plugsl

High tension cablel Distributor

<1.8L Engine>

l

Crank angle sensor <2.0L DOHC Engine>

0 Ignition coil

(5) Emission control systeml

Crankcase ventilation systeml

Exhaust gas recirculation systeml

Vacuum leak

(6) Others

0 Ignition timing

l

Idle speed

Troubles with the MPI system are often caused by

poor contact of harness connector. It is, therefore,

important to check harness connector contact.

Page 461 of 1216

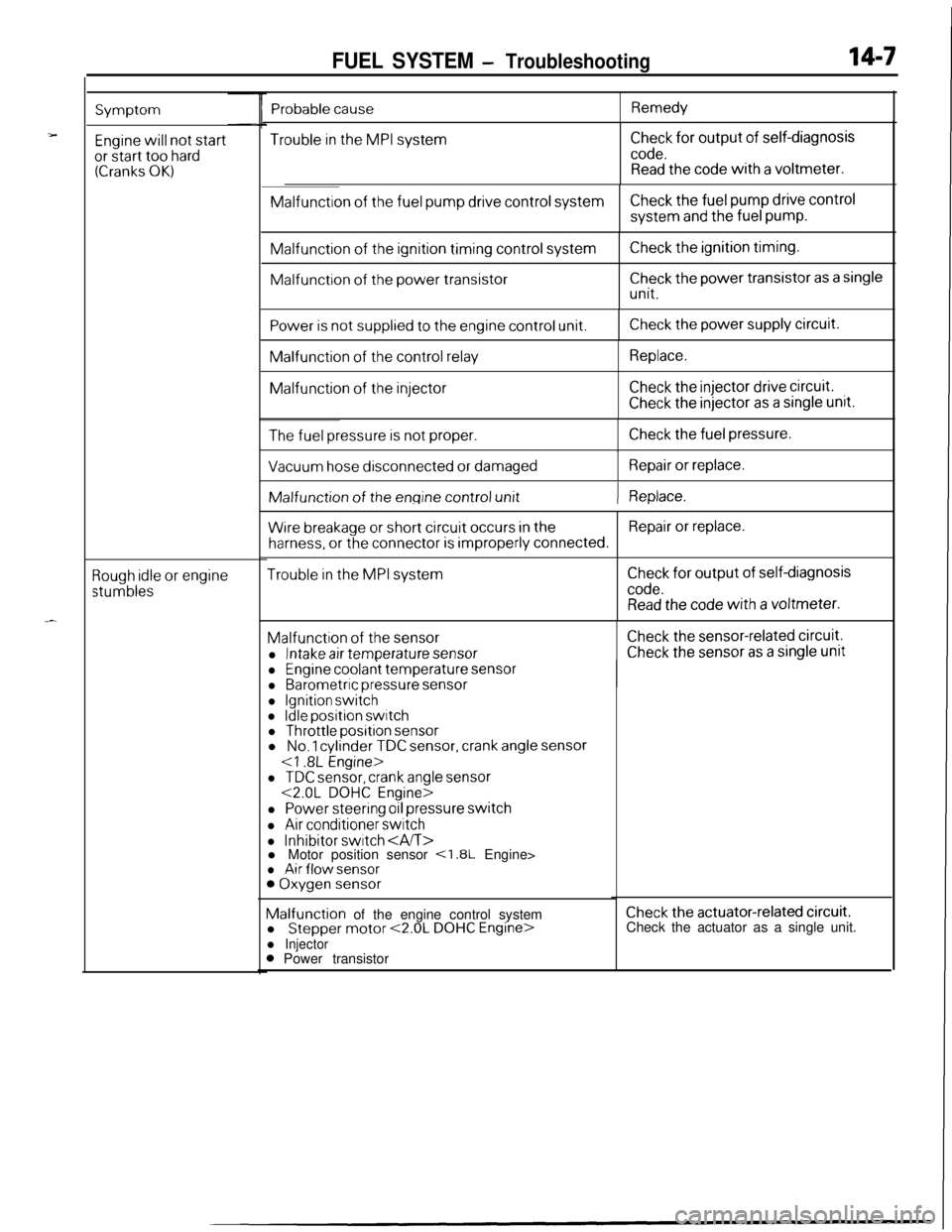

FUEL SYSTEM - Troubleshooting14-7

Symptom

Engine will not startor start too hard(Cranks OK)

Rough idle or engine

stumbles

Trouble in the MPI systemCheck for output of self-diagnosis

code.Read the code with a voltmeter.Malfunction

of the fuel pump drive control systemCheck the fuel pump drive controlsystem

and the fuel pump.Malfunction

of the ignition timing control systemMalfunction

of the power transistor

Check the ignition timing.

Check the power transistor as a single

unit.

Power is not supplied to the engine control unit.Check the power supply circuit.Malfunction

of the control relayMalfunction

of the injector

Replace.

Check the injector drive circuit.

Check the injector as a single unit.

The fuel pressure is not proper.Check the fuel pressure.

I

Vacuum hose disconnected or damagedRepair or replace.IMalfunction of

the engine control unit) Replace.

Wire breakage or short circuit occurs in theRepair or replace.

harness, or the connector is improperly connected.

Trouble in the MPI systemCheck for output of self-diagnosis

code.Read the code with a voltmeter.Malfunction

of the sensor

l Intake air temperature sensor

Check the sensor-related circuit.

Check the sensor as a single unit

Probable causeRemedy

l Engine coolant temperature sensorl Barometric pressure sensor

l Ignition switchl Idle position switchl Throttle position sensorl No. 1 cylinder TDC sensor, crank angle sensor

l TDC sensor, crank angle sensor<2.0L DOHC Engine>

l Power steering oil pressure switch

l Air conditioner switch

l Inhibitor switch l Motor position sensor <1.8L Engine>l Air flow sensor0 Oxygen sensorMalfunction of the engine control system

l

Stepper motor <2.0L DOHC Engine>l Injector0 Power transistor

Check the actuator-related circuit.Check the actuator as a single unit.