wheel MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 25 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - :;k%ii::& and25

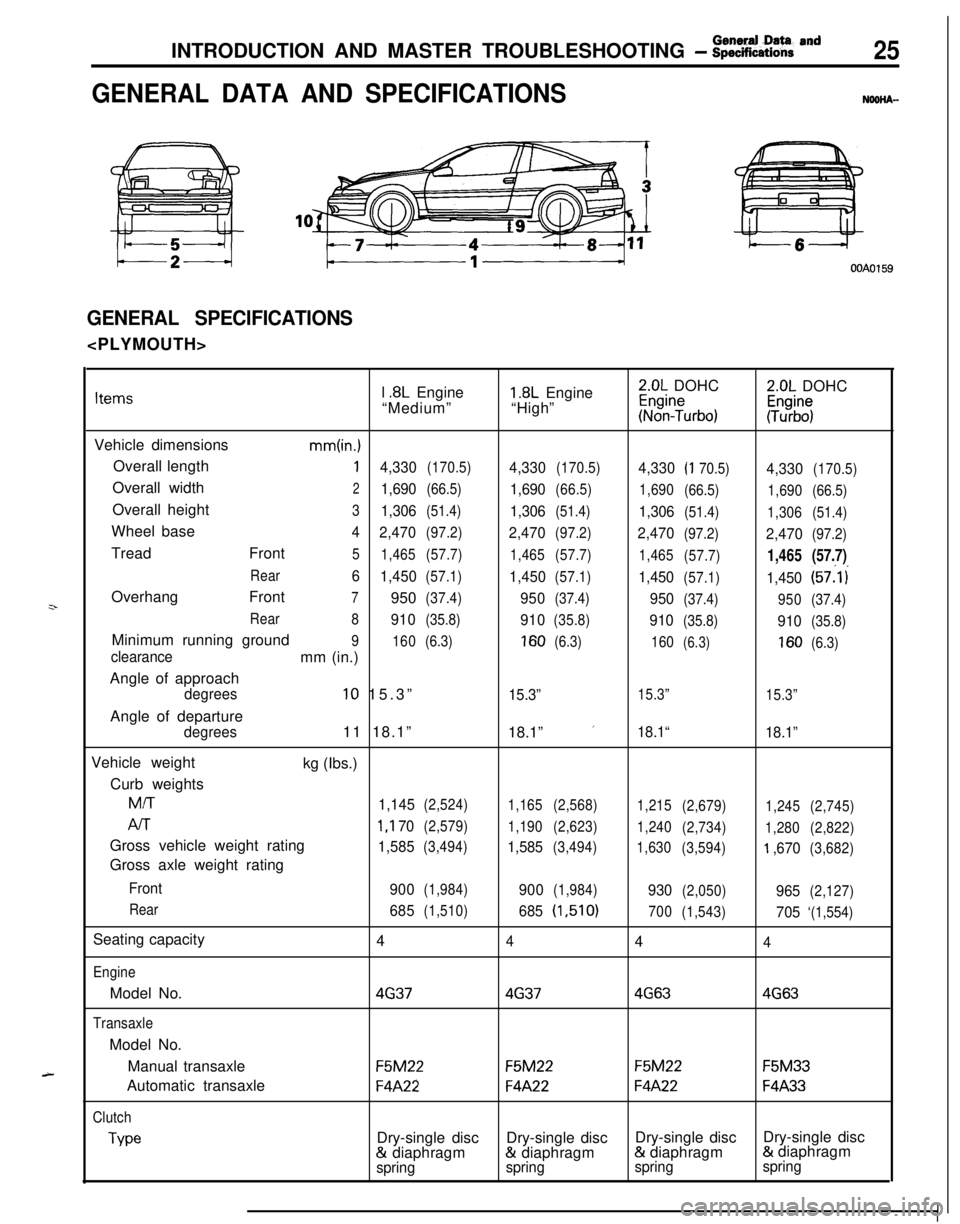

GENERAL DATA AND SPECIFICATIONSNOOHA-

OOAOl59

GENERAL SPECIFICATIONS

z-

A-l

.8L Engine1.8L Engine2.0L DOHC2.0L DOHCItems“Medium”“High”~%n?urbo):Tz%$

Vehicle dimensions

mm(in.)Overall length

14,330(170.5)4,330(170.5)4,330(I 70.5)4,330(170.5)Overall width

21,690(66.5)1,690(66.5)

1,690

(66.5)

1,690(66.5)Overall height

31,306(51.4)1,306(51.4)1,306(51.4)

1,306(51.4)Wheel base

4

2,470(97.2)2,470(97.2)2,470(97.2)2,470(97.2)Tread Front

5

1,465(57.7)

1,465(57.7)

1,465

(57.7)1,465(57.7)

Rear6

1,450(57.1)1,450(57.1)1,450(57.1)1,450(57:l i

Overhang Front

7950(37.4)950(37.4)950(37.4)

950(37.4)

Rear

8

910(35.8)910(35.8)910(35.8)910(35.8)Minimum running ground

9

160(6.3)160(6.3)

160(6.3)160(6.3)clearancemm (in.)

Angle of approach

degrees10 15.3”15.3”15.3”

15.3”Angle of departure

degrees11 18.1”

18.1” ’18.1“

18.1”Vehicle weight

kg (Ibs.)

Curb weights

M/T

1,145(2,524)

1,165(2,568)

1,215

(2,679)

1,245(2,745)

AIT1 ,I 70(2,579)

1,190(2,623)

1,240

(2,734)

1,280(2,822)Gross vehicle weight rating

1,585(3,494)1,585(3,494)

1,630

(3,594)‘I ,670(3,682)Gross axle weight rating

Front

900(1,984)900(1,984)930(2,050)965(2,127)

Rear

685(1,510)685(1,510)

700

(1,543)705‘(1,554)Seating capacity

4

444

EngineModel No.

4G3746374G634G63

TransaxleModel No.

Manual transaxle

F5M22F5M22F5M22F5M33Automatic transaxle

F4A22F4A22F4A22F4A33

Clutch

TypeDry-single discDry-single discDry-single discDry-single disc& diaphragm& diaphragm& diaphragm& diaphragm

springspringspringspring

Page 26 of 1216

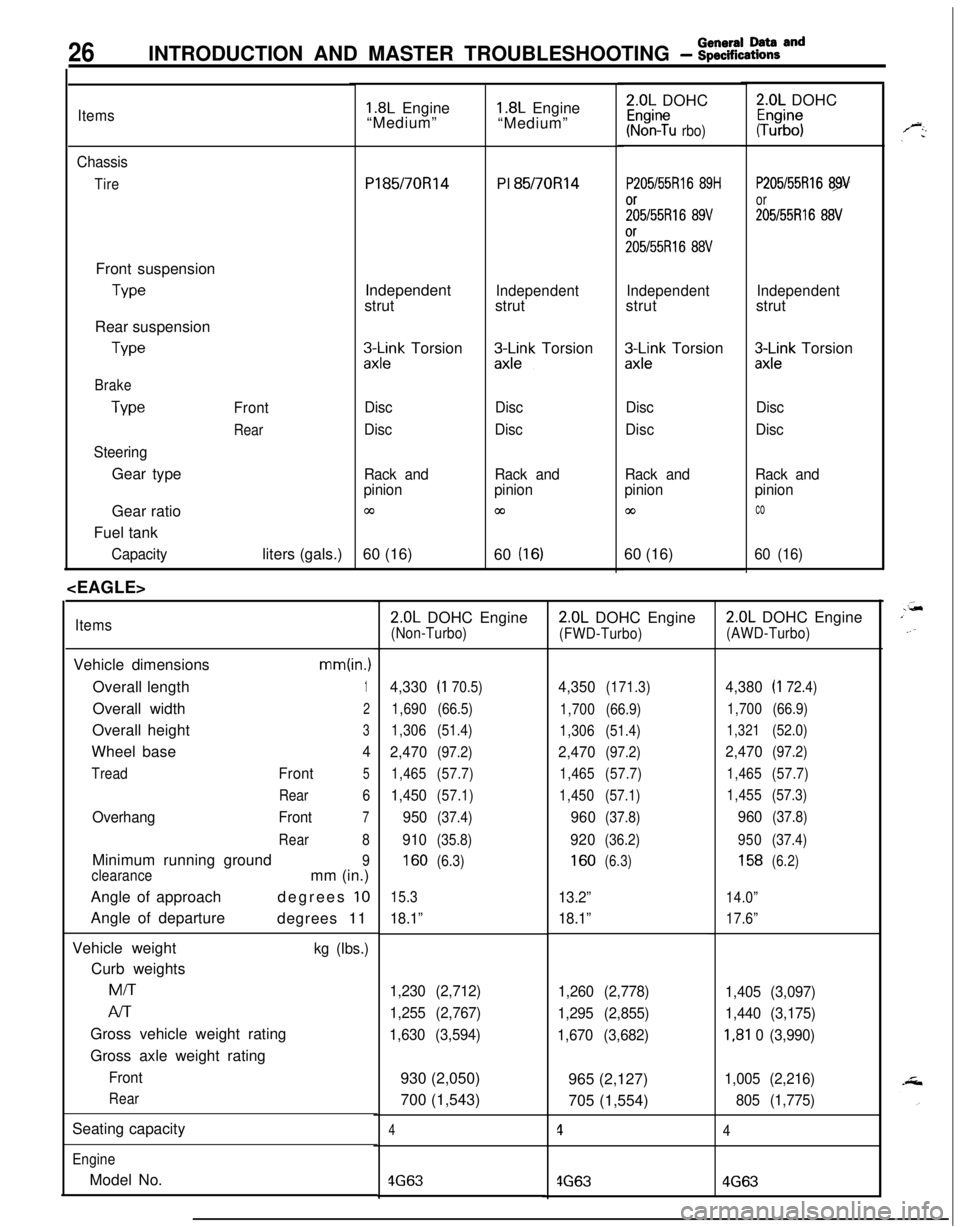

26INTRODUCTION AND MASTER TROUBLESHOOTING - :;:%:a=and

Items

Chassis

TireFront suspension

TypeRear suspension

We

Brake

Type

SteeringGear typeFront

RearGear ratio

Fuel tank

Capacityliters (gals.)

1.8L Engine

“Medium”Pl85/70R14

PI 85/70Rl4

Independent

strut

Independentstrut

3l\Fk Torsion&k-k Torsion

Disc

DiscDisc

Disc

Rack and

pinion

03

Rack and

pinion

cn60 (16)

60

(16)

ItemsVehicle dimensions

mm(in.)Overall length

1Overall width

2Overall height

3Wheel base

4

TreadFront5

Rear6

OverhangFront7

Rear8Minimum running ground

9

clearancemm (in.)

Angle of approachdegrees

10Angle of departure

degrees 11

Vehicle weight

kg (Ibs.)Curb weightsMiT

Al-rGross vehicle weight rating

Gross axle weight rating

Front

RearSeating capacity

EngineModel No.

1.8L Engine

“Medium”2.0L DOHC

Kr%n?u rbo)

P205/55Rl6 89H

;;5/55R16 89V%55R16

88V

Independentstrut

zx;;k Torsion

Disc

Disc

Rack and

pinion

co60 (16)

2.0L DOHC

#b”;

P205/55Rl6 89

or

205155R16 88V

Independentstrut

3Lnk Torsion

Disc

Disc

Rack and

pinion

co

60 (16)

2.0L DOHC Engine(Non-Turbo)

4,330(I 70.5)

1,690(66.5)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

950(37.4)

910(35.8)

160(6.3)

15.3

18.1”

1,230 (2,712)

1,255 (2,767)

1,630 (3,594)930 (2,050)

700 (1,543)

4

4G63

2.0L DOHC Engine

(FWD-Turbo)

4,350(171.3)

1,700(66.9)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

960(37.8)

920(36.2)

160(6.3)

13.2”

18.1”

1,260 (2,778)

1,295 (2,855)

1,670 (3,682)965 (2,127)

705 (1,554)

1

4G63

2.0L DOHC Engine

(AWD-Turbo)

4,380(I 72.4)

1,700(66.9)

1,321(52.0)

2,470(97.2)

1,465(57.7)

1,455(57.3)

960(37.8)

950(37.4)

158(6.2)

14.0”

17.6”

1,405 (3,097)

1,440 (3,175)

I,81 0 (3,990)

1,005 (2,216)

805 (1,775)

4

4G63

Page 31 of 1216

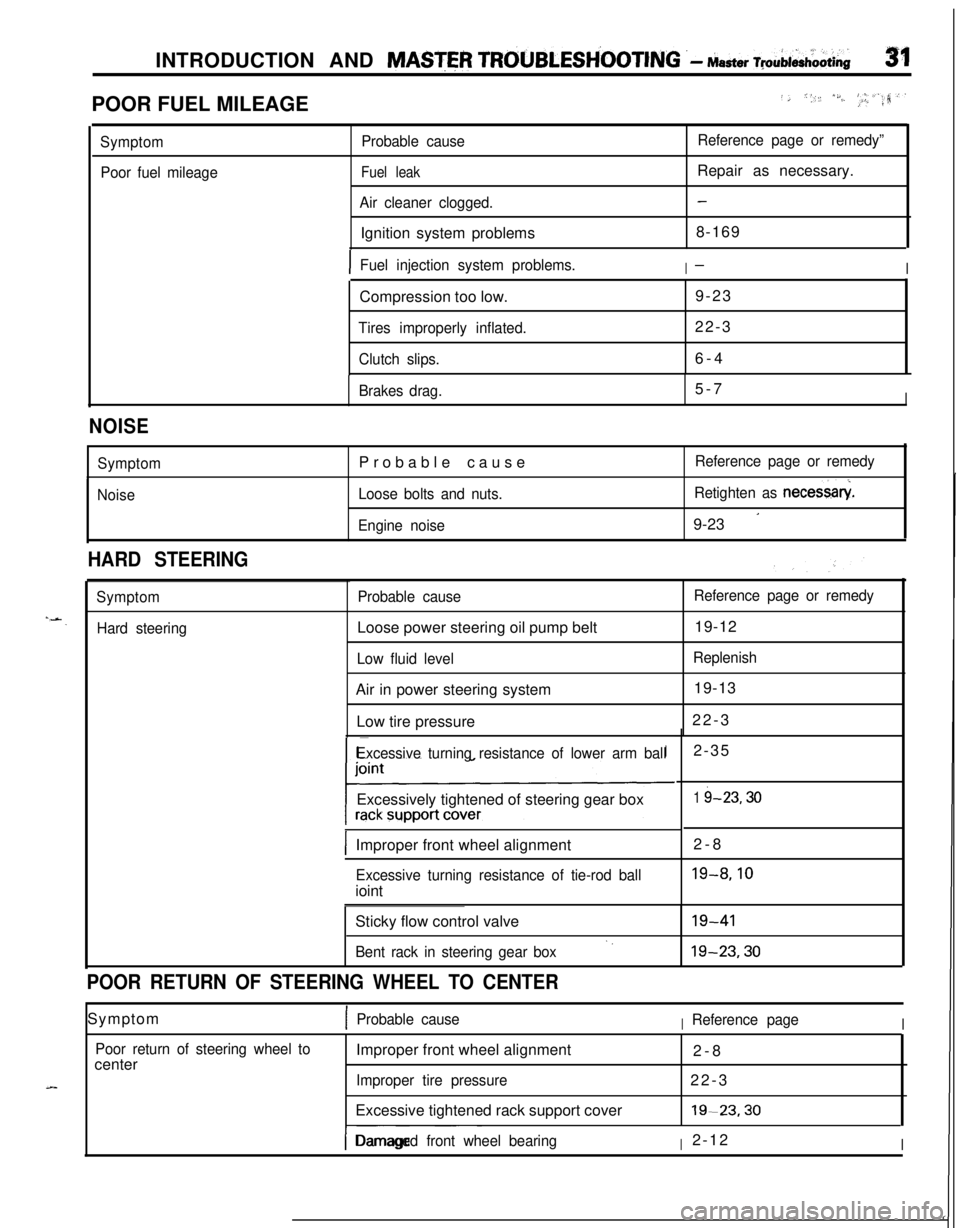

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 32 of 1216

32INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

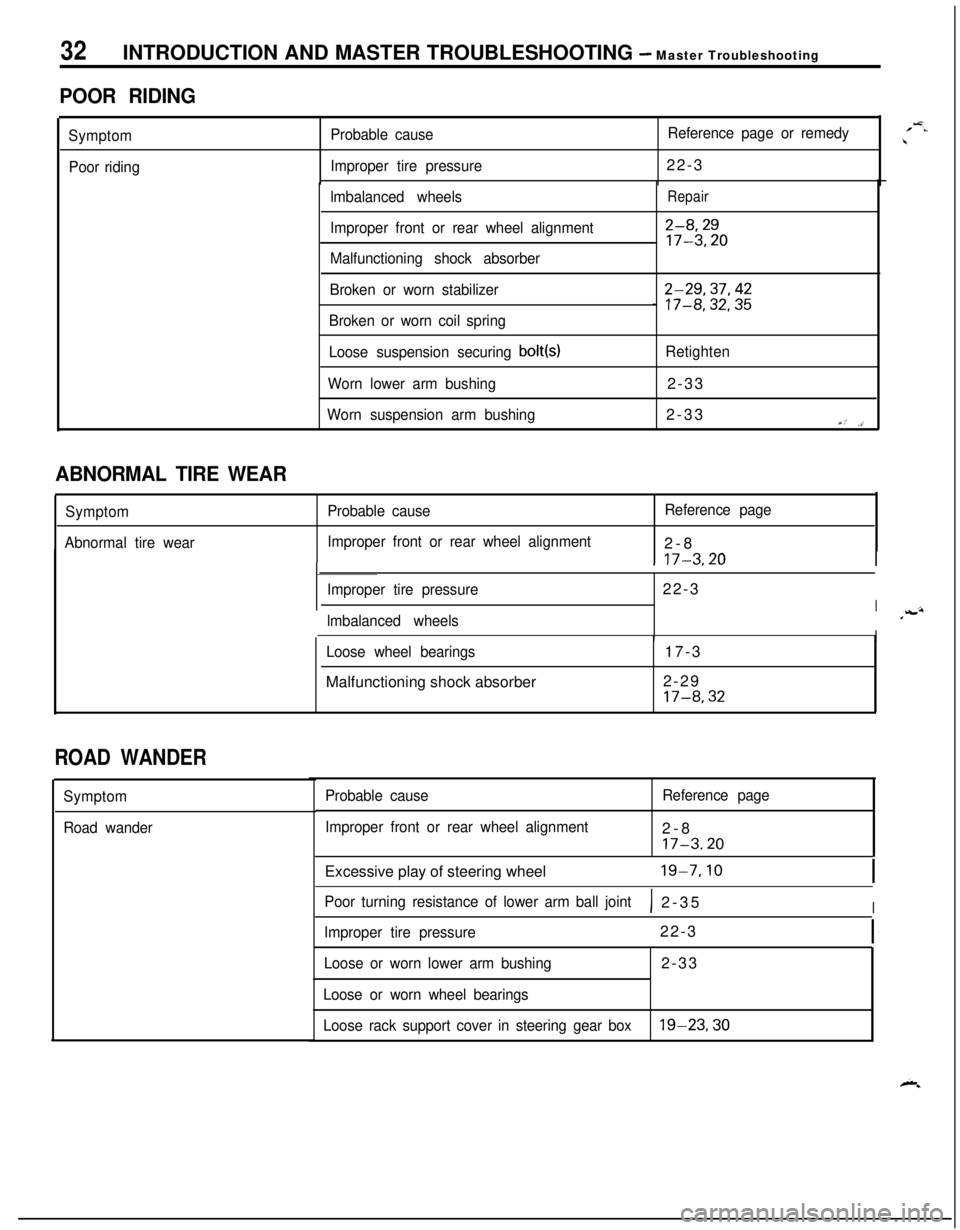

POOR RIDING

Symptom

Poor ridingProbable causeReference page or remedy

Improper tire pressure22-3

lmbalanced wheels

Improper front or rear wheel alignment

Malfunctioning shock absorberRepair

2-8,2917-3.20

Broken or worn stabilizer

Broken or worn coil spring2-29,37,42_ 17-8,32,35

Loose suspension securing bolt(s)Retighten

Worn lower arm bushing2-33

Worn suspension arm bushing2-33Y,’ ,>’

1 17-3.20I

ABNORMAL TIRE WEAR

Symptom

Abnormal tire wearProbable causeReference page

Improper front or rear wheel alignment2-8

Improper tire pressure22-3

Ilmbalanced wheelsIILoose wheel bearingsMalfunctioning shock absorber17-3

2-29

17-8,32

ROAD WANDER

Symptom

Road wanderProbable cause

Improper front or rear wheel alignmentReference page2-8

17-3.20Excessive play of steering wheel

19-7.10

Poor turning resistance of lower arm ball joint1 2-35I

Improper tire pressure22-3

Loose or worn lower arm bushing2-33

Loose or worn wheel bearings

Loose rack support cover in steering gear box

19-23,30

/-=..\

Page 33 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

VEHICLE PULLS TO ONE SIDE

Symptom

Vehicle pulls to one sideProbable causeReference pageI

Improper front or rear wheel alignment

lmbalanced or worn tires

Uneven tire pressure2-817-3,2022-3

Excessive turning resistance of lower arm ball2-35

joint

Wheel bearing seizureReplace

Broken or weak coil spring2-29

Bent front axle drive shaft

2-15,3-13

Deformed lower arm2-35

STEERING WHEEL SHIMMY

SymptomSteering wheel shimmy

L

Probable cause

Improper front or rear wheel alignmentReference page or remedy2-8

17-3,20

Improper tire pressure22-3

lmbalanced wheelsReplace

Poor turning resistance of lower arm ball joint2-35

Excessive play of steering wheel

19-7,lO

Broken or weak front stabilizer2-33

Worn lower arm bushing2-33

Malfunctioning shock absorber2-29

17-8,32

Broken or weak coil spring

Wear, play, or seizure of wheel bearing

Wear, play, or seizure of drive shaft ball joint

Replace

2-15.3-13

BOTTOMING

I-SvmotomProbable cause1 Reference page or remedy[Bottoming

Overloaded vehicle

Broken or weak coil springMalfunctioning shock absorberCorrect2-29

l7-8,32

Page 34 of 1216

34INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

WHEEL BEARING TROUBLESHOOTING

TroublePitting

Flakrng

Crackrng

Flat spotting

Nicks

Smearing

Rust, corrosionwear

3rscolorationSympton

Pitting occurs because of uneven rotation of race

and bearing surfaces

The surface peels because of uneven rotation of

the race and bearing surfaces

Chipping or cracking of cage or roller edges

When large load is applied, race and roller

contact surfaces compress, formingindentations

Instead of rolling along race surface, rollers slide,

thus damaging surface

Damage or wear caused by minute particles

adhering to surfaces results in rough movement

and such high temperatures that parts of surface

melt

Appears on various areas of the bearing

Wear of surface areas caused by friction

Grease discoloration results from grease

deterioration which causes particles of

pigment contained in grease to adhere

to surfaces

Heat discoloration will appear

as a deep brown on purple

Probable cause

Excessive bearing preload

Excessive load’

End of bearing life

Improper bearing assembly

Impact when bearing was installed

(such as being hit with a hammer)

Excessive bearing preload

Excessive load

Vibration when bearings are not

used, such as during shipment on

freight cars, transport trucks, etc.

Insufficient grease

Excessive bearing preload

Excessive load

Faulty oil seal

Excessive variation of loads on ” .j’

bearings

Use of grease other than that

specified

Insufficient grease

Use of grease other than that

specrfied

Faulty oil sealPresence of water or moisture

Insufficient grease

Foreign matter

Rust or corrosion due to moisture

Use of grease other than that

specified

Faulty oil seal

Jse of grease other than thatspecified

-aulty oil seallxcessive bearing preloadExcessive load

Page 38 of 1216

0-4 LUBRICATION AND MAINTENANCEScheduled Maintenance Table/Recommended Lubricants- and Lubricant Capacities TableSCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

F.Mileage Intervals Kilometers in ThousandsSevere Usage

Service to be(Miles in Thousands)ConditionsMaintenance

Item

Performed24 36 48 60 72 80 84 96

(:,:) (15) (22.5) (30) (37.5) (45) (50) (52.5) (60) * B ’ D E F G

Air CleanerReplaceElementMore FrequentlyXX

Spark PlugsReplace

XXXx xx

Engine Oil$$~~~h~vev orEvery 4,800 km (3,000 miles)xxxx x

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 km (6,000 miles)xxxx x

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditionsA-Driving in dusty conditionsE-Driving in sandy areas

B-Trailer towing or police, taxi, or commercial typeF-Driving in salty areas

operationG-More than 50% operation in heavy city trafic during

C-Extensive idlinghot weather above 32°C (90°F)D-Short trip operation at freezing temperatures

(engine not thoroughly warmed up)

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLENOONA- --z.

RECOMMENDED LUBRICANTS

Items

Engine Oil

Manual Transaxle

TransferRecommended lubricantskF&cesisification

SG or SG/CD (For further details, refer to SAE viscosity

MOPAR Hypoid Gear

Oil/API classification GL4 or higher, SAE 75W-85W

Automatic TransaxleMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176) or Dia

ATF SP or Equivalent

Power SteeringMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176VAutomatictransmission fluid or “DEXRON” or “DEXRON II”

Rear Axle

Brake and Clutch

Rear Wheel BearingsRefer to

P.O-6.

MOPAR Brake Fluid/Conforming to DOT 3

MOPAR Front Wheel Bearing Grease, or MOPAR Multi-MileageLubricant/Multipurpose grease NLGI Grade 2EP

Hood Lock Latch,, Door Lock Strikers,

Seat Adjusters, Lrftgate Lock, Parking

Brake Cable MechanismMOPAR Lubriplate/Multipurpose grease NLGI Grade 2

Engine CoolantMOPAR Antifreeze Permanent-Type Coolant/High quality

ethylene-glycolantifreeze coolant

Door Hinges, Liftgate Hinges

Engine oil

/

N

Page 46 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Service

L-4GoodOOA0051C9FW1014K512(9) Supply 4 liters (8.5 pints) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is

6.1 liters (12.9 pints).

Actually however, approx. 4.5 liters (9.5 pints) of fluid

can be replaced because rest of fluid remains in torque

converter.]Specified fluid: MOPAR ATF PLUS (Automatic

Transmission Fluid Type 7176) or

Dia ATF SP or Equivalent

(10)Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever

momentarily to each position, ending in “N” Neutral

position.

(1 l)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature.

Fluid level should be between upper and lower marks of“HOT” range. Insert dipstick fully to prevent dirt from

entering transaxle.

11 .ENGINE COOLANT (Change)NOOSBEAcCheck the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug

securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens,

remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the

.radiator, cap securely.

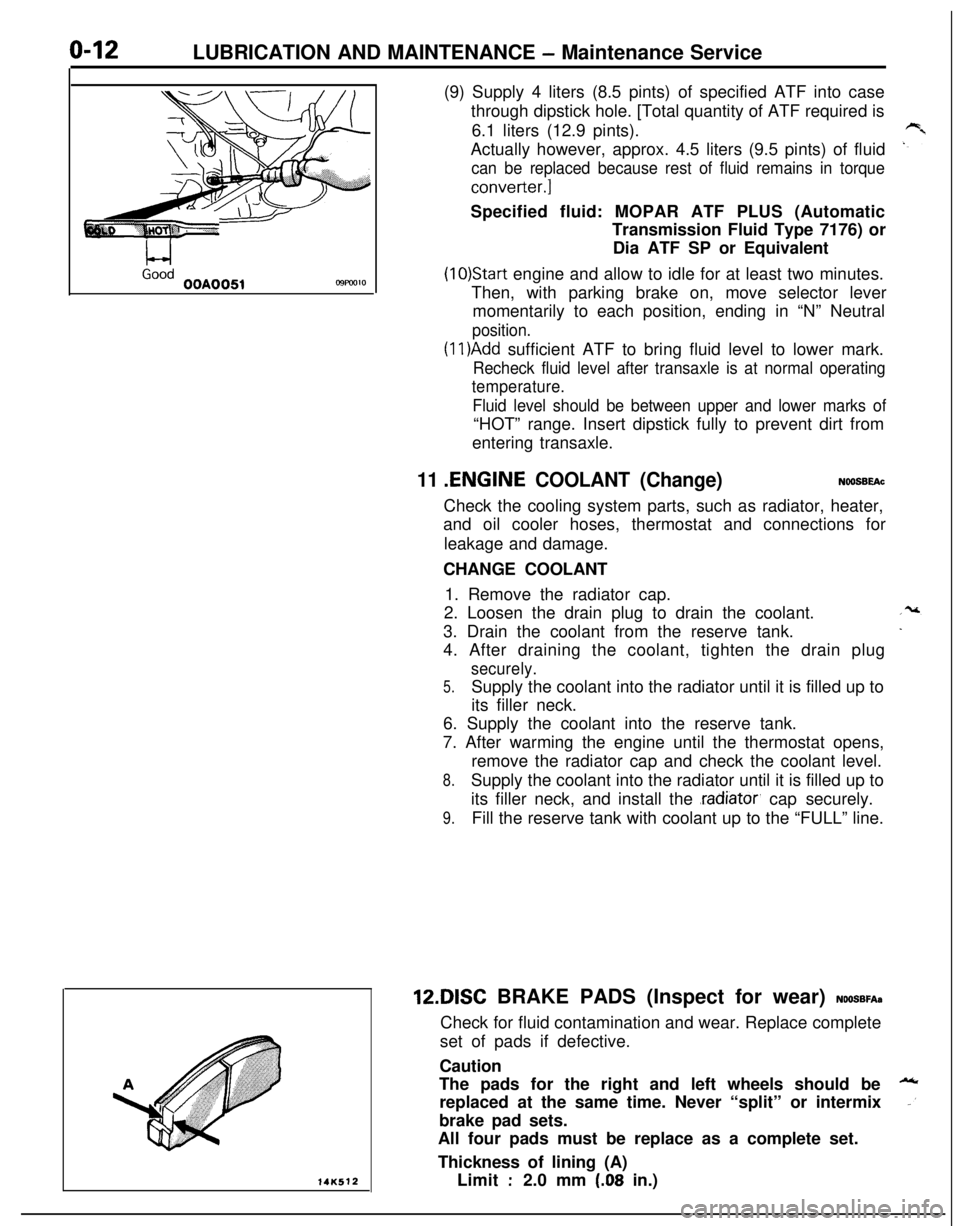

9.Fill the reserve tank with coolant up to the “FULL” line.12DISC BRAKE PADS (Inspect for wear)

NOOSBFA~Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

replaced at the same time. Never “split” or intermix

brake pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit

:2.0 mm (.08 in.)

Page 47 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Serviceo-13

OOAOlB6

13.BRAKE HOSES (Check for deteriorati.on or

leaks)NwBBnAs

Inspection of brake hoses and tubing should be included inall brake service operations.

The hoses should be checked for:

1. Correct length, severe surface cracking, pulling, scuf-

fing or worn spots. (If the fabric casing of the hoses is

exposed by cracks of abrasion in the rubber hose cover,

the hoses should be replaced. Eventual deterioration ofhose may occur with possible bursting failure.)

2. Faulty installation, casing twisting or interference with

wheel, tire of chassis.

14.BALL JOINT AND STEERING LINKAGE SEALS

(Inspect for grease leaks and damage)

NWSBJAb1. These components, which are permanently lubricated

at the factory, do not require periodic lubrication.

Damaged seals and boots should be replaced to

prevent leakage or contamination of the grease.

2. Inspect the dust cover and boots for proper sealing,

leakage and damage. Replace them if defective.

15.DRIVE SHAFT BOOTS (Inspect for grease leaksand damage)

NWSBJAc1. These components, which are permanently lubricated

at the factory, do not require periodic lubrication.

Damaged boots should be replaced to prevent leakage

or contamination of the grease.

2. Inspect the boots for proper sealing, leakage and

damage. Replace it if defective.

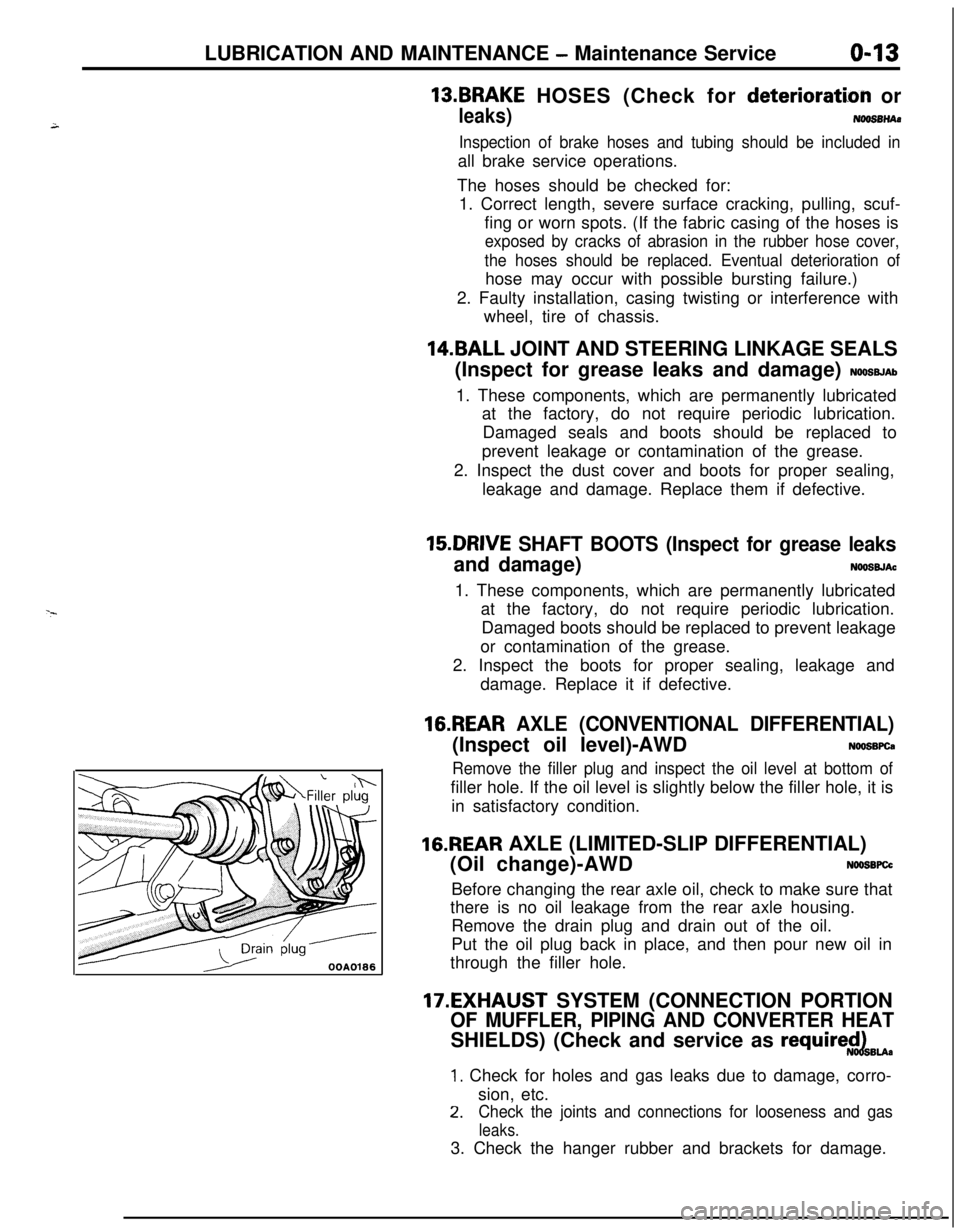

16.REAR AXLE (CONVENTIONAL DIFFERENTIAL)(Inspect oil level)-AWD

NWSBFCa

Remove the filler plug and inspect the oil level at bottom offiller hole. If the oil level is slightly below the filler hole, it is

in satisfactory condition.

16.REAR AXLE (LIMITED-SLIP DIFFERENTIAL)

(Oil change)-AWD

N66SBFCcBefore changing the rear axle oil, check to make sure that

there is no oil leakage from the rear axle housing.

Remove the drain plug and drain out of the oil.

Put the oil plug back in place, and then pour new oil in

through the filler hole.

17.EXHAUST SYSTEM (CONNECTION PORTION

OF MUFFLER, PIPING AND CONVERTER HEATSHIELDS) (Check and service as

require$dBu.

1. Check for holes and gas leaks due to damage, corro-

sion, etc.

2.Check the joints and connections for looseness and gas

leaks.3. Check the hanger rubber and brackets for damage.

Page 49 of 1216

FRONTSUSPENSION

’

CONTENTSNOZAA-CENTERMEMBER AND

CROSSMEMBER..............................................44

DRIVESHAFT..................................................15HUB AND KNUCKLE

......................................9

LOWERARM

...................................................33

~SERVICE ADJUSTMENT PROCEDURES.......8

FrontWheelAlignment................................8Hub End Play Inspection

.............................8

WheelBearingAdjustment..........................9

SPECIALTOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SPECIFICATIONS.............................................2General Specifications

..................................2

Lubricants......................................................5Service Specifications

...................................4

TorqueSpecifications...................................4STABILIZER BAR

.............................................37

STRUTASSEMBLY.........................................29