tow MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 19 of 1216

c

--INTRODUCTION AND MASTER

TROUBLESHOOTtNG - Towing and Hoi&gT9

I-

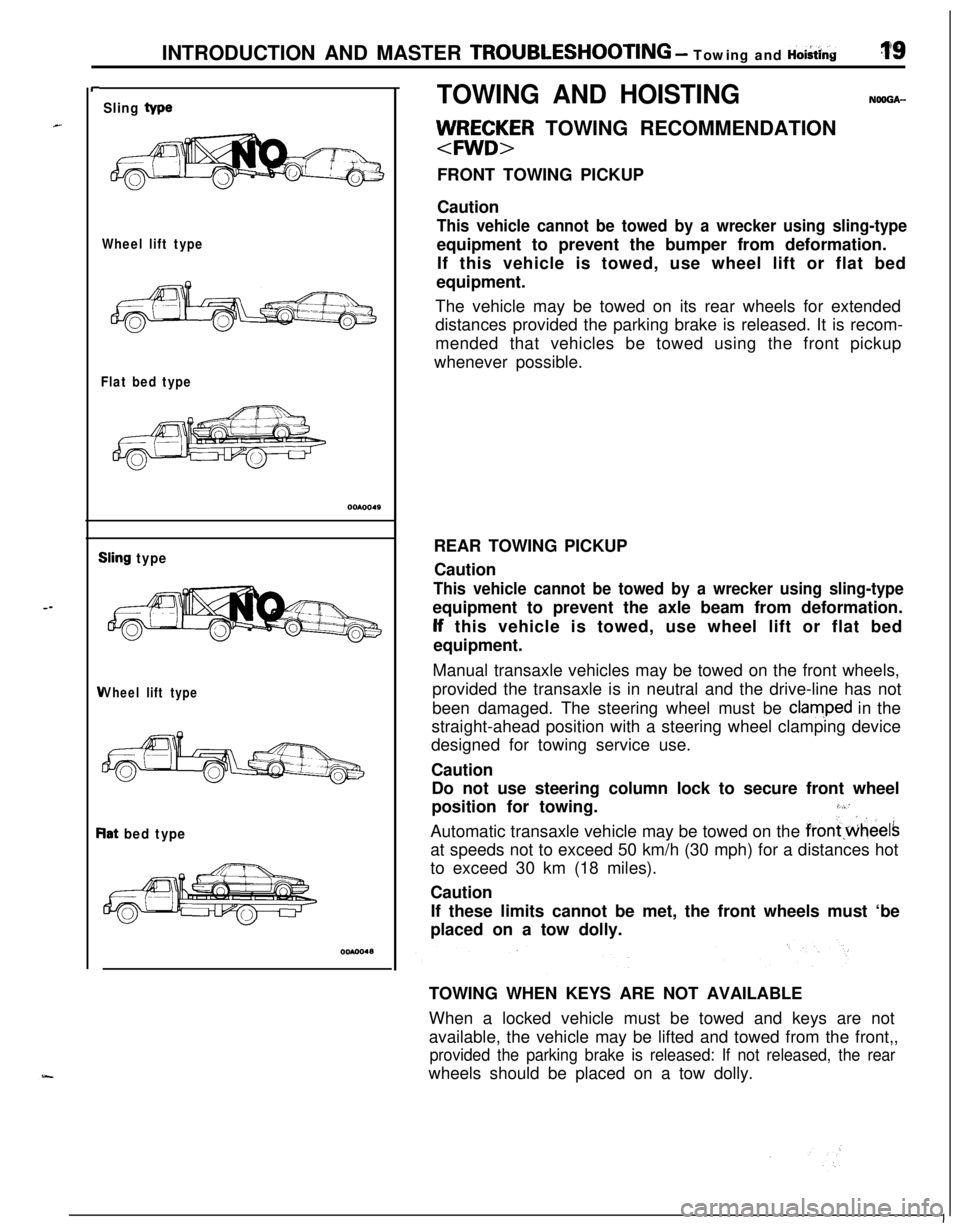

Sling type

Wheel lift type

Flat bed type

iling type

Vheel lift type

lat bed type

TOWING AND HOISTINGNOOGA-

llJ/RE;~R TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-typeequipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed

equipment.

The vehicle may be towed on its rear wheels for extended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front pickup

whenever possible.

REAR TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-typeequipment to prevent the axle beam from deformation.lf this vehicle is towed, use wheel lift or flat bed

equipment.

Manual transaxle vehicles may be towed on the front wheels,

provided the transaxle is in neutral and the drive-line has not

been damaged. The steering wheel must be

clam,ped in the

straight-ahead position with a steering wheel clamping device

designed for towing service use.

Caution

Do not use steering column lock to secure front wheel

position for towing.

3,“’Automatic transaxle vehicle may be towed on the

frontwheelsat speeds not to exceed 50 km/h (30 mph) for a distances hot

to exceed 30 km (18 miles).

Caution

If these limits cannot be met, the front wheels must ‘be

placed on a tow dolly.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not

available, the vehicle may be lifted and towed from the front,,

provided the parking brake is released: If not released, the rearwheels should be placed on a tow dolly.

I

Page 20 of 1216

20INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting

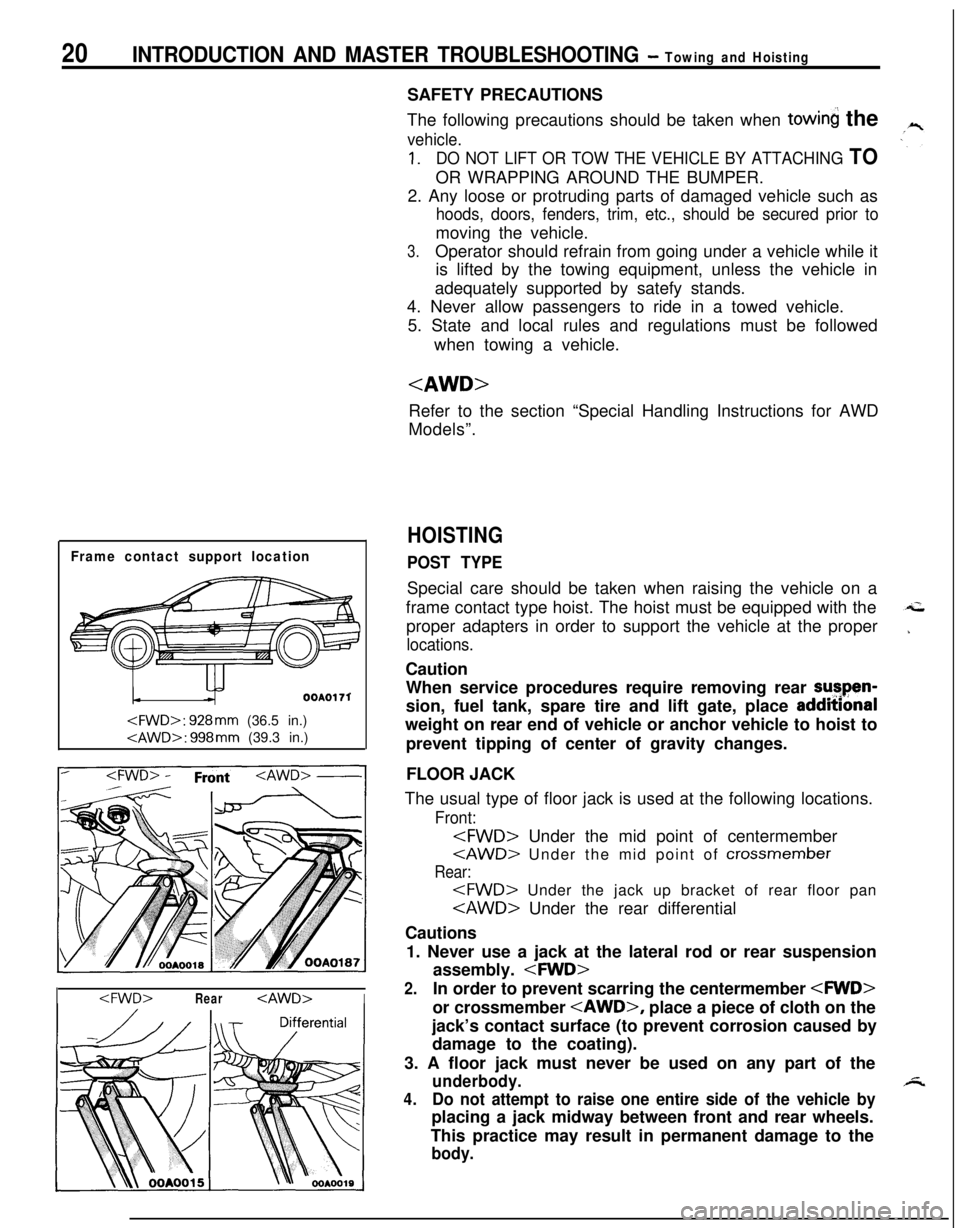

Frame contact support location

OOAOI 71

I

The following precautions should be taken when

towin the

vehicle.

1.DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING TOOR WRAPPING AROUND THE BUMPER.

2. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior tomoving the vehicle.

3.Operator should refrain from going under a vehicle while it

is lifted by the towing equipment, unless the vehicle in

adequately supported by satefy stands.

4. Never allow passengers to ride in a towed vehicle.

5. State and local rules and regulations must be followed

when towing a vehicle.

Refer to the section “Special Handling Instructions for AWD

Models”.

HOISTING

POST TYPESpecial care should be taken when raising the vehicle on a

frame contact type hoist. The hoist must be equipped with the

proper adapters in order to support the vehicle at the proper

locations.Caution

When service procedures require removing rear sutpen-

sion, fuel tank, spare tire and lift gate, place addmonal

weight on rear end of vehicle or anchor vehicle to hoist to

prevent tipping of center of gravity changes.

FLOOR JACK

The usual type of floor jack is used at the following locations.

Front:

Rear:

Cautions

1. Never use a jack at the lateral rod or rear suspension

assembly.

2.In order to prevent scarring the centermember

jack’s contact surface (to prevent corrosion caused by

damage to the coating).

3. A floor jack must never be used on any part of the

underbody.

4.Do not attempt to raise one entire side of the vehicle byplacing a jack midway between front and rear wheels.

This practice may result in permanent damage to the

body.

Page 21 of 1216

--

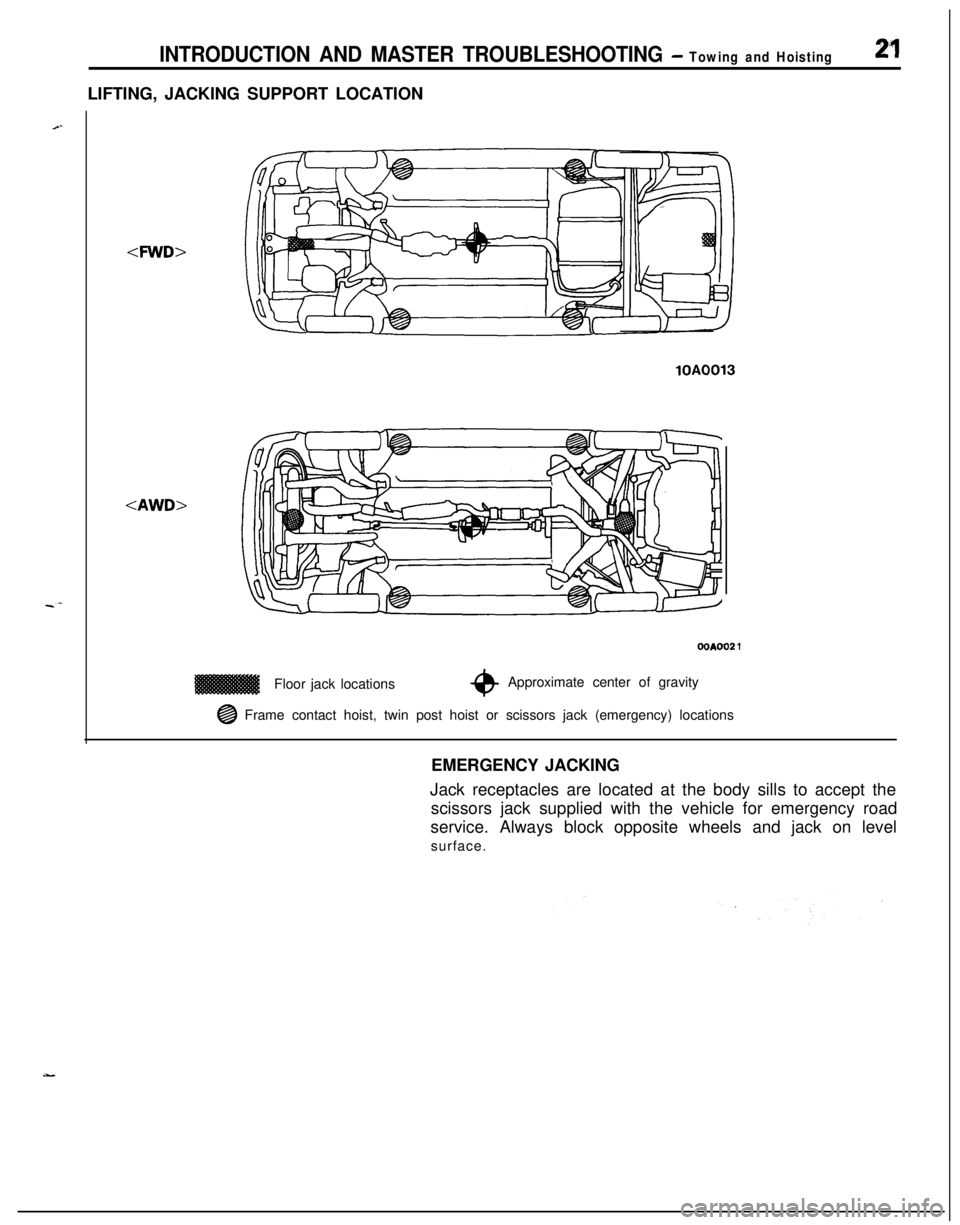

INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting2”1LIFTING, JACKING SUPPORT LOCATION

-4WD>

lOAFloor jack locations

OOAOO2 1

*Approximate center of gravity

@ Frame contact hoist, twin post hoist or scissors jack (emergency) locations

EMERGENCY JACKING

Jack receptacles are located at the body sills to accept the

scissors jack supplied with the vehicle for emergency road

service. Always block opposite wheels and jack on level

surface.

Page 22 of 1216

22 INTRODUCTION AND MASTER TROUBLESHOOTING - %%c%:k! ‘nstructions

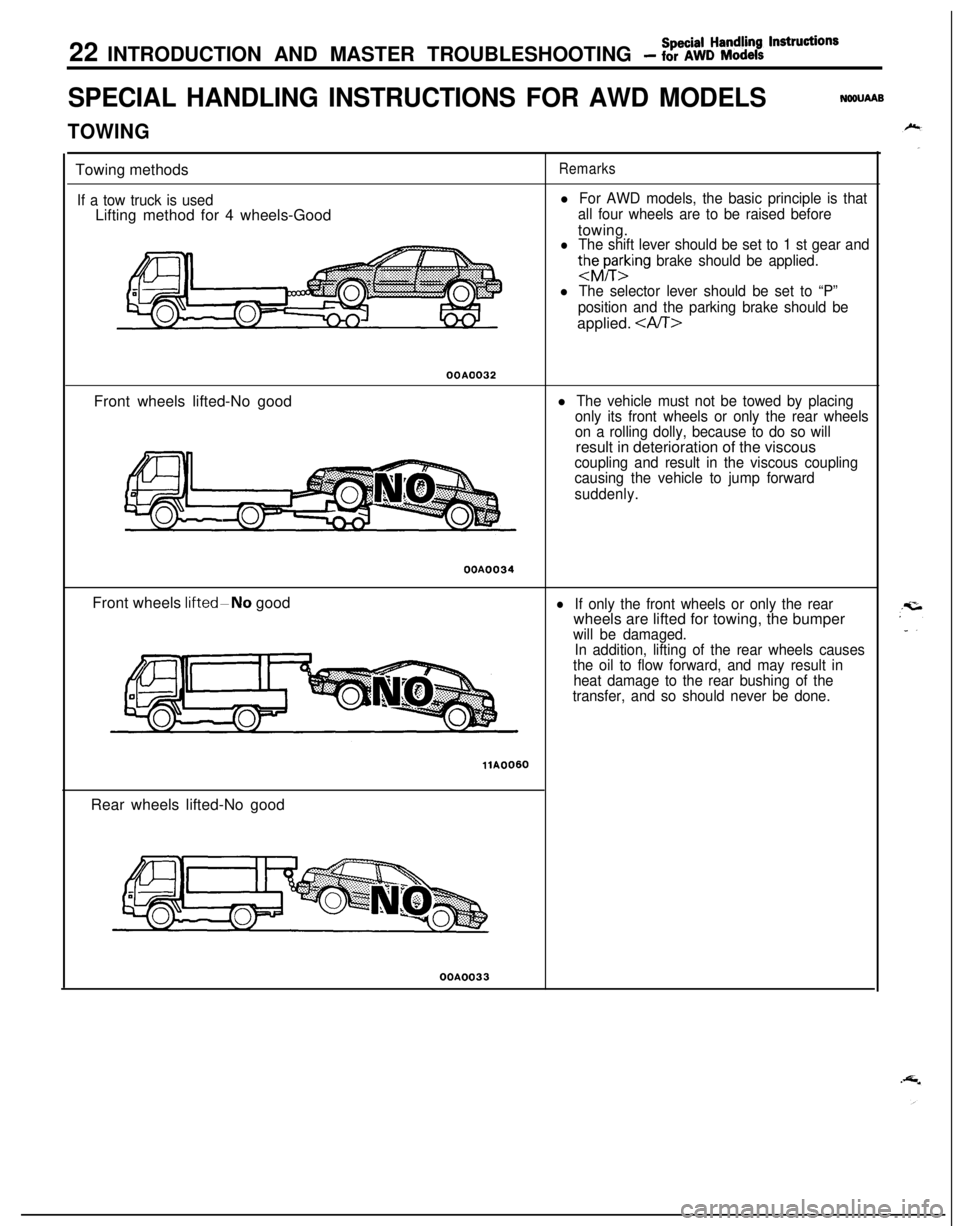

SPECIAL HANDLING INSTRUCTIONS FOR AWD MODELSNWUAAB

TOWINGTowing methods

If a tow truck is usedLifting method for 4 wheels-Good

Remarks

l For AWD models, the basic principle is that

all four wheels are to be raised beforetowing.

l The shift lever should be set to 1 st gear and

thhrting brake should be applied.

l The selector lever should be set to “P”

position and the parking brake should beapplied.

OOAO032Front wheels lifted-No good

l The vehicle must not be towed by placing

only its front wheels or only the rear wheels

on a rolling dolly, because to do so willresult in deterioration of the viscous

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.OOA0034

Front wheels

IifteddNo goodlIf only the front wheels or only the rearwheels are lifted for towing, the bumper

will be damaged.

In addition, lifting of the rear wheels causes

the oil to flow forward, and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

llA0060Rear wheels lifted-No goodOOA0033

Page 36 of 1216

o-2LUBRICATION AND MAINTENANCE - General Information

GENERAL INFORMATIONNGQPA--Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by theSociety of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

SEVERE SERVICEVehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one ormore of the following conditions:

1.Trailer towing or police, taxi, or commercial type

operation2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above

32°C (90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE

lOW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans

to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be’ taken, therefore, when changingengine oil, to minimize the amount and length of

exposure time to used engine

pi! on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classfication system defines gear lubricants

in terms of usage. Typically gear lubricants conform-ing to API

GL-4 or GL-5 with a viscosity of SAE

75W-85W are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the NLGI designation andare further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified, Multi-

Purpose Grease,

NLGI grade 2 should be used.

MOPAR Multi-Mileage Lubricant, P&t Number

2525035 or equivalent, meets these requirement

and is recommended.

FUEL USAGE STATEMENT

Use gasolines having a minimum anti-knock index

(Octane Value) of 87,

(R + M)/2. This designation is

comparable to a Research Octane Number of 91.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed toaccept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED

TO FUELIndiscriminate use of fuel system cleanng agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials usedin fuel system component parts.

Page 38 of 1216

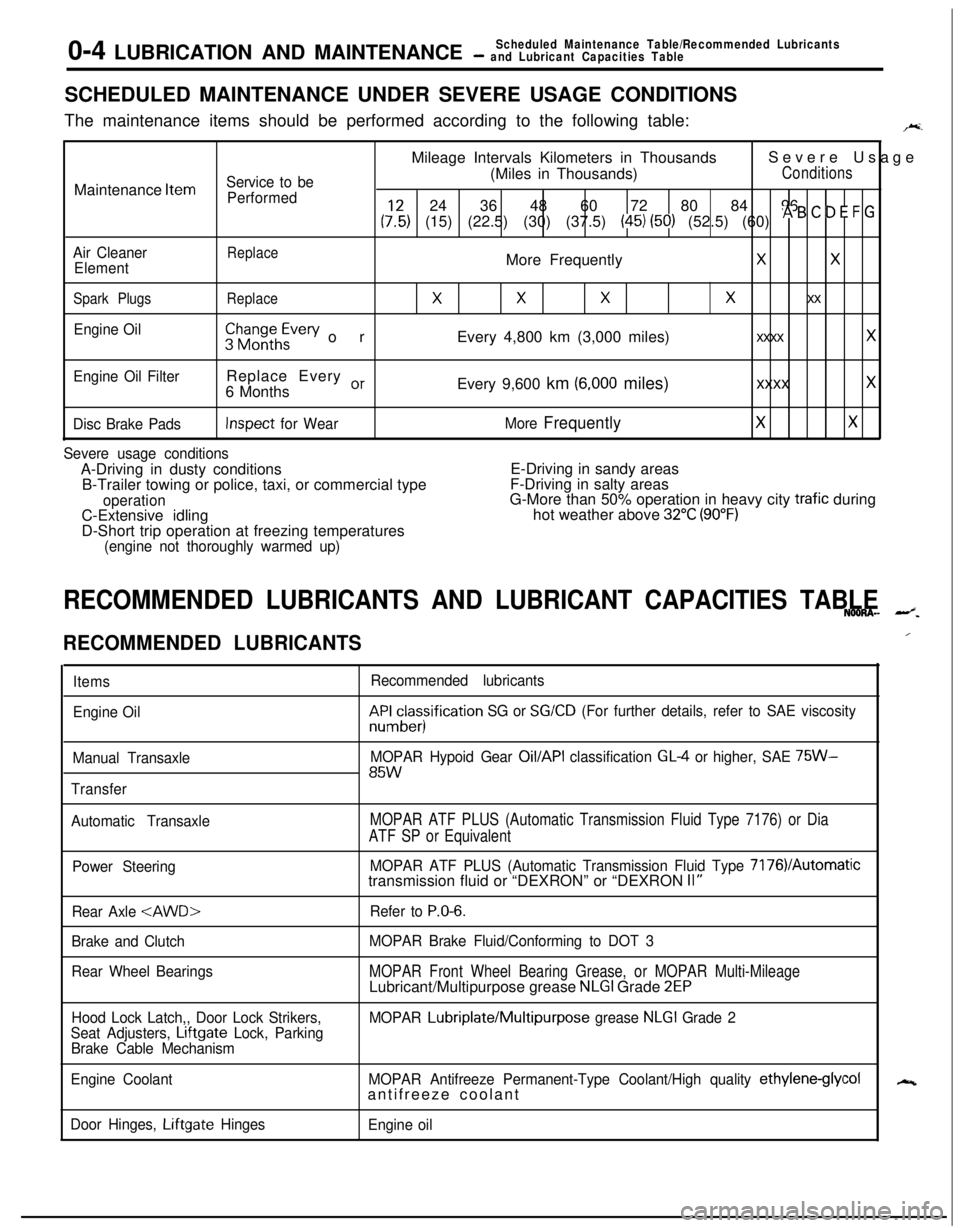

0-4 LUBRICATION AND MAINTENANCEScheduled Maintenance Table/Recommended Lubricants- and Lubricant Capacities TableSCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

F.Mileage Intervals Kilometers in ThousandsSevere Usage

Service to be(Miles in Thousands)ConditionsMaintenance

Item

Performed24 36 48 60 72 80 84 96

(:,:) (15) (22.5) (30) (37.5) (45) (50) (52.5) (60) * B ’ D E F G

Air CleanerReplaceElementMore FrequentlyXX

Spark PlugsReplace

XXXx xx

Engine Oil$$~~~h~vev orEvery 4,800 km (3,000 miles)xxxx x

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 km (6,000 miles)xxxx x

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditionsA-Driving in dusty conditionsE-Driving in sandy areas

B-Trailer towing or police, taxi, or commercial typeF-Driving in salty areas

operationG-More than 50% operation in heavy city trafic during

C-Extensive idlinghot weather above 32°C (90°F)D-Short trip operation at freezing temperatures

(engine not thoroughly warmed up)

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLENOONA- --z.

RECOMMENDED LUBRICANTS

Items

Engine Oil

Manual Transaxle

TransferRecommended lubricantskF&cesisification

SG or SG/CD (For further details, refer to SAE viscosity

MOPAR Hypoid Gear

Oil/API classification GL4 or higher, SAE 75W-85W

Automatic TransaxleMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176) or Dia

ATF SP or Equivalent

Power SteeringMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176VAutomatictransmission fluid or “DEXRON” or “DEXRON II”

Rear Axle

Brake and Clutch

Rear Wheel BearingsRefer to

P.O-6.

MOPAR Brake Fluid/Conforming to DOT 3

MOPAR Front Wheel Bearing Grease, or MOPAR Multi-MileageLubricant/Multipurpose grease NLGI Grade 2EP

Hood Lock Latch,, Door Lock Strikers,

Seat Adjusters, Lrftgate Lock, Parking

Brake Cable MechanismMOPAR Lubriplate/Multipurpose grease NLGI Grade 2

Engine CoolantMOPAR Antifreeze Permanent-Type Coolant/High quality

ethylene-glycolantifreeze coolant

Door Hinges, Liftgate Hinges

Engine oil

/

N

Page 56 of 1216

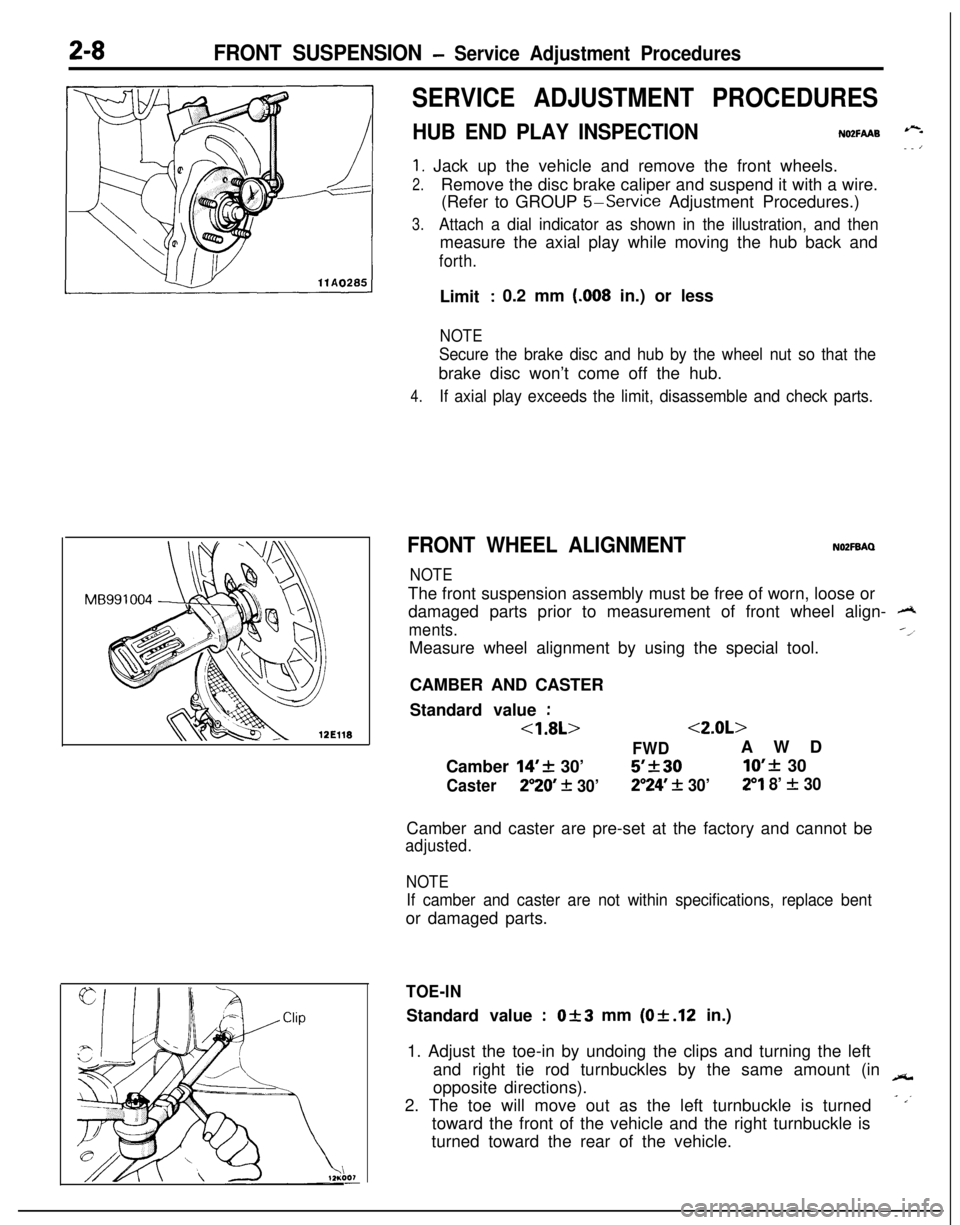

2-8FRONT SUSPENSION - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

HUB END PLAY INSPECTIONNO2FAAB --- ’

1. Jack up the vehicle and remove the front wheels.

2.Remove the disc brake caliper and suspend it with a wire.

(Refer to GROUP

5-Service Adjustment Procedures.)

3.Attach a dial indicator as shown in the illustration, and thenmeasure the axial play while moving the hub back and

forth.Limit

: 0.2 mm (.008 in.) or less

NOTE

Secure the brake disc and hub by the wheel nut so that thebrake disc won’t come off the hub.

4.If axial play exceeds the limit, disassemble and check parts.

FRONT WHEEL ALIGNMENTNOZFBAQ

NOTEThe front suspension assembly must be free of worn, loose or

damaged parts prior to measurement of front wheel align-

A

ments.--l

Measure wheel alignment by using the special tool.

CAMBER AND CASTER

Standard value

:

<1.8L><2.0L>

FWDAWD

Camber

14’+ 30’5’k3010’f 30

Caster250 + 30’2”24’ + 30’29 8’ f 30Camber and caster are pre-set at the factory and cannot be

adjusted.

NOTE

If camber and caster are not within specifications, replace bentor damaged parts.

TOE-INStandard value

:Of3 mm (Of.12 in.)

1. Adjust the toe-in by undoing the clips and turning the left

and right tie rod turnbuckles by the same amount (in

-opposite directions).

2. The toe will move out as the left turnbuckle is turned

- ,’toward the front of the vehicle and the right turnbuckle is

turned toward the rear of the vehicle.

Page 114 of 1216

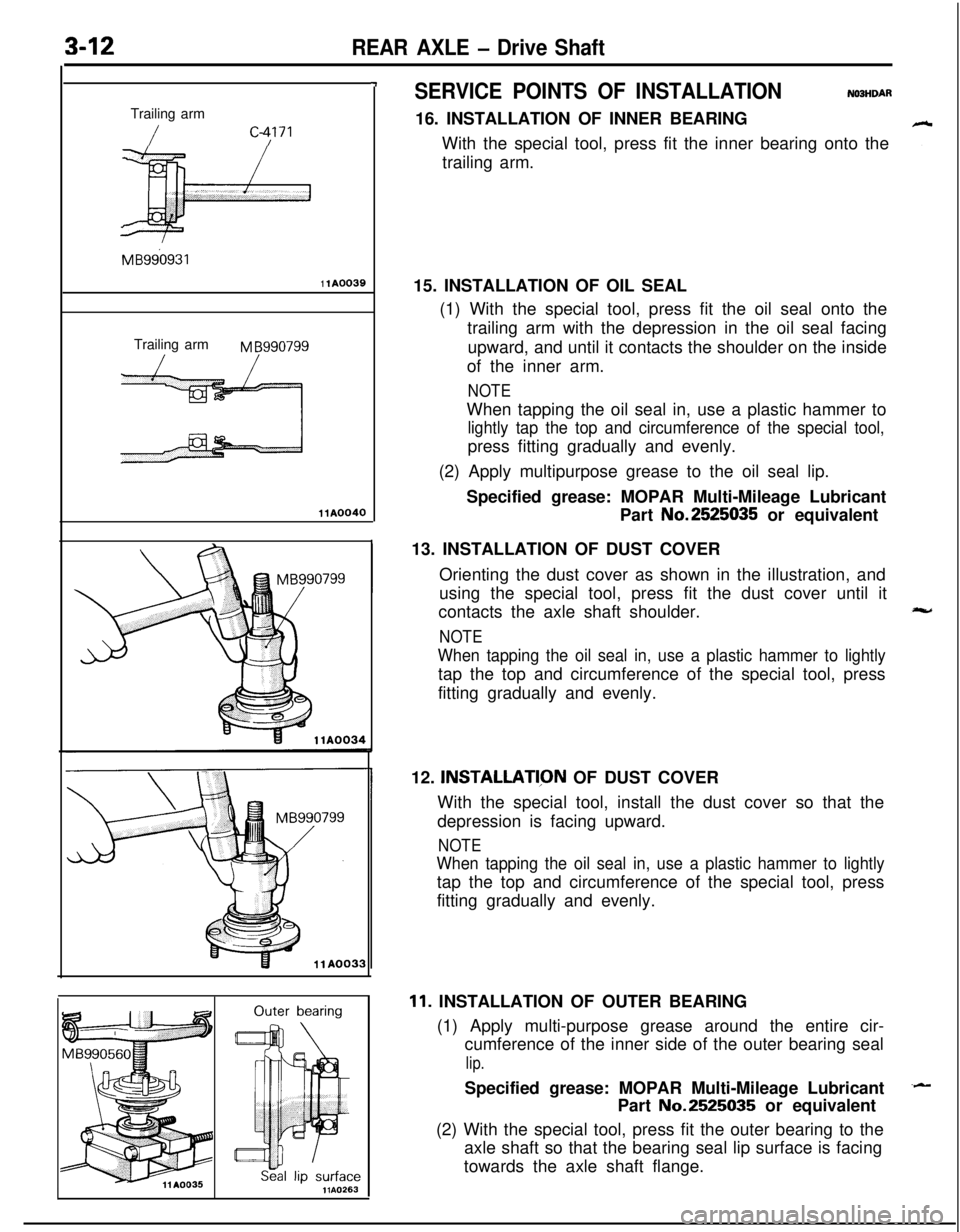

3-12REAR AXLE - Drive ShaftTrailing arm

/c-4171

F

MB960931

1 lA0039Trailing arm

M B990799

11 A0040

7

llAO263

SERVICE POINTS OF INSTALLATIONN03HDAR16. INSTALLATION OF INNER BEARING

With the special tool, press fit the inner bearing onto the

trailing arm.

15. INSTALLATION OF OIL SEAL

(1) With the special tool, press fit the oil seal onto the

trailing arm with the depression in the oil seal facing

upward, and until it contacts the shoulder on the inside

of the inner arm.

NOTEWhen tapping the oil seal in, use a plastic hammer to

lightly tap the top and circumference of the special tool,press fitting gradually and evenly.

(2) Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

13. INSTALLATION OF DUST COVER

Orienting the dust cover as shown in the illustration, and

using the special tool, press fit the dust cover until it

contacts the axle shaft shoulder.

NOTE

When tapping the oil seal in, use a plastic hammer to lightlytap the top and circumference of the special tool, press

fitting gradually and evenly.

12.

INSTALLATl,ON OF DUST COVER

With the special tool, install the dust cover so that the

depression is facing upward.

NOTE

When tapping the oil seal in, use a plastic hammer to lightlytap the top and circumference of the special tool, press

fitting gradually and evenly.

11. INSTALLATION OF OUTER BEARING

(1) Apply multi-purpose grease around the entire cir-

cumference of the inner side of the outer bearing seal

lip.Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(2) With the special tool, press fit the outer bearing to the

axle shaft so that the bearing seal lip surface is facing

towards the axle shaft flange.

Page 115 of 1216

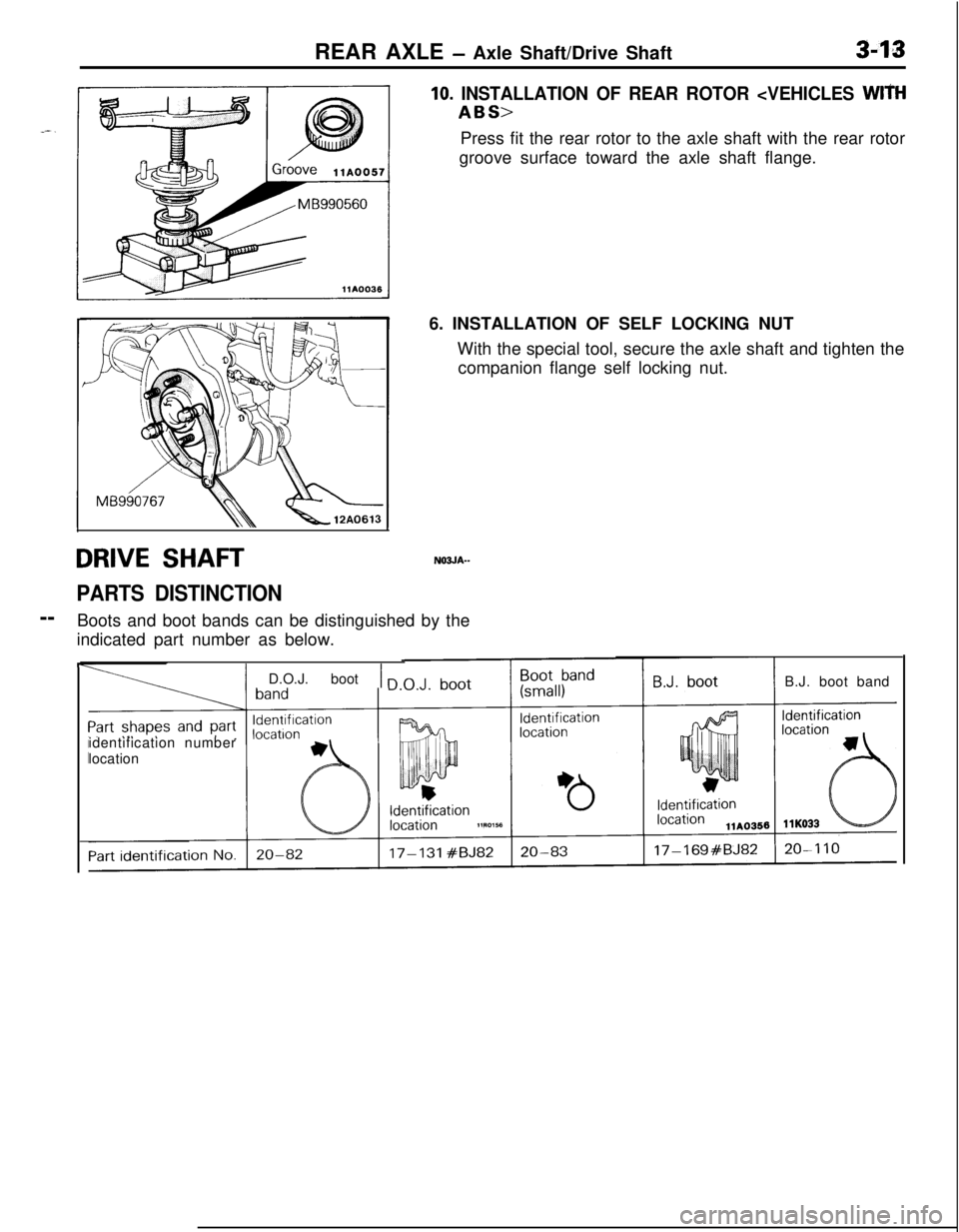

REAR AXLE - Axle Shaft/Drive Shaft3-13

DRIVE SHAFTN03JA--

PARTS DISTINCTION--

Boots and boot bands can be distinguished by the

indicated part number as below.

10. INSTALLATION OF REAR ROTOR

groove surface toward the axle shaft flange.

6. INSTALLATION OF SELF LOCKING NUT

With the special tool, secure the axle shaft and tighten the

companion flange self locking nut.

F

I

IIidentification number

location

1 D.O.J. boot 1 nB.J. boot band

Page 235 of 1216

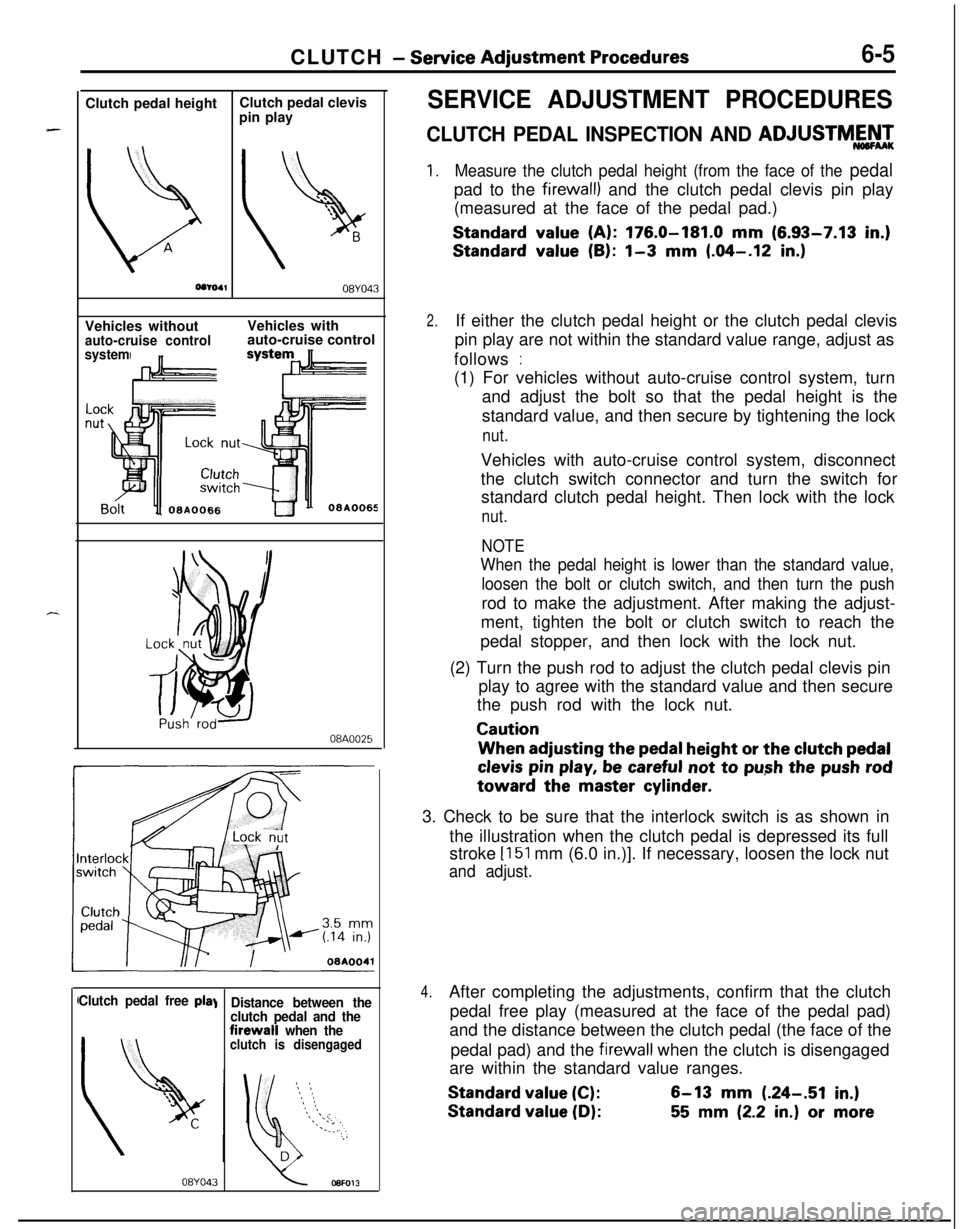

CLUTCH - Service Adjustment Procedures6-5Clutch pedal height

b

AClutch pedal clevis

pin play

08YO43Vehicles without

auto-cruise control

systemVehicles with

auto-cruise control

08A0025I

Clutch pedal free pIa\

08YO43

Distance between the

clutch pedal and thefirewall

when theclutch is disengaged

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTMY’,

1.Measure the clutch pedal height (from the face of the pedalpad to the

firewall) and the clutch pedal clevis pin play

(measured at the face of the pedal pad.)

Standard value (A): 176.0-181.0 mm (6.93-7.13 in.)

Standard value (B): l-3 mm (.04-.12 in.)

2.If either the clutch pedal height or the clutch pedal clevis

pin play are not within the standard value range, adjust as

follows

:(1) For vehicles without auto-cruise control system, turn

and adjust the bolt so that the pedal height is the

standard value, and then secure by tightening the lock

nut.Vehicles with auto-cruise control system, disconnect

the clutch switch connector and turn the switch for

standard clutch pedal height. Then lock with the lock

nut.

NOTE

When the pedal height is lower than the standard value,

loosen the bolt or clutch switch, and then turn the pushrod to make the adjustment. After making the adjust-

ment, tighten the bolt or clutch switch to reach the

pedal stopper, and then lock with the lock nut.

(2) Turn the push rod to adjust the clutch pedal clevis pin

play to agree with the standard value and then secure

the push rod with the lock nut.

CautionWhen adjusting the

pedal height or the clutch pedal

clevis pin play, be careful not to push the push rodtoward the master

cylinder.3. Check to be sure that the interlock switch is as shown in

the illustration when the clutch pedal is depressed its full

stroke

[151 mm (6.0 in.)]. If necessary, loosen the lock nut

and adjust.

4.After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of the

pedal pad) and the

firewall when the clutch is disengaged

are within the standard value ranges.

Standard value (C):6-13 mm (.24-.51 in.)

Standard value (D):55 mm (2.2 in.) or more