wheel MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 61 of 1216

FRONT SUSPENSION - Hub and Knuckle2-13

llA0281

Snar,

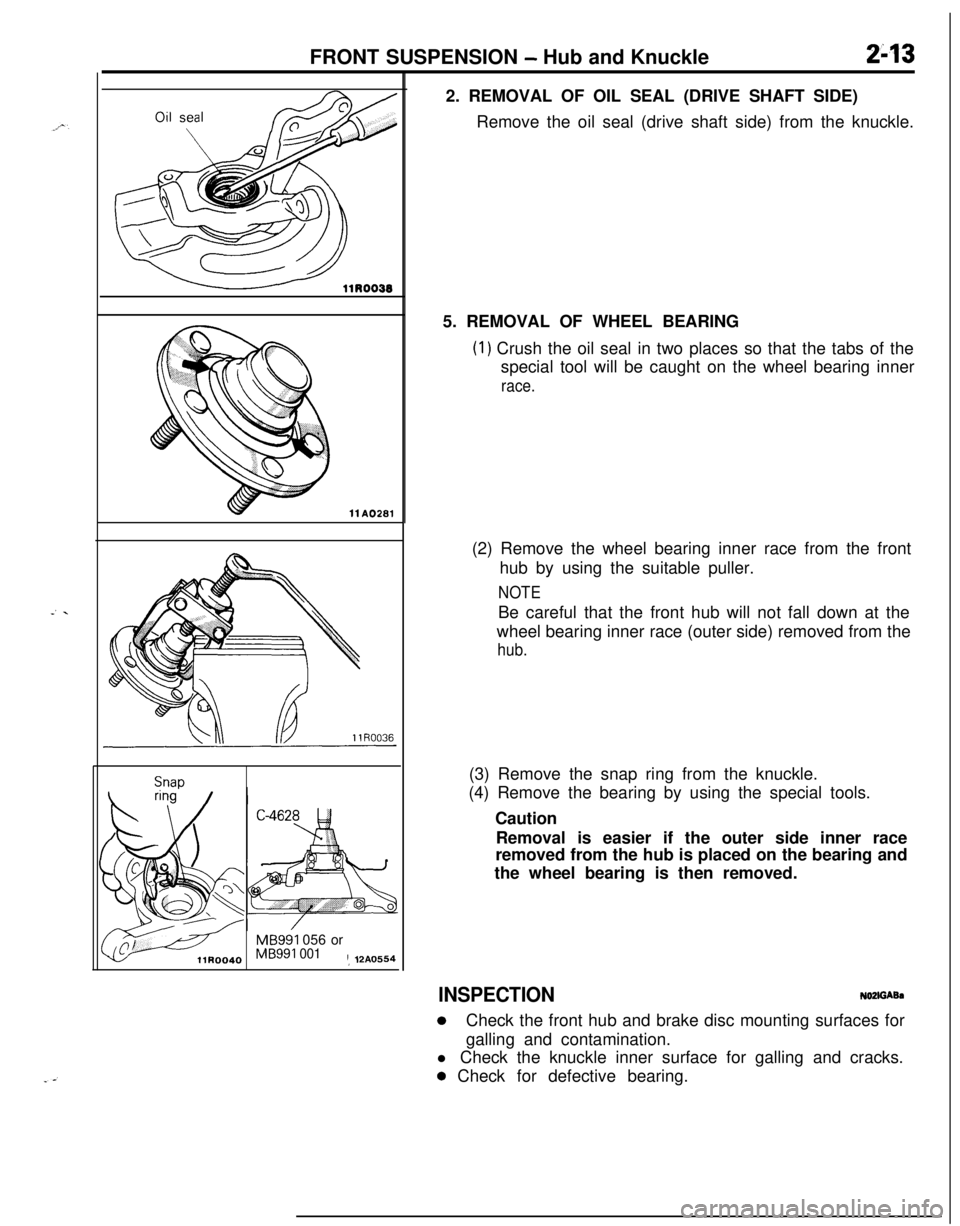

MB991 056 orMB991 001! 12A05542. REMOVAL OF OIL SEAL (DRIVE SHAFT SIDE)

Remove the oil seal (drive shaft side) from the knuckle.

5. REMOVAL OF WHEEL BEARING

(1) Crush the oil seal in two places so that the tabs of the

special tool will be caught on the wheel bearing inner

race.(2) Remove the wheel bearing inner race from the front

hub by using the suitable puller.

NOTEBe careful that the front hub will not fall down at the

wheel bearing inner race (outer side) removed from the

hub.(3) Remove the snap ring from the knuckle.

(4) Remove the bearing by using the special tools.

Caution

Removal is easier if the outer side inner race

removed from the hub is placed on the bearing and

the wheel bearing is then removed.

INSPECTIONNOZffiAkh

0Check the front hub and brake disc mounting surfaces for

galling and contamination.

l Check the knuckle inner surface for galling and cracks.

0 Check for defective bearing.

Page 62 of 1216

2-14FRONT SUSPENSION - Hub and Knuckle

llR0032

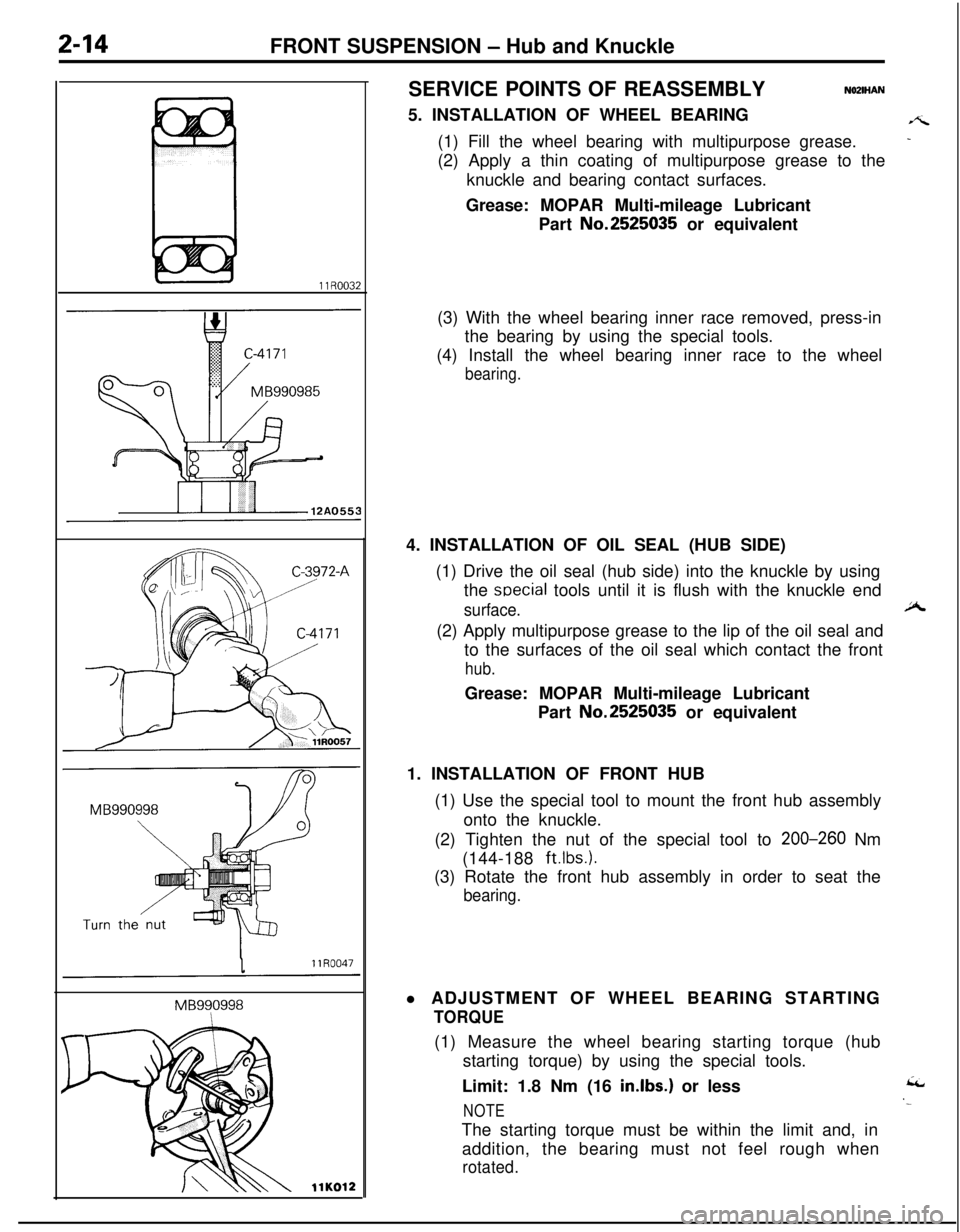

llK012SERVICE POINTS OF REASSEMBLY

NOZIHAN5. INSTALLATION OF WHEEL BEARING

A(1) Fill the wheel bearing with multipurpose grease.

-(2) Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(3) With the wheel bearing inner race removed, press-in

the bearing by using the special tools.

(4) Install the wheel bearing inner race to the wheel

bearing.4. INSTALLATION OF OIL SEAL (HUB SIDE)

(1) Drive the oil seal (hub side) into the knuckle by using

the

soecial tools until it is flush with the knuckle end

surface.A(2) Apply multipurpose grease to the lip of the oil seal and

to the surfaces of the oil seal which contact the front

hub.Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

1. INSTALLATION OF FRONT HUB

(1) Use the special tool to mount the front hub assembly

onto the knuckle.

(2) Tighten the nut of the special tool to 200-260 Nm

(144-188

ft.lbs.).(3) Rotate the front hub assembly in order to seat the

bearing.l ADJUSTMENT OF WHEEL BEARING STARTING

TORQUE(1) Measure the wheel bearing starting torque (hub

starting torque) by using the special tools.

Limit: 1.8 Nm (16

in.lbs.) or lessic

‘-NOTEThe starting torque must be within the limit and, in

addition, the bearing must not feel rough when

rotated.

Page 65 of 1216

FRONT SUSPENSION - Drive Shaft247Pry bar

13E526

12RO426Cotter pin

/

/HubllR0015

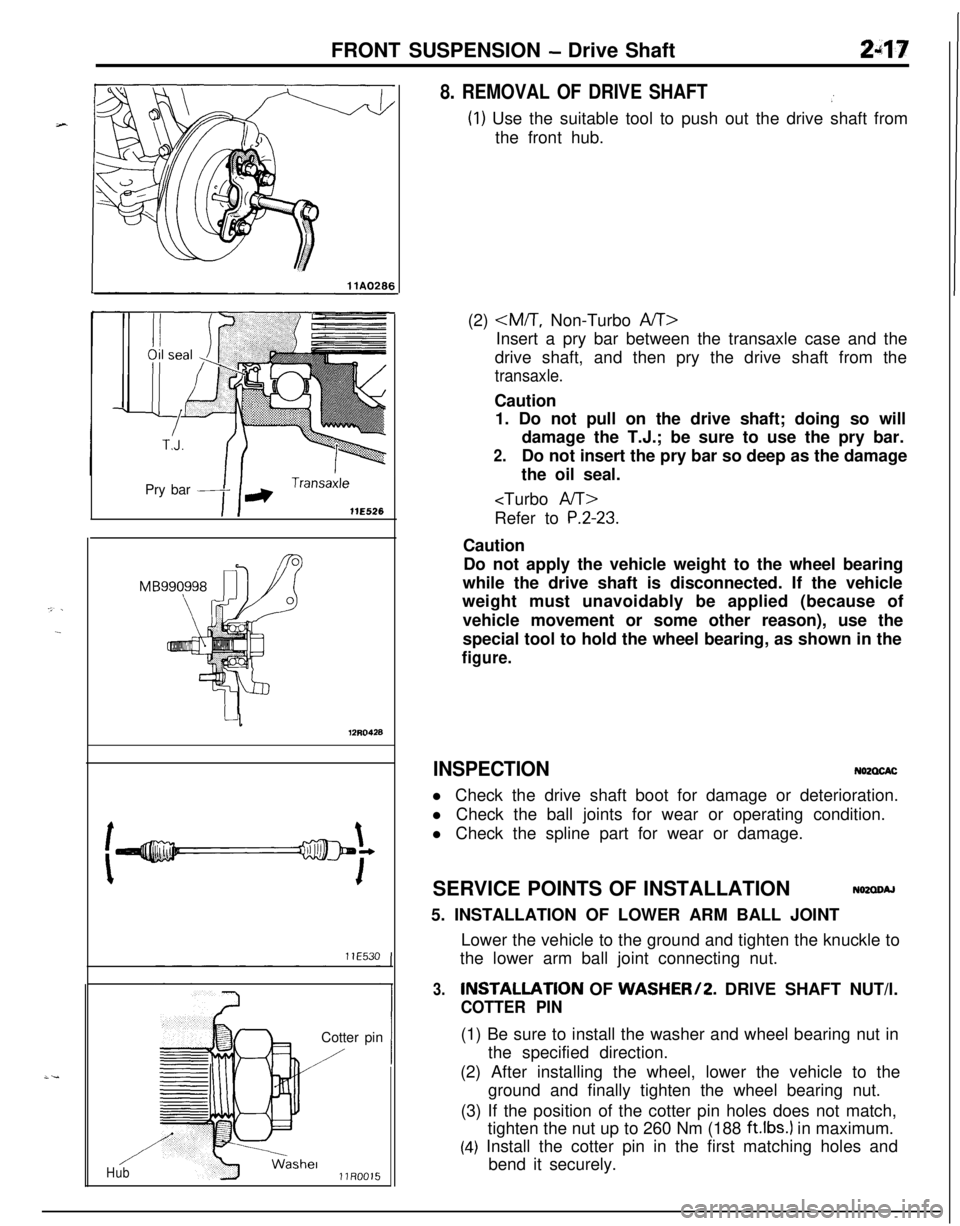

8. REMOVAL OF DRIVE SHAFT.’

(1) Use the suitable tool to push out the drive shaft from

the front hub.

(2)

Insert a pry bar between the transaxle case and the

drive shaft, and then pry the drive shaft from the

transaxle.Caution

1. Do not pull on the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as the damage

the oil seal.

P.2-23.Caution

Do not apply the vehicle weight to the wheel bearing

while the drive shaft is disconnected. If the vehicle

weight must unavoidably be applied (because of

vehicle movement or some other reason), use the

special tool to hold the wheel bearing, as shown in the

figure.

INSPECTIONN62CXACl Check the drive shaft boot for damage or deterioration.

l Check the ball joints for wear or operating condition.

l Check the spline part for wear or damage.

SERVICE POINTS OF INSTALLATION

N62aoAJ5. INSTALLATION OF LOWER ARM BALL JOINT

Lower the vehicle to the ground and tighten the knuckle to

the lower arm ball joint connecting nut.

3.INSTALLATlON OF WASHER/2. DRIVE SHAFT NUT/l.

COTTER PIN(1) Be sure to install the washer and wheel bearing nut in

the specified direction.

(2) After installing the wheel, lower the vehicle to the

ground and finally tighten the wheel bearing nut.

(3) If the position of the cotter pin holes does not match,

tighten the nut up to 260 Nm (188

ft.lbs.) in maximum.

(4) Install the cotter pin in the first matching holes and

bend it securely.

Page 78 of 1216

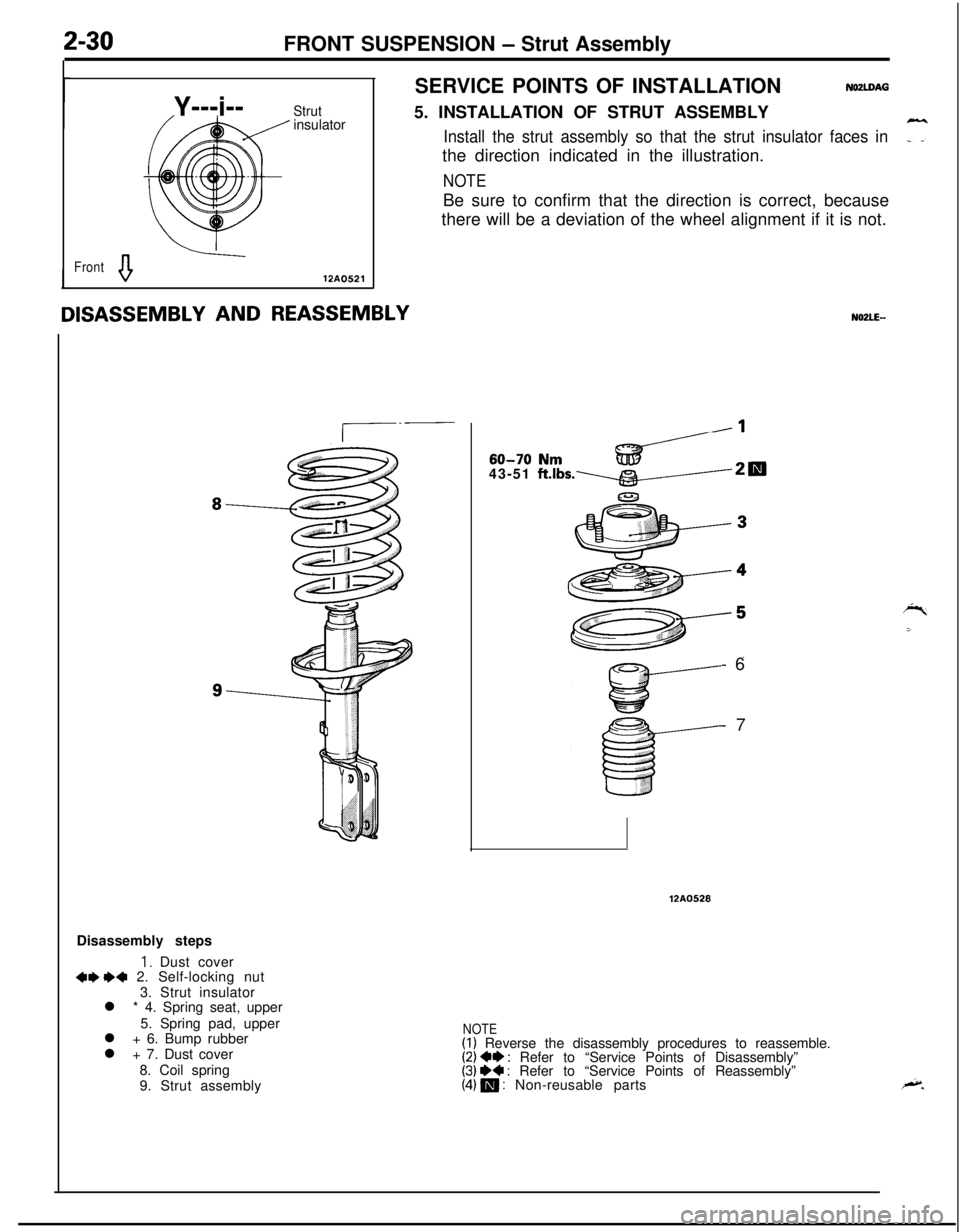

2-30FRONT SUSPENSION - Strut Assembly

Y---i--

Strutinsulator

Fronta12A0521SERVICE POINTS OF INSTALLATION

NOZLDAG5. INSTALLATION OF STRUT ASSEMBLY

Install the strut assembly so that the strut insulator faces in7the direction indicated in the illustration.

NOTEBe sure to confirm that the direction is correct, because

there will be a deviation of the wheel alignment if it is not.

Disassembly steps

I, Dust cover+e I)+ 2. Self-locking nut

3. Strut insulator

l * 4. Spring seat, upper

5. Spring pad, upper

l + 6. Bump rubber

l + 7. Dust cover

8. Coil spring

9. Strut assembly

N02LE-43-51

ft.lbs.~d/-2~60-70 Nm

-6

-7

12A0528

NOTE(I) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”(3) e+ : Refer to “Service Points of Reassembly”(4) m : Non-reusable parts

Page 92 of 1216

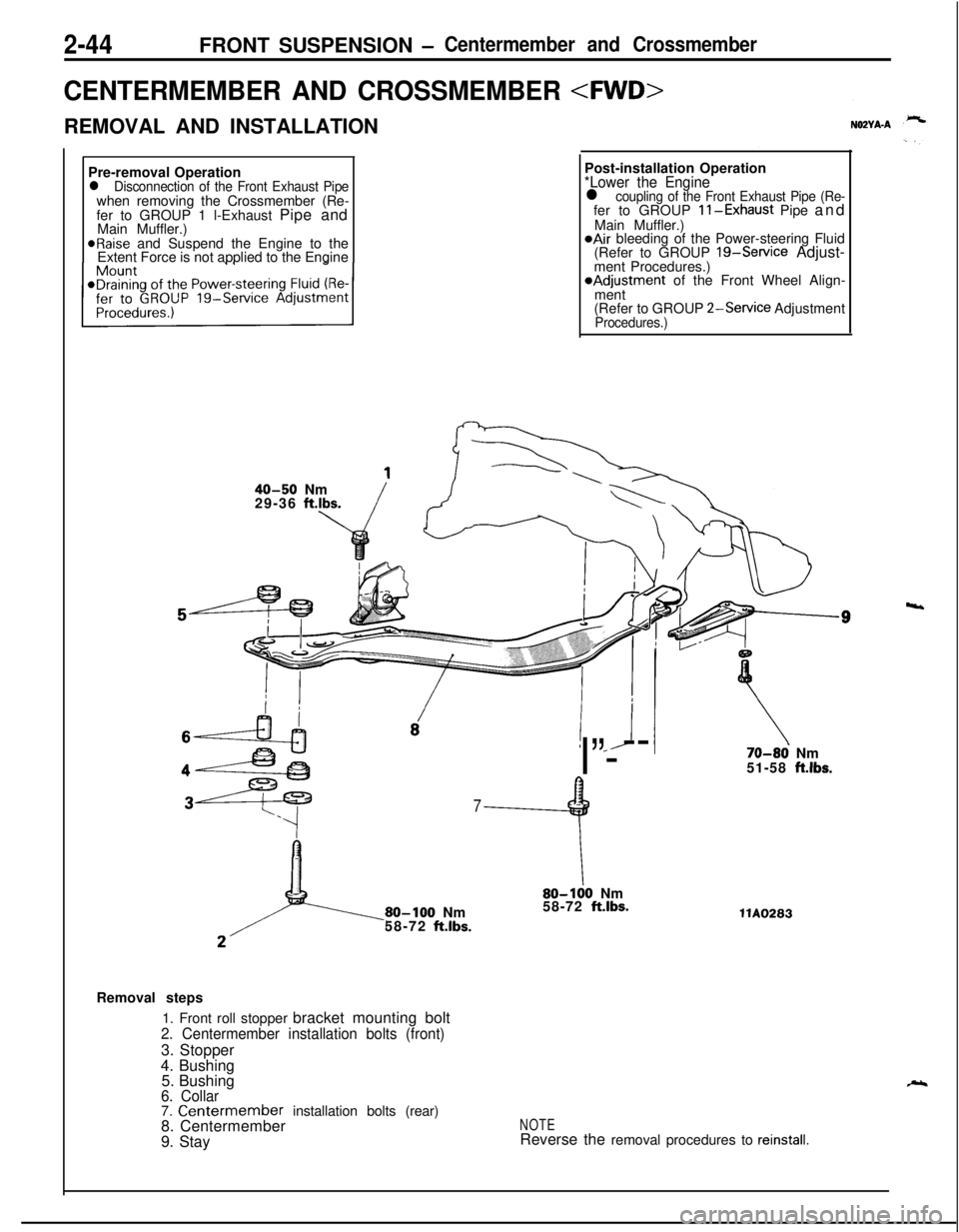

2-44FRONT SUSPENSION -Centermember and Crossmember

CENTERMEMBER AND CROSSMEMBER

REMOVAL AND INSTALLATION

Pre-removal Operation

l Disconnection of the Front Exhaust Pipewhen removing the Crossmember (Re-

fer to GROUP 1 l-Exhaust Pipe and

Main Muffler.)

@Raise and Suspend the Engine to the

Extent Force is not applied to the EnginePost-installation Operation

*Lower the Enginel coupling of the Front Exhaust Pipe (Re-fer to GROUP ll-Exhaust Pipe and

Main Muffler.)

@Air bleeding of the Power-steering Fluid

(Refer to GROUP 19-Service Adjust-

ment Procedures.)*Adjustment of the Front Wheel Align-

ment

(Refer to GROUP

2-Service AdjustmentProcedures.)

40-50 Nm

29-36 ft.lbs.

! *J

I”---

7

9

80-100 Nm

58-72 ft.lbs.

\80-100 Nm

58-72 ft.lbs.

70-86 Nm

51-58 ft.lbs.llA0283

Removal steps

1. Front roll stopper bracket mounting bolt

2. Centermember installation bolts (front)3. Stopper

4. Bushing

5. Bushing

6. Collar7. Centermember installation bolts (rear)

8. Centermember

9. StayNOTEReverse the removal procedures to reinstall.

4

Page 103 of 1216

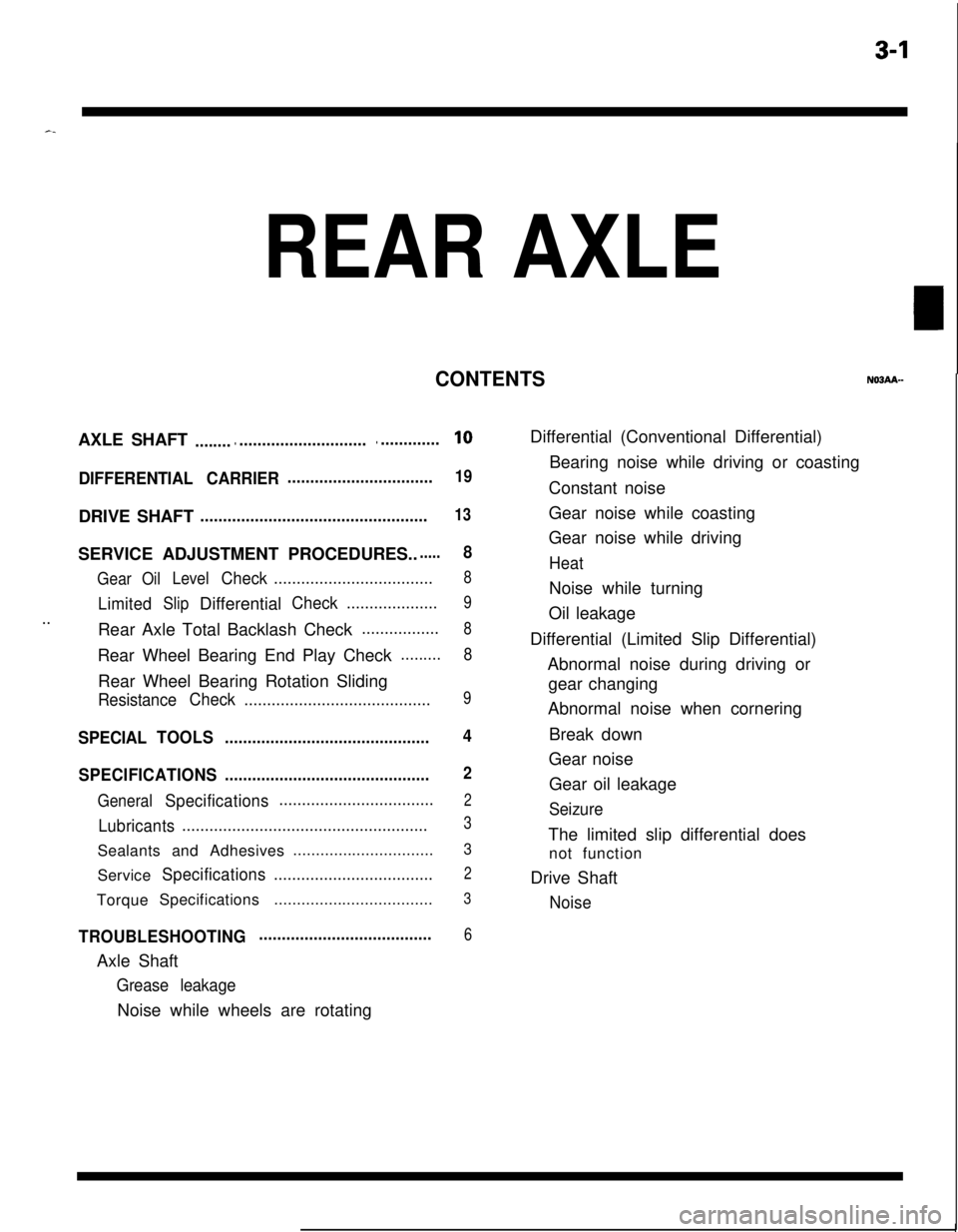

3-1

REAR AXLE

CONTENTSAXLE SHAFT

...................................................10

DIFFERENTIAL CARRIER................................19DRIVE SHAFT

..................................................13SERVICE ADJUSTMENT PROCEDURES..

.....8

GearOilLevelCheck...................................8

LimitedSlipDifferentialCheck....................9

..Rear Axle Total Backlash Check.................8Rear Wheel Bearing End Play Check

.........

8Rear Wheel Bearing Rotation Sliding

ResistanceCheck.........................................9

SPECIALTOOLS.............................................4

SPECIFICATIONS.............................................

2

GeneralSpecifications..................................2

Lubricants......................................................3Sealants and Adhesives...............................

3Service

Specifications...................................2TorqueSpecifications...................................

3

TROUBLESHOOTING......................................6Axle Shaft

Grease leakageNoise while wheels are rotatingDifferential (Conventional Differential)

Bearing noise while driving or coasting

Constant noise

Gear noise while coasting

Gear noise while driving

HeatNoise while turning

Oil leakage

Differential (Limited Slip Differential)

Abnormal noise during driving or

gear changing

Abnormal noise when cornering

Break down

Gear noise

Gear oil leakage

SeizureThe limited slip differential does

not function

Drive Shaft

Noise

Page 104 of 1216

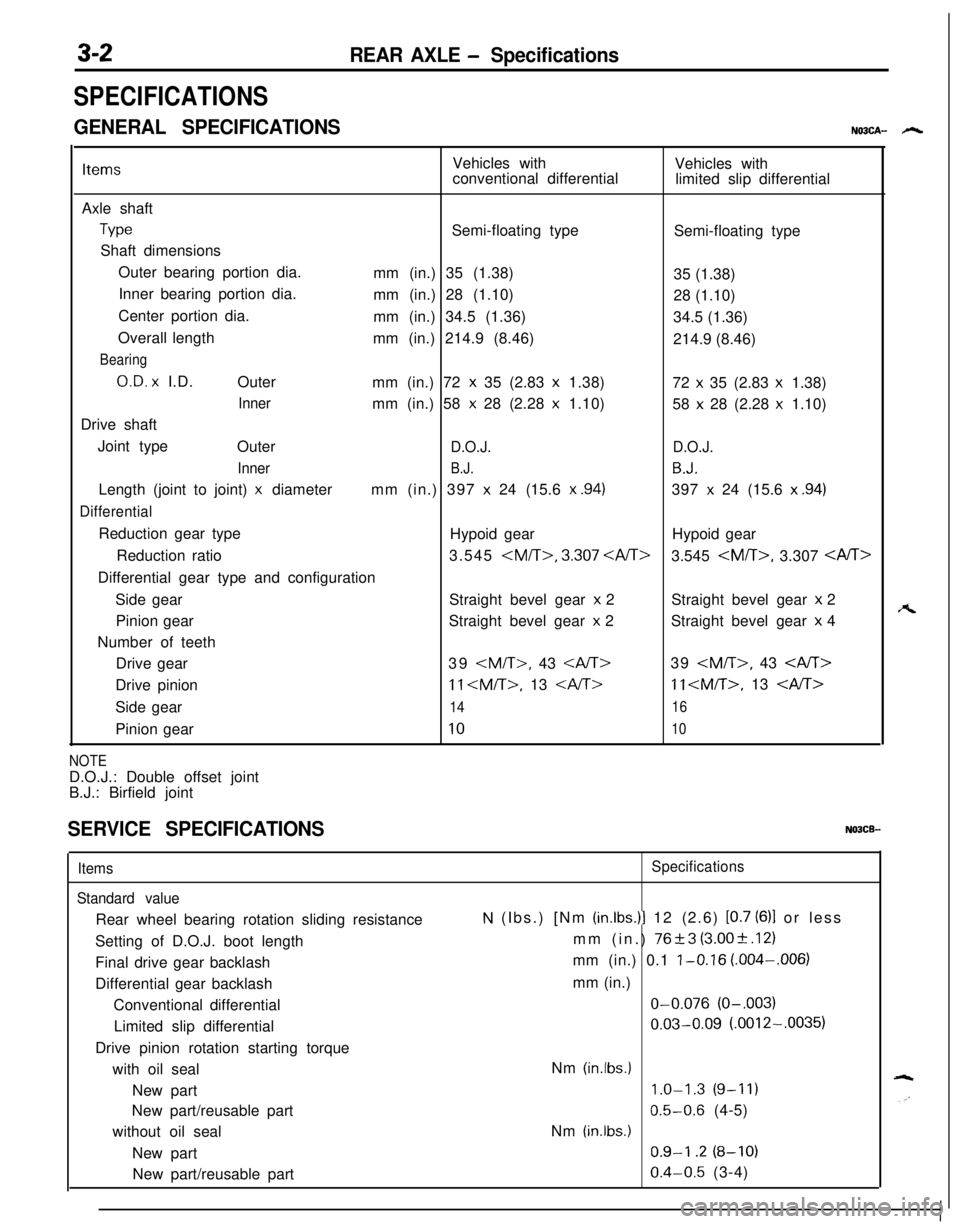

3-2REAR AXLE - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSNO3CA- h

ItemsVehicles with

Vehicles with

conventional differential

limited slip differential

Axle shaft

TypeSemi-floating type

Semi-floating type

Shaft dimensions

Outer bearing portion dia.

mm (in.) 35 (1.38)

35 (1.38)

Inner bearing portion dia.

mm (in.) 28 (1.10)

28 (1.10)

Center portion dia.

mm (in.) 34.5 (1.36)

34.5 (1.36)

Overall length

mm (in.) 214.9 (8.46)

214.9 (8.46)

Bearing

O.D. x I.D.

Outer

mm (in.) 72 x 35 (2.83 x 1.38)

72 x 35 (2.83 x 1.38)

Innermm (in.) 58 x 28 (2.28 x 1.10)

58 x 28 (2.28 x 1.10)

Drive shaft

Joint type

Outer

D.O.J.D.O.J.

Inner

B.J.B.J.Length (joint to joint)

x diametermm (in.) 397 x 24 (15.6 x .94)397 x 24 (15.6 x .94)

DifferentialReduction gear type

Hypoid gearHypoid gear

Reduction ratio3.545

3.545

Side gearStraight bevel gear

x 2Straight bevel gear x 2

Pinion gearStraight bevel gear

x 2Straight bevel gear x 4

Number of teeth

Drive gear39

11

Side gear

1416Pinion gear

1010

NOTED.O.J.: Double offset joint

B.J.: Birfield joint

SERVICE SPECIFICATIONSNOBCB-

Items

Standard valueRear wheel bearing rotation sliding resistance

Setting of D.O.J. boot length

Final drive gear backlash

Differential gear backlash

Conventional differential

Limited slip differential

Drive pinion rotation starting torque

with oil seal

New part

New part/reusable part

without oil seal

New part

New part/reusable partSpecifications

N (Ibs.) [Nm (in.lbs.)l 12 (2.6) [0.7 (6)l or less

mm (in.)

76+3 (3.00+.12)

mm (in.) 0.1

l-0.16 (.004-,006)

mm (in.)O-0.076

(O-.003)

0.03-0.09 (.0012-.0035)

Nm

(in.lbs.)

1.0-1.3 (9-11)

0.5-0.6 (4-5)

Nm

(in.lbs.)

0.9-I .2 (8-10)

0.4-0.5 (3-4)

A

Page 105 of 1216

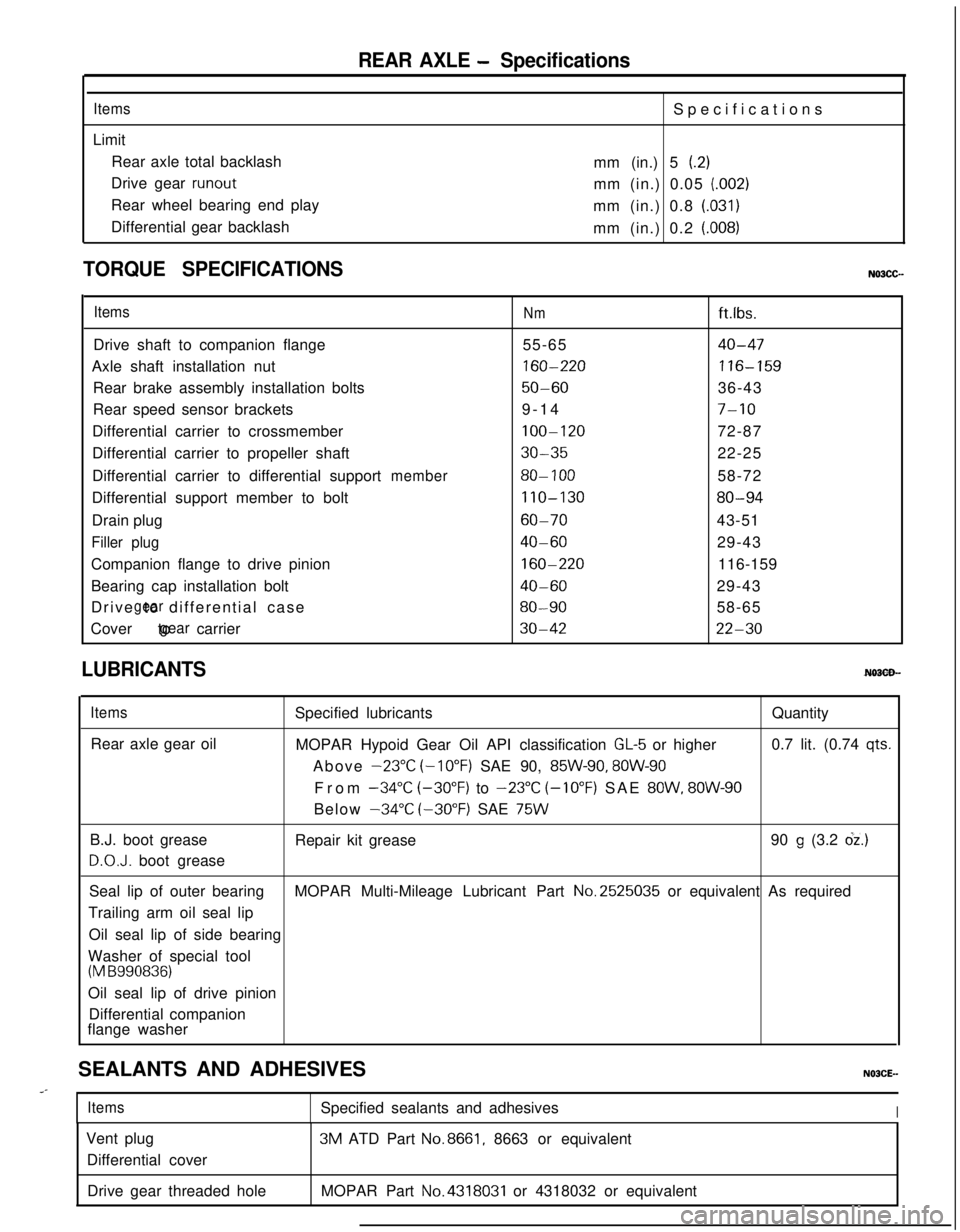

REAR AXLE - Specifications

ItemsLimit

Rear axle total backlash

Drive gear

runoutRear wheel bearing end play

Differential gear backlashSpecifications

mm (in.) 5

(.2)mm (in.) 0.05

(.002)mm (in.) 0.8

(.031)mm (in.) 0.2

(.008)

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Drive shaft to companion flange55-65

40-47Axle shaft installation nut

160-220116-159Rear brake assembly installation bolts

50-6036-43

Rear speed sensor brackets9-14

7-10Differential carrier to crossmember

100-12072-87

Differential carrier to propeller shaft

30-3522-25

Differential carrier to differential support

member80- 10058-72

Differential support member to bolt

110-13080-94Drain plug

60-7043-51

Filler plug40-6029-43

Companion flange to drive pinion

160-220116-159

Bearing cap installation bolt

40-6029-43

Drive to differential case

gear80-9058-65

Cover to carrier

gear30-4222-30

LUBRICANTS

ItemsRear axle gear oilSpecified lubricantsQuantity

MOPAR Hypoid Gear Oil API classification

GL-5 or higher0.7 lit. (0.74 qts.Above

-23°C (-10°F) SAE 90, 85W-90, 8OW-90From

-34°C (-30°F) to -23°C (-10°F) SAE 8OW, 8OW-90Below

-34°C (-30°F) SAE 75WB.J. boot grease

D.O.J. boot greaseRepair kit grease90

g (3.2 dz.)Seal lip of outer bearingMOPAR Multi-Mileage Lubricant Part No.2525035 or equivalent As required

Trailing arm oil seal lip

Oil seal lip of side bearing

Washer of special tool

(M B990836)Oil seal lip of drive pinion

Differential companion

flange washer

SEALANTS AND ADHESIVES

..-

ItemsSpecified sealants and adhesivesIVent plug

Differential cover3M ATD Part

No.8661, 8663 or equivalent

Drive gear threaded holeMOPAR Part

No.4318031 or 4318032 or equivalent

Page 106 of 1216

REAR AXLE - SDecial Tools

SPECIAL TOOLSN03DA--

ToolNumber

Name

UseMB990767

End yoke holderMeasurement of rotation torque of the limiter

/slip differentialStop axle shaft turning

CT-l 003Axle shaft pullerPress-fitting the drive pinion rear bearing outerace

Sliding hammer set

Removal of the axle shaftMB990560

Bearing removerRemoval of the axle shaft dust cover, oute

bearing and rear rotor

Press-in the outer wheel bearing and rear rotorMB991115

Oil seal installer

Press-fitting of drive shaft oil seal

Side bearing puller

Removal of the side

Page 108 of 1216

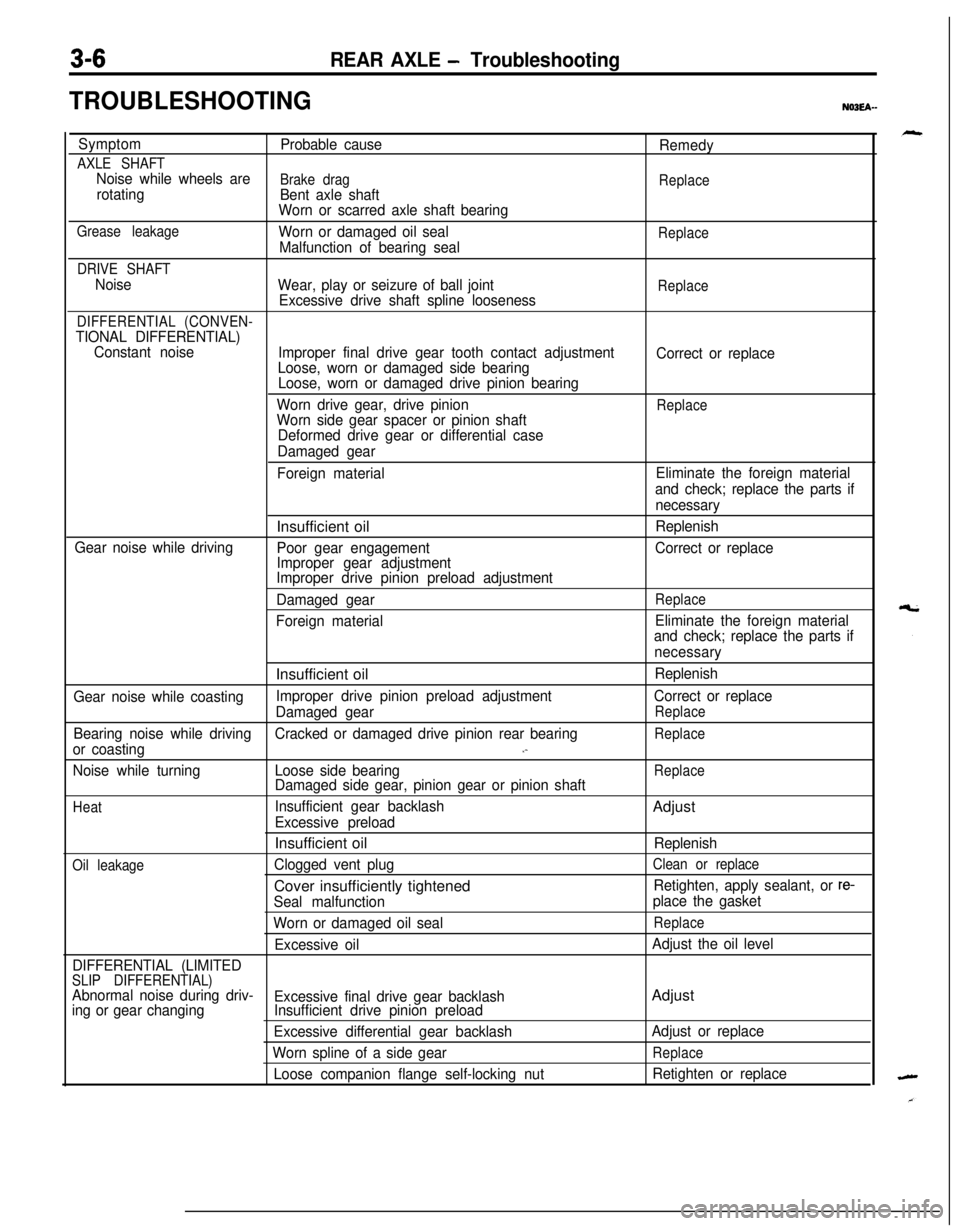

3-6REAR AXLE - Troubleshooting

TROUBLESHOOTINGNO3EA-

Symptom

Probable cause

Remedy

AXLE SHAFTNoise while wheels areBrake drag

Replacerotating

Bent axle shaft

Worn or scarred axle shaft bearing

Grease leakageWorn or damaged oil sealReplaceMalfunction of bearing seal

DRIVE SHAFT

Noise

Wear, play or seizure of ball jointReplaceExcessive drive shaft spline looseness

DIFFERENTIAL (CONVEN-TIONAL DIFFERENTIAL)

Constant noise

Improper final drive gear tooth contact adjustment

Correct or replace

Loose, worn or damaged side bearing

Loose, worn or damaged drive pinion bearing

Worn drive gear, drive pinion

ReplaceWorn side gear spacer or pinion shaft

Deformed drive gear or differential case

Damaged gear

Foreign materialEliminate the foreign material

and check; replace the parts if

necessaryInsufficient oil

Replenish

Gear noise while driving

Poor gear engagementCorrect or replace

Improper gear adjustment

Improper drive pinion preload adjustment

Damaged gear

Replace

Foreign materialEliminate the foreign material

and check; replace the parts if

necessaryInsufficient oil

Replenish

Gear noise while coastingImproper drive pinion preload adjustmentCorrect or replace

Damaged gear

Replace

Bearing noise while drivingCracked or damaged drive pinion rear bearingReplace

or coasting.-

Noise while turningLoose side bearingReplaceDamaged side gear, pinion gear or pinion shaft

HeatInsufficient gear backlashAdjust

Excessive preloadInsufficient oil

Replenish

Oil leakageClogged vent plugClean or replaceCover insufficiently tightened

Retighten, apply sealant, or re-

Seal malfunctionplace the gasket

Worn or damaged oil seal

Replace

Excessive oilAdjust the oil level

DIFFERENTIAL (LIMITED

SLIP DIFFERENTIAL)Abnormal noise during driv-

Excessive final drive gear backlashAdjusting or gear changingInsufficient drive pinion preload

Excessive differential gear backlashAdjust or replace

Worn spline of a side gear

Replace

Loose companion flange self-locking nutRetighten or replace