window MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1045 of 1216

23-lBODY

CONTENTSN23Ak-

AERO PARTS..........................................74

CENTRAL DOOR LOCKING SYSTEM...........70

DOOR ASSEMBLY....................................63

DOOR GLASS AND REGULATOR................66

DOORHANDLEANDLATCH.....................69

DOOR MIRROR........................................72

DOOR MOULDING AND

DRIP LINE WEATHERSTRIP........................72

....DOOR RUNCHANNEL...............................71

DOOR TRIM AND WATERPROOF FILM........65

ELECTRIC REMOTE CONTROLLED

MIRROR SWITCH.....................................73

FENDER..................................................51

FLOOR CONSOLE....................................84

FRONT BUMPER......................................39

FRONT SEAT..........................................90

FUEL TANKFILLERDOOR.........................38

GARNISHES............................................47

HEADLINING...........................................89

HOOD....................................................34

INSTRUMENT PANEL................................79

LIFTGATE...............................................36

LIFTGATE WINDOWGLASS......................62

LOOSE PANEL.........................................53

MOULDING.............................................48

POWER WINDOW....................................67

QUARTERWINDOWGLASS......................61

REAR BUMPER........................................43

REAR SEAT............................................93

SEAT BELT.............................................94

SERVICE ADJUSTMENT PROCEDURES........31

Door Adjustment....................................32

Door Glass Adjustment............................32Door Inside Handle Play Check..................

32

Door Outside Handle Play Check................32

Floor PanInspection...............................

33Fuel Filler Door Adjustment.......................

31

Hood Adjustment...................................31

Liftgate Adjustment.................................31

Water Test...........................................33

SPECIAL TOOLS......................................5

SPECIFICATIONS.....................................2

General Specifications..............................

2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................77TRIMS

....................................................85

TROUBLESHOOTING................................6WINDOW

GLASS.....................................54

WINDSHIELD...........................................58

Page 1046 of 1216

23-2

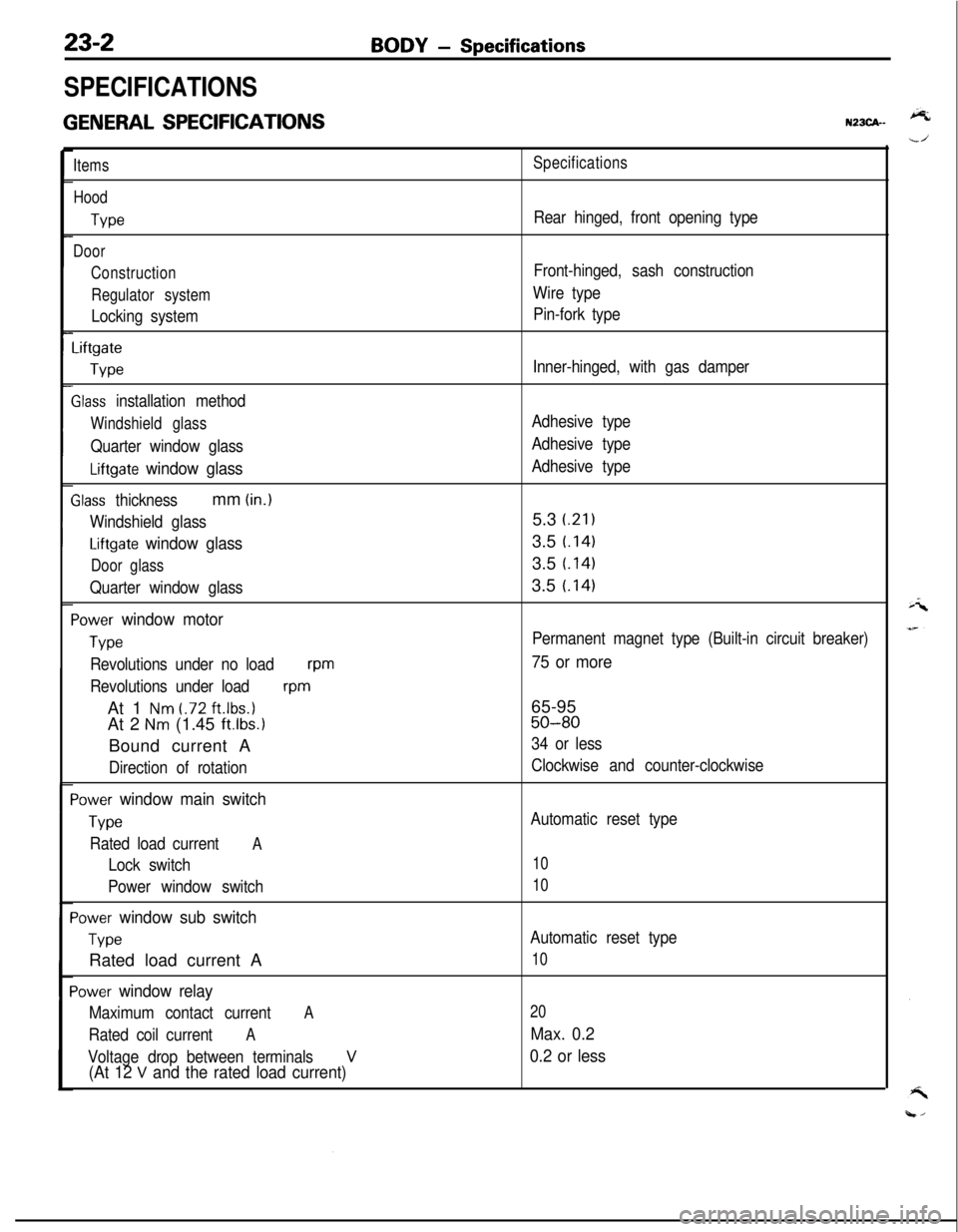

SPECIFICATIONS

GENERAL SPECIFICATIONS

BODY - Specifications

N23CA--

Items

Hood

We

Door

Construction

Regulator system

Locking system

Liftgate

We

Slass installation method

Windshield glass

Quarter window glass

Liftgate window glass

Zlass thicknessmm (in.)

Windshield glass

Liftgate window glass

Door glass

Quarter window glass

‘ower window motor

Type

Revolutions under no loadwm

Revolutions under load

wmAt 1

Nm t.72 ft.lbs.1At 2

Nm (1.45 ft.lbs.1Bound current A

Direction of rotation

‘ower window main switch

Type

Rated load currentA

Lock switch

Power window switch

‘ower window sub switch

TvwRated load current A

‘ower window relay

Maximum contact currentA

Rated coil currentA

Voltage drop between terminalsV(At 12 V and the rated load current)

Specifications

Rear hinged, front opening type

Front-hinged, sash construction

Wire type

Pin-fork type

Inner-hinged, with gas damper

Adhesive type

Adhesive type

Adhesive type5.3

i.21)3.5

t.1413.5

t.1413.5

t.141

Permanent magnet type (Built-in circuit breaker)

75 or more65-95

50-80

34 or less

Clockwise and counter-clockwise

Automatic reset type

10

10

Automatic reset type

10

20

Max. 0.2

0.2 or less

Page 1048 of 1216

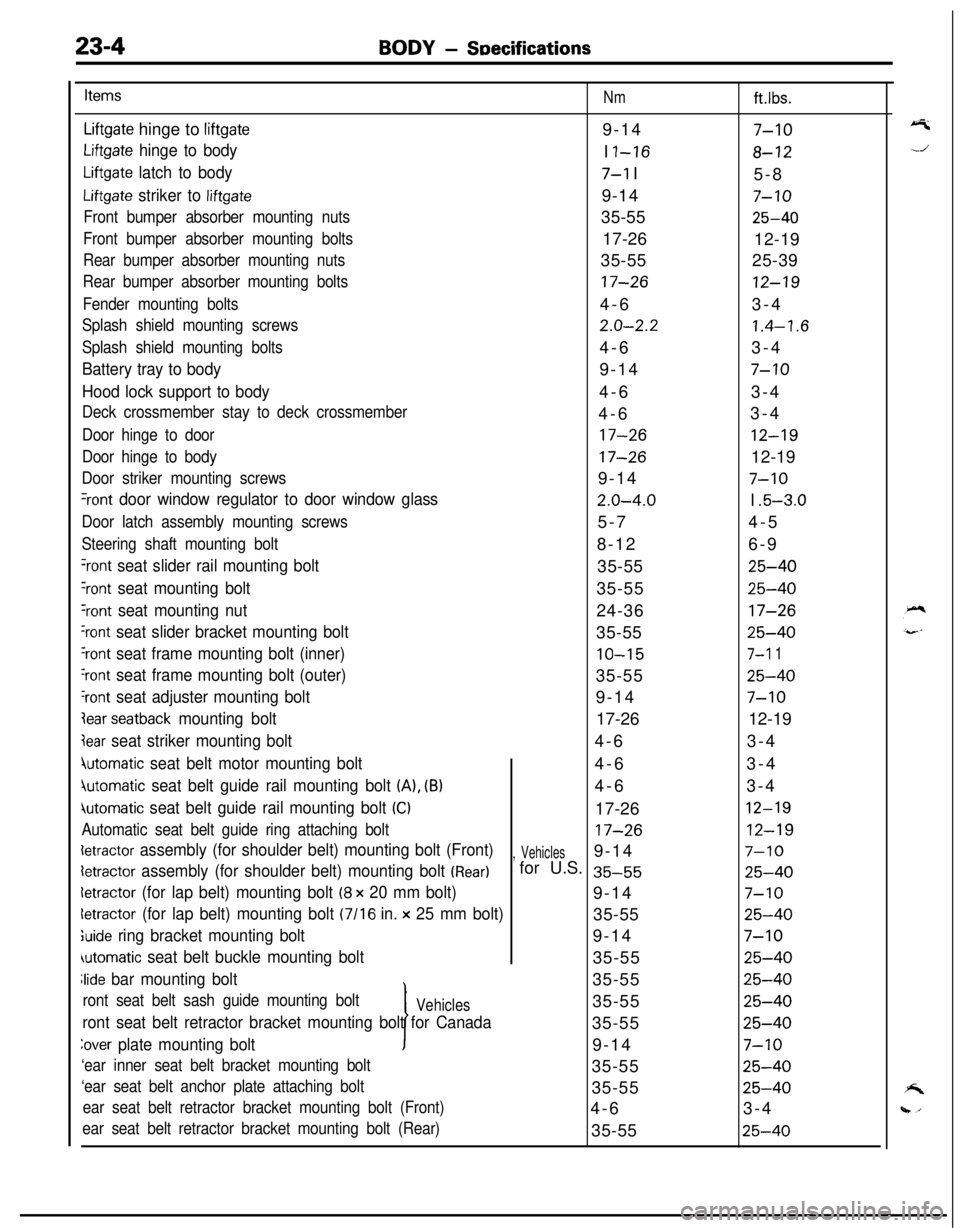

23-4BODY - SDecifications

Items

Nmft.lbs.

Liftgate hinge to liftgate9-147-10

Liftgate hinge to bodyI I-168-12

Liftgate latch to body7-l I

5-8

Liftgate striker to liftgate9-147-10

Front bumper absorber mounting nuts35-5525-40

Front bumper absorber mounting bolts17-26

12-19

Rear bumper absorber mounting nuts35-5525-39

Rear bumper absorber mounting bolts17-2612-19

Fender mounting bolts4-63-4

Splash shield mounting screws2.0-2.21.4-1.6

Splash shield mounting bolts4-63-4

Battery tray to body9-147-10

Hood lock support to body4-63-4

Deck crossmember stay to deck crossmember4-63-4

Door hinge to door17-2612-19

Door hinge to body17-2612-19

Door striker mounting screws9-147-10

%ont door window regulator to door window glass2.0-4.0I .5-3.0

Door latch assembly mounting screws5-74-5

Steering shaft mounting bolt8-126-9

‘rant seat slider rail mounting bolt35-5525-40

Yont seat mounting bolt35-5525-40

‘rant seat mounting nut24-3617-26

‘rant seat slider bracket mounting bolt35-5525-40

‘rant seat frame mounting bolt (inner)10-157-l 1

‘rant seat frame mounting bolt (outer)35-5525-40

‘rant seat adjuster mounting bolt9-147-10

lear seatback mounting bolt17-2612-19

jear seat striker mounting bolt4-63-4

4utomatic seat belt motor mounting bolt4-63-4

jutomatic seat belt guide rail mounting bolt (A), (B)4-63-4

iutomatic seat belt guide rail mounting bolt (Cl17-2612-19

Automatic seat belt guide ring attaching bolt17-2612-19

detractor assembly (for shoulder belt) mounting bolt (Front), Vehicles9-147-10

detractor assembly (for shoulder belt) mounting bolt (Rear)for U.S. 35-5525-40

detractor (for lap belt) mounting bolt (8 x 20 mm bolt)9-147-10

letractor (for lap belt) mounting bolt (7116 in. x 25 mm bolt)35-5525-40

;uide ring bracket mounting bolt9-147-10

automatic seat belt buckle mounting bolt35-5525-40

Jide bar mounting bolt

I35-55

25-40

ront seat belt sash guide mounting boltVehicles35-5525-40

ront seat belt retractor bracket mounting bolt for Canada35-5525-40

Zover plate mounting bolt9-147-10

‘ear inner seat belt bracket mounting bolt35-5525-40

‘ear seat belt anchor plate attaching bolt35-5525-40

ear seat belt retractor bracket mounting bolt (Front)4-63-4

ear seat belt retractor bracket mounting bolt (Rear)35-5525-40

Page 1049 of 1216

BODY - Specifications/Special Tools23-5

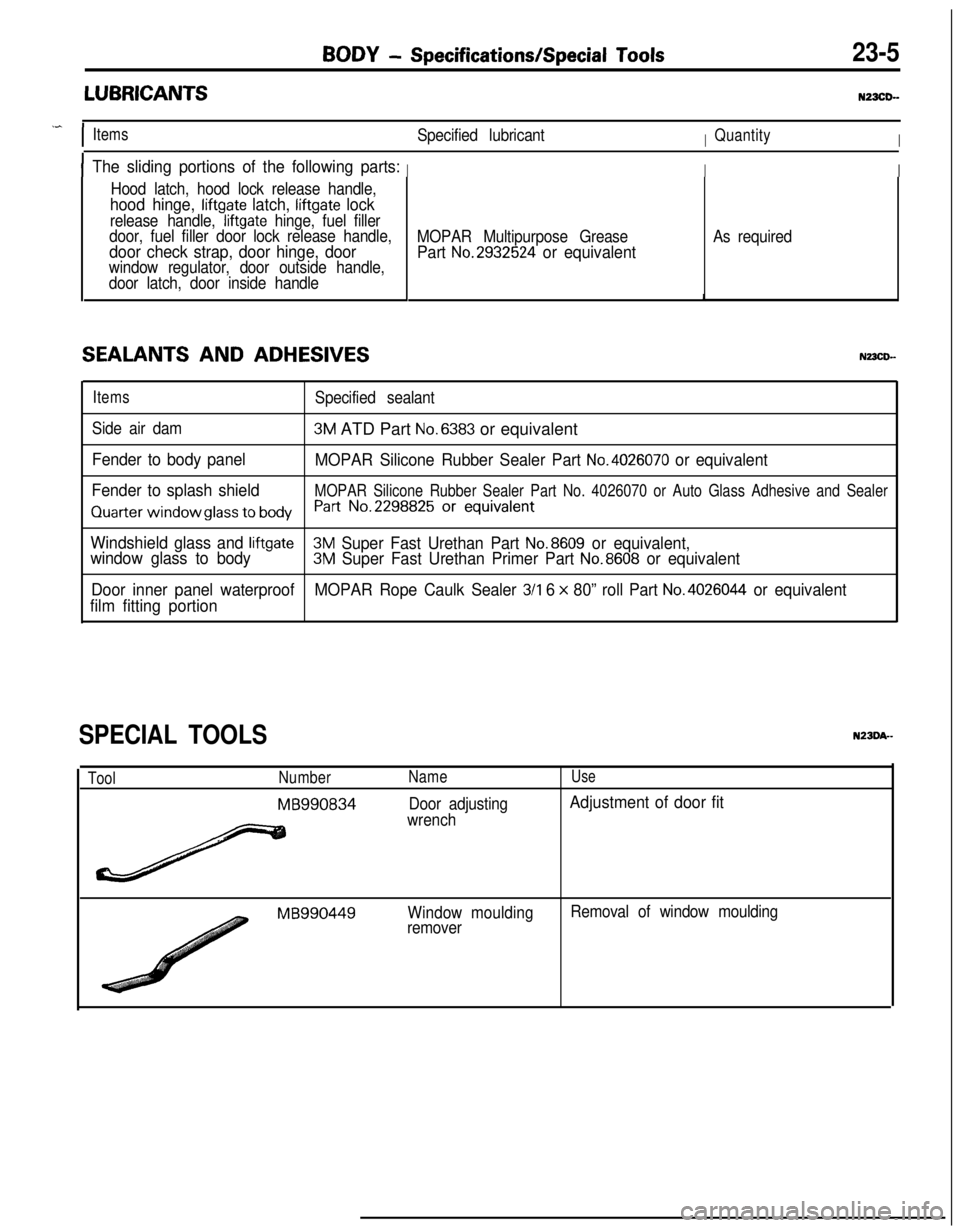

LUBRICANTSNZXD-

.^

IItemsSpecified lubricantIQuantityI

IThe sliding portions of the following parts:III

Hood latch, hood lock release handle,

hood hinge, liftgate latch, liftgate lock

release handle, liftgate hinge, fuel filler

door, fuel filler door lock release handle,

door check strap, door hinge, doorwindow regulator, door outside handle,

door latch, door inside handle

SEALANTS AND ADHESIVES

MOPAR Multipurpose Grease

Part No.2932524 or equivalent

As required

ItemsSpecified sealant

Side air dam

3M ATD Part No.6383 or equivalent

Fender to body panel

MOPAR Silicone Rubber Sealer Part No.4026070 or equivalent

Fender to splash shield

MOPAR Silicone Rubber Sealer Part No. 4026070 or Auto Glass Adhesive and Sealer

Quarter window glass to bodyh-t No.2298825 Or equivalent

Windshield glass and liftgate3M Super Fast Urethan Part No.8609 or equivalent,

window glass to body3M Super Fast Urethan Primer Part No.8608 or equivalent

Door inner panel waterproofMOPAR Rope Caulk Sealer

3/l 6 x 80” roll Part No.4026044 or equivalent

film fitting portion

SPECIAL TOOLS

ToolNumber

MB990834

Name

Door adjusting

wrench

Use

Adjustment of door fit

MB990449Window moulding

removerRemoval of window moulding

Page 1050 of 1216

BODY - Troubleshooting

TROUBLESHOOTINGN23EFd

HOOD, LIFTGATE, GLASS AND DOORS

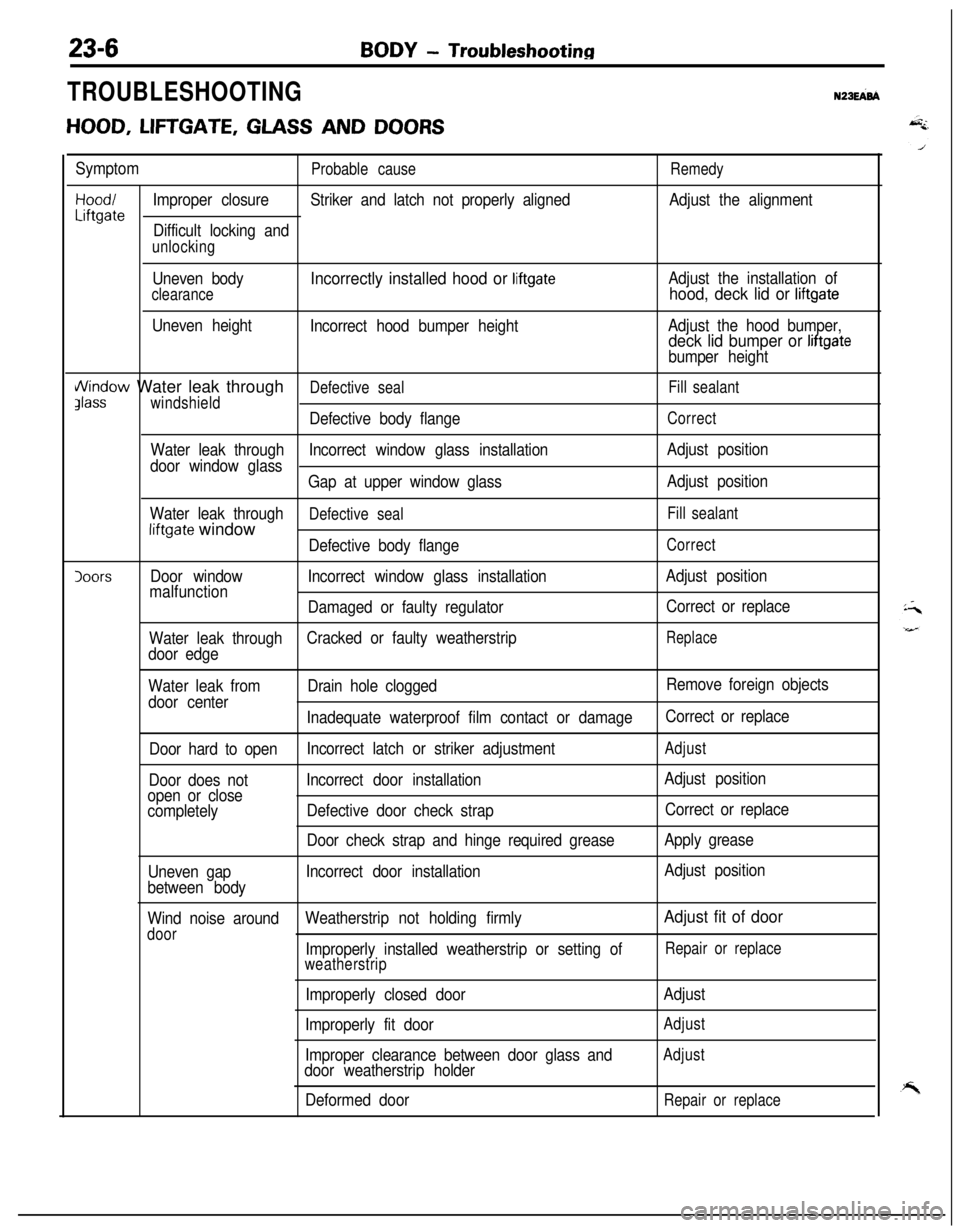

SymptomProbable causeRemedy

Hood/Improper closureStriker and latch not properly alignedAdjust the alignmentLiftgateDifficult locking and

unlocking

Uneven body

clearance

Uneven height

Incorrectly installed hood or liftgate

Incorrect hood bumper heightAdjust the installation of

hood, deck lid or liftgate

Adjust the hood bumper,deck lid bumper or liftgate

bumper height

i/\/indow Water leak throughDefective sealFill sealantJlasswindshield

Defective body flangeCorrect

Water leak throughIncorrect window glass installationAdjust position

door window glass

Gap at upper window glassAdjust position

Water leak through

Defective sealFill sealantliftgate window

Defective body flangeCorrect

IoorsDoor windowIncorrect window glass installationAdjust position

malfunction

Damaged or faulty regulatorCorrect or replace

Water leak throughCracked or faulty weatherstrip

Replace

door edge

Water leak fromDrain hole cloggedRemove foreign objects

door center

Inadequate waterproof film contact or damageCorrect or replace

Door hard to openIncorrect latch or striker adjustment

Adjust

Door does notIncorrect door installationAdjust position

open or close

completelyDefective door check strapCorrect or replace

Door check strap and hinge required greaseApply grease

Uneven gapIncorrect door installationAdjust position

between body

Wind noise aroundWeatherstrip not holding firmly

Adjust fit of door

doorImproperly installed weatherstrip or setting ofRepair or replace

weatherstrip

Improperly closed door

Improperly fit door

Improper clearance between door glass and

door weatherstrip holder

Deformed doorAdjust

Adjust

Adjust

Repair or replace

Page 1053 of 1216

BODY - Troubleshooting23-9

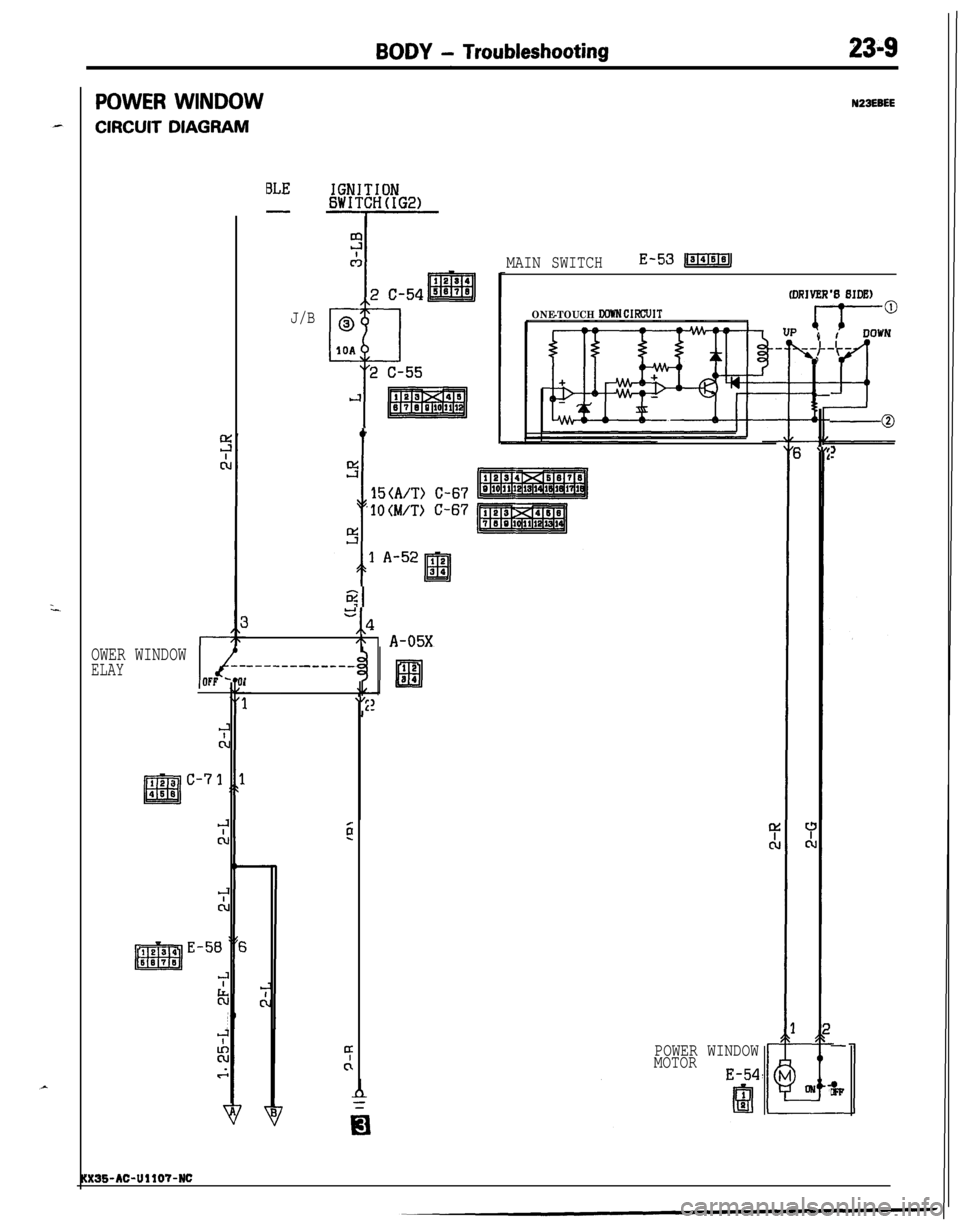

POWER WINDOW

CIRCUIT DIAGRAM

N23EBEE

MAIN SWITCHE-53JIGl=MJ

ONE-TOUCH WWN CIFXXJITJ/B

I

8

c

\,:

-0

t

!Ti

i

15(A/T) C-67

'1OWT) C-67

5

e,,*

'\ A-05X

-------___-_

1

\I2

OWER WINDOWELAY

128 C-7

El468

-

&

POWER WINDOW

MOTOR

E-54

:3S-AC-UllO?-NC

Page 1054 of 1216

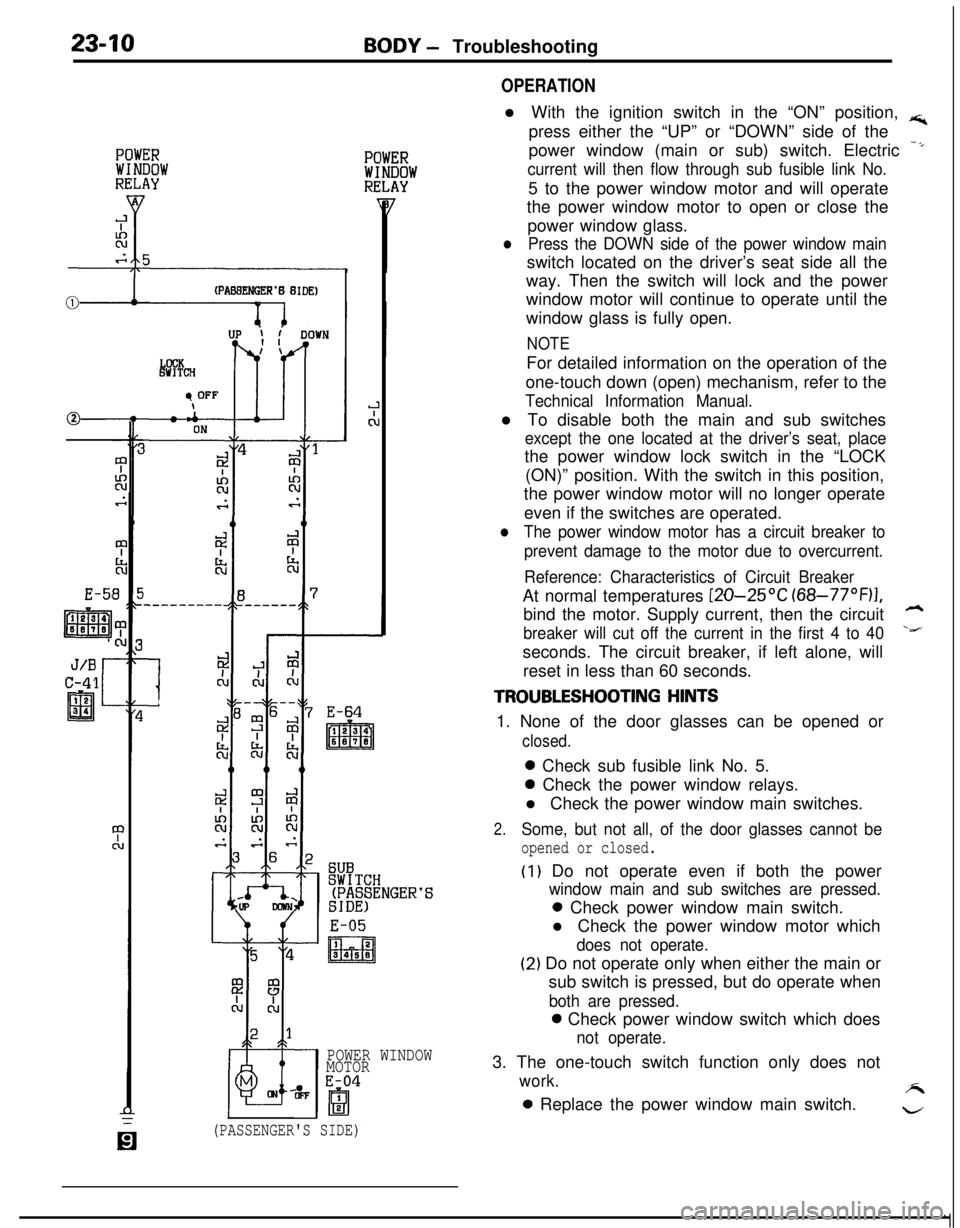

23-10BODY - Troubleshooting

(PABBENGER’B BIDE)v 1

E-51

‘S

E-05

I2

m3458

POWER WINDOW

MOTOR

E-04

OPERATIONl With the ignition switch in the “ON” position,

rs;,press either the “UP” or “DOWN” side of the

power window (main or sub) switch. Electric

-*

current will then flow through sub fusible link No.5 to the power window motor and will operate

the power window motor to open or close the

power window glass.

lPress the DOWN side of the power window mainswitch located on the driver’s seat side all the

way. Then the switch will lock and the power

window motor will continue to operate until the

window glass is fully open.

NOTEFor detailed information on the operation of the

one-touch down (open) mechanism, refer to the

Technical Information Manual.l To disable both the main and sub switches

except the one located at the driver’s seat, placethe power window lock switch in the “LOCK

(ON)” position. With the switch in this position,

the power window motor will no longer operate

even if the switches are operated.

lThe power window motor has a circuit breaker to

prevent damage to the motor due to overcurrent.

Reference: Characteristics of Circuit BreakerAt normal temperatures

[ZO-25OC (68-77”F)I,bind the motor. Supply current, then the circuit

h

breaker will cut off the current in the first 4 to 40\&’seconds. The circuit breaker, if left alone, will

reset in less than 60 seconds.

TROUBLESHOOTING HINTS1. None of the door glasses can be opened or

closed.0 Check sub fusible link No. 5.0 Check the power window relays.

l Check the power window main switches.

2.Some, but not all, of the door glasses cannot be

opened or closed.

(I) Do not operate even if both the power

window main and sub switches are pressed.0 Check power window main switch.

l Check the power window motor which

does not operate.

(2) Do not operate only when either the main or

sub switch is pressed, but do operate when

both are pressed.0 Check power window switch which does

not operate.3. The one-touch switch function only does not

work.A0 Replace the power window main switch.

w

(PASSENGER'S SIDE)

Page 1076 of 1216

23-32BODY - Service Adjustment Procedures

‘C16A0711

18AO38t

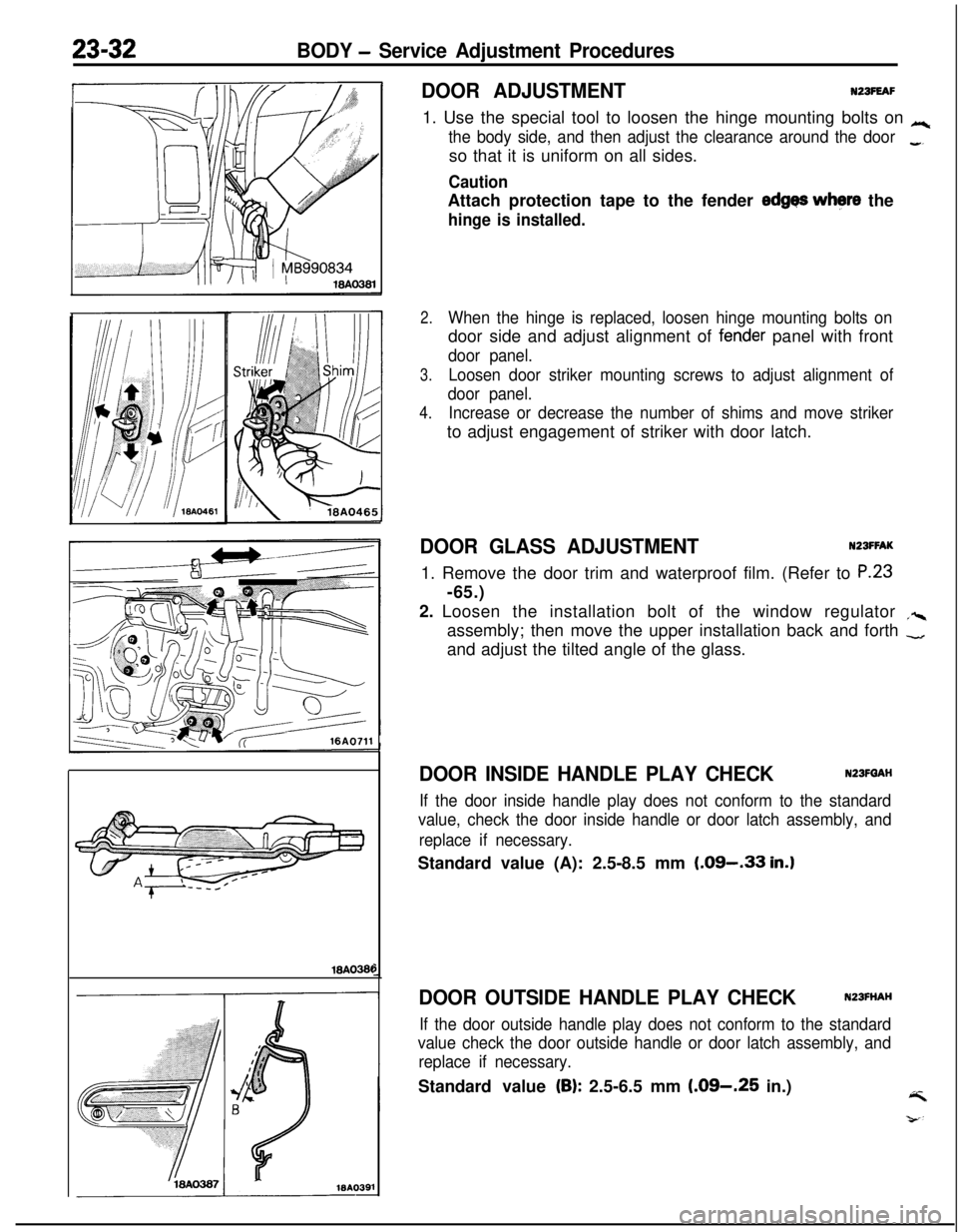

DOOR ADJUSTMENTNZBFEAF1. Use the special tool to loosen the hinge mounting bolts on

Lc

the body side, and then adjust the clearance around the door_so that it is uniform on all sides.

CautionAttach protection tape to the fender

edges where the

hinge is installed.

2.When the hinge is replaced, loosen hinge mounting bolts ondoor side and adjust alignment of

fen,der panel with front

door panel.

3.Loosen door striker mounting screws to adjust alignment of

door panel.

4.Increase or decrease the number of shims and move strikerto adjust engagement of striker with door latch.

DOOR GLASS ADJUSTMENTNZSFFAK1. Remove the door trim and waterproof film. (Refer to

P.23-65.)

2. Loosen the installation bolt of the window regulator

,%assembly; then move the upper installation back and forth

-and adjust the tilted angle of the glass.

DOOR INSIDE HANDLE PLAY CHECKN23FQAH

If the door inside handle play does not conform to the standard

value, check the door inside handle or door latch assembly, and

replace if necessary.Standard value (A): 2.5-8.5 mm

(.09-.33 in.)

DOOR OUTSIDE HANDLE PLAY CHECKN23FHAH

If the door outside handle play does not conform to the standard

value check the door outside handle or door latch assembly, and

replace if necessary.Standard value

(B): 2.5-6.5 mm (.09-.25 in.)4

Page 1092 of 1216

23-48

MOULDINGBODY

- Moulding

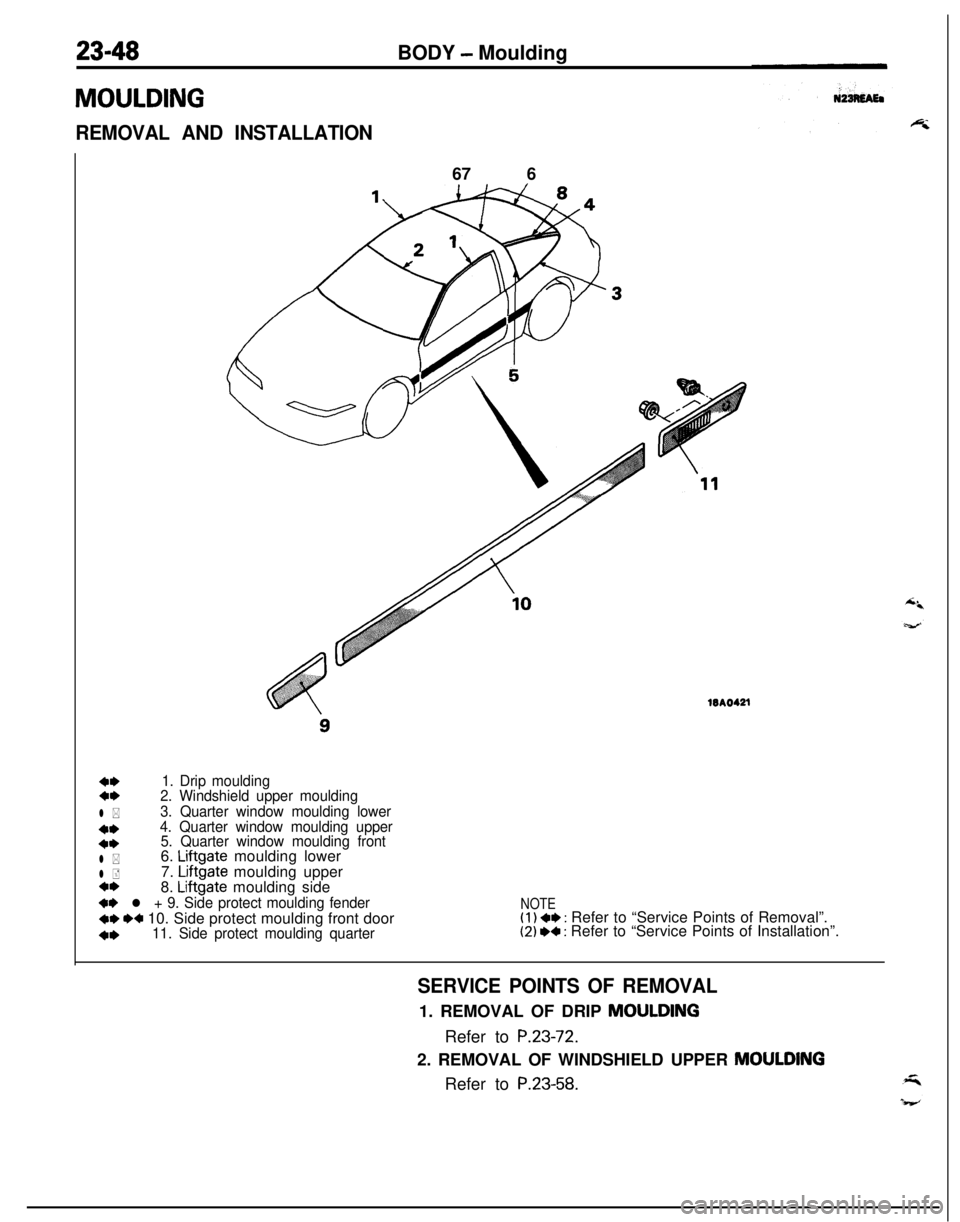

REMOVAL AND INSTALLATION67 6WA0421

4,1. Drip moulding4,2. Windshield upper moulding

l *3. Quarter window moulding lower

**4. Quarter window moulding upper

4*5. Quarter window moulding front

l *6. Liftgate moulding lower

l +7. Liftgate moulding uppera*8. Liftgate moulding side

+* l + 9. Side protect moulding fender

+e I)+ 10. Side protect moulding front door

4,11. Side protect moulding quarter

NOTE(1) ** : Refer to “Service Points of Removal”.(2) I)+ : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL1. REMOVAL OF DRIP MOULDING

Refer to

P.23-72.2. REMOVAL OF WINDSHIELD UPPER

MOULDINGRefer to

P.23-58.

Page 1093 of 1216

BODY - Moulding23-493.

REMOVAL OF QUARTER WINDOW MOULDING LOWER/

4. QUARTER WINDOW MOULDING UPPER/B. QUARTERWINDOW MOULDING FRONT

Refer to

P.23-61.6. REMOVAL OF

LIFTGATE MOULDING LOWERI7. LIFT-GATE MOULDING

UPPER/8. LIFTGATE MOULDING

SIDERefer to

P.23-62.

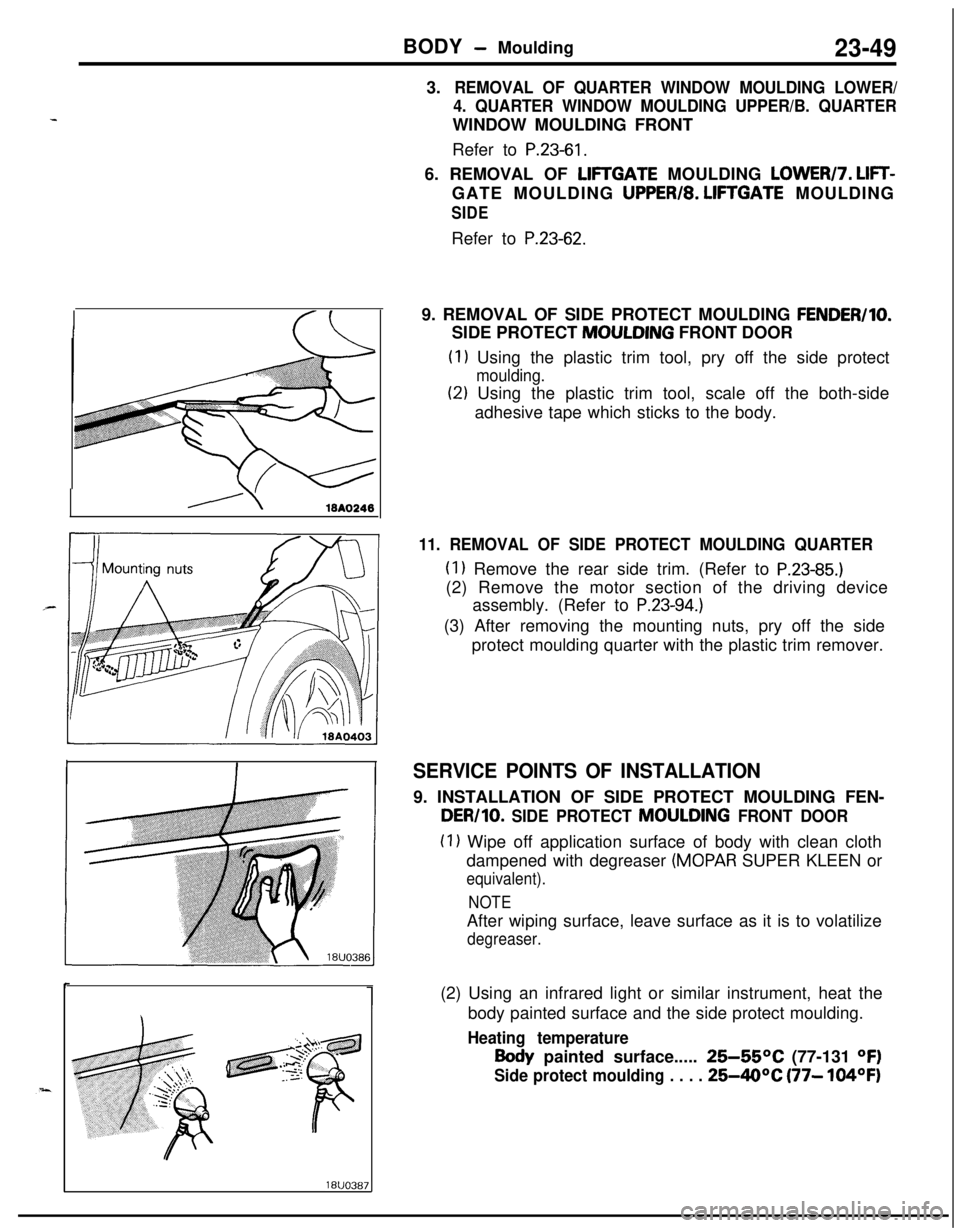

19. REMOVAL OF SIDE PROTECT MOULDING

FENDER/IO.SIDE PROTECT MOULDING FRONT DOOR

(1) Using the plastic trim tool, pry off the side protect

moulding.

(2) Using the plastic trim tool, scale off the both-side

adhesive tape which sticks to the body.

11. REMOVAL OF SIDE PROTECT MOULDING QUARTER

(1) Remove the rear side trim. (Refer to P.23-85.)(2) Remove the motor section of the driving device

assembly. (Refer to

P.23-94.)(3) After removing the mounting nuts, pry off the side

protect moulding quarter with the plastic trim remover.

SERVICE POINTS OF INSTALLATION9. INSTALLATION OF SIDE PROTECT MOULDING FEN-

DER/10. SIDE PROTECT MOULDING FRONT DOOR

(1) Wipe off application surface of body with clean cloth

dampened with degreaser

(MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.(2) Using an infrared light or similar instrument, heat the

body painted surface and the side protect moulding.

Heating temperature

Body painted surface..... 25-55OC (77-131 OF)

Side protect moulding . . . . 25-40°C (77- 104OF)