electric MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 553 of 1216

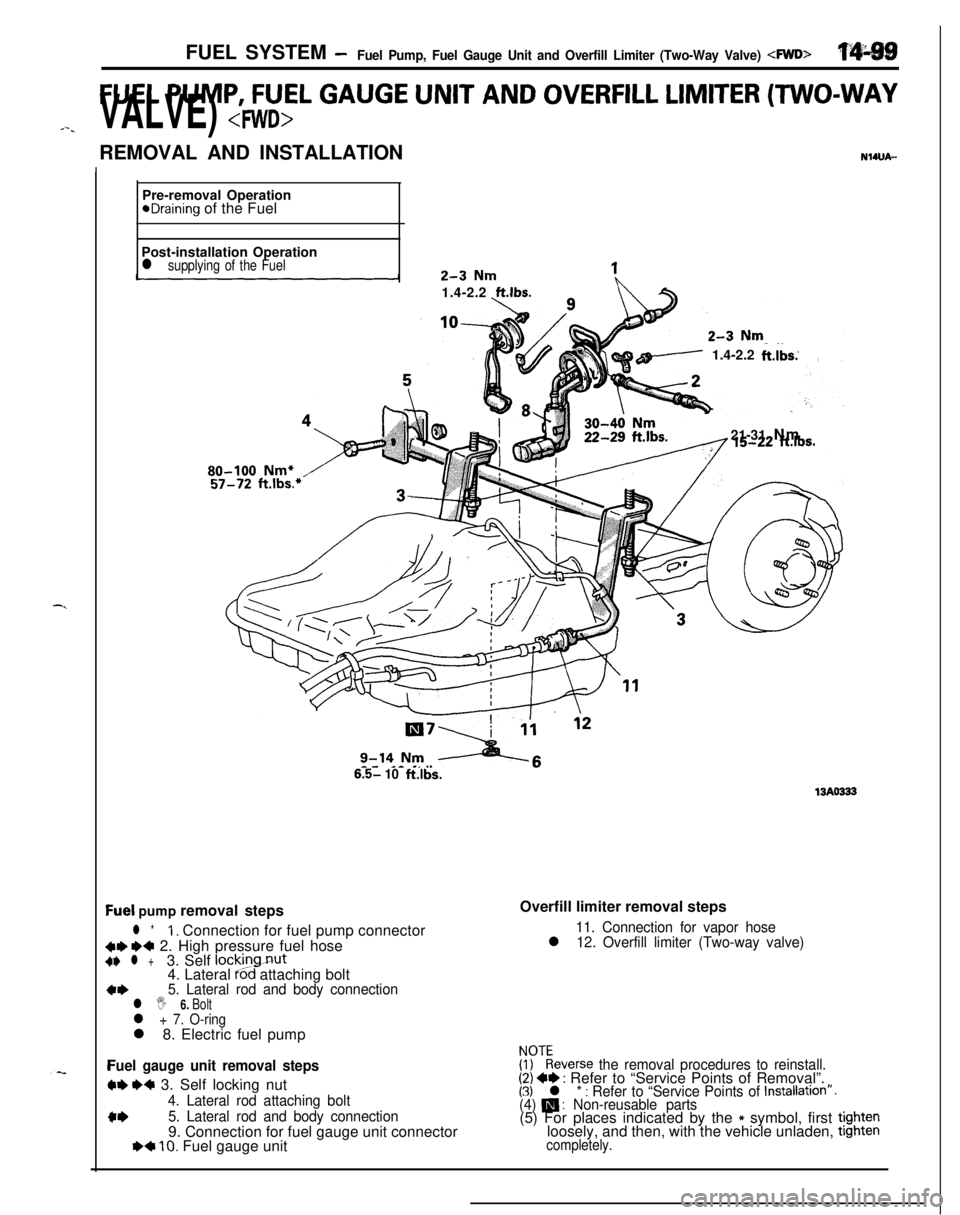

FUEL SYSTEM -Fuel Pump, Fuel Gauge Unit and Overfill Limiter (Two-Way Valve)

FUEL PUMP, FUEL GAUGE UNIT AND OVERFILL LIMITER (TWO-WAY

J-.VALVE)

NWJA-Pre-removal Operation

eDraining of the Fuel

Post-installation Operation

l supplying of the Fuel1.4-2.2

ft.lbs.

/ 1.4-2.2ft.lbs.

21-31 Nm

80-100 Nm+

6.5- 10ftlbs.

13AO333

Qel pump removal steps

l *1. Connection for fuel pump connector

C+ ~~ 2. High pressure fuel hoseC+ l +3. Self lockingnut

4. Lateral Pod attaching bolt

a*5. Lateral rod and body connectionl I 6. Boltl + 7. O-ringl 8. Electric fuel pump

Fuel gauge unit removal steps

W e+ 3. Self locking nut

4. Lateral rod attaching bolt

c*5. Lateral rod and body connection9. Connection for fuel gauge unit connector

I)+ 10. Fuel gauge unitOverfill limiter removal steps

11. Connection for vapor hosel 12. Overfill limiter (Two-way valve)

FF:everse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5) For places indicated by the * symbol, first tightenloosely, and then, with the vehicle unladen, tighten

completely.

Page 554 of 1216

14-100 FUEL SYSTEM- Fuel Pump, Fuel Gauge Unit and Overfill Limiter (Two-Way Valve) 4WD>SERVICE POINTS OF REMOVAL

NI4tmM2. DISCONNECTION OF HIGH PRESSURE FUEL HOSE

Refer to

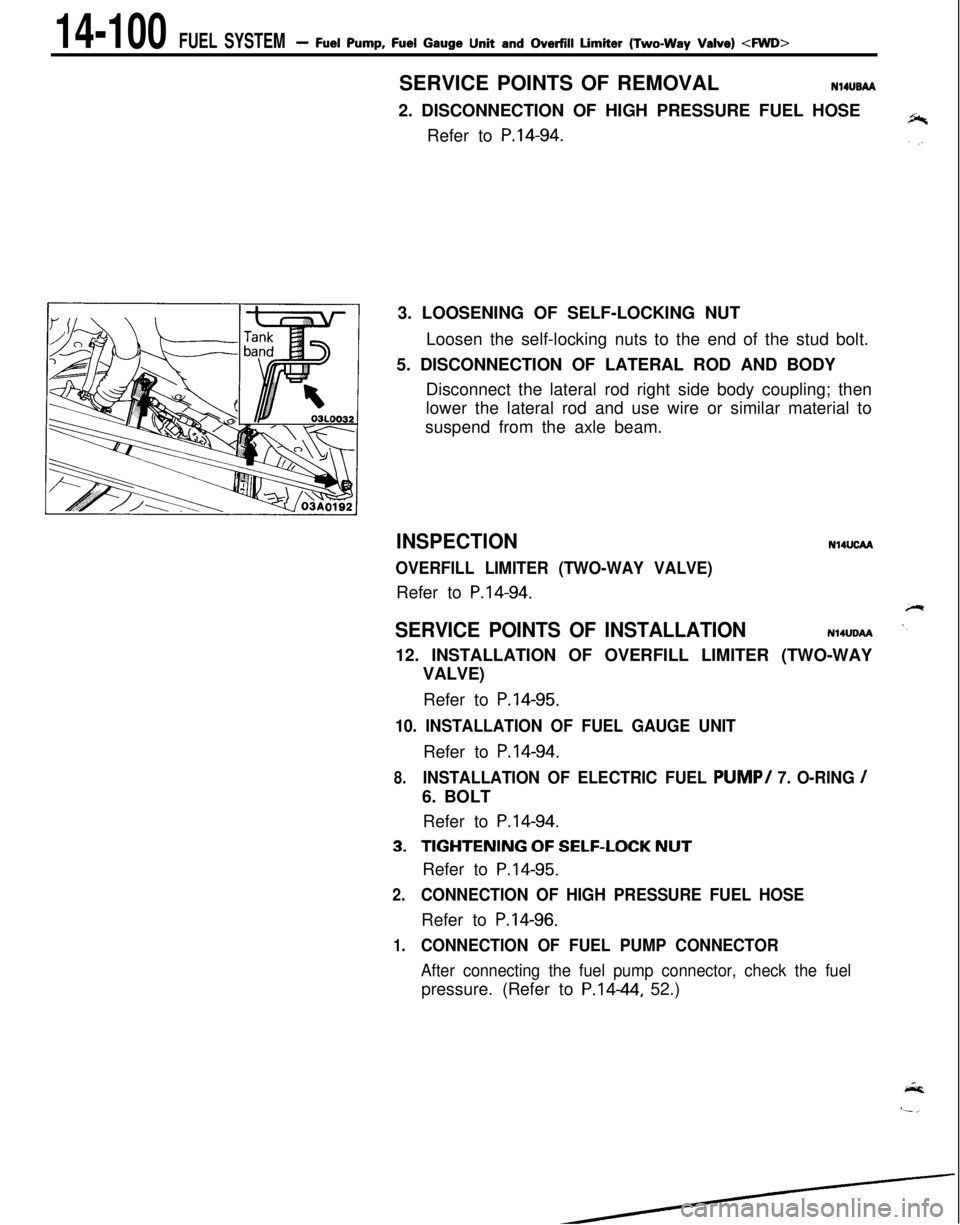

P.14-94.3. LOOSENING OF SELF-LOCKING NUT

Loosen the self-locking nuts to the end of the stud bolt.

5. DISCONNECTION OF LATERAL ROD AND BODY

Disconnect the lateral rod right side body coupling; then

lower the lateral rod and use wire or similar material to

suspend from the axle beam.

INSPECTION

OVERFILL LIMITER (TWO-WAY VALVE)Refer to

P.14-94.

N14UcM

SERVICE POINTS OF INSTALLATIONN14UDAA12. INSTALLATION OF OVERFILL LIMITER (TWO-WAY

VALVE)

Refer to

P.14-95.

10. INSTALLATION OF FUEL GAUGE UNITRefer to

P.14-94.

8.INSTALLATION OF ELECTRIC FUEL PUMP/ 7. O-RING /6. BOLT

Refer to

P.14-94.

3.TIGHTENING OF SELF-LOCK NUTRefer to

P.14-95.

2.CONNECTION OF HIGH PRESSURE FUEL HOSERefer to

P.14-96.

1.CONNECTION OF FUEL PUMP CONNECTOR

After connecting the fuel pump connector, check the fuelpressure. (Refer to P.1444, 52.)

Page 1045 of 1216

23-lBODY

CONTENTSN23Ak-

AERO PARTS..........................................74

CENTRAL DOOR LOCKING SYSTEM...........70

DOOR ASSEMBLY....................................63

DOOR GLASS AND REGULATOR................66

DOORHANDLEANDLATCH.....................69

DOOR MIRROR........................................72

DOOR MOULDING AND

DRIP LINE WEATHERSTRIP........................72

....DOOR RUNCHANNEL...............................71

DOOR TRIM AND WATERPROOF FILM........65

ELECTRIC REMOTE CONTROLLED

MIRROR SWITCH.....................................73

FENDER..................................................51

FLOOR CONSOLE....................................84

FRONT BUMPER......................................39

FRONT SEAT..........................................90

FUEL TANKFILLERDOOR.........................38

GARNISHES............................................47

HEADLINING...........................................89

HOOD....................................................34

INSTRUMENT PANEL................................79

LIFTGATE...............................................36

LIFTGATE WINDOWGLASS......................62

LOOSE PANEL.........................................53

MOULDING.............................................48

POWER WINDOW....................................67

QUARTERWINDOWGLASS......................61

REAR BUMPER........................................43

REAR SEAT............................................93

SEAT BELT.............................................94

SERVICE ADJUSTMENT PROCEDURES........31

Door Adjustment....................................32

Door Glass Adjustment............................32Door Inside Handle Play Check..................

32

Door Outside Handle Play Check................32

Floor PanInspection...............................

33Fuel Filler Door Adjustment.......................

31

Hood Adjustment...................................31

Liftgate Adjustment.................................31

Water Test...........................................33

SPECIAL TOOLS......................................5

SPECIFICATIONS.....................................2

General Specifications..............................

2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................77TRIMS

....................................................85

TROUBLESHOOTING................................6WINDOW

GLASS.....................................54

WINDSHIELD...........................................58

Page 1054 of 1216

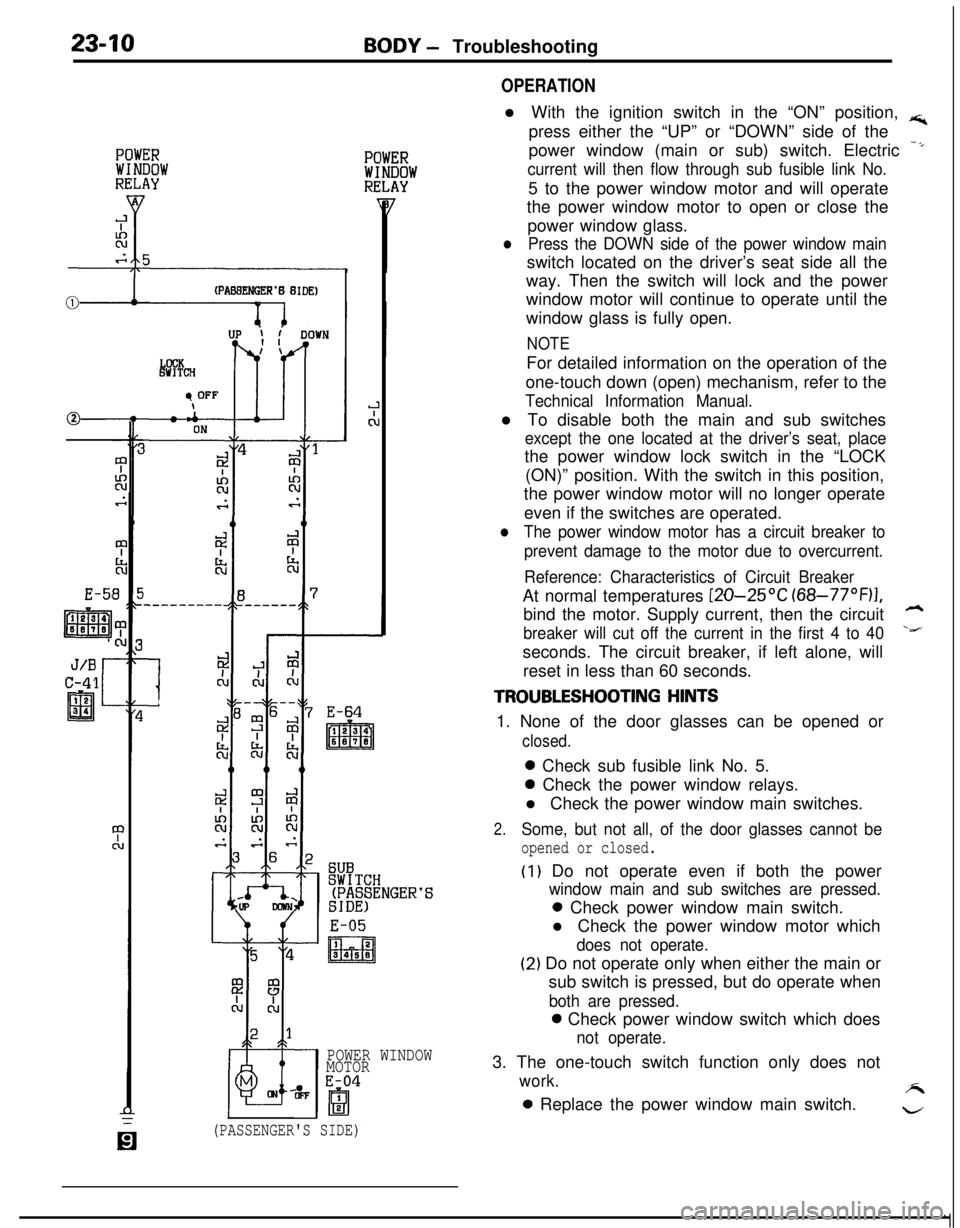

23-10BODY - Troubleshooting

(PABBENGER’B BIDE)v 1

E-51

‘S

E-05

I2

m3458

POWER WINDOW

MOTOR

E-04

OPERATIONl With the ignition switch in the “ON” position,

rs;,press either the “UP” or “DOWN” side of the

power window (main or sub) switch. Electric

-*

current will then flow through sub fusible link No.5 to the power window motor and will operate

the power window motor to open or close the

power window glass.

lPress the DOWN side of the power window mainswitch located on the driver’s seat side all the

way. Then the switch will lock and the power

window motor will continue to operate until the

window glass is fully open.

NOTEFor detailed information on the operation of the

one-touch down (open) mechanism, refer to the

Technical Information Manual.l To disable both the main and sub switches

except the one located at the driver’s seat, placethe power window lock switch in the “LOCK

(ON)” position. With the switch in this position,

the power window motor will no longer operate

even if the switches are operated.

lThe power window motor has a circuit breaker to

prevent damage to the motor due to overcurrent.

Reference: Characteristics of Circuit BreakerAt normal temperatures

[ZO-25OC (68-77”F)I,bind the motor. Supply current, then the circuit

h

breaker will cut off the current in the first 4 to 40\&’seconds. The circuit breaker, if left alone, will

reset in less than 60 seconds.

TROUBLESHOOTING HINTS1. None of the door glasses can be opened or

closed.0 Check sub fusible link No. 5.0 Check the power window relays.

l Check the power window main switches.

2.Some, but not all, of the door glasses cannot be

opened or closed.

(I) Do not operate even if both the power

window main and sub switches are pressed.0 Check power window main switch.

l Check the power window motor which

does not operate.

(2) Do not operate only when either the main or

sub switch is pressed, but do operate when

both are pressed.0 Check power window switch which does

not operate.3. The one-touch switch function only does not

work.A0 Replace the power window main switch.

w

(PASSENGER'S SIDE)

Page 1058 of 1216

23-14BODY - Troubleshooting

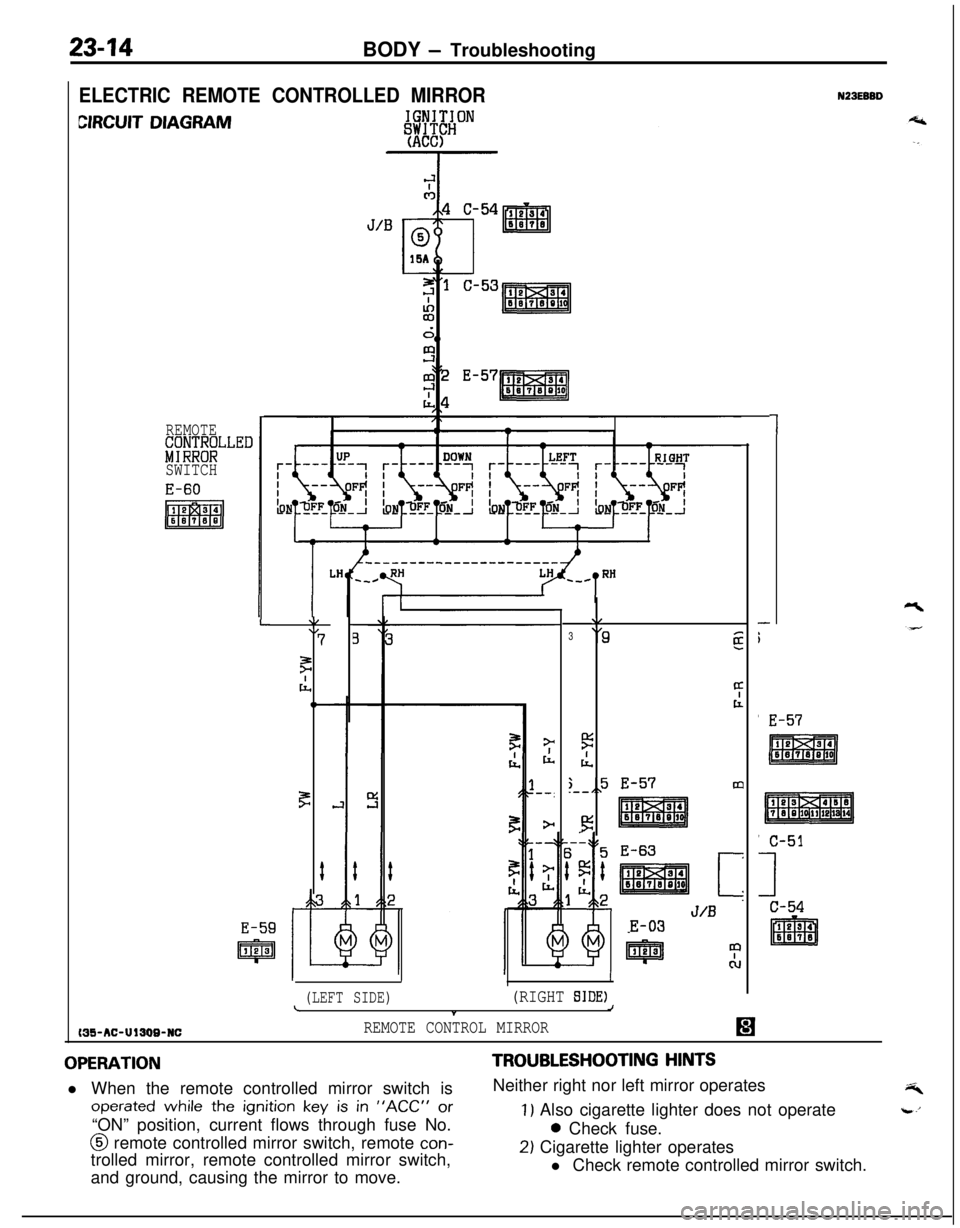

ELECTRIC REMOTE CONTROLLED MIRROR

CIRCUIT DIAGRAM

REMOTE&;;NT;LLED

SWITCH

MS-AC-UlSW-NC

L\/\I7

F

cl,,C

F

#

E-59

IpJJ%J

\/

3‘9g

4t

5

IL

;,,5 E-57m.--

!3

E-63

[z

J/BE-03

II

(LEFT SIDE)(RIGHT SIDE)LJt

REMOTE CONTROL MIRROR

1

-

i'

E-57

N23EBBD

OPERATIONl When the remote controlled mirror switch is

operated while the ignition key is in “ACC” or“ON” position, current flows through fuse No.@ remote controlled mirror switch, remote

con-trolled mirror, remote controlled mirror switch,

and ground, causing the mirror to move.

TROUBLESHOOTING HINTSNeither right nor left mirror operates

1) Also cigarette lighter does not operate0 Check fuse.

2) Cigarette lighter operates

l Check remote controlled mirror switch.

Page 1060 of 1216

23-16BODY - Troubleshooting

OPERATION

Key-reminder warning0 Battery voltage is always supplied, through sub

fusible link No.

@, to the key-reminder switch.0 When the driver’s seat door is opened while the

ignition key is still in the key cylinder, the door

switch is switched ON, electricity flows to sub

fusible link No.

0, the key-reminder switch, the

buzzer, the door switch, and ground, and the

buzzer sounds.

Seat belt warning0 Battery voltage is applied, through fuse No.

0,to the seat belt timer when the ignition key is at

the “ON” position.0 Electricity flows to sub fusible link No. @, the

key-reminder switch, the seat belt warning light,

the seat belt timer, and ground, and the seat beltwarning light illuminates for approx. 6 seconds.0

If the driver does not buckle the seat belt, the seatbelt switch is switched ON, electricity flows to

sub fusible link No. @, the key-reminder switch,the buzzer, the seat belt switch, the seat belt

warning timer, and ground, and the buzzer

sounds for approx. 6 seconds.0 When the driver buckles the seat belt, the seat

belt switch is switched OFF and the buzzer stops.

TROUBLESHOOTING HINTS

Key-reminder warningThe key-reminder warning doesn’t sound.

(1) The seat belt warning function is OK.

l Check the door switch.

(2) The seat belt warning also doesn’t function.0 Check the buzzer.

Seat belt warning1. The seat belt warning doesn’t function.

(1) The seat belt warning light illuminates.0 Check the seat belt switch.

(2) The seat belt warning light also does not

function (but the key-reminder warning

functions normally. 10 Check the seat belt timer.

(3) The seat belt warning light also does not

function (and the key-reminder warning also

does not function).0 Check the key-reminder switch.

2.The buzzer doesn’t stop even though the driver’s

seat belt has been buckled.0 Check the seat belt switch.

3.The seat belt warning light doesn’t illuminate (but

the buzzer sounds).l Check the light bulb.

’ I

Page 1063 of 1216

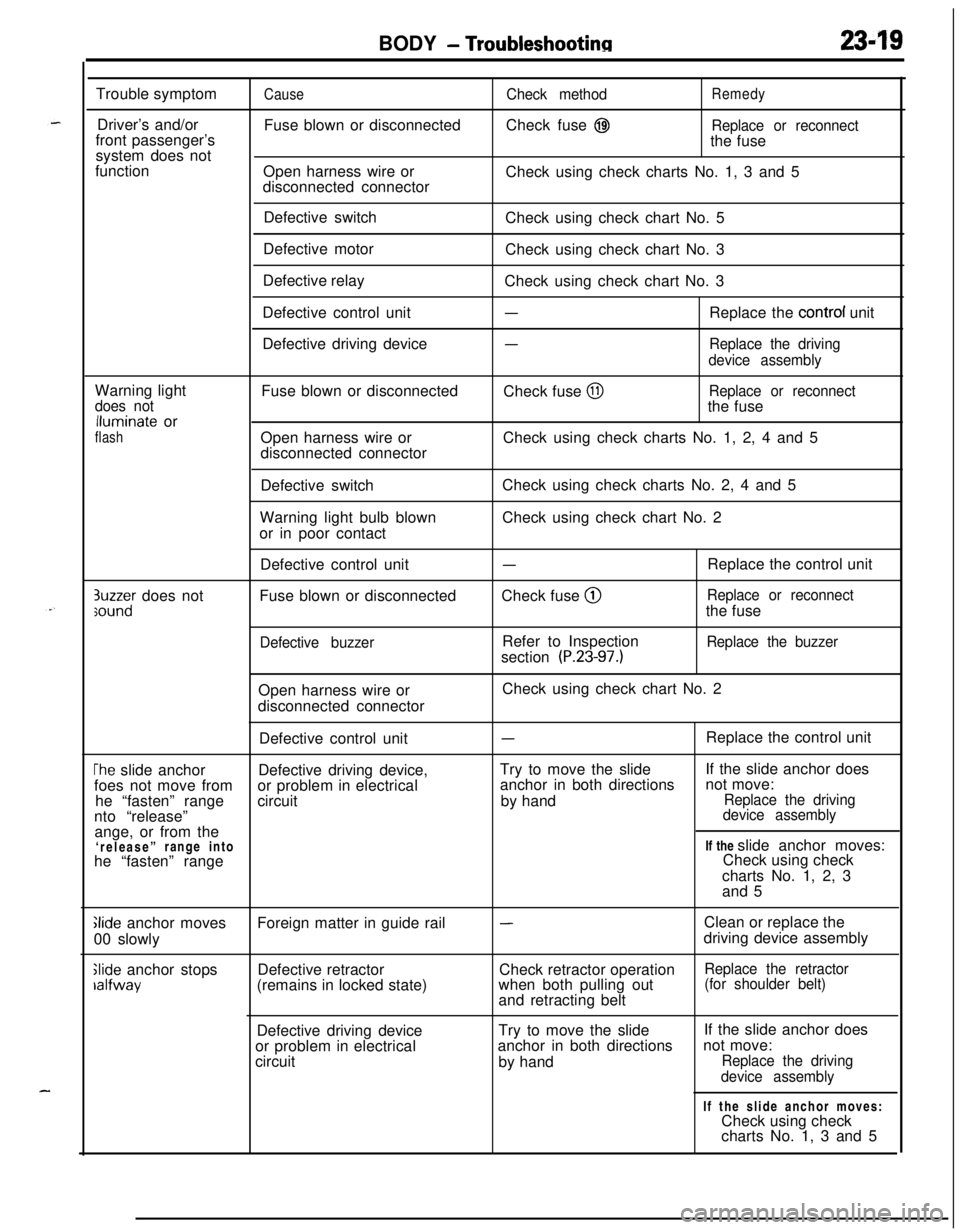

BODY - Troubleshootinn2349Trouble symptom

Driver’s and/or

front passenger’s

system does not

function

CauseFuse blown or disconnected

Open harness wire or

disconnected connectorCheck methodRemedyCheck fuse

@IReplace or reconnectthe fuse

Check using check charts No. 1, 3 and 5

Defective switch

Defective motor

Defective relay

Defective control unit

Defective driving deviceCheck using check chart No. 5

Check using check chart No. 3

Check using check chart No. 3

-Replace the control unit

-Replace the driving

device assemblyWarning light

does notlluminate or

flashFuse blown or disconnected

Open harness wire or

disconnected connectorCheck fuse

@IReplace or reconnectthe fuse

Check using check charts No. 1, 2, 4 and 5

Defective switch

Warning light bulb blown

or in poor contactCheck using check charts No. 2, 4 and 5

Check using check chart No. 2

3uzzer does notsoundDefective control unit

Fuse blown or disconnected

Defective buzzer

-Check fuse @

Refer to Inspection

section

(P.23-97.)Replace the control unit

Replace or reconnectthe fuse

Replace the buzzerOpen harness wire or

disconnected connectorCheck using check chart No. 2

Defective control unit

-Replace the control unit

The slide anchorDefective driving device,Try to move the slideIf the slide anchor does

foes not move fromor problem in electricalanchor in both directionsnot move:

he “fasten” rangecircuitby hand

Replace the drivingnto “release”device assemblyange, or from the

‘release”range intoIf the slide anchor moves:

he “fasten” rangeCheck using check

charts No. 1, 2, 3

and 5

Glide anchor moves

00 slowly

Slide anchor stopsralfwayForeign matter in guide rail

Defective retractor

(remains in locked state)

-Clean or replace the

driving device assembly

Check retractor operation

Replace the retractorwhen both pulling out(for shoulder belt)and retracting belt

Defective driving deviceTry to move the slide

or problem in electricalanchor in both directions

circuit

by handIf the slide anchor does

not move:

Replace the driving

device assemblyIf the slide anchor moves:

Check using check

charts No. 1, 3 and 5

Page 1109 of 1216

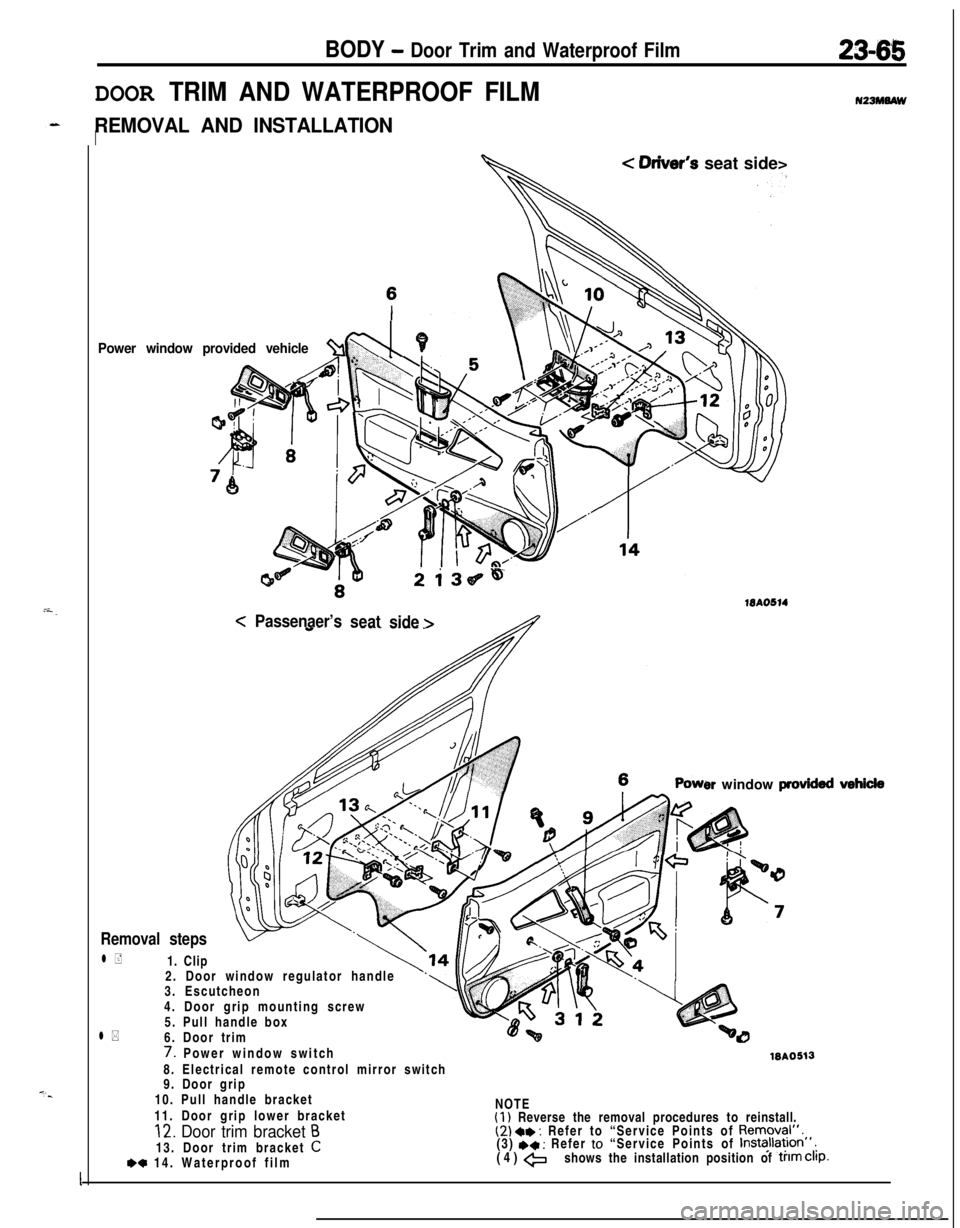

BODY - Door Trim and Waterproof Film2345

DOOR TRIM AND WATERPROOF FILM

REMOVAL AND INSTALLATIONI

Power window provided vehicle%l \PL

< Oriver’s seat side>

2i36~4

15AO514<

Passenaer’s

seat

side >

er window provkkd

Removal steps2. Door window regulator handle

3. Escutcheon

4. Door grip mounting screw

5. Pull handle box

l *6. Door trim

l +1. Clip

7. Power window switchWA05138. Electrical remote control mirror switch

9. Door grip

10. Pull handle bracket

11. Door grip lower bracketNOTE

(1) Reverse the removal procedures to reinstall.12. Door trim bracket B(2) a* : Refer to “Service Points of Removal”.13. Door trim bracket

C(3) +* : Refer to “Service Points of Installa~lon”,

*c 14. Waterproof film(4) +shows the installation position of trim Clip.

I

Page 1116 of 1216

23-72BODY -Door Moulding and Drip Line Weatherstrip/Door Mirror

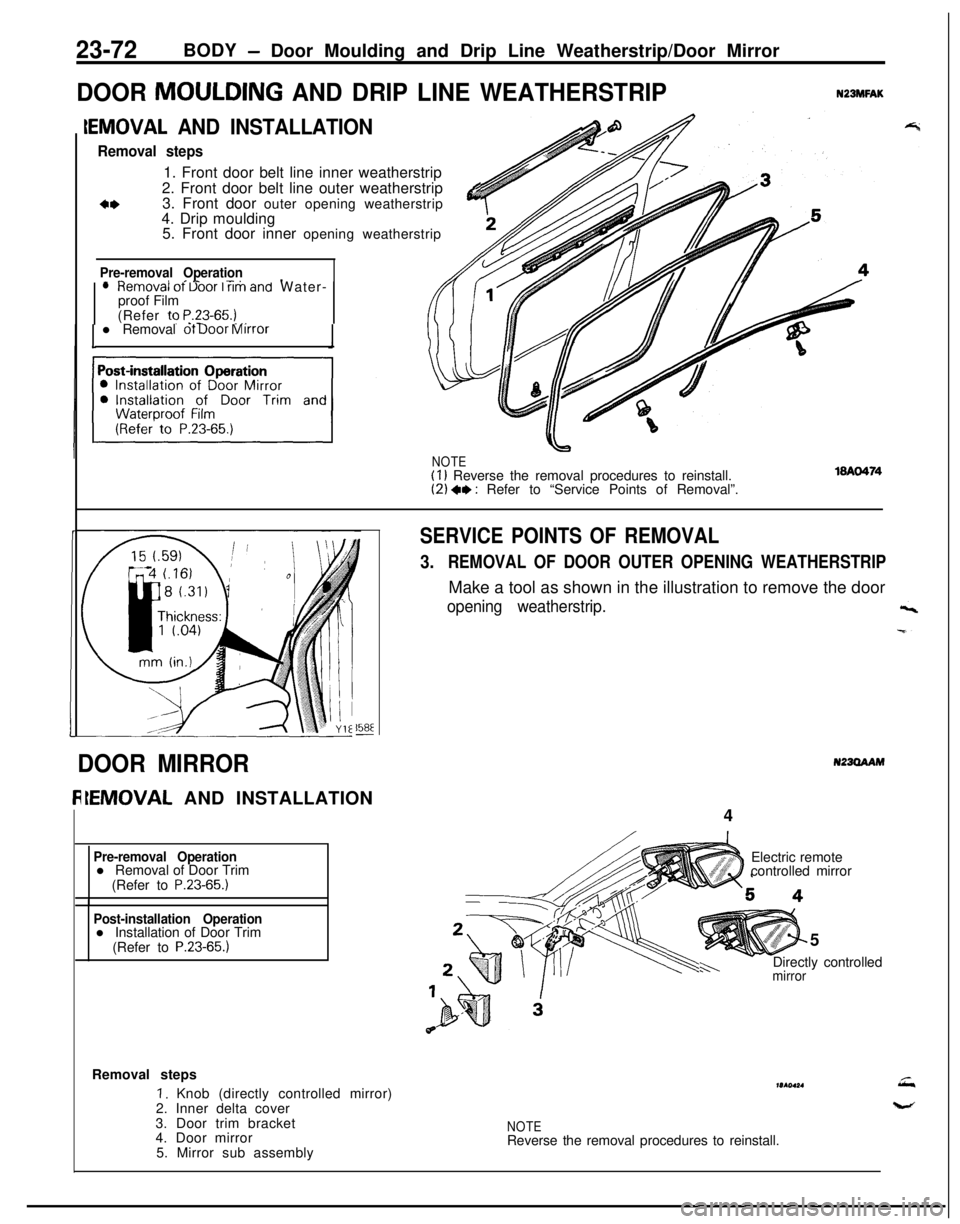

DOOR MOULDING AND DRIP LINE WEATHERSTRIPNZBMFAK

IEMOVAL AND INSTALLATION

Removal steps1. Front door belt line inner weatherstrip

2. Front door belt line outer weatherstrip

3. Front door outer opening weatherstrip

&4. Drip moulding

5. Front door inner opening weatherstrip

Pre-removal Operation- ^II_ -..lHemOVal ot Uoor I rim and Water-

proof Film

(Refer to

P.23-65.) _,. -l Removal ot Door Mirror

NOTE(I 1 Reverse the removal procedures to reinstall.(2) +, : Refer to “Service Points of Removal”.

158E-

SERVICE POINTS OF REMOVAL

3.REMOVAL OF DOOR OUTER OPENING WEATHERSTRIPMake a tool as shown in the illustration to remove the door

opening weatherstrip.

N23OAAMDOOR MIRROR

IEMOVAL AND INSTALLATION

4

Pre-removal Operationl Removal of Door Trim

(Refer to

P.23-65.)

Post-installation Operationl Installation of Door Trim

(Refer to

P.23-65.)5

mirrorh-.Directly controlled Electric remote

controlled mirror

Removal steps

I. Knob (directly controlled mirror)

2. Inner delta cover

3. Door trim bracket

4. Door mirror

5. Mirror sub assemblymr(ol*.

NOTEReverse the removal procedures to reinstall.

Page 1117 of 1216

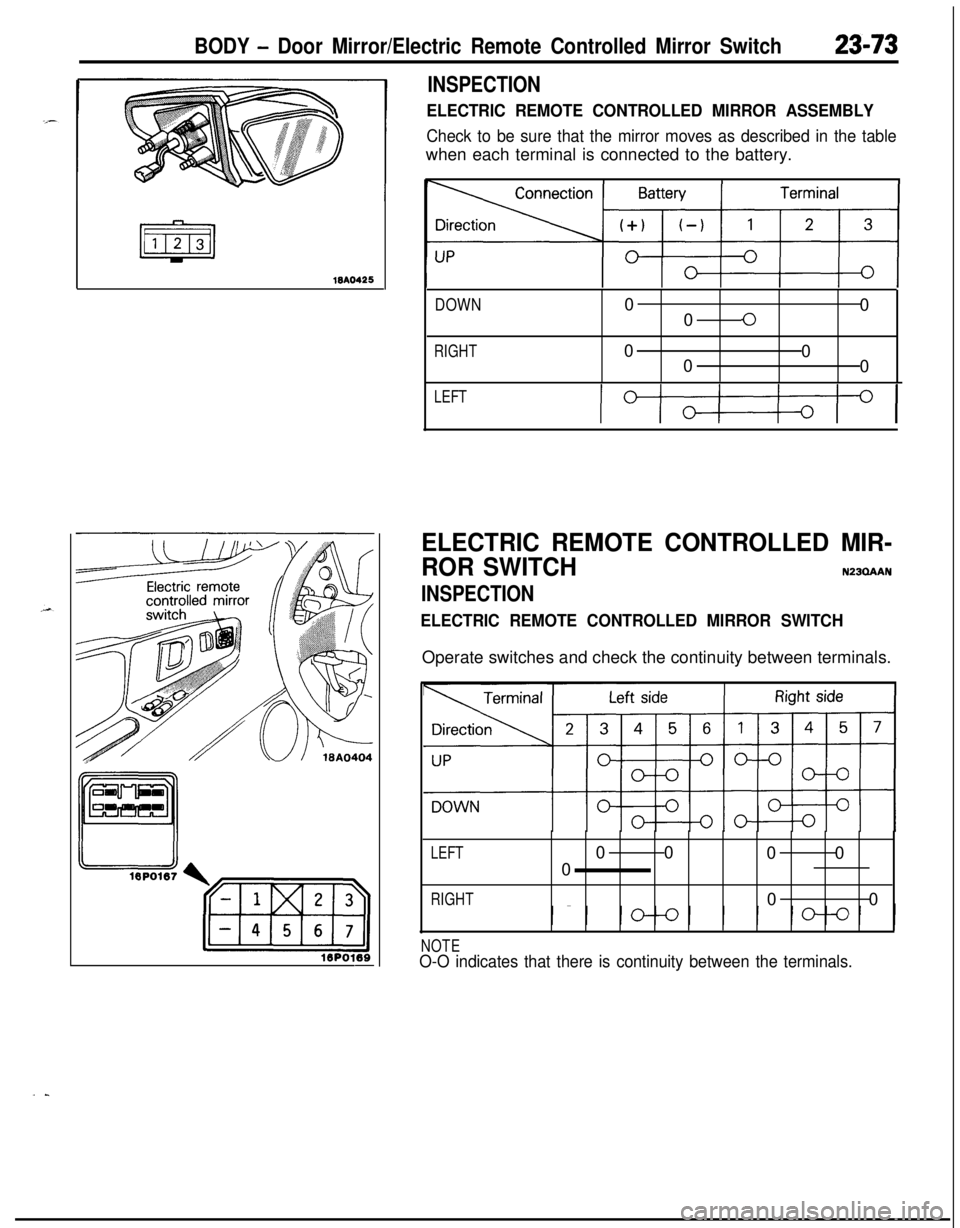

BODY - Door Mirror/Electric Remote Controlled Mirror Switch23-73

18AO425

16P0109-

INSPECTION

ELECTRIC REMOTE CONTROLLED MIRROR ASSEMBLY

Check to be sure that the mirror moves as described in the tablewhen each terminal is connected to the battery.

DOWN0

0

00

RIGHT0

0

0

0

LEFT

IOI

ELECTRIC REMOTE CONTROLLED MIR-

ROR SWITCH

N23QAAN

INSPECTION

ELECTRIC REMOTE CONTROLLED MIRROR SWITCHOperate switches and check the continuity between terminals.

LEFT00

00

0

RIGHT00

NOTEO-O indicates that there is continuity between the terminals.

..