electric MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 253 of 1216

COOLING - Troubleshootina7-5

TRO,UBLESHOOTlNG

Symptom

OverheatProbable causeInsufficient engine coolant

Too high an anti-freeze concentrationRemedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace

Inoperative electric cooling fan

Faulty thermosensor

Replace

Faulty electrical motorReplace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator finsCorrect

Water leaks

Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substanceCorrect or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperatureFaulty thermostatReplace

Page 309 of 1216

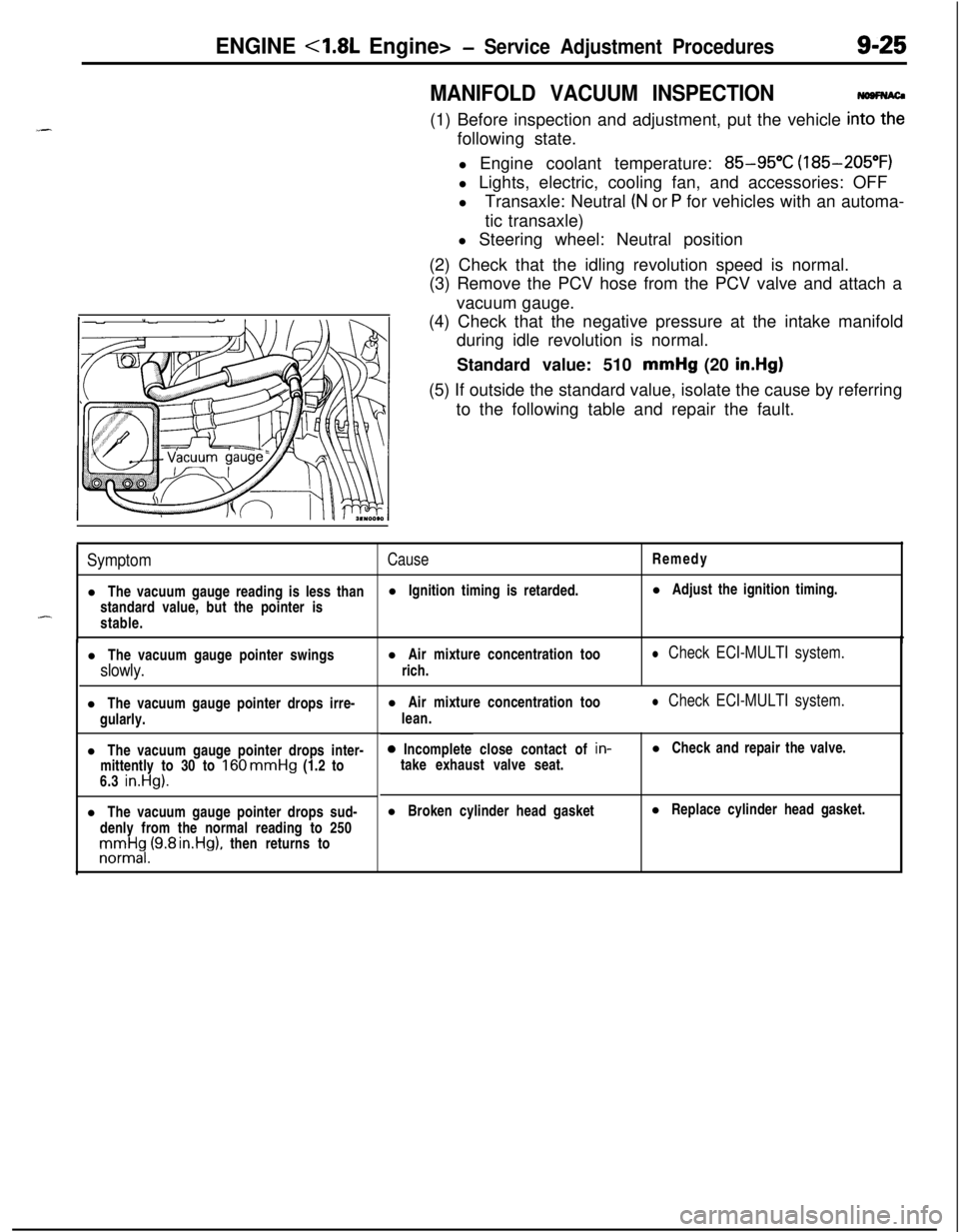

ENGINE <1.8L Engine>- Service Adjustment Procedures9-25

MANIFOLD VACUUM INSPECTION(1) Before inspection and adjustment, put the vehicle

in=following state.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric, cooling fan, and accessories: OFF

lTransaxle: Neutral

(N or P for vehicles with an automa-

tic transaxle)

l Steering wheel: Neutral position

(2) Check that the idling revolution speed is normal.

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value: 510 mmHg (20

in.Hg)(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

SymptomCauseRemedy

l The vacuum gauge reading is less thanl Ignition timing is retarded.l Adjust the ignition timing.

standard value, but the pointer is

-stable.

l The vacuum gauge pointer swingsl Air mixture concentration too

slowly.rich.

l Check ECI-MULTI system.l The vacuum gauge pointer drops irre-

gularly.

l The vacuum gauge pointer drops inter-

mittently to 30 to

160 mmHg (1.2 to

6.3 in.Hg).l The vacuum gauge pointer drops sud-

denly from the normal reading to 250rronnrt$,(9.8 rn.Hg), then returns tol Air mixture concentration too

lean.

l Check ECI-MULTI system.0 Incomplete close contact of in-

take exhaust valve seat.l Check and repair the valve.

l Broken cylinder head gasketl Replace cylinder head gasket.

Page 359 of 1216

_-

a--ENGINE

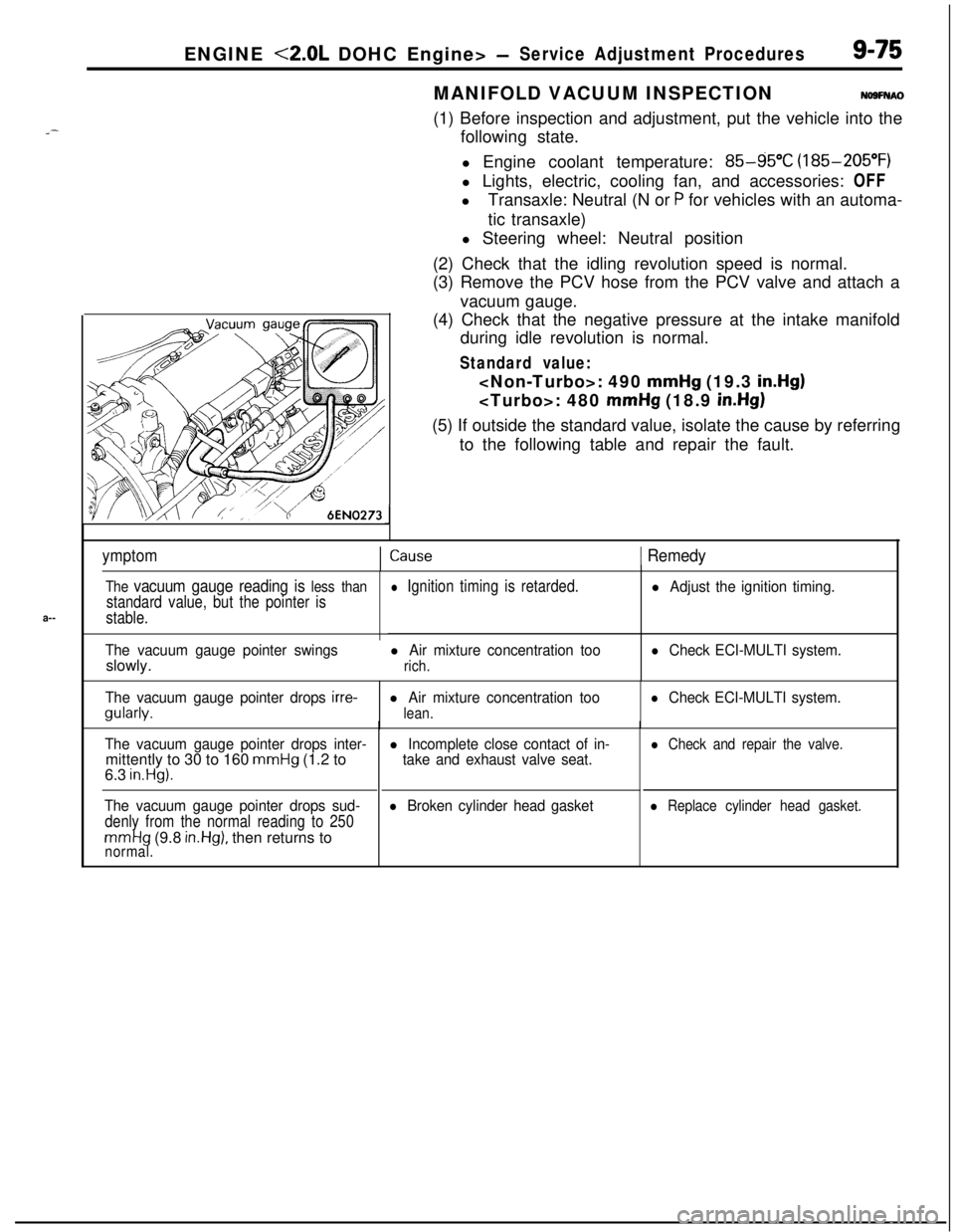

<2.0L DOHC Engine> -Service Adjustment Procedures9-75

JMANIFOLD VACUUM INSPECTION

NO9FNAO(1) Before inspection and adjustment, put the vehicle into the

following state.

l Engine coolant temperature:

85-g5”C (185-205°F)

l Lights, electric, cooling fan, and accessories: OFF

lTransaxle: Neutral (N or

P for vehicles with an automa-

tic transaxle)

l Steering wheel: Neutral position

(2) Check that the idling revolution speed is normal.

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value:

mmHg (19.3 in.Hg)

mmHg (18.9 in.Hg)(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

ymptomICause1 Remedy

The vacuum gauge reading is less than

standard value, but the pointer is

stable.

The vacuum gauge pointer swingsslowly.

l Ignition timing is retarded.

l Air mixture concentration too

rich.

l Adjust the ignition timing.

l Check ECI-MULTI system.

The vacuum gauge pointer drops

irre-gularly.l Air mixture concentration too

lean.

l Check ECI-MULTI system.

The vacuum gauge pointer drops inter-mittently to 30 to 160

mmHg (1.2 to

6.3 in.Hg).

The vacuum gauge pointer drops sud-

denly from the normal reading to 250

mmHg (9.8 in.Hg), then returns tonormal.

l Incomplete close contact of in-

take and exhaust valve seat.

l Broken cylinder head gasket

l Check and repair the valve.

l Replace cylinder head gasket.

Page 456 of 1216

14-2FUEL SYSTEM - Specifications

FUEL SYSTEM

SPECIFICATIONS

GENERAL SPECIFICATIONSNW%-

4.8L Engine>

Items

Fuel

Tank capacity

Return system

Filter

Fuel pump

Type

Driven by

Throttle bodyThrottle

bore

Throttle position sensor

Idle speed control servo

Idle position switchMotor position

sensor

Engine control unitIdentification

model No.

For Federal and Canada

For California

SensorsAir flow

sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensorOxygen

sensor

Vehicle speed sensorInhibitor switch

No. 1 cylinder top dead center sensor

Crank angle sensor

EGR temperature sensor

Control relay type

Injector type and number

Injector identification mark

Purge control solenoid valve

EGR control solenoid valve

Fuel pressure regulator

Regulated pressure

Specificationsliter

(gal.) 60 (15.9)

Equipped

High pressure type

Electrical, in-tank type

Electric motor

mm (in.) 50 (1.97)

Variable resistor type

Electric motor

Contact type, within idle speed control servo

Variable resistor type

E2T33674

E2T33673

Karman vortex type

Semiconductor diffusion typeThermistor typeThermistor type

Zirconia type

Reed switch type

Contact switch type

Photo interrupter type

Photo interrupter typeThermistor type

Contact switch type

Electromagnetic, 4

N210H

ON/OFF type solenoid valveDuty

cycle type solenoid valve

kPa (psi) 335 (47.6)

Page 457 of 1216

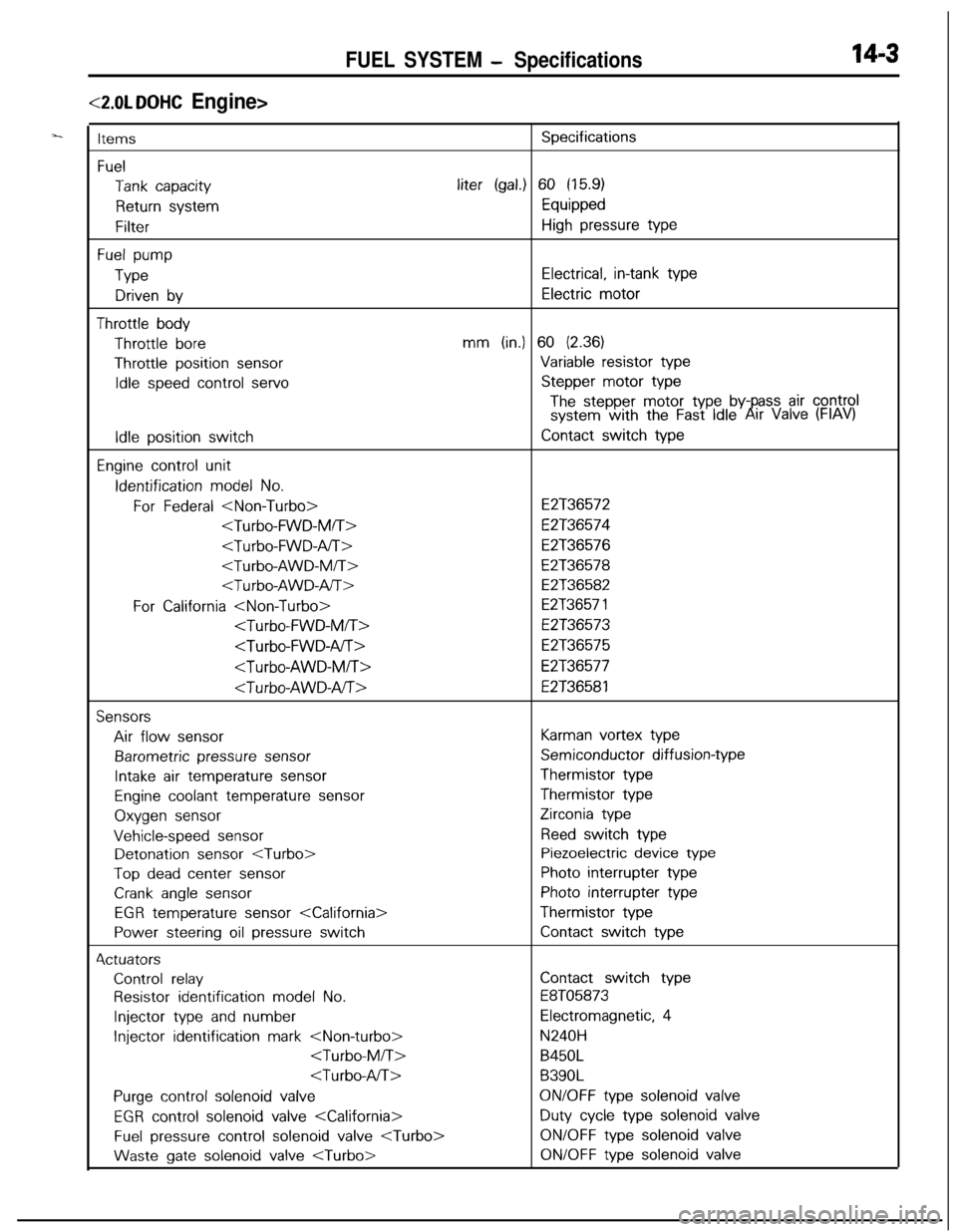

FUEL SYSTEM - Specifications14-3

<2.0L DOHC Engine>

ItemsSpecifications

Fuel

Tank capacityliter (gal.) 60 (15.9)

Return systemEquipped

FilterHigh pressure type

Fuel pump

TypeElectrical, in-tank type

Driven byElectric motor

Throttle bodyThrottle

boremm (in.) 60 (2.36)Throttle position

sensorVariable resistor type

Idle speed control servoStepper motor type

The stepper motor type by- ass air controlsystem with the Fast Idle6!rr Valve (FIAV)

Idle position switchContact switch type

Engine control unitIdentification

model No.

For Federal

E2T36574

E2T36576

E2T36578

E2T36582

For California

E2T36573

E2T36575

E2T36577

E2T36581

SensorsAir flow

sensorKarman vortex type

Barometric pressure sensorSemiconductor diffusion-type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Vehicle-speed sensorReed switch typeDetonation

sensor

Top dead center sensorPhoto interrupter type

Crank angle sensorPhoto interrupter type

EGR temperature sensor

Power steering oil pressure switchContact switch type4ctuators

Control relayContact switch type

Resistor identification model No.E8T05873

Injector type and numberElectromagnetic, 4

Injector identification mark

B450L

B390L

Purge control solenoid valveON/OFF type solenoid valve

EGR control solenoid valve

Fuel pressure control solenoid valve

gate solenoid valve

Page 459 of 1216

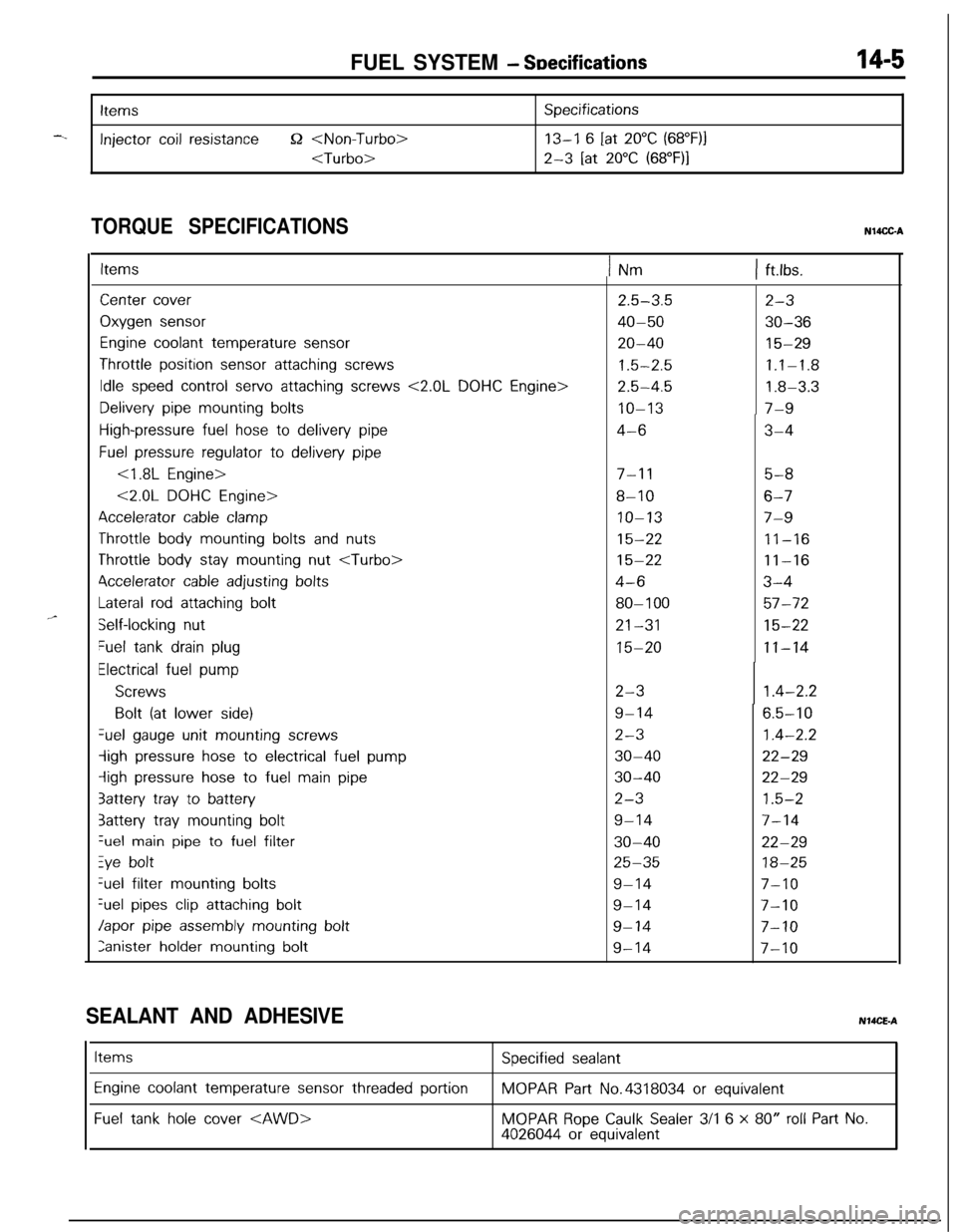

FUEL SYSTEM - SDecifications14-5

-.

Items

Injector coil resistance52

Specifications

13-I 6 [at 20°C (68”F)j

2-3 [at 20°C (68”F)I

TORQUE SPECIFICATIONSN14CC-A

,,-

ItemsINm1 ft.lbs.

Center cover

Oxygen sensor

Engine coolant temperature sensor

Throttle position sensor attaching screws

Idle speed control servo attaching screws <2.0L DOHC Engine>

Delivery pipe mounting bolts

High-pressure fuel hose to delivery pipe

Fuel pressure regulator to delivery pipe

<1.8L Engine>

<2.0L DOHC Engine>

Accelerator cable clamp

Throttle body mounting bolts and nuts

Throttle body stay mounting nut

4ccelerator cable adjusting bolts

Lateral rod attaching bolt

Self-locking nut

Fuel tank drain plug

Electrical fuel pump

Screws

Bolt (at lower side)Gel

gauge unit mounting screws

-ligh pressure hose to electrical fuel pump

iigh pressure hose to fuel main pipe

3attery tray to battery

3attery tray mounting boltGel

main pipe to fuel filter

Zye boltGel filter

mounting bolts

%el pipes clip attaching bolt

Japor pipe assembly mounting bolt

Ianister holder mounting bolt

2.5-3.5

40-50

20-40

1.5-2.5

2.5-4.5

IO-13

4-6

7-l 15-8

8-106-7

IO-137-9

15-2211-16

15-2211-16

4-63-4

80-l 0057-72

21-3115-22

15-2011-14

2-3

9-14

2-3

30-40

30-40

2-3

9-14

30-40

25-35

9-14

9-14

9-14

9-14

2-3

30-36

15-29

1.1-1.8

1.8-3.3

7-9

3-4

1.4-2.2

6.5-10

1.4-2.2

22-29

22-29

1.5-2

7-14

22-29

18-25

7-10

7-10

7-10

7-10

SEALANT AND ADHESIVENMCE-A

Items

Engine coolant temperature sensor threaded portion

Fuel tank hole cover

Specified sealant

MOPAR Part No.4318034 or equivalent

MOPAR Rope Caulk Sealer 3/l 6 x 80” roll Part No.4026044 or equivalent

Page 495 of 1216

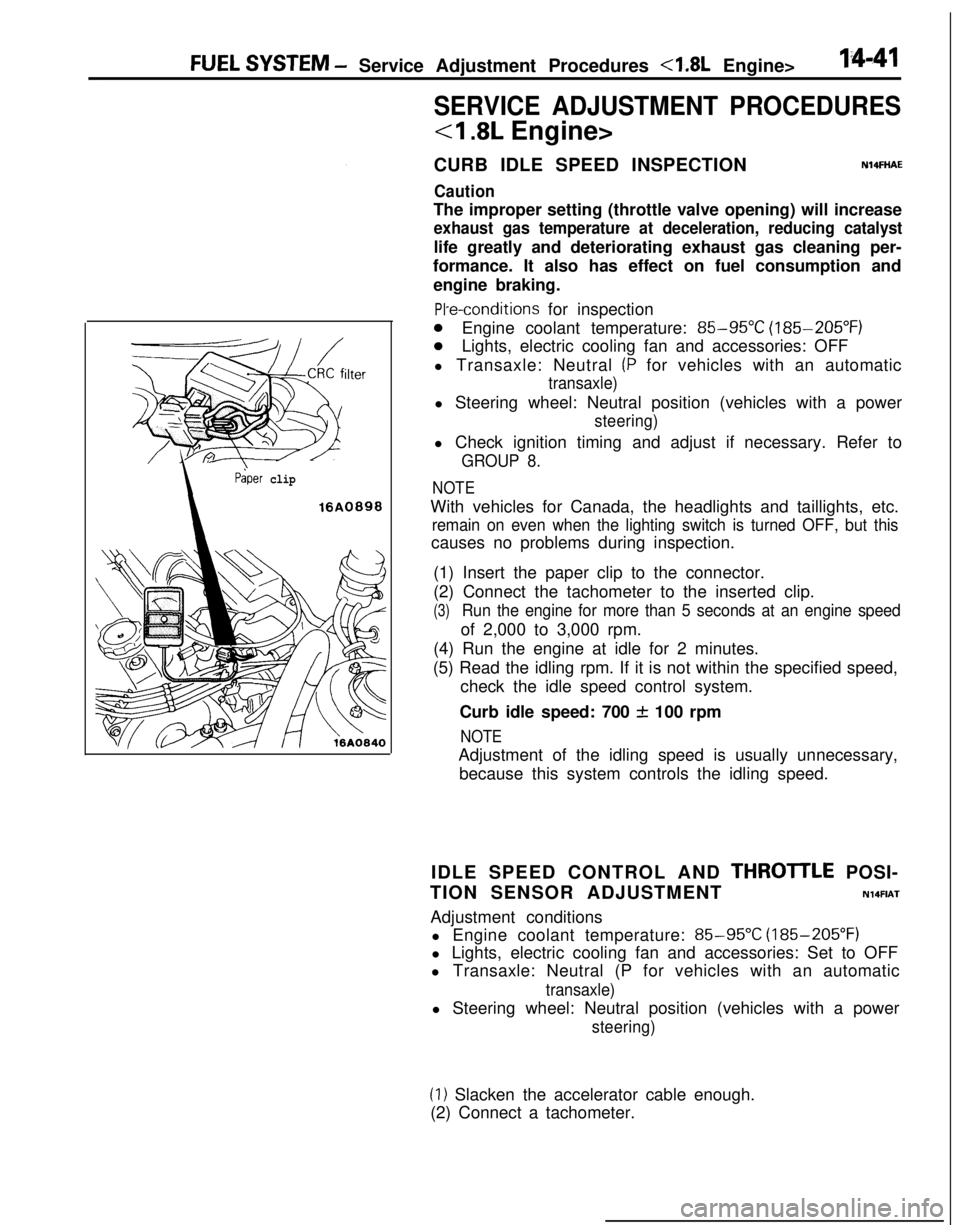

FUEL SYSTEM - Service Adjustment Procedures <1.8L Engine>l-4-41

SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

CautionNlIFiiAE

The improper setting (throttle valve opening) will increase

exhaust gas temperature at deceleration, reducing catalystlife greatly and deteriorating exhaust gas cleaning per-

formance. It also has effect on fuel consumption and

engine braking.

ilter

Paper clip

16A0898

PI-e-conditions for inspection

0Engine coolant temperature: 85-95°C (185-205°F)

0Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)l Steering wheel: Neutral position (vehicles with a power

steering)l Check ignition timing and adjust if necessary. Refer to

GROUP 8.

NOTEWith vehicles for Canada, the headlights and taillights, etc.

remain on even when the lighting switch is turned OFF, but thiscauses no problems during inspection.

(1) Insert the paper clip to the connector.

(2) Connect the tachometer to the inserted clip.

(3)Run the engine for more than 5 seconds at an engine speedof 2,000 to 3,000 rpm.

(4) Run the engine at idle for 2 minutes.

(5) Read the idling rpm. If it is not within the specified speed,

check the idle speed control system.

Curb idle speed: 700

f 100 rpm

NOTEAdjustment of the idling speed is usually unnecessary,

because this system controls the idling speed.

IDLE SPEED CONTROL AND

THROTlLE POSI-

TION SENSOR ADJUSTMENT

N14FIATAdjustment conditions

l Engine coolant temperature:

85-95X (185-205°F)

l Lights, electric cooling fan and accessories: Set to OFF

l Transaxle: Neutral (P for vehicles with an automatic

transaxle)l Steering wheel: Neutral position (vehicles with a power

steering)

(1) Slacken the accelerator cable enough.

(2) Connect a tachometer.

Page 502 of 1216

14-48FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>

SERVICE ADJUSTMENT PROCEDURES

<2.0L DOHC Engine>

CURB IDLE SPEED INSPECTION

Caution

N14FHADThe improper setting (throttle valve opening) will increase

exhaust gas temperature at deceleration, reducing

catalys-tic converter life greatly and deteriorating exhaust gas

cleaning performance. It also has effect on fuel ‘consump-

tion and engine braking.

Pre-conditions for inspection

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

lTransaxle: Neutral (P for vehicles with automatic transaxle)l Steering wheel: Neutral position (vehicles with a power-

steering)l Check ignition timing and adjust if necessary. Refer to

GROUP 8.

NOTEWith vehicles for Canada, the headlights and taillights, etc.

remain on even when the lighting switch is turned OFF, but thiscauses no problems during inspection.

(1) Connect the tachometer to the engine speed detection

terminal.

(2)Run the engine for more than 5 seconds at an engine speedof 2,000 to 3,000 rpm.

(3) Run the engine at idle for 2 minutes.

(4) Read the idling rpm. If it is not within the specified speed,

check the idle speed control system.

Curb idle speed:

750f 100 rpm

NOTE1. Adjustment of the idling speed is usually unnecessary,

because this system controls the idling speed.

2.For rpm, one-half of the actual engine rpm is indicated,so the actual engine rpm is two times the indicated

value shown by the tachometer.

BASIC IDLE SPEED ADJUSTMENT

N14FHBIPre-conditions for inspection

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan, and accessories: OFF

lTransaxle: Neutral (P for vehicles with automatic transaxle)l Steerig wheel: Neutral position (vehicles with a

power-

steering)(1) Connect a tachometer.

Page 547 of 1216

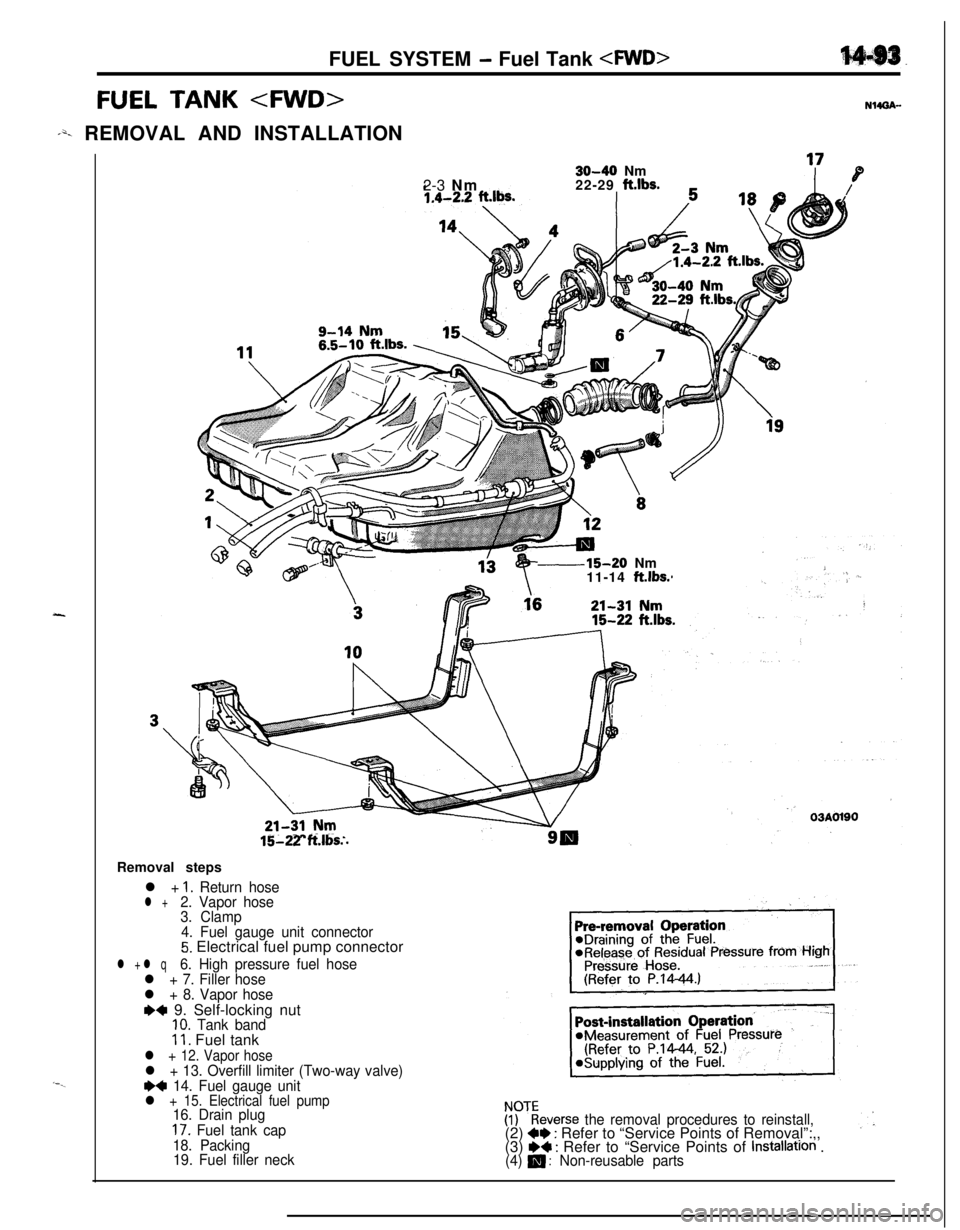

FUEL SYSTEM - Fuel Tank

FUEL TANK cFWD>

,*. REMOVAL AND INSTALLATION

q?&g

NlMA-30-40 Nm

2-3 Nm22-29 ft.lbs.

---15-20 Nm

11-14 ft.lbs.

15-22 ft.lbs.Removal steps

l + 1. Return hosel +2. Vapor hose

3. Clamp

4. Fuel gauge unit connector

5. Electrical fuel pump connector

l + l q6. High pressure fuel hose

l + 7. Filler hose

l + 8. Vapor hose

~~ 9. Self-locking nut10. Tank band11. Fuel tank

l + 12. Vapor hosel + 13. Overfill limiter (Two-way valve)I)+ 14. Fuel gauge unitl + 15. Electrical fuel pump16. Drain plug

17. Fuel tank cap

18. Packing

19. Fuel filler neck$TEeverse the removal procedures to reinstall,(2) +e : Refer to “Service Points of Removal”:,,

(3) *+ : Refer to “Service Points of lnstallatlon .(4) m : Non-reusable parts

Page 548 of 1216

14-94FUEL SYSTEM - Fuel Tank

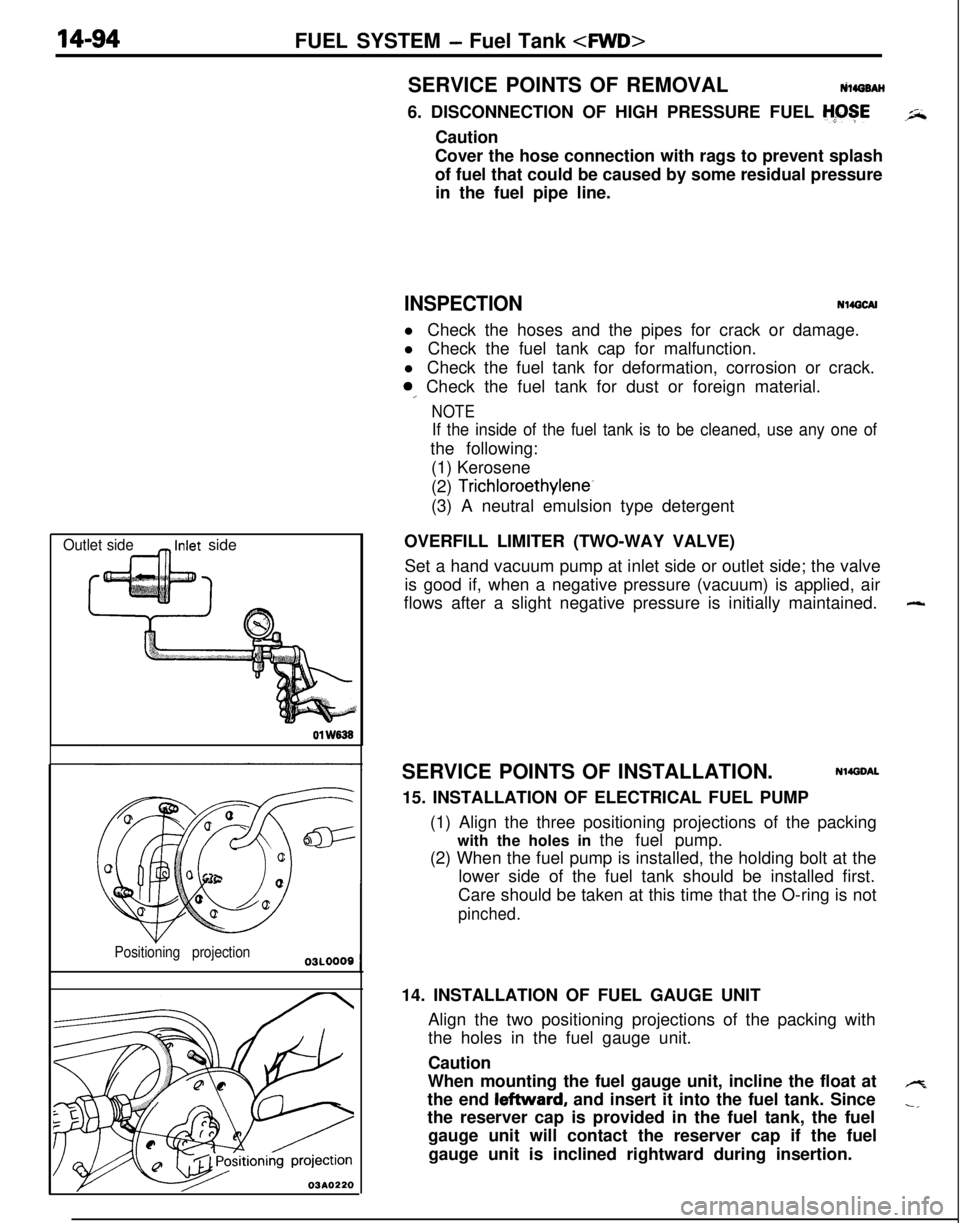

Outlet side_ Inlet side01

W838

Positioning projection

03A0220SERVICE POINTS OF REMOVALtilirro8AH

6. DISCONNECTION OF HIGH PRESSURE FUEL

H;OSECaution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

INSPECTIONN14GCAll Check the hoses and the pipes for crack or damage.

l Check the fuel tank cap for malfunction.

l Check the fuel tank for deformation, corrosion or crack.

0,. Check the fuel tank for dust or foreign material.

NOTE

If the inside of the fuel tank is to be cleaned, use any one ofthe following:

(1) Kerosene

(2)

Trichloroethylene-(3) A neutral emulsion type detergent

OVERFILL LIMITER (TWO-WAY VALVE)

Set a hand vacuum pump at inlet side or outlet side; the valve

is good if, when a negative pressure (vacuum) is applied, air

flows after a slight negative pressure is initially maintained.

SERVICE POINTS OF INSTALLATION.

Nl4DDAL15. INSTALLATION OF ELECTRICAL FUEL PUMP

(1) Align the three positioning projections of the packing

with the holes in the fuel pump.

(2) When the fuel pump is installed, the holding bolt at the

lower side of the fuel tank should be installed first.

Care should be taken at this time that the O-ring is not

pinched.14. INSTALLATION OF FUEL GAUGE UNIT

Align the two positioning projections of the packing with

the holes in the fuel gauge unit.

Caution

When mounting the fuel gauge unit, incline the float at

the end leftward, and insert it into the fuel tank. Since

the reserver cap is provided in the fuel tank, the fuel

gauge unit will contact the reserver cap if the fuel

gauge unit is inclined rightward during insertion.

-

4

-,