wheel torque MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 657 of 1216

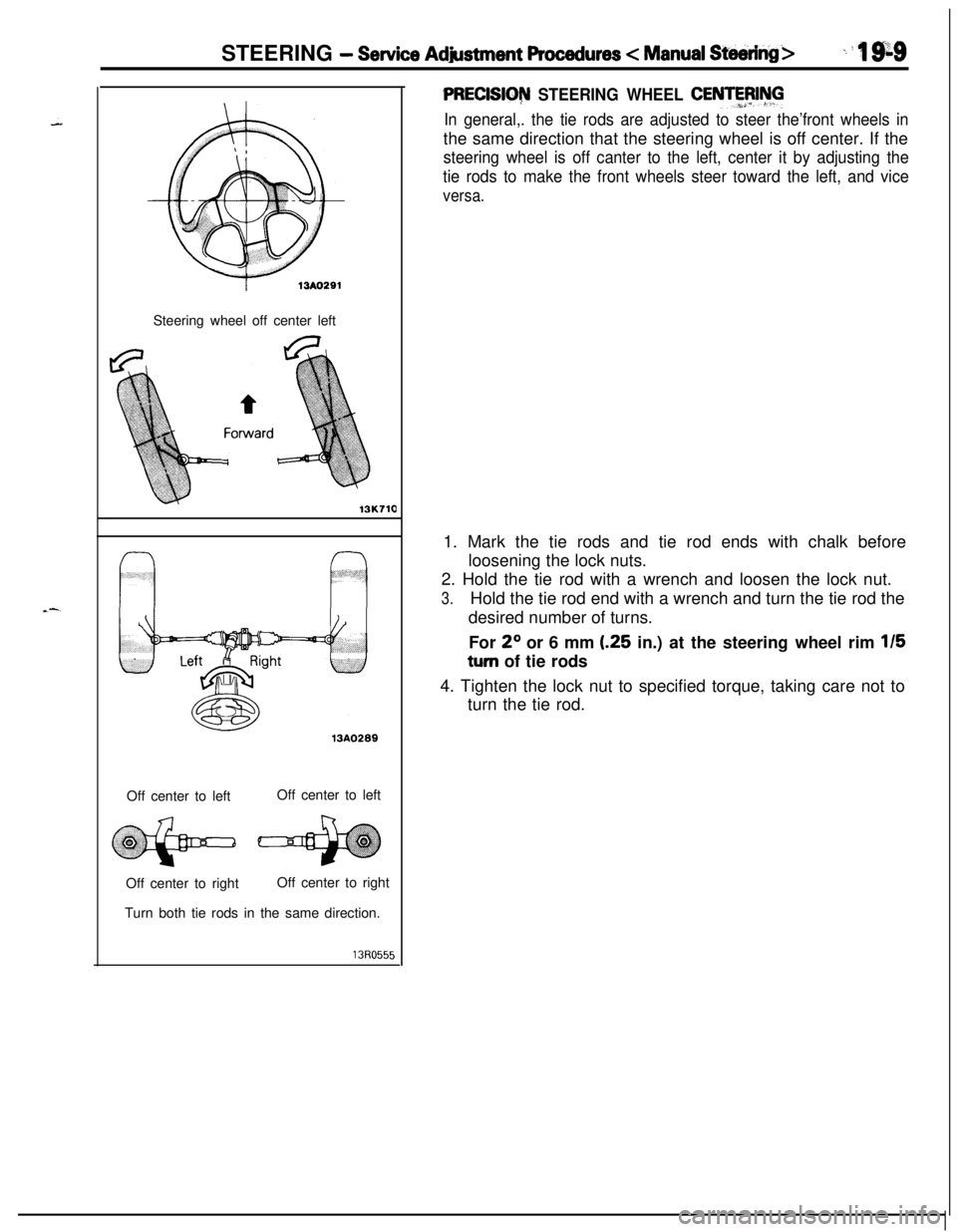

STEERING - Service Adjustment Procedures < Manual Steering>_ i ‘I 9;sSteering wheel off center left

13K71013A0289

Off center to leftOff center to left

Off center to rightOff center to right

Turn both tie rods in the same direction.

PRECISIG~ STEERING WHEEL CENTFFJIhll

In general,. the tie rods are adjusted to steer the’front wheels inthe same direction that the steering wheel is off center. If the

steering wheel is off canter to the left, center it by adjusting the

tie rods to make the front wheels steer toward the left, and vice

versa.1. Mark the tie rods and tie rod ends with chalk before

loosening the lock nuts.

2. Hold the tie rod with a wrench and loosen the lock nut.

3.Hold the tie rod end with a wrench and turn the tie rod the

desired number of turns.

For

2O or 6 mm (.25 in.) at the steering wheel rim 115

turn of tie rods

4. Tighten the lock nut to specified torque, taking care not to

turn the tie rod.

Page 658 of 1216

19-10STEERING - Service Adjustment Procedures c Power Steering>

r13A029213A0293

r

1

i

SERVICE ADJUSTMENT PROCEDURES

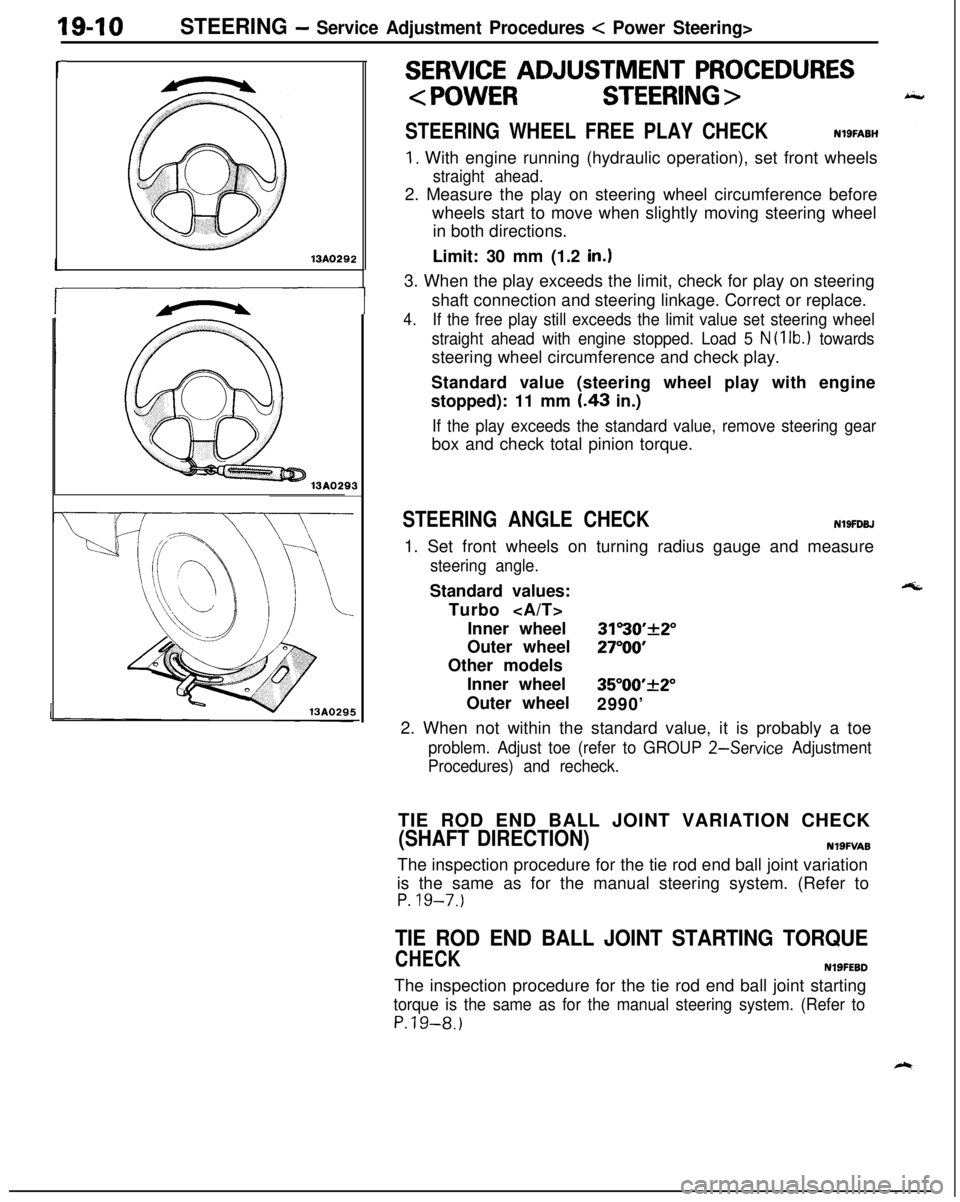

STEERING WHEEL FREE PLAY CHECKNlSFABH

1. With engine running (hydraulic operation), set front wheels

straight ahead.2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm (1.2

in.13. When the play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4.If the free play still exceeds the limit value set steering wheel

straight ahead with engine stopped. Load 5

N (1 lb.1 towardssteering wheel circumference and check play.

Standard value (steering wheel play with engine

stopped): 11 mm

I.43 in.)

If the play exceeds the standard value, remove steering gearbox and check total pinion torque.

STEERING ANGLE CHECKN19FDBJ1. Set front wheels on turning radius gauge and measure

steering angle.Standard values:

Turbo

Inner wheel

31”30’+2”Outer wheel

27”OOOther models

Inner wheel

35”00’_+2”Outer wheel

2990’

2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 2-Service Adjustment

Procedures) and recheck.TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)N19FVA8The inspection procedure for the tie rod end ball joint variation

is the same as for the manual steering system. (Refer to

P. 19-7.)

TIE ROD END BALL JOINT STARTING TORQUE

CHECKNlSFEBDThe inspection procedure for the tie rod end ball joint starting

torque is the same as for the manual steering system. (Refer to

P.19-8.)

Page 662 of 1216

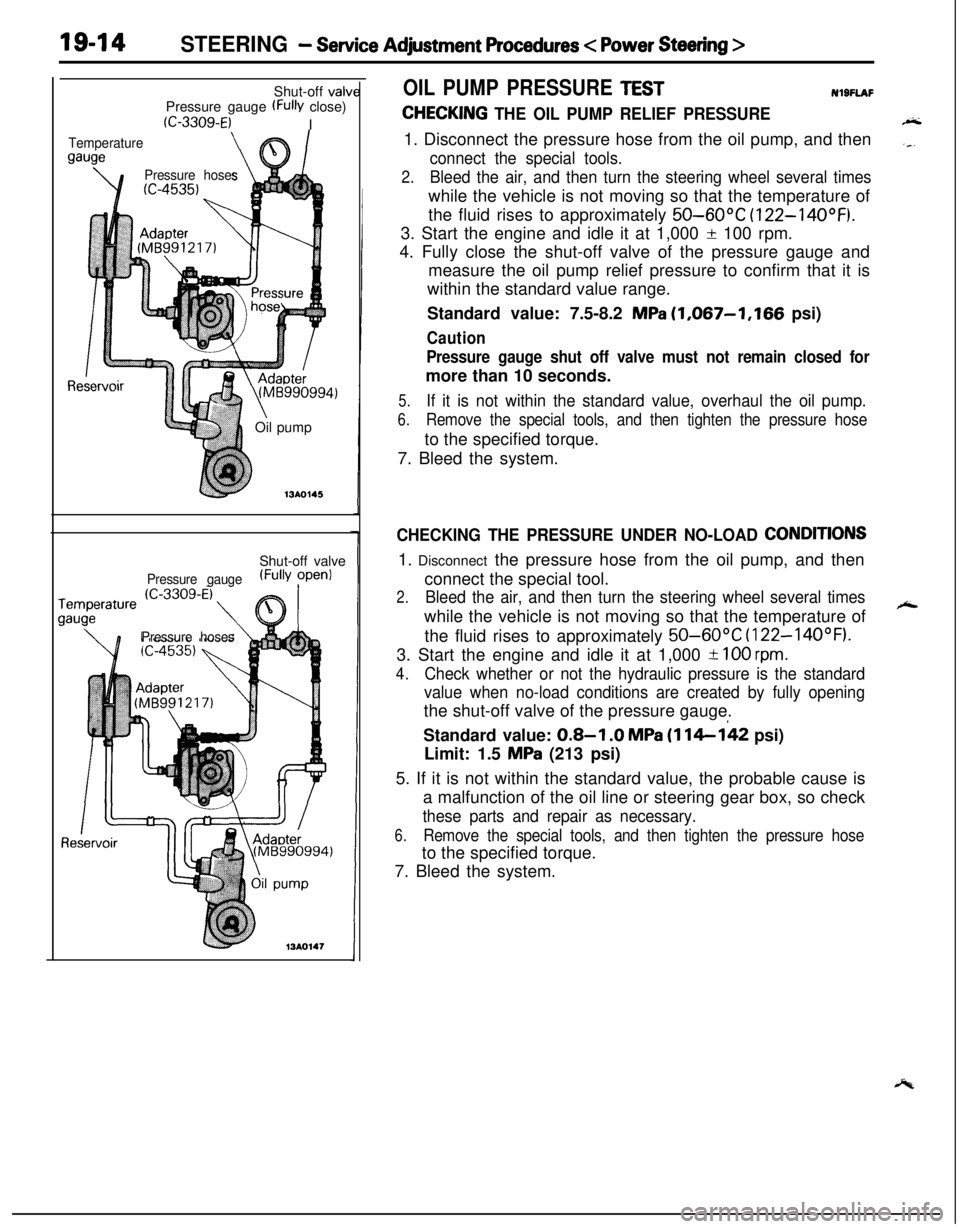

19-14STEERING - Service Adjustment Procedures < Power Steering >Shut-off valv

Pressure gauge

(FW close)

(C-3309-E)I

Temperature

gauge

\e’\

Pressure hoses

Re(Mti990994)

\Oil pump

713AO145Shut-off valve

Pressure gauge(FullY ?penl

Pressure hoses

OIL PUMP PRESSURE TESTNl9FlAF

CHECKING THE OIL PUMP RELIEF PRESSURE1. Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. Start the engine and idle it at 1,000

f 100 rpm.

4. Fully close the shut-off valve of the pressure gauge and

measure the oil pump relief pressure to confirm that it is

within the standard value range.

Standard value: 7.5-8.2

MPa (1,067-1,166 psi)

Caution

Pressure gauge shut off valve must not remain closed formore than 10 seconds.

5.If it is not within the standard value, overhaul the oil pump.

6.Remove the special tools, and then tighten the pressure hoseto the specified torque.

7. Bleed the system.

CHECKING THE PRESSURE UNDER NO-LOAD CONDITIONS1. Disconnect the pressure hose from the oil pump, and then

connect the special tool.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. Start the engine and idle it at 1,000

-t 100 rpm.

4.

Check whether or not the hydraulic pressure is the standard

value when no-load conditions are created by fully openingthe shut-off valve of the pressure gauge.

Standard value:

0.8-I .O MPa (114-142 psi)

Limit: 1.5

MPa (213 psi)

5. If it is not within the standard value, the probable cause is

a malfunction of the oil line or steering gear box, so check

these parts and repair as necessary.

6.Remove the special tools, and then tighten the pressure hoseto the specified torque.

7. Bleed the system.

Page 663 of 1216

-

c. .

STEERING - Service Adiustment Procedures

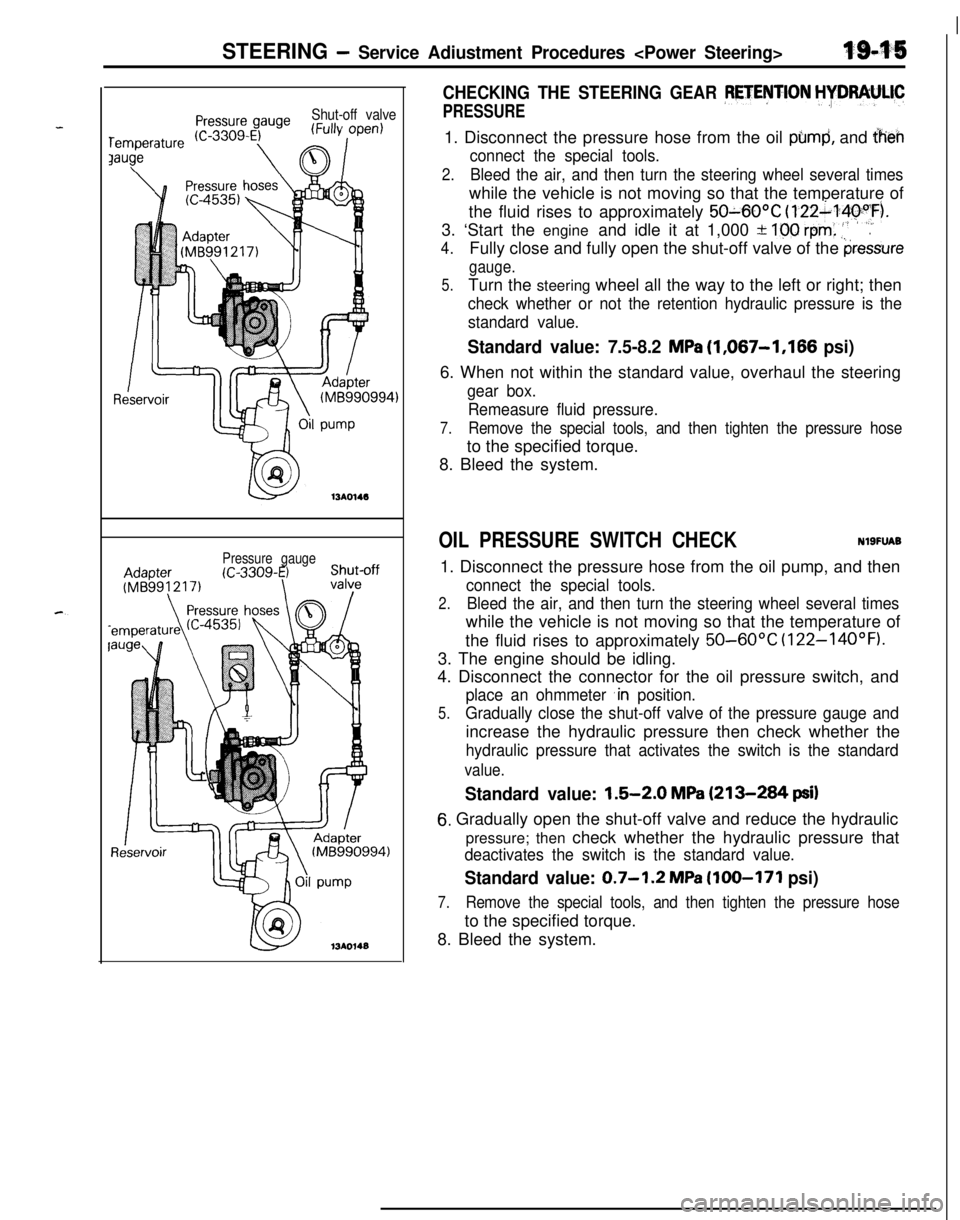

Shut-off valve

Pressure gauge

CHECKING THE STEERING GEAR PETENTION HYDRAULIC

PRESSURE1. Disconnect the pressure hose from the oil

pbmd, and iheh

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50~60OC (122~14pyF).

3. ‘Start the engine and idle it at 1,000 +

100 rem: .‘,’.

4.Fully close and fully open the shut-off valve of the pressure

gauge.

5.Turn the steering wheel all the way to the left or right; then

check whether or not the retention hydraulic pressure is the

standard value.

Standard value: 7.5-8.2 MPa (1,067-1,166 psi)6. When not within the standard value, overhaul the steering

gear box.

Remeasure fluid pressure.

7.Remove the special tools, and then tighten the pressure hoseto the specified torque.

8. Bleed the system.

OIL PRESSURE SWITCH CHECKNlSFUAB1. Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. The engine should be idling.

4. Disconnect the connector for the oil pressure switch, and

place an ohmmeter ,in position.

5.Gradually close the shut-off valve of the pressure gauge andincrease the hydraulic pressure then check whether the

hydraulic pressure that activates the switch is the standard

value.

Standard value: 1.5-2.0 MPa (213-284 psi)

6. Gradually open the shut-off valve and reduce the hydraulic

pressure; then check whether the hydraulic pressure that

deactivates the switch is the standard value.

Standard value: 0.7-1.2 MPa (100-171 psi)

7.Remove the special tools, and then tighten the pressure hoseto the specified torque.

8. Bleed the system.

Page 896 of 1216

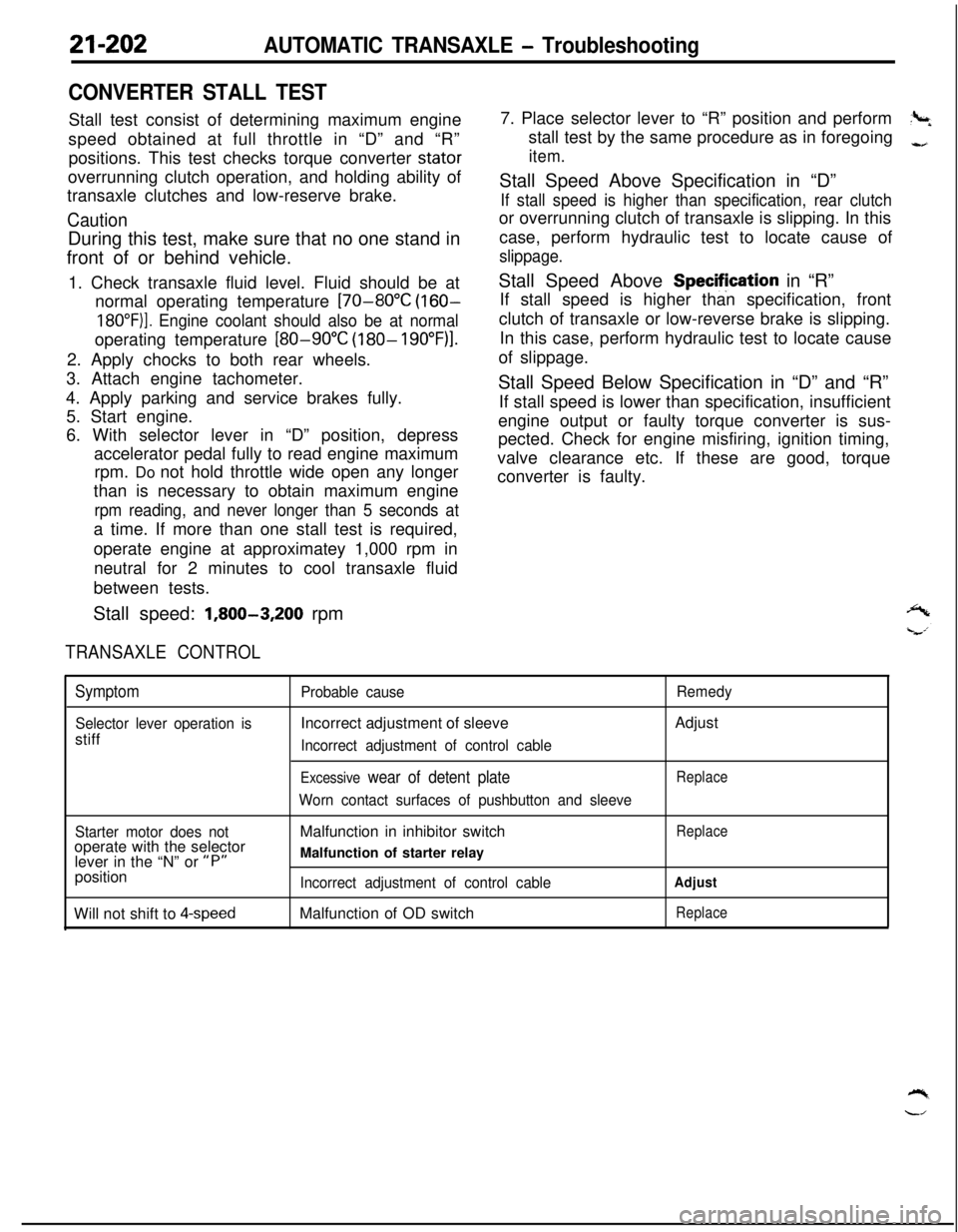

21-202AUTOMATIC TRANSAXLE - Troubleshooting

CONVERTER STALL TESTStall test consist of determining maximum engine

speed obtained at full throttle in “D” and “R”

positions. This test checks torque converter stator

overrunning clutch operation, and holding ability of

transaxle clutches and low-reserve brake.

CautionDuring this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature

[70-80°C (160-

18O”F)]. Engine coolant should also be at normaloperating temperature

[80-90°C (180- 19O”F)l.2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds ata time. If more than one stall test is required,

operate engine at approximatey 1,000 rpm in

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed:

1,800-3,200 rpm

TRANSAXLE CONTROL7. Place selector lever to “R” position and perform

?+stall test by the same procedure as in foregoing

-,

item.Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutchor overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.Stall Speed Above Specifjcation in “R”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping.

In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance etc. If these are good, torque

converter is faulty.

Symptom

Selector lever operation isstiff

Probable causeIncorrect adjustment of sleeve

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton and sleeveRemedyAdjust

Replace

Starter motor does notoperate with the selector

lever in the “N” or

“P”position

Will not shift to

4-speedMalfunction in inhibitor switch

Malfunction of starter relay

Incorrect adjustment of control cableMalfunction of OD switch

Replace

Adjust

Replace

Page 1039 of 1216

22-l-.

WHEELS

AND TIRES

CONTENTSNZZAA-

SERVICE ADJUSTMENT PROCEDURES.......4TROUBLESHOOTING......................................3

Tire

InflationPressureCheck......................4Bald Spots

TireWearCheck..........................................4Cracked Treads

Wheel

RunoutCheck...................................4Feathered Edge

SPECIFICATIONSRapid Wear at Center.............................................2

General

Specifications..................................2Rapid Wear at Shoulders

ServiceSpecificationsScalloped Wear...................................2Wear on One Side

7TorqueSpecifications...................................2

WHEEL AND TIRE..........................................5

Page 1040 of 1216

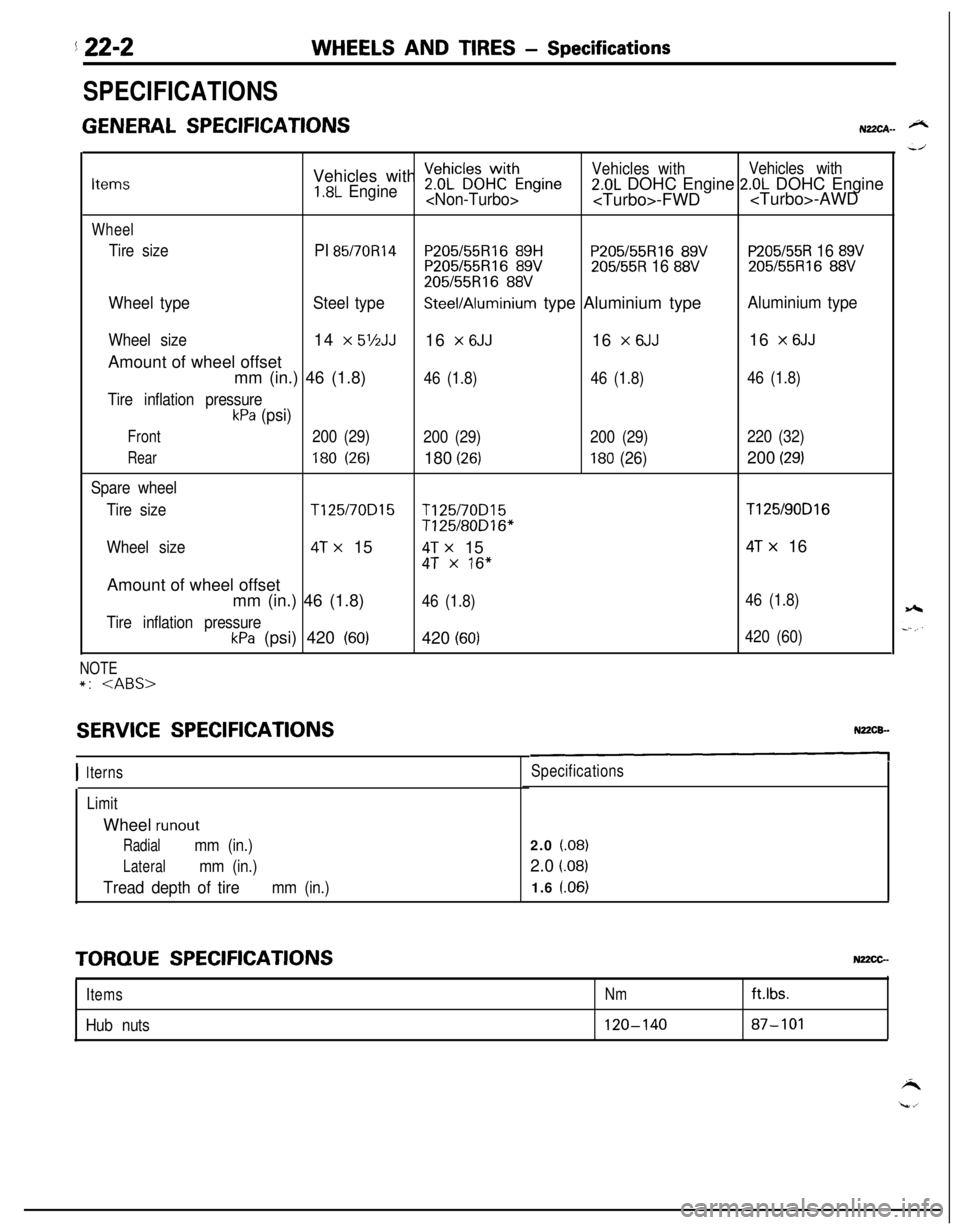

5 22-2WHEELS AND TIRES - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSN22CA- @NVehicles with

~eDhL”~~HWCthEngineVehicles withVehicles withItems1.8L Engine2.0L DOHC Engine 2.0L DOHC Engine

Wheel

Tire sizePI 85/70R14P205155Rl6 89HP205/55R16 89VP205/55R 16 89VP205155R16 89V205/55R 16 88V205/55R16 88V

205/55R16 88V

Wheel typeSteel typeSteel/Aluminium type Aluminium typeAluminium type

Wheel size14 x 5’/2JJ16 x 6JJ16 x 6JJ16 x 6JJAmount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi)

Front200 (29)

200 (29)200 (29)220 (32)

Rear180 (26)180 (26)180 (26)200 (29)

Spare wheel

Tire size

T125/70D15T125/70D15T125/90D16

T125/80D16*

Wheel size

4T x 154T x 154T x 16

4T x 16”Amount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi) 420 (60)420 (60)420 (60)

NOTE*:

SERVICE SPECIFICATIONS

I 1terns

LimitWheel

runout

Radialmm (in.)

Lateralmm (in.)

Tread depth of tiremm (in.)

Specifications2.0

(.08)2.0

i.08)1.6 l.06)

TORQUE SPECIFICATIONSNz2cG-

ItemsNm

Hub nuts120-140ftlbs.87-101