wheel torque MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 613 of 1216

Special Tools/Troubleshooting/REAR SUSPENSION

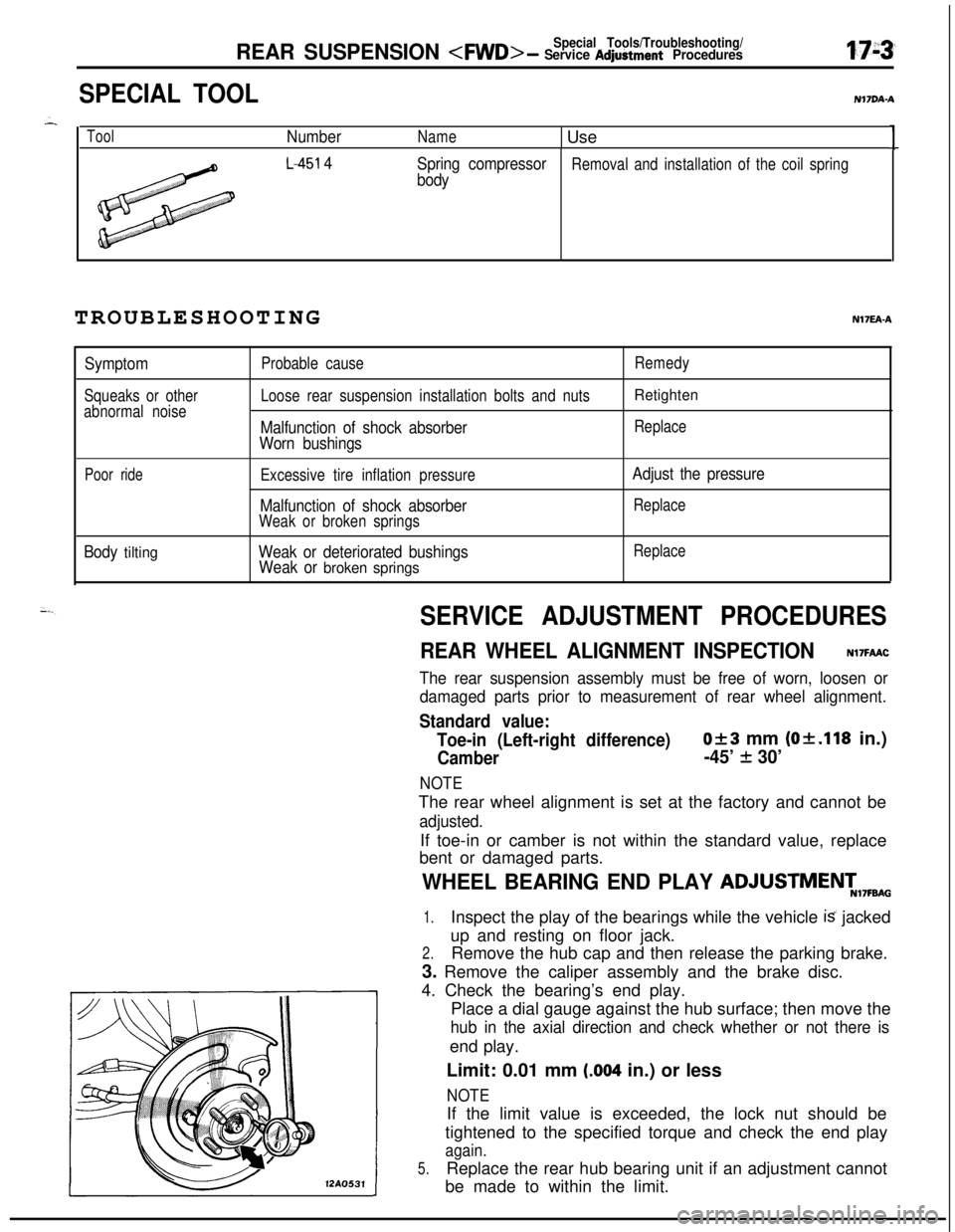

SPECIAL TOOLN17DA.A

ToolNumberName1 Use1

L-451 4

Spring compressorRemoval and installation of the coil spring

bodyTROUBLESHOOTINGNI’IEA-A

Symptom

Squeaks or other

abnormal noiseProbable cause

Loose rear suspension installation bolts and nuts

Malfunction of shock absorber

Worn bushings

Remedy

Retighten

Replace

Poor rideExcessive tire inflation pressure

Malfunction of shock absorberWeak or broken springs

Adjust the pressure

Replace

Body tiltingWeak or deteriorated bushings

Weak or broken springs

Replace

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FAAC

The rear suspension assembly must be free of worn, loosen or

damaged parts prior to measurement of rear wheel alignment.

Standard value:

Toe-in (Left-right difference)

Of3 mm (Of.118 in.)

Camber-45’ + 30’

NOTEThe rear wheel alignment is set at the factory and cannot be

adjusted.If toe-in or camber is not within the standard value, replace

bent or damaged parts.

WHEEL BEARING END PLAY ADJUSTMENT,7FBA0

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2.Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there isend play.

Limit: 0.01 mm

(.004 in.) or less

NOTE12AO531If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

Page 615 of 1216

REAR SUSPENSION

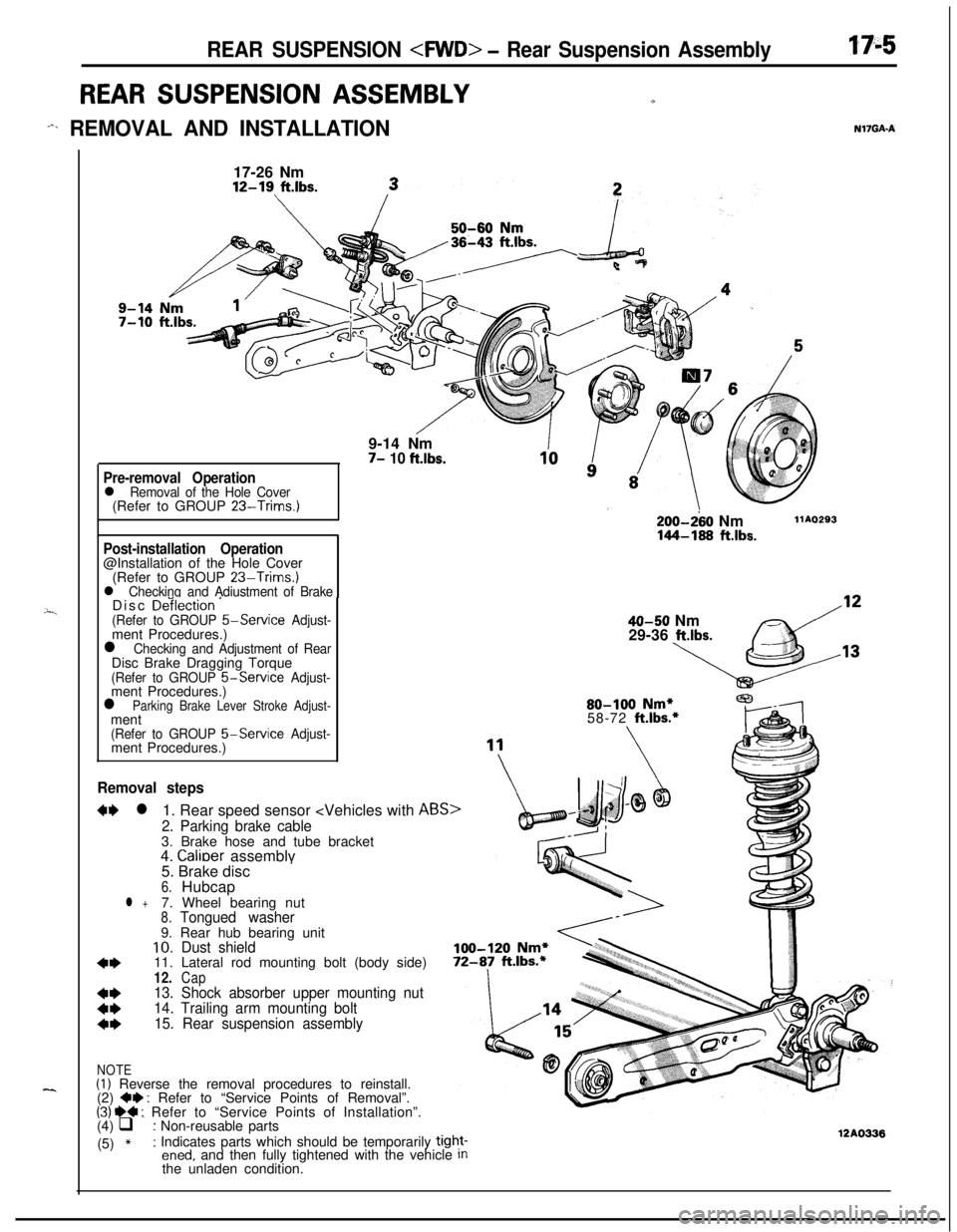

REAR SUSPENSION ASSEMBLYu

-%. REMOVAL AND INSTALLATIONN17GAA

---i

--..17-26 Nm12-19

ft.lbs.9-14 Nm

7- 10 ft.lbs.

Pre-removal Operationl Removal of the Hole Cover(Refer to GROUP 23-Trims.)

Post-installation Operation@Installation of the Hole Cover

(Refer to GROUP

23-Trims.)l Checking and Adiustment of BrakeDisc De‘ilection ’(Refer to GROUP 5-Service Adjust-ment Procedures.)

l Checking and Adjustment of RearDisc Brake Dragging Torque

(Refer to GROUP &Service Adjust-ment Procedures.)

l Parking Brake Lever Stroke Adjust-ment

(Refer to GROUP 5-Service Adjust-ment Procedures.)

Removal steps

W l1. Rear speed sensor

2. Parking brake cable3. Brake hose and tube bracket

4.

Calioer assemblv

200-280 Nm144-168 ftlbs.

llAO293

40-50 Nm

29-36 ltlbs.80-100

Nm*58-72 ft.lbs.*5. Brake disc

’6.Hubcapl +7. Wheel bearing nut8.Tongued washer9. Rear hub bearing unit

10.Dust shield

4*11. Lateral rod mounting bolt (body side)12.Cap

t:

13. Shock absorber upper mounting nut

14. Trailing arm mounting bolt

4*15. Rear suspension assembly

NOTE(I) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”.(31 ~~ : Refer to “Service Points of Installation”.

(4) q : Non-reusable parts

(5)

*: Indicates parts which should be temporarily tight-ened, and then fully tightened with the vehicle Inthe unladen condition.12AO336

Page 622 of 1216

17-12REAR SUSPENSION

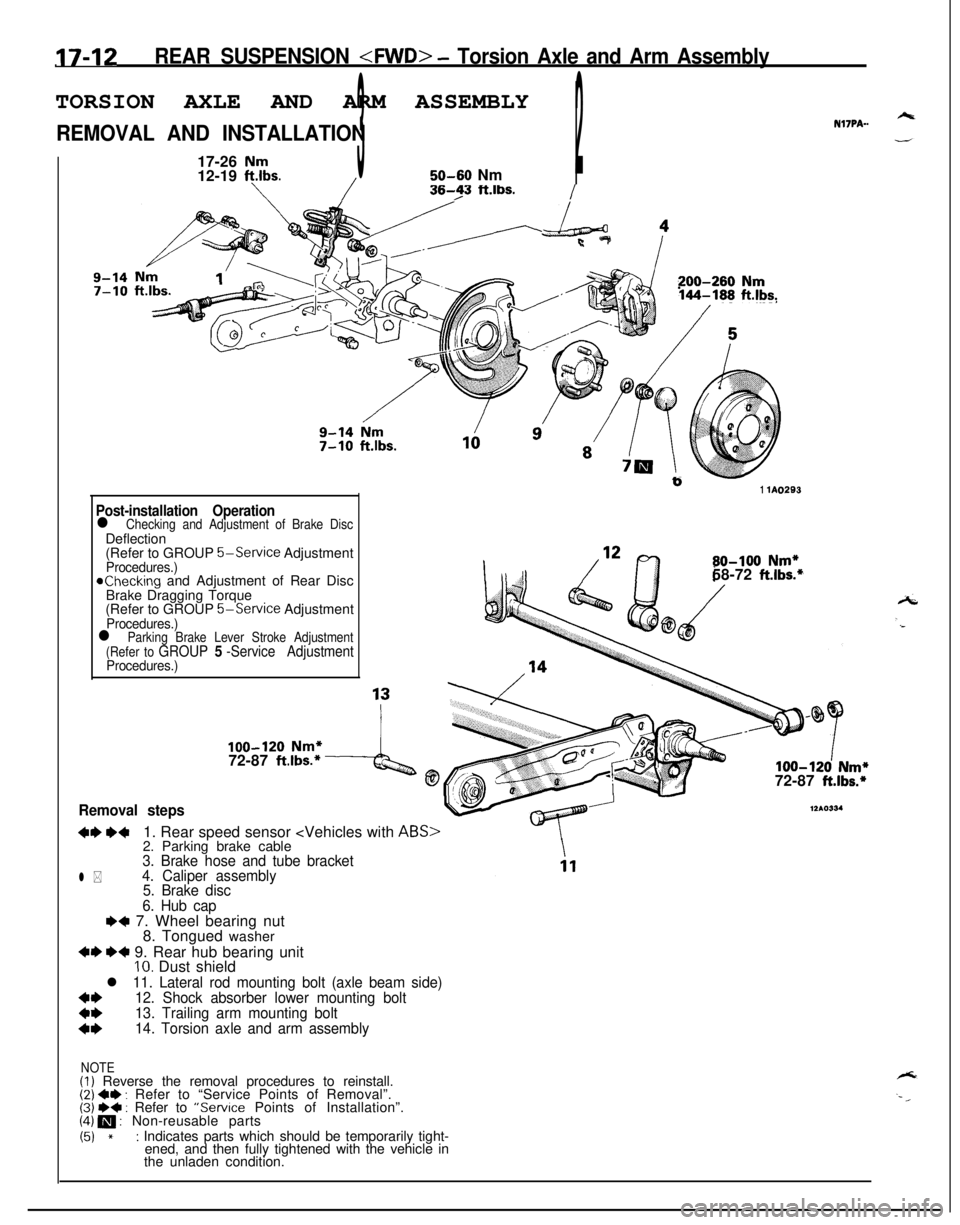

REMOVAL AND INSTALLATIONNl’IPA-.

17-26

Nm12-19 ft.lbs.350-60 Nm2/I

/36-23 ft.lbs./

Nm1’200-260 Nm144-188 ft.lbs.

b1 lA0293

Post-installation Operationl Checking and Adjustment of Brake DiscDeflection

(Refer to GROUP

5-Service AdjustmentProcedures.)achecking and Adjustment of Rear Disc

Brake Dragging Torque

(Refer to GROUP

5-Service AdjustmentProcedures.)

80-100 Nm*58-72 ft.lbs.*

l Parking Brake Lever Stroke Adjustment

(Refer to GROUP 5 -Service AdjustmentProcedures.)

100-120 Nm*72-87 ft.lbs.*4@100-120 Nm*72-87 ft.lbs.*

Removal steps

+I) ++1. Rear speed sensor

12*0334

l *

3. Brake hose and tube bracket

4. Caliper assembly

5. Brake disc

6. Hub cap

e+ 7. Wheel bearing nut

8. Tongued washer

+I) *+ 9. Rear hub bearing unitIO. Dust shield

l 11. Lateral rod mounting bolt (axle beam side)

*I)12. Shock absorber lower mounting bolt

13. Trailing arm mounting bolt

14. Torsion axle and arm assembly

NOTE(I) Reverse the removal procedures to reinstall.(2) ~~ : Refer to “Service Points of Removal”.(3j W+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

(51 *: Indicates parts which should be temporarily tight-

ened, and then fully tightened with the vehicle in

the unladen condition.

Page 624 of 1216

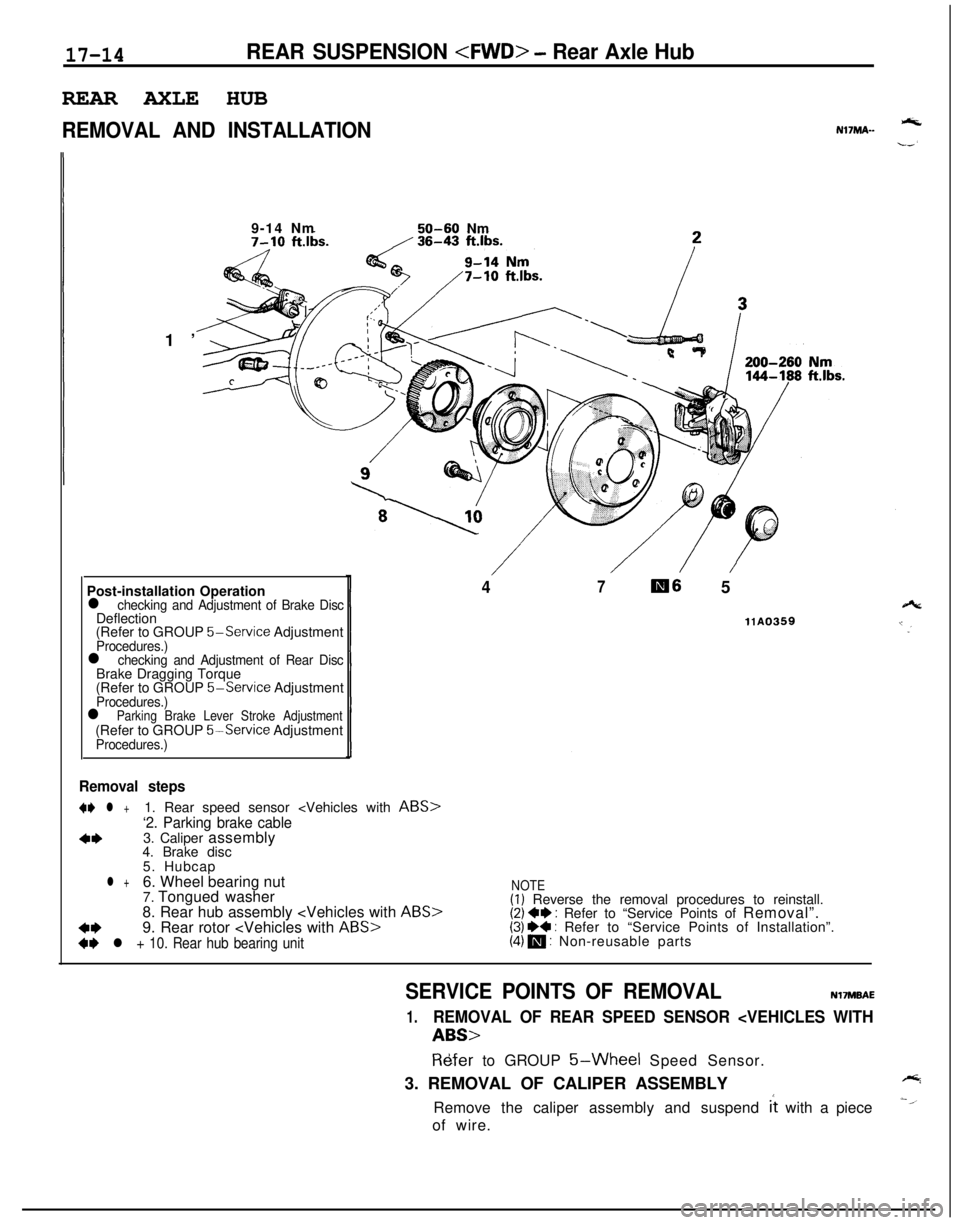

17-14REAR SUSPENSION

REMOVAL AND INSTALLATIONNl’IMA--1’9-14 Nm

50-60 Nm

Post-installation Operation

l checking and Adjustment of Brake DiscDeflection

(Refer to GROUP

5-Service AdjustmentProcedures.)l checking and Adjustment of Rear DiscBrake Dragging Torque

(Refer to GROUP

5-Service AdjustmentProcedures.)l Parking Brake Lever Stroke Adjustment(Refer to GROUP 5%Service AdjustmentProcedures.)

47m6 5

llA0359

Removal steps

+* l +1. Rear speed sensor

‘2. Parking brake cable

4*3. Caliper assembly

4. Brake disc

5. Hubcap

l +6. Wheel bearing nut

7. Tongued washer

8. Rear hub assembly

4*9. Rear rotor

+I) l + 10. Rear hub bearing unit

NOTE(I) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) I)+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

SERVICE POINTS OF REMOVALNVMBAE

1.REMOVAL OF REAR SPEED SENSOR

R6fer to GROUP 5-Wheel Speed Sensor.

3. REMOVAL OF CALIPER ASSEMBLY

Remove the caliper assembly and suspend

it with a piece

of wire.

Page 649 of 1216

STEERING

CONTENTSNISAA-

MANUAL STEERINGGEAR BOX.................21

POWER STEERINGGEAR BOX...................

28

POWER STEERING

HOSES........................

46

POWER STEERING OIL PUMP....................39

SERVICE ADJUSTMENT PROCEDURES

Steering Angle Check..............................7

Steering Wheel Centering.........................8

Steering Wheel Free Play Check.............:..7Tie Rod End Ball Joint Starting Torque

Check..................................................8Tie Rod End Ball Joint Variation Check

(Shaft direction).....................................7

SERVICE ADJUSTMENT PROCEDURES

< POWER STEERING >.............................

10

Bleeding...............................................13Fluid Level Check...................................

12

Fluid Replacement..................................12

i;,

Oil Pressure Switch Check........................15

Oil Pump Pressure Test...........................14

Stationary Steering Effort Check.................11Steering Angle Check..............................

10

Steering Wheel Centering.........................1 1

Steering Wheel Free Play Check................10Steering Wheel Return to Center Check.......

11Tie Rod End Ball Joint Starting Torque

Check..................................................10Tie Rod End Bail Joint Variation Check

(Shaft direction).....................................10

V-Belt Tension Check..............................12

SPECIAL TOOLS......................................6

SPECIFICATIONS.....................................2;

General Specifications..............................2

Lubricants.............................................5

Sealants and Adhesives............................5

Service Specifications.............‘................2

Torque Specifications,. . . . . . . . . . . . . . . . . ..*..........3

STEERING WHEEL AND SHAFT.................. 16

Page 650 of 1216

19-2STEERING - Specifications

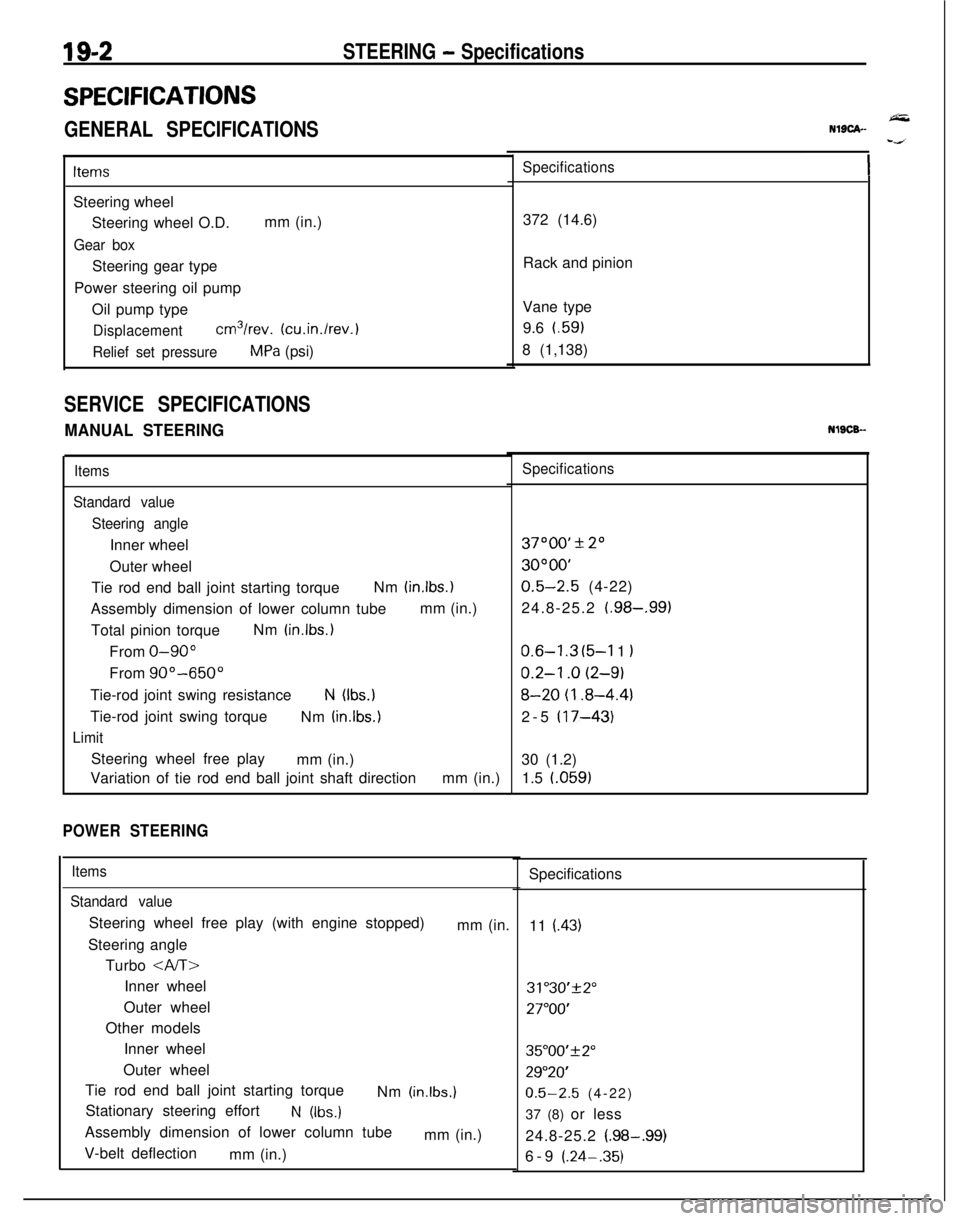

SPECIFICATIONS

GENERAL SPECIFICATIONS

ItemsSteering wheel

Steering wheel O.D.mm (in.)

Gear boxSteering gear type

Power steering oil pump

Oil pump type

Displacementcm3/rev. (cu.in./rev.)

Relief set pressureMPa (psi)

SERVICE SPECIFICATIONS

MANUAL STEERING

Items

Standard value

Steering angleInner wheel

Outer wheel

Tie rod end ball joint starting torqueNm

(in.lbs.)Assembly dimension of lower column tubemm (in.)

Total pinion torqueNm

(in.lbs.)From

O-90”From

90”-650”Tie-rod joint swing resistance

N (Ibs.)Tie-rod joint swing torque

Nm

(in.lbs.)

LimitSteering wheel free play

mm (in.)

Variation of tie rod end ball joint shaft directionmm (in.)

POWER STEERING

Items

Standard valueSteering wheel free play (with engine stopped)

mm (in.

Steering angle

Turbo

Inner wheel

Outer wheel

Other models

Inner wheel

Outer wheel

Tie rod end ball joint starting torque

Nm

(in.lbs.)Stationary steering effort

N (Ibs.)Assembly dimension of lower column tube

mm (in.)

V-belt deflection

mm (in.)

NlSCA--

Specifications372 (14.6)

Rack and pinion

Vane type

9.6 t.59)

8 (1,138)NlSCB-

Specifications37000’

* 20

3OOOO’

0.5-2.5 (4-22)

24.8-25.2

(.98-,991

0.6-l .3 (5-l 1 I

0.2-l .o (2-9)

8-20 (I .8-4.4)2-5

(17-43)30 (1.2)

1.5 l.059)

Specifications

11

(.43)

31"30'+2"

27"OO'

35"00'f2"

29"20'

0.5-2.5 (4-22)

37 (8) or less

24.8-25.2

(.98-.99)6-9 (.24-.35)

Page 651 of 1216

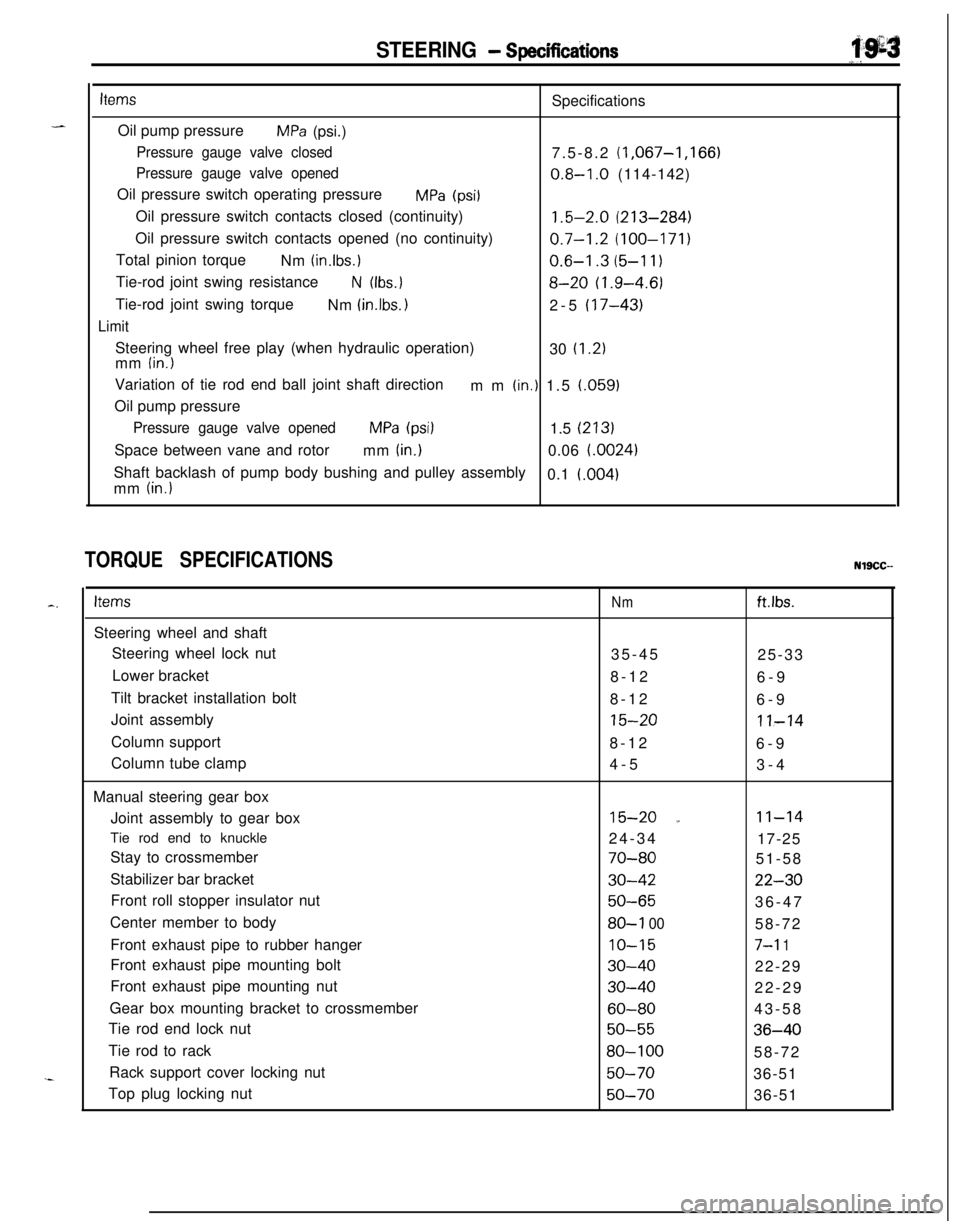

-

STEERING - Specificdions

i’.g=s

“,.

itemsSpecifications

Oil pump pressure

MPa (psi.)

Pressure gauge valve closed7.5-8.2 (1,067-1,166)

Pressure gauge valve opened0.8-I .O (114-142)

Oil pressure switch operating pressure

MPa (psi1Oil pressure switch contacts closed (continuity)

1.5-2.0 (213-284)Oil pressure switch contacts opened (no continuity)

0.7-1.2 (100-171)Total pinion torque

Nm

(in.lbs.)0.6-I .3 (5-l 1)Tie-rod joint swing resistance

N (Ibs.18-20 (1.9-4.6)Tie-rod joint swing torque

Nm

(in.lbs. 12-5 (17-43)

LimitSteering wheel free play (when hydraulic operation)

30

(1.2)mm (in.)Variation of tie rod end ball joint shaft direction

mm

(in.) 1.5 (.059)

Oil pump pressure

Pressure gauge valve openedMPa (psi)1.5 (213)Space between vane and rotor

mm

(in.)0.06 i.0024)Shaft backlash of pump body bushing and pulley assembly

0.1

i.004)mm (in.)

TORQUE SPECIFICATIONSNlSCC--

c.ItemsSteering wheel and shaft

Steering wheel lock nut

Lower bracket

Tilt bracket installation bolt

Joint assembly

Column support

Column tube clamp

Manual steering gear box

Joint assembly to gear box

Tie rod end to knuckle

Stay to crossmember

Stabilizer bar bracket

Front roll stopper insulator nut

Center member to body

Front exhaust pipe to rubber hanger

Front exhaust pipe mounting bolt

Front exhaust pipe mounting nut

Gear box mounting bracket to crossmember

Tie rod end lock nut

Tie rod to rack

Rack support cover locking nut

Top plug locking nutNmftlbs.35-45

25-33

8-12

6-9

8-12

6-9

15-2011-148-12

6-9

4-5

3-4

15-20 a11-1424-34

17-25

70-8051-58

30-4222-30

50-6536-47

80-l 0058-72

IO-157-l 1

30-4022-29

30-4022-29

60-8043-58

50-5536-40

80-10058-72

50-7036-51

50-7036-51

Page 655 of 1216

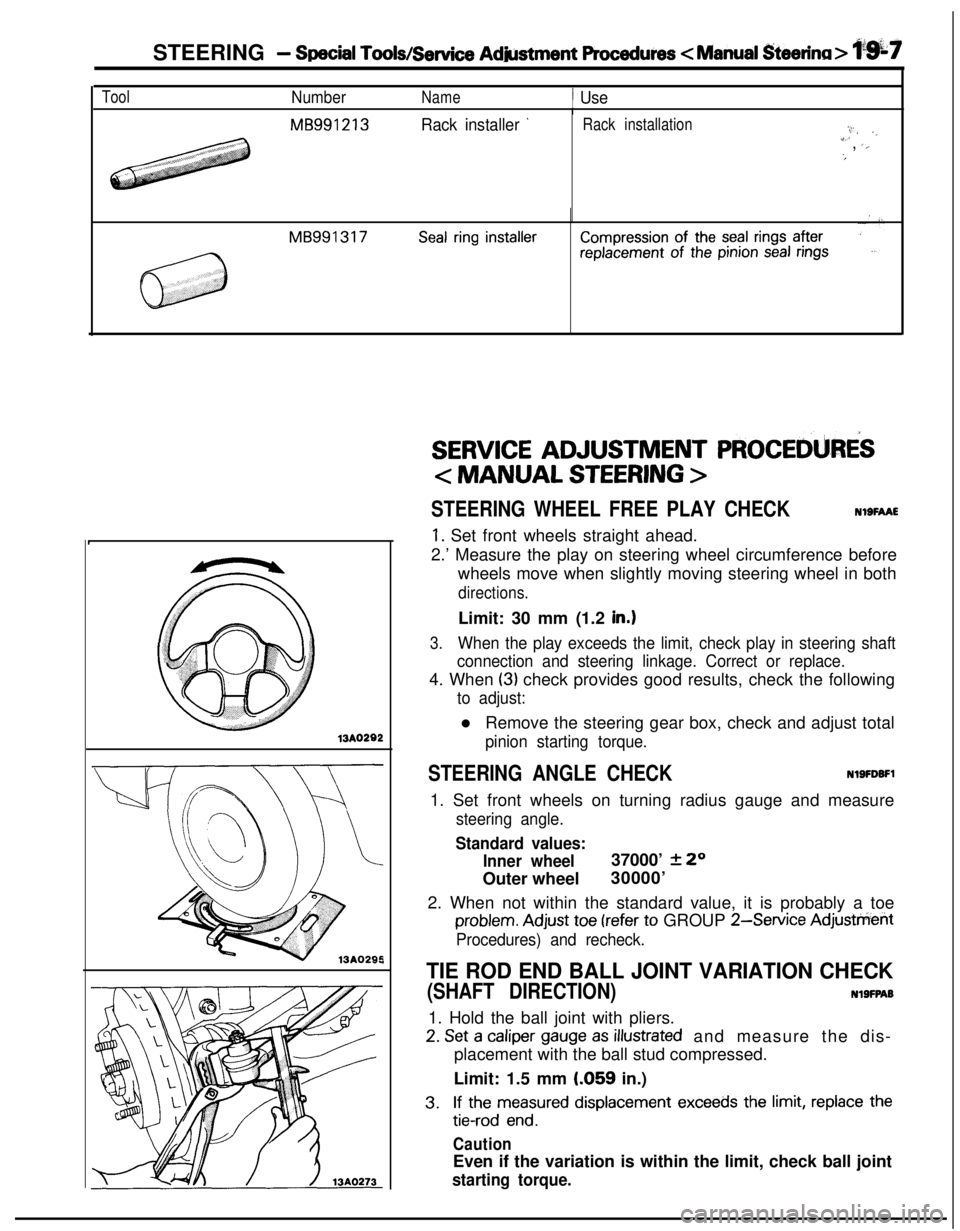

STEERING - Special Tools/Service Adjustment Procedures

ToolNumberName1 UseI

MB991213Rack installer ’Rack installation:,.I/ ._i’, ‘,‘#

MB991317Seal ring installerCompression of the seal rings afterreplacement of the pinion seal rings13A0282

,

SERVICE ADJUSTMENT PROCEDURiS

< MANUAL STEERING >

STEERING WHEEL FREE PLAY CHECKNOSFAAE

1. Set front wheels straight ahead.

2.’ Measure the play on steering wheel circumference before

wheels move when slightly moving steering wheel in both

directions.Limit: 30 mm (1.2

in.1

3.When the play exceeds the limit, check play in steering shaft

connection and steering linkage. Correct or replace.4. When

(3) check provides good results, check the following

to adjust:l Remove the steering gear box, check and adjust total

pinion starting torque.

STEERING ANGLE CHECKNlSFDBFl1. Set front wheels on turning radius gauge and measure

steering angle.

Standard values:

Inner wheel37000’

2 20

Outer wheel30000’

2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 2-Service Adjusttierit

Procedures) and recheck.

TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)NlSFPAB1. Hold the ball joint with pliers.

2. Set a caliper gauge as illustrated and measure the dis-

placement with the ball stud compressed.

Limit: 1.5 mm

LO59 in.)

3.If the measured displacement exceeds the limit, replace the

tie-rod end.

CautionEven if the variation is within the limit, check ball joint

starting torque.

Page 656 of 1216

19-8STEERING - Service Adjustment Procedures < Manual Steering>

136005!Tape or mark

on steering

column cover

Tape or mark

on steering

wheel hub16A0901

Dotted lines

show wheel

Tape or mark

on steering

wheel rim

nce off-center

16AOOOl

IO036 splines

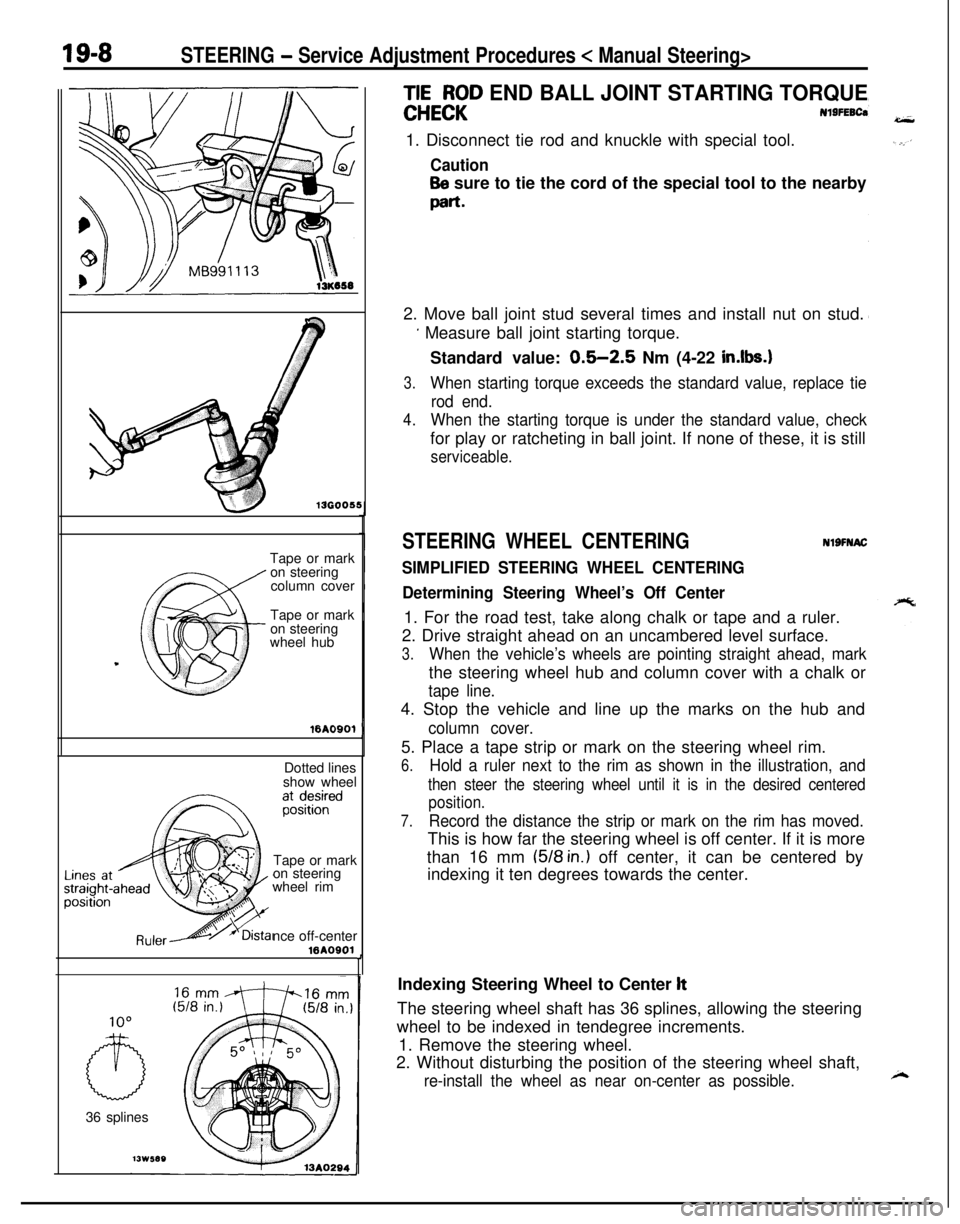

;EEE;D END BALL JOINT STARTING TORQUE

Nl9FEBCa1. Disconnect tie rod and knuckle with special tool.

Caution

Be sure to tie the cord of the special tool to the nearby

part-2. Move ball joint stud several times and install nut on stud.

’ Measure ball joint starting torque.

Standard value:

0.5-2.5 Nm (4-22 in.lbs.1

3.When starting torque exceeds the standard value, replace tie

rod end.

4.When the starting torque is under the standard value, checkfor play or ratcheting in ball joint. If none of these, it is still

serviceable.

STEERING WHEEL CENTERINGNlSFNAC

SIMPLIFIED STEERING WHEEL CENTERING

Determining Steering Wheel’s Off Center1. For the road test, take along chalk or tape and a ruler.

2. Drive straight ahead on an uncambered level surface.

3.When the vehicle’s wheels are pointing straight ahead, markthe steering wheel hub and column cover with a chalk or

tape line.4. Stop the vehicle and line up the marks on the hub and

column cover.5. Place a tape strip or mark on the steering wheel rim.

6.Hold a ruler next to the rim as shown in the illustration, and

then steer the steering wheel until it is in the desired centered

position.

7.Record the distance the strip or mark on the rim has moved.This is how far the steering wheel is off center. If it is more

than 16 mm

(518 in.) off center, it can be centered by

indexing it ten degrees towards the center.

,Indexing Steering Wheel to Center

ltThe steering wheel shaft has 36 splines, allowing the steering

wheel to be indexed in tendegree increments.

1. Remove the steering wheel.

2. Without disturbing the position of the steering wheel shaft,

re-install the wheel as near on-center as possible.