brake light MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 592 of 1216

14-138AUTO-CRUISE CONTROL SYSTEM - Service Adjustment Procedures

07A0051

07AOO50

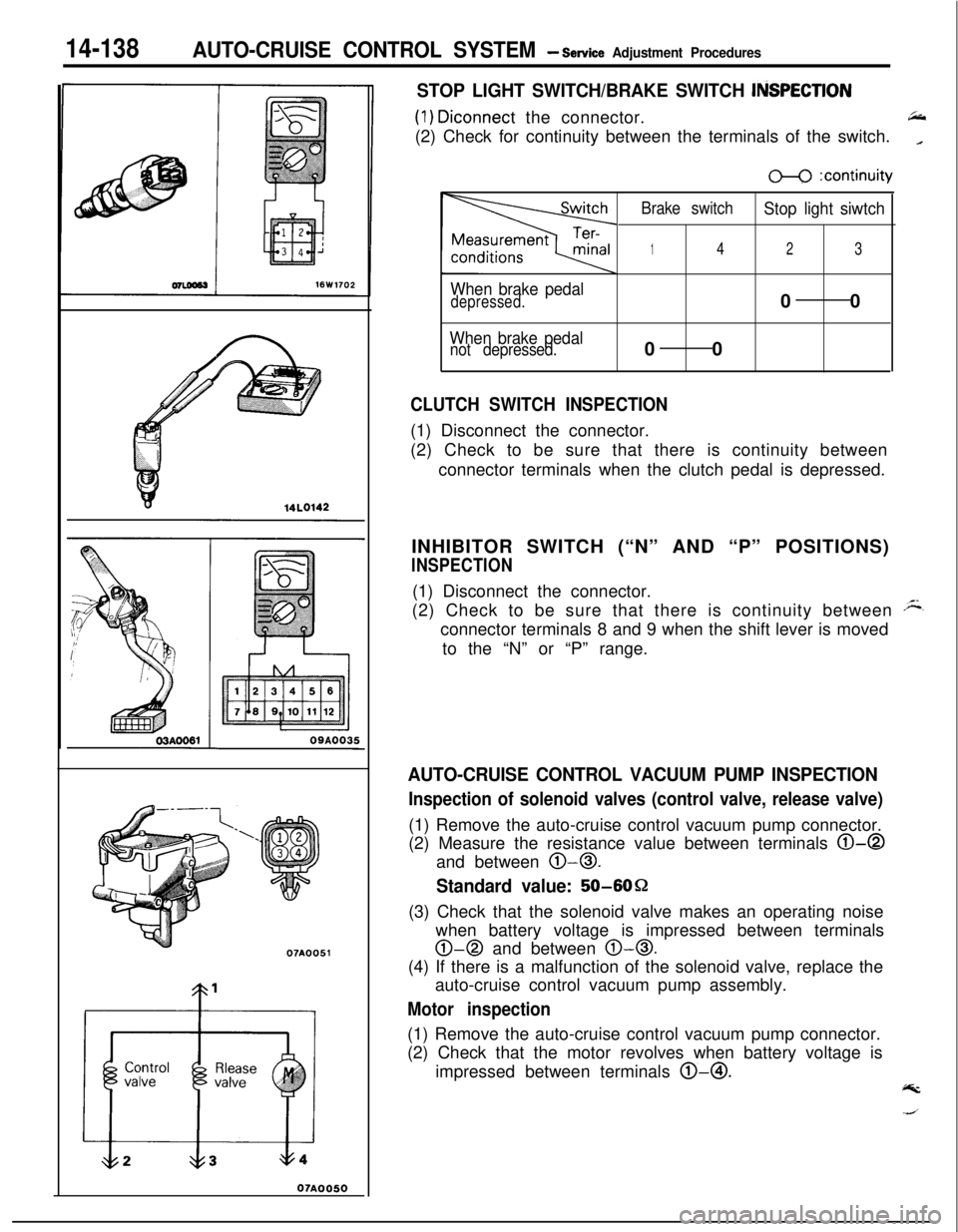

STOP LIGHT SWITCH/BRAKE SWITCH ItiSPECTlON

(1) Diconnect the connector.66(2) Check for continuity between the terminals of the switch.

_

When brake pedaldepressed.

When brake pedalnot depressed.

m :continuity

Brake switch

Stop light siwtch

142300

00

CLUTCH SWITCH INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

connector terminals when the clutch pedal is depressed.

INHIBITOR SWITCH (“N” AND “P” POSITIONS)

INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

Aconnector terminals 8 and 9 when the shift lever is moved

to the “N” or “P” range.

AUTO-CRUISE CONTROL VACUUM PUMP INSPECTION

Inspection of solenoid valves (control valve, release valve)(1) Remove the auto-cruise control vacuum pump connector.

(2) Measure the resistance value between terminals

0-0and between

0-0.

Standard value: 50-6OQ

(3) Check that the solenoid valve makes an operating noise

when battery voltage is impressed between terminals

0-0 and between 0-0.(4) If there is a malfunction of the solenoid valve, replace the

auto-cruise control vacuum pump assembly.

Motor inspection(1) Remove the auto-cruise control vacuum pump connector.

(2) Check that the motor revolves when battery voltage is

impressed between terminals @-@I.

@k

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 633 of 1216

REAR SUSPENSION

14AO520

12AOlOQ

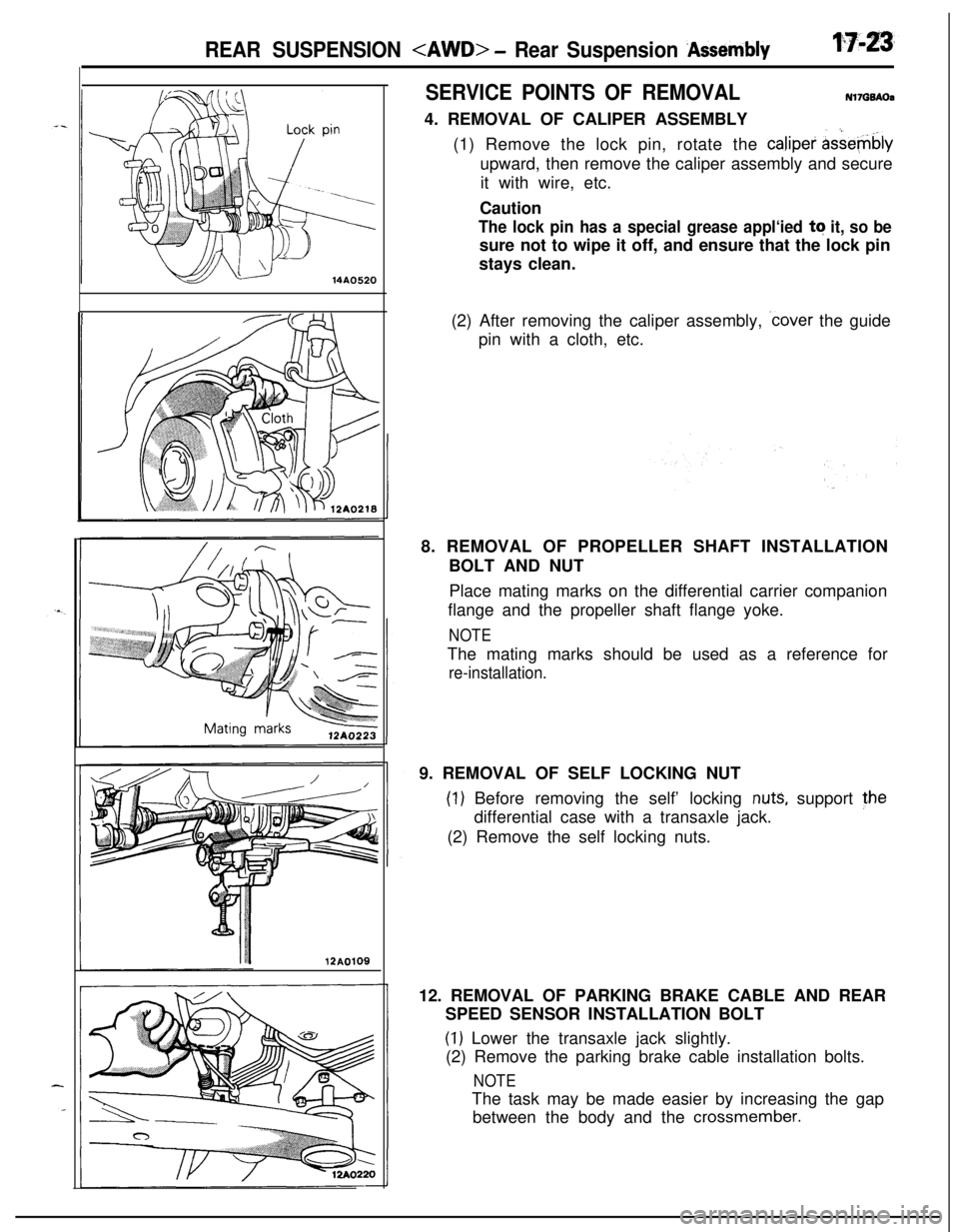

SERVICE POINTS OF REMOVALN17GQAOa4. REMOVAL OF CALIPER ASSEMBLY

(1) Remove the lock pin, rotate the calipei

&&e-@blyupward, then remove the caliper assembly and secure

it with wire, etc.

Caution

The lock pin has a special grease appl‘ied tq it, so besure not to wipe it off, and ensure that the lock pin

stays clean.

(2) After removing the caliper assembly,

.cover the guide

pin with a cloth, etc.

8. REMOVAL OF PROPELLER SHAFT INSTALLATION

BOLT AND NUT

Place mating marks on the differential carrier companion

flange and the propeller shaft flange yoke.

NOTEThe mating marks should be used as a reference for

re-installation.9. REMOVAL OF SELF LOCKING NUT

(1) Before removing the self’ locking nuts, support the

differential case with a transaxle jack.

(2) Remove the self locking nuts.

12. REMOVAL OF PARKING BRAKE CABLE AND REAR

SPEED SENSOR INSTALLATION BOLT

(1) Lower the transaxle jack slightly.

(2) Remove the parking brake cable installation bolts.

NOTEThe task may be made easier by increasing the gap

between the body and the

crossmember.

Page 695 of 1216

TRANSAXLE ’

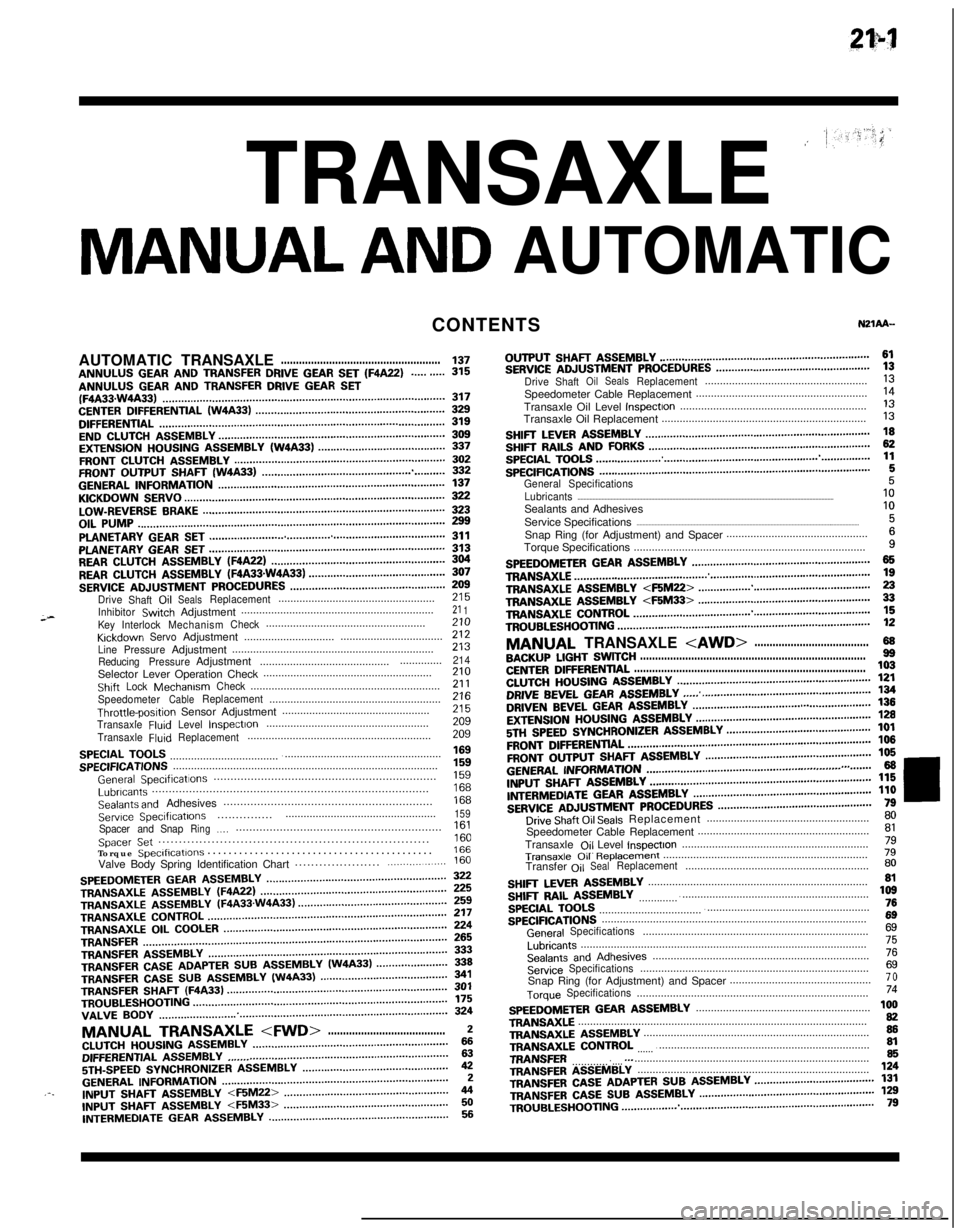

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 717 of 1216

MANUAL TRANSAXLE

TRANSAXLE ASSEMBLY

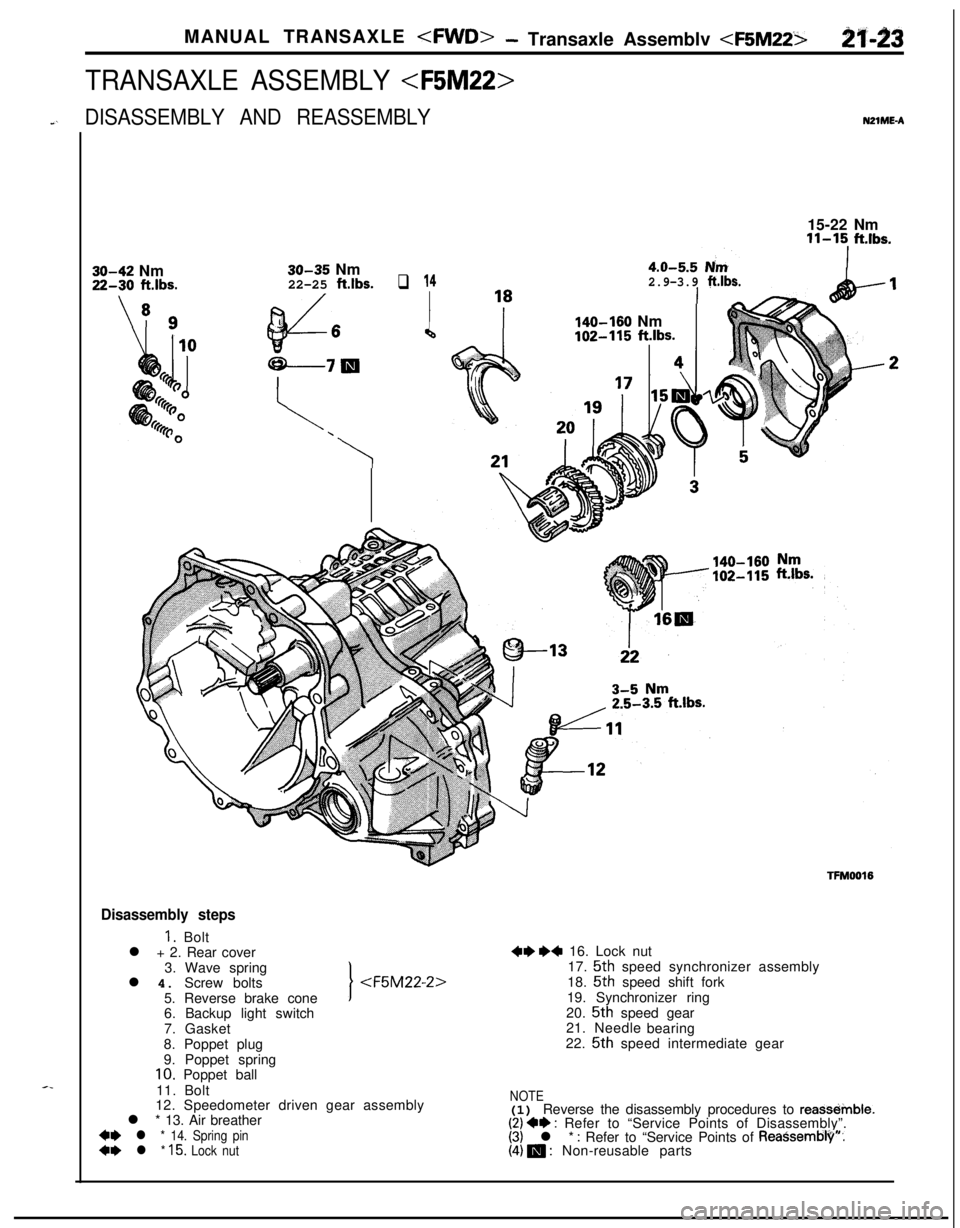

.._DISASSEMBLY AND REASSEMBLYN21ME-A

__

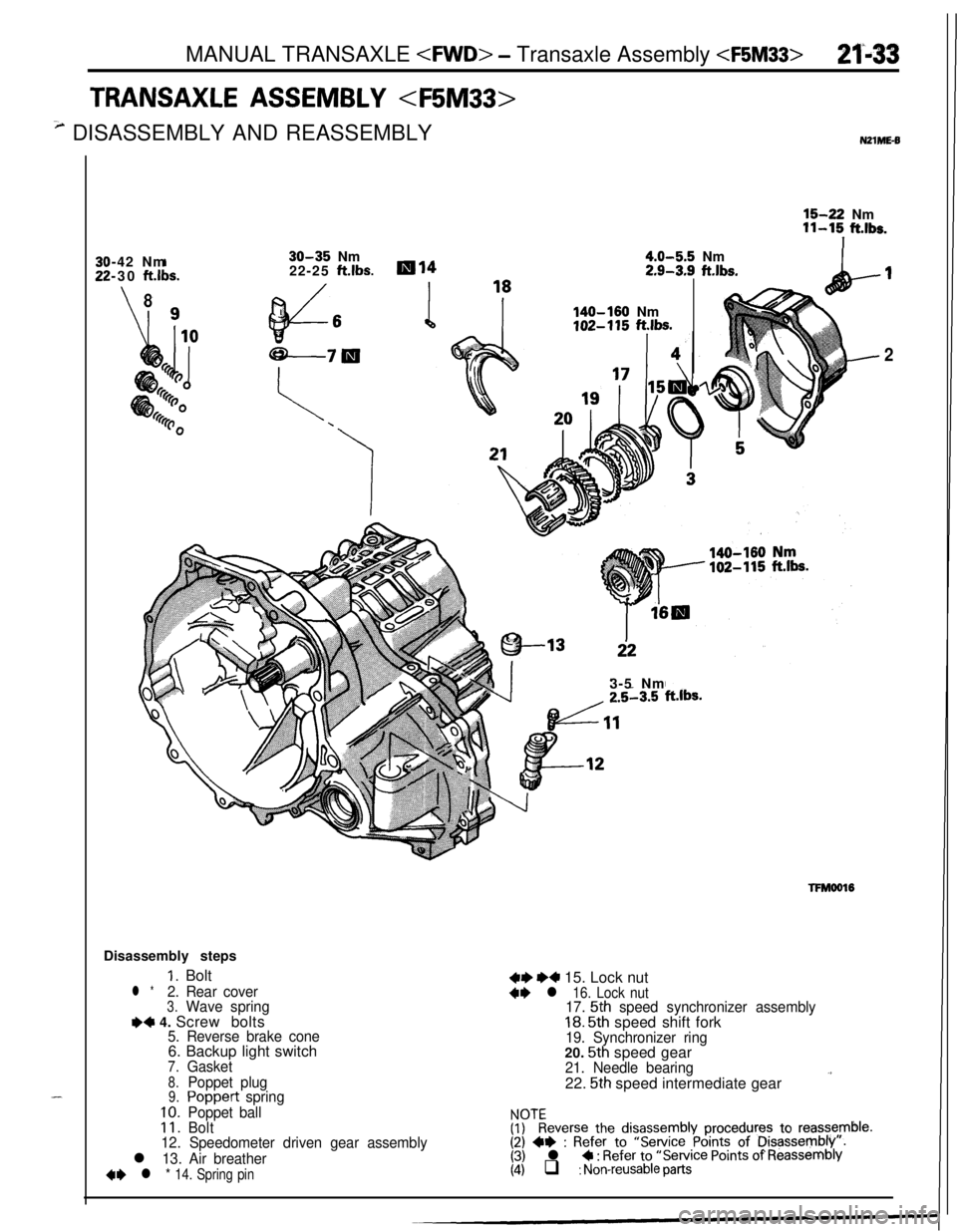

30-42 Nm22-30 ft.lbs.30-35 Nm22-25 ftlbs.q l4

ig5 !

----7m

IQ15-22 Nm

II-15 ft.lbs.

4.0-5.5 Nm2.9-3.9 ft.lbs.1I”I

a

140-160 Nmf

102-115 ft.lbs.

Disassembly steps

1. Bolt

l + 2. Rear cover

3. Wave spring

l 4. Screw bolts

5. Reverse brake cone

6. Backup light switch

7. Gasket

9. Poppet spring

10. Poppet ball

11. Bolt

12. Speedometer driven gear assembly

l * 13. Air breather

*I) l * 14. Spring pin+I) l * 15. Lock nut

140-160102-115

TFMOOl6

+e I)+ 16. Lock nut

17. 5th speed synchronizer assembly

18. 5th speed shift fork

19. Synchronizer ring

20. 5th speed gear

21.Needle

bearing

22. 5th speed intermediate gear

NOTE(1) Reverse the disassembly procedures to reasseinble.

(2) ++ : Refer to “Service Points of Disassembly”.(3) l * : Refer to “Service Points of ReaSsembly”:(4) m : Non-reusable parts

Page 727 of 1216

MANUAL TRANSAXLE

TRANSAXLE ASSEMBLY

3 DISASSEMBLY AND REASSEMBLYNZlME-6

--42 Nm

-30

ft.lbs.

\8I Q

30-35Nm

22-25ft.lbs.ml4

ff3d6 i

18

4.0-5.5Nm2.9-3.9ft.lbs.

-n

140-160 Nm102-115ft.&s.

3-5 Nm

16-22 Nm11-15 ft.lbs.1Disassembly steps

‘I. Bolt

l *2. Rear cover3.Wave springe4 4. Screw bolts5. Reverse brake cone6. Backup light switch

7.Gasket

8.Poppet plug9.Poppert spring

10.Poppet ball11.Bolt

12. Speedometer driven gear assembly

l 13. Air breather

4* l * 14. Spring pin

,I

2

TFMool6

4+ e4 15. Lock nut+e l 16. Lock nut17. 5th speed synchronizer assembly18. 5th speed shift fork19. Synchronizer ring20. 5th speed gear21. Needle bearing22.

5th speed intermediate gear.’

$?everse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly:.(3) l C : Refer to “Service Points of Reassembly(4) q : Non-reusable parts

Page 769 of 1216

MANUAL TRANSAXLE

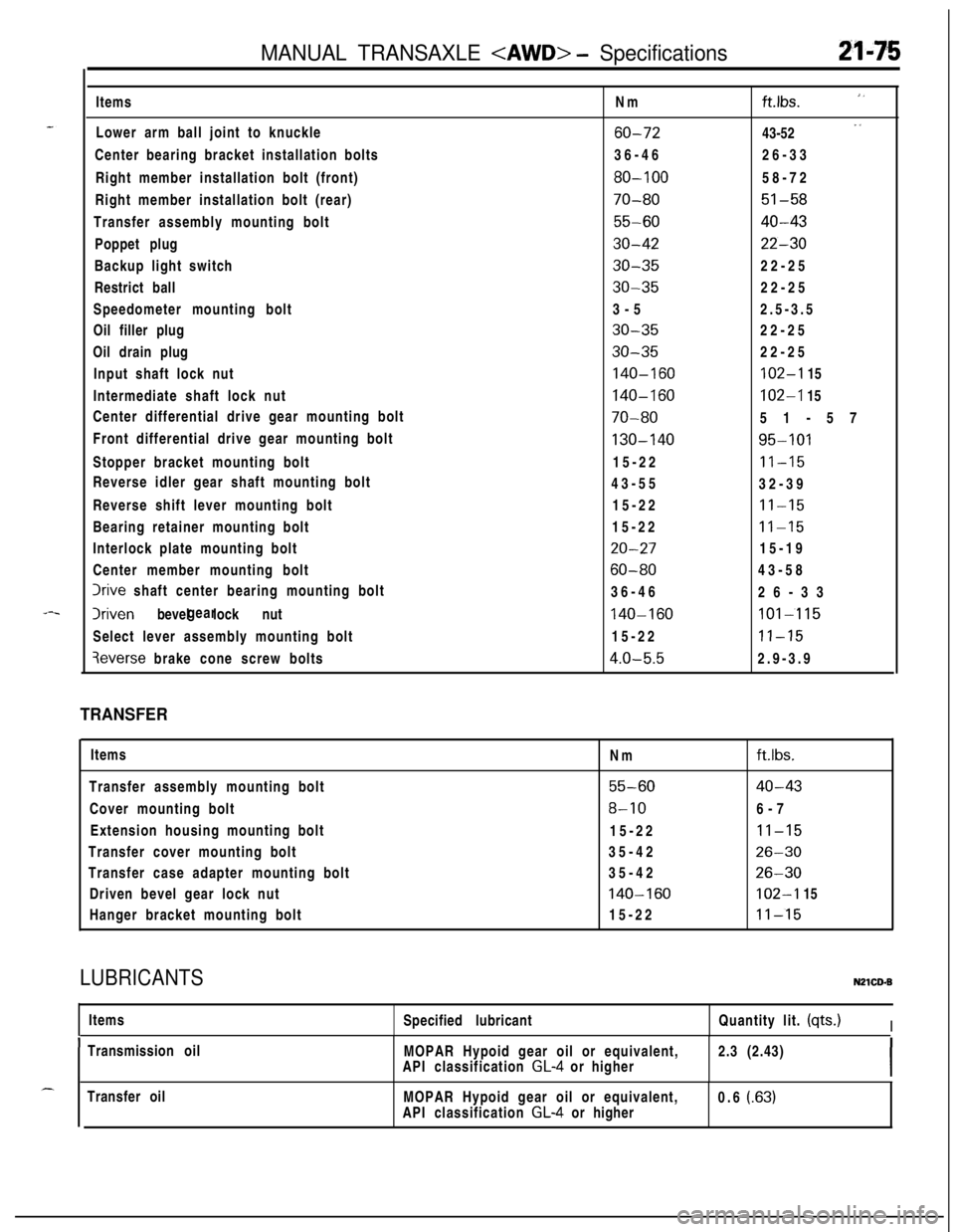

Lower arm ball joint to knuckle

Center bearing bracket installation bolts

Right member installation bolt (front)

Right member installation bolt (rear)

Transfer assembly mounting bolt

Poppet plug

Backup light switch

Restrict ball

Speedometer mounting bolt

Oil filler plug

Oil drain plug

Input shaft lock nut

Intermediate shaft lock nut

Center differential drive gear mounting bolt

Front differential drive gear mounting bolt

Stopper bracket mounting bolt

Reverse idler gear shaft mounting bolt

Reverse shift lever mounting bolt

Bearing retainer mounting bolt

Interlock plate mounting bolt

Center member mounting bolt

Irive shaft center bearing mounting bolt

Iriven bevel lock nutgear

Select lever assembly mounting bolt

3everse brake cone screw boltsNm

ft.Ibs. ”

60-7243-52 “

36-4626-33

80-10058-72

70-8051-58

55-6040-43

30-4222-30

30-3522-25

30-3522-25

3-52.5-3.5

30-3522-25

30-3522-25

140-160102-I 15

140-160102-I 15

70-8051-57

130-14095-10115-22

11-1543-55

32-39

15-22

11-1515-22

11-15

20-2715-19

60-8043-58

36-46

26-33

140-160101-11515-22

11-15

4.0-5.52.9-3.9

TRANSFERItems

Transfer assembly mounting bolt

Cover mounting bolt

Extension housing mounting bolt

Transfer cover mounting bolt

Transfer case adapter mounting bolt

Driven bevel gear lock nut

Hanger bracket mounting boltNm

ft.lbs.

55-6040-43

8-106-7

15-22

II-1535-42

26-3035-42

26-30

140-160102-I 15

15-22

11-15

LUBRICANTSN21CD.BItems

Specified lubricantQuantity lit. (qts.)

I

ITransmission oil

MOPAR Hypoid gear oil or equivalent,2.3 (2.43)

API classification GL-4 or higherITransfer oil

MOPAR Hypoid gear oil or equivalent,

API classification

GL-4 or higher0.6 (.63)

Page 780 of 1216

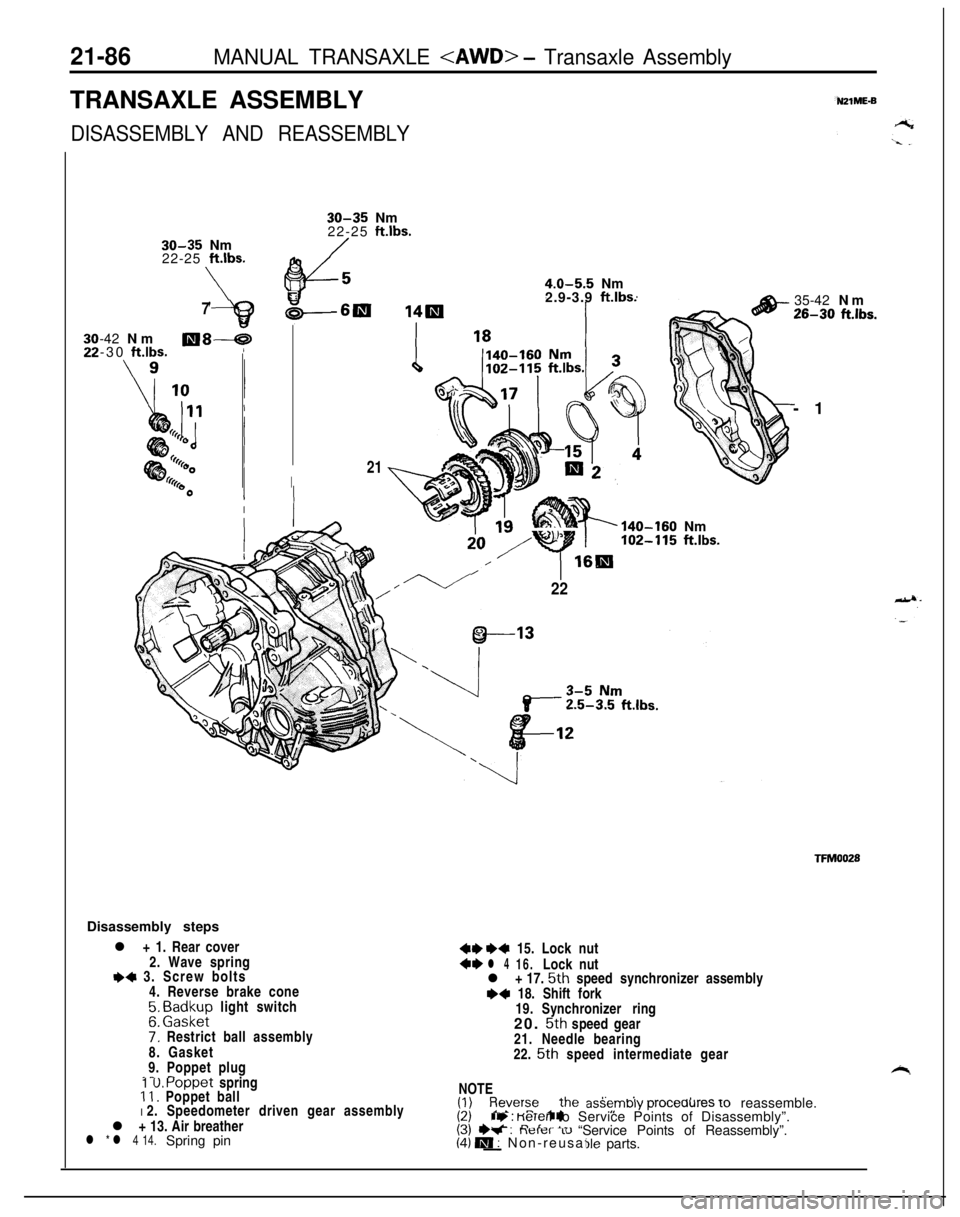

21-86MANUAL TRANSAXLE

DISASSEMBLY AND REASSEMBLY

30-35 Nm

22-25 ft.lbs.

\

30-35 Nm

22-25 Wbs.

4.0-5.5 Nm\62.9-3.9 ft.lbs.7-42 Nm

-30

ft.lbs.llI8-59

I21IDisassembly steps

l + 1. Rear cover

2. Wave spring

I)+ 3. Screw bolts

4. Reverse brake cone

;. E;zk;p light switch

7: Restrict ball assembly

8. Gasket

9. Poppet plug

.- ^1 U. Poppet spring11. Poppet ball

I 2. Speedometer driven gear assembly

l + 13. Air breather

l * l 4 14.Spring pin

140-160 Nm

w ”Y

102-115 ft.lbs.

16Bl/

22

++ I)+ 15. Lock nut+el 416.Lock nut

l + 17. 5th speed synchronizer assembly~~ 18. Shift fork

19.Synchronizer ring

20.

5th speed gear

21.Needle bearing

22.

5th speed intermediate gear35-42 Nm

26-30 ft.lbs.-1

TFMOOZSNOTE

(1) Revers_e the di?: ’(2) +-(3) +v : neler 10(4) IW : Non-reusat-yle parts.assembly

proceaures 10 reassemble.ry : KeTer to Service Points of Disassembly”.“-I-- I- “Service Points of Reassembly”.

’

i

Page 905 of 1216

AUTOMATIC TRANSAXLE - Service Adjustment Procedures21-21109A0146

OQMOO45

control lever

control lever

5 mm

Section A-A

(2 in.)Manual

controllever

Switch body

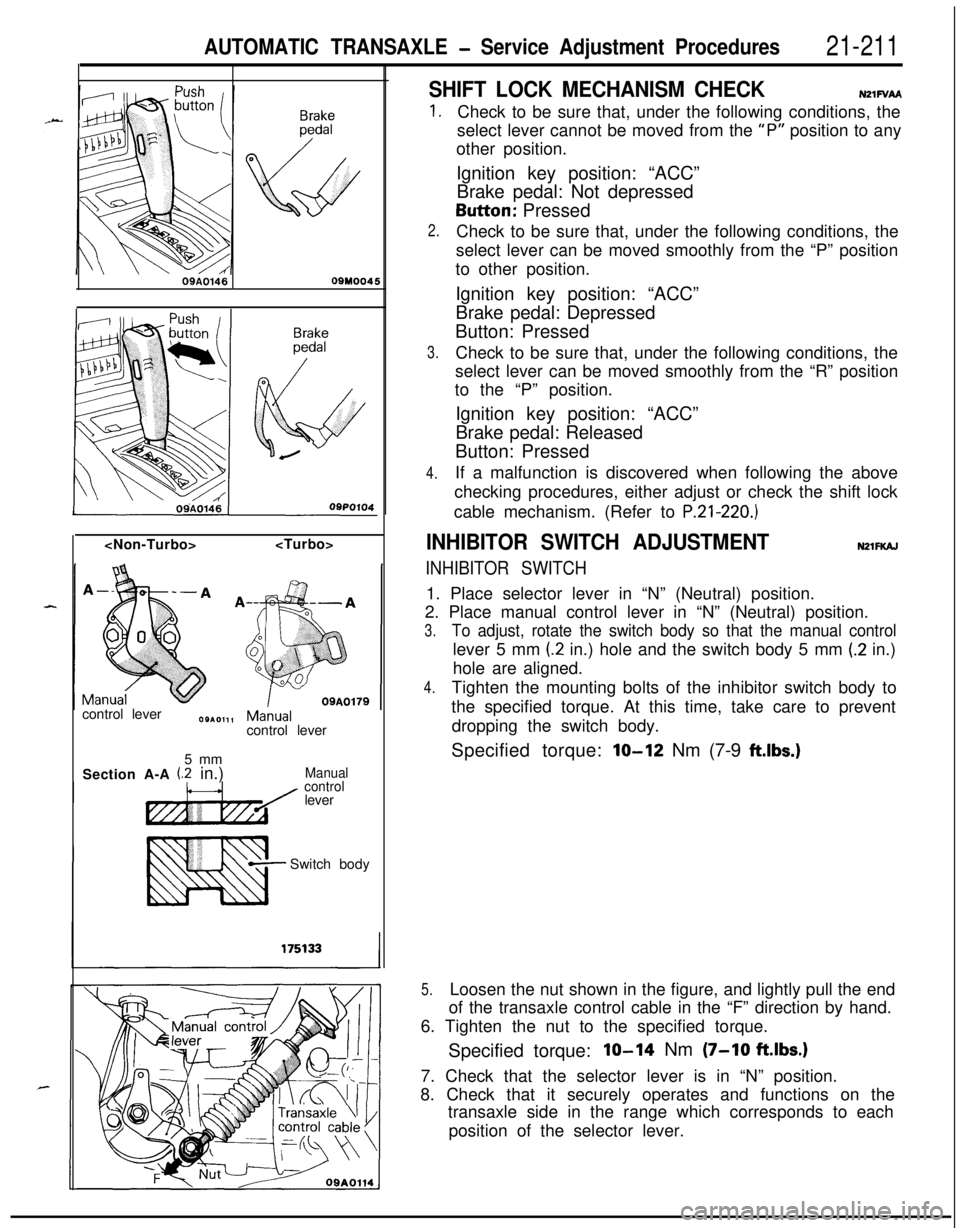

SHIFT LOCK MECHANISM CHECKN21FVAA

1.

2.

3.

4.Check to be sure that, under the following conditions, the

select lever cannot be moved from the

“P” position to any

other position.

Ignition key position: “ACC”

Brake pedal: Not depressedButton: Pressed

Check to be sure that, under the following conditions, the

select lever can be moved smoothly from the “P” position

to other position.

Ignition key position: “ACC”

Brake pedal: Depressed

Button: Pressed

Check to be sure that, under the following conditions, the

select lever can be moved smoothly from the “R” position

to the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button: Pressed

If a malfunction is discovered when following the above

checking procedures, either adjust or check the shift lock

cable mechanism. (Refer to

P.21-220.)

INHIBITOR SWITCH ADJUSTMENTNZlFKAJ

INHIBITOR SWITCH1. Place selector lever in “N” (Neutral) position.

2. Place manual control lever in “N” (Neutral) position.

3.To adjust, rotate the switch body so that the manual controllever 5 mm

(2 in.) hole and the switch body 5 mm (.2 in.)

hole are aligned.

4.Tighten the mounting bolts of the inhibitor switch body to

the specified torque. At this time, take care to prevent

dropping the switch body.

Specified torque:

lo-12 Nm (7-9 ftlbs.)

5.Loosen the nut shown in the figure, and lightly pull the end

of the transaxle control cable in the “F” direction by hand.

6. Tighten the nut to the specified torque.

Specified torque:

IO-14 Nm (7-10 ftlbs.)7. Check that the selector lever is in “N” position.

8. Check that it securely operates and functions on the

transaxle side in the range which corresponds to each

position of the selector lever.