service MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1032 of 1216

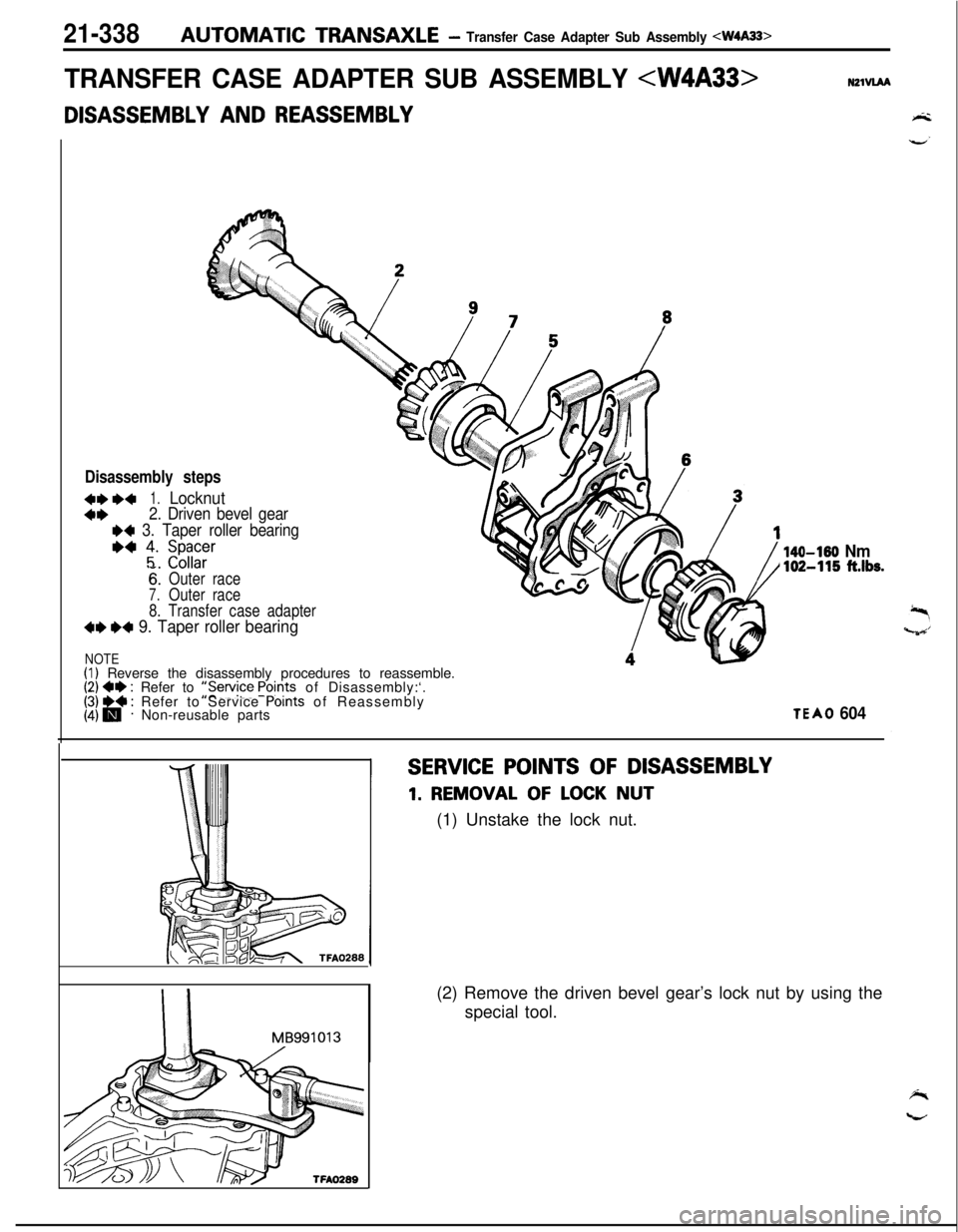

21-338AUTOMATIC TRANSAXLE- Transfer Case Adapter Sub Assembly 4W4A33>

TRANSFER CASE ADAPTER SUB ASSEMBLY

AND REASSEMBLY

Disassembly steps

4**+1.Locknut

4*2. Driven bevel gear

I)4 3. Taper roller bearing

*4 ;. ;z;;r

6:Outer race

7.Outer race

8. Transfer case adapter

4e W 9. Taper roller bearing

NOTE(I) Reverse the disassembly procedures to reassemble.(2) 4e : Refer to ::Service Points of Disassembly:‘.[j &@ j Refer to Service Points of Reassembly

Non-reusable parts

140-150 Nm102-115 ft.lbs.

TEA0 604

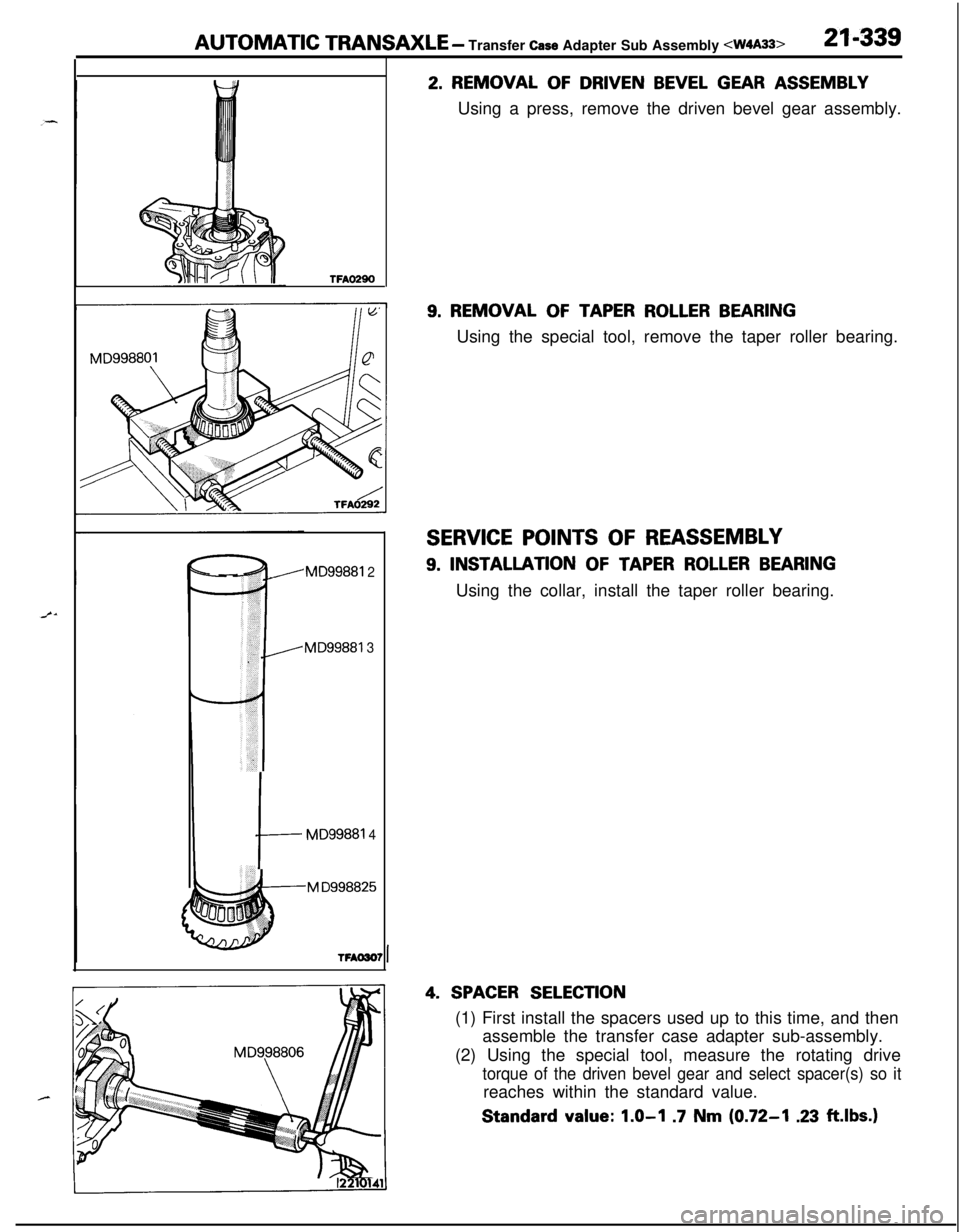

SERVICE POINTS OF DISASSEMBLY

1. REMOVAL OF LOCK NUT

(1) Unstake the lock nut.

I IMB991013

TFAO289(2) Remove the driven bevel gear’s lock nut by using the

special tool.

Page 1033 of 1216

AUTOMATIC TRANSAXLE - Transfer Case Adapter Sub Assembly

TFAO290

MD99881 2

MD99881 3

M D998825

I

MD99881 4

2. REMOVAL OF DRIVEN BEVEL GEAR ASSEMBLY

Using a press, remove the driven bevel gear assembly.

9. REMOVAL OF TAPER ROLLER BEARINGUsing the special tool, remove the taper roller bearing.

SERVICE POINTS OF REASSEMBLY

9. INSTALLATION OF TAPER ROLLER BEARINGUsing the collar, install the taper roller bearing.

4. SPACER SELECTION(1) First install the spacers used up to this time, and then

assemble the transfer case adapter sub-assembly.

(2) Using the special tool, measure the rotating drive

torque of the driven bevel gear and select spacer(s) so itreaches within the standard value.Standard

value: 1.0-l .7 Nm (0.72-I .23 ft.lbs.)

Page 1035 of 1216

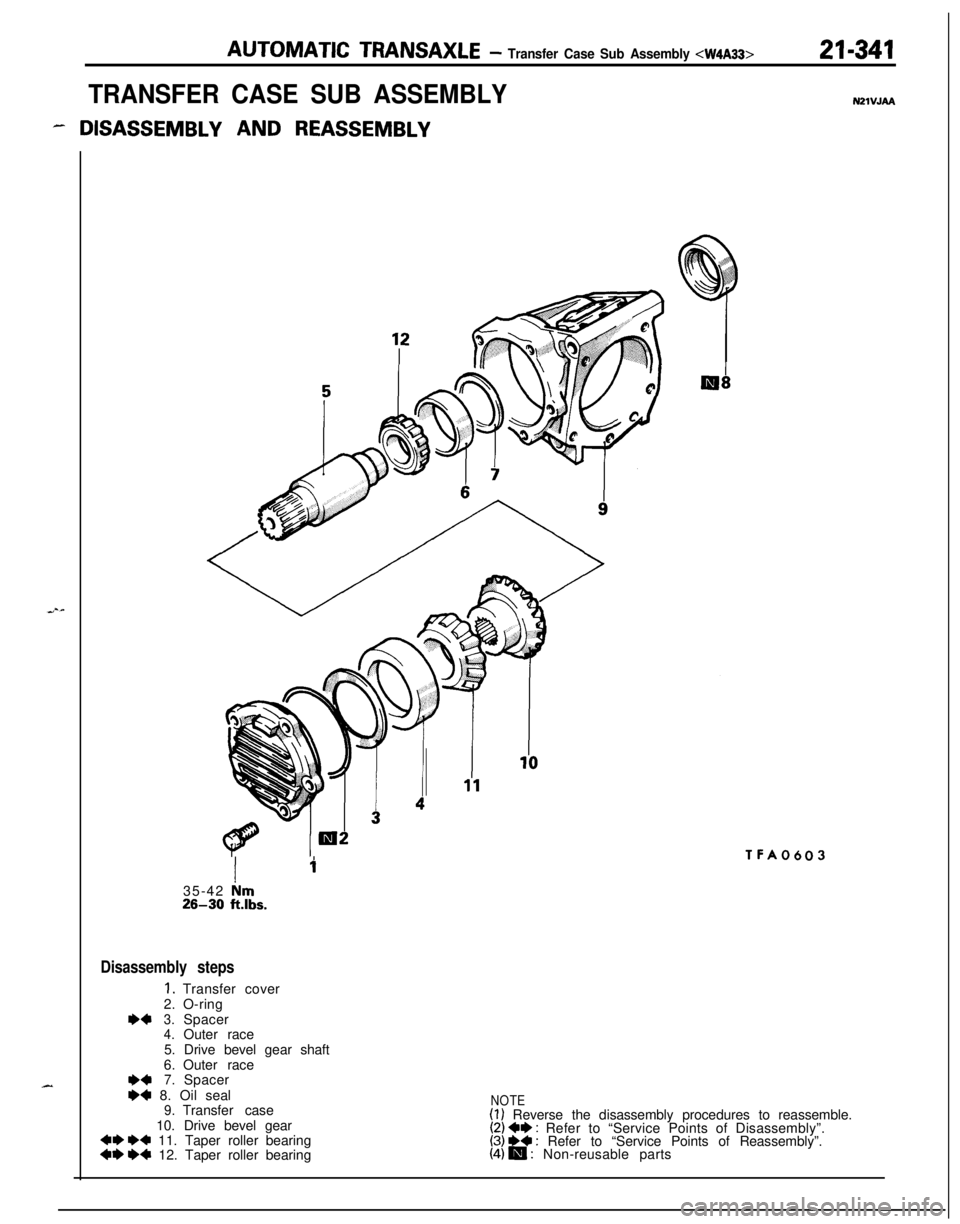

AUTOMATIC TRANSAXLE- Transfer Case Sub Assembly

TRANSFER CASE SUB ASSEMBLY

- DISASSEMBLY AND REASSEMBLY

NZlVJAA

Ii35-42

irn26-30 ftlbs.

Disassembly steps

1.Transfer cover

2.O-ring

r)+3.Spacer4.Outer race

5. Drive bevel gear shaft

6.Outer race

**7.Spacer

I)+ 8. Oil seal9.Transfer case

10. Drive bevel gear

~~ e+ 11. Taper roller bearing~~ e+ 12. Taper roller bearing

TFA0603

NOTE(1) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) ~~ : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

Page 1036 of 1216

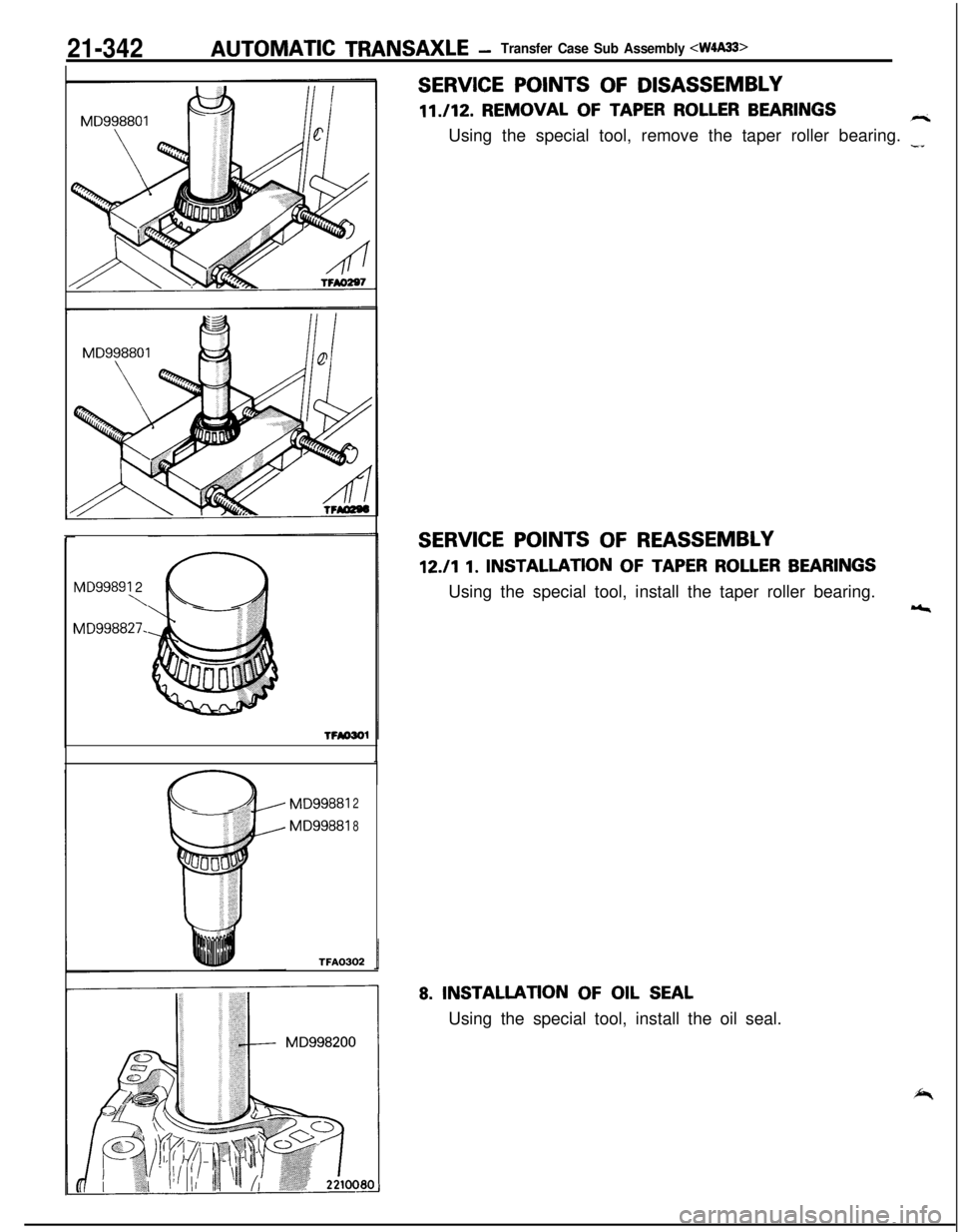

21-342AUTOMATIC TRANSAXLE -Transfer Case Sub Assembly

MD99891 2\

MD998827.

MD998812

MD998818

TFA0302

SERVICE POINTS OF DISASSEMBLY11./12. REMOVAL

OF TAPER ROLLER BEARINGSriUsing the special tool, remove the taper roller bearing.

-I

SERVICE POINTS OF REASSEMBLY

12./l 1. INSTALLATION OF TAPER ROLLER BEARINGSUsing the special tool, install the taper roller bearing.

r,

8. INSTALLATION OF OIL SEALUsing the special tool, install the oil seal.

Page 1039 of 1216

22-l-.

WHEELS

AND TIRES

CONTENTSNZZAA-

SERVICE ADJUSTMENT PROCEDURES.......4TROUBLESHOOTING......................................3

Tire

InflationPressureCheck......................4Bald Spots

TireWearCheck..........................................4Cracked Treads

Wheel

RunoutCheck...................................4Feathered Edge

SPECIFICATIONSRapid Wear at Center.............................................2

General

Specifications..................................2Rapid Wear at Shoulders

ServiceSpecificationsScalloped Wear...................................2Wear on One Side

7TorqueSpecifications...................................2

WHEEL AND TIRE..........................................5

Page 1040 of 1216

5 22-2WHEELS AND TIRES - Specifications

SPECIFICATIONS

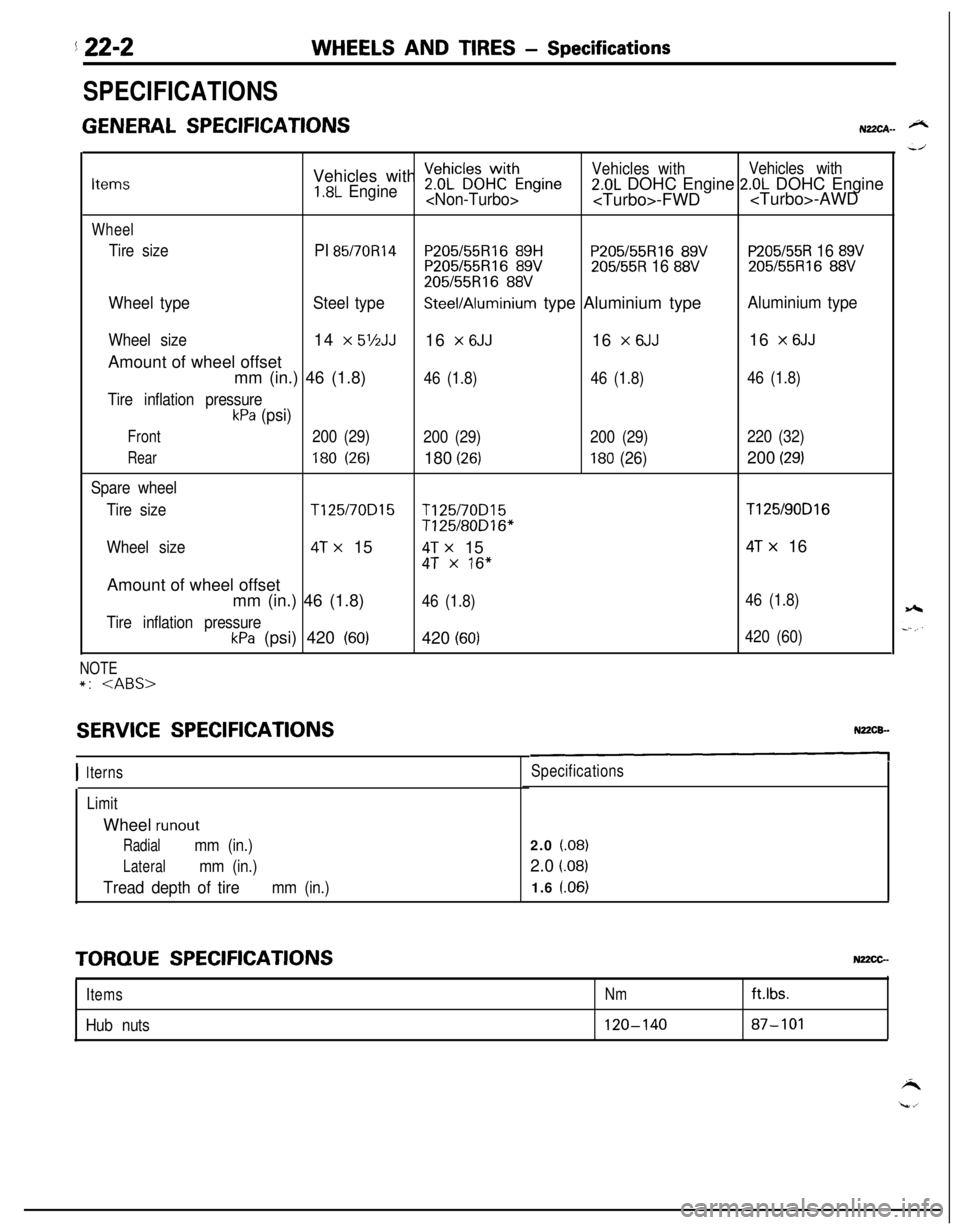

GENERAL SPECIFICATIONSN22CA- @NVehicles with

~eDhL”~~HWCthEngineVehicles withVehicles withItems1.8L Engine2.0L DOHC Engine 2.0L DOHC Engine

Wheel

Tire sizePI 85/70R14P205155Rl6 89HP205/55R16 89VP205/55R 16 89VP205155R16 89V205/55R 16 88V205/55R16 88V

205/55R16 88V

Wheel typeSteel typeSteel/Aluminium type Aluminium typeAluminium type

Wheel size14 x 5’/2JJ16 x 6JJ16 x 6JJ16 x 6JJAmount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi)

Front200 (29)

200 (29)200 (29)220 (32)

Rear180 (26)180 (26)180 (26)200 (29)

Spare wheel

Tire size

T125/70D15T125/70D15T125/90D16

T125/80D16*

Wheel size

4T x 154T x 154T x 16

4T x 16”Amount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi) 420 (60)420 (60)420 (60)

NOTE*:

SERVICE SPECIFICATIONS

I 1terns

LimitWheel

runout

Radialmm (in.)

Lateralmm (in.)

Tread depth of tiremm (in.)

Specifications2.0

(.08)2.0

i.08)1.6 l.06)

TORQUE SPECIFICATIONSNz2cG-

ItemsNm

Hub nuts120-140ftlbs.87-101

Page 1042 of 1216

22-4WHEELS AND TIRES - Service Adjustment Procedures

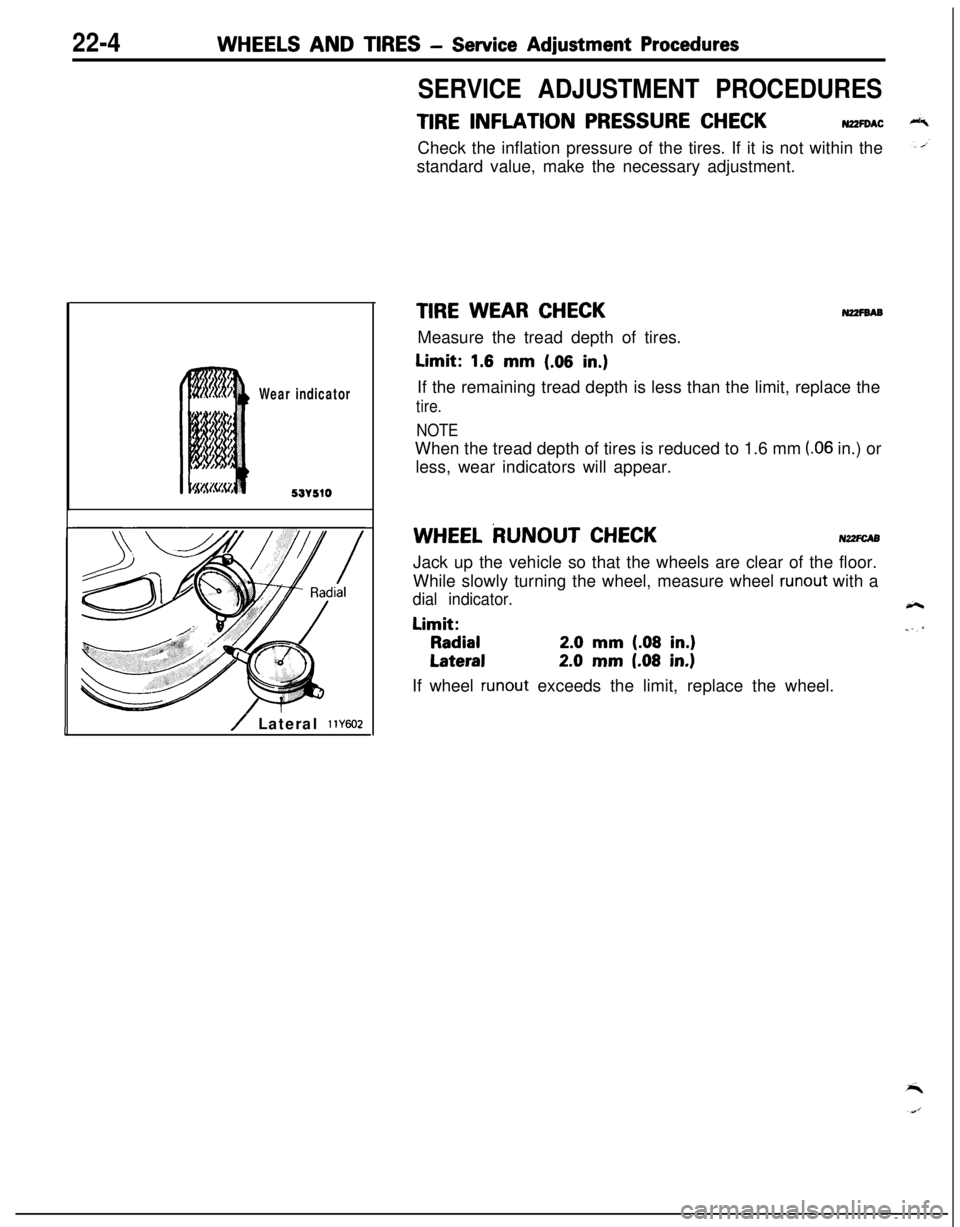

Wear indicator

53r510

/ Lateral 11Y602

SERVICE ADJUSTMENT PROCEDURES

TIRE INFLATION PRESSURE CHECKN2ZFOACCheck the inflation pressure of the tires. If it is not within the

standard value, make the necessary adjustment.

TIRE WEAR CHECKN2zFsABMeasure the tread depth of tires.Limit:

1.6 mm (.06 in,)If the remaining tread depth is less than the limit, replace the

tire.

NOTEWhen the tread depth of tires is reduced to 1.6 mm

(.06 in.) or

less, wear indicators will appear.

WHEEL RUNOUT CHECKNZ2FCA5Jack up the vehicle so that the wheels are clear of the floor.

While slowly turning the wheel, measure wheel

runout with a

dial indicator.Limit:

Radial2.0 mm (.08 in.)

Lateral2.0 mm (.08 in.)If wheel

runout exceeds the limit, replace the wheel.

Page 1043 of 1216

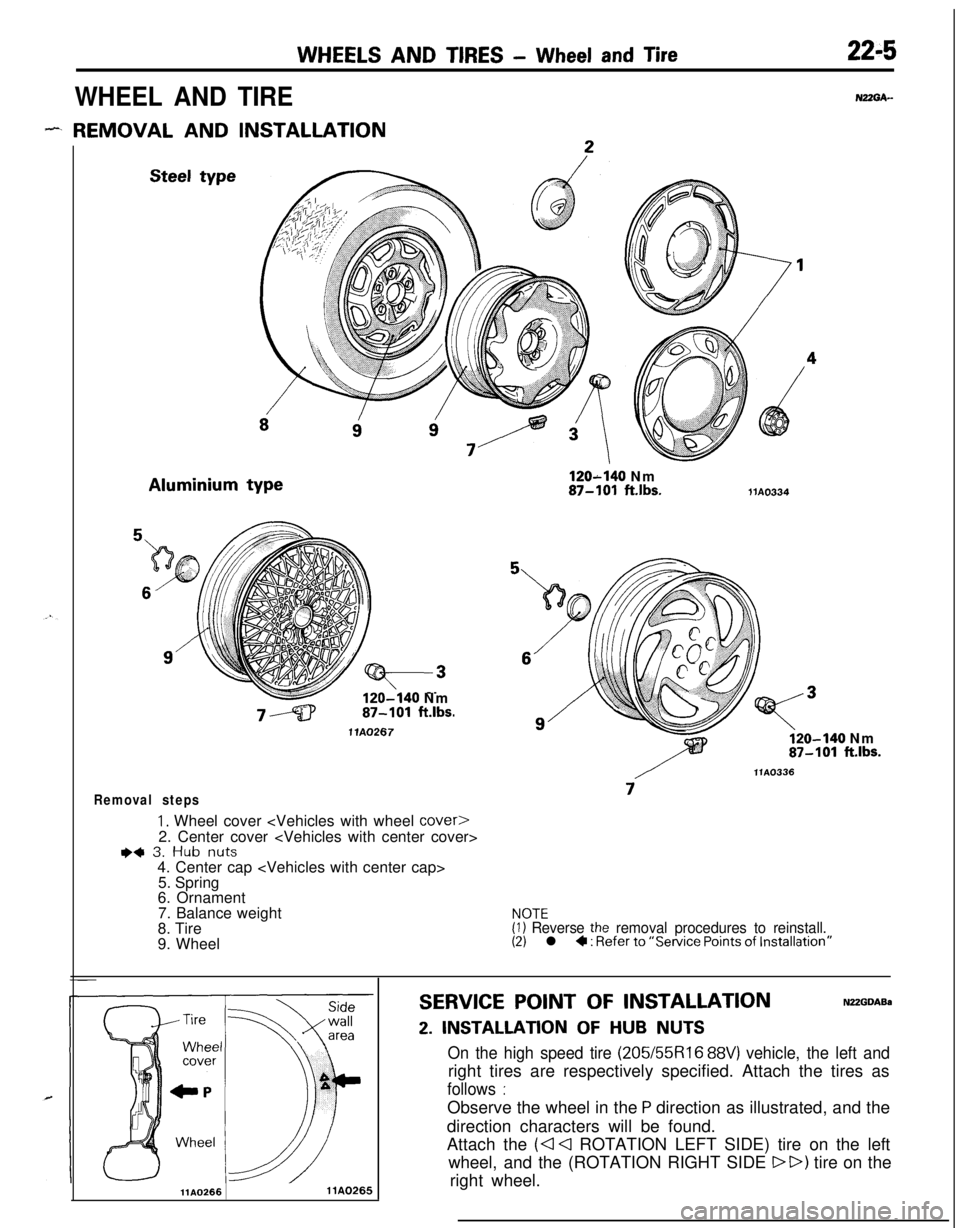

WHEELS AND TIRES - Wheel and Tire22-5

WHEEL AND TIRE

- REMOVAL AND INSTALLATIONSteel typeAluminium type

120-140 Nm87-101 ft.lbs.

1 lA0267

Removal steps

1. Wheel cover

I)+ 3. Hub nuts4. Center cap

5. Spring

6. Ornament

7. Balance weight

8. Tire

9. WheelNUGA-

120-140 Nm87-101 ftlbs.liA0334

o-140 Nm87-101 ft.lbs.

/llA0336

7

NOTE(1) Reverse the removal procedures to reinstall.(2) l 4 : Refer to “Service Points of Installation”

llAO2661 lAO265

SERVICE POINT OF INSTALLATIONNUGDABa

2. INSTALLATION OF HUB NUTS

On the high speed tire (205/55R16 88V) vehicle, the left andright tires are respectively specified. Attach the tires as

follows :Observe the wheel in the

P direction as illustrated, and the

direction characters will be found.

Attach the

(a Cl ROTATION LEFT SIDE) tire on the left

wheel, and the (ROTATION RIGHT SIDE

DD) tire on the

right wheel.

Page 1045 of 1216

23-lBODY

CONTENTSN23Ak-

AERO PARTS..........................................74

CENTRAL DOOR LOCKING SYSTEM...........70

DOOR ASSEMBLY....................................63

DOOR GLASS AND REGULATOR................66

DOORHANDLEANDLATCH.....................69

DOOR MIRROR........................................72

DOOR MOULDING AND

DRIP LINE WEATHERSTRIP........................72

....DOOR RUNCHANNEL...............................71

DOOR TRIM AND WATERPROOF FILM........65

ELECTRIC REMOTE CONTROLLED

MIRROR SWITCH.....................................73

FENDER..................................................51

FLOOR CONSOLE....................................84

FRONT BUMPER......................................39

FRONT SEAT..........................................90

FUEL TANKFILLERDOOR.........................38

GARNISHES............................................47

HEADLINING...........................................89

HOOD....................................................34

INSTRUMENT PANEL................................79

LIFTGATE...............................................36

LIFTGATE WINDOWGLASS......................62

LOOSE PANEL.........................................53

MOULDING.............................................48

POWER WINDOW....................................67

QUARTERWINDOWGLASS......................61

REAR BUMPER........................................43

REAR SEAT............................................93

SEAT BELT.............................................94

SERVICE ADJUSTMENT PROCEDURES........31

Door Adjustment....................................32

Door Glass Adjustment............................32Door Inside Handle Play Check..................

32

Door Outside Handle Play Check................32

Floor PanInspection...............................

33Fuel Filler Door Adjustment.......................

31

Hood Adjustment...................................31

Liftgate Adjustment.................................31

Water Test...........................................33

SPECIAL TOOLS......................................5

SPECIFICATIONS.....................................2

General Specifications..............................

2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................77TRIMS

....................................................85

TROUBLESHOOTING................................6WINDOW

GLASS.....................................54

WINDSHIELD...........................................58

Page 1047 of 1216

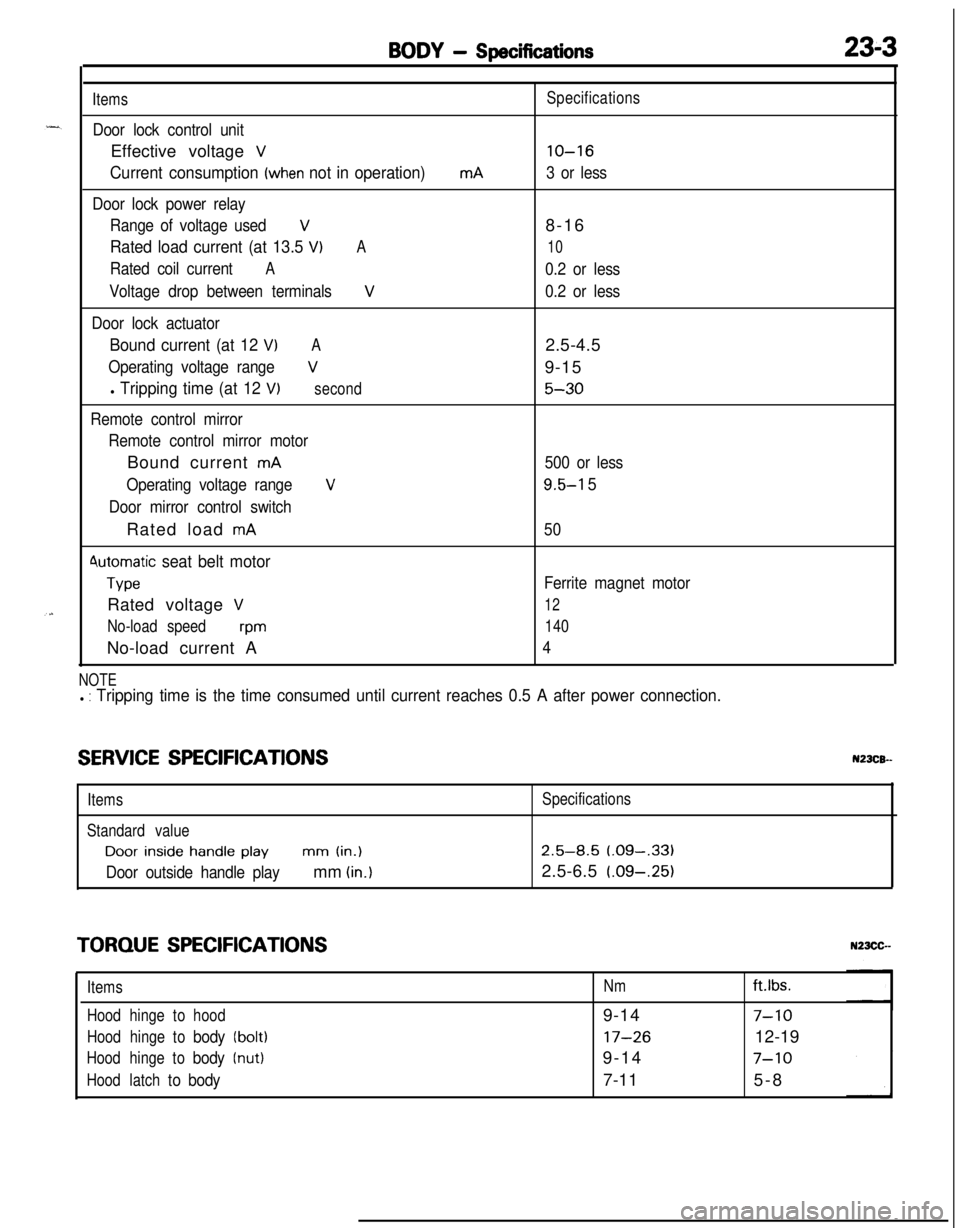

BODY - Specifications23-3

Items

Door lock control unitEffective voltage

V

Current consumption (when not in operation)

Door lock power relay

Range of voltage used

V

Rated load current (at 13.5 VIA

Rated coil currentA

Voltage drop between terminalsV

Door lock actuator

Bound current (at 12 VIA

Operating voltage rangeV

l Tripping time (at 12 V)second

Remote control mirror

Remote control mirror motorBound current

mA

Operating voltage range

V

Door mirror control switchRated load

mA

4utomatic seat belt motor

TypeRated voltage

V

No-load speedwmNo-load current A

mASpecifications

lo-16

3 or less8-16

10

0.2 or less

0.2 or less2.5-4.5

9-15

5-30

500 or less

9.5-l 5

50

Ferrite magnet motor

12

140

4

NOTEl : Tripping time is the time consumed until current reaches 0.5 A after power connection.

SERVICE SPECIFICATIONSN23CB--

ItemsSpecifications

Standard valueDoor

inside handle playmm (in.)2.5-8.5 (.09-,331

Door outside handle playmm (in.)2.5-6.5 (.09-.25)

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Hoodhingetohood9-14

7-10

Hoodhingetobody(bolt)17-2612-19

Hoodhingetobody(nut)9-147-10

Hoodlatchtobody7-115-8